Page 1

ASSEMBLY INSTRUCTIONS

40’ x 40’ CERTIFIED ANCHOR

BANDSHELL

Please read all assembly/installation instructions before the installation or removal of this product.

SALES OFFICES:

1100 BURCH DRIVE

PO BOX 3477

EVANSVILLE, IN 47733

USA

PHONE: 812-867-2421

FAX: 812-867-0547

1-800-544-4445

EMAIL: tents@anchorinc.com

www.anchorinc.com

PRODUCTION FACILITIES:

EVANSVILLE, IN

Quality, Craftsmanship and Service since 1892

BS4040 0612EC4531

Page 2

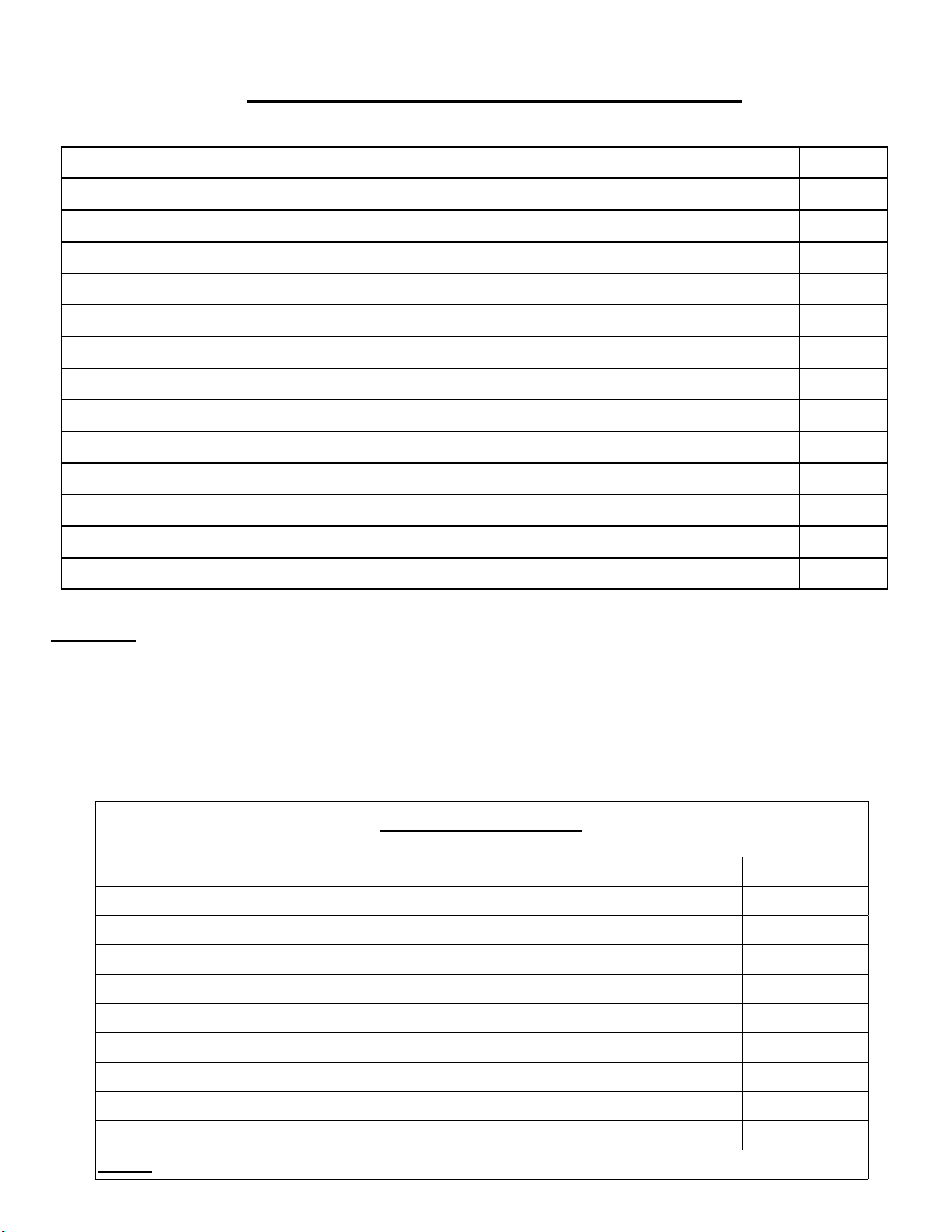

40’ x 40’ BANDSHELL PACKING LIST

DESCRIPTION:

Three (3) sections of bandshell fabric in canvas bags. Marked FRONT, MIDDLE, And REAR.

