Page 1

PHONE: 812-867-2421

FAX: 812-867-0547

1-800-544-4445

EMAIL: tents@anchorinc.com

EC 4557 venue 1112

www.anchorinc.com

Page 2

Index

Introduction ............................................................................................................................ 3

Safety notes ......................................................................................................................... 3

VENUE Sizes and Configurations ...................................................................................... 4

Recommended Installation Tools ....................................................................................... 6

Installation Kit .................................................................................................................... 6

1 Squaring Tent and Setting Base Plates ............................................................................ 7

1.1 Squaring the Tent Layout ............................................................................................... 7

1.2 Setting Baase Plates ...................................................................................................... 7

2 Assembling Arches .......................................................................................................... 11

2.1 Pre-assembly of Arch Components ............................................................................. 11

2.2 Assembly of Uprights and Rafters (& Rafter Extensions, if applicale) ......................... 11

2.3 Assembly of Cable Bracing .......................................................................................... 13

3 Erecting the Structure ...................................................................................................... 15

3.1 Preparation for Raising Arches .................................................................................... 15

3.2 Raising the End Arch (First Arch) ................................................................................. 15

3.3 Raising the Second Arch .............................................................................................. 15

3.4 Completing Installation of Uprights and Roof Cable Bracing ....................................... 18

3.5 Installing Gable End Framing ....................................................................................... 19

4 Installing Fabric Panels .................................................................................................... 22

4.1 Installing Mid Fabric Panels ......................................................................................... 22

4.2 Installing Gable End Fabric Panels .............................................................................. 22

4.3 Installing Optional Fabric Walls .................................................................................... 23

5 Dismantling ....................................................................................................................... 25

6 Routine Inspection and Maintenance ............................................................................. 26

6.1 Installation Period ......................................................................................................... 26

6.2 Visual Inspection of Components ................................................................................. 26

7 Specifications ……….………………………………………………………………………….. 27

2

Page 3

Introduction

The following instructions describe in a methodical manner the assembly and raising of the Anchor Venue frame tent.

Please read all instructions before the installation or removal of this product.

Work from step to step.

Before erecting any tents or membrane structures, fi rst obtain permits and approvals as required from the local building and

fi re code offi cials on the jurisdiction of your installation.

PLEASE PAY SPECIAL ATTENTION TO SAFETY WARNINGS AND CAUTIONS FOR PREVENTION OF ACCIDENTS.

Regarding the contents of this document:

The illustrations and photos are made to show clearly the construction and dismantling procedures and also for identifi cation

of the components. Not all illustrations/photos correspond to the actual dimensions and size. Explanations and/or notes have

been added to these illustrations/photos.

If you have questions, please call your sales representative at the phone number listed on the front of this manual.

Safety Notes

• Please read through this assembly manual completely before beginning your installation. Be sure the proper equipment

and safety precautions are in place. We hope that you enjoy the design features of the Anchor Venue frame tent each

time the unit is installed.

• Consult your local utility locator service or the National Utility Locating Contractors Association (NULCA) prior to installation.

• Prior to actual tent assembly, be sure to look up, down, above & below for obstacles, pipes, wires, trouble, etc.Be alert to

avoid contact of frame sections with any overhead power lines near the site.

• Keep site clear of debris to avoid tripping, especially while carrying frame parts or bundle of fabric.

• When moving frame sections by hand, use proper lifting techniques to protect the back, and avoid pinching fi ngers while

making hardware connections.

• The installation method described here requires coordination of tasks between workers. A safe installation is dependent

on that coordination. Work cooperatively as a team.

• Be sure all pins and bolts are installed and secured correctly during assembly.

• Ensure that all purlin hooks are correctly seated in their rafter brackets.

• Replace damaged or worn components with Anchor OEM components.

• To prevent injuries, wear suitable protective clothing such as hard hats, steel toed shoes, etc.

• Do not drag bundle of fabric on concrete, asphalt, or ground as this can cause damage to the fabric from abrasion through

the bag.

• This tent is manufactured for use as a temporary structure. Evacuation is recommended if threatening or windy weather

occurs. See caution on back page of this manual.

3

Page 4

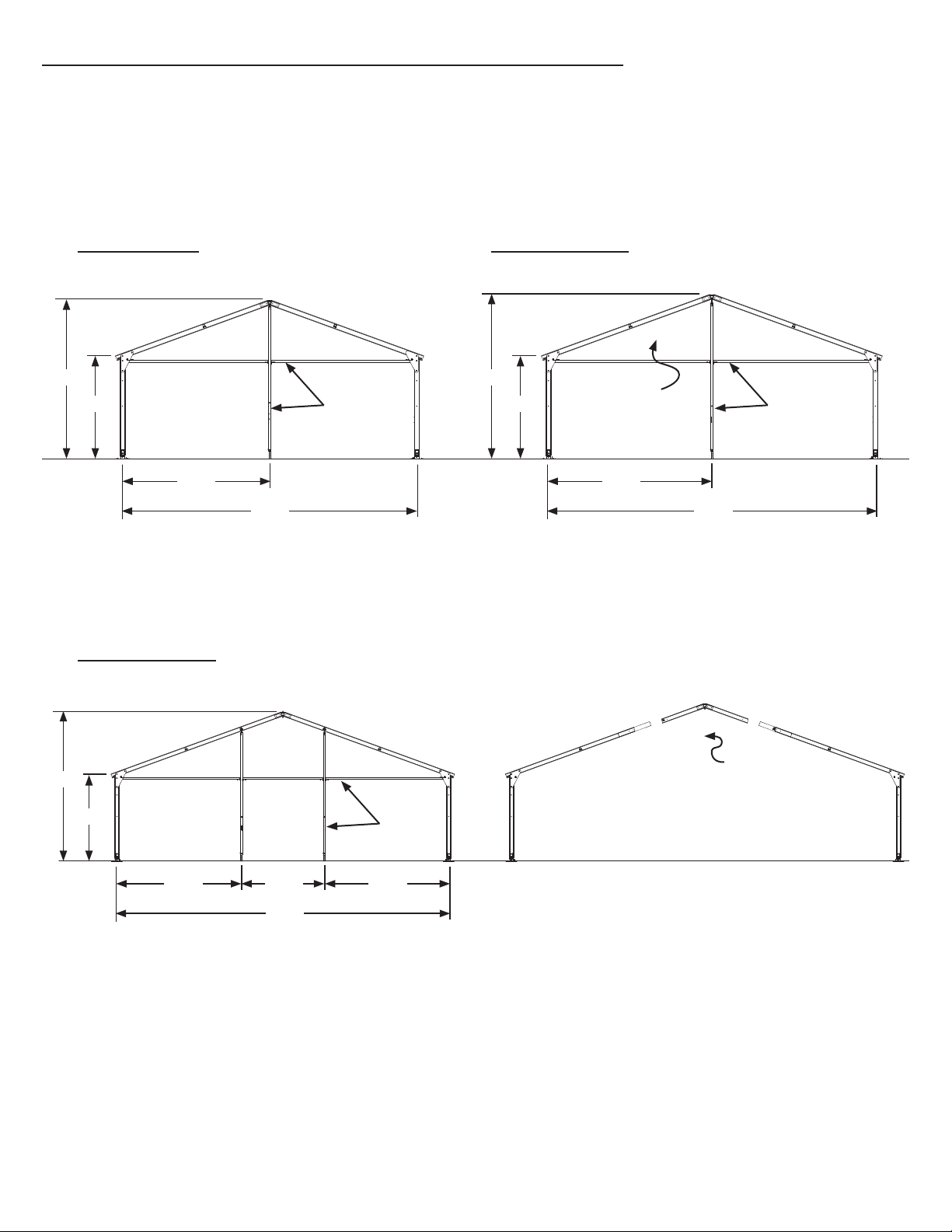

VENUE SIZES AND CONFIGURATIONS

9 METER

4.9 m

3.0 m

12 METER

10 METER

4 .5 m

4.5 m

9 m

Gable end

framing

5.0 m

3.0 m

Rafter size (typ.)

