Page 1

Assembly Instructions

NAVI-TRAC Liner

30’ thru 50’ Wide (Smooth or Gathered)

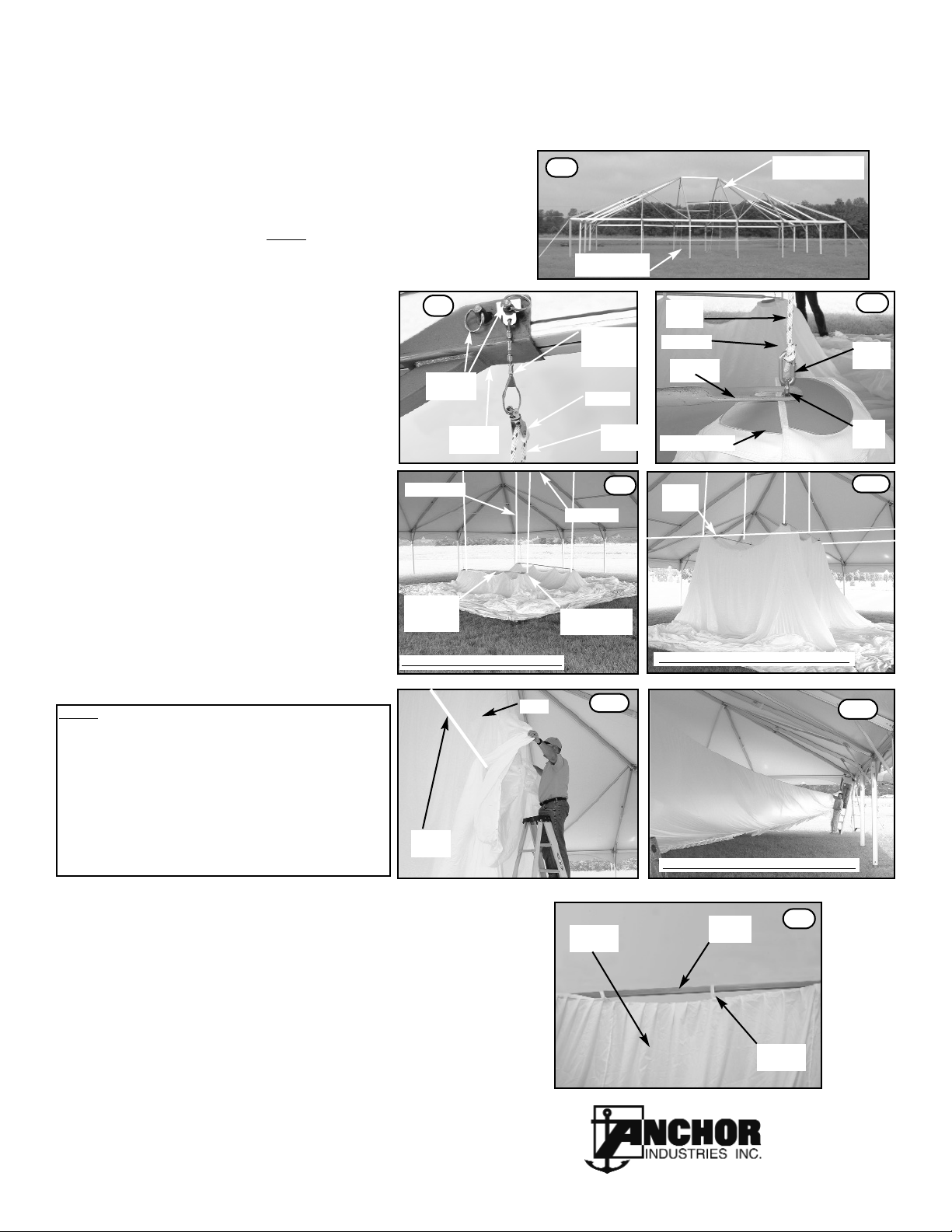

1.

The NAVI-TRAC liner will be hoisted by ropes passing through pulleys

attached to the ridge brace pins or bracket near the peak of the frame.

It will be easier to install these peak/ridge pulleys AS the NAVI-TRAC

frame is being assembled and before the legs are installed (see fig.2).

The outer top should be installed before

the liner.

3.

2.

Preparation:

Pass the eyelet of each pulley lanyard over the gravity

pins that secure the ridge braces on each side of the

NAVI-TRAC peak (see fig.2). (On 30’ wide units, a

beam bracket is supplied to secure directly to the

pulley.) Pass the pull ropes through the pulleys so

that the quick links at the end of the ropes hang at

ground level. When ready, each rafter should have (2)

pulley lanyards with hanging ropes. (see fig.4)

Attach Pulley/Lanyards to Ridge Brace Pins:

Lap Liner Sections/Install Support Bars:

To join end and mid liner sections, overlap and

secure the matching velcro edges using the snap

fasteners. Then seal the velcro edges peak to eave.

