Page 1

Perfectshade®

Assembly Instructions

SALES OFFICES:

1100 BURCH DRIVE

PO BOX 3477

EVANSVILLE, IN 47733 USA

EC 3958

PHONE: 800-322-8368

or 812-867-2421

FAX: 812-867-4636

EMAIL: oad@anchorinc.com

www.anchorinc.com

PRODUCTION FACILITIES:

EVANSVILLE, IN

PS 0409

Page 2

Warning: The Perfect Shade Structure is intended for concrete Install only. Installer is solely responsible for evaluating the quality of the concrete and its suitability for this structure.

Concrete installation surface must be level.

Manpower Required:

Three experienced installers should be able to assemble any size frame with fabric in two hours.

Caution:

Please read through this assembly manual completely before beginning your installation. Be sure the proper

equipment and safety precautions are in place. We hope that you enjoy the design features of the Perfect Shade

Structure.

1. Be aware to avoid contact of frame sections with any overhead power lines near the site.

2. Consult the local utility company prior to installation in order to avoid all underground power lines and gas

lines or other utility easements.

3. Keep site clear of debris to avoid tripping, especially while carrying frame parts or bundle of fabric.

4. When moving frame sections by hand, use proper lifting techniques to protect the back, and avoid pinching

fi ngers while making hardware connections.

5. Do not drag bundle of fabric on concrete, asphalt, or ground as this can cause damage to the fabric from abrasion through the bag.

6. The installation method described here requires coordination of tasks between workers. A safe installation is

dependent on that coordination. Work cooperatively as a team.

7. This tent is manufactured for use as a temporary sun shade structure. Evacuation is recommended if threatening or windy weather occurs.

