Page 1

Technical Specifications *

Accuracy: < 2% of FS range under constant conditions

Analysis:

Application:

Approvals: CE

Area Classification: General purpose

Alarms:

Calibration:

Compensation: Barometric pressure and temperature

Connections: 1/4" compression tube fittings

Controls:

Data Acquisition:

Display:

Enclosure: Painted aluminum 7.5” x 10.8” x 12.25” panel mount

Flow: Not flow sensitive; recommended flow rate 2 SCFH

Linearity: > .995 over all ranges

Pressure:

Power:

Range ID:

Recovery Time: 60 sec in air to < 10 PPM in < 1 hour on N2 purge

Response Time: 90% of final FS reading < 10 seconds

Sample System:

Sensitivity: < 0.5% of FS range

Sensor Model:

Sensor Life: 24 months in < 1000 PPM O2 at 25ºC and 1 atm

Signal Output: 4-20mA isolated, 0-1V, and 0-5V

Temp. Range:

0-10, 0-100, 0-1000 PPM, 0-1%, 0-25% (CAL) FS

Auto-ranging or manual lock on a single range

Oxygen analysis in inert, helium, hydrogen, mixed and

acid (CO2) gas streams

Two adjustable form C relay contacts non-latching;

“weak sensor” indicator; power failure; system failure

Max interval—3 months. Use certified span gas with O2

content (balance N2) approximating 80% of full scale for

fast 20-30 minute recovery to online use. Alternatively,

air calibrate with clean source of compressed or ambient

(20.9% O2) air on 0-25% range and allow 60 minutes on

zero gas to recover to 10 ppm. For optimum accuracy,

calibrate one range higher than the range of interest.

Water resistant keypad; menu driven range selection,

calibration, alarm and system functions

Selectable data point intervals

Graphical LCD 5” x 2.75”; resolution .01 PPM; displays

real time ambient temperature and pressure

Inlet - regulate to 5-30 psig to deliver 2 SCFH flow;

vent - atmospheric

Universal 100-240 VAC; option heater system (specify

110 or 220 VAC)

1-5V; Optional (1) 4-20mA non-isolated OR (2) relay

contacts w/ 4-20mA or 1-5V

Stainless steel wetted parts consisting of flow control and

sample/bypass valves, flow indicator

GPR-12-333 for non-acid (CO2) gas streams

XLT-12-333 for gas mixture with > 0.5% CO2

5ºC to 45ºC (GPR sensor), -10°C to 45°C (XLT)

GPR-1600

PPM Oxygen Analyzer

Advanced Full Featured Process PPM O2 Analyzer

Advanced Sensor Technology

Unmatched Performance in PPM O2 Analysis

Unmatched Expected Life & Warranty

Unmatched Recovery to 10 PPM

Sensitivity < 0.5% FS Range

Excellent Compatibility with 0-100% CO2

Bypass Sample System

2 Field Selectable Alarm Setpoints

Auto Ranging or Single Fixed

Options: Temperature Control

Auto-Zero and Auto-Cal

Remote Communication via USB,

RS232, RS485

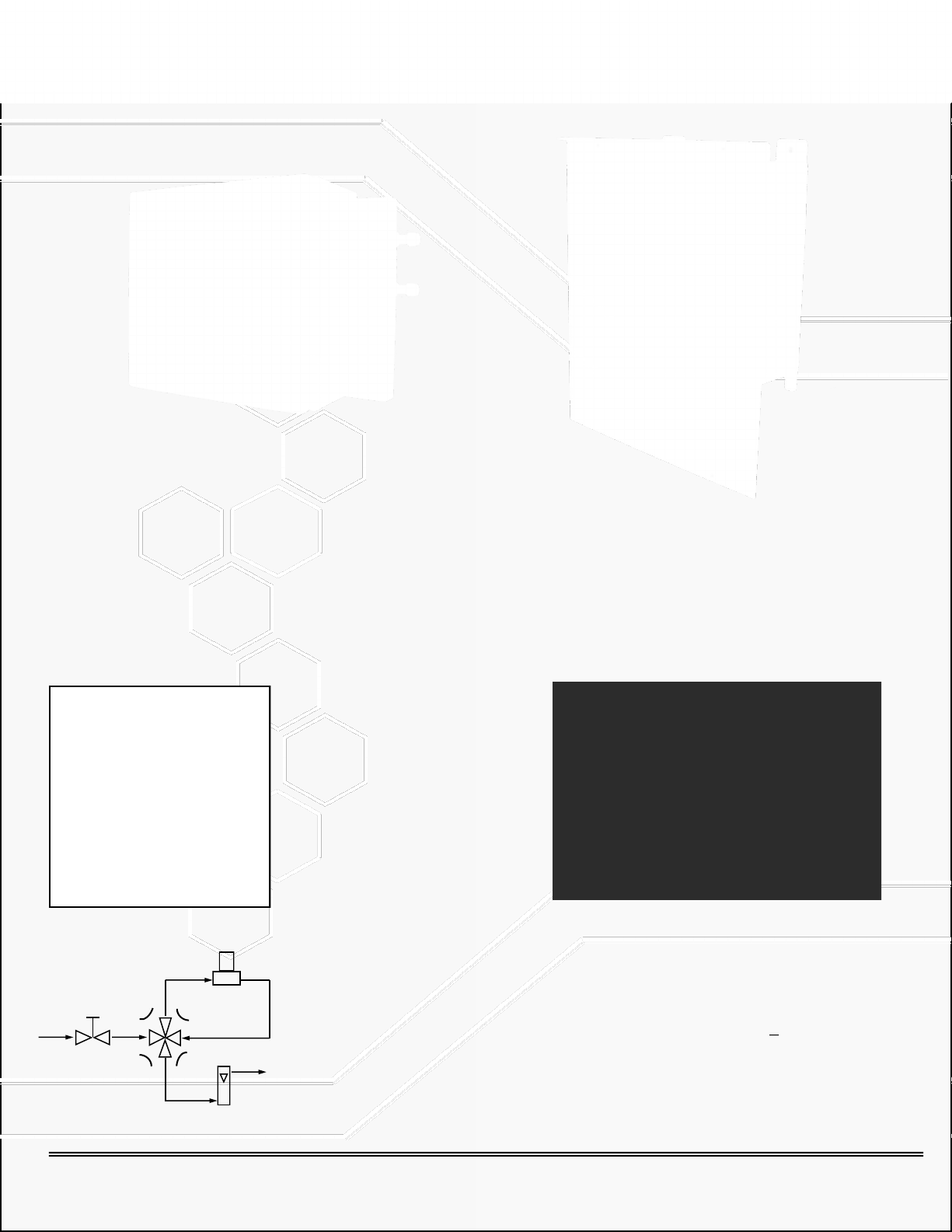

Integral stainless steel bypass sample system

significantly increases user productivity. The

bypass valve isolates the sensor from high

oxygen levels when changing sample lines.

Warranty: 12 months analyzer; 12 months sensor

Optional Equipment

ISO 9001:2008 Certified

19” rack, wall mounting, auto zero/cal, remote communication-contact factory

* Specification subject to change without notice.

2855 Metropolitan Place, Pomona, CA 91767 USA ♦ Tel: 909-392-6900, Fax: 909-392-3665, www.aii1.com, e-mail: info@aii1.com Rev 10/15

INTERTEK Certificate No. 485

Page 2

GPR-1600 W

GPR-1600 W306

The sensor is the heart of any analyzer . . . which means sensor technology is the

critical factor in analyzer performance . . . don’t settle, get the best !

Sensor Housing

Constructed from stainless steel as are

all wetted parts, this unique design

features a compression type o-ring

seal that virtually eliminate air leaks.

An APIMS mass spectrometer verified

that the Bypass Sample System including this housing is capable of

accurately and repeatedly distinguishing hourly changes of 1 ppb oxygen

concentration.

Advancements:

Signal output 2x higher

Innovative design, materials

Bypass Sample System

Integral stainless steel bypass sample

system significantly increases user

productivity. The bypass isolates the

sensor from high oxygen levels when

2855 Metropolitan Place, Pomona, CA 91767 USA ♦ Tel: 909-392-6900, Fax: 909-392-3665, www.aii1.com, e-mail: info@aii1.com Rev 10/15

changing sample lines.

Proprietary mfg process

Insensitive to vibration

Retain compact design

Low cost of ownership

Performance:

Accuracy < + 1% FS

Sensitivity 0.5% FS (50 ppb)

Service life 24 mos < 100 ppm

Recovery air to 10 ppm < 1 hr.

Op temp -20⁰C in 0-100% CO2

No sensor maintenance

Galvanic PPM

Oxygen Sensor

Page 3

Advanced Instruments Inc.

GPR-1600

PPM Oxygen Analyzer

Owner’s Manual

Revised October 2013

2855 Metropolitan Place, Pomona, California 91767 USA ♦ Tel: 909-392-6900, Fax: 909-392-3665, e-mail:

info@aii1.com

Page 4

Table of Contents

Introduction 1

Quality Control Certification 2

Safety & Installation 3

Features & Specificat io n s 4

Operation 5

Maintenance 6

Spare Parts 7

Troubleshooting 8

Warranty 9

Advanced Instruments Inc.

Material Safety Data Sheets 10

2

Page 5

Advanced Instruments Inc.

1. Introduction

Your new oxygen analyzer is a precision piece of equipment designed to give you years of use in a variety of

industrial oxygen applications.

This analyzer is d esigned to measur e oxygen concentrati on in inert gases, gaseous hydroc arbons, hydrogen, an d a

variety of gas mixt ures. In order t o derive maximum perf ormance f rom your new oxygen an alyzer, ple ase read an d

follow the guidelines provided in this Owner’s Manual.

The serial number o f th i s an alyzer may be fou n d o n t h e inside the analyzer. You sho u l d note the serial n u m ber in the

space provided and r etain this Owner’s Manual as a permanent record of your purchase, for future reference and for

warranty considerations.

Serial Number: _______________________

Every effort has been made to select the most reliable state of the art materials and components designed for

superior perfor mance and minim al cost of ownersh ip. This analyz er was tested tho roughly by the manufacturer for

best performan ce. However, modern el ectronic devices do require ser vice from time to ti me. The warran ty include d

herein plus a s taf f o f t r a i n ed professional technicians to quickly ser vi c e your analyzer is your assurance that w e stand

behind every analyzer sold.

