Page 1

Assembly Instructions

Navi-Trac® LT/CS Pavilion

12’ to 24’ Projection

EVANSVILLE, INDIANA

Please read all assembly / installation instructions before the installation or removal of this product.

PHONE: 812-867-2421

SALES OFFICES:

1100 BURCH DRIVE

PO BOX 3477

EVANSVILLE, IN 47733 USA

Quality, Craftsmanship and Service since 1892

EC 3597

FAX: 812-867-0547

1-800-544-4445

EMAIL: tents@anchorinc.com

www.anchorinc.com

PRODUCTION FACILITY:

EVANSVILLE, IN

NTLTPAV 0211

Page 2

NAVI-TRAC LT PAVILION INSTALLATION SAFETY

GUIDELINES

Your own installation techniques will evolve to fit the varied needs of your clients, the experience level of your installation

crews, the nature of other tentage that may be common to the installation site being planned, and the equipment that you

may have available or with which you feel most comfortable. Whatever techniques you adapt for your crews, we encourage you to keep safety utmost in mind.

Please read through this assembly manual completely before beginning your installation. Be sure the proper equipment,

crew and safety precautions are in place. We hope that you enjoy the design features of the Navi-Trac Lite™ Pavilion

each time the unit is installed.

1. It is recommended that workers wear safety shoes and hard-hats on site.

2. When moving frame sections by hand, use proper lifting techniques to protect the back, and avoid pinching

fingers while making hardware connections.

3. Be sure all workers are cautious and attentive to the falling paths of frame sections being raised or

lowered.

4. Be aware to avoid contact of frame sections with any overhead power lines near the site.

5. When anchoring the structure, avoid all underground power lines and gas lines or other utility easements.

6. Keep site clear of debris to avoid tripping, especially while carrying frame parts or bundles of fabric.

7. Do not drag bundles of fabric on concrete, asphalt, or ground as this can cause damage to the fabric from

abrasion through the bag.

8. Do not climb onto the fabric “roof” of the structure. When necessary, work safely from a ladder of

appropriate size.

9. When standing frame sections to vertical, or when lowering, use a smooth motion and have other

workers “foot” the base of the section to avoid slippage along the ground.

10. When installing gabled end units, be sure all beams are stabilized either by safety guys or cross cabling until connected to a section of the unit that is already stabilized in this manner.

11. When installing a unit in which the overall length exceeds 60 ft, add one extra X-cabled bay for each addi-

tional 60 ft of length. To meet design loads, no more than 60 ft of consecutive length can remain non-X-

cabled.

12. The installation method described here requires coordination of tasks between workers. A safe installation is

dependent on that coordination. Please work cooperatively as a team.

2

Page 3

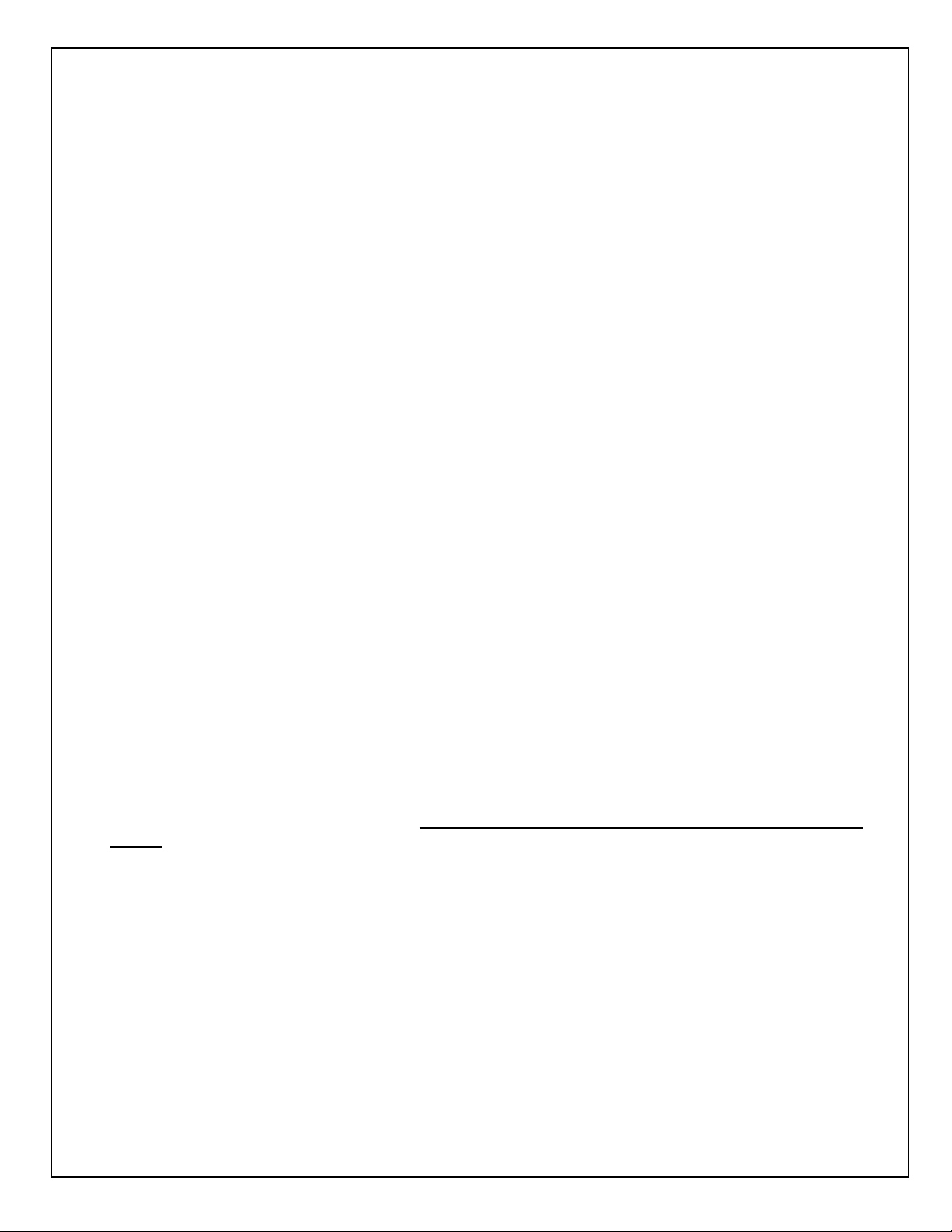

Parts List

NAVI-TRAC LT/CS PAVILION INV 10X20 10X10 12X20 12X10 14X20 14X10 16X20 16X10 18X20 18X10 20X20 20X10 22X20 22X10 24X20 24X10

