Page 1

Analytical Industries, Inc.

PI2- UHP-50

PPB OXYGEN ANALYZER

OWNERS MANUAL

Revised Sep 20, 2016 Rev 2

Revised July 10, 2017 Rev 3

Revised Mar 05, 2018 Rev 4

Revised Sep 17, 2018 Rev 5

Page 2

Analytical Industries, Inc.

2

Table of Contents

Introduction

1

Quality Control Certification

2

Safety

3

Features & Specifications

4

Operation

5

Maintenance

6

Spare Parts

7

Troubleshooting

8

Warranty

9

(UHPDS) Material Safety Data Sheet

1

0

Page 3

Analytical Industries, Inc.

3

1. Introduction

Your new PI2-UHP 50/100 PPB oxygen analyzer is a precision device designed to give you years of use for

analyzing single digit PPB (parts per billion) level oxygen concentrations. This micro-processor based analyzer

features the new breakthrough “Pico-Ion” Sensor Technology developed exclusively by Advanced Instruments

Inc. and an extensive sample system digitally controlled to offer the user the utmost in performance and

simplicity. The sample system consists of 316L stainless steel pneumatic valves with orbital welded or VCR type

connections.

The sample system features separate sample and span inlets, a pressure regulator and flow control orifice,

sample bypass loop for isolating the sensor and an integral oxygen scrubber (PI2-UHP 50/100 only) for consistent

zero gas, all of which are controlled by the user friendly micro-processor based electronics.

The digital electronics also feature auto or manual ranging, auto-zero and auto-calibration at user specified

intervals, data acquisition, temperature compensated output, user selected signal averaging and temperature

coefficient for fine tuning the sensor performance in varying temperature environments.

This analyzer is designed to measure the oxygen concentration in inert gases, gaseous hydrocarbons, hydrogen

and a variety of gas mixtures.

In order to derive maximum performance from your new oxygen analyzer, please read and follow the guidelines

provided in this Owner’s Manual.

The serial number of this analyzer may be found on the inside and at the back of the analyzer. You should note

the serial number in the space provided below and retain this Owner’s Manual as a permanent record of your

purchase, for future reference and for warranty considerations.

Serial Number: _______________________

Every effort has been made to select the most reliable, state of the art materials and components designed for

superior performance and minimal cost of ownership. This analyzer was tested thoroughly by the manufacturer

for best performance.

Advanced Instruments, Inc., appreciates your business and pledges to make every effort to maintain the highest

possible quality standards with respect to product design, manufacturing and service.

Page 4

Analytical Industries, Inc.

4

2. Quality Control Certificate

Page 5

Analytical Industries, Inc.

5

3. Safety

This section summarizes the essential generic precautions applicable to all analyzers. Additional precautions

specific to individual analyzers are contained in the following sections of this manual. To operate the analyzer

safely and obtain maximum performance, follow the basic guidelines outlined in this Owner’s Manual.

Caution: This symbol is used throughout the Owner’s Manual to CAUTION and alert the user to

recommended safety and/or operating guidelines.

Danger: This symbol is used throughout the Owner’s Manual to identify sources of immediate

DANGER such as the presence of hazardous voltages.

Read Instructions: Before operating the analyzer read the instructions.

Retain Instructions: The safety precautions and operating instructions found in the Owner’s Manual should

be retained for future reference.

Heed Warnings: Follow all warnings on the analyzer, accessories (if any) and in this Owner’s Manual.

Follow Instructions: Observe all precautions and operating instructions. Failure to do so may result in

personal injury or damage to the analyzer.

Inlet Sample Pressure: Recommended 30-50 PSIG, 100 PSIG maximum.

Outlet Pressure: The sample gas must be vented atmospheric pressure.

Instrument Air Pressure: Operation of the pneumatic valves which require a dedicated source of

compressed air with a minimum of 80-100 psig: Note: Do not attempt to use the sample gas to operate the

pneumatic valves.

Oxygen Sensor: DO NOT open the sensor. The sensor contains a corrosive liquid electrolyte that could be

harmful if touched or ingested, refer to the Material Safety Data Sheet contained in the Owner’s Manual

appendix. Avoid contact with any liquid or crystal type powder in or around the sensor or sensor housing, as

either could be a form of electrolyte. Leaking sensors should be disposed of in accordance with local

regulations.

Mounting: The analyzer is approved for indoor use only. It may be used outdoors with optional enclosures.

Mount the analyzer as recommended by the manufacturer.

Power: Supply power to the analyzer only as rated by the specification in Section 4 and/or markings on the

analyzer enclosure. The wiring/cords that connect the analyzer to the power source should be installed in

accordance with recognized electrical standards and so they are not pinched, particularly near the power source

and the point where they attach to the analyzer. Never yank a power cord to remove it from an outlet or from

the analyzer.

ENSURE THAT POWER LINE INCULDES “SURGE PROTECTER” AND RFI/EMI FILTER TO PREVENT

INTERFERENCE FROM EXCESSIVE LINE VOLTAGE VARIATIONS

Operating Temperature: The maximum recommended operating temperature is 45 ºC. However, an

operating temperature of less than 35 oC is ideal to obtain maximum life of the oxygen sensor.

Heat: Situate and store the analyzer away from a direct source of heat.

Liquid and Object Entry: The analyzer should not be immersed in any liquid. Care should be taken so that

liquids are not spilled into and objects do not fall into the inside of the analyzer.

Handling: Do not use force when using the switches and knobs. Before moving your analyzer, be sure to

disconnect the wiring/power cord and any cables connected to the output terminals of the analyzer.

Serviceability: Except for replacing the oxygen sensor, there are no parts inside the analyzer for the operator

to service. Only trained personnel with authorization of their supervisor should conduct maintenance.

Troubleshooting: Consult the guidelines in Section 8 for advice on the common operating errors before

concluding that your analyzer is faulty. Do not attempt to service the analyzer beyond those means described

in this Owner’s Manual. Do not attempt to make repairs by yourself as this will void the warranty as per Section

Page 6

Analytical Industries, Inc.

6

9 and may result in electrical shock, injury or damage. All other servicing should be referred to qualified service

personnel.

Cleaning: The analyzer should be cleaned only as recommended by the manufacturer. Wipe off

dust and dirt from the outside of the unit with a soft damp cloth then dry immediately. Do not use

solvents or chemicals.

Oxygen Sensor: DO NOT open the sensor. The sensor contains a corrosive liquid electrolyte that could be

harmful if touched or ingested, refer to the Material Safety Data Sheet contained in the Owner’s Manual

appendix. Avoid contact with any liquid or crystal type powder in or around the sensor or sensor housing, as

either could be a form of electrolyte. Leaking sensors should be disposed of in accordance with local

regulations.

Nonuse Periods: Keep oxygen sensor from exposure to high oxygen levels as described in this manual (see

section Operation). Disconnect the power when the analyzer is left unused.

Warning: The analyzer must not be disconnected from power and gas line for more than a few hours to a

day. If it becomes necessary to disconnect power for extended period, remove sensor cable from

PCB A-1146 to disconnect sensor from electronic circuit. Failure to do so will keep sensor reacting with

oxygen that will continue to diffuse through sensor housing and may damage the sensor (with sample gas

flowing, oxygen diffusion through sensor housing becomes insignificant as it dilutes with sample gas).

It is recommended that the analyzer remain powered with gas flowing (if high purity sample gas is not

available, a gas with low PPM gas may be used with a flow rate as low as 0.1 SCFH). This will keep the sensor

ready for sampling a gas.

If it becomes necessary to transport the analyzer from one place to another, disconnect analyzer power only

when analyzer is to be transported and re-installed within a few hours to a day.

Caution: PI2-UHP-M analyzer is equipped with MANUAL VALVE, turn sample inlet and sample outlet valves to

OFF position before removing sample gas connection. Failure to adhere to this instruction may result in

permanent damage to the sensor.

Page 7

Analytical Industries, Inc.

7

4. Specifications

Page 8

Analytical Industries, Inc.