Advanced Instruments Inc. appreciates your business and pledge to make effort to maintain the highest possible

quality standards with respect to product design, manufacturing and service.

3

Page 6

Advanced Instruments Inc.

Customer: Order No.:

Model:

GPR-1600 PPM Oxygen Analyzer S/N _____________________

( ) XLT-12-333 PPM Oxygen Sen so r S/N _____________________

TOOL-1001 5/16” Combination Wrench

Configuration:

Ranges: 0-10 PPM, 0-100 PPM, 0-1000 PPM, 0-1%, 0-25%

( ) A-1174-10 PCB Power Supply / Interconnect, 5x Relay Contacts Range ID

( ) Sample, span, zero inlet solenoid valves

( X ) Temperature controlled heater system 85°F specify: ( ) 110VAC (X ) 220VAC

Power: 100/120/220/250 VAC (universal without temperature controlled heater systems)

( ) GPR-1600-W306 option general purpose panel mount 18.2x16x10”

Test

System start-up diagnostics satisfactory

Auto/manual range

Alarm relays activate/deactivate with changes in O2 concentration

Alarm bypass

Analog outputs: Signal output 4-20mA

Range ID: ( X ) 1-5 VDC or ( ) 5x relay contacts plus 1x common

Recovery from air to < 10 PPM in < 60 minutes

Baseline drift on zero gas < ± 2% FS over 24 hour period

Noise level < ± 1.0% FS

Span calibration gas value

Span adjustment within 10-50% FS

Peak to peak over/under shoot < 0.5% FS

Overall inspection for physic a l def ec t s

Options

Notes

2. Quality Control Certification

Date:

Pass

Sensor: ( ) GPR-12-333 PPM Oxygen Sensor

Accessories: Owner’s Manual

CABL-1008 Power Cord

( ) Stainless steel sensor housing, manual flow control and bypass valves, ¼” compression

Enclosure: ( X ) Std. panel mount (“T”) 7.5x10.8x12”; ( ) “TO” option 7.75x 7.75x12”

A-1146-10 PCB Assembly Main / Display Software V. ______

( X ) A-1146-10 PCB Power Supply / Interconnect, 1-5V Range ID

type fittings for sample inlet and vent

( ) Delete sample/bypass valve from above (T and TO options)

( ) Bezel for 19” rack mount 19x12x12” option

( ) GPR-1600-W option general purpose wall mount 12x12x8”

4

Page 7

Advanced Instruments Inc.

Standard:

Manufacturing Procedure No. P-1057 Rev-1,

Published 1/1/1996 and related publications

Mfg. Item No.:

GPR-1600 Series

Description:

ppm Oxygen Analyzer

Serial No.:

___________________________

Customer:

___________________________

Purchase Order:

___________________________

Quantity:

1 of

Warranty Date:

12 months from ______________

Date:

______________

Place:

Pomona, CA

By print name:

Signature:

Title:

The certificate applies to the an al yzer specificall y o r d er ed to use componen t s f o r o xy gen s ervice. Check the QC of the

analyzer to ensure whether such an option was ordered.

Certificate of Cleaning

Oxygen Service

Compressed Gas Association,

Publication: G-4.1 Edition 4,

Title: Cleaning Equipment for Oxygen Service,

The undersigned war rants on behalf of Manufacturer that the product identified

above conforms t o the man ufactu ring, t esting and p ackagi ng crit eria set fo rth by

the ‘Standard’ specified above.

5

Page 8

Advanced Instruments Inc.

Directives:

2006/95/EC Low Voltage

2004/108/EC Electromagnetic Compatibility

Standards:

EN 61010-1 Safety

EN 61326-1 Minimum Immunity Test

ISO 9001:2008

Compliance:

All applicable standards

Products:

General purpose online oxygen analyzers:

GPR-1600UHP series

GPR-1600MS series GPR-16MS series

GPR-1600 series GPR-16 series

GPR-1900 series GPR-19 series

GPR-2600 series GPR-26 series

GPR-2900 series GPR-29 series

GPR-3100 series GPR-31 series

GPR-1500 series GPR-15 series

GPR-2500 series GPR-25 series

GPR-1500AIS GPR-15A series

GPR-1800AIS GPR-18MS/18/28

GPR-2500AIS GPR-980 series

GPR-2800AIS GPR-35

General purpose portable oxygen analyzers:

GPR-1200MS series GPR-12MS series

GPR-1200 series GPR-12 series

GPR-1100 series GPR-11 series

GPR-1000

GPR-2000 series GPR-20 series

GPR-3000 series GPR-30 series

GPR-3500MO GPR-35MO

Intended Use:

Analyze oxygen concentration in a gas mixture in a non-explosive atmosphere.

Manufacturer:

Analytical Industries, Inc. dba Advanced Instruments, Inc.,.

2855 Metropolitan Place

Pomona, California 91767 USA

Tel: 909-392-6900, Fax: 909-392-3665

e-mail: info@aii1.com

Date:

September 15, 2013

Place:

Pomona, California 91767 USA

We hereby declare the above product meets the provisions of the directives and

Patrick Prindible

Vice President & QA Manager

Declaration of Conformity

standards specified. All supporting documents are retained on the premises of the

manufacturer and the notified body above.

6

Page 9

Advanced Instruments Inc.

3. Safety Guidelines

Safety

This section summ arizes t he basic precaut ions a pplica ble to all analy zers. Addition al prec aut ions spec ific to individu al

analyzer are contained in the following sections of this manual. To operate the analyzer safely and obtain maximum

performance follow the basic guidelines outlined in this Owner’s Manua l .

Caution: This symbol is used throughout the Owner’s Manual to CAUTION and alert the user to

recommended safety and/or operating guidelines.

Danger: This symbol is used throughout the Owner’s Manual to identify sources of immediate

DANGER

Read Instructions: Before operating the analyzer read the instructions.

Retain Instructions: The safety precautions and operating instructions found in the Owner’s Manual should be

retained for future reference.

Heed Warnings Follow Instructions: Follow all warnings on the analyzer, accessories (if any) and in this Owner’s

Manual. Observ e all precaut ion s and o peratin g ins truc tion s. Failur e to do so m ay r esult i n perso nal i njury or d amage

to the analyzer.

Heat: Situate and store the analyzer away from sources of heat.

Liquid and Object Entry: The analyz er should n ot be imm ersed in any liqu id. Care sh ould be taken so that liqui ds

are not spilled into and objects do not fall into the inside of the analyzer.

Handling: Do not use f or ce wh en usi ng th e sw itc he s an d kn obs. Bef or e movi n g your an alyz er be su re to di sc onn ect

the wiring/power cord and any cables connected to the output terminals located on the analyzer.

such as the presence of hazardous voltages.

Maintenance

Serviceability: Except for repl acing the oxygen senso r, there are no part s inside the analyz er for the operator to

service.

Only trained personnel with the authorization of their supervisor should conduct mai nt e na nce.

Oxygen Sensor: DO NOT open the sensor. The sensor c ontains a c orrosiv e liquid electrol yte that could be harmful

if touched or ingeste d, refer to the Material Saf ety Data Sheet c ontained in th is Owner’s Man ual. Avoid co ntact with

any liquid or cr ystal typ e pow der in o r arou nd the sensor o r senso r hou sing, a s eith er cou ld be a fo rm of electrolyte.

Leaking sensors should be disposed of in accordance with local regulations.

Troubleshooting: Consult th e gui delin es in sectio n 8 fo r a dvice on the c ommo n oper atin g error s befo re c onc luding

that your analyzer is faulty. Do not attempt to service the analyzer b eyond those means described in this Owner ’s

Manual.

Do not attempt to make r epair s by yourse lf as th is will vo id th e warran ty, as det ailed by s ect ion 9, an d may result in

electrical shock, injury or damage. All other servicing should be referred to qualified service personnel.

Cleaning: T he analyzer sho uld be cleane d only as reco mmended b y the manufact urer. Wi pe off dust and di rt from

the outside of the unit with a soft damp cloth then dry immediately. Do not use solvents or chemicals.

Nonuse Periods: Disconnect the power when the analyzer is left unused for a long period of time.

7

Page 10

Advanced Instruments Inc.

Installation

Gas Sample Stream: En sure the gas stream co mposition of the application is c onsistent with the specificatio ns of

the analyzer/sen sor and review the application co nditions before initiating the installation. Con sult f actory to ensure

the sample is suitable for analysis.

Contaminant Gases: A gas scrubber and flo w indicat or wit h integral metering v alve ar e require d upstrea m of the

of the analyzer to remove interfering gases such as oxides of sulfur and nitrogen or hydrogen sulfide that can

produce false re adings, reduce th e expected life of the sensor and void sensor warran ty if not identifie d at time of

order placement. Consult factory for recommendations concerning the proper selection and installation of

scrubber/filter components.

Expected Sensor Life

With reference to the publish specificat ion located as the last p age of this manual, the exp ected life of all oxygen

sensors is pred icated on the basis of oxygen concentration (< 10,000 PPM), tempera ture (7 7°F/25°C) an d pressure

(1 atmosphere) in “normal” applications. As a rule of thumb senso r life is inversely prop ortional to changes in the

parameters. Deviations of the gas concentration and or temperature outside of the spec i f ications will af f ec t t he life of

the sensor. Avo id exposure to oxygen l evels above 1% (10,000 PPM) for hours at a time.

Failure to do so may result in damage to the sensor(s) as follows:

GPR Series PPM sensors – red uc ed sen sor l ife an d loss o f lo w end sen siti vi ty wh en exposed con tinu ou sly to

20.9% oxygen; sensor will last approximately 6-8 months and may develop a low end offset > 1-2 PPM

XLT Series PPM sensors - reduced sensor life and loss of low end sensitivity (XLT sensor exposed

continuously to the 20.9% O2 content of air will last approximately 7 days).

Accuracy & Calibration

Refer to section 5 Operation. The 0-25% Range is provided only for the purpose of air calibration which is

recommended on ly if span gas is not available. Br inging the analyzer bac k online after calibrat ion with the 20.9%

oxygen content of air, takes longer than calibrating the analyzer with a span gas, for example, 80 PPM oxygen.

