Anchor VEHICLE MAINTENANCE SHELTER User Manual

Assembly Instructions

Vehicle Maintenance Shelter

25’ x 32’ - VMS

With Extension Kits

Please read all assembly/installation instructions before the installation or removal of this product.

Assembly Instructions are also available on the web at: www.anchorinc.com

EC 3399

Sales Offices

1100 Burch Dr

P O Box 3477

Evansville, IN 47733

Phone (812) 867-2421

Fax (812) 867-0547

(800) 544-4445

Production Facilities

Bradenton, FL

Evansville, IN

VMS 0807 R2

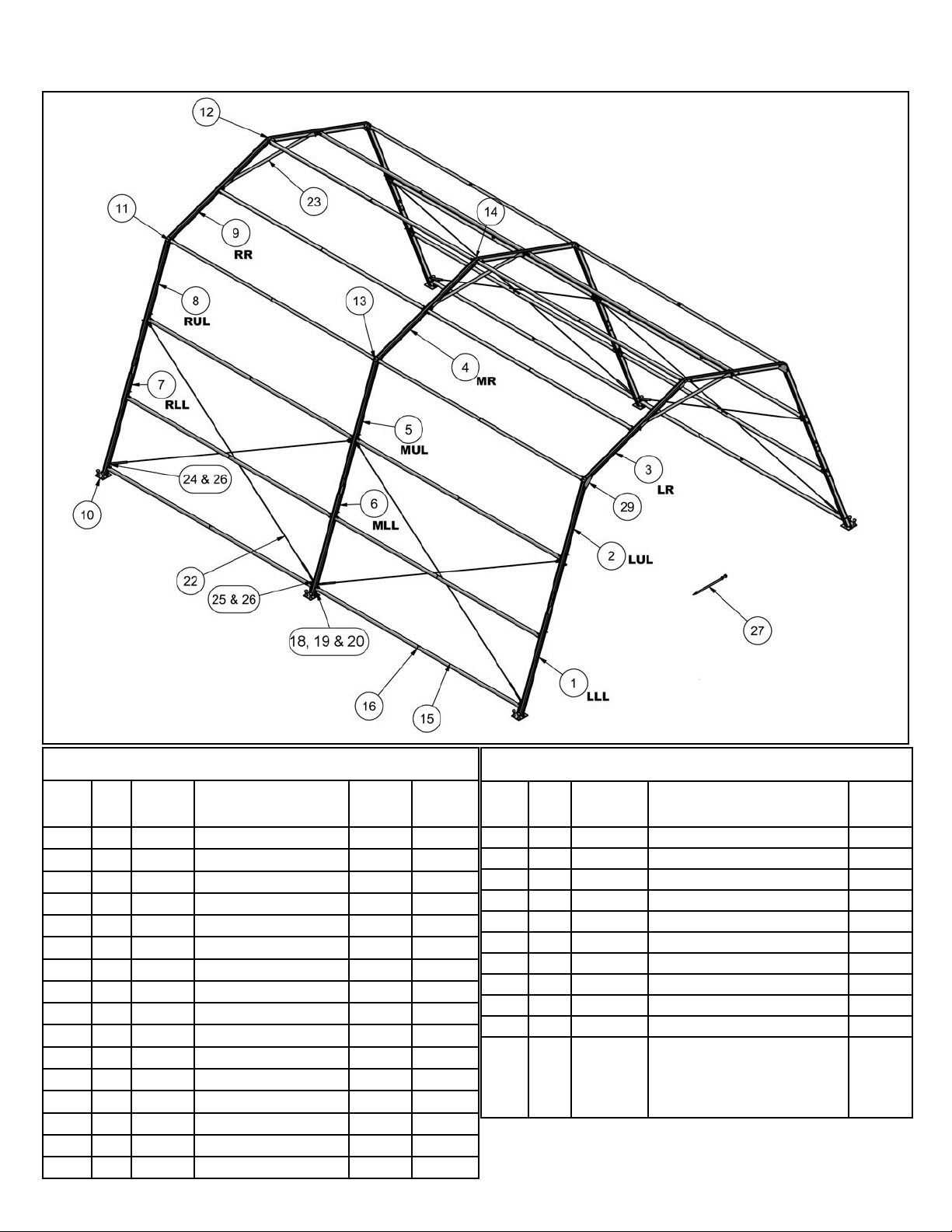

VMS Standard Frame Terminology and Parts List

VMS (25’ x 32’) Parts List

Item

Qty Part No. Description

No.