COMPONENT DESCRIPTION # MID MID MID MID MID MID MID MID

ALUMINUM EXTRUSION

ANODIZED W/5 CHANNEL OPENINGS

EAVE-10'-0" 8004400 2121212121212121

REAR EAVE-10'-0" 8004475 2121212121212121

EAVE-10' PROJECTION 80932C 3 1

EAVE-12' PROJECTION 80760 3 1

EAVE-14' PROJECTION 80789 3 1

EAVE-16' PROJECTION 80761 3 1

EAVE-18' PROJECTION 80762 31

EAVE-20' PROJECTION 80763 31

EAVE-22' PROJECTION 80764 31

EAVE-24' PROJECTION 80765 31

EAVE SPLICE-24' PROJECTION 80766 31

RAFTER -10' PROJECTION 80931C 3 1

RAFTER -12' PROJECTION 80751 3 1

RAFTER-14' PROJECTION 80752 3 1

RAFTER-16' PROJECTION 80753 3 1

RAFTER-18' PROJECTION 80754 31

RAFTER-20' PROJECTION 80755 31

RAFTER-22' PROJECTION 80756 31

RAFTER-24' PROJECTION 80757 31

RAFTER SPLICE-22' PROJECTION 80758 31

RAFTER SPLICE-24' PROJECTION 80759 31

UPRIGHTS:

UPRIGHT - 8'-0" 80044506262626262628282

UPRIGHT - 9'-0" 8004480

UPRIGHT - 10'-0" 8004455

UPRIGHT REAR SPLICE-10' PROJECTION 80934C 3 1

UPRIGHT REAR SPLICE-12' PROJECTION 80768 3 1

UPRIGHT REAR SPLICE-14' PROJECTION 80769 3 1

UPRIGHT REAR SPLICE-16' PROJECTION 80770 3 1

UPRIGHT REAR SPLICE-18' PROJECTION 80771 31

UPRIGHT REAR SPLICE-20' PROJECTION 80772 31

UPRIGHT REAR SPLICE-22' PROJECTION 80773 31

UPRIGHT REAR SPLICE-24' PROJECTION

MISC. COMPONENTS:

RIDGE 10'-0" 80767 2121212121212121

RAFTER BRACE 3580666 313131

10'-0" PURLIN (NAVI-TRAC) 80410 2 121212121

MID TENSIONING TUBE 807792121212121212121

MID TENSIONING TUBE SPLICE 80780 1111111111111111

CONTAINER #1:

BASE PLATE ADJUSTABLE-4 HOLE 80775 6262626262626262

BASE PLATE ADJUSTABLE-2 HOLE 8004505 22

RIDGE WELDMENT ASSEMBLY 80750 3131313131313131

15.5 DEGREE EAVE WELDMENT 80790 1111111111111111

15.5 DEGREE EAVE END RIGHT WELDMENT 80777 11111111

15.5 DEGREE EAVE END LEFT WELDMENT 80778 11111111

END UPRIGHT EAVE WELDMENT 3582180 22

FRAME ATTACHING BRACKET ASSEMBLY 80781 3131313131313131

NAVI-TRAC LT/CS PAVILION INV 10X20 10X10 12X20 12X10 14X20 14X10 16X20 16X10 18X20 18X10 20X20 20X10 22X20 22X10 24X20 24X10

COMPONENT DESCRIPTION # MID MID MID MID MID MID MID MID

CONTAINER #2: #1417C #1418C #1403 #1404 #1405 #1406 #1407 #1408 #1409 #1410 #1411 #1412 #1413 #1414 #1415 #1416

RAFTER "X" CABLE ASSY-10' PROJECTION 80936C 4

RAFTER "X" CABLE ASSY-12' PROJECTION 80782 4

RAFTER "X" CABLE ASSY-14' PROJECTION 80783 4

RAFTER "X" CABLE ASSY-16' PROJECTION 80784 8

RAFTER "X" CABLE ASSY-18' PROJECTION 80785 8

RAFTER "X" CABLE ASSY-20' PROJECTION 80786 8

RAFTER "X" CABLE ASSY-22' PROJECTION 80787 8

RAFTER "X" CABLE ASSY-24' PROJECTION 80788 8

CONTAINER #3:

1/2-13 x 3 1/4" Shoulder Eye Bolt (Navi-Trac) 3020525 22244444

TENSION LOCK PIN 3102865 6262626262124184184

1/2-13 x 2 3/4" H.H.C.S. GRD.5 ZC. 3023425 3162

1/2-13 HEX JAM NUT ZC.W/ NYLON INSERT 3024630 3162

OPTIONAL:

