Page 1

Oxygen Analyzers for Industrial Gases

GPR-1600, GPR-2600, GPR-3100

High-accuracy oxygen analyzers for monitoring gas in industrial processes

where trace oxygen from low parts per million to pure O2 has to be precisely

measured. Utilizing AII’s high performance galvanic oxygen sensors these

advanced instruments are simple to use with a common, across-the-range

chassis, HMI and menu structure, so an operator only needs to learn

operation of just one instrument for multiple gas analysis applications

at various oxygen levels. Available as bench-, 19” rack-, panel- and wallmounted for flexible installation.

%

PPM

Highlights

• High accuracy (±0.02ppm in lowest range)

• Four measurement ranges with manual or

auto-ranging

• 24 month sensor life with normal usage

• Sample in CO2 backgrounds with XLT sensor

• Bench, rack or wall mounting options

• Two Alarms

• Integrated bypass valve (for GPR-1600)

• Easy access and sensor replacement

• Easy to use HMI

Applications

• Purity of product in industrial gas manufacture

• Trace oxygen in hydrogen generation by

electrolysis

• Monitoring oxygen generators

• Measuring oxygen in metallurgical processes-

heat treatment and annealing

• Gas measurement in poultry stunners

• Analysis of gas in double glazing manufacture

www.aii1.com

Page 2

34456

7

3030404505060

70

8

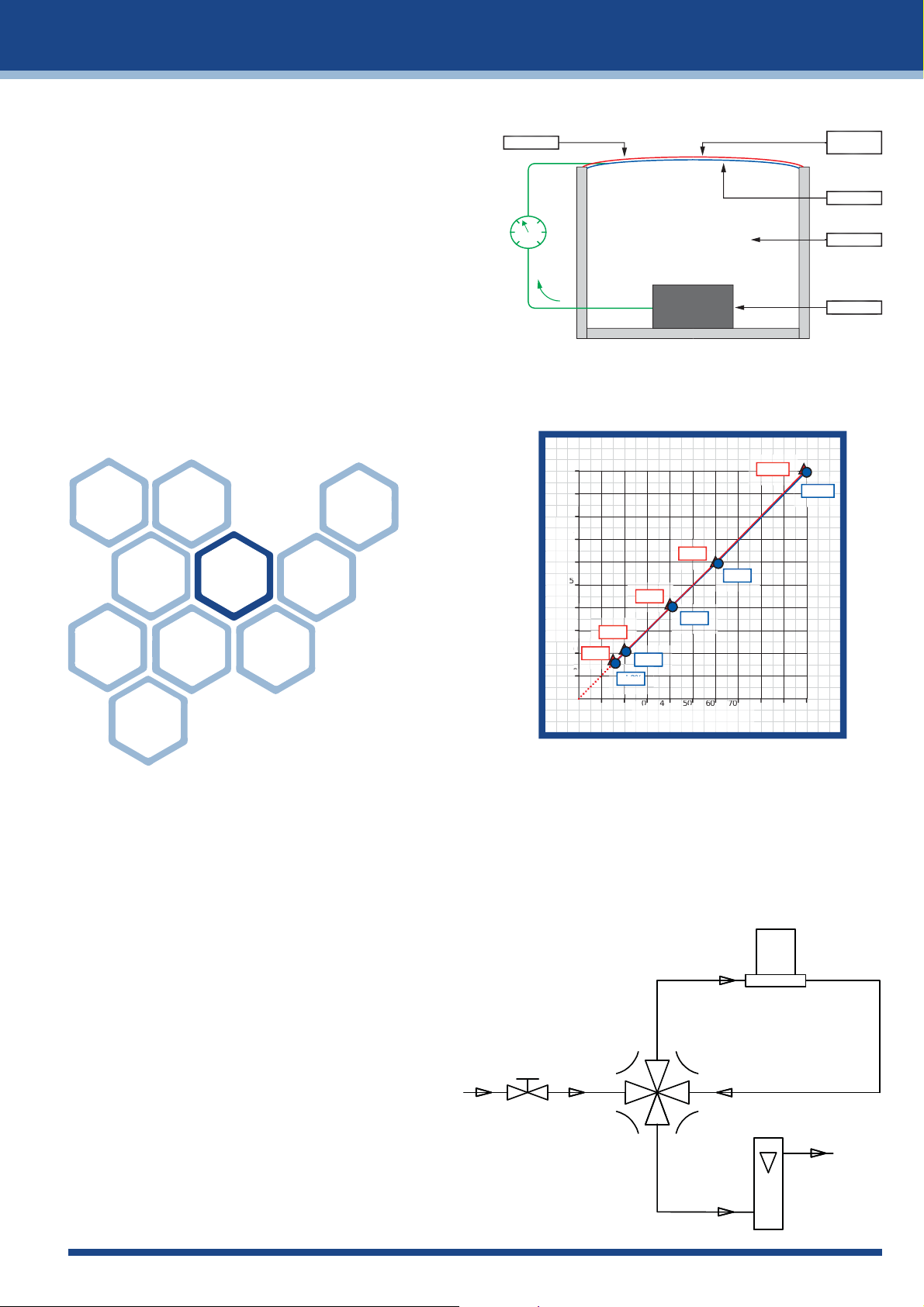

Sensor Technology

The sensors from AII have been designed to avoid potential

weaknesses common in typical galvanic cell design. Our

materials, construction and assembly methods have been

continuously refined over decades. Each sensor type

has been specifically engineered to provide the optimum

balance between performance and longevity for individual

applications. The result is confidence in the measurement

and low maintenance. In the absence of oxygen, the

sensor will produce zero output and the sensor is linear

up to 100%, therefore only a span calibration is required

in most cases (see graph).

Membrane

