Page 1

Advanced Instruments Inc.

GPR-2500 GB

% Oxygen Transmitter

Owner’s Manual

Revised May 17, 2017

2855 Metropolitan Place, Pomona, CA 91767 USA ♦ Tel: 909-392-6900, Fax: 909-392-3665, e-mail: info@aii1.com, www.aii1.com

Page 2

Table of Contents

Introduction 1

Quality Control Certification 2

Safety 3

Features & Specifications 4

Operation 5

Maintenance 6

Spare Parts 7

Troubleshooting 8

Warranty 9

Material Safety Data Sheets 10

Advanced Instruments Inc.

2

Page 3

Advanced Instruments Inc.

1. Introduction

Your new oxygen transmitter incorporated an advanced electrochemical sensor specific to oxygen along with

s

tate-of-the-art digital electronics designed to give you years of reliable precise oxygen measurements in

variety of industrial oxygen applications. To obtain maximum performance om your new oxygen transmitter,

read and follow the guidelines p

please rovided in this Owner’s Manual.

Every effort has been made to select the most reliable state of the art materials and components, to design the

transm and minimal cost of ownership. This transmitter was tested roughly by

the manufacturer prior to shipment for best performance. However, modern electronic devices do require

service me. The warranty included herein plus a staff of trained professional technicians to

quickly ansmitter is your assurance that we stand behind every transmitter sold.

The serial number of this transmitter may be found on the inside the transmitter. You should note the serial

numbe ded and retains this Owner’s Manual as a permanent record of your purchase, for

future nd for warranty considerations.

Serial Number: _______________________

A

p

itter for superior performance tho

from time to ti

service your tr

r in the space provi

reference a

dvanced Instruments Inc. appreciates your business and pledges to make every effort to maintain the highest

ossible quality standards with respect to product design, manufacturing and service.

fr

3

Page 4

Advanced Instruments Inc.

Quality Control & Calibration Certification

Customer: Date:

Order No.:

Model: GPR-2500 Oxygen Transmitter S/N:

Configuration

Accessories: Owner’s Manual

: A-1161-IS-2 Rev C4 PCB Assembly, Main Batch:

A-1182-2 Rev B PCB Assembly, Interconnection (18-28 VDC) Batch:

Ranges: 0-1%, 0-5%, 0-10%, 0-25%

Temperature compensation

A-2221 Flow Housing, 1/8" SS tubing, connections

Wall mount enclosure, painted aluminum 3"x4"x2"

Sensor: ( ) GPR-11-32-4 Oxygen Sensor

( ) XLT-11-24-4 Oxygen Sensor S/N:

B-3170 Sample / Calibration Module

Software

Ver:

Expected Observed

Value Value Pass

Test & Verify: Default zero

Default span in air @ 40 µA

Span calibration upper limit in air @ 55 uA

Span calibration lower limit in air @ 35 uA

Reading after air (20.9%) calibration

Baseline drift over 1 hour period (+5% FS) on 1% range

Noise level (+1% FS) on 1% range

Analog signal output 4-20 mA full scale

Overall inspection for physical defects

Options: NA

Other: NA

.00 + .05 low

range

19.0% to

23.0%

20.5% to

21.3%

20.5% to

21.3%

20.5% to

21.3%

+ 0.05%

Oxygen

+ 0.01%

Oxygen

4

Page 5

Advanced Instruments Inc.

3. Sa

fety

General

This section summari

Tra di na recautions specific to individual transmitter are contained in the g sectio of

nsmitter. Ad

this o rate the transmitter safely and obtain maximum performance follow the basic guidelines

manual. To pe

outlined in this Owner’s Manual.

Caut : T symbol is used throughout

ion his the Owner’s Manual to CAUTION and alert the user to

recom d safety and/or operating guidelines.

Warning: Th

presence of electrostatic discharge.

Danger: This anual to identify sources of immediate

DANGER suc

Instructions: efore operating the transmitter read the in

Read B structions.

Retain Instructions: tructions found in the Own should be

retained for futu

eed Warnin w all warnings M

H gs: Follo on the transmitter, accessories (if any) and in this Owner’s anual.

Follow Instructions: erating instructions. Failure t y result in

personal injury or damage to the transmitter.

zes the essential precautions applicable to the GPR-2500 GB

mende

is symbol is used throughout the Owner’s Manual to

symbol is used throughout the Owner’s M

h as the presence of hazardous voltages.

The safety precautions and operating ins

re refere

nce.

Observe all precautions and op o do so ma

percent Oxygen

followintio l p ns

Warn

and alert the user of the

er’s Manual

Pressure and Flow

GPR-2500 GB PPM Oxygen Transmitter is designed for measuring controlled atmo ide a glove box.

s a n gas and using the Glove Box Housing Assembly photo s n 4

Specification) which is eq ctions and are intended to operate at positive

pressure or for calibra as, inlet pressure but be regulated to . The

sample/span gas mus .

uipped with 1/8” tube fitting conne

tion with external span g 5-30 psig

t be vented to atmospheric pressure

sphere ins

(refer to Calibration require flowing spa ectio

Oxygen sensor

DO NOT open the sen electrolyte that cou rmful if touched o

ingested, refer to the M er’s Manual ap . Avoid contact with

any liquid or crystal type powd sor or sensor housing, as either e a form of

electrolyte. Leaking se accordance with local regulatio

sor. The sensor contains a corrosive liquid ld be ha

aterial Safety Data Sheet contained in the Own

er in or around the sen

nsors should be disposed of in

pendix

could b

ns.

r

Mounting

The transmitter is approved for indoor use only. Mount the transmitter as recommended by the manufacturer.

Power supply

Supply power to the transmitter only as rated by the specification or markings on the transmitter enclosure. The

wiring that connects the transmitter to the power source should be installed in accordance with recognized

electric dar . N er yank wiring to remove it from a terminal connection. Power consump n is less

th

al stan

an 60 t 24 VDC.

mA a

ds ev

tio

5

Page 6

Advanced Instruments Inc.

OTperating temperature

he maximum recommended operating temperature is 45ºC, (at temperatures above 25oC, the user is

expected to accept

intermittent basis, th

Heat

Situate and store the transmitter away from sources of heat.

Liquid and object entry

The tran

and obje

smitter should not be immersed in any liquid. Care should be taken so that liquids are not spilled on

cts do not fall on the transmitter

a dramatic reduction in expected sensor life – refer to analyzer specification). On

e transmitter may be operated up to 50

o

C

Mainte

Except f are no parts inside the transmitter for the operator to service.

Only trained personnel with authorization of their supervisor should conduct maintenance.

Troubl

Consult efore concluding that your

transmitter is faulty. Do not attempt to service the transmitter beyond those m

Manual.

personnel.

conducting surface (to discharge any electrostatic charge on the body)

nance

or replacing the oxygen sensor, there

eshooting

e guidelines in Section 8 for advice on the common operating errors bth

eans described in this Owner’s

Do not attempt to make repairs by yourself as this will void the warranty as per Section 10 and ma

CLEANING: The transmitter should be cleaned only as recommended by the manufacturer. Wipe off

dust and dirt from

solvents or chemicals. Do not touch the transmitter enclosure without first touching any solid

the outside of the unit with a soft damp cloth then dry immediately. Do not use

y

ce

rviresult in electrical shock, injury or damage. All other servicing should be referred to qualified se

Non-use period

If the transmitter is equipped with a range switch advance th

p

ower when the transmitter is left unused for a long period of time. Store transmitter away from source of heat.

e switch to the OFF position and disconnect the

6

Page 7

Advanced Instruments Inc.