8

5. Operation

Principle of Operation

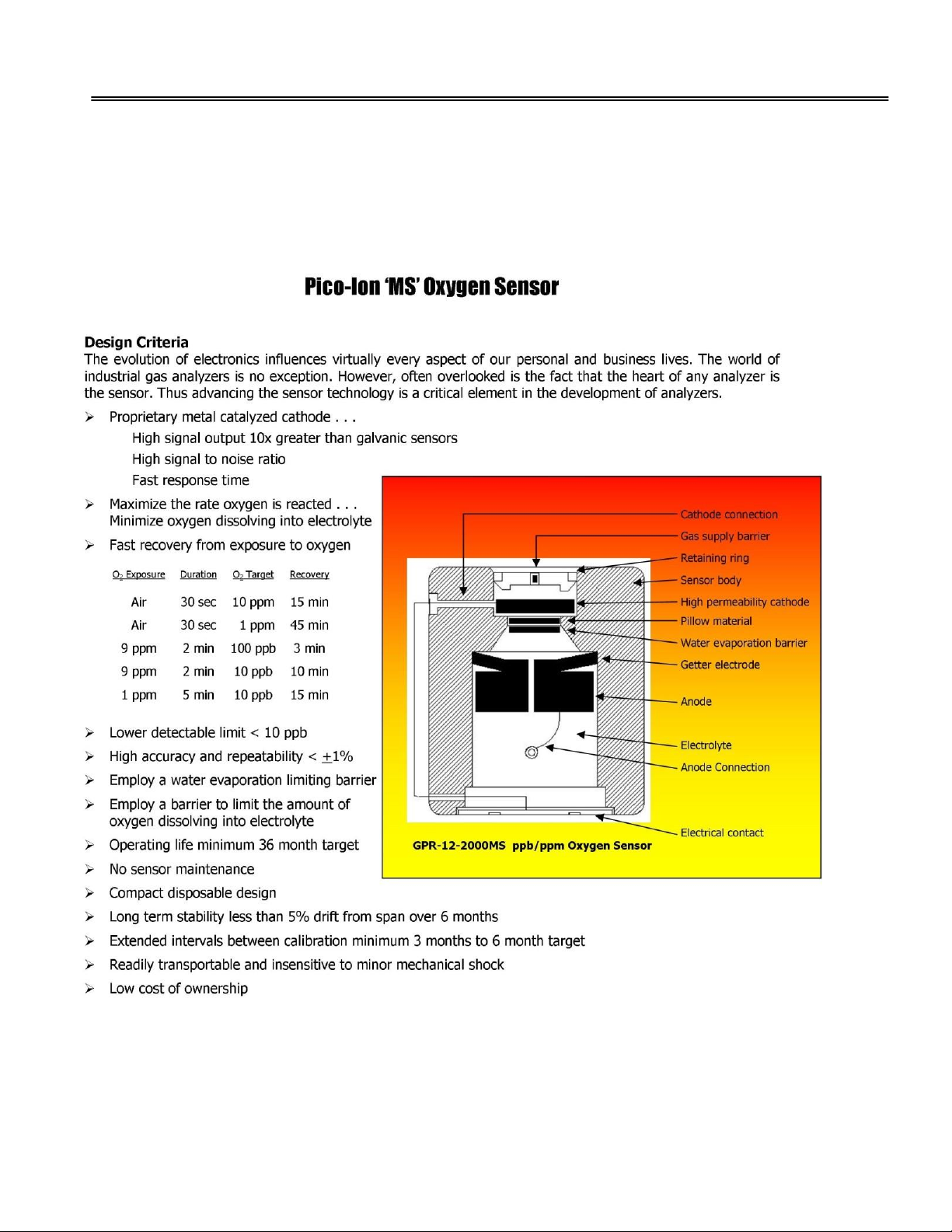

A breakthrough sensor technology of the second generation Pico-Ion oxygen sensor measures the partial

pressure of oxygen from less than 3 PPB to 100 PPM level in inert gases, gaseous hydrocarbons, helium,

hydrogen and mixed gas streaUHP.

Oxygen, the fuel for this electrochemical transducer, reacts chemically at the sensing electrode to produce an

electrical current output proportional to the oxygen concentration in the gas phase. The sensor’s signal output is

linear over all four ranges and remains virtually constant over its useful life. The sensor requires no maintenance

or electrolyte addition and is easily and safely replaced at the end of its useful life.

Page 9

Analytical Industries, Inc.

9

Sample System Flow Schematic

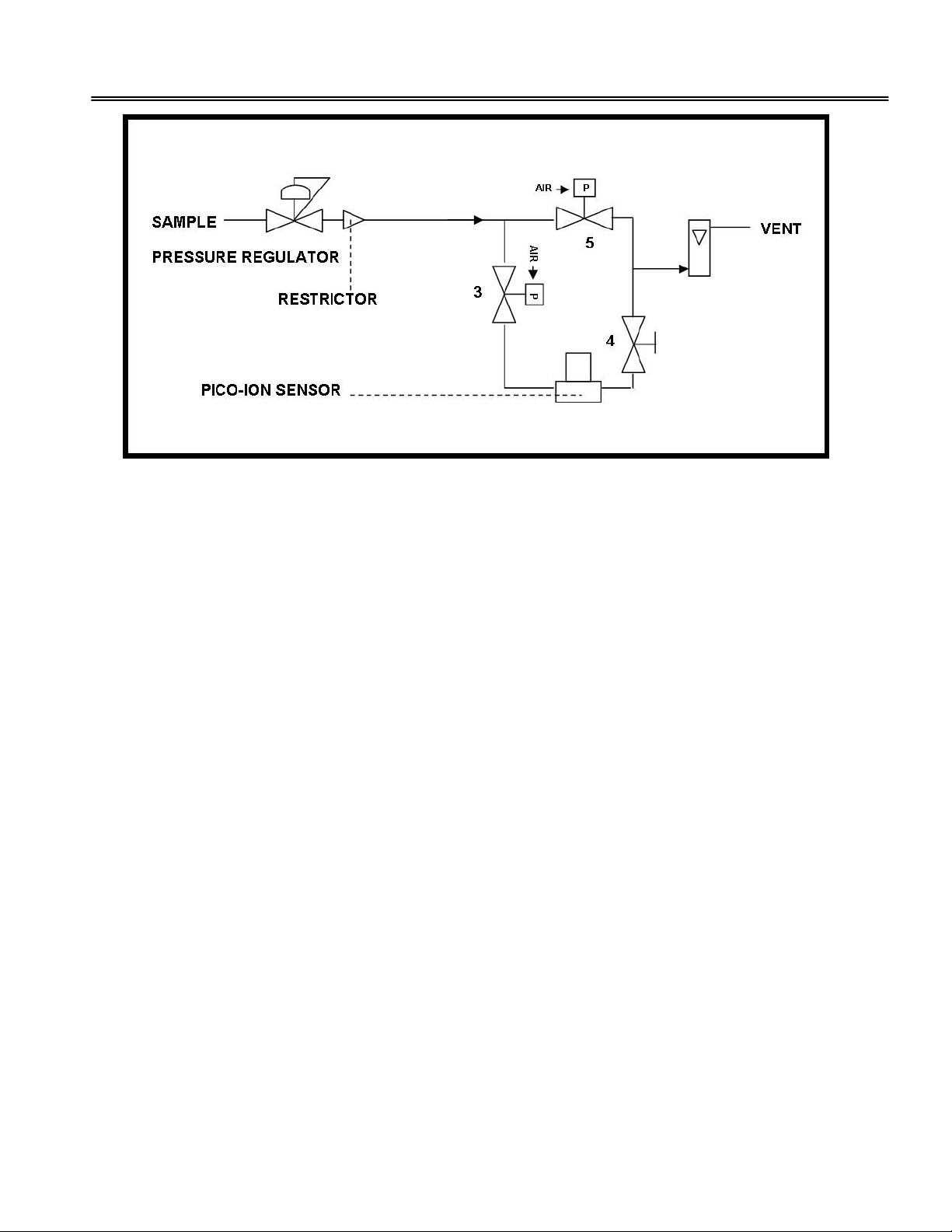

The PI2-UHP 50/100 analyzer is equipped with a micro-processor controlled sample system that features precise

flow control and pneumatic valves for introducing sample or span gases, isolating the sensor with an integral

bypass loop during standby and upset conditions and an oxygen scrubber for delivering consistent zero gas

(during zero calibration) to the sensor.

Note: The pneumatic valves require a minimum of 80 psig pressure to open. The maximum pressure allowed is

100 psig.

Valve Operation: OPEN CLOSED

Mode: BYPASS 1, 5 2, 3,4,6,7

ZERO 1,4,6,7 2,3,5

SPAN 2,3,4 1,5,6,7

SAMPLE 1,3,4 2,5,6,7

STANDBY NONE 1,2,3,4,5,6,7

Flow schematic of PI2-UHP 50/100

The PI2-UHP 50/100-B analyzer is equipped with a micro-processor controlled sample system that except that

these models do not have integral oxygen scrubber and separate Span gas inlet.

Note: The menus displayed by the PI2-UHP-50/100 B have been modified to reflect the absence of the span

inlet port and zero scrubber system.

Page 10

Analytical Industries, Inc.

10

Valve Operation: OPEN CLOSED

Mode: BYPASS 5 3,4

ZERO 3,4 5

SPAN 3,4 5

SAMPLE 3,4 5

STANDBY NONE 3,4,5

Flow Schematic of PI2-UHP 50/100-B

Caution: Do not change the valve positions until instructed to do so in this manual.

Page 11

Analytical Industries, Inc.

11

Other Sample Handling Considerations

The sample system may include optional components positioned upstream of the analyzer such as additional

pressure regulator, particulate filter, isolation/directional flow control valves etc. Check the QC sheet to confirm

the Sample System of your analyzer.