Materials

Assemble the necessary zero, sample and span gases and optional components such as valves, coalescing or

particulate fil ters, and pum ps as dictated by th e application; stainless steel tubing is essen tial for maintaining the

integrity of the gas stream for PPM measurements.

Operating Temperature

The sample must be suffici ently coo led before i t enters th e analyzer and any opt ional co mponents. A c oiled 10 fo ot

length of ¼” stainless steel tubing is sufficient for cooling sample gases as high as 1,800ºF to ambient. The

maximum recommended operating temperatu re is 45º C. On an intermittent basis, unless the user is willin g t o accept

a reduction in exp ected sensor lif e – refer to analyz er specification , the analyzer may be o perated at 50 degr ee

temperatures above 25

temperature. As an example, if the analyzer is continuously operated at 35oC, the expected sensor life will be

reduced by ~25%.

Pressure and Flow

All electrochem ical oxygen senso r s respond to partial pressure changes in o xygen. The senso rs ar e equally capable o f

analyzing the oxyg en cont ent of a flo wing sample ga s stream o r monito ring the ox ygen concent ration in am bient air

(such as in a confined space in a control room or an open area such as a landfill or bio-pond).

Sample systems an d flo win g gas s ampl es are g ener ally r equ ir ed fo r appl icat ion s in vol ving o xy gen m easu remen t s in a

gas mixture. Fo r sub PPM measur ements, the use of stainless steel tubing and fittin gs is critica l to maintaining th e

integrity of the gas stream to be sampled. Further, the inlet sample pressure must always be higher than the

pressure at the outlet vent, which is normally at atmospheric pressure.

To analyze a gas stre am, th e gas must flow or be dr awn th rough t he senso r hou sing. The internal sampl e syst em of

the analyzer may include sam ple/bypass valves, shut off valve, a flow control (please che ck the QC sheet to ensure

o

C, the user can expect a reduction in sensor life of ~ 2.5% per degree increase in

o

C. At

8

Page 11

Advanced Instruments Inc.

the included s ample system) , a f low in dicato r and a st ainle ss st eel s ensor h ousin g with an o -ring seal to pr even t the

leakage of air int o the sensor housin g.

Inlet Pressure

Analyzers design ed for flowing samples under positive pressure or for samples at atm ospheric or slightly ne gative

atmospheres, are equi pped with bulkhead tube fitting co nnections at the rear of the analyzer. T he recommended

operating sample pressure is between 5-30 PSIG.

A pressure great er than 30 PS IG may preven t the solen oid valve s from opera ting proper ly (GPR-1600-AV

only). Further, the pres sure of Sample, Sp an and Zero gas must be within 10 PSIG for ease of control of

gas flow rate.

Outlet Pressure

In positive sample pressure applic ations, the sam ple must be vented to ambient air or in a vent with pressure les s

than the sample inlet pressure. If the sample is vented to a line at pressure above ambient, a back pressure

regulated set at no greater 1-2 PSIG must be installed on the downstream of the sensor to ensure a constant

pressure on the sensor.

Flow Rate

Flow rates of 1-5 SCFH caus e no appreci able ch ange in the o xygen rea ding. Howev er, f low rates a bove 5 SCFH may

generate a backpressure on the sensor and cause erroneous oxygen readings.

The analyzer is equ ipped wi th a flo w cont rol valve with a flow indicato r upstream of the sen sor housing. A flow rate

of 2 SCFH or 1 liter per minute is recommended for optimum performance.

Caution

Do not place your finger over the vent ( it pressurizes th e sensor) to test the f low indicator when gas is

flowing to the senso r. R emovi ng your fing er (th e restr ictio n) gen erat es a vac uum o n the senso r and m ay

damage the sensor (voiding the sensor warranty).

Recommendations to avoid erroneous oxygen readings and damaging the sensor:

Do not place your finger over the vent (it pressurizes the sensor) to test the flow indicator when gas is flowing to

the sensor. Removing your finger (the restriction) generates a vacuum on the sensor and may damage the

sensor.

Assure there are no restrictions in the sample or vent lines.

Avoid excessive flow rate, flow rate above 5 SCFH may generate backpressure on the sensor.

Avoid sudden releases of backpressure that can severely damage the sensor.

Avoid the co llection of liqu ids or particul ates on the sensor, they block the di ffusion of oxygen into the senso r -

wipe away any liquid and particulate with a damped cloth only.

Moisture & Particulates

Installation of a suitable coalescing and or particulate filter is required to remove liquid condensates, and/or

particulates fro m the sample gas to prevent clo gging of the sampling system . Moisture and/or particulat es do not

necessarily dam age the sensor itself but collection of moisture/ partic ulat e on the sensin g sur face c an bloc k or inh ibit

the diffusion of sam ple gas into th e sen so r thus re su lt i n g in a redu ction of sensor signal output – an d t h e appearance

of a sensor failu re. Consult factory for recommendations concern ing the proper selection of coalescing/particulate

filters.

Moisture and/or particulates collect ed at the sensor may be removed by either blowing on the sensing su rface or

gently wiping the sensing surface with damp cloth.

Caution: Minim ize the e xposure o f sensor t o air dur ing thi s cleanin g process. Air c alibrat ion follo wed by

purging with zero or a ga s with a lo w PPM oxygen c oncent ration is r ecommen ded follo wing th e cleaning

process.

Mounting

The standard analyzer is ap proved for indoor use only. Outdoor use requi res optional enclosures, c onsult factory.

Mount analyzer as recommended in this manual.

9

Page 12

Advanced Instruments Inc.

The analyzer is configured for panel mounting and requires a 7.5x10.8” (T configuration) cutout with 4 holes for the

analyzer’s front panel. Optional configurations include a panel mount (TO configuration) with 7.75x7.75” cutout; 19”

bezel for rack mounting either the T or TO; 12x12x8” wall mount enclosure (GPR-1600W) and 18.2x16x10” panel

mount configuration (GPR-1600W-306).

Gas Connections

Sample Inlet an d Sample Vent gas lines for PPM analysis r equire 1/8” or ¼ ” stainless steel compr essi o n f ittings; hard

plastic tubing with a low gas permeability factor may be used for measurements of oxygen above 1000 PPM.

Power

Supply power t o the analyzer on ly as rated by the specific ation or markings on th e analyzer enclosure.

The wiring that connects the analyzer to the power source should be installed in accordance with

recognized elec trical standard s. Ensure that the analyzer enclosure is properly grounded and meet s the

requirements of recommended local electrical standards.

Never yank wiring to remove it from a terminal connection.

AC powered analyzers consume a maximum of 30 watts, without the optional heaters. With optional

110 VAC or 220 VAC heaters installed, the maximum power consumption is 230 watts.

10

Page 13

Advanced Instruments Inc.

4. Features & Specifications

11

Page 14

Advanced Instruments Inc.

5. Operation

5.1 Principle of Operation

The GPR-1600 Oxygen Analy zers incorpor ates a variety of PPM range advanc ed galvanic f uel cell type senso rs. The

analyzer is configured for panel mounting and requires a 7.5x10.8” (T configuration) cutout with 4 holes for the

analyzer’s front panel. Optional configurations include a panel mount (TO configuration) 7.75x7.75” with cutout; 19”

bezel for rack mounting either the T or TO; 12x12x8” wall mount enclosure (GPR-1600W); 18.2x16x10” panel mount

configuration (GPR-1600W-306) using the wall mount enclosure. Contact the factory for additional information on

options. All configurations are tested and calibrated by the manufacturer prior to shipment.

The GPR-1600 series analyzers and sensors conform to CE standards and are manufactured under a Quality

Assurance System, certified by an independent agency, in accordance with ISO 9001:2004 standards.

Advance Galvanic Sensor Technology

All galvanic sen sors fu nction on the sam e principl e and ar e specific to oxygen. The y measu re the parti al pre ssure of

oxygen ranging from low PPM to 100 % levels in inert gases, gas eous hydr ocarbons, helium , hydrogen, mixed gases

and acid gas st reams. Oxygen, the fuel for this electrochemical transducer, diffuses into the sensor and

reacts chemically at the sensing electrode to produce an electrical current output proportional to the

oxygen concentration in the gas phase. The sensor’s signal output is linear over all measuring ranges and

remains virtually constant over its useful life. The sensor req u ir es n o m ain t en an ce and is easily an d safely replaced at

the end of its useful life.

Proprietary adv ancements in the design and ch emistry add signif icant advantages t o an extremely v ersatile oxygen

sensing technology. Sensors for low PPM analysis rec over fr om air to PPM levels in minu tes, exhi bit longer life, offer

extended operating range of -20°C to 50°C, have excellent compatibility with CO

sensors) and reliable quality thus giving the user a significant advantage over other competitors. Other

advancements inc lude extendi ng the expec ted life of o ur new generation o f percentage r ange sensor s to five to ten

years with fast er response times and gr eater stability. Another si gnificant development involves the first galvanic

oxygen sensor cap able of measuring o xygen purity co ntinuously and expanded operating temperature r ange from 40°C to 50°C. Consult factory for selection of sensors for your specific applications.

and acid gases (XLT series

2

12

Page 15

Advanced Instruments Inc.

5.2 Electronics

The signal generated by the sensor is processed by state of the art low powered micro-processor based digital

circuitry. T he first st age amplif ies and converts the electrical c urrent into voltage signal. The seco nd stage el imin ates

the low frequenc y noise. The third stag e employs a high frequency f ilter and compensates f or the sensor’s signal

output variations caused by ambient tem perature variat io ns. The result is a very stable sensor signal.

Sensor’s response time of 90 % o f a “step change” is less tha n 10 -30 seconds (actu al experience ma y var y due to the

integrity of sam ple line connecti ons, dead volume and flo w rate selected) o n all ranges under am bient monitoring

conditions. Sensitivity is typically 0.5% of full scale of the lowest range of analysis.

Additional features of the micro-processor based electro nics inc lude manual or au to ranging, auto-zero and auto -cal,

isolated 4-20mA sign al fo r sig nal out put, optional 4-20 mA as range ID, separ at e rel ay co ntac ts rat ed 3 0 VDC m ax @

1A or 110/220 VAC @ 5A are provided for the alarm feature. Optional range ID contacts are rated at 30 VDC @1A.