9 METER 10 METER

5.0 m

5.0 m

Gable end

framing

10 m

5.4 m

3.0 m

4.5 m

1.5 m

6.0 m

3.0 m

12 m

Gable end

framing

4.5 m

4.5 m

Splice size

12 METER 12-9 METER

4

Page 5

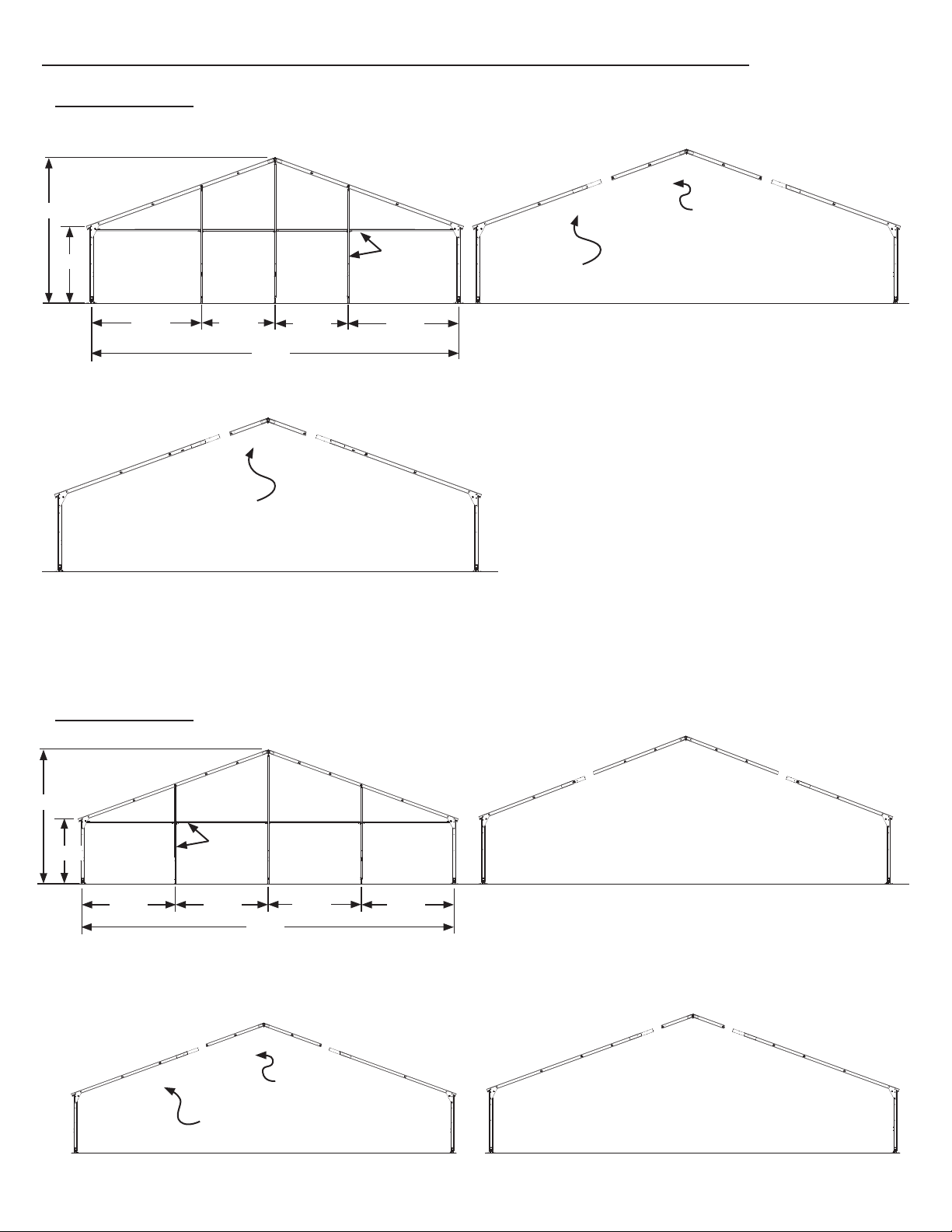

VENUE SIZES AND CONFIGURATIONS (cont’d)

15 METER

3.0 m

5.9 m

3.0 m

7.5 m

4.5 m

6.0 m

Splice size (typ.)

3.0 m

3.0 m

12 m

15 METER

1.5 m

15-12 METER

Gable end

framing

4.5 m

4.5 m

Rafter size (typ.)

Splice size

15-9 METER

18 METER

6.5 m

3.0 m

4.5 m

6.0 m

9.0 m

Gable end

framing

4.5 m

18 m

18 METER

3.0 m

Rafter size (typ.)

4.5 m

Splice size

4.5 m

4.5 m

4.5 m

18-9 METER

(Non-Certified)

1.5 m

7.5 m

18-15 METER18-12 METER

5

Page 6

Recommended Installation Tools

• Sledge Hammers/Stake Driver

• Tape Measures

• String Lines

• Level

• 1 1/8” Wrenches

• Drop Cloths

• Step Ladders (8’ and 12’ Recommended)