To avoid damaging the sensor or sample system, observe the following guidelines:

1. Do not draw a vacuum or over-pressure the sensor. When sample gas flows into the analyzer, any

restriction on the vent line will cause a pressure build up within the analyzer sample system, a sudden

release of the sample pressure will draw a vacuum on the sensor.

2. The vacuum generated in 1 above may cause the sensor to leak electrolyte (voiding the sensor

warranty). The electrolyte leakage may damage the electrical contacts of the upper section of the sensor

housing assembly, the electrolyte might enter in the sample system and if it does, it will require a

complete overhaul of the sample system.

3. Do not supply sample gas with pressure above the recommended limit. High positive pressure can

damage the integral pressure regulator, the sensor and or other sample system components.

4. Do not introduce calibration span gas from a pressurized cylinder without first regulating the pressure to

within the recommended limits (30-50 PSIG).

CAUTION: Do not vent the sample to a line with pressure above atmospheric pressure. If the vent line pressure

is above atmospheric (below 10-20 inches of water and is varying, use a back-pressure regulator set at 20 inches

of water to stabilize the pressure at the sensor.

Installation

The PI2-UHP 50/100 series Oxygen Analyzers consist of an electronic

module, sensor housing and sample system housed in a 13.9”W x

9.9”H x 13.4”D enclosure suitable for bench-top or cart applications.

The enclosure can be panel or rack mounted with an optional bezel.

The analyzer includes a temperature controlled heating system to

maintain the temperature of the sensor at a pre-set temperature of

85 ◦F. The analyzer has been tested and calibrated by the

manufacturer prior to shipment.

Note: Analyzer is shipped from the factory with sensor placed in a

separate bag sealed under nitrogen. Install sensor as instructed later

in this section.

Caution: Do not change the factory settings of the analyzer until instructed to do so in this manual.

Sample/Span Gas Connections Considerations

Assemble the necessary hardware for mounting the analyzer and optional components (if provided or required by

the user). Perform the following steps

1. Use ¼” stainless steel compression type fittings for air input and sample vent line connections. Use ¼”

Face Seal type fittings for sample and span gas inlet connections. Caution: use clean/fresh gaskets for

making Face Seal type connections.

2. Use cleaned, preferably electro polished SS tubing for all sample/span gas connections. Plastic tubing

rated at 150 psig may be used to provide instrument air.

3. Review the application/sample analysis conditions to ensure the sample gas is suitable for analysis.

Sample and Span gas pressure 30-50 psig

Recommended sample and span gas pressure 30-50 PSIG (maximum pressure of 150 psig is acceptable). The 3050 psig pressure is recommended for ease of controlling of the gas flow rate by using the integral pressure

regulator.

Page 12

Analytical Industries, Inc.

12

Caution: The integral pressure regulator is rated at a maximum of 150 psig input pressure. Excessive pressure

may permanently damage the pressure regulator and may also introduce undue pressure on the oxygen sensor.

Instrument air pressure - 80 psig

Analyzer sampling system consists of seven pneumatically controlled diaphragm valves. The valves are actuated

by solenoid valves that deliver air to the pneumatic valves. Minimum pressure required to activate the pneumatic

valve is 80 psig. Set the instrument air at 80 PSIG. A maximum air pressure of 100 psig may be used. However,

do not use air pressure above 100 psig. Excessive pressure may damage the solenoid valves controlling the

pneumatic valves.

Caution: The pneumatic valves require a dedicated source of instrument air at a minimum of 80 psig. Do not

attempt to split the sample gas feed to operate the pneumatic valves.

Power Requirement

The analyzer is rated at 100-240 VAC. Before establishing power to the analyzer, check the rating printed at the

back of the analyzer to ensure that the power available meets the required ratings.

Caution: Incorrect power may result in safety hazard and damage to the analyzer.

Establish power to the analyzer by the power cable provided with the analyzer. Ensure that EMI/RFI filter is

attached as close as possible to the analyzer power input terminal.

ENSURE THAT POWER LINE INCULDES “SURGE PROTECTER” AND RFI/EMI FILTER TO PREVENT INTERFERENCE

FROM EXCESSIVE LINE VOLTAGE VARIATIONS

Signal Output

The analyzer provides 0-1 VDC, 0-5 VDC and 4-20 mA isolated full scale output. Keep signal output lines separate

from AC power lines. For optimum results when connecting signal output to an external recording device, e.g., a

printer or a PLC, do not bundle signal output wires with power cable (bundling signal output and AC power line

may introduce excessive noise on the signal output line). Keep wire lengths taking signal output to a recording

device to less than three meters.

Mounting the Analyzer

The PI2- UHP 13.9”Wx9.9”Hx13.4”D configuration is designed for bench-top or cart use. The analyzer can be

panel 15”Wx12”H or rack 19”Wx12”H mounted with the optional bezels. When mounting the analyzer in a 19”

rack, allow sufficient room to access terminal connections at the rear of the enclosure.

When equipped with the optional bezels, the PI2- UHP bolts directly to any flat vertical surface, wall or bulkhead

plate with the appropriate cutout. To facilitate servicing the interior of the analyzer, position it approximately 5

feet off the floor.

Establishing Gas Connections

The PI2-UHP is designed for positive pressured samples and requires connections for incoming sample, span

calibration gas, instrument air (for the solenoid valves controlling the pneumatic valves) and the sample/span gas

vent.

NOTE: PI2-UHP-B does not have a separate Span inlet port. For these models, the user must connect the Span

gas to the Sample inlet port by using a TEE adaptor and a THREE-WAY valve for manually selecting the Sample

or Span gas.

Page 13

Analytical Industries, Inc.

13

Note: The preset of the integral pressure regulator and a restrictor in the sample line regulate the flow of the

incoming sample and span gas.

Procedure

1. Connect the instrument air supply to the tube fitting labeled AIR. Set air pressure at 80-100 psig.

2. Connect sample vent line to the tube fitting labeled SAMPLE VENT. Caution: Vent sample to

atmosphere. Use minimum ¼ inch tubing and keep the vent tube as short as possible (to minimize the

back pressure on the sensor)

3. Connect sample line to the face seal fitting connection labeled SAMPLE IN. Set sample input pressure

at 30-50 psig.

4. Connect span gas line to the face seal fitting connection labeled SPAN IN. Set the span pressure at

30-50 psig.

Caution: When making Face Seal sample and span gas connections, use fresh, clean and unscratched gaskets to

ensure leak free connections. To tighten connections, always use two ranches to prevent twisting of bulkhead

fittings.

Purging Sample and Span Gas Lines

It is recommended that before tightening the Face Seal connection, bleed the sample/span tubing up to the

sample/span port of the analyzer for 5-10 minutes to remove air trapped in the sample/span gas tubing.

Page 14

Analytical Industries, Inc.

14

Establishing Power to the Analyzer

Power to the analyzers is supplied by an integral universal 100-240VAC power supply. The appropriate AC line

voltage is supplied by using a standard power cord connected to the universal power entry module. Ensure that

EMI/RFI filter on the power cord remains intact and close to the power entry module.

ENSURE THAT POWER LINE INCULDES “SURGE PROTECTER” AND RFI/EMI FILTER TO PREVENT INTERFERENCE

FROM EXCESSIVE LINE VOLTAGE VARIATIONS

Check power rating of the analyzer printed at the back of the analyzer and make sure that a proper

AC voltage supply is available. Incorrect AC power may cause safety hazard and damage to the

analyzer.

Electrical Connections

ALL CONNECTIONS ARE MADE VIA TERMINAL BLOCKS AND ARE MARKED AS BELOW. TO MAKE ELECTRICAL

CONNECTIONS, PUSH THE LEVER WITH SMALL SCREW DRIVER, INSERT WIRE WHEN SLOT OPENS

RANGE ID –V

RANGE ID +V

4-20 + mA

4-20 – mA

0-5 -V

0-5+V

-V

+V

L-FLO B (optional)

L-FLO A (optional)

GND

+ 15 VDC

THRM 2

THRM 1

SEN –

SEN +

SYS FAIL B

SYS FAIL A

BNC Alarm contact normally closed

BC Alarm contact common

BNO Alarm contact normally open

ANC Alarm contact normally closed

AC Alarm contact common

ANO Alarm contact normally open

Page 15

Analytical Industries, Inc.

15

Alarm Relays and Signal Output Connections

As illustrated above the signal output (0-1 V, 0-5 V and 4-20 mA full scale), range ID voltage output, low and

high oxygen alarm relay contacts, low flow alarm contacts (optional feature), external sensor input (optional

feature) system fail alarm contact and +15 VDC auxiliary power (to actuate external solenoid valve option) are

hard wired (PCB mounted) terminal blocks located at the rear of the analyzer.

Remote Switch Functions (Optional)

The Remote Switch option allows the user to control the analyzer remotely through the back of the analyzer.