1 2 80810 Left Lower Leg 25.8

2 2 80813 Left Upper Leg 18.6

3 2 80816 Left Rafter 20.6

4 2 80819 Mid Rafter 21.2

5 2 80820 Mid Upper Leg 19.4

6 2 80821 Mid Lower Leg 28.7

7 2 80822 Right Lower Leg 25.8

8 2 80823 Right Upper Leg 18.6

9 2 80846 Right Rafter 20.6

10 6 80839 Base Plate Weldment 7.6

11 4 80824 Eave End Weldment 9.9

12 2 80827 Peak End Weldment 9. 8

13 2 80828 Eave Mid Weldment 9.9

14 1 80829 Peak Mid Weldment 9.8

15 44 80830 Half Purlin 7.7

16 22 80831 Purlin Splice 2.2

2

Pounds

per Item

Label

LLL

LUL

LR

MR

MUL

MLL

RLL

RUL

RR

VMS (25’ x 32’) Parts List (cont’d)

Item

*No weight is listed for items under one pound.

**(10) Stakes are used for gable end fabric installation. (5)

Stakes per end.

Qty Part No. Description

No.

18 8 3023897 J Bolt 19 8 3025387 Washer 20 8 3024390 Wing Nut 22 8 80834 Cable for 16’-0” Bay 5.0

23 3 3582260 Ridge Brace 16.4

24 4 3023260 3/8” x 3” Bolt 25 2 3020445 Eye Bolt 26 6 3024015 Eye Nut 27 22** 3704230 Dbl. Hd. Stake (1” x 30”) 8.0

29 4 80847 Eave Cover -

Installation Kit:

30 1 8003720

(2) Pull ropes (30a)

(1) Zipper tool (30b)

(4) Frame lifts (30c)

Pounds

per Item

25.0

8’-1 3/4”