• Chalk/Spray paint

• Stake Puller

• 4” x 4” x 18” Wood Blocks for Shims

Installation Kit

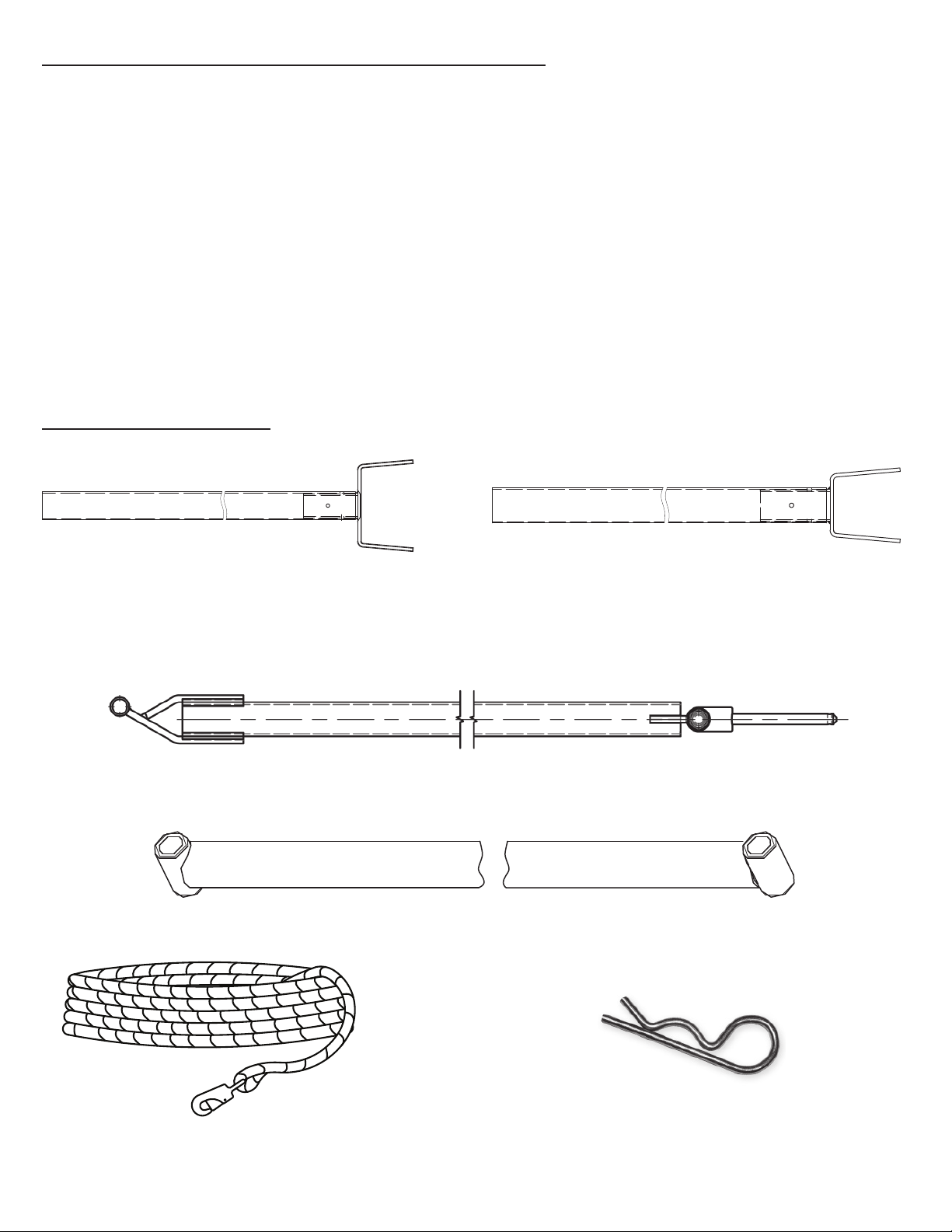

(1) Purlin Fork (14’) (1) Purlin Fork (13’)

(2) Diagonal Beam Braces

(1) Measuring Rod

(3) Pull Ropes

6

(2) R Clips

Page 7

Step 1: Squaring Tent and Setting Base Plates

1.1 Squaring the Tent Layout: The area in which the tent is to be installed should be as level as possible. Any

deviation in the surface may result in difficulties when installing the tent. Consult the Local Code Official for required

clearances and setbacks from any adjoining structures. Site the tent and establish the front and one side of the tent

that will be used to square the first corner of the tent.

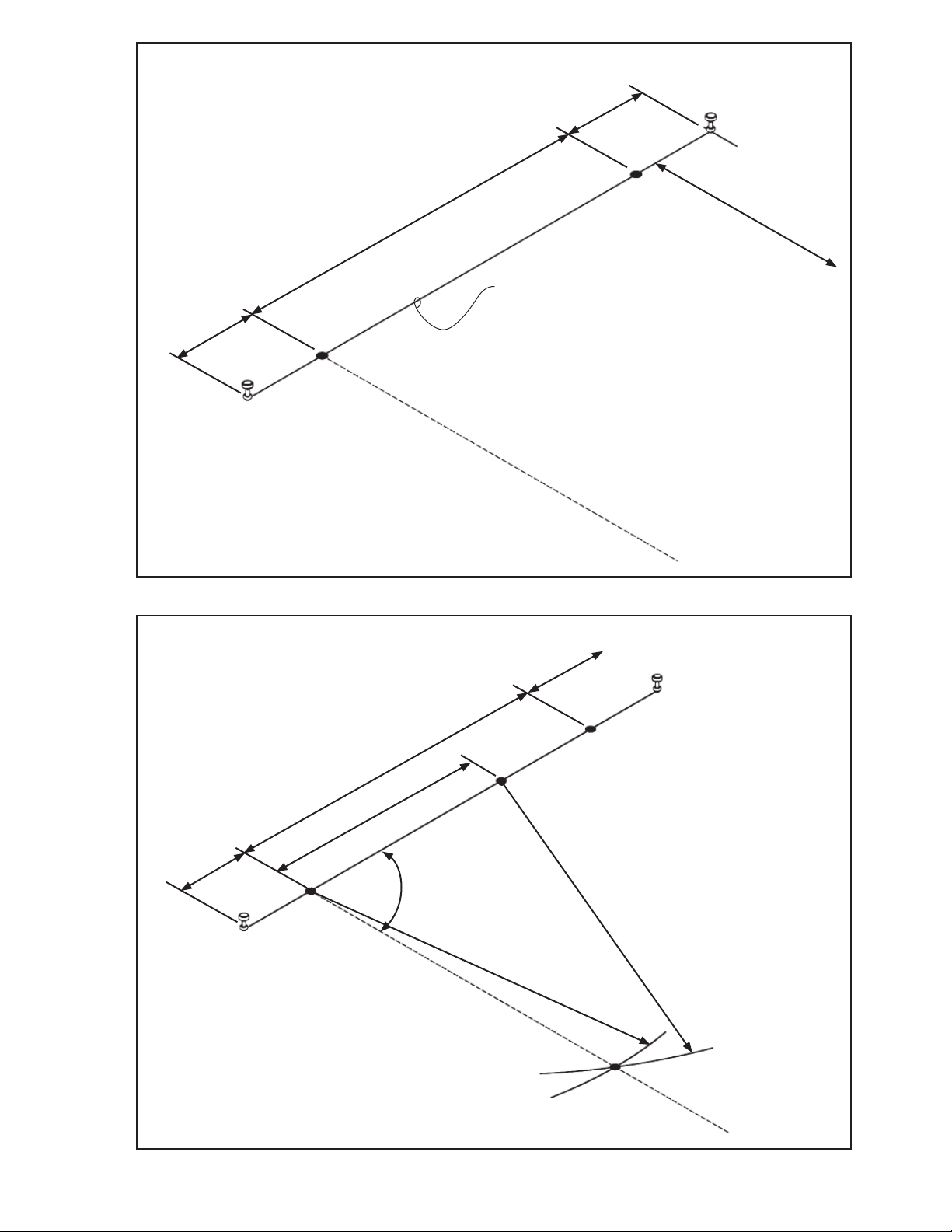

1.1.1 Stretch a string line along the tent’s length plus 2m past each end using stakes to establish the baseline A-B

(side of tent) as shown in Figure 1.1a. The edges of side base plates must align with this string line.

1.1.2 From point A, measure 3 meters along the string line toward point B and mark this point D. See Figure 1.1b.

1.1.3 From point A, measure in the direction of Point C a distance of 4 meters. Mark on the ground an arch on a 4

meter radius from point A. See Figure 1.1b.

1.1.4 From point D, measure toward the arc just made in step 1.1.3 a distance of 5 meters. Mark on the ground another arc on a 5 meter radius from point D and intersecting with the first arc made in step 1.1.3. Where these two

arcs intersect, mark this point E. See Figure 1.1b.

1.15 Stretch another string line along the tent’s front from point A toward point E. This string line will be 90 degrees

to string line A-B. Without changing the angle, extend this string line 2m past width of tent to establish point C.

Check to make sure the string line from A to C still passes thru the intersection of the two arcs at point E. This

line establishes the front of the tent. See Figure 1.1c.