Overlap the reinforcement peak patches, carefully

sealing the matching velcro. Align the holes of the

patches and insert the eye bolt down thru both

patches. From underneath, thread the eye nut onto

the eye bolt and tighten.

5.

Attach Liner at the (4) Corners:

After hoisting the liner to the peak of the frame and securing it,

drape the liner over the cross-cables, as needed (see fig.5-A).

Then, spread the liner to the (4) corners of the frame and secure

it by passing the liner corner straps around the hip pin just above

its R-shaped cotter key. Pass the loose end of the strap back

through its fastex buckle and tension it as needed (see fig.7-A).

1

2

3

5-A

5-B

PULL

ROPE

PULLEY

PULLEY

LANYARD

EYELET

GRAVITY

PIN

PULL

ROPE

QUICK

LINK

PEAK PATCH

VELCRO

RIDGE

BRACE

PULLEY ROPES

HANGING

PULLEY LANYARDS

PRE-INSTALLED

EYE

BOLT

SUPPORT

BAR

LINER READY

TO BE HOISTED

Peak Patches

with eye bolt

Pull Ropes

SUPPORT

BARS (Thru

Loops

4-A

4

Slide support bars through the web loops on the top

side of the liner. Slip the notches at each end of the

bars over an eye bolt in the reinforcement patches

and connect the quick links at the ends of the pulley

ropes to these eye bolts (see fig.3)

NOTE: On Navi-Tracs 40’ wide or less, the

cross-cable is removed after installation, so that

step #3 above can be completed as shown in

fig.4, before the liner is hoisted. However, in the

50’ wide Navi-Trac, cross-cables must be left in.

Therefore, the liner sections should be raised

one at a time to a level just above the crosscable (see fig.4A and 5A). From a ladder, the

sections and support bars can then be lapped

and joined above the cross-cables.

Working above the cross-cables (50’W)

To hoist the liner, pass the loose ends of the pulley ropes through

the eye fittings on the outsides of the intermediate upright weldments at the sides of the unit. Pull the ropes uniformly and then

tie-off to the same eye fittings to secure the hoisted liner. At the

top of the 40’ and 50’ hip ends, attach the fastex straps to the

ridge brace (see fig.6)

Hoisting the liner to the peak:

4.