Extension

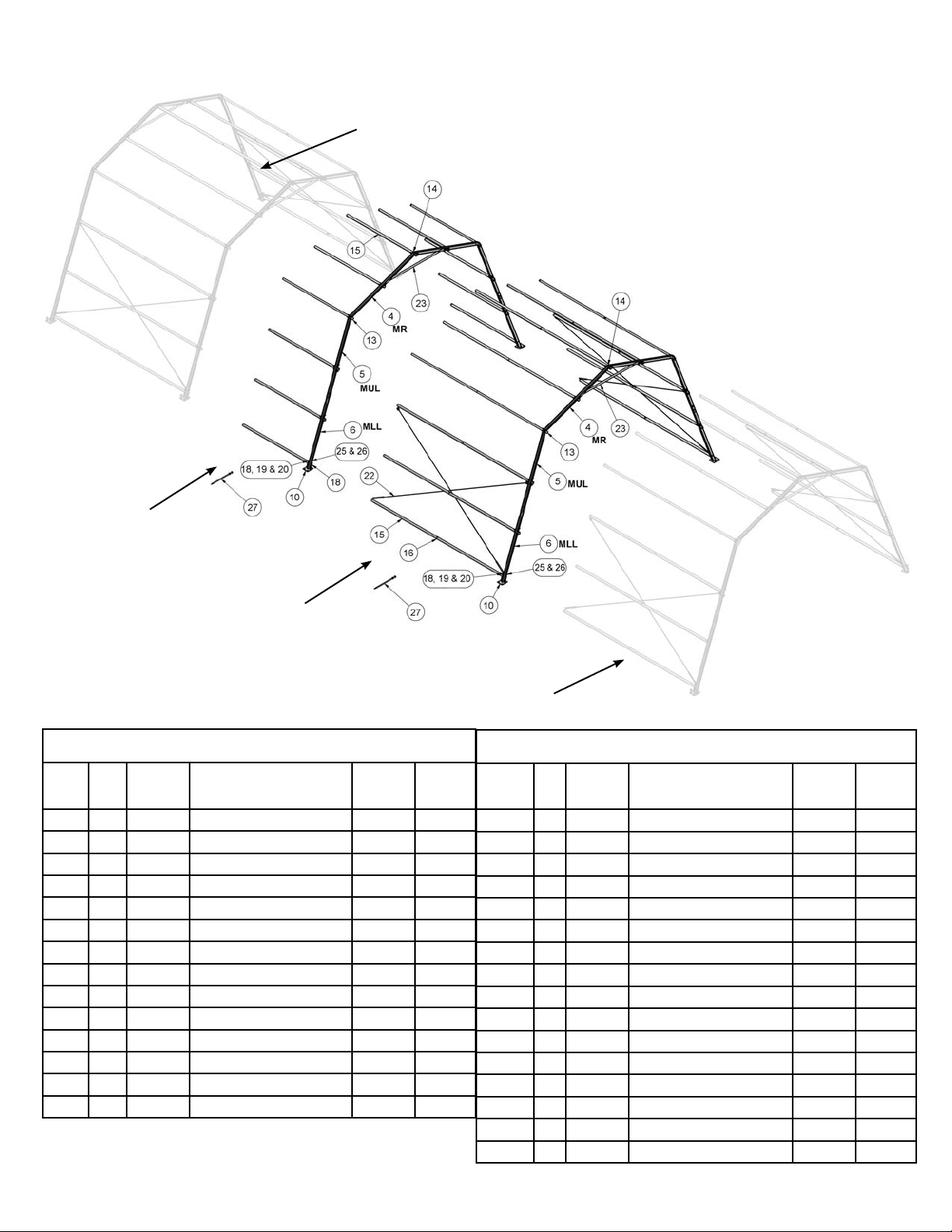

VMS Frame Extensions Terminology

Standard frame parts

shown ghosted.

16’

Extension

8’ Frame Extension Kit

Item

Qty Part No Description

No.

4 2 80819 Mid Rafter 21.2

5 2 80820 Mid Upper Leg 19.4

6 2 80821 Mid Lower Leg 28.7

10 2 80839 Base Plate Weldment 7.6

13 2 80828 Eave Mid Weldment 9.9

14 1 80829 Peak Mid Weldment 9.8

15 11 80830 Half Purlin 7.7

18 4 3023897 J Bolt 19 4 3025387 Washer 20 4 3024390 Wing Nut 23 1 3582260 Ridge Brace 16.4

24 2 3023246 3/8” Bolt x 2 3/4” 27 4 3704230 Dbl Hd Stake 1” x 30” 8.0

31 2 3024445 3/8” Nylock Nut -

No weight is listed for items under one pound.

*

per Item

Standard frame parts

shown ghosted.

Pounds

Label

MR

MUL

MLL

Item # Qty Part # Description

4 2 80819 Mid Rafter 21.2

5 2 80820 Mid Upper Leg 19.4

6 2 80821 Mid Lower Leg 28.7

10 2 80839 Base Plate Weldment 7.6

13 2 80828 Eave Mid Weldment 9.9

14 1 80829 Peak Mid Weldment 9.8

15 22 80830 Half Purlin 7.7

16 11 80831 Purlin Splice 2.2

18 4 3023897J Bolt 19 4 3025387Washer 20 4 3024390Wing Nut 22 4 80834 Cable for 16’-0” Bay 5.0