Remote switch function logic:

FUNCTION

INPUT A

INPUT B

INPUT C

SPAN CAL

OPEN

OPEN

SHORTED

ZERO CAL

OPEN

SHORTED

OPEN

BYPASS

OPEN

SHORTED

SHORTED

SAMPLE

SHORTED

OPEN

OPEN

STANDBY

SHORTED

OPEN

SHORTED

Shorted = Contact connected to +15V for 2 seconds

Inserting/Connecting Wires to Terminal Blocks

The terminal blocks have push-levers. When push-levers are pressed downward, the slots open to allow insertion

of wires in the slots. Use a small bladed screwdriver and press one lever of the terminal block down to open

contact slot. Insert the appropriate contact wire into the slot and release the lever to secure the wire in the

terminal block.

Caution: Use wires with proper ratings. Strip the insulation of the wires no more than 3/16”. Assure the stripped

wire ends of the cable are fully inserted into the terminal slots and do not touch each other or the back panel of

the analyzer enclosure.

Run signal and AC power lines separately to avoid EMI/RFI interference.

Danger: While connecting cables to relay terminals, ensure there is no voltage on cables to prevent electric

shock and possible damage to the analyzer.

To make a connection upon relay activation, connect live cable to the common terminal C and secondary cable to

the normally open NO terminal. To break a connection upon relay activation, connect live cable to the common C

and connect secondary cable to the normally closed NC terminal.

High and Low Oxygen Alarm Relays

The analyzer is equipped with two user adjustable alarUHP. When activated the alarUHP trigger SPDT Form C

non-latching relays @ 5A, 30VDC or 240VAC resistive. The alarUHP are fully adjustable by selecting the

appropriate ALARM menu option.

The alarm set point represents a value of oxygen. When the oxygen reading exceeds (high alarm) or falls below

(low alarm) the alarm set point, the relay is activated and the LCD displays the alarm condition.

Note: To prevent chattering of the relays, a 2% hysteresis is added to the alarm set point. This means that the

alarm will remain active until the oxygen reading has fallen 2% below the alarm set point (high alarm) or risen

2% above the alarm set point (low alarm) after the alarm was activated.

Note: The alarUHP may be deactivated by selecting the appropriate ALARM menu option (explained later in this

chapter). This feature is useful while replacing the oxygen sensor or during calibration when the oxygen reading

might well rise above the alarm set point and trigger a false alarm.

Page 16

Analytical Industries, Inc.

16

Power/System Failure Alarm

A dry contact rated at 30VDC @ 1A is provided as a power failure alarm. The contact is normally closed but opens

when the power to the analyzer is switched off or interrupted.

4-20 mA, 0-1 V and 0-5 V Full Scale Signal Output

The analyzer provides 0-1 V and 0-5 V full scale with negative ground and a 4-20mA full scale (isolated ground)

signals for external recording devices.

Caution: The integral 4-20mA voltage to current converter is internally powered and does not require external

power. DO NOT supply any voltage to either of the two terminals of the 4-20mA signal output. Failure to do so

will permanently damage the signal processing PCB.

Range Identification Voltage and 4-20 mA Output

A voltage output corresponding to each range is provided. The range ID voltage for first range is 5V and it

decreases by 1 V (to 4V, 3V and 2V) as the range shifts to the second, third and fourth range. An optional 4-20

mA range ID is also available. With 4-20 mA range ID, first range corresponds to 20 mA and dropping by 4 mA

with each range. Consult factory for this option.

Low Flow Alarm Option

An optional low flow alarm is available. The contact of the low flow alarm closes when gas flow falls below a

preset value, for example, below 1 SCFH. The alarm contact is rated at 30VDC @ 1A. Consult factory for this

option.

Two- way USB Communication Port

A real time bi-directional data lines is provided via USB port. This allows the access to the analyzer from a remote

computer to obtain status of the analyzer and/or initiate analyzer functions remotely.

Caution: In order to access the analyzer through a computer, you will require the proprietary optional software

(AII Configuration Software) from the factory. The software is available at a nominal charge.

By connecting a computer to the analyzer, all analyzer operational features can be accessed through the

computer, including the ability to store unlimited analyzer data on the computer hard disk.

RS-232 or RS-484 Communication Port

Optional RS-232 or RS-485 communication ports are available

Page 17

Analytical Industries, Inc.

17

Establishing Power to the Electronics

Once the power cord is inserted into to the power entry module at the rear of the enclosure, as illustrated above,

connect the plug end of the power cord to an appropriate AC outlet. When power is supplied to the analyzer, the

analyzer perforUHP self-diagnostic checks and the 5” x 2.75” graphical back-lit LCD displays the following

message

The analyzer will automatically go into the STANDBY mode

The main screen contains information pertinent to the analyzer. This information consist of

• Temperature and pressure at the upper left corner.

• The current MODE of the analyzer is indicated at the middle center of the LCD. A user customizable name

appears across the top center line of the LCD.

• Date and time at the upper right corner.

• Left hand side of the LCD shows if Alarm 1 & 2 are currently active (Example shows Alarm 1 active and

Alarm 2 inactive) and the speaker symbol is if the audible alarm is active or not.

Page 18

Analytical Industries, Inc.

18

• At the center of the LCD displays the current reading of the sensor and below that displays the range the

analyzer is currently in (0-50PPB manual range). AUTO will appear underneath the range ID when Auto

Ranging is selected.

• Right hand side of the LCD displays:

o BG: Background Gas selected.

o SC: Signal Conditioning option selected.

o A-Bypass: Auto Bypass enabled.

o A-Span: Auto Span Calibration enabled.

o A-Zero: Auto Zero Calibration enabled.

o Out Hold: Holds output until user has finished servicing analyzer.

o Def Rnge: Default Range enabled.

• Bottom right hand side of LCD displays if the analyzer is locked with a passcode.

What if Power to the Analyzer is interrupted?

In the event power to the analyzer is interrupted, all pneumatic valves will close. When power is restored, the

analyzer will return to operation in the STANDBY mode. The analyzer requires user intervention to bring analyzer

back to the same conditions that existed prior to power interruption.

Menu Navigation

Sample Screen:

• Press Menu/Esc to show Main Menu (if the menu is locked, a passcode prompt will appear)

• Press Enter to show graph screen

• Press Up to bypass an active alarm or accept a span or zero calibration in progress

• Press Down to abort a span or zero calibration in progress

• Hold Menu/Esc and Enter for ½ second to restart analyzer

• Hold Menu/Esc for ½ second to clear non-critical error messages

Main Menu:

• Press Up/Down to move selection pointer

• Press Enter to select a menu item

• Press Menu/Esc to return to previous menu

Graph Screen:

• Press Enter to cycle graph (O2, Temperature, Pressure)

• Press Menu/Esc to return to sample screen or Data Logging menu

• Press Up/Down to go to Next/Previous graph page (page number is displayed in upper-right corner,

page 1 is most recent data)

• Hold Up/Down for ½ second to zoom graph to next higher/lower range

Numeric/Alpha-numeric entry:

• Press or hold Up/Down to increase/decrease digit value

• Press Enter to edit next digit to the right or accept entry (right-most digit)

• Press Menu/Esc to edit the next digit to the left or abort entry (left-most digit)

Page 19

Analytical Industries, Inc.

19

There are several sub-menus within each main menu. The details of selecting certain features within a menu or

sub-menu are given below

Page 20

Analytical Industries, Inc.

20

Temperature Controlled Heater System

The PI2-UHP-50/100 series analyzers are equipped with a PID temperature control system. The controller is

programmed to maintain the temperature inside of the analyzer enclosure at 85F.

Caution: Do not change this setting. A higher temperature setting may drastically reduce sensor life and

possibly cause damage to the electronic circuitry of both the controller and the analyzer.

Warning: Keep the front door securely fastened/closed when the temperature controller is ON.

When power is applied to the temperature controller, the controller

tunes itself and control the temperature at the pre-set

temperature. It is recommended that when analyzer door is to

open (for example during trouble shooting), set the temperature

set point at 60F to turn the heater off to prevent overheating the

analyzer. When operating the analyzer under normal conditions,

set the temperature between 85F.

To changing the Temperature set point:

1. Press SEL to display the current set point

2. Press the UP/DOWN arrows until the desired value is displayed

3. Press SEL to accept the new set point value

Heater Runaway Protection

Part of the temperature controlled heater system is a runaway protection

circuit. The analyzer is protected in the event the temperature controller

should fail and thereby allowing the heater to runaway thus damaging the

interior of the analysis unit.

The runaway protection is provided by a J2 type device (a closed circuit

contact) positioned between the temperature controller and the heater.

This device cuts the power to the heater if the temperature inside the

analysis unit exceeds 70C (158 oF). Should the J2 device cut power to the

heater, correct the problem and replace the J2 device (the J2 device is a

single shot device and can’t be reset; once it is in an open circuit, it must

be replaced to restore power to heater)

J2 Heater runaway protection

Page 21

Analytical Industries, Inc.