STAKES FOR BASE PLATES - 1"x30" DBL. HEAD

STEEL STAKE

80774 31

37042306262626262628282

#1409 #1410 #1412#1404 #1405 #1407 #1408#1403 #1406#1417C #1418C #1416#1411 #1414 #1415#1413

3

Page 4

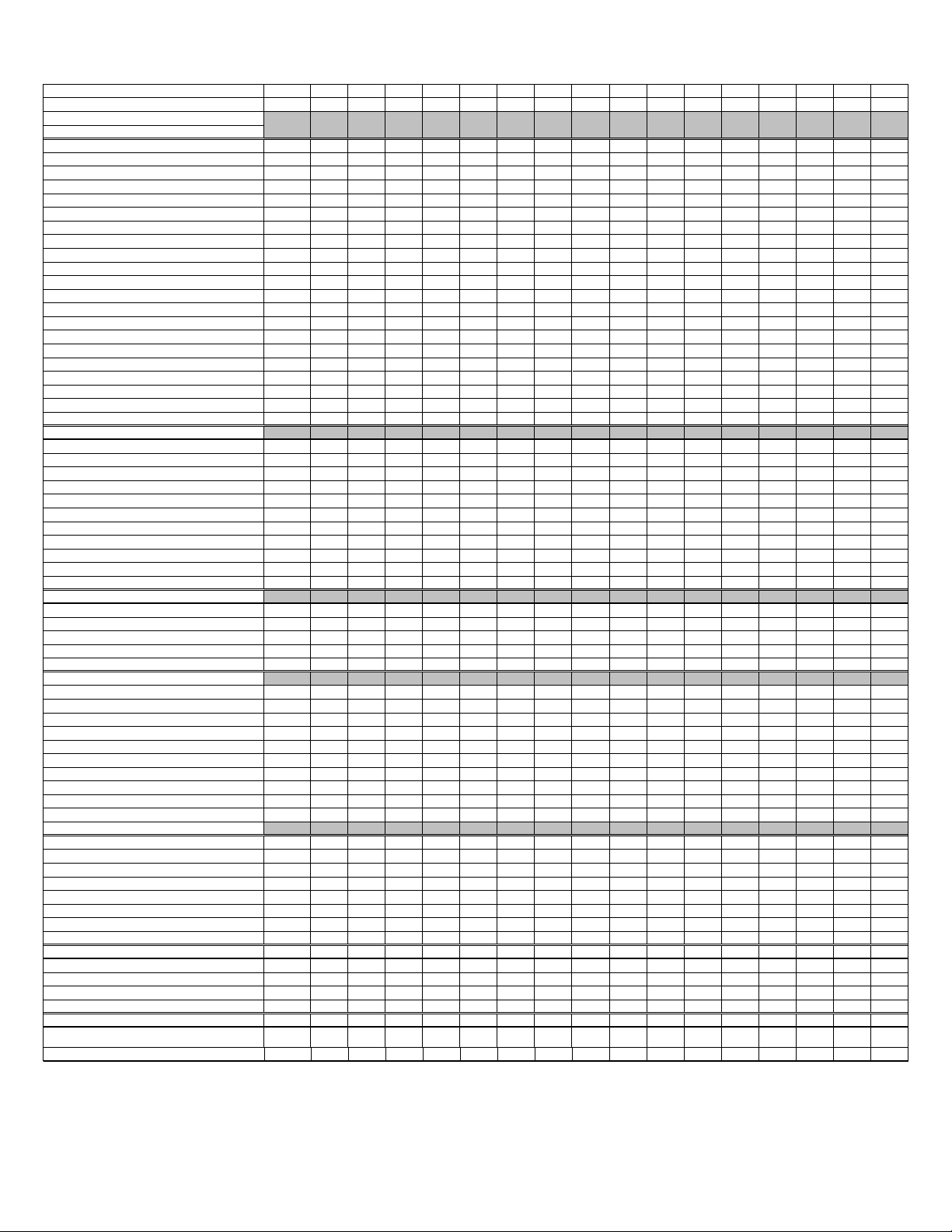

PARTS ILLUSTRATIONS

EWP

EAVE WELDMENT

EAVE

REAR EAVE - DROP IN

TENSIONING

TUBE SPLICE

E - 10

EAVE END R/L

WELDMENT

(RIGHT SHOWN)

EE - 10

EAVE/PROJECTION (NUMBER DENOTES

PROJECTION SIZE)

EPR

EPL - LEFT

(OPPOSITE

SHOWN)

EAVE 24’ PROJECTION

RWP

EP-24

RAFTER

RIDGE WELDMENT

EP - SIZE

RP- 24

24’ EAVE SPLICE

RP - SIZE

RS-22 or RS-24

TENSIONING TUBE

UR-SIZE

END UPRIGHT EAVE

WELDMENT

PURLIN

UPRIGHT REAR UPPER SPLICE

UPRIGHT 8’

TENSION LOCK

PIN

EYE NUT AND BOLT

U-8

RAFTER BRACE

RIDGE

RAFTER SPLICE PROJECTION

BAP

BASE PLATE

ADJUSTABLE

4-HOLE

BASE PLATE

ADJUSTABLE

2-HOLE

BA

RAFTER “X” CABLE

PARTS SHOWN ARE NOT TO SCALE.

4

FRAME A TT ACHING BRACKET

Page 5

(1) FRAME ATTACHING

BRACKET ASSY SUPPLIED FOR EACH UPRIGHT

REAR UPPER SPLICE FOR

ATTACHMENT TO EXIST.

BUILDING.