Electrolyte

0202020

0

0

2

2

-

0H

0H

i

-

0H

-

0H

-

0H

-

-

0H

-

0H

-

0H

-

0H

-

0H

Pb0 Pb0

-

0H

0H

0H

0H

0H

0H

02020

2

-

-

0H

-

0H

-

0H

-

-

0H

-

0H

-

0H

-

0H

0

2

0

2

2

-

0H

-

0H

-

0H

-

-

0H

-

0H

0H

-

0H

-

-

0H

-

-

0H

-

-

0H

-

0H

Layer

Cathode

Electrolyte

Anode

Sensor Construction

100

90

80

70

60

50

40

30

Oxygen Reading / Output

20.9%

0

20

15.2%

10

15.2%

0

0 10 20 30 40 50 60 70 80 90 100

60.6%

40.0%

40.3%

21.0%

100.2%

100.0%

60.3%

% Oxygen Concentration

Typical sensor output

The Analytical Industries’ XLT sensor

For applications with a background gas containing more than 0.5% CO2, the specially designed XLT sensor should be

selected. With most standard electrochemical sensors an alkaline electrolyte is used and this is neutralised over time

when exposed to acidic gases, such as CO2. To combat this, AII developed the XLT sensor with a special electrolyte

formula and has the added benefit of being able to operate in temperatures as low as -10°C.

Bypass sample system

To protect the sensor when switching sample lines or

during no-flow situations, there is an integral 4-way valv e.

This both extends the life of the trace oxygen sensor

and reduces the time to reach process measurements as

samples with low ppm O2 can be trapped in the cell until

the pipework is flushed.

www.aii1.com

4

31

2

Page 3

Common features:

GPR-3100

• Barometric pressure & temperature compensation

• Stainless steel wetted parts

• 4 measurement ranges (manual or auto-selected)

• Range Identification output

• 4-20mA, 0-1V and 0-5V outputs

• 2 off user configurable alarm relays

• Universal mains powered

Options:

• Auto-Zero & auto-calibrations facilities

• Digital communication options

• Relay contacts for range ID

GPR-1600

As standard the GPR-1600 has an integral bypass sample

system. The analyzer can be temporarily exposed to

ambient air to perform a span calibration (20.9% O2).