30” Steel Stake (for Base plates)

Front Pole, 32’-4” long aluminum

Rear Pole, 28’-4” long aluminum

Pole Base Plate with Bolt & Nut

1’-9 1/4” Cable (3/8”) with 1’-0” turnbuckle and shackle Guy (Point A)

1’-3 3/4” Cable (3/8”) with 1’-0” turnbuckle and shackle Guy (Point B)

2’-2 1/2” Cable (3/8”) with 1’-0” turnbuckle and shackle Guy (Point D)

1’-5 3/4” Cable (3/8”) with 1’-0” turnbuckle and shackle Guy (Point E & F)

2’-3 1/2” Cable (3/8”) with 1’-0” turnbuckle and shackle Guy (Point G)

28’-11 3/8” (3/8”) Cable with 1’-0” turnbuckle and shackle Guy (Point I)

(1) 7/8” Shackle, (2) Pear Rings, (4) 1’-0” Turnbuckles for Double Guy (Point C)

(1) 7/8” Shackle, (2) 12’-4” Cables (5/8”, (4) 1’-0” Turnbuckles for Double Guy (Point H)

Quantity

3

8

2

2

4

2

2

2

4

2

2

2

2

CAUTION

DESCRIPTION:

100’ Tape Measure

Pole Stand (Tripod Type)

Pull Rope Assembly

Support Guy

36’-0” Take-up Double Block & Tackle

20’-0” Pole

Drop Cloths (approx. 40’ x 50’)

The installation of the Anchor Bandshell should be performed/supervised by knowledgable tent

installers with a clear understanding of safety issues as well as the methods of anchoring.

The installer/owner should read the assembly instructions completely prior to any installation.

Special attention should be given to anchoring! It is the responsibility of the installer/owner to

assure proper anchoring at all points and that the anchoring system meet the load requirements

defined on the blue print information included (see page 9). Additionally, blue prints are available for all “Certified” Bandshell orders.

TOOLS REQUIRED

(NOT PROVIDED WITH BANDSHELL)

Quantity

2

4

2

2

2

4

3

Drop Cloths (approx. 15’ x 40’)

Stake or Anchor Installation Tools (Manual or Power Drive Anchor Installers)

3

As Required

NOTE: Tools may be purchased from Anchor Industries Inc. or supplied by installer.