21

Normal Operation of Analyzer

Sample Mode

Press Menu/Esc to advance to the main menu. Move cursor to select Valves: Standby and press Enter. Using

Up/Down, select Sample.

Auto Ranging Mode

In AUTO RANGING mode, output signal will shift to higher range when oxygen reading exceeds 99.9% of the

current range. Output will shift to the next lower range when oxygen reading drops to 85% of the next lower

range.

For example, if analyzer is reading 10 PPB on 0-100 PPB range and an upset occurs, output will shift to 0-1 PPM

range when oxygen reading exceeds 99.9 PPB. Conversely, once the upset condition is corrected, output will shift

back to 0-100 PPB range when oxygen reading drops to 0.085 PPM.

Note: In AUTO RANGING Mode, analog signal output (voltage and mA) will always correspond to the percent of

full scale range displayed. For example, at 50.0 PPB on 0-100 PPB range, analog signal will be 0.5 V and 12 mA.

Similarly, at 0.50 PPM on 0-1 PPM range, analog signal will be 0.5 V and 12 mA.

Manual Ranging Mode

In MANUAL RANGING, output will not shift automatically. Instead, when oxygen reading exceeds 125% of the

upper limit of the current range, output will freeze at 125% value of the selected range but analyzer display will

shift to the next higher range and show actual oxygen concentration.

To select MANUAL RANGING, select SAMPLE and press ENTER, then select MANUAL RANGING and then advance

cursor to the appropriate range and press ENTER again.

Note: In MANUAL RANGING, signal output will max out at about 125% of the selected range (even though

oxygen reading on the LCD will shift to the next higher range).

In MANUAL RANGING, following information will appear on the LCD display.

Page 22

Analytical Industries, Inc.

22

Installing the Oxygen Sensor

The analyzer is shipped with oxygen sensor separately bagged in a nitrogen filled metalized PE bag. Use the

procedure listed below to install the sensor or to replace an expired sensor. Sensor should be installed only after

the analyzer installation is complete and Sample and Span gas line have been connected and purged.

GPR-13-2000 UHP-2/2E series sensors are for nitrogen, argon, hydrogen and helium application. For any

other gas mixture application, consult factory.

WARNING: The GPR-13-2000 UHP-2/2E sensor can be used for any of

the above gas, however, if the sensor has been used with any one gas, allow

several sufficient time for the sensor to stabilize with new sample gas before

commencing analysis

CAUTION: Before removing the oxygen sensor from the sealed bag, perform

the following checks

1. Ensure all gas connections are secure and tight.

2. Select Sample valves from the main menu and ensure that the sample

pressure is set at 30-50 PSIG and air pressure is set at 80 PSIG.

3. Set the sample flow rate between 1-2 SCFH by adjusting the Pressure

Regulator setting. Ideal flow 1-2 SCFH.

4. Allow the analyzer sample system to purge for about 5 minutes (this

step is required only if the analyzer has been installed for the first

time).

5. From Main Menu, select Calibration, Enter sensor serial number

located on the box the sensor is shipped in.

6. Loosen the hex screw (or thumbwheel) at the bottom of the sensor

housing by using 5/16” ranch provided or by turning the thumb wheel. Remove the upper section of the

sensor housing by turning it 90 degree and then lifting it straight up.

7. Remove sensor from the sealed bag. Use a sharp pair of scissor to cut the bag. Do not use a spike to

poke the bag (this method may accidently damage sensor).

8. Place sensor with sensor's sensing surface facing down in the bottom section of the sensor housing

immediately (with gold color two ring PCB facing up). Remove the two red colored taps from the PCB of

the sensor. Place upper section of the sensor housing on top of sensor and gently lower it down until it

sits on the bottom section of the housing. Turn the upper section of the housing 90 degree and then

tighten the screw at the bottom of the sensor housing (after finger tight, turn the screw one full turn) or

tighten by turning the thumb wheel.

9. Confirm that sample flow rate is between 1-2 SCFH (adjust flow by turning the knob of the pressure

regulator as necessary). Ideal Sample flow is 1-2 SCFH.

Caution: Do not attempt to calibrate analyzer until it has reached a stable base line. This process may take up to

12-24 hours period. However, you may confirm that the newly installed sensor has the proper output by using a

span gas; with span gas flowing, analyzer will display an oxygen reading close to the span gas value plus the O2

reading before span gas was introduced. If the difference in the oxygen reading before and after introducing

span gas is not close to the span gas value (+/-30% of the span gas value with Factory Default Span setting, see

details later in this Section), you may consider replacing with another sensor.

Page 23

Analytical Industries, Inc.

23

What to Expect During the First 24 Hours

After analyzer installation has been completed, sample and span gas lines have been connected and purged,

install sensor as instructed in the section above. After sensor installation, analyzer should demonstrate a

downward trend for several hours. Generally, analyzer reading should drop below 100 PPM in less than 10-15

minutes and below 1 PPM in less than 1-2 hours. It is strongly recommended that the user record analyzer output

on a recording device, e.g., chart recorder or a PLC, to confirm downward trending of the analyzer.

Caution: This “clean-up time” or “recovery time” or “purge down time” depends on the user – the length of time

sensor has been exposed to ambient air before it was installed and how well sample gas line was purged before it

was connected to the analyzer sample input.

In the above graph, trending shown is very typical after a new sensor installation. Within 24 hours of installation

of new sensor, output dropped to less than 60 PPB and continued to trend down. This downward trend would

continue but the degree of trending down will decrease with time and eventually get to a stable reading.

NOTE: If after 2 hours of installation, oxygen value displayed is not below 1-2 PPM, perform a complete check of

all external sample system connections and allow a low ppm gas to flow overnight before concluding that sensor

is defective and notifying the factory.

Caution: Allow approximately 24 hours to stabilize the sensor before attempting initial Zero and/or Span

calibration of analyzer.

General guidelines for Analyzer Calibration

A typical downward trend of a newly installed

analyzer/sensor on N2 sample gas with oxygen

concentration near zero. Analyzer is in Auto Ranging mode

0-1 PPM

0-100 PPB

Page 24

Analytical Industries, Inc.

24

Zero Calibration

Theoretically, with zero gas, analyzer should display 0 PPB. However, even with pure gas (no oxygen), analyzer

will display a signal anywhere from 5-60 PPB. This oxygen value is called as the “Zero Offset” This offset is

contributed by

1. Minor leakage in the sample line connections.

2. Residual oxygen dissolved in sensor’s electrolyte

3. Tolerances in electronics components

In order to achieve accurate results in the low PPB levels, analyzer must be “Zero calibrated” before accurate

measurements could be made.

Zero Calibration Procedure

PI2-UHP-50/100 analyzer has an integral oxygen scrubber/purifier that removes oxygen from sample gas and

produces a zero gas for zero calibration; the scrubber can remove oxygen from a sample gas containing 1-2 PPM

oxygen down to less than 1 PPB.

The PI2-UHP-B and PI2-UHP-M do not have the integral Zero scrubber. To perform Zero calibration with PI2UHP-B or PI2-UHP-M, user must provide a true zero gas.

In order to perform a ZERO calibration,

• From the MAIN MENU screen, select Calibration.

• From CALIBRATION menu, select Zero Calibrate.

• The valves will actuate to Zero Bypass for 30 seconds to ensure the line is purged down before

continuing to Zero Calibration.

• On the bottom left of the LCD Zero Cal will appear with Up = Accept, Down = Abort. A timer of 15

minutes will appear underneath the valve mode selected. After the 15-minute timer is up then the

analyzer will attempt to perform the zero calibration. The user may Accept or Abort the calibration at any

time. Ensure reading is stable before prematurely Accepting the zero calibration.

After ZERO calibration, analyzer will automatically return to the previous valve mode selected.

CAUTION: If zero calibration is performed pre-maturely (analyzer still trending down), analyzer may show a

negative reading in the SAMPLE mode.

AUTO ZERO option may be used at subsequent ZERO calibrations. With AUTO ZERO calibration enabled, the

analyzer will count down from the user selected value to automatically perform a zero calibration every X amount

of days (i.e. 30 days). If the auto zero fails the analyzer will attempt to calibrate 24 hours after the failed

calibration. Passed/Failed calibrations are stored in the calibration log.

Span Calibration

Oxygen sensors produce a certain amount of current per unit of oxygen concentration. However, due to the

tolerances involved in various components of the sensor, sensor’s current signal may vary from one sensor to

another. This variation, however, is within approximately +/- 30-50% of the nominal sensor signal. In order to

achieve accurate results, sensor must be calibrated by using a certified span gas.

Page 25

Analytical Industries, Inc.

25

Span Calibration Procedure

Analyzer may be calibrated by using a certified span gas with oxygen content 5-8 PPM balance nitrogen. If

analyzer is being used for He or Ar or H2 application, ideal span gas should contain 5-8 PPM oxygen balance the

gas being sampled.