Whenever the analy zer is span c alibrated, a uniqu e algorithm predicts and displays a message indicatin g a ‘weak

sensor’ (if the sensor output has fallen below a certain level), suggesting the sensor be replaced in the near future.

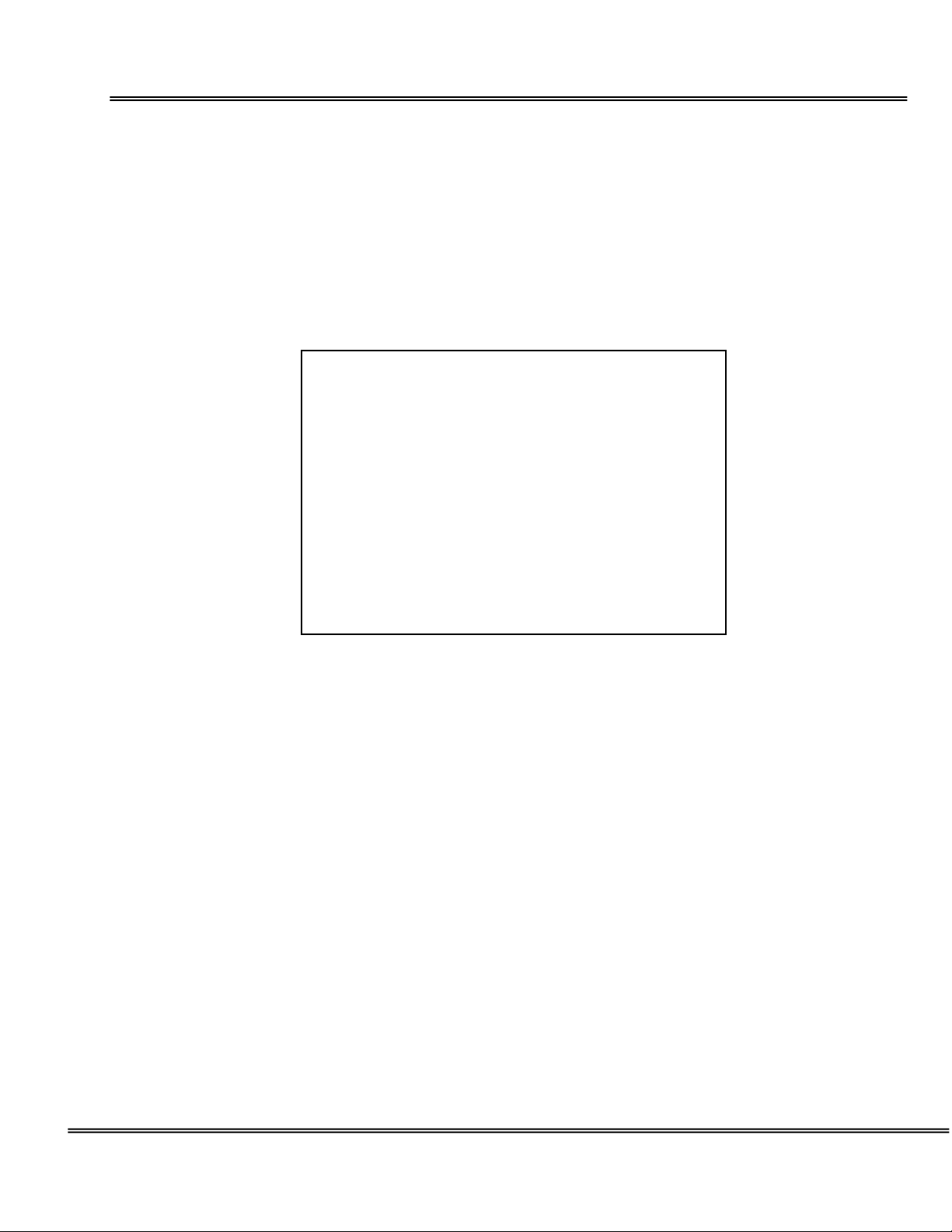

5.3 Sample System

For accurate measu rements, the sam ple gas must be prop erly presented t o the sensor. In stan dard form, the GPR1600 is equipped with a sample system that complements the performance capabilities of the advanced oxygen

sensor.

The integral sam ple syst em of the anal yzer is shown sc hematicall y below ( please ch eck the QC sheet in th is manual

to ensure the analyzer is equipped with the sample system ordered).

Advanced Instrum ents Inc. offers a full l ine of sample ha ndling, c onditioni ng and experti se to meet your application

requirements. Contact us at 909-392-6900 or e-mail us at

info@aii1.com for your specific requirements.

13

Page 16

Advanced Instruments Inc.

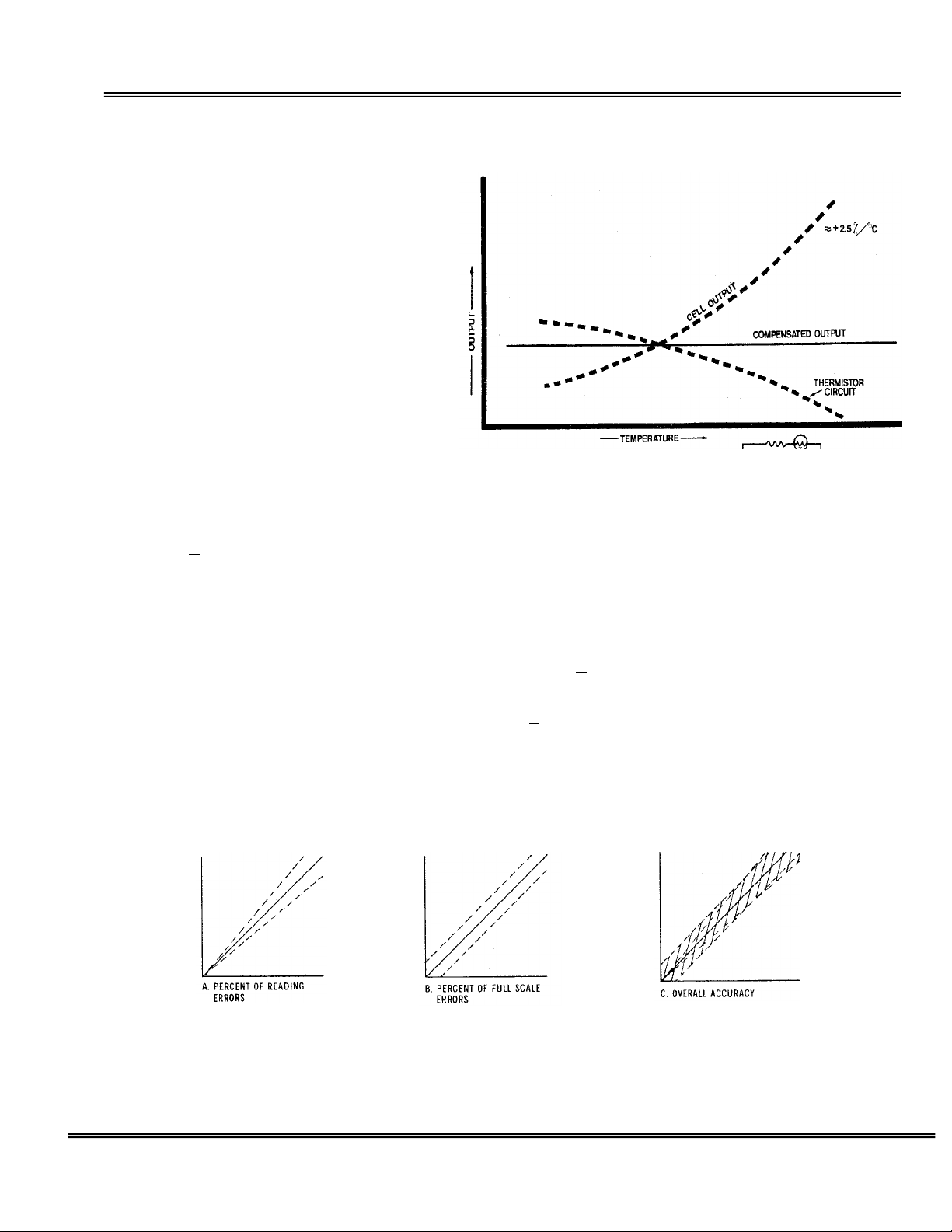

5.4 Accuracy Overview

Single Point Calibration: As previously described

the galvanic oxygen sensor generates an electrical

current proportional to the oxygen concentration in

the sample gas. I n the ab senc e of ox ygen the senso r

exhibits an absolute zero, e.g. the sensor does not

generate a cu rrent output in the absen ce of oxygen.

Given the linearity and absolute zero properties,

single point calibration is possible.

Pressure: Because sensors are sensitive to the

partial pressure of oxygen in the sample gas, their

output is a function of the number of molecules of

oxygen 'per unit volume'. For best accuracy, the

pressure of the sam pl e g as and that of the calibration

gas must be the same (in reality within 2-5 psi) so

that when the SAM PLE/S PAN gas es are switc hed, th e

gas flow rate would not drastically change.

Temperature: The rate at which oxygen molecules diffuse into th e sensor is controlled by a T eflon membrane

otherwise known as an 'oxygen diffusion limiting barrier. The fact that all diffusion processes are temperature

sensitive, the senso r's electrical o utput also varie s with temper ature. This var iation is relat ively constant (2.5% per

ºC chan ge in temperature). A tem perature compensation c ircuit employing a thermistor offsets this effect with an

accuracy of +

that is virtually independent of small ambient temperature variation. To mini mize error in oxygen m easurement , the

calibration of th e analyzer shou ld be carried out as c lose as possible to t he temperature dur ing sampling. A small

temperature variation of ~10º F will produce < 2% error.

Accuracy:

1) 'Percent of reading errors', illustrated by Graph A below, such as +

compensation circuit due to the tolerances of the resistors and thermistor.

2) 'Percent of full scale errors', illustrated by Graph B, such as +

tolerances in th e electro nic compon ents, which are r eally mini mal due to tod ay's technology and the fact that other

errors are 'spanned out' during calibration.

Graph C illustrat es these 'w orse case' s pecificatio ns that are ty pically use d to develo p an analyzer's overall accuracy

statement of < 1% of full scale at constant temperature or < 5% o ver the operati ng tem perature range. QC testing

is typically < 1% prior to shipment.