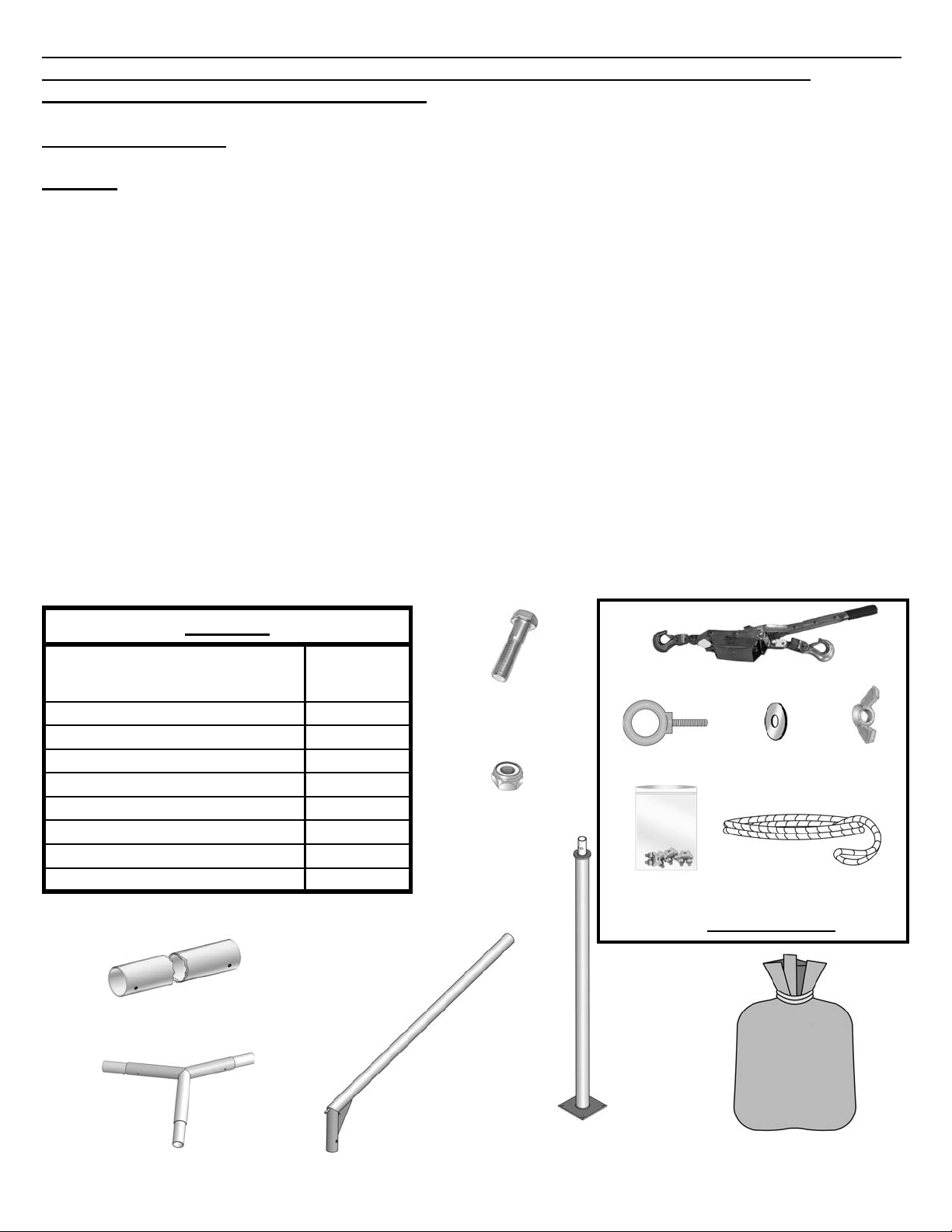

Parts List

Part Name

Upright with Base Plate 4

Hip Weldment 4

Peak Weldment 2

Ridge Tube 1

Hex Head Cap Screw 1/2 x 3 1/4” 4

1/2” Nylock Nut 4

Fabric top in bag with wire rope & clamps 1

Installation Kit (purchased separately) 1

Qty. for (1)

Frame

1/2” Hex

Head Cap

Screw

1/2” Nylock

Nut

Come-a-long (2)

Eyebolt (2) Neoprene

Washer (4)

Pull Rope (2)

(4) Wire Rope

Clamps

(spares)

Installation Kit

Wing nut

(2)

Ridge Tube

Peak Weldment

Hip Weldment

Upright with

Baseplate

Fabric top Bag

with wire rope & clamps

attached to top.