RIDGE

WELDMENT

ASSY

RWP

UPRIGHT REAR

UPPER SPLICE

UR-12

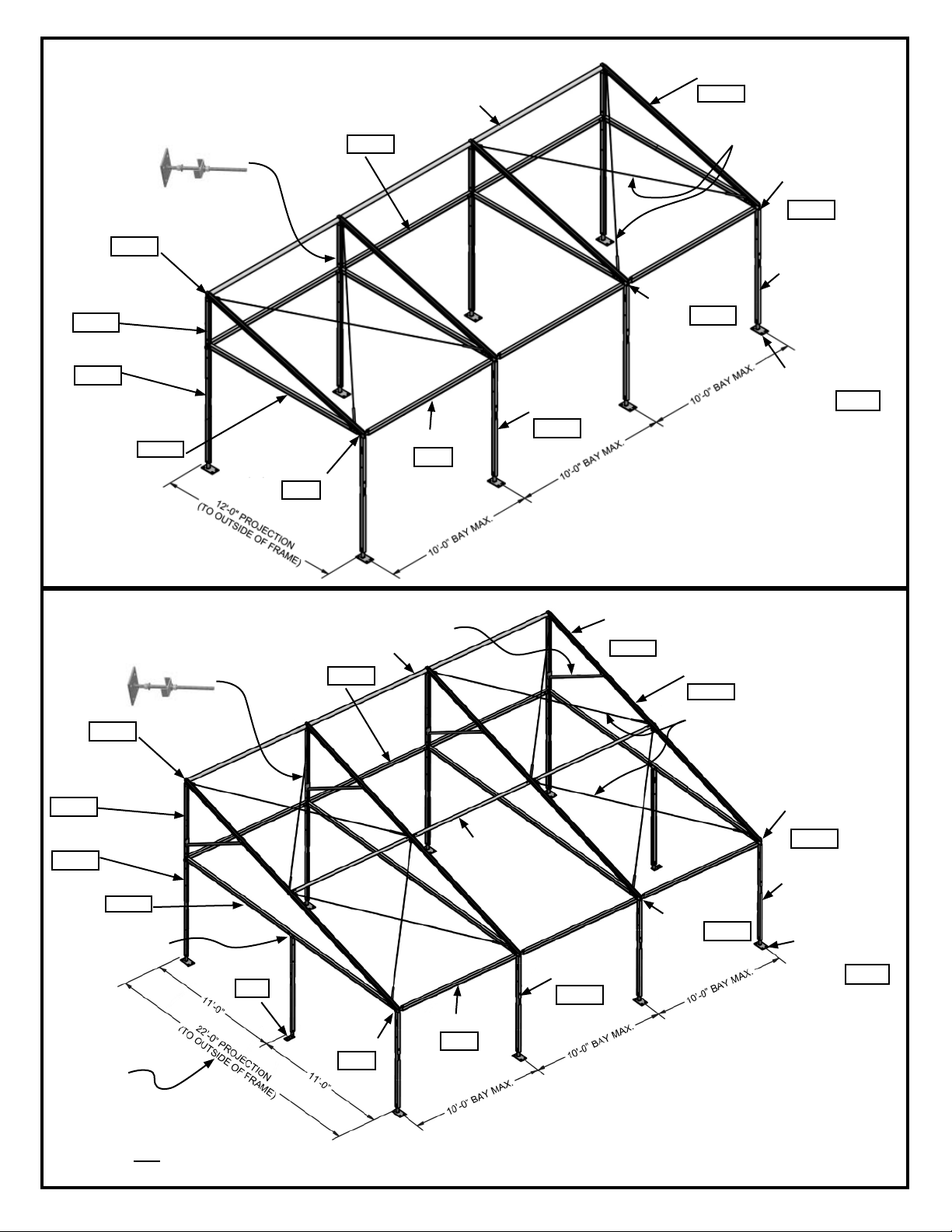

ASSEMBLED FRAME ILLUSTRATIONS

RIDGE

REAR EAVE,

DROP-IN

EE-10

EAVE WELDMENT

RAFTER - 12’ PROJECTION

RP-12

RAFTER “X” CABLES

END LEFT

WELDMENT

EPL

NOTE: UPRIGHTS

ARE 8’ TO 10’ ADJUSTABLE HEIGHT.

EWP

UPRIGHT-8’

U-8

EAVE PROJECTION 22’

NOTE: STAKES ARE OPTIONAL, NOT SUPPLIED WITH

STANDARD UNIT.

(1) FRAME ATTACHING

BRACKET ASSY SUPPLIED FOR EACH UPRIGHT

REAR UPPER SPLICE FOR

ATTACHMENT TO EXIST.

BUILDING.

RIDGE

WELDMENT

ASSY

UPRIGHT REAR

UPPER SPLICE

EP-12

RWP

UR-22

UPRIGHT-8’

U-8

EAVE PROJECTION 22’

EP-22

END UPRIGHT

EAVE WELDMENT

BASE PLATE

ADJ. 2-HOLE

EAVE END

RIGHT WELD.

EPR

REAR EAVE,

DROP-IN

BA

EAVE - SLIDE

IN

E10

RAFTER BRACE ONLY

ON 20’ OR MORE PROJECTION FRAMES.

RIDGE

EE-10

PURLIN

UPRIGHT-8’

U-8

12’ PROJECTION SHOWN

UPRIGHT-8’

U-8

Most parts have labels affi xed

as noted in the outlined boxes.

Numbers refer to length.

RS-22

RAFTER SPLICE - 22’

PROJECTION

RS-22

RAFTER - 22’ PROJECTION

RP-22

RAFTER “X” CABLES

EAVE WELDMENT

EWP

BASE PLATE

ADJUSTABLE 4-HOLE

END LEFT

WELDMENT

BAP

EPL

NOTE: UPRIGHTS

ARE 8’ TO 10’ ADJUSTABLE HEIGHT.

BASE PLATE

ADJUSTABLE 4-HOLE

BAP

NOTE: UPRIGHT

CENTERED ON END,

REQUIRED ABOVE 20’

PROJECTION.

NOTE: 24’ PROJ. HAS EAVE

PROJECTION AND EAVE

SPLICE PROJECTION

EAVE END

RIGHT WELD.

EPR

EAVE - SLIDE

IN

E10

NOTE: STAKES ARE OPTIONAL, NOT SUPPLIED WITH

STANDARD UNIT.

Most parts have labels affi xed

as noted in the outlined boxes.

Numbers refer to length.