Example 1: As illustrat ed by Graph A any error dur ing a span adju stment, e.g., at 20.9% (air) of full scale range

would be multipl ied b y a f ac tor of 4.78 (100/20.9) when used for measurem ent s of 95-100 % oxygen concentrations.

Conversely, an error during span adjustment at 100% of full scale range will be reduced proportionately for

measurements of lower oxygen concentrations. Refer to the Calibration section for additional details.

5% or better (over th e operating temper ature range of th e analyzer) and generates an o utput signal

In light of the above parameters, the overall accuracy of an analyzer is affected by two factors:

5% inherited error in the temperature

1-2% linearity errors generally associated with

14

Page 17

Advanced Instruments Inc.

Four mounting holes on four corners to secure

5.5 Mounting the Analyzer

The standard GPR-1600 is designed to be panel mounted and requires a cutout that accommodat es the enclosure

and 4 mounting bolts. The design also lends itself to 19” rack mounting with an optional bezel or wall mount

enclosures as illustrated below.

5.5.1 Procedure

1. The standard GPR-1600 is designe d for panel mounting dir ectly to any flat vertic al surface, wall or bu lkhead

plate with the appropriate c ut out and four ¼” diameter holes for in sertion of the mounting studs through the

front mounting bazel.

2. When mounting the analyzer, position it approximately 5 feet above the floor for better viewin g purposes and

easy access to various functions of the analyzer. Leave suff icient room for ac cess to t he t ermina l con nectio ns at

the rear of the enclosure.

3. Note: The pr oximity of t he analyzer t o the sampl e point and use of optional sample con ditioning com ponents,

such as a sample coo ling coil, a coalesci ng filter and or a parti culate filter may h ave an impact on sam ple lag

time and hence the analyzer response time.

analyzer on a flat vertical surface

15

Page 18

Advanced Instruments Inc.

Rear of analyzer showing the SAMPLE, SPAN, ZERO AND

Flow Control Valve

5.5.2 Gas Connections

The GPR-1600 with its standar d flo w thr ough co nfigur ation is desi gned fo r positi ve sample pressure and requi res ¼”

compression type connections for incoming sample, span and zero gas and outgoing vent lines.

The user is responsible for providing calibration gases and other optional components (if not purchased with the

analyzer).

Caution: The sample, span and zero gas pressu re must be set between 5-30 PSIG and must be within 5 PSIG of

each gas. Failure t o do so w ill cause a su dden spike

in the gas flow when switching from sample to

span/zero gas and back which may cause an

upward/downward spike on the analyzer signal

output.

Flow Control Valve: A flow control valve is

mounted upstream of the sensor and provides

means of controlling the flow rate of the sample,

span and zero gase s. Sample flow rate of 1-5 SCFH

cause no appreciabl e change i n the oxygen reading.

However, for optimum performance, a flow rate of

1-2 SCFH is recommended.

Caution: Do not place your finger over the fitting

designated as t he vent (it pr essu rizes the sen sor) to

test the gas flow. Blocking of the gas vent will

pressurize the sensor and by suddenly removing

finger, a slight vacuum will b e pulled on the senso r

which may damage the sensor.

VENT ports (Span and Zero ports are optional)

16

Page 19

Advanced Instruments Inc.

5.5.3 Procedure

1. Caution: Do not change any of the factory’s setting until instructed.

2. Regulate the sample gas pressure and sample flow as described in the section “Pressure & Flow” above.

3. Install the “Sample Vent” line connection to the fitting labeled SAMPLE VENT.

4. Install th e incoming sample, span and zero gas line to the fitting labeled SAM PLE, SPAN and ZERO (Span and

Zero ports are optional, check the QC certificate for the options included with your analyzer).

5. Set the flow rate to 1-2 SCFH.

6. Keep the Sample/Bypass Valve at Bypass position.

7. Allow gas to flow through the analyzer for 3-5 minutes before proceeding for installation of sensor (the analyzer

is generally shipped with the sensor installed but if the sensor is included in a separate sealed bag, follow

instructions to install the sensor Section 5.7).

5.6 Electrical Connections

Incoming power for the 100-250V AC powered analyzers is supplied through a universal power entry module. A

standard computer type power cord (Part# A-1008) is required for the universal power entry module. A well

grounded insulated power cable is recommended to avoid noise resulting from unwanted interference.

The appropriate AC po wer su pply (1 10V o r 220V) m ust speci fied be sp ecified at order plac ement if t he analy zer is to

be equipped with a temperature controlled heater system.

Power consumption is approximately 30 watts without optional heater and 150-200 watts with the heater system.

Caution: Integral 4-20mA co nverters ar e inter n ally pow ere d and do not require exter na l po wer . DO NOT sup ply any

voltage to any of the terminals of the 4-20 mA signal output or the 4-20 mA range ID. If a power is suppli ed, th e 420 mA chip can be permanently damaged.

17

Page 20

Advanced Instruments Inc.

Power input terminal

Signal and alarm output terminals

Sensor Housing

Optional Range ID

The standard 1-5 VDC output i s provided for range identification, as describe d below. An optional 4-20 mA signal or

5 independent rela y contact represent ing 5 ranges a my be provided as well. Check the QC certificate to verify the

option(s). The appropriate relay contac t will close when a spec ific range is selec ted. The dry c ontacts are rated at

30VDC @ 1A.

The voltage or 4-20 mA Range ID; Range 1= 5V or 20 mA

Range 2 = 4V or 16 mA

Range 3 = 3V or 12 mA

Range 4 = 2V or 8 mA

Range 5 = 1V 0r 4 mA

Interior of the GPR-1600 with optional Wall Mount Enclosure

18

Page 21

Advanced Instruments Inc.

5.6.1 Procedure

1. As illustrated above the al arm relays and sign al output connec tions are hard wired t o push-open type t erminal

blocks located at the rear of the analyzer.

2. Use a small bladed scr ewdriver to push the lev er down and insert the stripped end of the wire into the slot.

NOTE: Strip insulation of the wir es no more than 3/16 inch in length.

3. Insert the stripped end of the cables int o the appro priate term inal slots assur ing no bare wire remains ex posed

that could come in contact with the back panel of the analyzer enclosure.

4. Release the lever to secure the wires in the receptacle.

5. To connect to an active relay or “fail saf e”, conn ect the live c able to the c ommon ter minal C an d the seco ndary

cable to the normally open NO terminal.

6. To break the connection upon rela y acti vati on, connect the secondar y cable to the norma ll y close d NC termi na l .

Danger: While connecting th e cables t o the rela y terminal s, ensure th ere is no vo ltage on the cables t o

prevent electric shock and possible damage to the analyzer.

Caution: Assure the st ri pped w ire end s of the c a ble ar e f ull y in sert ed in to the t erm inal slo ts an d do no t

touch each other or the back panel of the analyzer enclosure.

5.6.2 Oxygen Level Alarms

The analyzer is configured with two user a djustable thre shold type alarm r elays that can be configured in the field

from the ALARM option on the MAIN MENU as follows:

Establish independent alarm set points

Either Hi or Lo oxygen condition

Either On or Off (enabled or disabled)

Both alarms may be temporarily defeated using a user entered ‘timeout’ period (normally in minutes)

The alarm set poi nt repr esents an oxygen valu e. When th e oxygen r eading exceeds (high alarm) or falls below (low

alarm) the alarm set point, the relay is activated and the LCD displays the alarm condition.

When activated, the alarm function triggers the corresponding SPDT Form C non-latching relay rated @ 5A, 30VDC or

240VAC resistive. To prevent chattering of the relays, a 2% hyster esis is add ed to the al arm set point. This means

that the alarm wi ll remain active u ntil the oxygen re ading has fallen 2 % below the alarm set point (high alar m) or

risen 2% above the a larm set point ( low alarm) after the alarm was act ivated. The timeout feature is useful while

replacing the ox ygen senso r or du ring cal ibration when the oxygen readin g might w ell rise above th e alarm set point

and trigger a false alarm.

Note: When making connections the user must decide wheth er t o c o n f i gu r e/ connect Alarm 1 an d A larm 2 in failsafe

mode (Normally Open – NO – where the alarm relay de-en ergizes and c loses in an alar m conditio n) or non-failsafe

mode (Normally Closed – NC – where alarm relay energizes and opens in an alarm condition).

5.6.3 Power/System Failure Alarm

A dry contact rat ed at 30VDC @ 1A is provid ed as a pow er/system failur e alarm tha t activ ates when pow er suppl ied

to the analyzer’s circ uits is interr upted. The c ontact is norm ally closed but opens when the power t o the analy zer is

switched off or interrupted. The power fail alarm cannot be disabled.

19

Page 22

Advanced Instruments Inc.

5.6.4 4-20 mA Signal Output

The analyzer provides a 4-20mA full scale signal with a fully isolated ground for external recording devices. The

integral IC on the main PCB provides 4-20mA fu lly iso lated s i gnals for output and optional range I D. This IC does not

require any extern al power. To check the signal output of the 4-20mA E/I integrated circuit connect an ammeter as

the measuring devi ce and confirm the output is within +

Bypass switch t o OFF position). A finer adjustment of the zero offset of the 4-20mA c onverter can be achieved by

using AII Configuration Software via a PC. Consult factory for instr uctions.

0.1mA of 4mA (without sen sor installed or with the sensor

5.6.5 Range ID

The standard range ID is designated with a voltage output corresponding to a specific range. For example, 5V

corresponds to th e least sensitive range ( 25% on the GPR-1600 an alyzer) and drops 1V for each additional range.

Optional 4-20 mA signal as range I D is also available. With 4-20 mA range ID option, 20mA r epresents the least

sensitive range and it drops by 4mA (16mA, 12mA, 8mA, 4mA) fo r each additi onal ran ge. Plea se chec k the QC sheet

to confirm the range ID option ordered.

Relay contacts as sociated wit h each range may a lso be pro vided as rang e ID. With r elay contact s as range ID, the

common pin of all relays i s connected to th e terminal marked COMM and five (5) nor mally open rel ay contacts th at

close when the related range is active. The dry contacts are rated at 30VDC @ 1A.

Caution:

external voltage will permanently damage the 4-20mA converter.