1

Page 3

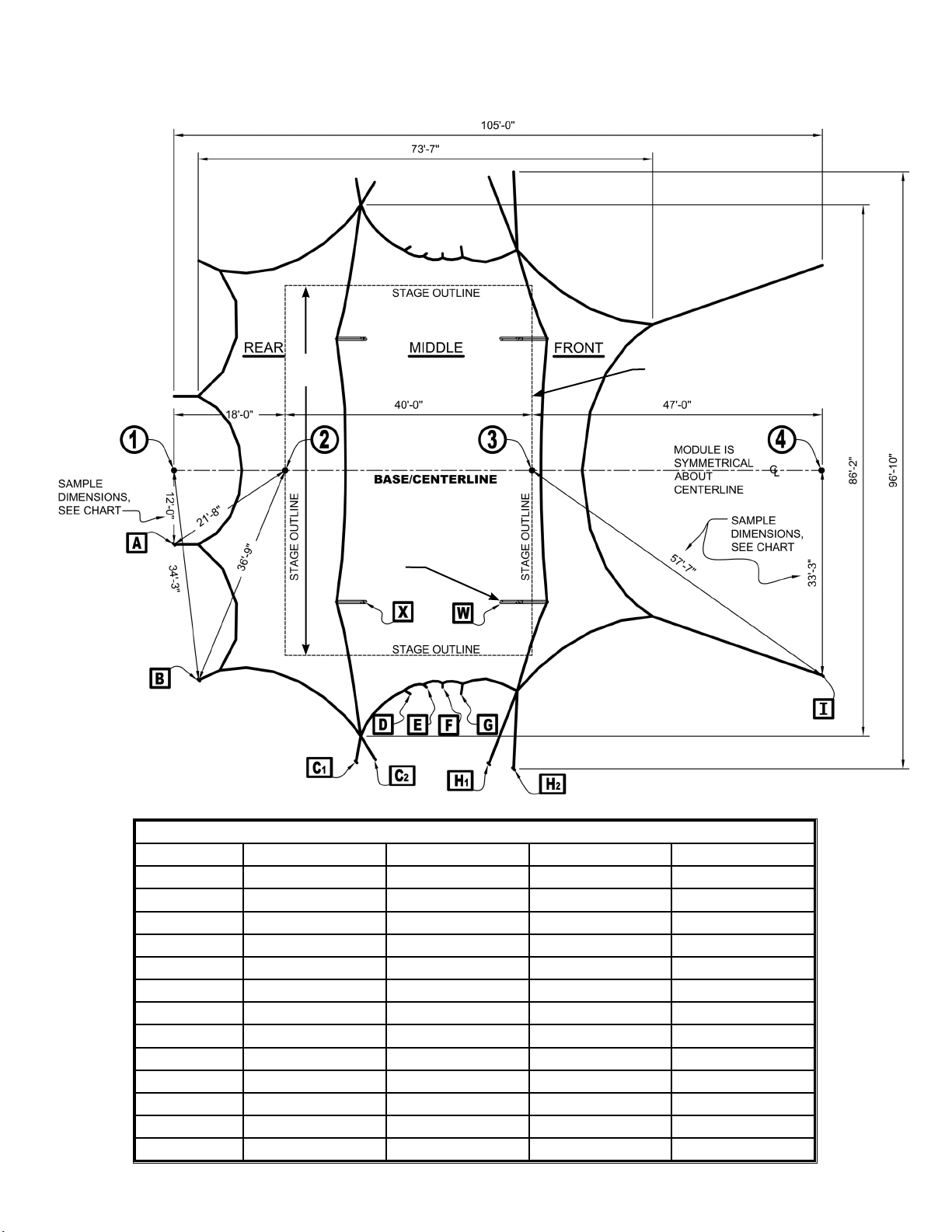

40’ x 40’ BANDSHELL

Pole & Anchor Layout

60’-0”

TYPICAL STAGE

POSITION

BASE OF CENTER

POLE

DIMENSION CHART FOR POLE & STAKE LAYOUT

STAKING PT.

A

B

C

1

C

2

D

E

F

G

H

1

H

2

I

X*

W*

*POLE BASE PLATE POSITIONS.

DIST. FROM 1 DIST. FROM 2 DIST. FROM 3 DIST. FROM 4

12’-0” 21’-8” - -

34’-3” 36’-9” - -

- 48’-8” 55’-2” -

- 48’-11” 53’-3” -

- 41’-6” 41’-3” -

- 42’-0” 39’-1” -

- 43’-5” 38’-0” -

- 46’-1” 38’-0” -

- 57’-11” 48’-1” -

- 60’-11” 48’-6” -

- - 57’-7” 33’-3”

-

-

25’-0” 34’-5”

41’-0

”

21’-11”

-

-

2

Page 4

40’ x 40’ BANDSHELL ASSEMBLY INSTRUCTIONS

MINIMUM OF EIGHT WORKERS ARE REQUIRED TO ASSEMBLE THE BANDSHELL.

1.

THE FIRST STEP IS TO LOCATE THE STAKE AND BASE PLATE POINTS, USING THE DIMENSION

CHART ON PAGE 2.

YOU WILL NEED TWO 100’ TAPE LINES AND HAVE SEVERAL MARKERS AVAILABLE TO

MARK THE ANCHOR POINTS. DO NOT USE MARKERS WITH SHARP EDGES. THE

FABRIC WILL REST ON SOME MARKERS BEFORE RAISING. A CAN OF QUICK-DRY SPRAY

PAINT WILL DO, IF PERMANENT MARKING OF SITE IS ALLOWED.

DETERMINE WHERE THE CENTER AND FRONT OF THE STAGE IS TO BE. POSITION THE

BASE/CENTER LINE SO THAT IT SPLITS THE STAGE IN HALF. LOCATE THE REFERENCE

POINTS 1 THRU 4 AND MARK EACH. POINTS 2 & 3 ARE AT THE FRONT AND REAR EDGE OF A

40’-0” DEEP STAGE.

NOW LOCATE AND MARK EACH POINT BY HOLDING THE END OF EACH TAPE AT THE

CORRECT REFERENCE POINT AND MATCH THE CHART DIMENSIONS ON EACH TAPE. NOTE

THAT THE POINTS ARE SYMMETRICAL ABOUT THE CENTER LINE.