22’ PROJECTION SHOWN

5

Page 6

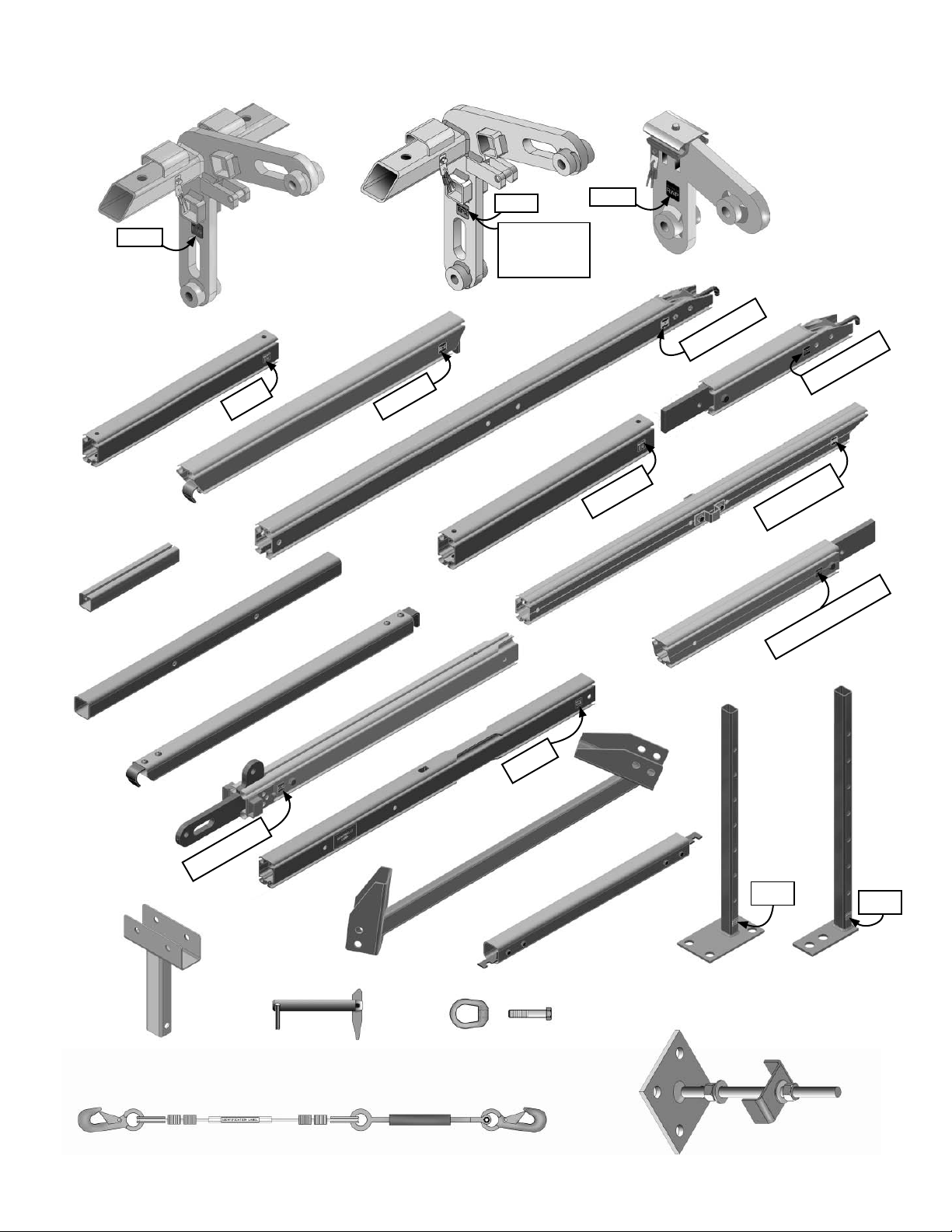

Point B

PLAN VIEW OF 3 BAY STRUCTURE

(22’ Projection shown)

BACK OF PAVILION

Point C

11’-1 7/8” for 22’ Projection

12’-1 7/8” for 24’ Projection

“A” DIMENSION - SEE TABLE

PLATE TO OUTSIDE OF BASEPLATE.

MEASURED FROM OUTSIDE OF BASE-

11’-5 1/16” for 22’ Projection

Point A

C

L

12’-5 1/16” for 24’ Projection

Front and Back

Uprights

10’-0” 10’-0” 10’-0”

C

L

Uprights

“B” DIMENSION - SEE TABLE

DIAGONAL IS MEASURED TO CENTER

BACK AND CENTER FRONT OF BASE-

PLATES AS SHOWN IN DETAILS.

C

L

FRONT OF PAVILION

30’-0”

Uprights

4-Hole base plate

(typ.)

Upright centered on

end required only

on structures above

20’ projection.

(2) Hole Base Plate

required at this

position only.

C

Front and Back

L

Uprights

Point D

LAYOUT DIMENSIONS

Pavilion Size “A” Dimension “B” Diagonal Dim.

12’ Projection x 30’ 12’-6 15/16” 32’-6 3/8”

14’ Projection x 30’ 14’-6 15/16” 33’-4 1/4”

16’ Projection x 30’ 16’-6 15/16” 34’-3 5/16”

18’ Projection x 30’ 18’-6 15/16” 35’-3 7/16”

20’ Projection x 30’ 20’-6 15/16” 36’-4 9/16”

22’ Projection x 30’ 22’-6 15/16” 37’-6 9/16”

24’ Projection x 30’ 24’-6 15/16” 38’-9 3/8”

To fi nd a diagonal measurement not listed here, use

this formula: width² + length² = diagonal²

Directions for Squaring the Tent

(see the diagram above)

1. Locate the four primary corners.

a. Using a tape measure, mark Points A & B (the width of the pavilion fi rst.

b. Using one tape measure, start from point B and measure the

length of the tent.

c. Using a second tape measure, start from point A and measure the

diagonal.

d. Mark the point at which these two tapes intersect. (Point C) This

will square the tent.

e. Using the same process, mark point D.

2. Locate points for intermediate uprights.

a. Using a tape measure running from points A

to B, mark for end uprights

(only on frames over 20’

projection).

b. Using a tape measure

running from points B to

C (or A to D) mark for side

uprights according to your

particular pavilion.

These markings will be

your guideline for tent

layout.