2

Page 3

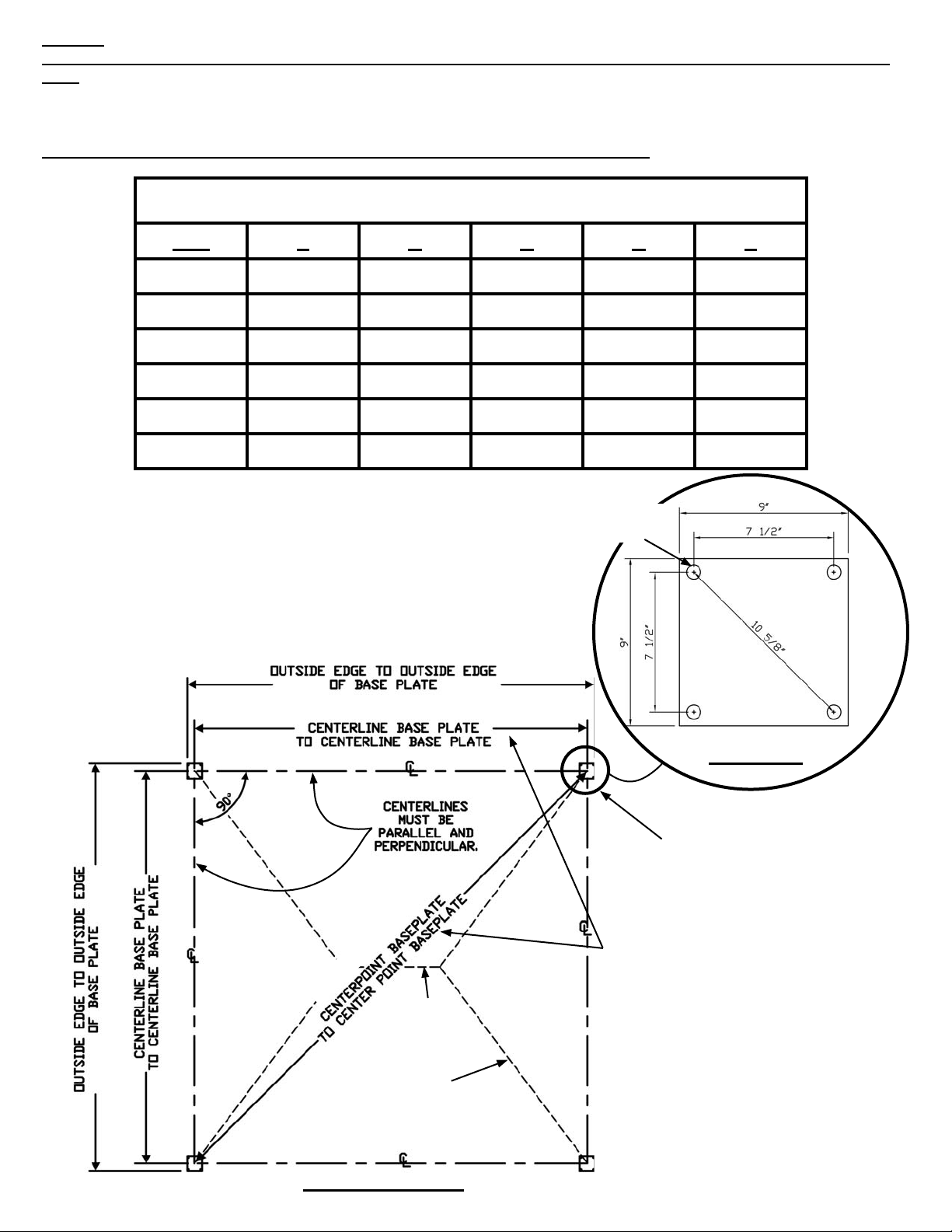

Step 1:

Choice of 1/2” diameter anchoring devices are at the discretion of the customer and not supplied by Anchor Industries.

Place anchoring devices as shown on the plan view below. (4) anchoring devices per base plate.

Note: For Your Convenience, (1) Template is supplied at the center of this manual.

DIMENSION CHART

FOR BASE PLATE LAYOUT

Size A B C D E

10’ x 10’ 9’- 10” 9’-10” 10’-7” 10’-7” 13’-10 7/8”

10’ x 15’ 14’- 10” 9’-10” 15’-7” 10’-7” 17 -9 9/16”

10’ x 20’ 19’- 10” 9’-10” 20’-7” 10’-7” 22’-1 5/8”

15’ x 15’ 14’- 10” 14’-10” 15’-7” 15’-7” 20’-11 3/4”

20’ x 20’ 19’- 10” 19’-10” 20’-7” 20’-7” 28’-0 9/16”

20’ x 30’ 29’- 10” 19’-10” 30’-7” 20’-7” 35’-9 7/8”

Caution: Concrete installation

surface must be level.

“C” Ref. dimension

Corner AA

“B”

“E” Diagonal

(4) 3/4” dia. holes for 1/2”

dia. anchoring devices.

“A”

Base Plate

Corner CC

Base Plate

(Typ. 4)

Dimensions are to center

points of base plates unless noted otherwise.

Ridge

“D” Ref. dimension

Corner BB

Frame shown in

dashed lines

Base Plate Layout

Corner DD

3

Page 4

Note the orientation of the corners to the ridge. Base plates

MUST be laid out in this order. -- AA, BB, CC and then DD.

Peak Weldments

Corner CC

Base Plate

Template

Ridge

Hip

Corner DD

Base Plate

Template

Corner BB

1st Base Plate

Template

Corner AA

2nd Base Plate

Template taped to

concrete surface.