WE RECOMMEND THAT YOU MARK YOUR TAPE LINES FOR EACH POINT TO DECREASE

LAYOUT TIME AND CHANCES OF ERRORS.

INSTALL STAKES OR ANCHORING DEVICES AT EACH POINT AS SHOWN ON LAYOUT. THEN,

2.

STAKE THE FOUR BASEPLATES AT POINTS X & W WITH THE HINGE BOLT PERPENDICULAR

TO THE CENTER LINE. WHEN INSTALLING AUGER STAKES, INSTALLER SHOULD BE FAMILIAR

WITH HOW TO PROPERLY SECURE TO GROUND AS WELL AS WITH MECHANICAL EQUIPMENT

AVAILABLE TO ASSIST IN THIS TASK. INSTALLATION DIRECTIONS CAN BE OBTAINED FROM

THE SUPPLIER OF AUGERS. EACH GUY CABLE PROVIDED WILL TERMINATE WITH A JAW/EYE

TURNBUCKLE WHICH MUST ADAPT TO THE ANCHORING SYSTEM YOU HAVE CHOSEN.

CAUTION: IT IS THE INSTALLER/OWNERS’ RESPONSIBILITY TO EVALUATE AND APPROVE

THAT ALL ANCHORING DEVICES MEET DEFINED LOADING. A PULL TEST OR ANALYSIS

SHOULD BE DONE ON THE STAKING OR ANCHORING SYSTEM TO ASSURE THE LOADING

INFORMATION INDICATED ON

THE “PULLOUT LOAD” PRINT

IS ADEQUATELY MET.