The integr al 4-20mA converters are int ernally powered and do not requir e external power. Applying any

5.6.6 Loss of Flow Alarm

The analyzer may be e quipped with an optional integral lo ss of flow/low flow alarm. The alarm is set at 1.5 SCFH .

The contact w ill close when th e gas flow exceed s 1.5 SCFH but will open when the gas flow falls below 1.5 SCFH.

The set point i s r elatively rou gh, therefore, to prevent fa lse alarm, set t h e gas flow rate above 2 SCFH. Check the QC

certificate to verify whether this option is available with your analyzer.

The contact is rated at 1A@30 VDC. Do not exceed the recommended rating.

5.6.7 Temperature Controlled Heater System with

Thermal Runaway Protection

The standard GPR-1600 Series analyzer is generally not equipped with the

heater system. H owever, in anticipation o f very low PPM (less t han 0.2

PPM) oxygen analysis, the user may elect to add the heat er system. If the

analyzer is equipped with an optional temperature controlled heater

system, open th e f r o n t door of the analyzer to ac c ess it. This un it is a PID

controller w hich operates bet ween 0-99°F. At the factory the controller is

programmed to maintain the temperature at 85°F.

Caution: Do not change th is setting. A higher tem perature

setting may dra stically reduce sensor life and possibly cause

damage to the elec tronic circuitry of both the controller and

the analyzer.

Warning: Keep th e front door securely fastened and closed when the

temperature controller is ON.

20

Page 23

Advanced Instruments Inc.

Nut holding two sections of the

J2 device

When power is a pplied to the temperature c ontroller, the contro ller tunes itself to eliminate and/or minimize the

over/under shoo t of temperature from the set point. It is reco mmended that at initial st art-up, when replacing th e

oxygen sensor or w hen trouble shoot ing, turn off t he power to the heater ( by setting the temp erature set point at

60°F to prevent overheating the analyzer). When operating the analyzer under normal conditions, set the

temperature controller at 85⁰F.

Changing the display value from °F to °C:

1. Push the UP ARROW and ENTER buttons down for 5 seconds to access the SECURE MENU

2. Press INDEX to advance to the F-C MENU

3. Select °C or °F by pressing the UP ARROW key

4. Press the ENTER key when F-C starts flashing on the display

5. Press INDEX to exit the SECURE MENU

Heater Runaway Protection

Part of the opt ional temperature co ntrolled heater system is a heater runaway protection circuit t hat protects the

electronics in t he event the te mperatur e contro ller should f ail and thereb y allowing t he heater to runaway dam aging

the components in side the analyzer.

The runaway protec tion is provided by a J2 t ype device positio ned between the

temperature con troller an d the heat er. Th is device cu ts-off power to the h eater if

the temperature inside the analyzer exceeds 70°C. Sh o u l d th e J2 devi c e cut power

to the heater, c or rect the pro b lem and r es et th e r unaw ay pr ot ecto r devic e (J2 w ill

conduct under normal conditions) by exposing it to 0°C for a few minutes (a

refrigerator freezer will do). NOTE, should the J2 fail to reset itself, replace it.

To access the J2, r emove the back c over of th e analyzer. Th e j2 is moun ted on a

white terminal block as shown in the figure above.

5.7 Installing a new Oxygen Sensor

The analyze r is equipped with an internal oxygen sensor that has been te sted and calibr ated by the manufac turer

prior to shipment an d is fully operatio nal from th e shipping c ontainers. Th e

sensor has been inst alled at the factory. However, it may be necessary to

install the senso r in the field. Caution: Complete “ESTABLISHING POWER

TO ANALYZER” section before proceeding.

Caution: DO NOT open/dissect the sensor. The sensor contains a

corrosive liquid electrolyte that could be harmful if touched or ingested,

refer to the Material Safety Data Sheet contained in the Owner’s Manual

appendix. Avoid c ontact with any liquid o r crystal type pow der in or aro und

the sensor or sensor housing, as either could be a form of electrolyte.

Leaking sensors should be disposed of in manner similar to that of a

common battery in accordance with local regulations.

sensor housing

21

Page 24

Remove two red taps from

sensor PCB before ins t al li ng

You may check the Sen sor ou tput in air, it must

be within ~500 uA to 950 uA

5.7.1 Procedure

1. Do not remove sensor from its original package until the analyzer is ready to accept sensor

installation.

2. Make sure that a low PPM gas is flowing thr o u gh the analyzer.

3. Set the sample flow rate between 1-2 SCFH

4. Loosen the nut at the bottom of the sensor housing with 5/16” ranch provided.

5. Twist the upper section of the sensor housing 90 degree and then pull it away.

6. Remove old sensor (if previously installed).

7. Remove the new sensor from the package (use a pair of scissors to cut the bag, do not use hands to

tear the bag)

8. Remove the two red ribbons from the two ring gold contact plate at the back of the sensor.

Advanced Instruments Inc.

Quick Air Calibration when installing a new sensor

1. Insert the sensor into the upper section of the sensor housing with the contact plate facing toward the

two gold pins of the sensor housing. Hold the sensor and the sensor housing in your hand while

keeping the sensor pushed against the two gold pins.

22

Page 25

Advanced Instruments Inc.

Hold the sensor pre ssed against the

2. Advance the cursor on the MAIN MENU to SAMPLE and press ENTER to accept the selection. Check the

oxygen reading; it should reach close to 20.0% (+7% -4%) indicating that the sensor has proper signal

output. At this time perform a quick air calibration (detailed instruction for span calibration follows).

3. After air calibration, insert the sensor into the bottom section of the sensor housing with metal screen

of the sensor facing down. Place the upper section of the sensor housing, push it gently downward and

twist it 90 degree until it fits on the lower section of the sensor housing. Tighten the nut (3/4 turn after

figure tight) holding the two section of the sensor housing.

contact pins inside the housing

23

Page 26

Advanced Instruments Inc.

5.7.2 Span Gas Preparation

The analyzer must be calibrated periodically; see the Calibration Section below for recommendations.

Required Components

1. Certified span gas cylinder with an oxygen concentration, balance nitrogen, approximating 80% of the full scale

range of analysis or one range above the intended measuring range.

2. Regulator to set gas pressu re to 5-30 psig (for the solenoid valves to operate proper ly, the differen ce between

the Span and Sample gas pressure must not exceed 5 PSIG).

3. Flow meter to set the flow between 1-2 SCFH (only if analyzer is not equipped with integral flow control device).

4. Suitable fittings and 1/8” or ¼” dia. metal tubing to connect the regulator to the flow meter inlet.

5. Suitable fitting and 1/8” or ¼” dia. 4-6 ft. in length of metal tu bing to c on nec t fr om t he fl o w met er ven t to t u be

fitting connection designated SAMPLE IN or SPAN IN (for analyzer with a separat e span po rt) at th e rear of t he

analyzer.

Procedure

1. With the span gas cylinder valve closed, install the regulator on the cylinder.

2. Open the regulator’s exit valve and partially open the pressure regulator’s control knob.

3. Open slightly the cylinder valve.

4. Loosen the nut connecting the regulator to the cylinder and bleed the pressure regulator.

5. Retighten the nut connecting the regulator to the cylinder

6. Adjust the regulator exit valve and slowly bleed the pressure regulator.

7. Open the cylinder valve completely.

8. Set the outlet pressure between 5-30 psig using the pressure regulator’s control knob.

9. Caution: Do not exceed th e recommende d pressure ran ge. Excessive pressure could cau se malfunctioning

of the solenoid valves resu lt in erro n eous readings.

24

Page 27

Advanced Instruments Inc.

System Self Test

Analog

OK

GPR Series Oxygen Analyzer

Standby

85⁰F 100Kpa

12/31/07 12:00:00

5.8 Establishing Power to the Electronics:

Once the power to th e el ec t r o n ics is established, the digital dis pl ay responds instan t an eo usly. When pow er is applied,

the analyzer performs several diagnostic system status checks termed “SYSTEM SELF TEST” as illustrated below:

CPU

Memory

RTC

Software Version X.XX

Advanced Instruments

2855 Metropolitan Place

Pomona, CA 91767

Tel: 909-392-6900

Fax: 909-392-3665

e-mail:

After 3 seconds the system defaults to the STANDBY mode and the LCD displays the following:

info@aii1.com

OK

OK

OK

* MAIN MENU

Sample

Span

Zero

Alarm

System

Standby

Auto Range

25

Page 28

Advanced Instruments Inc.

5.8.1 Menu Format

Menu selected – displayed on the top line in the upper left corner of the display.

Menu options available – all menus displayed on the left side of the LCD.

Menu option selected - indicated by the cursor (*) positioned to the left of the menu option selected.

System mode - indicated at the top center of the display.

Range mode and current auto or fixed manual range - displayed on the first line at the bottom of the display.

Temperature insi de of the analyzer and ambient pressure - displayed on the second line at the bottom of the screen.

Note:

In the event po w er t o t h e an alyzer is inter rupted, the system defaults to the “Standby” mode when power

is restored. To r esume sampling, advance the c ursor (*) to “Sample” mode, press ENTER to selec t and

select the range mode as described below.

5.8.2 Menu Navigation

The four (4) pushbuttons located on the front of the analyzer control the system’s micro-processor:

1. Green - ENTER (select)

2. Yellow UP ARROW – advance cursor up

3. Yellow DOWN ARROW – advance cursor down

4. Red – ESC (menu)

26

Page 29

Advanced Instruments Inc.

Standby

Standby

85⁰F 100Kpa

12/31/2011 12:00:00

Standby

85⁰F 100Kpa

12/31/2011 12:00:00

Select the menu option by advancing cursor (*) by repeatedly pressing the yellow UP/DOWN ARROW keys.

Accept the menu option selected with cursor (*) by pressing the green ENTER key.

Abort the menu option selected with cursor (*) and return to the previous menu by pressing the r ed ESC key.

Note:

If a selection is not made within 30 seconds, the system returns to the MAIN MENU.

5.8.3 Range Mode Selection

Advance the cursor (*) to the “Sample” option as illustrat e d an d pr ess the green ENTER key to accept the selection.

MAIN MENU

* Sample

Span

Zero

Alarm

System

Auto Range

The following menu appears:

* SAMPLE

Auto Range

Manual Range

Bypass

Standby

Auto Range

The analyzer is equipped with five (5) standard measuring ranges (see specification) and provides users with a

choice of sampli ng mod es. By ac cessing t he MAIN M ENU, u sers may s elect eit her the Auto Range or a fixed Manual

Range mode.