23 1 3582260Ridge Brace 16.4

25 2 3020445Eye Bolt 26 6 3024015Eye Nut 27 12 3704230Dbl Hd Stake 1”x 30” 8.0

16’ Frame Extension Kit

Pounds

per Item

Label

MR

MUL

MLL

3

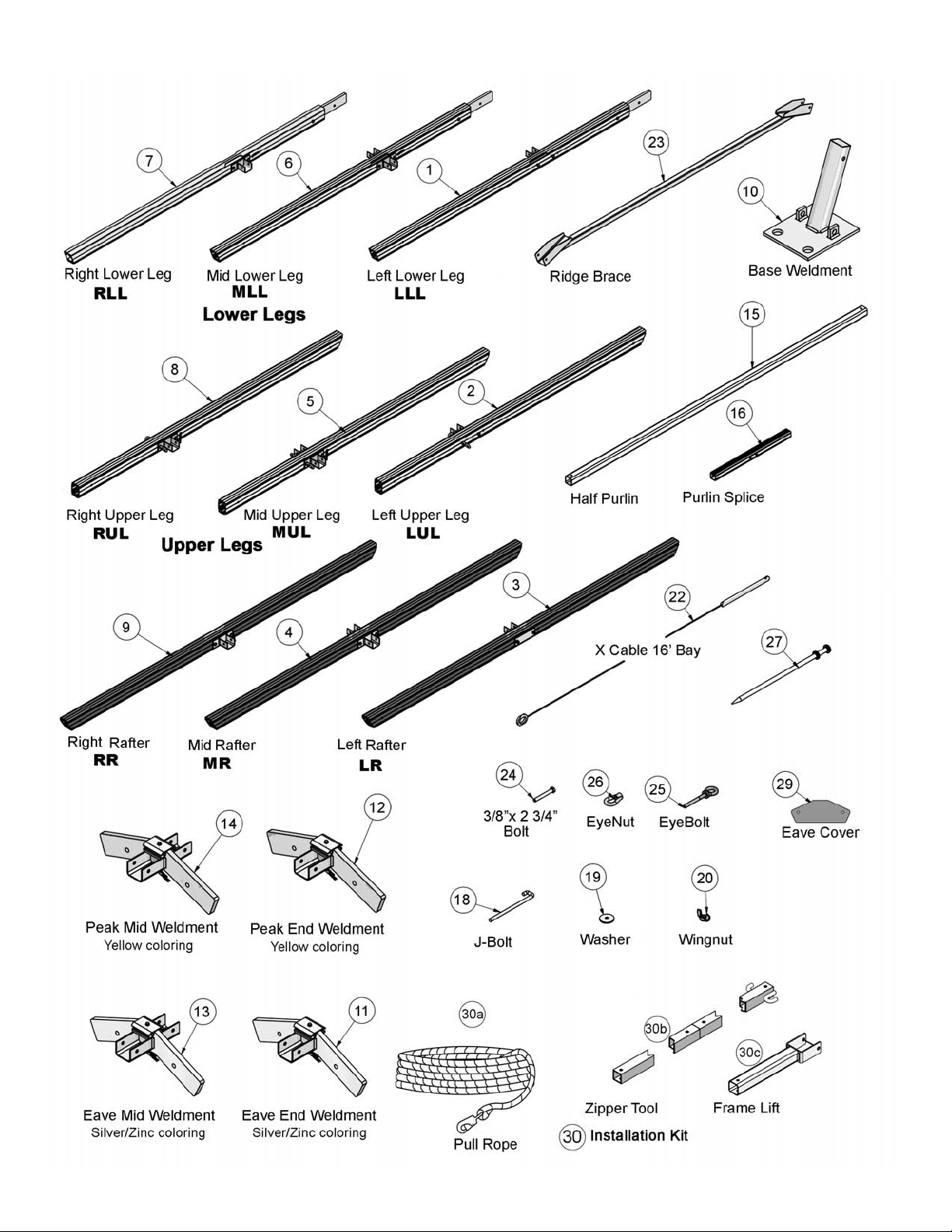

VMS Component Illustrations

4

VMS INSTALLATION SAFETY GUIDELINES

Please read through this assembly manual completely before beginning your installation. Be sure the proper equipment,

crew and safety precautions are in place. We hope that you enjoy the design features of the Vehicle Maintenance Shelter

each time the unit is installed.

1. Be aware to avoid contact of frame sections with any overhead power lines near the site.

2. When anchoring the structure, avoid all underground power lines and gas lines or other utility easements.

3. When moving frame sections by hand, use proper lifting techniques to protect the back, and avoid pinching

fingers while making hardware connections.

4. Be sure all workers are cautious and attentive to the falling paths of frame sections being raised or lowered.

5. Keep site clear of debris to avoid tripping, especially while carrying frame parts or bundles of fabric.

6. Do not drag bundles of fabric on concrete, asphalt, or ground as this can cause damage to the fabric from

abrasion through the bag.

7. Do not climb onto the fabric “roof” of the structure. When necessary, work safely from a ladder of

appropriate size.

8. When standing or lowering frame sections use a smooth motion.

9. Before installing fabric, be sure the frame is safely staked at baseplates and that X-cabling is in place.

10. The installation method described here requires coordination of tasks between workers. A safe installation is

Tools Required: 12’ Step Ladder

Sledge Hammer

50’ Tape Line

Note: This installation is for the standard 2-mid bay Base Unit unless noted otherwise.