4 Features & Specifications

7

Page 8

Advanced Instruments Inc.

5. Operation

Principle of Operation

The GPR-2500 GB incorporates a variety of advanced galvanic fuel cell type oxygen sensors. These sensors

are very specific to oxygen and generate an electrical signal proportional to the amount of oxygen present in a

gas stream. The selection of a particular type of sensor depends on the composition of the sample gas stream.

Consult the factory for recommendation.

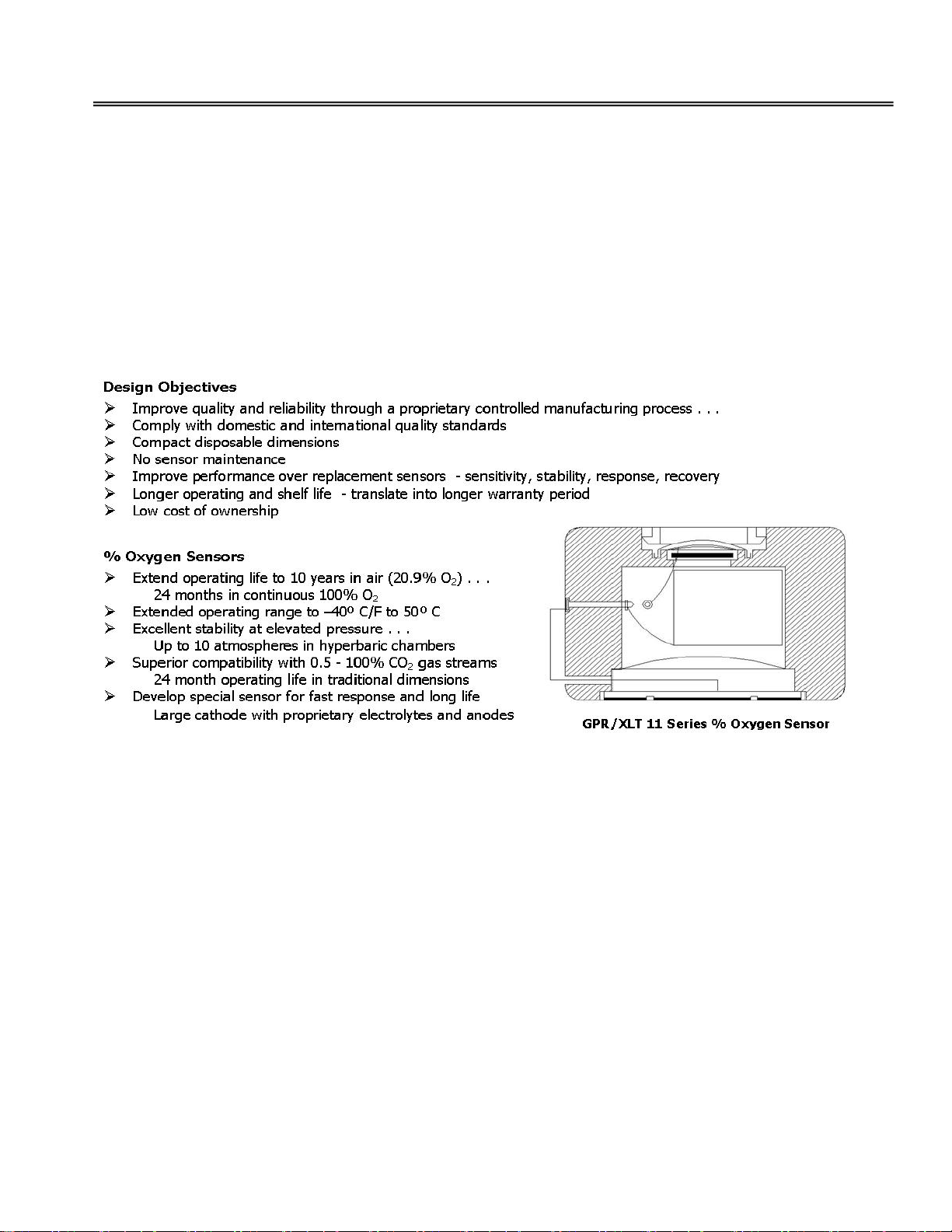

Advanced Galvanic Sensor Technology

All galvanic type sensors function on the same principle and are specific to oxygen. They measure the partial

pressure of oxygen from low PPM to 100% levels in inert gases, gaseous hydrocarbons, helium, hydrogen and

mixed gases

Oxygen, the fuel for this electrochemical transducer, diffusing into the sensor, reacts electrochemically at the

sensing electrode to produce an electrical current output proportional to the oxygen concentration in the gas

phase. The sensor’s signal output is linear over all measuring ranges and remains virtually constant over its

useful life. The sensor requires no maintenance and is easily and safely replaced at the end of its useful life.

Proprietary advancements in design and chemistry add significant advantages to this extremely versatile

oxygen sensing technology. Sensors for low % analysis recover from air to low % levels in seconds, exhibit

longer life and reliable quality. The expected life of our new generation of percentage range sensors now range

from 32 months to ten years with faster response times and greater stability. Another significant development

involves expanding the operating temperature range for percentage range sensors from -20°C to 50°C.

Contact factory for more specific information about your application.

Electronics

The signal generated by the sensor is processed by state of the art low power micro-processor based digital

circuitry. The first stage amplifies the signal. The second stage eliminates the low frequency noise. The third

stage employs a high frequency filter and compensates for signal output variations caused by ambient

temperature changes. The result is a very stable signal. Sample oxygen is analyzed very accurately. Response

time of 90% of full scale is less than 10 seconds (actual experience may vary due to the integrity of sample line

connections, dead volume and flow rate selected) on all ranges under ambient monitoring conditions.

8

Page 9

Advanced Instruments Inc.

Sensitivity is typically

the 4-20 mA loop curr

transmitter and the ground of the loop

NOTE: A 4-20mA signal output is provided on the two-wire 18-24VDC loop power source such as a PLC and

represents a full scale range of measurement. When operated in conjunction witt manufacturer’s recommended

optional intrinsic safety barrier, the GPR-2500 GB meets the intrinsic safety standards required for use in Class

1, Division 1, Groups C, D hazardous are

The GPR-2500 GB is also available in a version, requiring optiona

certified to ATEX Directive 94/9/EC, Ex II 2 G Ex ia IIB T4 Gb Tamb -20⁰C to + 50⁰C

Sample System

The GPR-250

bracket for sa

Advanced Instruments Inc. offers a full line of sample handling, conditioning and expertise to meet your

application requirements. Contact us at 909-392-6900 or e-mail us at info@aii1.com

0 GB is supplied with a unique Glove Box Housing Assembly that also includes a mounting

mpling (see photo section 4 Specifications) and flow housing with valves for calibration.

Accuracy and Calibration

Single Point Calibration: As previously described the

galvanic type oxygen sensor generates an electrical

current proportional to the oxygen concentration in the

sample gas. In the absence of oxygen the sensor

exhibits an absolute zero, e.g. the sensor does not

generate a current output in the absence of oxygen.

Given these linearity and absolute zero properties,

single point calibration is possible.