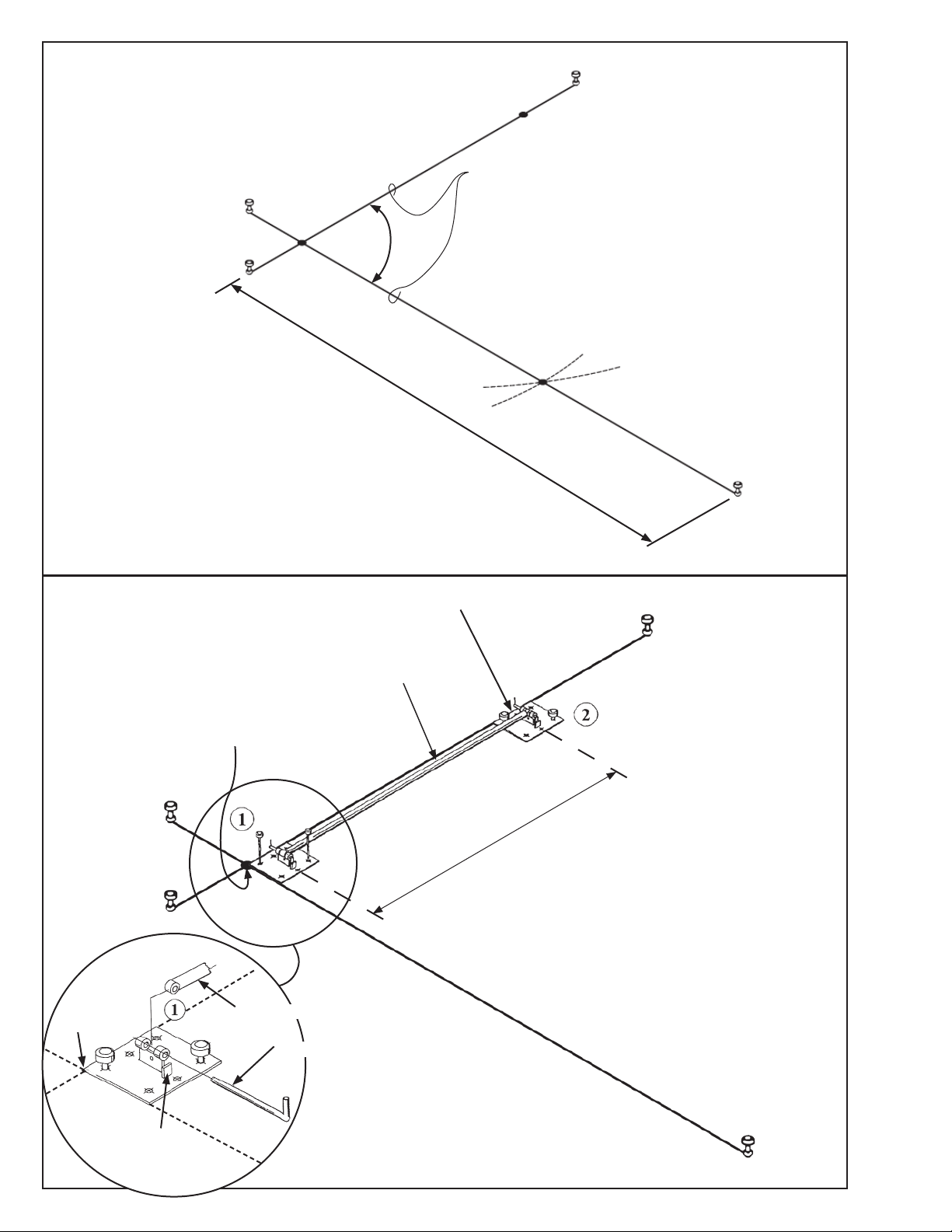

1.2 Setting Base Plates: Incorrect placement of base plates will create problems for the rest of the installation. Each

hole of each base plate requires stakes for proper installation. IMPORTANT: Safety Tabs on all base plates must

be oriented toward the interior of the tent. See Figure 1.2a. 6-Hole base plates use 48” stakes, 4-Hole and

2-Hole base plates use 31 1/2” stakes.

1.2.1 Starting at point A, place the outside corner of 6-Hole base plate #1 at point A, making sure the edges along

the front and side of the base plate align with the front and side string lines, respectively. Anchor with two (2)

stakes. See Figure 1.2a.

1.2.2 Connect the measuring rod with base plate L-Pin to base plate #1. Connect other end of the Measuring Rod to

base plate #2 with base plate L-Pin. See Figure 1.2a.

1.2.3 Adjust base plate #2 so that the outer edge of the base plate is aligned with the string line and anchor with two

(2) stakes.

1.2.4 Measure the width from the midpoint of base plate #1 to the midpoint of 6-Hole base plate #3 as shown in

Figure 1.2b. While maintaining the center line distance, orient the front edge of base plate #3 with the front

string line. Check the measurement again for the tent width between base plates #1 and #3 and anchor base

plate #3 with two (2) stakes.

1.2.5 To locate 4-Hole base plate #4, remove the base plate L-Pin from base plate #1, lift the Measuring Rod and

rotate about L-Pin in base plate #2 until it reaches the position of base plate #4. Adjust base plate #4 so that

the outer edge of the base plate is aligned with the side string line and mount the Measuring Rod using the base

plate L-Pin. See Figure 1.2c. Anchor the base plate with two (2) stakes. Repeat this procedure until all

baseplates on this side are fixed. IMPORTANT: All cable braced bays require 6-Hole base plates.

1.2.6 To locate the 6-Hole base plate in-line with base plate #3 (designated as base plate #7 in Figure 1.2c), mount

the Measuring Rod to base plate #3 and base plate #7 as described in step 1.2.5. Measure the width from the

midpoint of base plate #2 to the midpoint of base plate #7 similar to that shown in Figure 1.2b. Anchor the

base plate with two (2) stakes.

1.2.7 Repeat step 1.2.6 until all base plates on this side of the tent are anchored.

1.2.8 Finally, check the diagonal dimension at the midpoint of the four outer base plates. These dimensions should

be equal. Once the diagonal dimensions have been verified, return to each base plate and install the remaining

stakes. Stakes must be fully seated for proper installation.

7

Page 8

2m

2m

Tent Length

A

String Line

Tent Front

B

C

Tent Width

Figure 1.1a

A

B

Tent Length

D

3m

5m Arc

90º

4m Arc

Tent Front

E

C

Figure 1.1b

8

Page 9

B

A

Tent Side

90º

Tent Width + 2m

Align edge of Base Plate

with String Line.

String Line

E

C

Figure 1.1c

Point A

Measuring Rod

Place corner of Base Plate

#1 at Point A and align

edges with string lines.

6-hole

A

Measuring Rod

Base Plate L-Pin

6-hole

Tent Side

1st Bay Width

Tent Front

Safety Tab

Important: Make certain the base plate safety

tab is oriented toward the interior of the tent.

Figure 1.2a

9

Page 10

6-hole base plate.

Measuring point for

estimating width.

Rotate Measuring

Rod about pin in

base plate 4

Tape measure

6-hole base plate.

6-hole base plate.

Figure 1.2b

10

Tent Front

Figure 1.2c

Page 11

Step 2: Assembling Arches

2.1 Pre-assembly of arch components: Identify and layout all components according to Figure 2.1 for the entire

structure. NOTE: Setting uprights and rafters on 4 x 4 wood blocking (or whatever blocking may be available) will make

the insertion of the pins and bolts easier.

2.1.1 The following is a list of components required for each arch:

Quantity Description

2

2 Upright Assembly

4 ¾”-10 x 6” Bolts and Lock Nuts

4 (8)

1 Ridge Weldment

2 Rafter Extensions (if applicable)

2.1.2 Identify and layout (1) L-Pin with R-Clip next to each Base Plate. See Figure 2.2a.

2.1.3 Identify and layout (2) ¾” Lock Nut and Bolt next to each Upright/Rafter connection. See Figure 2.2b.

2.1.4 Identify and layout (4) ¾” Swivel-Lock Pins next to the Ridge Weldment. See Figure 2.2c.

2.1.5 If applicable, identify and layout (2) ¾” Swivel-Lock Pins next to each Rafter Extension.

2.1.6 If laying out components for a cable braced bay, refer to Section 2.3 for substitute components required.

Base Plate L-Pins 16mm x 230mm (9”) & R-Clips NOTE: 5/8” x 200mm (7 7/8”) L-Pins are used at

the Gable End base plates

¾” x 4” Swivel-Lock Pins (quantity in parenthesis is required if Rafter Extensions are used) NOTE:

5/8” x 4 ½” Swivel-Lock Pins are used at the Gable Ends.