Note: All uprights are identical, but proper orientation is

critical as noted in Step 3.

Figure 2

Step 2

Layout frame members as shown above in their approximate fi nal placement. (See base plate layout in Step 1)

Step 3

Stand one of the uprights over the installed anchors at Corner AA. (See Figure 2)

Warning: Examine the orientation of the upright so that when hip is attached it will be pointed toward the ridge. (See

Figure 3)

Step 4

Fasten the base plate to the anchors and tighten to snug. (See Figure 4)

Hip

Slide hip down

over upright aligning holes.

Note that hole thru

top of upright is

perpendicular to

hip and aligns with

hole in hip.

Upright

Figure 3

Upright

Remove template

before base plate

installation.

Figure 4

4

Page 5

Step 5

Attach the fi rst hip. Lift the Peak end of the hip up by climb-

ing a ladder (ladder placed at the approximate position of

the peak) (See Figure 5). Another person at the upright on a

ladder must direct the person at the peak end of the hip so

that it may be slipped into place on the upright. Make sure

the holes in the upright are aligned with those in the hip.

(See Figure 3) Loosely install bolt at hip to upright.

Step 6

Attach the Peak weldment to the hip. (Figure 6)

Warning: Examine the orientation of the peak weldment so

that the angles of the hips and ridge look to be pointing in

the proper directions.

Do not engage the valco button until later. For safety reasons, have the person at the peak stay at that position until

all hips are installed.

Step 7

Erect the second upright at Corner BB. The second upright

must be oriented as shown in Base Plate Layout and Figure

2.

Warning: Again examine the orientation of the upright so

that when hip is attached it will be pointed toward the ridge.

(See Figure 3)

Fasten the base plate to the anchors but with only a loose fi t

at this time for aid in installation.

Figure 5

Figure 6

Hip

Note: 12’ ladder used

at peak for 20’ frame.

Shorter ladder may

be used on smaller

frames

Hip

Peak

Step 8

Lift the peak end of the second hip up and place on the peak

weldment. Do not engage the valco button. (See Figure 7)

Step 9

It may be necessary to lean or tip the upright to align it so

that the hip can be slipped over the top of the upright. Once

the hip is on the upright, check to be sure that the holes in

the hip line up with the holes in the upright. If they do not

align, your upright may be turned incorrectly.

Loosely install bolt at hip to upright.

Tighten the base plate anchors to snug.

Step 10

Attach the ridge tube to the peak weldment by engaging the

valco button on the weldment into the hole in the ridge tube.

Attach the other peak weldment to the other end of the ridge

tube. (See Figure 8)

Step 11

Erect the third and fourth uprights (corners CC and DD).

Follow the instructions from Step 7 thru Step 9.

Step 12

Insert valco buttons of peak weldment into remaining hips.

Tighten all base plate bolts and tighten the bolts and nuts

from the hips to the uprights at this time.

Figure 7

Peak

Peak

Hips

Peak

Ridge

The Frame portion of the Perfect Shade is complete.

Figure 8

5

Page 6

Step 13

Remove fabric from bag. Do not drag over concrete or

other rough surfaces as this could damage the fabric.

Carry the fabric up the ladder to the ridge.

Throw the fabric over the ridge as shown in Figure 9. Be

certain that the fabric is right side up with the seams running perpendicular to the ridge. You will know the fabric

is right side up when the fl aps at the corners are on the

top side.

Step 14

At this point you need to decide which corner will be

the corner that will be your wire rope attachment corner.

(Corner AA or DD) This corner will be the one where the

wire rope loops are protruding from the corner of the

fabric. Let the fabric fall loosely down the hips, keeping

it fairly centered on the ridge. (Figure13)

Step 15

Start at the adjacent corner from the wire rope attachment corner that does not have the web handles. Pull

the top down over the corner and insert the Corner Pin

into the hole in the fabric. Tuck the wire rope under the

pin and then pull the corner fl ap down over the pin so

that the corner pocket catches on the pin. (See Figure

10).