Pressure: Because sensors are sensitive to the partial

pressure of oxygen in the sample gas, their output is a

function of the number of molecules of oxygen or

percentage 'per unit volume'.

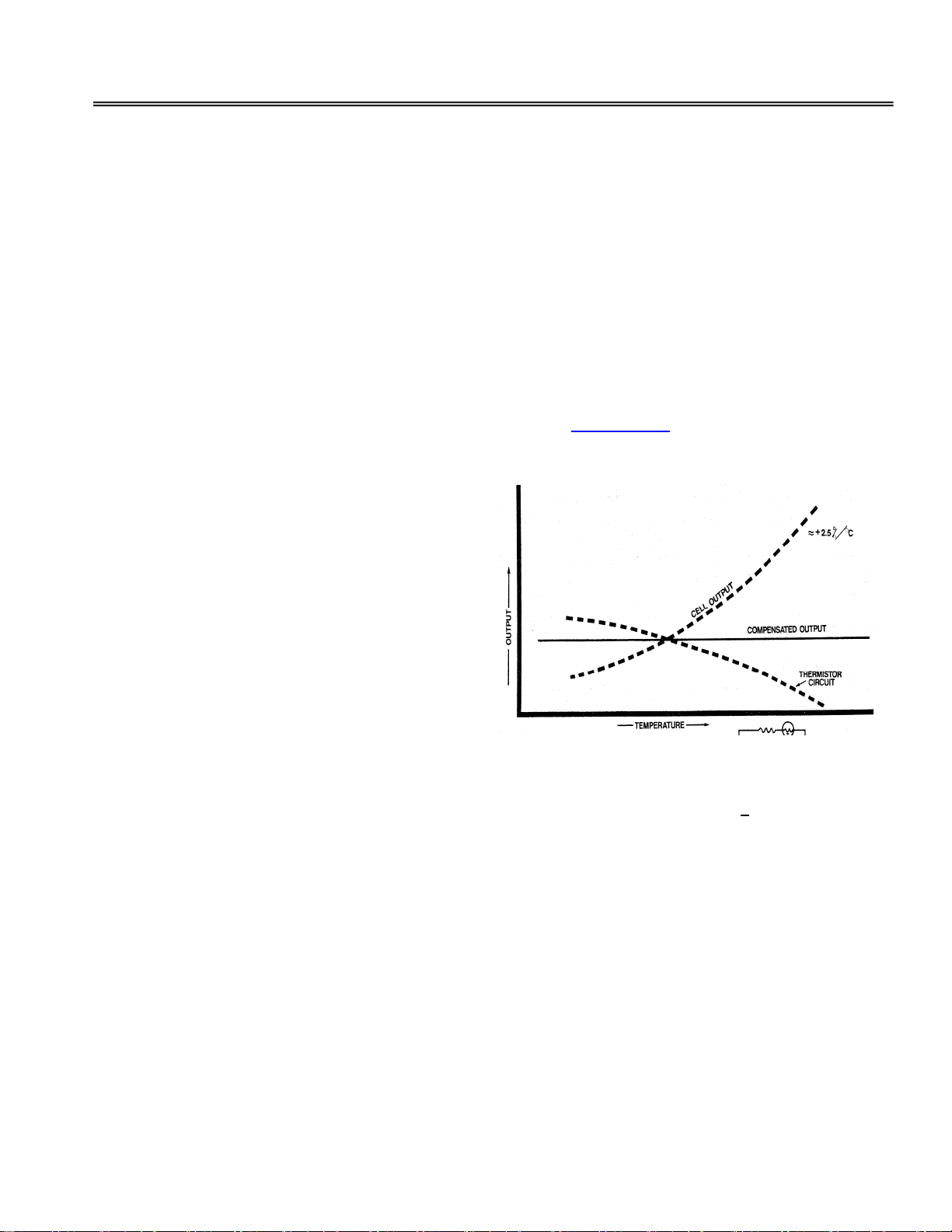

Temperature: The rate at which oxygen molecules

e sensor is controlled by a Teflon membrane otherwise known as an 'oxygen diffusion limiting diffuse into th

barrier' and all diffusion processes are temperature sensitive, the fact the sensor's electrical output will vary

with temperature is normal. This variation is relatively constant (2.5% per ºC). A temperature compensation

circuit employing a thermistor and a network of resisters offsets this effect with an accuracy of +

over a wide operating temperature range e.g., 5-45

independent of ambient temperature. There is extremely low error in measurement if the calibration and

sampling are performed at similar temperatures (within +/- 5 ºC. Conversely, a temperature variation of 10 º

may produce an error of >2% of full scale.

Accuracy:

errors: 1) 'percent of reading errors', illustrated by Graph A below and 2) 'percent of full scale errors', illustrated

by Graph B, such as1-2% errors in readout and calibration devices. Other errors are 'spanned out' during

calibration, especially when analyzer is calibrated close to the top end

In light of the above parameters, the overall accuracy of an analyzer is affected by two types of

0.5% of full scale low range. Oxygen readings may be recorded by an external device via

ent or 1-5 VDC by using a 250 ohms resistor between the negative terminal of the

power source.

as.

l intrinsic safety barriers, that has been

o

C can be obtained thus the signal output remains virtuall

of the measuring range.

5% or better

y

C

9

Page 10

Advanced Instruments Inc.

Transmitter Installation Considerations

ontents of sample stream C

Ensure the gas stream or composition of the controlled atmosphere of the application is consistent with the

specifications and review the application conditions before initiating the installation. Consult the factory if

necessary to ensure the sample is suitable for analysis.

Sample pressure and flow

All electrochemical oxygen sensors respond to partial pressure changes in oxygen. The sensors are equal

capable of analyzing the oxygen content of a flowing sample gas stream or monitoring

concentration in a co

Sample system for measuring oxygen in a flowing gas samples is generally required. The use of stainless

bing and fittings is critical for maintaining the integrity of the gas stream to be sampled tu

A flow indicator with an integral metering valve upstream of the sensor is recommended as a means of

ontrolling the flow rate of the sample gas. A flow rate of 2 SCFH or 1 liter per minute is recommenc

optimum performance.

ntrolled atmosphere.

the oxygen

ded for

Application - Sample Pressure - Positive

A flow indicator with integral metering valve positioned upstre

the sample flow rate between 1-2 SCFH. To reduce the

position a good quality needle valve upstream of the se

downstream of the sensor. If necessary, a pressure

upstream of the flow control valve to regulate the inle

Application - Sample Pressu

For sample at atmospheric pressure, (except when measurin

sampling pump should be positioned downstream of the

sensor and out to atmosphere. Install a flow meter down

sensor housing.

For sample at less than atmos

pump and the needle valve upstream of the sensor. In either app

approximately at 1-2 SCFH.

NOTE: If pump loading is a consideration, a second throttle valve on the pump’s inlet side may be necessary

provide a bypass path so the sample flow rate is within the above parameters.

Recommendations to avoid erroneous oxygen readings and damaging the sensor:

• Assure there are no restrictions in the sample or vent lines

• Avoid drawing a vacuum on the sensor that exceeds 14” of water column pressure

• Avoid excessive flow rates above 2

• Avoid sudden changes in the sample pressure.