2.2 Assembly of Uprights and Rafters (and Rafter Extensions if applicable): The assembly of the arch-

es is easier if working from one side to the opposite side.

2.2.1 Starting at Base Plate “1”, connect the bottom of the Upright Assembly to the Base Plate using the L-Pin as

shown in Figure 2.2a. The R-Clip will be inserted later when the Wall Ground Bars are installed. IMPOR-

TANT: The short leg of the L-Pin must be turned down and behind the Safety Bracket on the Base Plate to

keep the L-Pin from sliding out.

2.2.2 Connect Rafter to the Upright Assembly by sliding the Rafter between the two gusset plates and bolting together

using the ¾” Lock Nuts and Bolts as shown in Figure 2.2b. The connection is easier when inserting one bolt

then rotating the rafter until the second bolt hole is aligned. Tighten to 75 ft-lbs. IMPORTANT: At the gable

ends, the heads of all bolts must be on the exterior side of the gusset plate to minimize any snagging possibilities when installing the gable end fabric.

2.2.3 Connect Rafters (or Rafter Extensions) to Ridge Weldment using Swivel-Lock Pins as shown in Figure 2.2c.

Pay attention that the swivel-lock is turned ninety degrees after inserting. IMPORTANT: At the gable ends,

the head of the pin must be on the exterior side of the rafter to minimize any snagging possibilities when installing the gable end fabric.

2.2.4 If installing Rafter Extensions, connect the Rafter Extension to the Rafter using Swivel-Lock Pins as done to con-

nect the Rafter to the Ridge Weldment. Pay attention that the swivel is turned ninety degrees after inserting.

IMPORTANT: At the gable ends, the head of the pin must be on the exterior side of the rafter to minimize any

snagging possibilities when installing the gable end fabric.

2.2.5 Complete the Arch assembly by connecting the opposite Rafter to the Ridge Weldment, Rafter Extension to Raf-

ter (if applicable), Rafter to Upright and Upright to Base Plate according to steps 2.2.1 thru 2.2.4.

2.2.6 Assemble the remaining arches according to steps 2.2.1 thru 2.2.5.

11

Page 12

Step 2: Assembling Arches

3/4” Nuts

Upright

Assembly

Rafter

3/4” Bolts

Rafter or

Rafter

Extension

Swivel-Lock

Pins

Swivel-Lock

Pins

Ridge

Weldment

(Typ.)

Rafter or Rafter

Extension

Base Plate

(6 hole)

1

Figure 2.2b

Diagonal Beam

Brace (Typ.)

Upright

Assembly (Typ.)

Base Plate

(6 hole)

2

L pin with R clip

(Typ.)

Base Plate

(4 hole)

Rafter (Typ.)

Swivel-Lock

Pin (Typ.)

End Arch

3

Rafter Extension

(Typ.)

Figure 2.2c

Swivel-Lock

Pin (Typ.)

Ridge

Weldment

(Typ.)

L pin with R clip

(Typ.)

Upright

Assembly

Safety

Bracket

Note: Arches for (2) bays shown.

Figure 2.1

Base Plate

Figure 2.2a

Note: Setting uprights and rafters on 4 x 4 wood (or whatever may be available) will make the insertion of the pins and

bolts easier.

12

Page 13

2.3 Assembly of Cable Bracing: Install the cables so that the turn-buckles at the uprights are closest to the

ground and at the roof cables are closest to the eave. See Figure 2.3. The cables have color coded labels; green

labels indicate upright cables and blue labels indicate roof cables. IMPORTANT: Upright and Roof Cable Bracing is

required in the first and last bays of the structure and additionally at not more than FOUR open bays between braced bays.

2.3.1 At the Upright Assembly on both sides of the first and second arches, remove the top Lock Nut on the Upright and

replace with an Eye-Nut. The Eye-Nut is part of the Upright Cable Assembly and must be unhooked from the

shackle. When fully tightened, the Eye-Nut loop must be parallel to the Upright. See Figure 2.3a. At the End

Arch (first arch) the Eye-Nut must face toward the ground (toward the second arch when raised) and on the second arch the Eye-Nut must face upward, away from the ground (toward the first arch when raised). At all uprights

connect the Upright Cable Assembly (end opposite turn-buckle) to each Eye-Nut using the shackle provided; typical of four locations. The turn-buckle end must remain free until the arches are raised.

2.3.2 At Upright Assembly on both sides of the first and second arches, remove the outer most Lock Nut that connects

the gusset plate to the Rafter and replace with an Eye-Nut. The Eye-Nut is part of the Roof Cable Assembly.

When fully tightened, the Eye-Nut loop must be parallel to the Rafter. See Figure 2.3a. At the End Arch (first

arch) the Eye-Nut must face toward the ground (toward the second arch when raised) and on the second arch the

Eye-Nut must face upward, away from the ground (toward the first arch when raised).

2.3.3 At the Ridge Weldment on both the first and second arches, remove the Swivel-Lock Pins from the outer most

holes and replace each with a ¾” Bolt & Eye-Nut. The Eye-Nut is part of the Roof Cable Assembly and must be

unhooked from the shackle. When fully tightened, the Eye-Nut loop must be parallel to the Rafter. See Figure

2.3b. At the End Arch (first arch) the Eye-Nut must face toward the ground (toward the second arch when raised)

and on the second arch the Eye-Nut must face upward, away from the ground (toward the first arch when raised.

Connect the Roof Cable Assembly (end opposite turn-buckle) to each Eye-Nut using the shackle provided; typical

of four locations. The turn-buckle end must remain free until the arches are raised.

2.3.4 For all cable braced bays the installation sequence will be similar to steps 2.3.1 thru 2.3.3.

13

Page 14

Assembling Cable Bracing

Eye Nut in place

of lock nut

Upright

Assembly

3/4” Bolts

3/4” Nut

Rafter

3/4” Eye Nut

& Bolt in

place of Pin

Rafter or

Rafter

Extension

Swivel-Lock Pin

Swivel-Lock

Pin

3/4” Eye Nut

& Bolt in place

of Pin

Ridge

Weldment

(Typ.)

Rafter or Rafter

Extension

Diagonal Beam

Brace (Typ.)

Base Plate

(6 hole) (Typ.)

Upright

Assembly (Typ.)

Figure 2.3a

Figure 2.3b

Rafter (Typ.)

Rafter Extension

(Typ.)

Ridge

Weldment

(Typ.)

End Arch

14

Note: Arches for (1) bay shown.

Figure 2.3

Page 15

Step 3: Erecting the Structure

3.1 Preparation for Raising Arches: One advantage of the lightweight Venue structure is that only six experienced

installers are required to raise each arch. NOTE: The Diagonal Beam Braces supplied in the installation kit will be used

during the raising of the first and second arches.

3.1.1 Prior to raising the first arch connect the Diagonal Beam Braces to the eave gusset plates on both uprights by

inserting the top pin on the Diagonal Bean Brace up through the holes in the eave gusset plate as shown in Fig-

ure 3.1a. Secure to the eave gusset plate by using an R-Clip with string attached (R-Clip must have open-end

toward top of rafter). IMPORTANT: Make sure the tube on the pinning end of the Diagonal Beam Brace is pointing upward as shown in Figure 3.1b, otherwise the bottom of the upright on the second arch may be damaged.