Standard 4-hole Base Plate

6

2-Hole Base Plate for End Uprights

Page 7

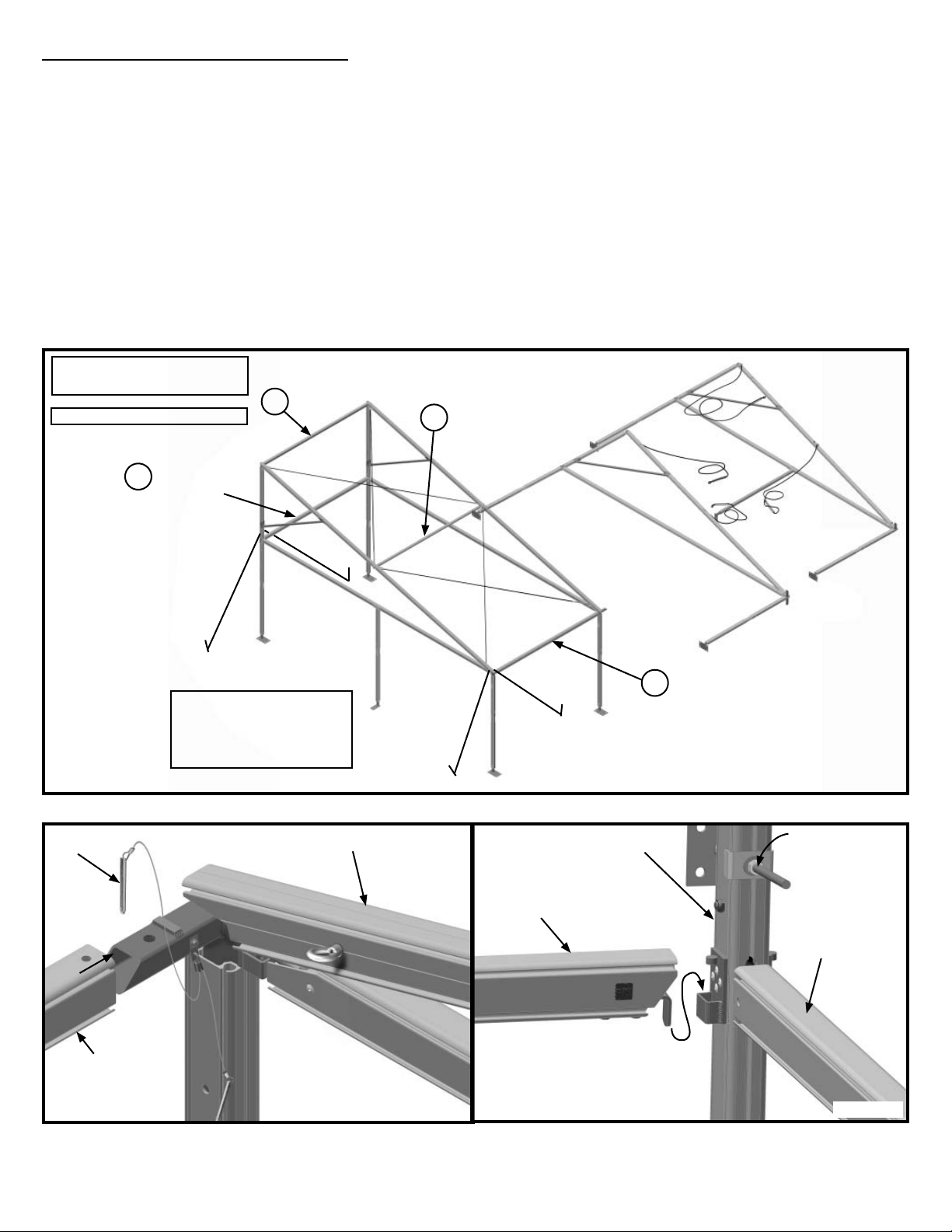

Step 1 - Parts Layout

•

Follow the directions on the previous page for squaring and marking

for the frame.

•

Lay out the parts neatly in their approximate location, as if the frame

were collapsed onto the ground.

(Figure 1a)

•

Upright

Rear

Upper

Splice

Step 2 - Beam Arch Assembly

Assemble the fi rst beam arch in the

•

following order:

Assemble upper triangle fi rst

1.

by fastening upright rear upper

splice to ridge weldment using

one of the pins attached to the

ridge weldment.

Drop hook end of Eave Projec-

2.

tion into Eave End Weldment

Bracket. (Figure 2a) Note: On

24’ projection, Eave projection

is spliced. Slide Eave Splice

Projection into 24’ Eave Projection and fasten using 1/2” bolt

and nut.

Drop slotted end of Eave

3.

Projection down over ear

located at bottom of upright

rear upper splice and pin

using a tension lock pin.

(Figure 2b)

Assemble Rafter Splice

4.

Projection to Rafter using

1/2” bolt and nut provided

(required only on frames

over 20’ projection)

Slide Rafter up onto ridge

5.

weldment and affi x using method detailed as follows:

On rafters with “X” cables in one of the adjacent bays such as end

•

bays (see illustration on page 5) connection must be made using the

eye nuts and bolts shipped with the “X” cables. Eye nut must face in

the direction of the “X” cabled bay because it is used for connection of

the “X” cables. (See Step 3)

In the case where there are two “X” cabled bay adjacent to one

•

another, the connection must be made using an eye bolt with eye nut.

(not usual)

On rafters with no “X” cables attach the rafter using the pin attached to

•

the ridge weldment.

6. On frames with 20’ projection or more, rafter brace is now attached to triangle.

Rafter Brace will only fi t one way- so if you are having trouble with alignment,

turn the brace around so that the opposite ends are now at the rafter and upright rear upper splice. (See Figure 2c)

7. Assemble uprights by sliding adjustable base plates into uprights and bolting

with bolts provided. See Figure 2d for assistance in assembling the upright in

the correct position.

8. On Rear upright, slide Upright rear upper splice down into bottom upright and

pin with a tension lock pin. See Figure 2d for assistance in assembling the

upright in the correct position.