NAVLI 05 06

Pulling Liner to the Corner of the Frame

Liner

CrossCable

CrossCable

6

HIP END

FABRIC

RIDGE

BRACE

FASTEX

STRAPS

EVANSVILLE, INDIANA USA

PULLEYS

Page 2

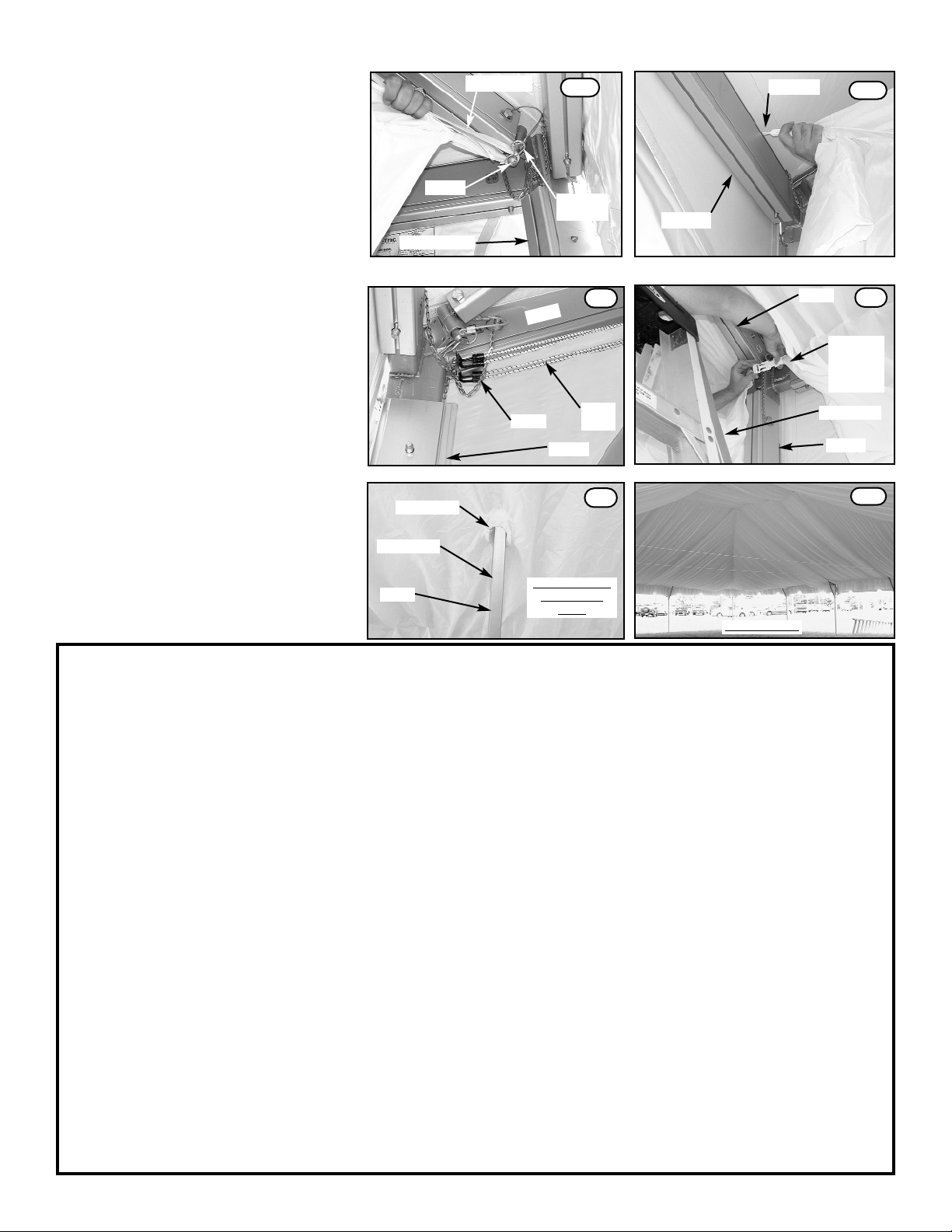

7-A

7-B

Eave Bar

Liner Tab

Joining Liner Sections at Uprights

Thank you for purchasing an Anchor product. In return, we pledge Quality, Service and Craftsmanship and

are available for any questions you may have or assistance you may need.

PHONE NUMBER 812-867-2421

FAX NUMBER 812-867-0547

Anchor products are of superior design and operate best within the parameters of these instructions. It is IMPERATIVE that the

instructions be carefully read and COMPLETELY FOLLOWED. Please read installation instructions before the installation or

removal of this product. Installation instructions are available at www.anchorinc.com.

For additional assistance consult: “The IFAI Procedural Handbook For The Safe

Installation And Maintenance Of Tentage” and the IFAI “Pullout Capacity Of Tent Stakes”,

both available from the IFAI Tent Rental Division.

CAUTION:

1. For each installation, the installer is solely responsible for evaluating the site and the proper securing method determined. Some

soils require different staking or securing than that provided with the tent. Due to this variety of soil conditions, these are the manufacturer’s suggested sequence of installation procedures. Anchor’s responsibility is limited to the construction of the tent. We are

not responsible for methods that installers may choose to secure the tent to the ground.

2. Inasmuch as the weather is unpredictable, good judgment and common sense must be incorporated within installation guidelines.

It is the responsibility of the tent installer/maintainer to determine the severity of the weather, proper time and method of installation

and/or erection and disassembly.

This product has been manufactured for use as a temporary structure. For the safety of all occupants, evacuation is recommended if

threatening weather occurs, or if there is any doubt concerning the safe use of this product.

3. Proper safety equipment should be used at all times to insure a safe installation and take down. We suggest a careful evaluation

be made to determine safety equipment needed, such as hard hats, steel-toe shoes, safety glasses and other as required.

4. Anchor stands behind its products in accordance with its standard Terms and Conditions of sale. A copy of our Terms and

Conditions of Sale can be obtained by contacting Anchor at the telephone number and/or address on this document.

8

9

10

11

Attach the Liner along the Eave Line

6.

To secure the liner to the eave bars, rotate

each liner tab 90 degrees, slip it into the upper

channel of the eave bar, and rotate 90 degrees

back to vertical to lock it in the channel (see

fig.7-B). Insert the liner tabs all around the

perimeter. If necessary, loosen some of the

corner straps (fig.7-A) until all liner tabs have

been inserted, then re-tighten the corner straps.

7.

Where liner sections join at uprights, hook the

liner shock cords of adjacent liner sections into

the bottom open end of the their common rafter

(see fig.8). Join the liner straps across the

front facing of the upright, and cinch together

using the Fastex buckle attached (see fig.9).

Sealing the Liner around Knee Braces

8.

On 40’ and 50’ units, smooth the liner cutouts

around each knee brace and complete the

velcro seal between all adjacent liner sections (see fig.10).

To smooth the lay of the liner, adjust corner

straps, velcro seals, and pulley ropes as

needed. (See fig.11)

Final Liner Adjustments

9.

Liner Smoothed

around Knee

Brace

Knee Brace

Liner Complete

Liner Cutout

Velcro

Upright

Rafter

Liner Strap

and

Fastex

Buckle

Knee Brace

Upright

Shock

Cords

Rafter

Hooks

Corner Strap

Corner Upright

Hip Pin

“R”-Cotter

Pin

28.2 03/23/05

Loading...

Loading...