3.1.2 Lay both of the Diagonal Beam Braces along and outside the second arch base plates as shown in Figure 3.2a.

3.1.3 Verify that the R-Clips for the base plate L-Pins are placed on the second arch base plates so they are readily

available to secure the pinning end of the Diagonal Beam Brace to the L-Pins once the first arch is raised.

3.2 Raising the End Arch (First Arch): Position three installers along the length of each rafter; one next to the ridge,

one at midpoint of rafter and one at the eave as shown in Figure 3.2b. This method of raising the arches requires coordination between workers for a safe installation. Use proper lifting techniques to protect the back by lifting with your legs.

3.2.1 Begin lifting the first arch in unison, being careful not to twist the arch. As the arch is lifted, the installers move

toward the uprights while maintaining contact with the arch. NOTE: The Diagonal Beam Braces will drag along

as the arch is lifted.

3.2.2 When the arch is nearly vertical and stable, one installer on each side can guide the tube on the pinning end of

the Diagonal Beam Brace onto the base plate L-Pin of the second arch as shown in Figure 3.2c. Secure the

Diagonal Beam Brace by installing the R-Clip.

3.2.3 IMPORTANT: Ensure that the pinning end of the Diagonal Beam Brace is slid away from under the bottom of

the second arch uprights to allow clearance for the upright to pivot vertically when raising the second arch. If the

pinning end of the Diagonal Beam Brace is underneath the bottom of the upright, the upright will be damaged when

raising the second arch.

3.3 Raising the Second Arch: Position installers as recommended for the first arch. See note in steps 3.2.3 before

raising the second arch.

3.3.1 Prior to raising the second arch, layout the eave, roof and ridge purlins in their respective position on the ground

adjacent to the first arch. To help expedite the stability of the second arch, connect the curved hook end of the

eave purlins to the brackets at the ends of the rafters on the first arch. The opposite end of the eave purlin can

rest on the ground until the second arch is in the vertical position.

3.3.2 Raise the second arch as described in steps 3.2.1 for the first arch. When the arch is vertical, one installer on each

side must swing the free end of the eave purlin, using the wide cradle purlin fork (supplied in the installation kit), to

drop the eave hook into the bracket at the ends of the rafters on the second arch as shown in Figure 3.3a. Use

the same technique and purlin fork to install the ridge purlin into the brackets at the ridges. Use the roof cables to

help sway the arch and align the purlin hook with the ridge bracket.

3.3.3 Using the same technique with the narrow cradle purlin fork (supplied in the installation kit), install the remaining

roof purlins, making sure that the curved hook on the roof purlin is properly engaged in the rafter bracket before

swinging the opposite end in place as shown in Figure 3.3b.

3.3.4 The installation of the remaining arches will utilize the same technique described in steps 3.3.1 thru 3.3.3.

15

Page 16

Layout of all Arches

Figure 3.1a

Diagonal Beam

Brace

Raising First Arch

Diagonal Beam

Brace

Diagonal Beam

Brace

Figure 3.2a

Securing First Arch

Diagonal Beam

Brace

Figure 3.1b

16

Diagonal Beam

Brace

Figure 3.2b

Figure 3.2c

Page 17

Raising Second Arch

Eave/Ridge

Purlin

Eave/Ridge

Purlin

Other Pulins

Securing Second Arch

Purlins

Eave/Ridge

Purlin

Wide Cradle Purlin

Fork

Diagonal Beam

Brace

Figure 3.3a

Completing First Bay

Figure 3.3b

Figure 3.3c

17

Page 18

3.4 Completing Installation of Upright and Roof Cable Bracing: Turnbuckles may need to be fully extended

to attach cables. Refer to Figure 3.4 for cable configurations required for the Upright and Roof Cable Bracing.

3.4.1 The Upright Cables connect to the base plates by inserting an Eyebolt attached to the loose end of the cable

assembly thru the hole in the base plate vertical tab as shown in Figure 3.4a. Secure the Eyebolt with the

washer and nut provided. NOTE: The R-Clip provided will be used later to secure the wall ground rails at the End

Arches if the gable end walls are installed. Adjust the tension of the cables using the turnbuckles, tension only

enough to make frame stable. After the Upright Cables have been installed and tensioned, remove the Diagonal

Beam Braces.

3.4.2 The Roof Cables connect to the Eye-Nuts at the rafter eaves by using the shackle attached to the loose end of the

cable assembly. Adjust the tension of the cable using the turnbuckles. IMPORTANT: The Roof Cables must

be installed below the Roof Purlins.

3.4.3 The installation of the remaining cable braced bays will utilize the same technique described in steps 3.4.1 and

3.4.2.

3.4.4 Before erecting additional arches, plumb the first bay of uprights by adjusting the tension of the upright cables until

the uprights are vertically aligned. Next, adjust the roof cable to align the rafters vertically with the uprights. Once

the first bay of framing is plumb, continue erecting remaining arches as described in steps 3.3.1 thru 3.3.3.

18

Figure 3.4

Figure 3.4a

Page 19

3.5 Installing Gable End Framing: Refer to Venue Sizes and Configurations, pages 4 & 5, for layout of Gable End

framing for various tent widths. NOTE: The 9M and 10M only have Center Uprights, the 12M only has Intermediate

Uprights and the 15M and 18M have both Center and Intermediate Uprights. NOTE: A ladder will be necessary to pin

the top of the G.E. uprights to the end arches.

3.5.1 The following is a list of hardware required for each Gable End Upright:

Quantity Description

1 Locking L-Pin with Stop (16mm x 132mm)

1 Gable End Base Plate L-Pins 5/8” x 200mm (7 7/8”) & R-Clip

1 Anchor Structure Gable Upright Base Plate

2 31 ½” Stakes

3.5.2 At the Center Uprights, connect the insert weldment at the top of the G.E. Upright to the hinge tube at the bottom

of the Ridge Weldment using the Locking L-Pin with Stop. See Figure 3.5a. IMPORTANT: Pay attention that

the collar on the L-pin is engaged in the safety latch bracket at top of upright.

3.5.3 At the Intermediate Uprights, first connect the G.E. Upright/Rafter Connecting Bracket to the Rafter as shown in

Figure 3.5b. The heads of the bolts that are tightened to clamp the bracket to the rafter must be facing toward

the interior of the tent. Make sure the bolts are tight. Connect the insert weldment at the top of the G.E. Upright

to the hinge tube at the bottom of the G.E. Upright/Rafter Connecting Bracket using the 5/8” Swivel-Lock Pin. See

Figure 3.5b. IMPORTANT: Pay attention that the collar on the L-pin is engaged in safety latch bracket at top

of upright.

3.5.4 After the G.E. Uprights are connected to the arches, swing the G.E. Upright out from either side of vertical and

insert the G.E. Base Plate into the bottom of the G.E. Upright. Swing the upright back to vertical. Adjust the G.E.

Base Plate in or out to suit the adjoining grade and pin using the G.E. Base Plate L-Pin and R-Clip. See Figure

3.5d. IMPORTANT: Do not stake at this time.

3.5.5 Insert a ¾” Bolt thru the only open holes in the Eave Gusset Plates at both main uprights and secure the LockNut. Make sure the head of the bolts are on the exterior side of the gusset plate to minimize any snagging possibilities when installing the gable end fabric. See Figure 3.5c.

3.5.6 Install the gable end eave purlins by starting with the G.E. Wing Eave Purlins. Place the hooked end over the bolt

installed in step 3.5.5 and drop into place. See Figure 3.5c. Swing the opposite end with the adjustable eave

hook up until the hook is above the bracket on the G.E. Upright, align and drop into place. See Figure 3.5d.

Using the purlin fork to pivot the eave purlin into place will allow the installer to work from the ground.

