Page 1

Assembly Instructions

80’ Wide System

NEW CENTURY® TENT

Please read installation instructions before the installation or removal of this product.

SALES OFFICE

1100 BURCH DRIVE

PO BOX 3477

EVANSVILLE, IN 47733 USA

WEB

EC4435

PHONE: 812-867-2421

FAX: 812-867-0547

1-800-544-4445

PRODUCTION FACILITY

EVANSVILLE, IN

CEN80 1011

Page 2

Index

Introduction..........................................................................................................3

Safety Notes................................................................................................................ 3

Manpower/Tools Required ............................................................................................4

Parts Illustrations ..........................................................................................................4

Web Guy Layout - Square End Tent and Staking Table ...........................................5

Web Guy Layout - Round End Tent ........................................................................... 6

Web Guy - Staking Guidelines.................................................................................... 7

Layout at Site ................................................................................................................8

Lacing Instructions .....................................................................................................8

Pole Cap ....................................................................................................................9

Tie down after Lacing ...............................................................................................9

Raising Side Poles ....................................................................................................9

Raising Center Poles ................................................................................................10

Winch Tensioning........................................................................................................ 10

Final Adjustment and Take Down................................................................................. 11

2

Page 3

Introduction

The installation of this Century Tent should be performed/supervised by knowledgeable tent installers with a clear understanding of safety issues as well as the methods of anchoring. The requirements as specified with blue print (supplied by

Anchor Industries Inc.) must be followed. The installer/owner must read the assembly instructions completely prior to any

installation. Particular attention must be given to anchoring! See Caution Statement on back page of this manual

Work from step to step.

Before erecting any tents or membrane structures, fi rst obtain permits and approvals as required from the local building and

fi re code offi cials on the jurisdiction of your installation.

PLEASE PAY SPECIAL ATTENTION TO SAFETY WARNINGS AND CAUTIONS FOR PREVENTION OF ACCIDENTS.

Regarding the contents of this document:

The illustrations and photos are made to show clearly the construction and dismantling procedures and also for identifi cation

of the components. Not all illustrations/photos correspond to the actual dimensions and size. Explanations and/or notes have

been added to these illustrations/photos.

If you have questions, please call your sales representative at the phone number listed on the front of this manual.

Safety Notes

Please read through this assembly manual completely before beginning your installation. Be sure the proper equipment •

and safety precautions are in place. We hope that you enjoy the design features of the tent each time the unit is installed.

Consult your local • utility locator service or the National Utility Locating Contractors Association

(NULCA) prior to installation.

•

Prior to actual tent assembly, be sure to look up, down, above & below for obstacles, pipes, wires, •

trouble, etc.

Be alert to avoid contact of Tent poles with any overhead power lines near the site.•

Keep site clear of debris to avoid tripping, especially while carrying tent poles or bundle of fabric.•

When moving tent sections by hand, use proper lifting techniques to protect the back.•

The installation method described here requires coordination of tasks between workers. A safe installation is dependent •

on that coordination. Work cooperatively as a team.

Replace used or damaged components with original new ones.•

To prevent injuries, wear suitable protective clothing such as hard hats, steel toed shoes, etc.•

Do not drag bundle of fabric on concrete, asphalt, or ground as this can cause damage to the fabric from abrasion through •

the bag.

This tent is manufactured for use as a temporary structure. Evacuation is recommended if threatening or windy weather •

occurs. See caution on back page of this manual.

3

Page 4

MANPOWER REQUIRED

Five experienced installers

should be able to assemble an

80’ x 70’ tent in approximately

five hours.

TOOLS REQUIRED

Sledge Hammers

Stake Driver

2 Measuring Tapes

LAYOUT & CHECK

Utilize parts list for a quick I.D. and a check list to

ensure that you have all the parts.