Seam running

perpendicular

to ridge.

Corner Pin.

Ridge

Wire rope

attachment

corner with

ends hanging

loose

Figure 9

Corner Flap

Step 16

Proceed to the corner diagonally opposite the fi rst cor-

ner. Using short bursts, pull the fabric down over the

corner using the web handles and attach as in Step 15.

(See Figure 11).

Step 17

Proceed to the corner opposite the wire rope attachment

corner. Using the same technique as on Step 16, attach

this corner.

Step 18

Proceed to the last corner (The wire rope attachment

corner - See Figure 12). Slide a pull rope from the installation kit (sold separately) through the web handles as

shown in Figure 11. Pull the corner down

until the hole is caught over the corner

pin. (A second person on a ladder may be

required to guide the pull rope so that the

corner is more easily pulled into place.)

Remove the pull rope. Note that the cable

loops will be hanging loose.

Step 19

Attach the eyebolts, neoprene washers and

wing nuts. (See Figure 13) These will be

attached to the two uprights adjacent to

the wire rope attachment corner with the

eyebolts facing the wire rope attachment

corner. Place one neoprene washer each

side of the plate, neoprene side down, between the eyebolt and wing nut to prevent

scratching of the frame fi nish.

Wire Rope

Wire Rope

Pull Rope

Wire rope

attachment

corner.

Figure 11

Figure 12

Figure 10

Web

Handles

Wire rope

attachment

corner.

6

Page 7

Step 20

For 20’ frame, attach the ropes from the installation kit (sold

separately) to the eyebolts by slipping one end of the rope

through the eyebolt and then slip the other end through

that loop so that the rope is extended its full length. Attach the loose end of the come-a-long to the end loop and

expand the come-a-long all the way out so it is close to the

wire rope connection corner as shown in Figure 14.

Connect the ratchet-end snap on the come-a-long to the

wire rope coming from around the other side of the top.

(Figure 14). Do this for both sides.

For 15’ frame, slip one end of the rope through the eyebolt and attach both end loops of the rope (so that rope is

doubled) to the come-a-long as explained above.

For 10’ frame, attach the come-a-long directly to the eyebolt

as explained above.

Eye

Bolt

Figure 13

Step 21

Slowly advance come-a-longs, with a just a few cranks on

one and then the other so that both come-a-longs have the

same amount of tension at the same time. When you are

satisfi ed with the tension on the cables, you must fasten

them using the cable clamps attached to the top fabric inside a plastic bag or in the installation kit (sold separately).

Using a pair of vice grips, if available, clamp or hold the

two cables together on one side (Examine

each side to see which side is most accessible). (Figure 15) Fasten one of the cable

clamps onto the cables and tighten. Fasten a second cable clamp right beside the

fi rst one and tighten. (Figure 16)

Wire

Rope

Clamps

Step 22

Now loosen the tension on each of the

come-a-longs until you can easily remove

them. Go to the other side of the wire

rope attachment corner and attach the remaining (2) cable

clamps to the wire ropes.

Now carefully remove the come-a-longs, ropes, and eyebolts.

To fi nish the corner, unsnap the tabs and wrap the loose

ends of the wire ropes up into the tabs and also the web

handles so they may be hidden away under the corner fl ap.

Snap them into the keeper tabs and pull the fl ap down onto

the corner pin to fi nish. (Figure 17)

Come-a-longs

Wire rope

Rope thru

eyebolt in

frame

Figure 14

Vice Grips

Removal of top:

You must attach the come-a-longs and ropes onto the

looped ends of the wire ropes and

tension them as shown in Figure

14 before removing the cable

clamps or injury could occur.

Then work backwards with the

steps above.