• Avoid the collection of liquids or particulates on the sensor, they block the diffusion of oxygen into the

sensor.

re - Atmospheric or slightly negative

pheric pressure, push the sample through the sensor housing by positioning the

SCFH which generate backpressure on the sensor.

regulator (with a metallic diaphragm) is recommended

t pressure between 5-30 psig.

am of the sensor is recommended for controlling

possibility of leakage for low ppm measurements,

nsor to control the flow rate and position a flow indicator

g oxygen in a glove box), an optional external

sensor to draw the sample from the process, by the

stream of the sensor to control the flow through the

lication, when pump is used, set the flow

Removal of moisture & particulates from sample gas

stallation of a suitable coalescing and/or particulate filter is required to remove condensation, moisture and/or

In

articulates from the sample gas to prevent erroneous analysis readings and damage to the sensor. Moisture

p

nd/or particulates do not necessarily damage the sensor, however, collection on the sensing surface can

a

lock or inhibit the diffusion of sample gas into the sensor resulting in a reduction of sensor signal output – and

b

e appearance of a sensor failure when in fact the problem is easily remedied by blowing off the liquid

th

ondensed on the front of the sensor.

c

ly

steel

to

10

Page 11

Advanced Instruments Inc.

Power & Signal Connections

Power input connections

Transmitter is designed to operate with 18-24 VDC loop power. It

provides 4-20 mA signal representing full scale of analysis on the

ower loop.

p

Locate the appropriate power source, for example, a PLC to

meet the transmitter power requirements, Connect power to

the power input terminal block mounted on the side of the

main enclosure. Ensure that positive of the

connected to the + of the terminal block of the transmitter and the

ground of the power is connected to the - terminal of the transmitter.

Signal output connections

The 4-20mA current output is obtained by connecting the current measuring device between the negative

terminal of power source

the main transmitter enclosure. The current flows fro

pin 2 to ground of the power source.

To check the 4-20 mA signal output, connect an ammeter, as illustrated below, as the current measuring

device and confirm the output is within 4 mA +/- 0.1mA with the transmitter LCD display reading 000.

and the negative terminal, marked (-), located in a small box mounted on the side of

azardous area operation H

When used in conjunction with the optional intrinsic safety barriers, the design of the

recognized standards as intrinsically safe for operation in Class I, II, III; Division I, II; Groups C-G hazardous

areas.

The GPR-2500 GB is also available in a version, requiring optional intrinsic safety barriers, that has been

certified to ATEX Directive 94/9/EC, Ex II 2 G Ex ia IIB T4 Gb Tamb -20⁰C to + 50⁰C

C

18-28VD

+ + +

_ _ _

Current Measuring Device Intrinsic Safety Barrier

4-20 mA MTL7706+ or Equivalent

Pow

er input and signal output connections employing an intrinsic safety barrier

Locate the optional intrinsic safety barrier as close to the pow

possible.

power source is

m pin 1 (+ terminal) to pin 2 (negative terminal) and from

GPR-2500 GB meets

Transmitter

er source in the non-hazardous area as

Mounting the Transmitter

The GPR-2500 GB electronics enclosure and the sensor housing assembly (sensor housing designed for

mounting inside of Glove Box) can be mounted on any flat surface. Ideally, the transmitter electronics sh

be installed outside of the glove box.

11

ould

Page 12

Advanced Instruments Inc.

CAUTION: Minimize the length of cable from the sensor to the transmitter electronics (longer cable could pick

up EMI/RFI interfering signal that may interfere with o

transmitter should run through a separate conduit (bu

interference with measurements).

Gas Connections:

The GPR-2500 GB is de

requires that the sensor be screwed into the upper section of the Glove

Box Hou

housing span

calibratio st be

mounted in the sensor housing).

sing Assembly, as shown in the picture. However, the sensor

with two toggle valves is provided to bring the span gas in for

n of the transmitter (during span calibration, the sensor mu

signed for measuring a controlled atmosphere and

Senso

r mounted in the upper section of

the sens

or housing

xygen measurements. Furthermore, power to the

ndling up power with other power cords may create

Sensor housing with two toggle valves

for span calibration with a span gas

12

Page 13

Advanced Instruments Inc.

Installation of Oxygen Sensor

The GPR-2500 GB Oxygen Transmitters are tested and calibrated prior to shipment and accompanied by

qualified oxygen sensor packaged a in a separate shipping container. The sensor must be installed as instructed

elow.

b

Procedure

Caution: Do not change the factory settings until instructed to do in this

1. Open the barrier bag containing the new sensor.

2. Remove the spring from inside of the round metal connector of the s

positive and negative terminals

relatively short period of time after ins

connected to the sensor cable immediately. Failure to do s

to stabilize.

3. Screw the oxygen s ten plus one eighth (1/8) turn to ensure a

good seal between t nd the o-ring affixed to the sensor.

4. Assure the keyway registration of the female plug on the cable and male receptacle on the sensor

match up.

5. Push the female plug (including the knurled lock nut) molded to the cable into the male receptacle

attached to the new sensor.

6. Screw the knurled lock nut attached with the cable onto to the male connector of the sensor.

7. Proceed to calibration.

ensor into the sensor housing. Finger tigh

he sensor housing a

of the sensor shorted to ensure that sensor is ready to use in a

tallation). Note: After removing the spring, the sensor must be

manual.

ensor (the spring keeps the

o will prolong the time the sensor will require

13

Page 14

Advanced Instruments Inc.

Establishing Power to the Electronics

Once the two wires of the shielded cable are properly connected to the terminals marked "POWER IN" in the

small enclosure on the side of main transmitter enclosure, connect the other ends of the two wires to a suitable

18-24 V

When power is applied, the transmi

UP TEST” as illustrated below:

After self-diagnostic tests, transmitter display defaults automatically to the sampling mode and display the

DC power supply such as a PLC, DCS, etc.

tter performs several self-diagnostic system status checks termed “START-

START-UP TEST

ELECTRONICS – PASS

LOOP POWER – PASS

TEMP SENSOR – PASS

BARO SENSOR – PASS

S1010 1.16

signal value seen by the sensoxygen or..

20.9%

AUTO SAMPLING

25% RANGE

76 F 98 KPA

Menu Navigation

The four (4) pushbuttons located on the front of the transmitter operate the micro-processor:

Blue ENTER (select)

yellow UP ARROW

yellow DOWN ARROW

Green MENU (escape)

Main Menu

Access the MAIN MENU by pressing the MENU key:

14

MAIN MENU

SELECT RANGE

CALIBRATION

VIEW HISTORY

SYSTEM OPTIONS

Page 15

Advanced Instruments Inc.

Range Selection

The GPR-2500 GB transmitter is equipped with four (4) standard measuring ranges (see specification) and

provides users with a choice of sampling modes. By accessing the MAIN MENU, users may select either the

AUTO SAMPLING (ranging) or MANUAL SAMPLING (to lock on a single range) mode.

Note: For calibration purposes, use of the AUTO SAMPLE mode is recommended.

Auto/Manual

Access the MAIN MENU by press key.

Advance the revers RROW keys to highlight SELECT RANGE and press ENTER

The display will show nge of analysis. Press the ENTER to select MANUAL RANGE

and advance the cu and press ENTER.