Note: During span calibration, the analyzer will automatically switch to Auto Range mode.

5.8.4 Auto Range Sampling

In the Auto Range mode, the analyzer will automatically select the appropr iate full scale range depend ing on the

concentratio n of oxygen in a sampl e gas. The displa y will shift to the n ext higher range when the oxygen readi ng

exceeds 99.9% of the curren t r an ge. T h e display wil l shift to th e next lower range when th e oxygen readin g drops to

85% of the next lower range.

27

Page 30

Advanced Instruments Inc.

Procedure:

From the SAMPLE menu, advance the cursor (*) to the “Auto Range” option and press ENTER:

Standby

85⁰F 100Kpa

12/31/2011 12:00:00

Similarly, the Bypass and Standby modes do not apply to analyzers equipped with manual Sample System

Sample

85⁰F 100Kpa

12/31/2011 12:00:00

For example, if th e analyzer is reading 1 PPM on the 0-10 PPM range an d an u pset occurs, t h e display will shift t o t h e

0-100 PPM range when the oxygen re adin g exc eeds 9.99 PPM. Conver sely, o nc e the u pset co nditi on i s corr ected, the

display will shift back to the 0-10 PPM range when the oxygen reading drops to 8.5 PPM.

SAMPLE

* Auto Range

Manual Range

Bypass

Standby

Auto Range

Note:

Within seconds t he system assesses the oxyg en concentration, selec ts the appropriate range ( as described above)

and returns to the MAIN M ENU in the “Sample” mode. On the secon d line from the bo ttom o f the menu screen, th e

Auto Range mode is indicated along with the current full scale range.

For an optional automated Sampl e System, the syst em displays a messa ge "Opening Sa mple Valve". This

message does not apply to analyzers equipped with standard manually operated Sample System.

* MAIN MENU

Sample

Span

Zero

Alarm

System

Standby

Auto Range

5.00 PPM

0 to 10 PPM

28

Page 31

Advanced Instruments Inc.

Procedure:

From the SAMPLE menu, advance the cursor (*) to the “Manual Range” option and press ENTER:

Sample

85⁰F 100Kpa

12/31/2011 12:00:00

Sample

85⁰F 100Kpa

12/31/2011 12:00:00

5.8.5 Manual Range Sampling

In the manual ran ge m o de, th e disp lay will n ot shif t automa tic ally. Inst ea d, w hen the oxy gen r ead in g exc ee ds 125%

of the upper limi t of the c urr ent r ange, an” OVER RANGE” warning will b e displ aye d. Once the OVER RANGE warning

appears the user must advance the analyzer to the next higher range.

SAMPLE

Auto Range

* Manual Range

Bypass

Standby

Auto Range

The following display appears:

MANUAL RANGE

0 to 25%

0 to 1%

0 to 1000 PPM

0 to 100 PPM

* 0 to 10 PPM

Auto Range

Advance the cursor (*) to the desired fixed manual range, e.g. 0 to 10 PPM and press ENTER.

Within seconds th e syst em a ssess es th e ox ygen c onc ent ration and returns to the M AIN MEN U in th e “Sam ple” mo de.

On the second line at the bottom of the menu, the Manual R ange mode is indic ated along with the fixed full scale

range selected.

29

Page 32

Advanced Instruments Inc.

Sample

85⁰F 100Kpa

12/31/2011 12:00:00

Sample

85⁰F 100Kpa

12/31/2011 12:00:00

* MAIN MENU

Sample

Span

Zero

Alarm

System

Standby

5.00 PPM

Manual Range

If the oxygen reading exceeds 125% of the full scale fixed range manually selected, the system displays the

following message, e.g., on 0-10 PPM range:

* MAIN MENU

Sample

Span

Zero

Alarm

System

Standby

Manual Range

0 to 10 PPM

12.50 PPM

OVER RANGE

0 to 10 PPM

5.8.6 Setting Alarms

The analyzer is c onfigured wit h two user adjust able threshold ty pe alarm relays that can be configured in the field

from the ALARM option on the MAIN MENU as follows:

Establish independent set points

Either Hi or Lo

Either On or Off (enabled or disabled)

Both temporarily defeated using a user entered ‘timeout’ period (normally a few minutes)

The alarm set point repr esents a value. When the oxygen rea din g ex c eeds (high alarm) o r f all s b el o w ( l o w alarm) the

alarm set point, the relay is activated and the LCD displays the alarm condition.

When activated the alarms tri gger SPDT Form C non-latchi ng relays @ 5A, 30V DC or 240VAC resistive. To pr event

chattering of th e r elays, a 2% hysteresis is ad ded to the alarm set po i n t. T h i s m ean s th at th e al ar m w il l r em ain active

until the oxygen readi ng ha s f allen 2% below th e alar m s et po int (hi gh alar m) o r ris en 2 % above th e al arm set po int

(low alarm) after the alar m w as act ivated. T he tim eout f eatu re is usef ul w hile r eplac ing t he oxyg en sen sor or durin g

calibration when the oxygen reading might well rise above the alarm set point and trigger a false alarm.

Note: When making connections the user must decide whether to configure/connect Alarm 1 and Alarm 2 in failsafe

mode (Normally Open – NO – where the alarm relay de-en ergizes and c loses in an alar m conditio n) or non-failsafe

mode (Normally Closed – NC – where alarm relay energizes and opens in an alarm condition).

Procedure: Advance the cursor (*) to the “Alarm” option and press the green ENTER key to accept the selection.

30

Page 33

Advanced Instruments Inc.

Sample

85⁰F 100Kpa

12/31/2011 12:00:00

85⁰F 100Kpa 12/31/2011 12:00:00

85⁰F 100Kpa 12/31/2011 12:00:00

MAIN MENU

Sample

Span

Zero

* Alarm

System

Standby

5.00 PPM

Auto Range

The following menu appears:

ALARM Sample

* Set Alarm 1

Set Alarm 2

Alarm 1 HI

Alarm 2 LO

Alarm 1 ON

Alarm 2 OFF

Alarm Timeout

Auto Range 0 to 10 PPM

Advance the curso r ( * ) to the “Set Alarm 1” option and pres s the green ENTER key to accept the selec ti o n. The Menu

will then prompt to select the un its of alarm set points, f or example, % or PPM or PPB (PPB optio n is for GPR-1600UHP analyzer only).

After selecting the gas units, the following menu appears (assuming the user selected PPM units):

Sample

0 PPM

02

Press UP or DOWN

to change value

ENTER to Save

ESC to Return

Set Alarm 1 in PPM

0 to 10 PPM

Auto Range 0 to 10 PPM

Follow selection of set point, press the ENTER key to save the alarm value or ESC to return to the MAIN MENU.

Within a few seconds after pressing the ENTER key, the system returns to the MAIN MENU.

Repeat the above steps for “Set Alarm 2”.

Configure Alarm 1 and Alarm 2 as High or Low by ad vancing the cursor (*) to the desired feature as illustrated

below.

31

Page 34

Advanced Instruments Inc.

85⁰F 100Kpa 12/31/2011 12:00:00

Sample

85⁰F 100Kpa

12/31/2011 12:00:00

85⁰F 100Kpa 12/31/2011 12:00:00

ALARM Sample

Set Alarm 1

Set Alarm 2

* Alarm 1 HI

Alarm 2 LO

Alarm 1 ON

Alarm 2 OFF

Alarm Timeout

Auto Range 0 to 10 PPM

Press the ENTER key to toggle between the settings: HI and LO and/or ON and OFF.

Pressing the ENTER key will toggle the selection and the system will return to the MAIN MENU.

ALARM TIMEOUT: The Alar m Timeout feature allows the user to select a “time del ay” to prevent th e alarm from

triggering rela y immediat ely after the alarm c ondition occu rs. The time d elay featu re allow s the user from tri ggering

a false alarm du ring mainten ance or self induces sign al spike. In order to ent er the time delay, advance the cursor

(*) to the “Alarm” option and press the green ENTER key to accept the selection.

MAIN MENU

Sample

Span

Zero

* Alarm

System

Standby

5.00 PPM

Auto Range

The following menu appears:

ALARM Sample

*Set Alarm 1

Set Alarm 2

Alarm 1 HI

Alarm 2 HI

Alarm 1 ON

Alarm 2 ON

Alarm Timeout

Auto Range 0 to 10 PPM

Advance the cursor (*) to the “Alarm Timeout” option and press the green ENTER key to accept the selection.

The following menu appears:

0 to 10 PPM

32

Page 35

Advanced Instruments Inc.

Alarm Delay in Minutes

85⁰F 100Kpa 12/31/2011 12:00:00

Sample

85⁰F 100Kpa

12/31/2011 12:00:00

Sample

00 MIN

Press UP or DOWN

to change value

ENTER to Save

ESC to Return

Auto Range 0 to 10 PPM

Follow the prom pt above and press the ENTER key to save the alarm timeo ut value or ESC to return to the MAIN

MENU.

Within a few seconds after pressing the ENTER key, the system returns to the MAIN MENU.

5.8.7 System Menu

The analyzer is e quipped with a wide range of features that enables users to enhance performance and tailor their

interface with the analyzer. The SYSTEM menu shown below lists the features available and is followed by a

description of each function. Most of the functions are initi ated by togg ling between options by pre ssing the ENTER

key as previously described.

Advance the cursor (*) to the “Alarm” option and press the green ENTER key to accept the selection.

MAIN MENU

Sample

Span

Zero

Alarm

* System

Standby

Auto Range

The following menu appears:

* SYSTEM

Enable Low Flow Alarm

Disable Alarm During Cal

Signal Average

Range

Logging Interval

Temp Coeffici en t

View Data Graph

Set Clock (and Date)

Logging ON

Show Text

Display Negative (Reading) ON

5.00 PPM

0 to 10 PPM

33

Page 36

Advanced Instruments Inc.

microprocessor).

Disable Alarm During Cal

Press ENTER key to toggle between ENABLE and DISABLE.

off of

seconds when selecting LOW, MEDIUM OR HIGH option

Range

Same as Auto/Manual Range option found on SAMPLE menu.

purposes.

memory.

day.