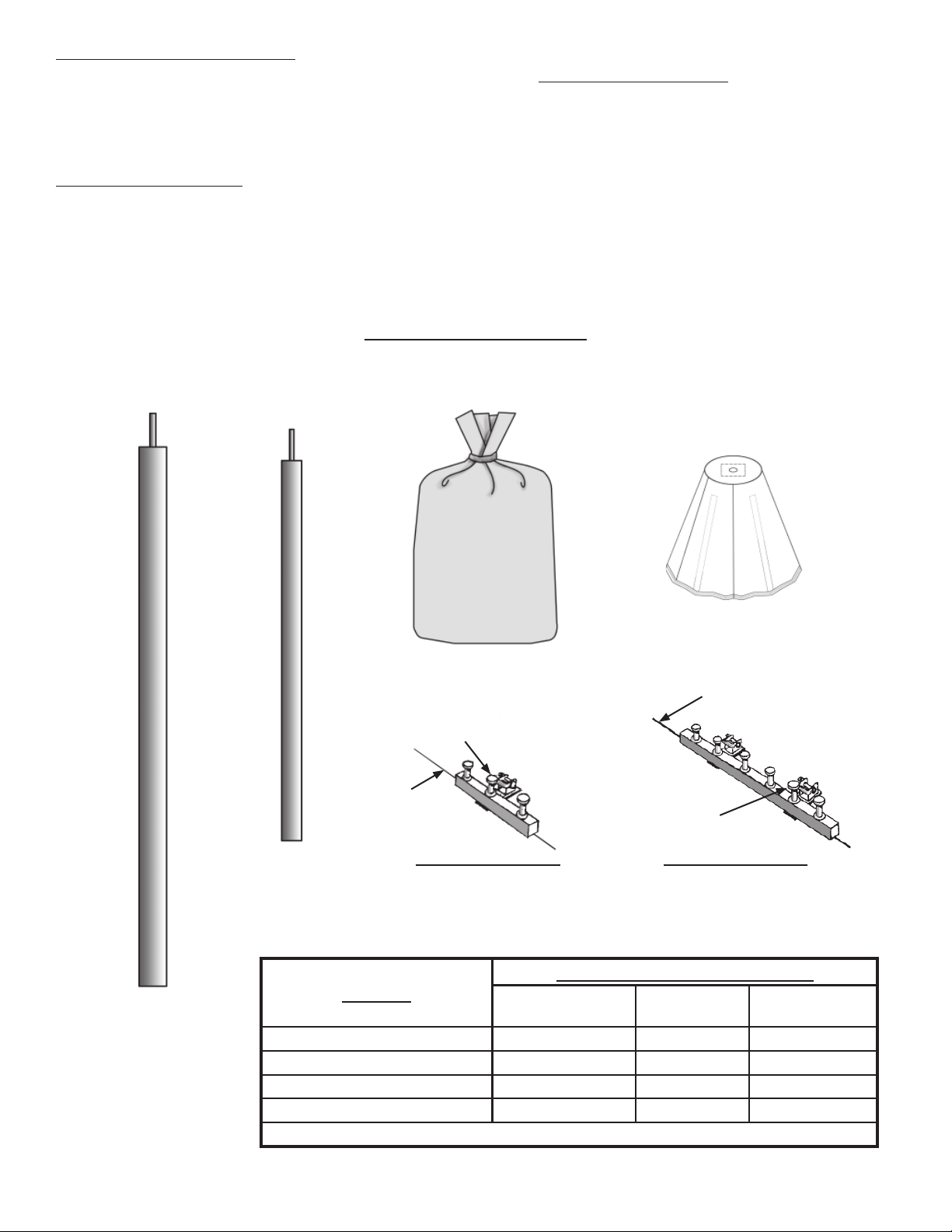

Parts Illustrations

Center Pole

Pole Cap

Bag with Fabric

Side Pole

Stake line

Section

Stake driven through

hole in bar and winch

plate

Stake driven through

hole in bar and

winch plate

Stake line

4’ STAKE BAR2’ STAKE BAR

QUANTITY PER SECTION

PARTS

BAG WITH FABRIC SECTION 2 1 1

CENTER POLE 2 2 2

SIDE POLE 24 4 6

POLE CAP (OPTIONAL) 2 2 2

SEE WEB GUY LAYOUTS & STAKING TABLES FOR STAKING REQUIREMENTS.

END (SQ. OR

ROUND) (PAIR)

20’ MIDDLE 30’ MIDDLE

4

Page 5

WEB GUY LAYOUT*

1

Square End - Sample Layout

MARK LOCATION OF STAKES, SIDE POLES & CENTER POLES

70’-0’ TENT LINE

MIDDLE

SECTION

CENTER

POLES

(TYP)

HOLE SIDE

END

SECTION

**106’-3 5/8”

LAYOUT SHOWS 20’ ENDS AND 30’ MID.

