Page 1

PZ-Series High Peak Appendix

PZHP 0912

Use this Appendix with the Anchor Structure PZ Manual

Assemble Arches as noted in the standard PZ manual except as follows for High Peak

1

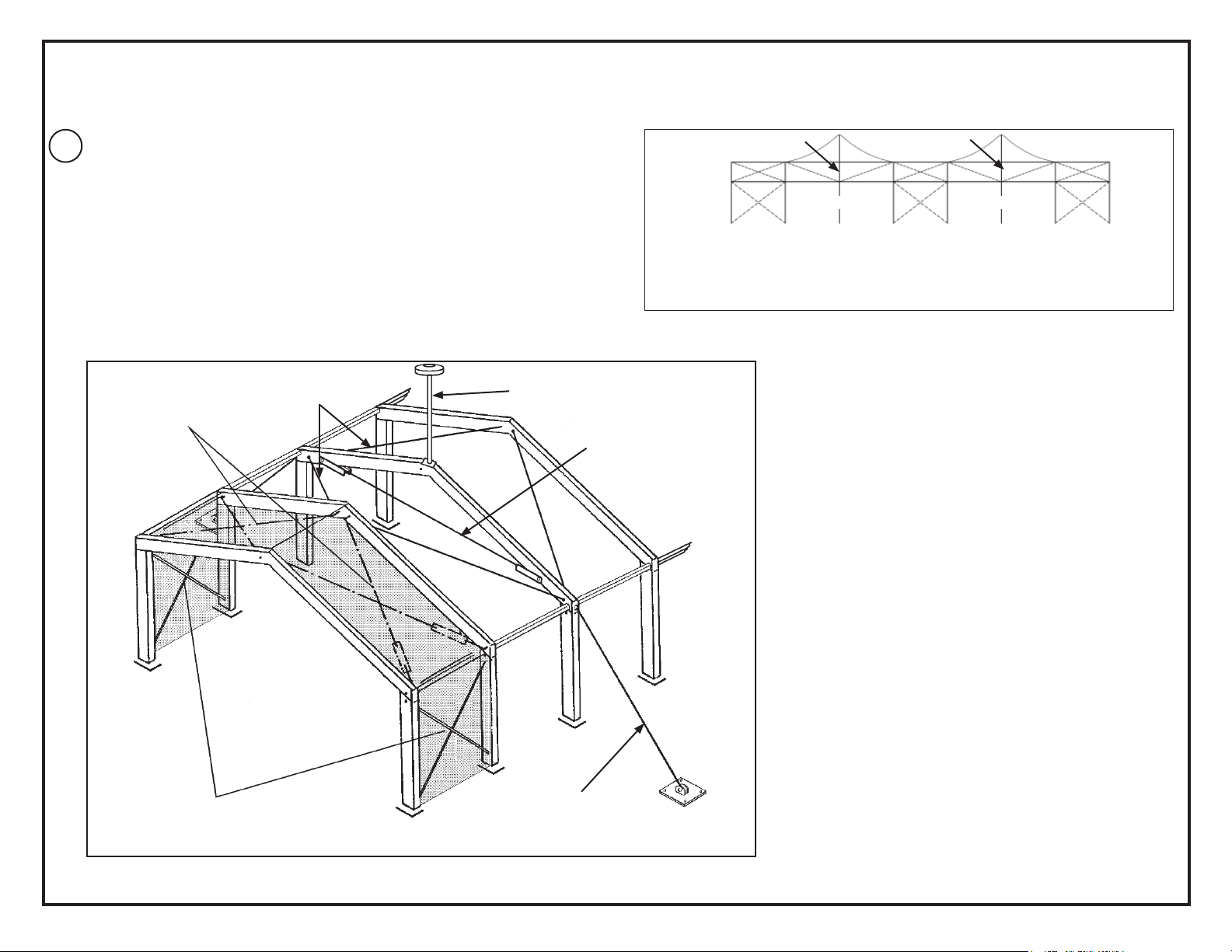

Arch: X-Cabling must be installed as shown in Figure 1a.

Figure 1b shows cabling in greater detail, the cross cable required on the High Peak

Arch, the cable guys required on the High Peak Arch and the High Peak attachment.

High Peak Bay

Roof Cables

Roof Cables

High Peak

Attachment

Standard X-Cabling must be installed in bays adjacent to to each set

of High Peak Bays.

Both Bays of the High Peak must have the modified X-Cabling as

shown above. Install as per Standard PZ instructions.