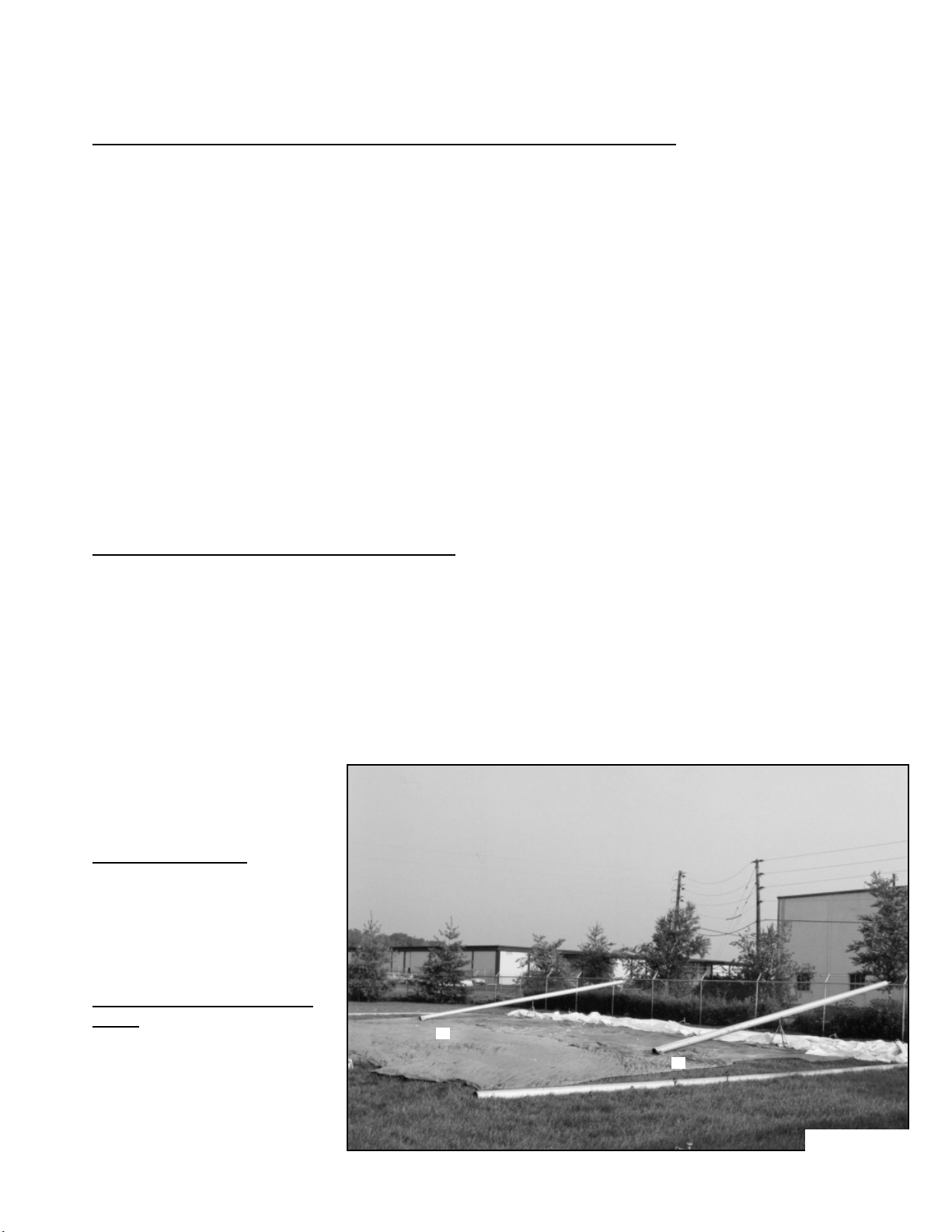

ASSEMBLE POLES. EACH

3.

POLE SECTION IS MARKED

WITH A LETTER. MATCH

SECTIONS WITH THE

SAME LETTER AND BOLT

TOGETHER.

4.

LAY DROP CLOTHS OVER

AREA TO PROTECT

BANDSHELL TOP

X

X

Photo 1

3

Page 5

UNFOLD REAR SECTION TO THE

5.

REAR OF POINTS X WITH LOOP

SIDE TOWARD THE FRONT OF THE

STAGE. WHEN COMPLETELY LAID

FLAT, FOLD THE LOOP SIDE BACK

ALMOST TO POINT A.

PLACE POLE STAND

6.

APPROXIMATELY 15’-0” DIRECTLY

BEHIND BASE PLATES AT BOTH

POINT X’S. MOUNT THE 28’-4”

REAR POLES IN BASE PLATE WITH

THE TOP TOWARD THE REAR AND

SITTING IN THE POLE STAND. THE

TOP OF THE POLE SHOULD BE

APPROXIMATELY 5’-0” OFF THE

GROUND.

(PHOTOS #1, & 2).

LAY DROP CLOTHS OVER POLES

7.

AND AROUND AREA FOR MIDDLE

SECTION PROTECTION.

BasePlate

Photo 2

8.

UNFOLD MIDDLE SECTION

BETWEEN BASE PLATES AT

POINTS X AND W, WITH THE LOOP

SIDE TOWARD THE FRONT OF

THE STAGE. WHEN COMPLETELY

LAID OUT, PLACE THE SPOKE

RINGS ON THE HOLE SIDE OF

THE MIDDLE SECTION OVER THE

POLE PINS, WHILE THREADING

THE CABLES THROUGH THE

RING. THEN, DO THE SAME WITH

THE SPOKE RINGS ON THE REAR

SECTION, PLACING THEM ON TOP

OF THE FIRST RINGS. FOLD LOOP

SIDE OF MIDDLE SECTION BACK

APPROXIMATELY 10’-0” PAST

POINTS X.

( PHOTO #3).

Photo 3

W

W

Photo 4

4

Page 6

9.

PLACE POLE STAND

APPROXIMATELY 15’0” DIRECTLY BEHIND

BASE PLATES AT BOTH

POINTS W. MOUNT THE

32’-0” FRONT POLES

IN BASE PLATE WITH

THE TOP TOWARD THE

REAR AND SITTING

IN THE POLE STAND.

THE TOP OF THE

POLE SHOULD BE

APPROXIMATELY 5’-0”

OFF THE GROUND.

(PHOTO #2).

LAY DROP CLOTHS

10.

OVER POLES AND

AROUND AREA FOR

FRONT SECTION

PROTECTION.

Photo 5

11.

UNFOLD FRONT

SECTION IN FRONT

OF BASE PLATES

AT POINTS W & W

WITH HOLE SIDE

TOWARD THE MIDDLE

SECTION. WHEN

COMPLETELY LAID

OUT, PLACE THE

TOP-HOLE RINGS ON

HOLE SIDE OF FRONT

SECTION OVER THE

POLE PINS, WHILE

THREADING THE

CABLES THROUGH

THE RING. THEN, DO

THE SAME WITH THE

TOP RINGS ON THE

LOOP SIDE OF THE

MIDDLE SECTION,

PLACING THEM ON

TOP OF THE FIRST RINGS. ( PHOTO #4).

Long loop

Photo 6

LACE ALL THREE SECTIONS TOGETHER. START AT TOP RING ON THE RIDGE SIDE WITH NO LONG

12.