30’ ENDS AND 20’ MIDS USE IDENTICAL

SPACING AND STAKING. SEE TABLE BELOW.

** To find diagonal measurement:

diagonal = width² + length²

REQUIRED DISTANCE

BETWEEN SIDE POLES

AND STAKE LINES:

7’ POLE STAKE OUT 5’ 3”

8’ POLE STAKE OUT 6’ 0”

10’ POLE STAKE OUT 7’ 6”

WEB GUY WITH 2’

STAKE BAR AND (3) 42”

STAKES (TYP. AS SHOWN)

80’-0” TENT LINE

LOOP SIDE

END

SECTION

Use diagonal measure-

ment to square layout

SIDE POLE

(TYP)

(2) WEB GUYS WITH 4’

STAKE BAR AND (6) 42” DBL.

HEAD STAKE (TYP. AS SHOWN)

Staking Table

Illustration Item No. Description

23000

37020A

3704242 (over 25)

33000

Century Guy w/

Winch

42” Double Hd.

Stake

2’-0” Stake Bar

w/ (3) Holes

(2) WEB GUYS WITH (2) 2’

STAKE BARS AND (6) STAKES

(TYP. AS SHOWN)

SEE STAKING GUIDELINES ON

PAGE 7.

Qty. for

80’ x 40’

(2) 20’ Ends

34 30 8 12

102* 90* 24* 36*

22 26 0 0

Qty. for

80’ x 40’ Round

(2) 20’ Ends

Qty. for

20’ Mid

Qty. for

30’ Mid

33100

23100 Winch Tool

4’-0” Stake Bar

w/ (6) Holes

6246

2201

5

Page 6

Round End - Layout

MARK LOCATION OF STAKES, SIDE POLES & CENTER POLES

40’-0’ TENT LINE

(2) WEB GUYS WITH (2) 2’

STAKE BARS AND (6) STAKES

(TYP. AS SHOWN)

REQUIRED DISTANCE BETWEEN

SIDE POLES AND STAKE LINES:

7’ POLE STAKE OUT 5’-3”

8’ POLE STAKE OUT 6’-0”

10’ POLE STAKE OUT 7’-6”

WEB GUY WITH 2’

STAKE BAR AND (3) 42”

STAKES (TYP. AS SHOWN)

80’-0” TENT LINE

(2) WEB GUYS WITH 4’

STAKE BAR AND (6) 42” DBL.

HEAD STAKE (TYP. AS SHOWN)

SEE STAKING GUIDELINES ON

NEXT PAGE.

IMPORTANT NOTE: TO KEEP TOP FROM SPINNING, STAKE THE CORNER GUYS IN THE “X”

POSITION SHOWN WITH DASHED LINES UNTIL

THE CENTER POLES ARE UP, THEN UNDO THE “X”

STAKING AND POSITION THE GUYS AS SHOWN IN

SOLID LINES.

* IMPORTANT NOTE: REFER TO CAUTION STATEMENT #2 FOR IMPORTANT WARNING ABOUT NUMBER OF

STAKES SUPPLIED. (SEE BACK PAGE OF THIS MANUAL)

THE INSTALLER MUST USE THE LOCAL SOIL CONDITIONS TO CALCULATE THE ACTUAL

NUMBER OF STAKES REQUIRED AND IS RESPONSIBLE FOR THE STAKING PATTERN AND

CONFIGURATION. ANCHOR PROVIDES ANCHORING PACKAGES FOR COMMON SOIL CLASSIFICATIONS;

CONTACT YOUR TENT SALES REPRESENTATIVE FOR MORE INFORMATION.

6

Page 7

WEB GUY - STAKING GUIDELINES

REQUIRED DISTANCE BETWEEN

SIDE POLES AND STAKE LINES:

7’ POLE STAKE OUT 5’ 3”

8’ POLE STAKE OUT 6’ 0”

10’ POLE STAKE OUT 7’ 6”

(1) WEB GUY

WITH 2’ STAKE BAR

AND (3) 42” DOUBLE

HEAD STAKES

(2) WEB GUYS WITH

(2) 2’ STAKE BARS

AND (6) STAKES

(2) WEB GUYS

WITH 4’ STAKE BAR

AND (6) 42” DOUBLE

HEAD STAKES

7

Page 8

2

LAYOUT AT SITE

Drive stakes at points located. Each 2’ stake

bar requires 3 stakes. A 4’ stake bar requires

6 stakes.