9. Assemble all Beam arches with baseplates in correct position for raising.

Upright

Eave End Weldment

Ridge

Weldment

Rafter Splice

Projection

Rafter Brace (only

on frames 20’ projection and larger.

End Upright

Eave Weldment

Upright (only on

frames over 20’

projection.)

Base Plate

Adjustable

4-Hole

Note: End Upright used only on

frames larger that 20’ projection.

Eave projection

Figure 2a

22’ Projection Frame Shown

Rafter

Eave Projection

Base Plate

Adjustable

2-Hole

Upright Rear Upper

Splice Ear

Upright Rear

Upper Splice

Rafter Brace

Cross-sectional view of

Navi-Trac Lite Beam

Channeled

side of upright.

toward inside

of frame.

Eave End

Weldment

Upright

Base Plate

Adjustable

4-Hole

Figure 1

Slot

Eave projection

Figure 2b

Rafter

Tension

Lock Pin

Figure 2c

Flat side of

upright. toward

outside of frame.

Figure 2d

7

Page 8

Step 3 - Raising the Beam Arches

Raise fi rst beam. Tie off securely or hold up using adequate installation personnel. Note: There are no stakes or guys

•

included with this frame, however, the installation kit (sold separately) includes eye bolt and eye nut for attaching to frame

along with safety webs that may be used to stake or tie-off frame to stabilize the fi rst beam while frame is being assem-

bled. See Figure 3a.

Raise the second beam arch, keeping base plate in place by using installation personnel or stakes (not included).

•

Note: Before Raising Beam Arches, all eye nuts and “X” Cables must be in place as

shown in Figure 3a. Turnbuckles should be open all the way.

22’ Projection Frame Shown

Frame sizes under 16’

projection have only (2)

cables per bay and no

purlins.

Eyenuts on

inside of Rafter

First beam arch assembled and raised.

1/2” x 3 1/4” cap screw

and eye nut may be used

with safety web guys from

installation kit for stabilizing

fi rst raised beam. (installation kit is an optional

purchase)

Note: If you are installing a 2-bay pavilion, both

bays must be “X” cabled, therefore, eye nuts and

eye bolts must be used at center beam arch (similar

to confi guration at right).

Eyenuts face

ground on second rafter.

Note: Turnbuckles

at free end.

Eyenut

Eyenuts on

inside of Rafter

Eyebolt and safety

webs from installation

kit may be temporarily

installed for stabilizing fi rst raised beam.

(Use eyebolt with

eyenut from standard

frame hardware.)

Figure 3a

8

Page 9

Before placing frame in fi nal position, attach

frame attaching bracket to upright rear upper

splice on each rear upright.

Remove stablizer plate, washer and hex nut from rod

•

on bracket.

Insert rod into upright rear upper splice from back of

•

pavilion.

Place stabilizer plate, washer and hex nut back onto

•

rod so that bracket stays in place. Do not tighten until

frame and fabric are completely assembled and installed. Do not use stabilizer plate at corner uprights.

Plate for connection to

existing structure.

Stablizer plate, washer

and hex nut

Stablizer plate may not

be used at corner uprights. Remove.

Figure 3b

U-Shaped stabilizer may not

be used at corner uprights

due to fabric interference.

Figure 3c

9

Page 10

Step 4 - Joining Beam Arches

Join in the order listed: (Figure 4a)

•

Front Eave - slide one end of front eave tube onto end eave weldment with bottom channel down. Align holes and pin

with one of the pins attached to the weldment. Figure 4b.

•

Gable End Mid Eave - drop gable end mid eave into brackets on upright rear upper splices. Figure 4c

•

Ridge - fi t ridge into slots provided in ridge weldment. Figure 4d.

•

Purlin - Drop curved end of purlin into rafter bracket. See fi gures 4e and 4f. Drop square hook end into the correspond-

ing rafter bracket.

•

Note: If optional installation kit has been used, remove eyenut at lower end of fi rst rafter and replace with nut

before snapping cables in place.

Note: If Installation Kit has been purchased, the short lifting bar may be used to lift bars into place.

Snap lower ends of cables onto their respective eye nuts. Square up frame by tightening turnbuckles

•

Parts labeled numerically in

the order to be installed.

22’ Projection Frame Shown

Gable End

3

Mid Eave

2

Ridge

4

Purlin

Longer

Pin

Front Eave

Frame sizes under 16’

projection have only (2)

cables per bay and no

purlins.

Rafter

Figure 4b

Upright Rear

Upper Splice

Gable End Mid

Eave

1

Front Eave

Figure 4a

Frame attaching

bracket.

Eave Projection

Figure 4c

10

Page 11

Ridge

Weldment

Curved hook end Square hook end

Purlin

Ridge

Rafter

Figure 4d

Figure 4e

Rafter

Purlin

Figure 4f

Step 4 - Cont’d

Continue raising beams and attaching them until frame is completely assembled. Connect all cables and tighten. Measure to

be sure frame is square and in proper position.

Step 5 - Fabric Mid Installation

With one installer at top of each rafter, feed eave end of kedar into top channel opening of ridge weldment and down into

•

rafter. (Figure 5a) Feed both kedars at the same time and at the same rate until the ends of the kedars are at end of rafter at eave. Optional method: Snap pull ropes onto pull rings at mid eaves and pull mids down from top after kedars are

started into channels simultaneously.

Raise back ends of mid kedars up until bottom of kedar can be fed down into top of channel on Upright Rear Upper

•

Splice. Feed both kedars down at the same time and at the same time until kedars are fully inserted into channels. (Figure 5b)

Continue this process until all mids are installed.

•

Mid

Pull Ring at

Mid Eave

~

Ridge Weldment

Eave end of kedar

Front curtain

folded back onto

top of mid

Rafter

Ridge of adjacent bay

Upright Rear

Upper Splice

Rafter

Mid

Kedar feeding down into

channel

Figure 5a

Figure 5b

11

Page 12

Step 6 - Fabric

Ends Installation

End Fabric

With one installer at

•

top of the end rafter,

feed eave end of

kedar into top channel opening of ridge

weldment and down

into rafter until end

of kedar reaches

the end of the rafter.