The following displa

Sampling

ing the MENU

e shade cursor using the A

*AUTO and the actual ra

rsor to the desired RANGE

y appears:

MAIN MENU

SELECT RANGE

CALIBRATION

HISTORY

VIEW

M OPTIONS

SYSTE

SELECT RANGE

*AUTO

25%

10%

5%

*1%

In the AUTO range, the display range when the oxygen reading exceeds 99.9% of

the upper limi of the current range. The display will shift to the next lower range when the oxygen reading

drops to 85% nge. In MANUAL range, the analyzer will be locked on the

sele

cted range. If the oxygen value goes above 25% of the upper limit of the MANUAL selected range, an

O

VER RANGE warning will be displayed.

t

of the upper limit of the next lower ra

will shift to the next higher

1.25 %

OVERRANGE

M

ANUAL SAMPLING

1% RANGE

76 F 98 KPA

Once the O ER RANGE warning appears the use must advance to the next higher range.

NOTE: Wi ing above 25% of the selected range, the analog signal output will increase but will

V r

th oxygen read

freeze at a maximum value of 1.2 V. After the oxygen reading falls below the full scale range, the voltage signal

will become normal.

Analyzer Calibration

The electro sors generate an electrical current that is linear or proportional to the oxygen

concentrat the absence of oxygen the sensor exhibits an absolute zero, i.e., the sensor

oes not generate a current output in the absence of oxygen. Given the properties of linearity and an absolute

d

ero, a single point calibration is possible.

z

15

chemical oxygen sen

n in a sample gas. Inio

Page 16

Advanced Instruments Inc.

The analyzer is equipped with “Zero Calibration” feature. However, as described below, zero calibration is

recommended only wh

en the application (or user) demands optimum accuracy of below 5% of the most

sensitive or lowest range available on the analyzer. For example, if the user requires analysis of a sample ga

below 0.05%, zero calibration may be required.

pan calibration, it is necessary to adjust the analyzer sensitivity for accurate measuremS

ents of oxygen by

using a standardized (certified) oxygen or by using ambient air (20.9%).

Zero Calibration

The maximum zero offset correction is limited to a ma

positive zero offset and 10% of the lowest range for negative zero offset.

Normally, zero calibration is performed when a new sensor is installed or changes are made in the sample

to flow through the analyzsystem connections. Allow the ZERO gas

low value and is stable. a

• Access the MAIN MENU by pressing the MENU key.

• A se shade cursor using the A highlight CALIBRATION.

dvance the rever

• ey to select the highlighted

ress the ENTER k

The following displ

ays appear:

MAIN MENU

SELECT RANGE

CALIBRATION

VIEW HISTORY

SYSTEM OPTIONS

• Advance the reverse shade cursor using the ARROW keys to highlight ZERO CALIBRATE.

• Press the ENTER key to select the highlighted menu option.

The following disp

lays appear:

0.015 %

O CAL RATIB

ZER ION

WAIT FOR S EADY RDG

ENTER TO CALIBRATE

MENU TO ABORT

T

Wait until the analyzer reading stabilizes (depending on the history of the sensor and then press the ENTER

key to calibrate (or MENU key to abort).

If the offset is less than 50% of the low

transmitter will return to the Sample mo

est range, by pressing ENTER will pass zero calibration and the

de. On the other hand, if the offset is above 50%, pressing ENTER will

fail calibration and the transmitter will return to Sample mode without completing the Zero calibration.

ximum of 50% of the lowest (most sensitive) range for

er and wait until the signal has dropped to

RROW keys to

ption. P menu o

>>>

CALIBRATION

SPAN CALIBRATE

ZERO CALIBRATE

DEFAULT SPAN

DEFAULT ZERO

OUTPUT CALIBRATE

OUTPUT SIMULATE

s

16

Page 17

Advanced Instruments Inc.

When in calibration mode, both Zero Calibration and Span Calibration, pressing the ENTER key results in

of the following two displays:

CALIBRATION

PASSED

OR

FAILED

CALIBRATION

Factory Default Zero Calibration

This feature will eliminate any previous zero calibration adjustment and display the actual signal output of the

sensor at a specified oxygen concentration. This feature allows the user to ensure that the accumulative zer

offset never exceeds 50% of the lowest range limit. To perform Default Zero Calibration,

• Access the MAIN MENU by pressing the MENU key.

• Advance the reverse shade cursor using the ARROW

• Press the ENTER key to select the highlighted menu option.

he following displays appear:

T

MAIN MENU

SELECT RANGE

CALIBRATION

VIEW HISTOR

SYSTEM OPTIO

>

>>

Y

NS

keys to highlight CALIBRATION.

CALIBRATION

SPAN CALIBRATE

ZERO CALIBRAT

DEFAULT SPAN

E

DEFAULT ZERO

OUTPUT CALIBRA

OUTPUT SIMULA

TE

TE

one

o

• Advance the reverse shade cursor using the ARROW keys to highlight DEFAULT ZERO.

• Press the ENTER key to select the highlighted menu option.

The following display appears and after 3 seconds the system returns to the SAMPLING mode:

FACTORY

DEFAULTS

SET

>>>

0.250%

AUTO SAMPLING

1% RANGE

76 F

17

Page 18

Advanced Instruments Inc.

Span Calibration Procedure

Air Calibration

This procedure requires only a source of clean ambien removal of the se r from its flow housing or

by pushing ambient air through the sor housing. T rm air calibration.

sen o perfo

• Remove the he screw-in sensor housing or pu ensor

sen or from ts sh th air through the se

housing thus exposing the sensor to ambient air or alternatively, flow a certified span gas

through the sensor housing.

• Advance the cursor on the MAIN MENU to CALIBRATE and press ENTER.

• Advance the cursor to SP

AN CALIBRATION and press ENTER

The following displays appear:

MAIN MENU

SELECT RANGE

CALIBRATION

VIEW HISTORY

SYSTEM OPTI

ONS

2

9%

0.

GAS CO

PRESS

TO CHA

ENTER

MENU TO RETURN

NCENTRATION

UP OR DOWN

NGE VALUE

TO SAVE

• By using the UP or DOWN arrow keys, enter the appropriate digit where the cursor is blinking

• Press the ENTER key to advance the underline cursor right or press the MENU key to

• Repeat until the complete span value has been entered.

the example above, a span value of 20.9% has been entered. In

After the spa ENTER key to accept SPAN

n value has been entered, the transmitter will prompt to press

CALIBRATION or MENU to ABORT.

Caution: Allow the transmi to stabilized be re accepting calib

tter reading fo ration.

After successful calibration, the transmitter will display “Passed Calib turn to the

Sample mode.

OTE: The transmitter is allowed to accept calibration when O2 reading is within the acceptable window. If the

N

2 reading is outside of this limit, by pressing ENTER to accept calibration will result in “Failed Calibration” and

O

turn to Sample mode without completing Span calibration.

re

t air and nso

>>>

>>>

CALIBRATION

SPAN CALIBRATE

ZERO CALIBRATE

DEFAULT SPAN

DEFAULT ZERO

OUTPUT CALIBRATE

OUTPUT SIMULATE

SPAN CALIBRATION

WAIT FOR STEADY

ENTER TO CALIBR

MENU TO ABORT

20.1%

RDG

ATE

value. advance the underline cursor left to reach to the desired digit of the gas

a message ration” and re

18

Page 19

Advanced Instruments Inc.

After pressing ENTER either of the following tw

SAMPLE mode.

PASSED

CALIBRATION

Default Span Calibration

Default Span Calibration will set the oxygen reading based on t

rase any previous span calibrae

troduced, the transmitter will display oxygen reading ithin -30 +50% of the span gas value, indicating that

in w

the sensor signal ou specified limits. T is feature allows the user to check the sensor’s signal

output to ensure s rking condition without removing it from the s nsor housing. To perform

default span calibr tio

tput is within the

nsor is in good wo

e

aen.