LOOP. LACE ACROSS THE RIDGE AND TIE OFF WITH THE LONG LOOP. THEN, LACE DOWN EACH

SLOPE AND TIE OFF AT EAVE WITH LONG LOOP. BE SURE THE LOOP SIDE WEB IS BETWEEN THE

GROMMET FLAP AND THE HOLE SIDE WEB. LACING REQUIRES WALKING ON THE BANDSHELL

TOP AND IT IS ADVISABLE TO REMOVE YOUR SHOES. (PHOTOS #5, 6 & 7).

5

Page 7

Photo 7

Long loop

13.

ATTACH FLAP SNAPS TO ROPES THAT ARE THROUGH D-RINGS ON TOP. SLOPE FLAPS ARE

SEPARATE FLAPS AND ARE TO BE SNAPPED TO ROPES ON BOTH SIDES. ONE SNAP SHOULD BE

ATTACHED TO THE ROPE BETWEEN EACH D-RING. (PHOTO #8).

Photo 8

14.

ATTACH GUY CABLES AT ALL POINTS (A THRU I). (SEE TABLE OF CABLES BELOW). CONNECT

THE END OPPOSITE THE TURNBUCKLE TO THE EAVE RING ON BANDSHELL.

NOTE: AT POINTS C & H, BE SURE THE LOOP SIDE PEAR SHAPED RING IS ON TOP OF THE HOLE

SIDE PEAR SHAPED RING; AND THAT THE PEAR SHAPED RINGS ARE TURNED, SO THE SHACKLE

IS PULLING ON THE SMALLER ENDS OF THE RINGS.

15.

ASSEMBLE RIGGING

A. SNAP ON SUPPORT GUY TO THE CABLES AT THE TOP OF EACH FRONT POLE AND LOOSELY

TIE OFF THE OTHER END TO POINT H2.

B. ATTACH ONE PULL ROPE TO THE CABLES AT THE TOP OF EACH FRONT POLE. CONNECT

ONE DOUBLE BLOCK & TACKLE AT BOTH POINT I’S. WITH THE BLOCKS FULLY EXTENDED, TIE

THE PULL ROPES TO THE BLOCKS. LOOSELY TIE OFF THE BLOCK & TACKLES.

C. LASH TWO SETS (2) 20’-0” POLES TOGETHER AT THE TOP AND SECURELY ATTACH ONE SET

TO RINGS ON EACH PULL ROPE. SET POLES UP, FORMING AN A-FRAME CANTILEVER TO LIFT

FRONT POLES (BOTTOM OF A-FRAME SHOULD BE APPROXIMATELY 12’ WIDE). (PHOTOS #9,

10, 11 & 12).

Location

Point

A

B

1’-9 1/4” Total Guy Length - (3/8”) Cable with (1) 1/2” x 1’-0” turnbuckle and (1) shackle

1’-3 3/4” Total Guy Length - (3/8”) Cable with (1) 1/2” x 1’-0” turnbuckle and (1) shackle

TABLE OF CABLES

Quantity

2

2

C1 & C2

D

E & F

G

H1 & H2

I

(1) 7/8” Shackle, (2) Pear Rings, (4) 3/4” x 1’-0” Turnbuckles for Double Guy

2’-2 1/2” Total Guy Length - (3/8”) Cable with (1) 1/2” x 1’-0” turnbuckle and (1) shackle

1’-5 3/4” Total Guy Length - (3/8”) Cable with (1) 1/2” x 1’-0” turnbuckle and (1) shackle

2’-3 1/2” Total Guy Length - (3/8”) Cable with (1) 1/2” x 1’-0” turnbuckle and (1) shackle

(1) 7/8” Shackle, (2) 12’-4” (5/8”) Cables , (4) 3/4” x 1’-0” Turnbuckles for Double Guy

28’-11 3/8” Total Guy Length - (3/8”) Cable with 1/2” x 1’-0” turnbuckle and (1) shackle

2

2

4

2

2

2

6

Page 8

BE SURE THE CABLE GUYS AT POINTS A, B AND C

16.

(BOTH HALVES - 6 PLACES) HAVE BEEN SECURED

TO ANCHORS. NOW, START PULLING ON ONE

OF THE BLOCK & TACKLES, RAISING THE FRONT

POLE UNTIL THE OPPOSITE FRONT POLE STARTS

TO MOVE. TIE OFF THE BLOCK & TACKLE AND DO

THE SAME WITH THE OTHER BLOCK & TACKLE,

SWITCHING BACK AND FORTH, WATCHING THE

REAR POLES ALSO, UNTIL THE FRONT POLES

FALL SLIGHTLY FORWARD. TIE OFF GUYS AT

POINTS I, REMOVE BLOCK & TACKLES AND

A-FRAME POLES. (PHOTOS #10, 11 & 12).