With Logging ON, the

stored from a few days to several weeks.

after calibration or after a process upset condition.

shows a negative reading or after premature Zero Offset calibration.

Advance the cursor (*) to the desired option, press ENTER key and follow the instructions below.

Enable Low Flow Alarm

Signal Average Press ENTER key to select and choose Low, Medium (default) or High –

Logging Interval Press ENTER key and a di splay appe ars simi lar to A larm Tim eout abov e for th e

Temp Coefficient Enables the user to f ine tune the temp erature com pensation (this feature is an

View Data Graph Provided that the “Logging” feature is toggled ON, selecting this feature

If the analyzer i s equipped with a low f low alarm, press ENTER key to toggle

between ENABLE and DISABLE (this feature is c urrently not controlled by t he

functions allows users to select their preference regarding the traderesponse time v s. noise filtering. The sign al averaging is rough ly 5, 8 and 10

user to enter the interval in minutes for capturing data points for logging

option, consult factory for more details).

provides a full-screen display or graph of the data points in the analyzer

Set Clock (and Date) Selecting this option gener ates a display for selec ting Time or Date with each

followed by a det ailed displa y for setting h our, minu te, second o r year, month ,

Logging Press ENTER key to toggle between ON and OFF.

analyzer will store the data in its internal memory. The internal memory is

limited to 32K. The total number data points that can be stored are 5500.

Depending on the ti me interval between the points selected, the da ta can be

Show Text Press ENTER key to toggle between “Text and Graph” display options:

1.) With Show Text option, large numbers of gas concentration (as

illustrated herein)

2.) Show Graph option, small numbers and a small gra phical trend of O2

reading. The Graph o nly shows a limited numb er of data poin ts. After

the graph has filled the limited space on the LCD, the graph will

refresh itself by “First in First out” methodology. This feature allows

the user to look at trending of the data when i nstalling a new senso r,

Display Negative (Reading) Press the ENTER key to toggle between ON and OFF. With “Display Negative”

ON, the analyzer w ill sho w negativ e num bers on the scr een in t he event sensor

34

Page 37

Advanced Instruments Inc.

Factory Default Zero:

The feature eliminates any previous zero calibration offset adjustment stored in

Zero Calibration:

Recommended for optimum accuracy. The user must ascertain that the oxygen

reading has reached a stable value and is below 50% of the most sensitive or

5.9 Installation & Start-up is now complete . . . Proceed to

calibrate the Analyzer

The electrochemical oxygen sensors manufactured by Analytical Industries Inc. (dba Advanced Instruments)

generate an elec trical current that is linear or pro portional to the oxy gen concentration in the sample gas. In the

absence of oxy gen th e sen sor exh ibits an absolute zero, e.g. the sensor doe s not generat e a cu rrent o utpu t in th e

absence of oxygen. Given the properties of linearity and an absolute zero, single point calibration is possible.

As described belo w , zero calibrati o n is r ec ommended only when the applicat io n (or user) demands optimum accu r acy

for analysis belo w 5% o f the most sen sitive or lowest range available on the analyzer. Span calibration in one of the

forms described below is suffic ient for all other measurements. When employed, Zero calibration should be

carried out after Span calibration.

5.9.1 Zero Calibration

Despite the abso lute zero inherent in el ectrochemical oxygen senso rs, the reality is that analyzers can display an

oxygen reading when sampling a zero gas due to:

Contamination or quality of the zero gas

Minor leakage in the sample line connections

Residual oxygen dissolved in t h e sen so r ’ s electrolyte

Tolerances of the electronic components

The zero capability (low end sensitivity) of every analyzer is qualified prior to shipment. However, because the

factory sample sy stem conditi ons differ fr om that of th e user, no ZERO OFFSET adjustment is made to the analyzer

by the factory

5.9.2 Span Calibration

Involves periodically, see Inte rvals section below, checking an d/or adjusting the electronic s to the sensor’s signal

output at a given oxy gen standard or a span ga s. After span calibration, maximum drift from calibration poin t with

varying temperatu re is approximat ely 0.11% of reading per °C change in am bien t temperature. T h er ef o r e, calibration

of the analyzer is recommended as close as possible to the sampling temperature conditions. The frequency of

calibration var ies w ith the a ppl icat ion co ndit ion s; th e degr ee o f ac cu rac y of t he measu reme nt r equir ed. Ho wever, the

interval between span calibrations should not exceed three (3) months.

Note: Regardless of the oxygen concentration of the standard used, the span calibration process takes

approximately 10 -15 minute s, how ever, the time r equired t o bring a PPM analyz er back on -line can var y, see Online

Recovery Time below.

5.9.3 Menu Functions - Zero Calibration

the analyzer memory.

This factory default calibration is recommended before performing a ZERO

CALIBRATION or when troubleshooting the analyzer. The factory default zero

calibration is not recommended when subsequent periodic SPAN CALIBRATION is

done.

35

Page 38

Advanced Instruments Inc.

lowest range available on the analyzer before the system will accept and perform a

the message “CALIBRATION FAILED” and returns to the “Sample” mode.

Factory Default Span:

The system eliminates any previous span calibration adjustment stored in the

Span Gas Units/Value:

After initiating either Auto or Manual Span from the SPAN CALIBRATION menu,

Span Calibration:

The user must ascertain that the oxygen reading has reached a stable value

inaccurate results.

Sample

85⁰F 100Kpa

12/31/2011 12:00:00

ZERO CALIBRATION.

If the user attempts to initiate the ZERO CALIBRATION function while the oxygen

reading is above 50% of the most sensitive or lowest range, the system displa ys

5.9.4 Menu Functions - Span Calibration

analyzer memory and displays an oxygen reading within +50% of the span gas

value currently flowing through the analyzer.

If the oxygen reading is outside +

perform Span calibration will result in “CALIBRATION FAILED” message and the

analyzer will return to the “Sample” mode. This feature allows the user to test

the sensor’s signal output without removing it from the sensor housing.

This function is recommended before performing a SPAN CALIBRATION or

when troubleshooting an analyzer.

50% of the span gas value, the attempt to

the system produces a display prompting the user to select span gas in PPM or

% units, which is followed by a second display prompting the user to enter a

numerical span gas value.

before completing Span Calibration. A premature Span calibration will result in

5.9.5 Calibration Procedure – Span Calibration

To perform Span calibration

1. Assure that the analyzer is in the Auto Range mode as described above.

2. Span gas is connected to the SPAN IN port at the rear of the analyzer

3. Set the span gas pressure betw een 5-30 PSIG (for the solenoid valve s to operate properl y, the difference

between the Span and Sample gas pressure must not exceed 5 PSIG) and set the flow at 1-2 SCFH

4. Allow the analyzer reading to stabilize before attempting calibration.

From Main Menu, Advance the cursor ( *) to th e “Span ” opt ion as illu str ate d and pre ss th e gr een EN TER key

to accept the selection.

MAIN MENU

Sample

* Span

Zero

Alarm

System

Standby

1.00 PPM

Auto Range

0 to 10 PPM

36

Page 39

Advanced Instruments Inc.

85⁰F 100Kpa 1/31/2011 12:00:00

85⁰F 100Kpa 12/31/2011 12:00:00

85⁰F 100Kpa 12/31/2011 12:00:00

The following menu appears:

SPAN

* Factory Default

Calibrate

Auto Range 0 to 10 PPM

Advance the cursor (*) to the Auto or Manual Span option and press ENTER. The following screen will appear

prompting the u ser to select calibra tion gas unit. Select % or PPM (PPB is a vailable with GPR-1600-UHP analy zer

only).

SPAN GAS

* Enter as PPM

Enter as %

Auto Range 0 to 10 PPM

After selecting the calibration gas units, following screen will appear.

080.00 PPM

Press UP or DOWN keys to change values

Select ENTER to save, ESC to return to previous digit

Auto Range 0 to 10 PPM

After acceptin g the sp an gas valu e, the m icro-c ontro ller w ill shu t the S ample valve and op en the Sp an val ve and the

following screen will appear (this is true with analyzers with sample system equipped with auto/pneumatic

sample/span/zer o valves) .

37

Page 40

Advanced Instruments Inc.

080 70.7 PPM

SPAN GAS ACTUAL O2 VALUE

ENTER TO CAL ESC TO ABORT . . .

Sample

85⁰F 100Kpa

12/31/2011 12:00:00

Note: When span v alve opens, assur e t hat the gas flow is t h e same as was set for S am p l e ga s. Fu r t h er, the analyzer

might show positiv e spike on the signal du e to excessive oxygen in the span gas line (d ue to minor leakage in the

gas line, oxygen fro m air dif fu ses into the g as line even th ou gh th e span gas lin e is u nd er pressu re) bu t wit hin a few

minutes the exces sive oxygen will pu rge out of the system and the analyzer wil l begin to analyze t he true oxygen

content of the span gas.

Span

Calibration in

Progress. . .

After the oxygen r eading has stabil ized, press ENTER to complete the Sp an Calibration (i f Manual Span optio n was

selected). If the user att empt s to complet e the SPAN CALIBRATION function while the oxygen reading is outside the

+/-50% of the span g as valu e ent ered, t he s ystem d isplay s th e messa ge “CALI BRATI ON F AILED” an d retu rns t o the

“Sample” mode.

5.9.6 Auto Span Calibration

In the Auto Span m ode, the micro pr ocessor will watc h the trending of th e oxygen reading. When the reading has

stabilized and is within +/-50% of t he span gas value entered, th e micro will adjust the o xygen reading to match

with the span gas value and retu rn to the Sampl e mode and star t displayi ng the true ox ygen reading in the sampl e

gas. The Aut o Calibration process may t ake from a few minutes to m ore than an hour (depending o n the level of

oxygen contamination of the span gas line).

After completing the Auto Calibration, the system returns to the MAIN MENU in the “Samp le” mode and displays th e

real time oxygen contents in the sample gas. The oxygen value will slowly trend down from the span gas value.

MAIN MENU

* Sample

Span

Zero

Alarm

System

Standby

Auto Range

8.00 PPM

0 to 10 PPM

5.9.7 Calibration Procedure – Zero Calibration

To perform Zero calibration

1. Ensure that the analyzer is in the Auto Range mode as described above.

38

Page 41

Advanced Instruments Inc.