Cross cable

High Peak Arch

High Peak Arch

High Peak Bays

High Peak Bays

Figure 1a

EC 4582

Upright Cables

Cable Guy

Figure 1b

PZHP 0912

Page 2

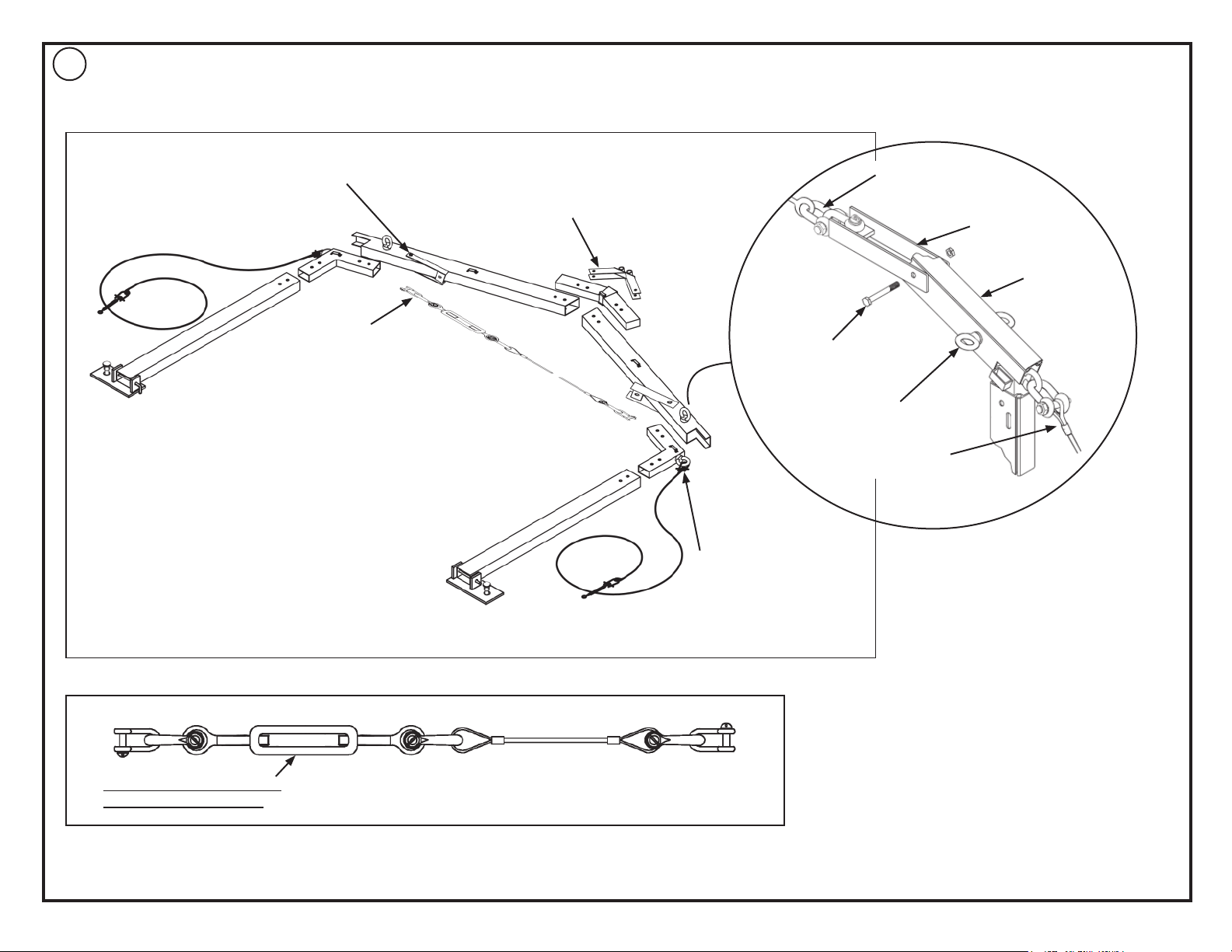

Assemble High Peak Arch as shown in Figure 2a while still lying on the ground.

2

Cross Cable Attachment Plate.

Cross Cable.

High Peak Arch

High Peak Mounting Plate. Install

using 10mm x 80mm bolt and nut.

Guy Cable

Cross Cable

Cross Cable

Attachment Plate.

Rafter

10mm x 80mm

bolt and nut.

Eye bolt and nut for

high peak bay roof

cables.

Guy Cable

Figure 2b

High Peak Arch Eave

Weldment with eye

bolt for guy cable

connection.

Figure 2a

Open turnbuckle all the way

before attaching to frame.

Cross Cable Detail

Figure 2c

2

Page 3

Raise all arches, connect all cables and adjust and secure all members as

3

indicated in the standard PZ installation manual.

Do not yet tighten Cross Cable until after installation of Fabric and High

Peak Attachment.

High Peak Arch

Cross Cable

Begin Fabric Installation with the High Peak Bays. Pull in as noted on the

4

standard PZ installation manual. See Figure 4a.

After fabric is pulled in, secure with Cam Buckle Strap at the end of each

rafter as shown in Figure 4b (6 places for each High Peak Mid). Pull

D-ring on strap until fabric is secured.

Strap for keeping fabric in

place while high peak is being

installed and until fabric can be

tensioned down.

Rafter

Figure 4b

Using a Step Ladder, Install High Peak Attachment to top of High Peak

5

Arch. Install as illustrated in Figure 5a. A second installer may be required

to help maneuver fabric as the High Peak Attachment is installed.