IF THERE ARE ENOUGH WORKERS, BOTH BLOCK

& TACKLES CAN BE PULLED AT THE SAME TIME.

SECURE AND TENSION ALL GUY CABLES,

17.

USE THE FOLLOWING ORDER TO PROPERLY

SHAPE THE TOP (ADJUSTING TURNBUCKLES AS

REQUIRED).

A. HOOK COME-ALONGS FROM POINTS H

ON TOP TO POINT H1 & H2 ANCHORS (USE STUB

ROPES IF NEEDED) ON EACH SIDE OF TENT (ALL

4 COME-ALONGS REQUIRED.) THEN, TENSION

EACH EQUALLY UNTIL THE FRONT POLES ARE

VERTICAL WHEN LOOKING FROM THE FRONT

AND POINT H IS ABOUT 11’-0” FROM THE GROUND

(BE SURE THE SUPPORT GUYS DO NOT BECOME

TIGHT AND HOLD THE POLES APART). SECURE

GUY CABLES AND REMOVE COME-ALONGS.

Photo 9

B. REPEAT STEP A AT POINTS C TO C1 & C2

WITH REAR POLES TO BE VERTICAL AND POINT C

ABOUT 3’-0” FROM THE GROUND.

C. TIGHTEN GUYS AT POINTS

A & B UNTIL REAR SECTION IS

TENSIONED UNIFORMLY AND

POINTS ARE ABOUT 2’-3” AND 1’-6”

RESPECTIVELY FROM THE GROUND.

D. TIGHTEN CABLES AT

POINTS I UNTIL FRONT SECTION

IS TENSIONED UNIFORMLY AND

POINT I IS ABOUT 12’-0” FROM THE

GROUND.

E. TIGHTEN CABLES AT POINTS

D, E, F, & G UNTIL POINTS ARE

ABOUT 4’-0” TO 5’-0” FROM THE

GROUND.

Photo 10

7

Page 9

NOTE:

1. TENSION TOP

SYMMETRICALLY ABOUT THE

CENTER LINE. PULL ON LIKE

POINTS ON EACH SIDE OF TENT

AT THE SAME TIME

(A & A, B & B, D & D, ETC).

2. THE POLES ARE TO

BE VERTICAL FROM THE

FRONT. THE FRONT POLES

ARE TO LEAN APPROXIMATELY

7’-5” FORWARD AND THE

REAR POLES ARE TO LEAN

APPROXIMATELY 4’-8”

BACKWARD.

18.

DOUBLE CHECK THAT ALL GUYS

AND STAKES ARE SECURE. DO

THIS AT LEAST DAILY, MORE

IN BAD WEATHER. THE GUYS

WILL TEND TO LOOSEN DUE TO

FABRIC STRETCH, WIND AND

STAKE MOVEMENT.

Photo 11

Photo 12

19.

LOOSELY TIE PULL ROPE TO

POINTS H1 OR H2 AND LEAVE

SUPPORT GUY IN PLACE.

THEY WILL BE USED FOR

DISASSEMBLY.

SEE PHOTOS OF COMPLETED

ASSEMBLY: PHOTOS #13, 14

& 15)

Photo 13

8

Page 10

40’ x 40’ BANDSHELL LOAD REQUIREMENTS

FOR ANCHORING SYSTEM

Photo 14

9

Page 11

DISASSEMBLY INSTRUCTIONS

Photo 15

1. DISASSEMBLY IS THE REVERSE OF ASSEMBLY, EXCEPT AS FOLLOWS:

A. BE SURE A-FRAME POLES ARE SECURELY FASTENED TO RING ON PULL ROPE.

THEY WILL BE LIFTED UP DURING THE FIRST STEPS AND MAY COME LOOSE.

B. THE BLOCK & TACKLE SHOULD BE PUT IN PLACE WITH A MINIMUM OF TAKE-UP.

C. CHECK SUPPORT ROPE, IT SHOULD NOT BE VERY TIGHT.

D. TO START THE POLES DOWN, RELEASE THE GUYS AT POINT I AND PUSH THE

FRONT POLES BACK (BE SURE THE BLOCK & TACKLE IS TIED OFF).