Note: During SPAN calibration process, analyzer automatically switches to the SPAN BYPASS mode for 30

seconds to purge SPAN gas line and then automatically switches to the SPAN mode.

To enter a span gas value:

• Go to the Calibration Menu.

• Select Span Gas: 08.00 PPM

• Using the Up/Down and Enter keys select the span gas value listed on the gas tank.

• Once the span gas value has been selected, select Span Background Gas: Nitrogen.

• Select span background gas and press Enter.

To initiate a span calibration

• Select Span Calibrate on the Calibration Menu.

• The valves will actuate to Span Bypass for 30 seconds to ensure the line is purged down before

continuing to Span Calibration.

• On the bottom left of the LCD Span Cal will appear with Up = Accept, Down = Abort. A timer of 15

minutes will appear underneath the valve mode selected. After the 15-minute timer is up then the

analyzer will attempt to perform the span calibration. The user may Accept or Abort the calibration at any

time. Ensure reading is stable before prematurely Accepting the span calibration.

NOTE: When span calibration routine is initiated, analyzer closes sample gas valve, opens span gas valve (PI2UHP-50/100 ONLY) and turns itself into the SPAN BYPASS mode for 30 seconds (to purge span gas line before

span gas enters the sensor housing). After purging span gas line, analyzer will automatically close BYPASS valve

and allow span gas to flow through the sensor housing.

CAUTION: The actual oxygen value detected must be between 30%-50% of the span gas value entered. If

actual oxygen reading is outside these limits, by pressing ENTER to accept calibration will result in “FAILED

CALIBRATION” and analyzer will return to the previous valve mode without completing SPAN calibration.

AUTO SPAN option may be used at subsequent SPAN calibrations. With AUTO SPAN calibration enabled, the

analyzer will count down from the user selected value to automatically perform a span calibration every X amount

of days (i.e. 30 days). If the auto span fails the analyzer will attempt to calibrate 24 hours after the failed

calibration. Passed/Failed calibrations are stored in the calibration log.

Page 26

Analytical Industries, Inc.

26

Sampling the Gas

After successful SPAN and ZERO calibration, place the analyzer in SAMPLE mode. You may select MANUAL

RANGING or AUTO RANGING option.

Analyzer will continue to analyze the sample gas unless otherwise instructed by the user.

Sampling Different gases

GPR-13-2000-UHP-2/2E sensor is recommended for N2, Ar, He and H2 background gases. When switching

analyzer from one sample gas to another, allow sufficient time for the sensor to stabilize with new sample gas

before commencing analysis.

When sampling He or H2, the analyzer is recommended to be SPAN calibrated with 5-8 PPM O2

balance the gas being sampled. NOTE: Correction factors for various gases will be available within

the next few weeks, with correction factors, the analyzer will be allowed to calibrate with a span

gas in any four background gases and used to sample any of the four gases.

Analyzer Transportation

For moveable cart applications - Before transporting the analyzer from one place to another, make sure the

second installation site is ready to install the analyzer. Follow the steps below

1. Place analyzer in Bypass mode.

2. Disconnect analyzer power

3. Disconnect sample, span gas lines and instrument air from analyzer.

4. Transport analyzer to new site as soon as possible

5. Establish sample, span and instrument air connections at the new installation site. CAUTION: Purge

sample and span gas lines before connecting to analyzer ports, failure to do so will increase the trending

down time.

6. Establish power to analyzer

7. Select BYPASS mode, set sample flow between 1-2 SCFH and purge for 5 minutes

8. Select Sample mode and let sample purge for 5 minutes

9. The analyzer will begin trending down

10. It is not necessary to re-calibrate the analyzer

Page 27

Analytical Industries, Inc.

27

Data Logging

In the Data Logging Menu the user can select the following options.

• Graph Screen:

o Press Enter to cycle graph (O2, Temperature, Pressure)

o Press Menu/Esc to return to sample screen or Data Logging menu

o Press Up/Down to go to Next/Previous graph page (page number is displayed in upper-right

corner, page 1 is most recent data)

o Hold Up/Down for ½ second to zoom graph to next higher/lower range

• Restart: Clears any information on the graphs and starts from zero.

• Interval: Sets the logging interval in minutes.

• Time: The user can change to time to match the location the analyzer is located.

• Date: The user can change the date to match the location the analyzer is located.

• Datapoints: How many datapoints have been taken since the data logging has begun.

• Started: The date and time data logging began.

• Avg: Average O2 reading of the sensor.

• High: Highest O2 reading since beginning of data logging.

• Low: Lowest O2 reading since beginning of data logging.

Page 28

Analytical Industries, Inc.

28

AlarUHP

In the AlarUHP Menu the user has the following options.

• AlarUHP: Enable or Disable both alarUHP.

• Alarm 1:

o Enable or Disable Function

o Setpoint: Set the value that the user wishes for the alarm to trigger.

o Mode: Low or High. If set Low the alarm will trigger when the reading travels below the setpoint.

If set High the alarm will trigger when the reading travels above the setpoint.

o Delay: Sets a timer delay for the alarm. When the O2 reading reaches the setpoint, the alarm will

trigger once the delay timer has expired. Setting delay to 00 will trigger the alarUHP immediately

when the O2 reading reaches the setpoint.

o Latching: If YES, active alarm must be manually bypassed.

o Failsafe: If YES, alarm relay is energized while inactive, de-energized while active.

• Alarm 2: Same as Alarm 1.

• Pulse Mode: Disables Alarm 2. Relay 1 energizes for 3 seconds on activate, relay 2 energizes for 3

seconds on de-activate.

• Tone: Enables/Disables the beeper when alarUHP are triggered.

System Menu

Security

• Lock Now: Will go to sample screen and require a user passcode to enter menus. (Default passcode:

2855).

• Set Passcode: Will allow the user to set a passcode.

• Auto Lock: Locks the menu if no keys are pressure for the set time. Setting to 0 disables Auto Lock.

Page 29

Analytical Industries, Inc.

29

Analog Output

• Output Hold:

o Display: Analog output follows the displayed O2.

o Freeze: Analog output stops updating and holds the last output reading.

o Zero: Analog outputs 0V or 4mA.

o Full-scale: Analog outputs 1V, 5V, or 20mA.

• Calibrate 0-1V: Allows the user to calibrate the 0-1V output.

• Calibrate 0-5V: Allows the user to calibrate the 0-5V output.

• Calibrate 4-20mA: Allows the user to calibrate the 4-20mA output.

• Test: Using Up/Down keys allows the user to test the analog outputs in increments of 20%.

Signal Conditioning

• None: No signal conditioning applied to the O2 signal.

• Average: Rolling average over the number of samples (N) provided by the user. A new sample is taken

every second.

• Fast:

o A: Attenuation. Change of reading divided by the attenuation equals final change in reading.

o T: Threshold. Set % of full scale of the signal that would be attenuated. The threshold compares

the current sample reading to the previous sample. i.e. T =2% of 50ppb range, 2% is 10ppb.

Any reading change of less than 10ppb will divide the change of reading by the attenuation

factor. So, if A = 100 and change of reading is 5ppb then the reading will only change by 0.05%.

Background Gas Factor

When sampling in other than Nitrogen the user needs to select the appropriate background gas.

• Argon

• Helium

• Hydrogen

When sampling a gas other than N2, for example, He or Ar, the analyzer is recommended to be SPAN calibrated

with 5-8 PPM O2 balance the gas being sampled.

Auto Bypass

When the O2 reading travels to 20% of the 3rd range the analyzer will automatically switch to bypass valves to

ensure the sensor does not get exposed to high amounts of oxygen. Exposure to high amounts of oxygen will

damage the sensor and auto bypass will help protect the sensor.

Show Negative

The analyzer provides the user with the option to choose whether they wish to display negative readings. This

feature is useful if the user prematurely zeroes the analyzer either inadvertently or knowingly during a quick start

situation.

Unit ID

User customizable identification of the analyzer. The name given to the analyzer displays on the top center of the

sample screen.

Page 30

Analytical Industries, Inc.

30

Temperature

User selectable temperature units, to display the temperature in either Fahrenheit or Celsius.

Pressure

User selectable pressure units, to display the pressure in either PSI or KPA.

Date Format

User selectable data format:

• YY/MM/DD

• DD/MM/YY

• MM/DD/YY

Info

The information screen displays the analyzer characteristics such as model number, serial number, firmware

version, and more.

Standby and Storage

Short term shutdown

This procedure is for momentarily shutting down and moving the analyzer from one site to another or for a

temporary shutdown.

1. Place the analyzer in the STANDBY mode. In the STANDBY mode, all pneumatic valves are closed and the

sensor is isolated from the ambient air.