3.5.7 Install the remaining gable end eave purlins between the G.E. uprights by first connecting the curved hook into

the G.E. upright bracket then swing the opposite end with the adjustable eave hook up until the hook is above the

bracket on the G.E. Upright, align and drop into place. See Figure 3.5d. Using the purlin fork to pivot the eave

purlin into place will allow the installer to work from the ground.

3.5.8 Plumb the G.E. Uprights (both axes) and anchor the base plates. CAUTION: Do not damage the uprights or

installation hardware when driving the stakes.

19

Page 20

Ridge Weldment

Center Upright

Locking L-Pin

Safety Latch Bracket

Figure 3.5a

Eave Gusset Plate

Rafter

Locking L-Pin

Safety Latch Bracket

Intermediate Upright

Figure 3.5b

Rafter

20

Gable End Wing

Eave Purlin

3/4” Bolt. Insert with

head on exterior

side.

Figure 3.5c

Page 21

Insert Weldment

Locking L-Pin

Safety Latch Bracket

Eave Purlin

Gable End Upright

Eave Purlin

R-Clip

Gable End Base

Plate

Purlin Bracket

Gable End Base

Plate L-Pin

L-Pin with R-Clip

properly seated.

Figure 3.5d

21

Page 22

Step 4: Installing Fabric Panels

4.1 Installing Mid Fabric Panels: Install Mid Fabric Panels first. Before installing, verify that all stakes are fully seated

and the cable braced bays are lightly tensioned. Use drop cloths (not included), pull ropes (supplied in Installation Kit) and

ladders to assist installation. When possible, choose installation side based on wind direction and space around installation area. Installation should be based on safety first.

4.1.1 Mid fabric panels should be fed into the rafters on the “downwind” side of the frame (fabric blowing away from the

frame). This will prevent fighting the mid blowing against the frame and reduce the effort required to guide the mid

into the kedar groove. Throw the snap ends of two pull ropes from the installation kit over the top of frame of one

bay. CAUTION: Be certain area is clear so as not to strike anyone while throwing the pull ropes over the top.

4.1.2 Using a drop cloth, lay the mid fabric next to the bottom of the uprights on the snap side of the mid bay. Snap the

pull ropes onto the web loops near each kedar edge. Mid should be loosely stacked to permit easy feeding into

the channels. See Figure 4.1a. IMPORTANT: Use the third pull-rope as a pull-back rope. Snap this rope to

one of the pull straps on the mid along with one of the pullropes. After the mid has been pulled up and over to the

other side of the mid, remove this rope from the strap and snap to the other two pull-ropes. Using this pull-back

rope, pull the pull-ropes back to the starting side of the frame and slide them over to the next bay. This step will

save time in having to throw the pull-ropes over the frame again. CAUTION: Be certain at all times that fabric is

not caught on any part of the frame to prevent damage to the fabric.

4.1.3 Using pull ropes, raise mid until the kedar is near the end of the rafter. With an installer on a ladder at each side

of the mid, feed the kedars into the kedar channels of the rafters. Once both kedars are in the channels, continue

to feed until the upper ends of the pull loops are even with the edge of the rafter.

4.1.4 Flip the tension pocket on top of the mid so it does not get caught on the purlins while pulling the mid through the

frame. At this point, the kedars on both sides of the mid should be fed into the channel evenly. Feed each kedar

into the channel for just a few more inches. There should be an installer at each installation end of the rafters to

guide the kedar into the kedar channel at all times. To prevent a bind, be sure to start and stop pulling both ropes

at the same time, and the same speed.

4.1.5 Using the pull ropes, slowly pull the mid up the rafter to within 2’-0” of the peak. Have the pullers reset their position to a location near the frame. Begin pulling the ropes at the same time to make sure the mid pulls smoothly

over the ridge and down the other side of the frame. Stop pulling the mid before the kedar exits the channel on

the rafter. The mid is in place.

4.1.6 Repeat steps 4.1.1 thru 4.1.5 for the remaining mids.

4.1.7 After all mids are in place, insert tension bars in tension pockets at both ends of all mids. Insert tension bar connector between tension bars and through tension strap loop. Tension mids until tight. Usually kedar will be near the

end of the channel when mid is tight. Make sure the bottom pocket line on all mids are level. Add and/or release

tension as necessary to adjust.

4.1.8 Mids are installed.

4.2 Installing Gable End Fabric Panels: Use drop cloths (not included), purlin fork and ladders to assist installation.

Gable ends are made in two pieces and are inserted into the top channel of the gable end rafters.

4.2.1 Begin by locating the lace portion (either grommet side or loop side) of one of the two pieces. Be sure that the piece

is right side out (pull ring will be on outside, FR/Warning label on inside).

4.2.2 Using the purlin fork, grab the ring with the end of the tool and push the kedar up through the channel until it is at

the center of the ridge. When both pieces of the gable end are installed in the channel and meet at the top, fasten

the rings together with the carabiner and begin lacing from the peak down to the bottom of the gable end. Tie off

the last loop. See figure 4.2a.

22

Page 23

4.2.3 Insert tension bars into tension pocket at bottom of gable end. Insert tension bar connector between tension bars

and through tension strap loop. Insert tension bar corner connectors at corners. See Figure 4.2b. Tension fabric until it is tight. Make sure the bottom pocket line on ends are level. Add and/or release tension as necessary

to adjust.

4.2.4 Repeat steps 4.2.1 thru 4.2.3 for opposite gable end.

4.2.5 Gable Ends are installed.

4.2.6

Now Tension all cables fully.

4.3 Installing Optional Fabric Walls: Use drop cloths (not included) and ladders to assist installation. Walls are

made in two pieces with FR/Warning labels on the inside, ground rail pockets on the outside. NOTE: Gable end wing

walls are used at outer bays of the gable ends and there are right and left versions. Mid walls are used at center gable

end bays and at all mid bays.

4.3.1 Start installing unlaced walls by inserting top of kedar into outside channel opening and slide upper portion of wall

to top of upright. Then insert bottom of kedar into channel opening and slide kedar down to bottom of upright.

Gather wall toward upright and start inserting wall tabs into channel of eave purlins. IMPORTANT: Gable end wall

tabs insert into Outer Channel of the eave purlins and Mid wall tabs insert into Inner Channel.

4.3.2 After all tabs are inserted, walls may be laced from top to bottom. Tie off bottom long loop.

4.3.3 Insert Ground Rails into bottom pocket of all mid walls and secure to base plate L-Pins at all mid uprights as shown

in Figure 4.3a.

4.3.4 Insert Ground Rails into top pockets of all gable end walls and secure to end of cable bracing eyebolt at base of

gable end corner upright (Fig. 4.3a) and to Gable End Base Plate L-Pin.

Figure 4.1a

23

Page 24

Mid

Tension Straps

Corner Upright

Tension Bar Corner

Connectors

Tension Bars in

Tension Pockets

Gable End

Figure 4.2a

Figure 4.2b

Ground Rail (Side)

Corner Upright

24

Gable Wall

Ground Rail (Gable end)

R-Clip

Side Wall

6-hole Baseplate

Figure 4.3a

Page 25

Step 5: Dismantling

For the dismantling of the tent follow the installation instructions in reverse.

The basics of dismantling:

(All fabric panels of the tent must be dry before removing and folding for storage.)

5.1 Remove all wall ground rails.

5.2 Remove the side and gable end walls, lay them on a drop cloth and fold. Return walls to cloth shipping bags

provided.

5.3 At the gable ends, release the gable end web tensioners, remove the tension bars, unlace the gable end panels

and remove onto a drop cloth and fold. Return to cloth shipping bags provided.