(Figure 6a)

Raise bottom end of

•

back kedar up until

bottom of kedar can

be fed down into

top of channel on

Upright Rear Upper

Splice. (Figure 6b)

After end fabric is in

•

place, fi esta buckles

on inside of fabric at

eave must be connected. Slide kedar pieces with d-ring into top/outside

channel of eave beam. Align these with corresponding

fi esta buckles. Slide web through d-ring as shown in

fi gure 6c. Tighten webs.

End Fabric is installed.

•

Rafter

Figure 6a

Rafter

Bottom end of

back kedar

Kedar

feeding

down into

channel

End Fabric

Figure 6b

Fiesta Buckle attached to inside of

end fabric. (Fabric

not shown.

12

Kedar piece

with D-ring

Figure 6c

Page 13

Step 7 - Fabric Tensioning

At back of pavilion, snap buckles of back-end straps to corresponding buckles at bottom of mids. Insert bottom hook into

•

slot at back of upright. Tighten just enough so that hook does not fall out of slot. (Figure 7a)

At front of mids, insert tension tubes into pockets under curtain. Between mids, use a tension tube splice to connect

•

tubes. (Figure 7b) Before insertion, hang tension strap with ratchet and hook over the tension tube splice. At ends, hang

tension strap over end of tension tube as shown in Figure 7c.

Insert hook of tension strap into slot in front upright. Crank ratchet until tension strap stays in place but do not tension.

•

Check mids to be sure they are all pulled to the same point in front and back. Check back end straps to be sure they are

tightened uniformly. When you have checked these things, you may now ratchet the front tension straps. Tighten until all

mids are uniformly snug.

Rear Corner Upright

Frame attaching

bracket

Use single back

end strap at corner

upright.

Connect male buckle to female buckle

at bottom of mid.

Rear Upright

Mid Fabric

Frame attaching

bracket

Mid Fabric

Use double back

end strap at

uprights between

mids.

Slot in upright

Slot in upright

TENSIONING

TUBE SPLICE

Tensioning Tube Splice

TENSIONING TUBE

is used between mids

fi ts into ends of tension

tubes.

Back View

Figure 7b

Tension Pocket with

tension tube inserted.

Tension strap over end

of tension tube at front

corner.

Inside view looking at tension

pocket under curtain.

Figure 7a

Figure 7c

13

Page 14

Step 8 - Fastening Frame to Existing Building

At back of pavilion, adjust the frame attaching bracket so that is is fi tted up to existing building.

•

Customer must determine and install the type of device that is best suited to attach frame to existing building.

•

U-Shaped stabilizer may not be

used at corner uprights due to

Connection to existing building

must be determined by customer.

fabric interference.

Frame Attaching Bracket

14

Page 15

Notes:

15

Page 16

EVANSVILLE, INDIANA

PHONE NUMBER

812· 867· 2421

FAX NUMBER

812· 867· 0547

Anchor products are of superior design and operate best within the parameters of these instructions. It is imperative

that the instructions be carefully read and COMPLETELY FOLLOWED. Please read installation instructions before the

installation or removal of this product. Installation instructions are available online at www.anchorinc.com or by calling

1-800-544-4445.

CAUTION:

1. For each installation, the installer is solely responsible for evaluating the site and the proper securing method

determined. Some soils require different staking or securing than that provided with the tent. Due to this variety of

soil conditions, these are the manufacturer’s suggested sequence of installation procedures. Anchor’s responsibility

is limited to the manufacture of the tent parts and materials. We are not responsible for methods that installers may

choose to erect and secure the tent to the ground.

2. The number of stakes suggested in the installation instructions do not necessarily meet all or any relevant codes

on the site of the tent installation. The number of stakes suggested will, in many cases, keep the tent erected,

however, due to various soil conditions; these stakes will be insuf¿ cient to keep the tent secure in high winds.

It is the tent installer’s responsibility, not the manufacturer, to determine the appropriate number of stakes to meet

the necessary wind loads on the site. Regardless of the number of stakes we suggest, we make no representation

or warranty as to whether this speci¿ c number of stakes will meet the local tent code. Anchor does not, nor can

it make any suggestions, representation, or warranties about the adequate staking required at each speci¿ c

installation site. Staking information provided in the installation instructions is not a suggestion about what is

necessary to meet a site-speci¿ c load.

For additional important information, consult: “The IFAI Procedural Handbook For the Safe Installation and

Maintenance of Tentage” and the IFAI Pocket Guide “Pullout Capacity of Tent Stakes”, both available from

the IFAI Tent Rental Division or on our website.

3. Inasmuch as the weather is unpredictable, good judgment and common sense must be incorporated within

installation guidelines. It is the responsibility of the tent installer/maintainer to determine the severity of the weather,

proper time and method of installation and/or erection and disassembly. Note: We recommend that snow and

ice be removed from the tent surface as soon as possible because accumulation will damage the tent

or fabric structure. Please consult with our Engineering Department about the maximum loads for each

product.

This product has been manufactured for use as a temporary structure. For the safety of all occupants, evacuation

is recommended if threatening weather occurs, or if there is any doubt concerning the safe use of this product.

4. Proper safety equipment should be used at all times to insure a safe installation and take down. We suggest a

careful evaluation be made to determine safety equipment needed, such as hard hats, steel-toe shoes, safety

glasses and other as required. It is our desire that all installations are safe. Please be aware of hidden dangers

both underground, i.e., gas lines, water lines, electrical lines, etc. and above the tent such as power lines and

telephone lines.

5. Anchor stands behind its products in accordance with its standard Terms and Conditions of sale. A copy of our

Terms and Conditions of Sale can be obtained by contacting Anchor at the telephone number and/or address on

this document.

28.2 03-04-09

Loading...

Loading...