• Acce U by pressing the MENU key.

• Adva hade cursor using the ARROW LIBRATION.

ss the MAIN MEN

nce the reverse s keys to highlight CA

• Press the ENTER key to select the highlighted menu o

The following display appears:

MAIN MENU

SELECT RANGE

CALIBRATION

VIEW HISTORY

SYSTEM OPTIONS

• Advance the reverse shade cursor using the ARROW key

• Press the ENTER key to select the highlighted menu option.

The following displays appear and after 3 seconds the system returns to the SAMPLING mode:

nalog Output Check- Output Simulate A

This feature allows the user to simulate the electronics and the signal output. A known current is added to the

ansmitter electronics internally to generate equivalent 4-20 mA signal output. This feature allows the user to

tr

heck all interconnections from the transmitter to the signal output recording device before installation of

c

ensor thus preventing the user to open the sensor bag before the transmitter installation is complete and

s

atisfactory. To simulate signal output

s

• Access the MAIN MENU by pressing the MENU key.

tion data. For example, with factory default settings, when a span gas is

FACTORY

DEFAULTS

SET

o messages will be displayed and the transmitter will return to

OR

FA

ILED

CALIBRATION

he actual signal output of oxygen sensor and

h

ption.

>>>

C

ALIBRATION

S

PAN CALIBRATE

ZER

O CALIBRATE

DEFAULT SPAN

DEFAULT ZERO

OUTPUT CALIBRATE

OUTPUT SIMULATE

s to highlight DEFAULT SPAN.

0.10

AUTO SAMPLING

76 F 98 KPA

1 %

1 % RANGE

19

Page 20

Advanced Instruments Inc.

• Advance the reverse shade cursor using the ARROW keys to highlight CALIBRATION and

then select OUTPUT SIMULATE.

• Press the ENTER key to select the highlighted menu option.

The following displays appear:

MAIN MENU

ELECT RANGE S

CALIBRATION

VIEW HISTORY

SYSTEM OPTIONS

>>>

OUTPUT SIMULATION

0% SPAN

0.00 V

PRESS UP OR DOWN TO ADJUST

OUTPUT ENTER/MENU TO RETURN

Pressing UP or DO se or decrease the output by 5% le signal each time. Check

the output on an e vice or a voltmeter/ammeter. h e external recording would

be the % of the fu sc ted, for example, ill repre e e will represent 8 mA

V and 50% span valu mA V of the 4-20 mA full scale. After SIMULATION is complete, press

ENTER/MENU key to PLE mode.

WN key will increa

ternal recording de

ll

e will represen

return to SAM

t 12

T

0% w nt 4 mA, 25% valu

sale signal selec

Note: To perform "Calibrate-Output Simulation", an external recording nected between the

egative terminal of the power source and negative terminal of the transmitter.

n

RATION

CALIB

SPAN CALIB ATE

ZERO CALIBRATE

DEFAULT SPAN

DEFAULT ZERO

OUTPUT CALIBRATE

OUTPUT SIMULATEI

R

of the full sca

e output on thx

device must be con

An

alog Output Adjustment-Output Calibrate

In rare instances the 4-20 mA signal output may not agree with the reading displayed on the LCD

nables the user to adjust the 4-20 mA signal output. e

• Access the MAIN MENU by pressing the MENU ke

• Advance the reverse shade cursor us the ARRO IBRATION.

• Press the ENTER and then advance the cursor to OUTPU ss ENTER. The

following d ear:

ispla ppys a

y.

W keys to highlight CALing

T SPAN and pre

MAIN MENU

SELECT RANGE

CALIBRATION

VIEW HISTORY

SYSTEM OPTIONS

>>>

CALIBRATION

SPAN CALIBRATE

ZERO CALIBRATE

DEFAULT SPAN

DEFAULT ZERO

OUTPUT CALIBRATE

OUTPUT SIMULATEPA

• Press the ENTER key to select the highlighted menu option and the following display appears:

20

. This feature

Page 21

Advanced Instruments Inc.

OUTPUT SPAN

20MA ADJUST

PRESS UP OR DOW

TO ADJUST OUTPUT

ENTER/MENU TO SAVE

N

• By p DOWN arrow, the signal output wil essing the Up or

ressing UP or l change. Keep pr

DOW utput is matches either 20Ma or perform "Output

N key until the o 4mA. Note: To

Calibrate", an external recording device must be conn utput port of the

transmitter.

• Press ENTER to SAVE the changes.

ampling a Gas

S

GPR-2500 GB may be used to monitor oxygen in a confined atmosphere such as a glove

box or in a sam a positive pressure. As stated above, to monitor oxygen in a glove box, mount the

Oxygen Transmitter

ple gas at

sensor in the upper section of the sensor housing assembly and allow the front end of the sensor exposed to

glove box atmos ure that the pressure inside of the glove box is relatively stable (minor changes in

the pressure in t to change in proportion to the changes in the pressure.

phere. Ens

side of glove box may cause the outpu

Procedure

ollowing calibration, the transmitter is ready for sampling a gas. To begin sample gas analysis

F

• Select the desired sampling mode - auto or manual – as described above.

• Use a suitable tubing to transport the sample gas to the transmitter (unless it is installed inside

of a glove box

• For sample gases under positive pre

pressure between 5-30 psig.

• For sample gases under atmospheric or slightly negative pressure, an optional external pump

is necessary to push the sample through the sensor housing at

rate.

• Assure the sample is adequately vented for optimum acc

safety.

iew History

V

This featu ge O2 concentration, maximum ambient

tem ation,

the use e.

lectronics System Options

E

This features allows

T

o enter password, from SYSTEM OPTIONS menu, select SECURITY, then enter four digit PASS CODE,

nume

a

fter which access to MENU options will be locked (access allowed only after entering the PASS CODE).

re allows the user to view the maximum, minimum and avera

perature, the number of days the sensor has been in service (at the time of installation and first calibr

r must enter YES to confirm "new sensor") and the number of days since the last calibration was don

the user to

et security; passwor

• S d protected operation

• Define ranges; choose a range betwe o ranges, f ll scale instead of 5%

cale.

full s

• Disp .00; negative signal, yes or no.

lay signal below 0

ral numbers only and press ENTER. Then select AUTO LOCK option and enter the number of minutes

OUTPUT ZERO

4MA ADJUST

PRESS UP OR DOWN

TO ADJUST OUTPUT

ENTER/MENU TO SAVE

ected to the signal o

ssure, the user must provide means of controlling the inlet

recommended sample flow

uracy, response and recovery – and

en tw or example, 2% fu

21

Page 22

Advanced Instruments Inc.

In the event PASS CODE is lost, enter the fact CODE 2855 to access the MENU and then reenter the new

Choosing the option to display negative numbe will allow the user to see the di .00 but the output

will be locked a

PASS CODE.

t 4 mA.

ory default PASS

r splay below 0

Standby

The tran

he

T sensor should remain connected during storage periods.

Store the trans

If storin

smitter has no special storage requirements.

mitter with the power OFF at a safe location and away from a direct heating source.

g for an extended period of time protect the transmitter from dust, heat and moisture.

6

. Maintenance

Generally, cleaning the ele

requirements of this transmitter.