E. BE SURE MATERIAL IS NOT CAUGHT AS YOU LET THE POLES DOWN ONTO

STANDS.

2. CARE AND STORAGE:

A. ALWAYS MAKE ABSOLUTELY SURE FABRIC IS DRY BEFORE STORING.

B. STORE IN PROVIDED SACKS IN A COOL, DRY AREA - AWAY FROM RODENTS.

RODENT PROTECTION MAY BE NECESSARY IF THEY ARE PLENTIFUL. KEEP OFF

FLOOR.

C. CLEAN FABRIC WITH MILD LAUNDRY DETERGENT AND A SOFT BRISTLED BRUSH.

A HIGH PRESSURE SPRAYER MAY BE USED, BUT KEEP THE NOZZLE 18” AWAY

FROM FABRIC. DO NOT USE STEAM CLEANERS.

D. SAND AND PAINT THE STEEL BASE PLATES, STAKES AND TOP OF POLES BEFORE

STORING TO ELIMINATE FUTURE RUSTING.

E. FOR SAFE BANDSHELL PERFORMANCE, CONDUCT REGULAR INSPECTION OF ALL

CABLES, WEBS, HARDWARE AND STRUCTURAL COMPONENTS. REPLACE

COMPONENTS IF THEY ARE WORN OR QUESTIONABLE.

10

Page 12

EVANSVILLE, INDIANA

PHONE NUMBER

812· 867· 2421

FAX NUMBER

812· 867· 0547

Anchor products are of superior design and operate best within the parameters of these instructions. It is imperative

that the instructions be carefully read and COMPLETELY FOLLOWED. Please read installation instructions before the

installation or removal of this product. Installation instructions are available online at www.anchorinc.com or by calling

1-800-544-4445.

CAUTION:

1. For each installation, the installer is solely responsible for evaluating the site and the proper securing method

determined. Some soils require different staking or securing than that provided with the tent. Due to this variety of

soil conditions, these are the manufacturer’s suggested sequence of installation procedures. Anchor’s responsibility

is limited to the manufacture of the tent parts and materials. We are not responsible for methods that installers may

choose to erect and secure the tent to the ground.

2. The number of stakes suggested in the installation instructions do not necessarily meet all or any relevant codes

on the site of the tent installation. The number of stakes suggested will, in many cases, keep the tent erected,

however, due to various soil conditions; these stakes will be insuf¿ cient to keep the tent secure in high winds.

It is the tent installer’s responsibility, not the manufacturer, to determine the appropriate number of stakes to meet

the necessary wind loads on the site. Regardless of the number of stakes we suggest, we make no representation

or warranty as to whether this speci¿ c number of stakes will meet the local tent code. Anchor does not, nor can

it make any suggestions, representation, or warranties about the adequate staking required at each speci¿ c

installation site. Staking information provided in the installation instructions is not a suggestion about what is

necessary to meet a site-speci¿ c load.

For additional important information, consult: “The IFAI Procedural Handbook For the Safe Installation and

Maintenance of Tentage” and the IFAI Pocket Guide “Pullout Capacity of Tent Stakes”, both available from

the IFAI Tent Rental Division or on our website.

3. Inasmuch as the weather is unpredictable, good judgment and common sense must be incorporated within

installation guidelines. It is the responsibility of the tent installer/maintainer to determine the severity of the weather,

proper time and method of installation and/or erection and disassembly. Note: We recommend that snow and

ice be removed from the tent surface as soon as possible because accumulation will damage the tent

or fabric structure. Please consult with our Engineering Department about the maximum loads for each

product.

This product has been manufactured for use as a temporary structure. For the safety of all occupants, evacuation

is recommended if threatening weather occurs, or if there is any doubt concerning the safe use of this product.

4. Proper safety equipment should be used at all times to insure a safe installation and take down. We suggest a

careful evaluation be made to determine safety equipment needed, such as hard hats, steel-toe shoes, safety

glasses and other as required. It is our desire that all installations are safe. Please be aware of hidden dangers

both underground, i.e., gas lines, water lines, electrical lines, etc. and above the tent such as power lines and

telephone lines.

5. Anchor stands behind its products in accordance with its standard Terms and Conditions of sale. A copy of our

Terms and Conditions of Sale can be obtained by contacting Anchor at the telephone number and/or address on

this document.

28.2 03-04-09

Loading...

Loading...