LACE

END

Spread drop cloths and unroll tent.

Any objects with sharp projections which must

remain on site under the tent should be padded

and taped.

NOTE: Both Loop side and hole side of sections are required for proper lace.

LACING INSTRUCTIONS

3

With tent sections on ground, overlap center

pole holes with grommet side on top.

Lace between center pole holes first. Push

first loop up through corresponding grommet.

Continue, passing each loop through a grommet

and the preceding loop.

Continue lacing process and cover lacing with

protective double rain flap by velcroing the short

flap first, then snapping the top flap to the rope

as you move toward the other center pole hole.

Tie off last long loop.

MIDDLE

END

STAKE BARS

SEE WEB GUY LAYOUTS FOR

STAKING CONFIGURATIONS.

CENTER POLE

HOLE

END

END

MIDDLE

LACE LOOP

CENTER POLE HOLES

FLAP

RING

SNAP

Then lace from center pole to eave on both

sides of tent. Tie off last long loop. Align

plates and attach hook to plates on inside of

tent, as shown.

RING

FLAP

LACE ROPE

WALL ROPE

POLE HOLE

VIEW FROM OUTSIDE

PLATE

HOOK

SNAP

LAST

LACING

LOOP

JUMP ROPE

VIEW

FROM

INSIDE

8

Page 9

POLE CAP

4

Overlap the pole hole plates in the mid and

end fabric lace line. Push fabric and plates

up into cap and secure from underneath by

threading the female, flanged pipe coupling

onto the male pipe fitting molded to the

inside top of the pole cap.

MOLDED CAP W/

MALE THREADED

PIPE FITTING

POLE CAP

LACE LINE

END

FABRIC

MID

FABRIC

TIE DOWN AFTER LACING

5

After lacing and snapping sections, attach guys and

insert loosely into tension winches.

WEB GUY

Winch

Drum

WEB

RELEASE

(Push Downward)

POLE PLATES

(OVERLAPPED)

WEBS ATTACHED

LOOSELY

STAKE

BARS

FEMALE PIPE

COUPLING (FLANGED)

LACE

Insert web guy into slot in winch drum and

rotate 1 1/2 to 2 times to secure web.

RAISE SIDE POLES

6

Start at downwind side. Insert each

side pole pin into side pole hole and

raise slightly less than perpendicular.

Bottom of each pole should be pointed

inward toward center of tent.

Wall ropes should run outside of corner

poles and side poles.

Tie jump rope around each side pole as

it is inserted in pole hole.

Continue around tent.

SEE WEB GUY LAYOUTS FOR

STAKING CONFIGURATIONS.

SIDE POLES INSTALLED

ON DOWNWIND SIDE

9

Page 10

7

RAISE CENTER POLES

Slowly raise center poles nearest to wind direction to approximate position. One installer to

guide center pole pin through hole to prevent

snagging or tearing of fabric as pole is being

raised into position.

Keep pole at a slant until other pole at the same

lace is raised. Tie jump ropes as each center

poles is placed in approximate position. Adjust

bases of poles to exact location and align poles

vertically.

CAUTION: At this point, it is required

to properly anchor bases of all center poles to

prevent movement.

JUMP ROPE

WINCH FOR TENSION

8

Good Precautionary Measure: It is a

good idea to have a spotter on outside

of tent to watch that center pole top pin

does not get caught on fabric as it is

being raised.

JUMP ROPE

If the footprint of the tent has been laid out properly

and the tent placed squarely within that footprint,

the following tensioning sequence is recommended:

1. Tension webs at the lace lines first.

2. Tension webs at the corners.

3. Tension webs at the ends.

4. Tension webs at the middles last.

NOTE: If the tent is not square, or if center poles

lean when laces are tensioned, reverse steps “1”

and “2” above.

At each side pole, release winch tension and place

bottom of side pole at the marked footprint eave

line location.

Insert web guy into winch. Pull excess through

winch. Tension, using winch bar. DO NOT USE

EXTENDERS ON WINCH BAR TOOL.