Place the Dished Boiler Head with support Pipe over the Spindle. Turn

the Spindle nut until Fabric is properly tensioned over the Dished Boiler

Head. Adjust Fabric as the High Peak Attachment is being raised so that

it is straight on the frame. Red Marking on Spinidle should NOT be visible

on spindle when Dished Boiler Head with Support Pipe is in final raised

position.

Now, using the turbuckle, tension the cross cable on the High Peak Arch

so that High Peak Arch does not move out of square. It may be necessary

to adjust tension on the cross cable as the Dished Boiler Head is being

raised.

Cam Buckle

Kedar

High

Peak

Fabric

Pull Rope

Dished Boiler

Head with

support pipe.

16mm x 120mm

Threaded bolts &

Nuts

High Peak Bays

Lubricant must be applied

to spindle prior to installation or removal of High Peak

Attachment.

Figure 3a

High Peak Fabric

Red Marking

Figure 4a

Spindle

Spindle Nut

Spindle Base

Plate

Mounting Plate

High Peak

Attachment

Eyebolts - use in place of

the standard bolts where

required.

Figure 5a

3

Page 4

Attach Turnbuckle of Cable Guy to Cable Guy Base

6

Plate. See Figure 6b.

Move Cable Guy Base Plate so that when

Turnbuckle is open, the baseplate is straight out

from High Peak Arch Base Plate and there is not

much slack in Cable Guy.

Stake Base Plate.

Tighten Turnbuckle on Cable Guy.

High Peak Installation is complete.

For Removal of High Peak, work steps backwards.

7

Flap with velcro

Cable Guy is already attached

at eave. When finished staking,

cover at eave with fabric flap.

Eave Line

Figure 6b

Turnbuckle - adjusted so cable

is taut.

Baseplate for Cable Guy.

Figure 6c

Cable Guy on High Peak Arch,

typical (2) places for each High

Peak.

Figure 6a

4

Page 5

28.2 03-04-09

FAX NUMBER

EVANSVILLE, INDIANA

812· 867· 2421

PHONE NUMBER

812· 867· 0547

CAUTION:

mined. Some soils require different staking or securing than that provided with the tent. Due to this variety of soil

conditions, these are the manufacturer’s suggested sequence of installation procedures. Anchor’s responsibility is

limited to the manufacture of the tent parts and materials. We are not responsible for methods that installers may

choose to erect and secure the tent to the ground.

the site of the tent installation. The number of stakes suggested will, in many cases, keep the tent erected, howev-

er, due to various soil conditions; these stakes will be insufficient to keep the tent secure in high winds. It is the tent

installer’s responsibility, not the manufacturer, to determine the appropriate number of stakes to meet the necessary

wind loads on the site. Regardless of the number of stakes we suggest, we make no representation or warranty as

to whether this specific number of stakes will meet the local tent code. Anchor does not, nor can it make any sug-

gestions, representation, or warranties about the adequate staking required at each specific installation site. Staking

information provided in the installation instructions is not a suggestion about what is necessary to meet a site-specific

load.

For additional important information, consult: “The IFAI Procedural Handbook For the Safe Installation and Mainte-

nance of Tentage” and the IFAI Pocket Guide “Pullout Capacity of Tent Stakes”, both available from the IFAI Tent

Rental Division or on our website.

tion guidelines. It is the responsibility of the tent installer/maintainer to determine the severity of the weather, prop-

er time and method of installation and/or erection and disassembly. Note: We recommend that snow and ice be

removed from the tent surface as soon as possible because accumulation will damage the tent or fabric structure.

Please consult with our Engineering Department about the maximum loads for each product.

This product has been manufactured for use as a temporary structure. For the safety of all occupants, evacuation is

recommended if threatening weather occurs, or if there is any doubt concerning the safe use of this product.

ful evaluation be made to determine safety equipment needed, such as hard hats, steel-toe shoes, safety glasses

and other as required. It is our desire that all installations are safe. Please be aware of hidden dangers both under-

ground, i.e., gas lines, water lines, electrical lines, etc. and above the tent such as power lines and telephone lines.

Anchor products are of superior design and operate best within the parameters of these instructions. It is imperative

that the instructions be carefully read and COMPLETELY FOLLOWED. Please read installation instructions before the

installation or removal of this product. Installation instructions are available online at www.anchorinc.com or by calling

1-800-544-4445.

1. For each installation, the installer is solely responsible for evaluating the site and the proper securing method deter-

2. The number of stakes suggested in the installation instructions do not necessarily meet all or any relevant codes on

3. Inasmuch as the weather is unpredictable, good judgment and common sense must be incorporated within installa-

4. Proper safety equipment should be used at all times to insure a safe installation and take down. We suggest a care-

5. Anchor stands behind its products in accordance with its standard Terms and Conditions of sale. A copy of our

Terms and Conditions of Sale can be obtained by contacting Anchor at the telephone number and/or address on this

document.

5

Loading...

Loading...