2. After short term shutdown, to restart,

2.1. Establish power to analyzer

2.2. Select Bypass mode

2.3. Set sample flow rate to 1-2 SCFH

2.4. Allow sample line to purge for 5 minutes

2.5. Select Sample valve and begin sampling

If the analyzer is not to be used for analyzing a sample gas, it is recommended that you keep the analyzer

running and have pure nitrogen (at least 99.999) flow through analyzer (to preserve gas, a flow rate as low as

0.1 SCFH should be sufficient). This will always keep analyzer in “ready state” for analyzing sample gases.

Long term Shutdown

If analyzer is to be stored for a long period of time (greater than 30 days), it is recommended to remove sensor

from analyzer and store analyzer in a clean environment. This is to prevent the likelihood of electrolyte leaking

out of sensor and damaging the sensor housing. WHEN STARTING ANALYZER AGAIN, YOU MUST INSTALL A

NEW SENSOR

Page 31

Analytical Industries, Inc.

31

6. Maintenance

Periodically, the oxygen sensor and oxygen scrubber will require replacement. The operating life of each is

determined by a number of factors that are influenced by the user and therefore difficult to predict. Under normal

operating conditions where the sensor and scrubber are exposed to oxygen levels below 10 PPM, expect a sensor

life of approximately 12-18 months and a scrubber life of several years.

Cleaning the electrical contacts of the sensor housing (when replacing the sensor) is the extent of the

maintenance requirements of this analyzer.

Serviceability: Except for replacing the oxygen sensor, there are no parts inside the analyzer for the operator to

service. Only trained personnel with the authorization of their supervisor should conduct maintenance.

Caution: DO NOT open/dissect the oxygen sensor. The sensor contains a corrosive liquid electrolyte that could be

harmful if touched or ingested, refer to the Material Safety Data Sheet contained in the Owner’s Manual

appendix. Avoid contact with any liquid or crystal type powder in or around the sensor or sensor housing, as

either could be a form of electrolyte. Leaking sensors should be disposed of in accordance with local regulations.

Sensor Replacement Procedure

To replace sensor, refer to section OPERATION of this manual.

O2 Scrubber Replacement (PI2-UHP-50/100 only)

Oxygen scrubber is designed to provide up to 10 years of continuous service provided it is not exposed to high

levels of oxygen (greater than 100 PPM) repeatedly or for extended periods of time. Should it become necessary

to replace oxygen scrubber, consult factory for recommendations.

Page 32

Analytical Industries, Inc.

32

7. Spare Parts

Recommended spare parts for the PI2-UHP-50/100 PPB O2 Analyzer:

Item No.

Description

GPR-13-2000 UHP-2/2E

PPB Oxygen Sensor for inert gases.

Other spare parts

CABL-1015

Cable Assembly for Solenoid Valves

CTRL-1004

Controller Temperature PID

HTR-1006

Heater

A-3919

Housing Sensor Bottom Assembly Stainless Steel

B-3048-1

Housing Sensor Upper Assembly Stainless Steel

MTR-1008

LCD Graphical Display 5” x 2.75”

ORNG-1007

O-ring 3/32 x 1-3/8 x 1-9/16 Viton

A-1146-24-rG-50

A-1146-24-rG-100

PCB Assembly Micro-processor / Display 0-50 PPB

PCB Assembly Micro-Processor / Display 0-100 PPB

A-1147-24-rG4-USB

A-1146-24-rG4-50-S

A-1146-24-rG4-100-S

A-1147-24-rG4-RS232

PCB Assembly Power Supply / Interconnection USB Port

PCB Assembly Micro-processor / Display 0-50 PPB RS-232

PCB Assembly Micro-processor / Display 0-100 PPB RS-232

PCB Assembly Power Supply / Interconnection RS-232

SNSR-1006

RTD Temperature Sensor

SNSR-1002

Runaway Protector J-2

VALV-1020

Valve Pneumatic ¼” Butt Weld Connections (replaces top

assembly only)

VALV-1023

Valve Solenoid with Mtg. Screws 3 or 7 Position Manifold

Page 33

Analytical Industries, Inc.

33

8. Troubleshooting

Symptom

Possible Cause

Recommended Action

Slow recovery

At installation, sensor was

exposed to air for too long.

Defective sensor

excessive, dead volume in

sample line

contaminated sample gas due to

leakage in sample line

connections

Abnormal zero gas

Sensor damaged in service due

to prolonged exposure to air or

electrolyte leakage

Sensor nearing end of life

Replace sensor while minimizing sensor

exposure to air

If recovery unacceptable or O2 reading fails

to reach 50% of lowest range after 48-72

hours of installation of sensor, check gas

connections and gas integrity before

replacing sensor again

Leak test the entire sample system:

Vary the flow rate (1-5 SCFH); O2 reading

that changes inversely to the changes in

flow rate indicates a leakage in the sample

system bringing gas to the analyzer

Correct source of leak

Qualify zero gas ( by using a second

analyzer). If problem persist,

Replace sensor

90 % Response

time slow

Increased dead legs or distance

of sample line

low flow rate

Reduce dead volume by reducing sample

tube length

Increase flow rate

O2 reading

doesn’t agree with

expected O2

values

Pressure and temperature of the

sample is varying

Abnormality in sample gas

Calibrate the analyzer at the sample

temperature, pressure and flow.

Main a constant sample flow.

Qualify sample gas (using a second

analyzer)

Continued

Corroded solder joints on sensor

PCB from corrosive sample or

electrolyte leakage from sensor

Corroded spring loaded contact

in upper section of sensor

housing from liquid in sample or

electrolyte leakage from sensor

Liquid covering sensing area of

sensor

Presence of interference gases

Unauthorized maintenance done

Replace sensor and if corroded contact,

return sensor to the factory for warranty

determination

Upper section of sensor housing: Clean

contacts with water, flow sample or zero gas

for 2-3 hours to flush sample system and

sensor housing

Sensor: Replace if leaking and return it to

the factory for warranty determination

Replace sensor, follow procedure in section

5 Operation

Page 34

Analytical Industries, Inc.

34

Sensor nearing end of life

Consult factory

Replace sensor, obtain authorized service

Replace sensor

Erratic, negative

or no O2 reading

possibly

accompanied by

electrolyte

leakage

O2 signal shows

periodic spikes

Cannot perform

Zero calibration

Cannot perform

zero calibration

even after

replacing sensor

Pressurizing the sensor by

flowing gas to the sensor with

the vent restricted and suddenly

removing the restriction draws a

vacuum on the sensor, causing

electrolyte leakage

Senor exposed to high O2 at

time of installation or during

normal use

Zero offset beyond acceptable

limit

Contaminated sample/zero gas

or exhausted O2 scrubber

Replace sensor re-calibrate the analyzer.

Remove any restriction on sample vent line.

Vent sample to atmospheric pressure.

Watch O2 signal for 24-48 hours, if the

spikes persist, replace sensor

Check source of zero gas, watch O2 on a

recording device, if trends down slowly, wait

until zero offset is less than 50% of the

lowest range, re-attempt zero calibration

Check integrity of sample/zero gas, if O2 in

sample gas is in the low PPB level but

analyzer still shows high zero offset, replace

exhausted O2 scrubber (integral to analyzer

or external)

O2 reading drifts

slowly upward

span requires

large gain

adjustment

Sensor exposed to high O2 for

an extended period of time or

Sensor is nearing end of its

useful life

Low sensor output signal

possibly due to moisture

condensation on sensor from

liquid in sample gas or

electrolyte leakage from sensor

Liquid covering sensing area of

sensor

Presence of interference gases,

e.g., CO2 ,Cl2, HCl

Replace sensor

Ensure there is no condensable moisture in

the sample gas. Flow sample or zero gas for

2-3 hours to flush moisture from sample

system and sensor housing

Sensor: Replace if leaking and return it to

the factory for warranty determination

Consult factory

O2 reading swings

too much with

minor variation in

ambient

temperature

Sensor exposed to high O2 for

an extended period of time,

sensor is damaged

Software bug

Replace sensor

Page 35

Analytical Industries, Inc.

35

The O2 reading

freezes even

though O2 in

sample is

changing.

Press the RESET button on A-1146 PCB to

restart analyzer. Watch start-up screen and

check self-diagnostic passes all tests. If any

of the tests fail, replace A-1146 PCB.

O2 reading same

in Sample and

Zero mode (Model

PI2--UHP only)

with known O2 in

sample gas

No O2 reading

with known O2

sample gas.

Defective O2 scrubber

Lost electrical contact between

sensor housing and PCB

Replace O2 scrubber

Test the continuity of sensor housing

contact pins and sensor cable wiring using a

voltmeter as follows:

Set the voltmeter to the audible continuity

Ohm “’ setting (common on Fluke devices)

Check the continuity between BLACK wire of

the 4-conductor sensor cable and the center

spring loaded contact pin inside the upper

section of the sensor housing

Check the continuity between the RED wire

and to the outer spring loaded contact pin

inside the upper section of the sensor

housing

Replace the upper section of the sensor

housing if either of continuity tests fails.