Sensor Replacement

Periodically, the oxygen sensor will require replacement. The operating life is determined by a number of

factors that are influenced by the user and therefore difficult to predict.

The normal op

Specifications.

Serviceability: Except for replacing the oxygen sensor, there are no parts inside the transmit

to servi

c . ne O ly trained personnel with the authorization of their supervisor should conduct maintenance.

Caution:

harmful if touc

conta

ct with any liquid or crystal type powder in or around the sensor or sensor housing, as either could be a

form of elect

erating conditions and expected life of the standard sensor are defined in section 4

DO NOT open the oxygen sensor. The sensor contains a corrosive liquid electrolyte that could be

hed or ingested, refer to the Material Safety Data Sheet contained in the Owner’s Manual. Avoid

rolyte. Leaking sensors should be disposed of in accordance with local regulations.

ctrical contacts or replacing filter elements is the extent of the maintenance

ter for the operator

7.

Spare Parts

Recommended spare parts for the GPR-2500 GB Series Oxygen Transmitter:

Item No. Description

GPR-11-32-4 Oxygen Sensor, for measuring O2 in inert gases

XLT-11-24-4 Oxyg

ther spare parts:

O

Item No. Description

FITN-1018 Connector SS 1/8” MNPT to 1/8” Tube

B-3170 Glove Box Housing Assembly

A-3051 Housing Flow Adaptor

A-1161-IS-1 Rev C4 PCB Assembly Main

A-1182-1 Rev B PCB Assembly Interconnection

VALV-1026 Valve, Toggle 1/8” NPT 1/8” Tube

22

en Sensor, for measuring O2 in gases containing

CO2

Page 23

Advanced Instruments Inc.

8. Troubleshooting

Symptom Possible Cause Recommended Action

Slow recovery

Abnormality in zero gas

High O2 reading

after installing or

placing sensor

re

High O2 reading

Sampling

Response time

low

O

reading doesn’t

2

ag

ree to expected

O

values

2

23

At installation, defective sensor

Air leak in sample system connection(s) Leak test the entire samp

Damaged in

air, electrolyte leak

to

Sensor nearing end of life

Transmitter calibrated before sensor Allow O2 reading to stabilize be

stabilized caused by:

1) Prolonged exposure to ambient air,

worse if sensor was unshorted

2) Air leak in sample system

connection(s)

3) Abnormality in zero gas

Flow rate exceed

Pressu

Improper sensor selection Replace GP

Abnorma

Air leak, nce of sample

line, low flow rate, volume of optional

filters and scrubbers

Press re

u and temperature of the sample

is diff e

Abnorma

service - prolonged exposure

s limits

rized sensor

lity in gas Qualify the gas

dead legs, dista

nt than span gas

lity in gas

Replace sensor if recovery unacceptable or

reading fails to reach 10% of lowest

O

2

range

Vary the flow rate, if the O

inversely with the change in flow rate

indicates an air leak - correct source of leak

Qualify zero gas (using portable transmitter)

Replace sensor

Replace sensor

the span/calibration adjustment

Continue purge with zero gas

Leak test the entire sample system (above)

Qualify zero gas (using portable transmitter)

Correct pressure and flow rate

Remove restriction on vent line or open

SHUT OFF valve completely

R/PSR sensor with XLT sensor

when CO

Leak test (above), reduce dead volume or

increase flow rate s

Calibrate the

preser

Qualify the gas (use a portable transmitter)

or acid gases are present

2

(use a portable transmitter)

transmitter (calibrate at

sure and temperature of sample)

le syste

2

m:

reading changes

fore making

Page 24

Advanced Instruments Inc.

Sy ptom Possible Cause Recommended Action m

Erratic O2 reading Test sensor independent from transmitter

or

reading

No O

2

Erratic O

reading

2

or

Negative O

read

2

or

reading

No O

2

possibly

accompanied by

electrolyte leakage

hange in sample pressure

C

irty electrical contacts in upper section

D

f sensor housing

o

Corroded solder joints on

om corrosive sample or efr

sensor PCB

lectrolyte

leakage from sensor

orroded spring loaded coC

section of sensor housing f

ample or electrolyte leakas

ntact in upper

rom liquid in

ge from sensor

Liquid covering sensing area

Improper sensor selection

resence of interference gaP

ses

resence of sulfur gases P

nauthorized mainteU

nance

Sensor nearing end of life

Pressurizing the sensor by flowing g

e sensor with the vent restrith

ing

SHUT OFF valve which places a vacuum

on the sensor in excess 4” of water

column, something which is strongly

iscouraged. The frond

t sensing

membrane is .000625 thick, heat sealed

to the sensor body and subject to tearing

hen vacuum is suddenly w

applied.

premature adjustmA

FFSET potentiometer is a common

O

ent of the ZERO

problem

as to

cted or

Remove sensor from housing. Using a voltmeter set to uA output; apply the (+) lead to

the outer ring of the sensor PCB and the (-)

lead to the center circle to obtain the

sensor’s output in air. Co

ntact factory with

result.

Sensors without PCB use mV setting.

te the transmitter (calibrate at

alibraC

pressure and temperature of sample)

Clean contacts with alcohol (minimize

exposure time of MS sensor to ambient air

extent possible) to

eplace sensor and return sensor to the R

ctory for warranty determination

fa

Upper section of s

ontacts with alcoc

gas for

2-3 hours to flush sample system

ensor housing: Clean

hol, flow sample or zero

and sensor housing

Sensor: Replace if leaking and return it to

e factory for warranty determinth

ation

ipe with alcohol and lint free towel or flW

ample or zero gas for 2-3 hours to flush

s

ow

eplace GPR/PSR sensor with XLT sensor R

when CO

or acid gases are present

2

Cons

ult factory

eplace sensor and install scruR

bber

Replace sensor, obtain authorized servic

e

Replace sensor

Zero the transmitter. If not successful

replace the sensor

Avoid drawing a vacuum on the sensor

From MAIN MENU select DEFAULT ZERO

24

Page 25

Advanced Instruments Inc.

9. Warrant

The design fa ansmitter is performed under a certified

Quality Assuran te

omponents for superior performance and minimal cost of ownersh

c

oroughly tested by the manufacturer and documented in the form

th

cluded in the Owner’ Manual accompanying every analyzer. Wh ated and maintained in accordance

in s

ith the recommendat ns in the Owner’s Manual, the units will pro

w io vide many years of reliable service.

and manu cture of the GPR-2500 GB PPM Oxygen Tr

ce Sys m that conforms to ISO 9001:2008 and inc

y

orporates state of the art materials and

ip. Prior to shipment every analyzer is

of a Quality Control Certification that is

en oper

C

overage

Under normal operatin conditions, the monitor, analyzers and sen r are warranted to be free of defects in

materials and workma ce w

specifications, said pe date of shipment by the m

and serial number of this analyzer are located on the rear of the an ustries Inc. reserves

the right in its sole dis n to invalidate this warranty if the serial number does not appear on the analyzer.