Caution -- DO NOT OVER TENSION TENT

BEYOND EAVE LINE. DO NOT PULL SIDE

POLES OR CENTER POLES BEYOND

VERTICAL POSITION.

CAUTION:

KEEP TO SIDE OF WINCH

WHEN TENSIONING. DO

NOT EXTEND LENGTH

OF WINCH BAR TOOL.

STAKE BAR

JUMP

ROPE

WEB

GUY

WINCH

JUMP

ROPE

10

Page 11

FINAL SIDE POLE

9

ADJUSTMENT

With side poles standing vertical and bases at

the marked side pole locations for the footprint,

ratchet webs to tension the top evenly.

Due to changes in climatic conditions, periodic

inspection and adjustment should be made.

Protective covers are recommended for all

stakes and stake bars.

10

TAKE DOWN

USE EXTREME CAUTION REMOVING

ALL POLES

1. Spread ground cover.

2. Loosen tension on all web winches.

3. Slowly slant side poles inward.

4. Remove center and side poles.

5. Reverse installation steps.

IMPORTANT

Check Guys periodically for tightness and

maintenance of good condition. Stakes

provided are for average soil conditions.

Sandy soil or asphalt may require additional staking. Proper installation suitable

to site conditions is the responsibility of

the installer. Store tent in a cool, dry area.

Never store while wet or damp.

11

Page 12

EVANSVILLE, INDIANA

PHONE NUMBER

812· 867· 2421

FAX NUMBER

812· 867· 0547

Anchor products are of superior design and operate best within the parameters of these instructions. It is imperative

that the instructions be carefully read and COMPLETELY FOLLOWED. Please read installation instructions before the

installation or removal of this product. Installation instructions are available online at www.anchorinc.com or by calling

1-800-544-4445.

CAUTION:

1. For each installation, the installer is solely responsible for evaluating the site and the proper securing method

determined. Some soils require different staking or securing than that provided with the tent. Due to this variety of

soil conditions, these are the manufacturer’s suggested sequence of installation procedures. Anchor’s responsibility

is limited to the manufacture of the tent parts and materials. We are not responsible for methods that installers may

choose to erect and secure the tent to the ground.

2. The number of stakes suggested in the installation instructions do not necessarily meet all or any relevant codes

on the site of the tent installation. The number of stakes suggested will, in many cases, keep the tent erected,

however, due to various soil conditions; these stakes will be insuf¿ cient to keep the tent secure in high winds.

It is the tent installer’s responsibility, not the manufacturer, to determine the appropriate number of stakes to meet

the necessary wind loads on the site. Regardless of the number of stakes we suggest, we make no representation

or warranty as to whether this speci¿ c number of stakes will meet the local tent code. Anchor does not, nor can

it make any suggestions, representation, or warranties about the adequate staking required at each speci¿ c

installation site. Staking information provided in the installation instructions is not a suggestion about what is

necessary to meet a site-speci¿ c load.

For additional important information, consult: “The IFAI Procedural Handbook For the Safe Installation and

Maintenance of Tentage” and the IFAI Pocket Guide “Pullout Capacity of Tent Stakes”, both available from

the IFAI Tent Rental Division or on our website.

3. Inasmuch as the weather is unpredictable, good judgment and common sense must be incorporated within

installation guidelines. It is the responsibility of the tent installer/maintainer to determine the severity of the weather,

proper time and method of installation and/or erection and disassembly. Note: We recommend that snow and

ice be removed from the tent surface as soon as possible because accumulation will damage the tent

or fabric structure. Please consult with our Engineering Department about the maximum loads for each

product.

This product has been manufactured for use as a temporary structure. For the safety of all occupants, evacuation

is recommended if threatening weather occurs, or if there is any doubt concerning the safe use of this product.

4. Proper safety equipment should be used at all times to insure a safe installation and take down. We suggest a

careful evaluation be made to determine safety equipment needed, such as hard hats, steel-toe shoes, safety

glasses and other as required. It is our desire that all installations are safe. Please be aware of hidden dangers

both underground, i.e., gas lines, water lines, electrical lines, etc. and above the tent such as power lines and

telephone lines.

5. Anchor stands behind its products in accordance with its standard Terms and Conditions of sale. A copy of our

Terms and Conditions of Sale can be obtained by contacting Anchor at the telephone number and/or address on

this document.

28.2 03-04-09

Loading...

Loading...