Vice Grips

Socket Ratchet

Wire Ropes

Figure 16

Keeper

tabs

Figure 15

Figure 17

7

Page 8

PERFECT SHADE EMBEDDED IN CONCRETE

ALTERNATE INSTALLATION INSTRUCTIONS

This page must be used in conjunction with standard Perfect Shade Installation Instructions

When installing a frame that will

be embedded in concrete, frame

must be assembled prior to

setting in concrete.

Step 1 Alternate

Using Dimension Chart in

Step 1, dig (4) 1’-3” minimum

diameter holes, 2’-3” deep or as

required by soil conditions or

local code.

Add 3” of gravel to bottom of

holes. (Bottom of pole must be

allowed to drain water)

Frame may be assembled with

uprights in holes. See steps 5

through 12 for frame assembly.

When frame is assembled,

plumb and level frame and

brace into position.

Fill concrete to ground level.

Allow concrete to dry 72 hours

before installing fabric. See

steps 13 through 22.

Note: Concrete and gravel for

setting uprights for embedded

frame is required. Installer to

supply.

8

Page 9

EVANSVILLE, INDIANA

PHONE NUMBER

812· 867· 2421

FAX NUMBER

812· 867· 0547

Anchor products are of superior design and operate best within the parameters of these instructions. It is imperative

that the instructions be carefully read and COMPLETELY FOLLOWED. Please read installation instructions before the

installation or removal of this product. Installation instructions are available online at www.anchorinc.com or by calling

1-800-544-4445.

CAUTION:

1. For each installation, the installer is solely responsible for evaluating the site and the proper securing method

determined. Some soils require different staking or securing than that provided with the tent. Due to this variety of

soil conditions, these are the manufacturer’s suggested sequence of installation procedures. Anchor’s responsibility

is limited to the manufacture of the tent parts and materials. We are not responsible for methods that installers may

choose to erect and secure the tent to the ground.

2. The number of stakes suggested in the installation instructions do not necessarily meet all or any relevant codes

on the site of the tent installation. The number of stakes suggested will, in many cases, keep the tent erected,

however, due to various soil conditions; these stakes will be insuf¿ cient to keep the tent secure in high winds.

It is the tent installer’s responsibility, not the manufacturer, to determine the appropriate number of stakes to meet

the necessary wind loads on the site. Regardless of the number of stakes we suggest, we make no representation

or warranty as to whether this speci¿ c number of stakes will meet the local tent code. Anchor does not, nor can

it make any suggestions, representation, or warranties about the adequate staking required at each speci¿ c

installation site. Staking information provided in the installation instructions is not a suggestion about what is

necessary to meet a site-speci¿ c load.

For additional important information, consult: “The IFAI Procedural Handbook For the Safe Installation and

Maintenance of Tentage” and the IFAI Pocket Guide “Pullout Capacity of Tent Stakes”, both available from

the IFAI Tent Rental Division or on our website.

3. Inasmuch as the weather is unpredictable, good judgment and common sense must be incorporated within

installation guidelines. It is the responsibility of the tent installer/maintainer to determine the severity of the weather,

proper time and method of installation and/or erection and disassembly. Note: We recommend that snow and

ice be removed from the tent surface as soon as possible because accumulation will damage the tent

or fabric structure. Please consult with our Engineering Department about the maximum loads for each

product.

This product has been manufactured for use as a temporary sunshade structure. For the safety of all occupants,

evacuation is recommended if threatening weather occurs, or if there is any doubt concerning the safe use of this

product.

4. Proper safety equipment should be used at all times to insure a safe installation and take down. We suggest a

careful evaluation be made to determine safety equipment needed, such as hard hats, steel-toe shoes, safety

glasses and other as required. It is our desire that all installations are safe. Please be aware of hidden dangers

both underground, i.e., gas lines, water lines, electrical lines, etc. and above the tent such as power lines and

telephone lines.

5. Anchor stands behind its products in accordance with its standard Terms and Conditions of sale. A copy of our

Terms and Conditions of Sale can be obtained by contacting Anchor at the telephone number and/or address on

this document.

28.1 03-04-09

Loading...

Loading...