Note: For installation of frames with extension kits, look for notes inside these outlined boxes for special instructions.

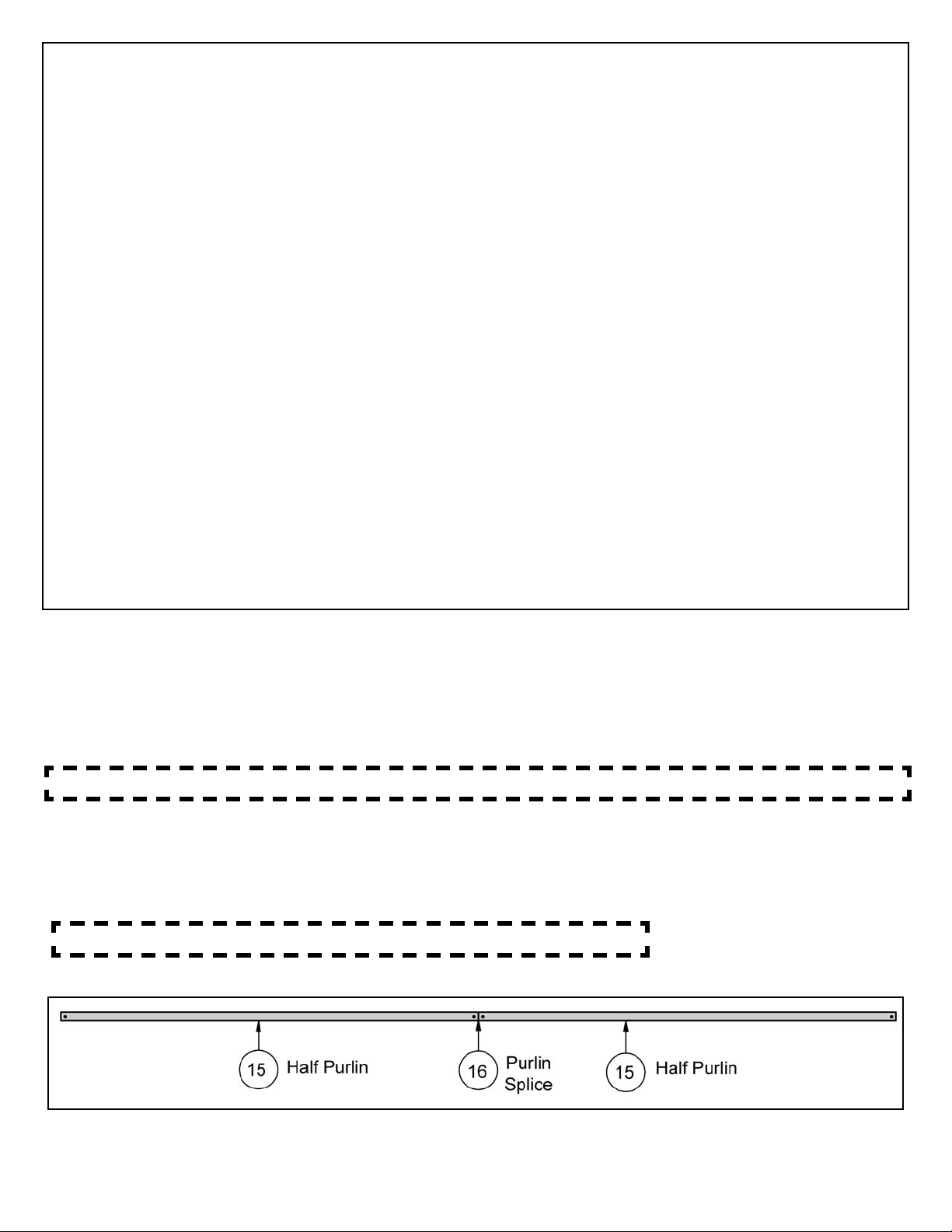

STEP 1

Assemble 18 purlins from two purlin halves (2”x2” aluminum tubes about 8’ long) and a purlin splice (Aluminum part 2’ long

with snap buttons in the center.) See Figure 1.

Note: On 8’ Extension kits - only (1) half purlin is required, and no purlin splice.

Figure 1

5

Loading...

Loading...