If your transmitter or a ective

workmanship, we will n, replace it at no charge to you. If we choose to repair your

purchase, we may use new or reconditioned replacement parts. If we choose to replace your Analytical

Industries Inc. analyze tio

This warranty applies rcha

give and it sets forth a

the first customer who submits a claim for a given serial number an ty period. Under no

circumstances will the warranty extend to more than one customer

g so

nship for the period specified in accordan

riod begins with the

cretio

ny component is determined to be def

repair it or, at our optio

r, we may replace it with a new or recondi

to all monitors, analyzers and sensors pu

ll our responsibilities. There are no other exp

ith the most recent published

anufacturer. The manufacturer information

alyzer. Analytical Ind

with respect to material and/or

ned one of the same or upgraded design.

sed worldwide. It is the only one we will

ress warranties. This warranty is limited to

d/or the above warran

or beyond the warranty period.

Limitations

Analytical Industries In . will not pay for: loss of time; inconvenienc

Inc. analyzer or prope caused by your Analytical Industries Inc. analyzer or its failure to work; any

special, incidental or c ny damage resul

of proper maintenance; unauthorized repair or modification of the a t

provided with the analyzer or other failure to follow the Owner’s Manual. Some states and provinces do not

allow limitations on ho exclusion nsequential damages, so

the above exclusions may not apply to you.

c e; loss of use of your Analytical Industries

rty damage

onsequential damages; or a ting from alterations, misuse or abuse; lack

nalyzer; affixing of any attachment no

w an implied warranty lasts or the of incidental or co

Exclusions

This warranty does not cover installation; defects resulting from accidents; damage while in transit to our

service location; dama , misuse or abus aintenance; unauthorized

repair or modification of the analyzer; affixing of any label or attachment not provided with the analyzer; fire,

ood, or acts of God; or other failure to follow the Owner’s Manual.

fl

ge resulting from alterations e; lack of proper m

Service

Call 909-392-6900 (o e-mail sales-medical@aii1.com) between 8

arrange to su

postage prepaid t

nalytical IndustriesA

a Advanced Instrum

db e

2855 Metropolitan Pla

Pomona, Ca 91767 U

Be sure to pack the an urely. Include your name, address, telephone number, and a description of the

operating problem. After repairing or, at our option, replacing your Analytical Industries Inc. analyzer, we will

ship it to you at no cost for parts and labor.

25

pply you

r :0 hru

:00 pm on Friday. Trained technicians

with the required parts. You may obta

o:

c.

In

nts Inc.

ce

SA

lyzer seca

will as

in warranty service by returning you analyzer,

0am and 5:30pm Pacific Time Monday t

ist you in diagnosing the problem and Thursday or before 12

s

Page 26

Advanced Instruments Inc.

10. MSDS – Material Safety Data Sheet

Product Identification

Product Name Oxygen Sensor Series - PSR, GPR, AII, XLT

Synonyms Electrochemical Sensor, Galvanic Fuel Cell

Manufacturer Analytical Industries Inc., 2855 Metropolitan Place, Pomona, CA 91767 U

Emergency Phone Number 909-392-6900

Preparatio

Specific Generic Ingredients

Carcinogens at levels > 0.1% None

Chemical (Synonym) and Family Potassium Hydroxide (KOH) – Base or Acetic Acid (CH

General Requirements

Physical Prope

Fire and Explosion Data

Special Fire Fighting Proce

Unusual Fire and Explosion Ha

Reactivity Data

n / Revision Date January 1, 1995

Notes Oxygen sensors are sealed, contain protective coverings and in normal conditions do not p

Others at levels > 1.0% Potassium Hydroxide or Acetic Acid, Lead

CAS Number Potassium Hydroxide = KOH 1310-58-3 or Acetic Acid = 64-19-7, Lead = Pb 743

Use Potassium Hydroxide or Acetic Acid - electrolyte, Lead - anode

Handling Rubber or latex gloves, safety glasses

Storage Indefinitely

health hazard. Information applies to electrolyte unless otherwis

rties

Boiling Point Range

Melting Point Range

Freezing Point

Molecular Weight KOH = 56 or Acetic Acid – NA, Lead = 207

Specific Gravity

Vapor Pressure

Vapo

r Density KOH – NA or Acetic Acid = 2.07

pH KOH > 14 or Acetic Acid = 2-3

Solubility in H

% Volatiles by Volume None

Evaporation Rate Similar to water

earance and Odor KOH = Colorless, odorless aqueous solution or Acetic Acid = Colorless, vinegar-like odor aqueous

App

Flash and Fire P

Flammable Limits

Extinguishing Method

O Complete

2

oints Not applicable

dures Not applicable

zards Not applicable

KOH = 100 to 115° C or Acetic Acid = 100 to 117° C

KOH -10 to 0° C or Acetic Acid – NA, Lead 327° C

KOH = -40 to -10° C or Acetic Acid = -40 to -10° C

KOH = 1.09 @ 20° C, Acetic Acid = 1.05 @ 20° C

KOH = NA or Acetic Acid = 11.4 @ 20° C

solution

Not flammable

Not applicable

Stability Stable

H) – Acid, Lead (Pb

3CO2

SA

resent a

e noted.

9-92-1

) – Metal

26

Page 27

Advanced Instruments Inc.

Conditions Contributing to Instability None

Incompatibility KOH = Avoid contact with strong acids or Acetic Acid = Avoid contact with strong bases

Hazardous Decomposition P

Conditions to Avoid

Spill or Leak

Steps if material is released Sensor is packaged in a sealed pl the

Waste Disposal Method ocal regulations ap

H

ealth Hazard Information

Primary Route(s) of Entry

Exposure Limits meter or Acetic Acid - ACGI

Ingestion rolyte could be harmful or fatal if swallowed. KOH = Oral LD50 (RAT) = 2433 mg/kg or Ac

Skin

Inhalation

Symptoms burning sensation. Skin contact - soapy

Medical Conditions Aggravated

Carcinogenic Referen

Other chemical known to the State of California to cause birth

Special Protection Information

Ventilatio None

Eye Safety glasses

Hand Rubber or latex gloves

Respirator Ty Not applicable

Other Prote ent None

n Requirements

pe

ctive Equipm

roducts KOH = None or Acetic Acid = Emits toxic fumes when heated

KOH = None or Acetic Acid = Heat

sensor lea t without

In accordance with federal, state and l plicable to the disposal of household

Potassium Hydroxide - ACGIH TLV 2 mg/cubic H TLV / OSHA PEL 10

Elect etic

ce Data KOH and Acetic Acid = NTP Annual Report on Carcinogens - not listed; LARC Monographs - not

ks inside the plastic bag or inside an analyzer sensor housing do not remove i

rubber or latex gloves and safety glasses and a source of water. Flush or wipe all surfaces

repeatedly with water el (fresh each time).

ppm er

Electrolyte is corrosive and eye contact could result in permanent loss of vision. Eye

Electrolyte is corrosive and skin contact could result in a chemical burn.

Eye contact - slick feeling.

Lead is listed as a defects or other

astic bag, check the sensor inside for electrolyte leakage. If

or wet paper tow

batteries.

Ingestion, eye and skin contact

(TWA), Lead - OSHA PEL .05 mg/cubic met

Acid = Oral LD50 (RAT) = 6620 mg/kg

Liquid inhalation is unlikely.

None

listed; OSHA - not listed

reproductive harm.

Special P

Precaut Do not remove the sensor’s protective n and

recautions

ions Teflo

PCB coverings.

Do not probe the sensor with sha

rp objects.

Wash hands thoroughly after handling.

Avoid contact with eyes, skin and clo

E

mpty sensor body may contain hazardous residue.

NTransportation

ot applicable

thing.

27

Loading...

Loading...