5.4 At the mid panels, release the web tensioners, remove the tension bars and pull out the mid panels onto a drop

cloth and fold. Return to cloth shipping bags provided.

5.5 Pull the gable end upright stakes and remove the gable end purlins and uprights.

5.6 Remove upright and roof cables at one end bay. IMPORTANT: The cabling in the opposite end braced bay

must remain.

5.7 While workers stabilize the end arch, remove all roof, ridge and eave purlins. Lower the arch onto wood blocking

to ease pin and bolt removal.

5.8 Continue removing purlins and lowering remaining arches until the last bay remains.

5.9 Install the Diagonal Beam Braces as noted in Step 3.2 to secure the first arch and allow the cabling to be

removed.

5.10 Once the Diagonal Beam Braces are secure, detach the roof and upright cables at the turnbuckle end. While

workers stabilize the second arch, remove the remaining roof, ridge and eave purlins and lower the second arch.

IMPORTANT: Ensure that the pinning end of the Diagonal Beam Brace is slid away from under the bottom of

the second arch uprights to allow clearance for the upright to pivot when lowering the second arch. If the pinning

end of the Diagonal Beam Brace is underneath the bottom of the upright, the upright will be damaged when lowering the second arch.

5.11 While workers stabilize the last arch, remove the Diagonal Beam Braces form the base plate pins at the second

arch and lower the last arch.

5.12 Remove bolts and pins from the arch connectors and disassemble the arch components. NOTE: Eave gusset

plates remain attached to the uprights.

5.13 Remove L-Pins connecting the uprights to the base plates.

5.14 Remove all stakes from the base plates.

5.15 After dismantling, sort and load all building components as best integrates with your transportation and storing

logistics.

5.16 Store fabric in a cool, dry area.

25

Page 26

Step 6: Routine Inspection and Maintenance

6.1 Installation Period

6.1.1 The entire tent structure system shall be inspected at regular intervals, but not less than two times per permit

use period to determine that the installation is maintained in accordance with Chapter 24 of the International

Fire Code and as required by the local code official in the jurisdiction of the installation.

6.1.2 Re-tension cable bracing , re-tighten bolted connections and re-tension fabric panels as follows:

- 24-hours after initial installation and every week thereafter

- after hot periods

- after periods of heavy rains

- after periods of strong winds

6.1.3 Inspect all stakes to ensure they are fully engaged.

6.1.4 Ensure all FR/Warning labels are clearly visible.

6.1.5 Do Not allow the accumulation of snow or ice

.

6.1.6 Check for deformation or damage.

6.1.7 If there are any damaged parts, replace them immediately with new original parts.

6.2 Visual Inspection of Components

6.2.1 Routinely conduct a visual inspection after every use.

6.2.2 Inspect purlin hooks and brackets for excessive wear or damage.

6.2.3 Inspect cables for kinks or frays.

6.2.4 Inspect bolt and pin connections for excessive wear or damage.

6.2.5 Inspect kedar cords for excessive wear or damage.

6.2.6 Inspect kedar channels to ensure they are open and free of sharp edges and burrs.

6.2.7 Inspect wall tabs for excessive wear or damage.

6.2.8 Routinely clean all fabric panels. Always thoroughly dry before storing.

26

Page 27

Step 7: Specifications

Clearspan Widths (meters): 9.0 / 10.0 / 12.0 / 15.0 / 18.0

Ridge Heights (meters): 4.9 / 5.1 / 5.4 / 5.9 / 6.45

Side Heights (meters): 3.0 / 4.0 with 1 meter extension

Minimum Length: Minimum bays provided in a given structure should ensure that the

structure length is greater than the structure width

Maximum Length: No Limit

Roof Pitch: 20 degrees

Bay Distance (meters): 5.0

Minimum number of Bays: 9M – 2 / 10M – 3 / 12M – 3 / 15M – 4 / 18M – 5

Extrusion Profiles (millimeters):

- Uprights & Rafters 160 x 100

- Gable End Uprights 130 x 70

- Ridge, Eave & G.E. Purlins 130 x 70

- Intermediate Roof Purlins 80 x 80

Rafter Extension Options: 12-9 / 15-9 / 15-12 / 18-9 / 18-12 / 18-15 (NOTE: 18-9 structure is

NOT certified)

Longest Components (meters): 9.8 (18.0 One-piece Rafter)

Main Frame Material: Aluminum 6061 – T6

Main Frame Finish: Anodized 204 R1

Connection Material: Steel, zinc plated or galvanized

Connection Type:

- Ridge Internal Steel Weldment

- Eave External Aluminum Gusset Plates

- Splice Internal Aluminum Insert

Engineering Certification: In compliance with ASCE 7 – 05 for 90 mph, 3 second wind gust

(NOTE: 18-9M structure is not certified)

27

Page 28

EVANSVILLE, INDIANA

PHONE NUMBER

812· 867· 2421

FAX NUMBER

812· 867· 0547

Anchor products are of superior design and operate best within the parameters of these instructions. It is imperative

that the instructions be carefully read and COMPLETELY FOLLOWED. Please read installation instructions before the

installation or removal of this product. Installation instructions are available online at www.anchorinc.com or by calling

1-800-544-4445.

CAUTION:

1. For each installation, the installer is solely responsible for evaluating the site and the proper securing method

determined. Some soils require different staking or securing than that provided with the tent. Due to this variety of

soil conditions, these are the manufacturer’s suggested sequence of installation procedures. Anchor’s responsibility

is limited to the manufacture of the tent parts and materials. We are not responsible for methods that installers may

choose to erect and secure the tent to the ground.

2. The number of stakes suggested in the installation instructions do not necessarily meet all or any relevant codes

on the site of the tent installation. The number of stakes suggested will, in many cases, keep the tent erected,

however, due to various soil conditions; these stakes will be insuf¿ cient to keep the tent secure in high winds.

It is the tent installer’s responsibility, not the manufacturer, to determine the appropriate number of stakes to meet

the necessary wind loads on the site. Regardless of the number of stakes we suggest, we make no representation

or warranty as to whether this speci¿ c number of stakes will meet the local tent code. Anchor does not, nor can

it make any suggestions, representation, or warranties about the adequate staking required at each speci¿ c

installation site. Staking information provided in the installation instructions is not a suggestion about what is

necessary to meet a site-speci¿ c load.

For additional important information, consult: “The IFAI Procedural Handbook For the Safe Installation and

Maintenance of Tentage” and the IFAI Pocket Guide “Pullout Capacity of Tent Stakes”, both available from

the IFAI Tent Rental Division or on our website.

3. Inasmuch as the weather is unpredictable, good judgment and common sense must be incorporated within

installation guidelines. It is the responsibility of the tent installer/maintainer to determine the severity of the weather,

proper time and method of installation and/or erection and disassembly. Note: We recommend that snow and

ice be removed from the tent surface as soon as possible because accumulation will damage the tent

or fabric structure. Please consult with our Engineering Department about the maximum loads for each

product.

This product has been manufactured for use as a temporary structure. For the safety of all occupants, evacuation

is recommended if threatening weather occurs, or if there is any doubt concerning the safe use of this product.

4. Proper safety equipment should be used at all times to insure a safe installation and take down. We suggest a

careful evaluation be made to determine safety equipment needed, such as hard hats, steel-toe shoes, safety

glasses and other as required. It is our desire that all installations are safe. Please be aware of hidden dangers

both underground, i.e., gas lines, water lines, electrical lines, etc. and above the tent such as power lines and

telephone lines.

5. Anchor stands behind its products in accordance with its standard Terms and Conditions of sale. A copy of our

Terms and Conditions of Sale can be obtained by contacting Anchor at the telephone number and/or address on

this document.

28.2 03-04-09

Loading...

Loading...