Check resistance between WHITE and

GREEN wires

Replace the upper section of the sensor

housing if the voltmeter reads outside the

range of 15-19K resistance

Replace the sensor after testing the

electronics and upper sensor housing

assembly as described below.

LED display does

not agree with 420mA signal

output

Minor variations in tolerances of

electronic components

Use AII Configuration software to correct

disagreement. If problem persist, Contact

the factory.

No 4-20mA output

No graphic on

LCD but has the

analog signal

output

Defective component or PCB

Electrostatic discharge could

cause graphic to disappear

Contact the factory.

Reset electronic by pressing RESET button

on A-1146 or turn the power the analyzer

OFF and then ON again.

Page 36

Analytical Industries, Inc.

36

9. Warranty

The design and manufacture of PI2 Series Oxygen Analyzers AND oxygen sensors are TESTED under a certified

Quality Assurance System that conforUHP to established standards and incorporates state of the art materials and

components for superior performance and minimal cost of ownership. Prior to shipment every analyzer is

thoroughly tested by the manufacturer and documented in the form of a Quality Control Certification that is

included in the Owner’s Manual accompanying every analyzer. When operated and maintained in accordance with

the Owner’s Manual, the units will provide many years of reliable service.

Coverage

Under normal operating conditions, the analyzer and sensor are warranted to be free of defects in materials and

workmanship for the period specified in accordance with the most recent published specifications, said period

begins with the date of shipment by the manufacturer. The manufacturer information and serial number of this

analyzer are located on the rear of the analyzer. Analytical Industries Inc. reserves the right in its sole discretion

to invalidate this warranty if the serial number does not appear on the analyzer.

If your analyzer and/or oxygen sensor is determined to be defective with respect to material and/or

workmanship, we will repair it or, at our option, replace it at no charge to you. If we choose to repair your

purchase, we may use new or reconditioned replacement parts. If we choose to replace your Analytical Industries

Inc. analyzer, we may replace it with a new or reconditioned one of the same or upgraded design. This warranty

applies to all monitors, analyzers and sensors purchased worldwide. It is the only one we will give and it sets

forth all our responsibilities. There are no other express warranties. This warranty is limited to the first customer

who submits a claim for a given serial number and/or the above warranty period. Under no circuUHPtances will

the warranty extend to more than one customer or beyond the warranty period.

Limitations

Analytical Industries Inc. will not pay for: loss of time; inconvenience; loss of use of your Analytical Industries

Inc. analyzer or property damage caused by your Analytical Industries Inc. analyzer or its failure to work; any

special, incidental or consequential damages; or any damage resulting from alterations, misuse or abuse; lack of

proper maintenance; unauthorized repair or modification of the analyzer; affixing of any attachment not provided

with the analyzer or other failure to follow the Owner’s Manual. Some states and provinces do not allow

limitations on how an implied warranty lasts or the exclusion of incidental or consequential damages, these

exclusions may not apply.

Exclusions

This warranty does not cover installation; defects resulting from accidents; damage while in transit to our service

location; damage resulting from alterations, misuse or abuse; lack of proper maintenance; unauthorized repair or

modification of the analyzer; affixing of any label or attachment not provided with the analyzer; fire, flood, or acts

of God; or other failure to follow the Owner’s Manual.

Service

Call Analytical Industries Inc. at 909-392-6900 (or e-mail info@aii1.com) between 8:00am and 5:30pm Pacific

Time Monday thru Thursday or before 12:00 pm on Friday. Trained technicians will assist you in diagnosing the

problem and arrange to supply you with the required parts. You may obtain warranty service by returning your

analyzer, postage prepaid to:

Analytical Industries, Inc

2855 Metropolitan Place, Pomona, Ca 91767 USA

Be sure to pack the analyzer securely. Include your name, address, telephone number, and a description of the

operating problem. After repairing or, at our option, replacing the analyzer, we will ship it to you at no cost for

parts and labor.

Page 37

Analytical Industries, Inc.

37

10. Material Safety Data Sheet – UHPDS

Product Identification

Product Name

Oxygen Sensor Series - PSR, GPR, AII, XLT

SynonyUHP

Electrochemical Sensor, Galvanic Fuel Cell

Manufacturer

Analytical Industries Inc., 2855 Metropolitan Place, Pomona, CA 91767 USA

Emergency Phone Number

909-392-6900

Preparation / Revision Date

January 1, 1995

Notes

Oxygen sensors are sealed, contain protective coverings and in normal conditions do not present a

health hazard. Information applies to electrolyte unless otherwise noted.

Specific Generic Ingredients

Carcinogens at levels > 0.1%

None

Others at levels > 1.0%

Potassium Hydroxide or Acetic Acid, Lead

CAS Number

Potassium Hydroxide = KOH 1310-58-3 or Acetic Acid = 64-19-7, Lead = Pb 7439-92-1

Chemical (Synonym) and Family

Potassium Hydroxide (KOH) – Base or Acetic Acid (CH3CO2H) – Acid, Lead (Pb) – Metal

General Requirements

Use

Potassium Hydroxide or Acetic Acid - electrolyte, Lead - anode

Handling

Rubber or latex gloves, safety glasses

Storage

Indefinitely

Physical Properties

Boiling Point Range

KOH = 100 to 115 C or Acetic Acid = 100 to 117 C

Melting Point Range

KOH -10 to 0 C or Acetic Acid – NA, Lead 327 C

Freezing Point

KOH = -40 to -10 C or Acetic Acid = -40 to -10 C

Molecular Weight

KOH = 56 or Acetic Acid – NA, Lead = 207

Specific Gravity

KOH = 1.09 @ 20 C, Acetic Acid = 1.05 @ 20 C

Vapor Pressure

KOH = NA or Acetic Acid = 11.4 @ 20 C

Vapor Density

KOH – NA or Acetic Acid = 2.07

pH

KOH > 14 or Acetic Acid = 2-3

Solubility in H2O

Complete

% Volatiles by Volume

None

Evaporation Rate

Similar to water

Appearance and Odor

KOH = Colorless, odorless aqueous solution or Acetic Acid = Colorless, vinegar-like odor aqueous

solution

Page 38

Analytical Industries, Inc.

38

Fire and Explosion

Data

Flash and Fire Points

Not applicable

Flammable Limits

Not flammable

Extinguishing Method

Not applicable

Special Fire Fighting Procedures

Not applicable

Unusual Fire and Explosion Hazards

Not applicable

Reactivity Data

Stability

Stable

Conditions Contributing to Instability

None

Incompatibility

KOH = Avoid contact with strong acids or Acetic Acid = Avoid contact with strong bases

Hazardous Decomposition Products

KOH = None or Acetic Acid = Emits toxic fumes when heated

Conditions to Avoid

KOH = None or Acetic Acid = Heat

Spill or Leak

Steps if material is released

Sensor is packaged in a sealed plastic bag, check the sensor inside for electrolyte leakage. If the

sensor leaks inside the plastic bag or inside an analyzer sensor housing do not remove it without

rubber or latex gloves and safety glasses and a source of water. Flush or wipe all surfaces repeatedly

with water or wet paper towel (fresh each time).

Disposal

In accordance with federal, state and local regulations.

Health Hazard Information

Primary Route(s) of Entry

Ingestion, eye and skin contact

Exposure Limits

Potassium Hydroxide - ACGIH TLV 2 mg/cubic meter or Acetic Acid - ACGIH TLV / OSHA PEL 10

PPM (TWA), Lead - OSHA PEL .05 mg/cubic meter

Ingestion

Electrolyte could be harmful or fatal if swallowed. KOH = Oral LD50 (RAT) = 2433 mg/kg or Acetic

Acid = Oral LD50 (RAT) = 6620 mg/kg

Eye

Electrolyte is corrosive and eye contact could result in permanent loss of vision.

Skin

Electrolyte is corrosive and skin contact could result in a chemical burn.

Inhalation

Liquid inhalation is unlikely.

SymptoUHP

Eye contact - burning sensation. Skin contact - soapy slick feeling.

Medical Conditions Aggravated

None

Carcinogenic Reference Data

KOH and Acetic Acid = NTP Annual Report on Carcinogens - not listed; LARC Monographs - not

listed; OSHA - not listed

Other

Lead is listed as a chemical known to the State of California to cause birth defects or other

reproductive harm.

Page 39

Analytical Industries, Inc.

39

Special Protection Information

Ventilation Requirements

None

Eye

Safety glasses

Hand

Rubber or latex gloves

Respirator Type

Not applicable

Other Protective Equipment

None

Special

Precautions

Precautions

Do not remove the sensor’s protective Teflon and PCB coverings. Do not

probe the sensor with sharp objects. Wash hands thoroughly after

handling.

Avoid contact with eyes, skin and clothing. Empty sensor body may contain

hazardous residue.

Transportation

Not applicable

Loading...

Loading...