Options: External bypass system

Heated sample system

Measurement ranges: 0-10 ppm, up to 0-1% O2 (0-

25% for calibration only).

The GPR-3100 is fitted with a temperature controlled

sample handing system to provide an isothermal

environment for the sample for increased accuracy.

Measurement ranges: 0-100% up to 90-100% O

2

GPR-2600

The GPR-2600 is an ideal instrument to monitor oxygen

in applications which involve purging from ambient air to

low percentage levels of oxygen with a variety of gases.

Options: Heated sample system

Measurement ranges: 0-1% up to 0-25% O

2

Installation Options

There are 4 mounting options available for the range

(HxWxD):

• Bench mounting (dimensions: 35.3 x 25.1 x 34cm)

• Panel mounting (dimensions: 19 x 27.4 x 28.6cm)

• 19” rack mounting with optional bezel

(dimensions: 19 x 48 x 72cm)

• Wall mounting (dimensions: 34.6 x 26.7 x 17.8cm)

• Wall mounting W

(dimensions 34.6 x 31.8 x 19.7cm)

• Wall mounting W306

(dimensions 46.4 x 40.7 x 17.2cm)

www.aii1.com

Page 4

Technical Specifications

GPR-1600 GPR-2600 GPR-3100

Measurement range

Accuracy

0-10, 0-100, 0-1000 ppm,

0-1%

0-1%, 0-5%, 0-10%, 0-25%

(0-25% calibration only)

< ±2% of selected range

±0.1% at constant conditions after calibration with 95-100% oxygen (GPR-3100)

0-100%, plus suppressed zero

ranges.

50, 80, or 90-100%

Response time T90 < 10 seconds T90 < 13 seconds

Recovery time

60 sec in air to < 10 ppm in <

1 hour on N

purge

2

Not applicable Not applicable

Sensitivity (LDL) 50 ppb 50 ppm 0.1% oxygen

Linearity < 0.5% of scale

GPR-12-333 GPR-11-32-4

Sensor model

Sensor life at 25°C

and 1 atm

XLT-12-333 for gas mixture

with > 0.5% CO

2

24 months in < 1000 ppm O

XLT-11-24-4 for gas mixture

with > 0.5% CO

2

GPR-11-32-4 32 months;

XLT-11-24-4 24 months

2

GPR-11-120-OP

24 months in 100% oxygen

Calibration interval Typically: 1-3 months

Inlet pressure 0.34 – 2 barg (5-30 psig) with atmospheric vent 248 bar g (3600psig)

Flow rate (constant) 0.5 - 1.0 Nl/min (1-2 SCFH)

Gas connections 1/4" compression tube fittings

Display Graphical LCD 12.7 x 7cm (5 x 2.75”); resolution 0.01

Enclosure

Compensation

See individual mounting options for dimensions

Barometric pressure and temperature;

Temperature controlled sample system and sensor (GPR-3100 only)

Painted aluminum

Analog output 4-20 mA isolated, 0-1V, and 0-5V

Range ID 1-5 V or 4-20mA, optional relay contacts

Communications Choose from RS485, RS232 or USB

Alarms Two user-adjustable alarm relays

Operating temperature

GPR sensor: 5°C to 45ºC (41°F to 113°F)

XLT sensor: -10°C to 45°C (14°F to 113°F)

Power Universal 100-240 V AC

Analytical Industries Inc. 2855 Metropolitan Place, Pomona, CA 91767 USA

Tel: 909-392-6900, Fax: 909-392-3665, www.aii1.com, e-mail: info@aii1.com

Please note: Analytical Industries Inc. adopts a continuous development program which sometimes necessitates specification changes without notice.

www.aii1.com

Please contact us for the latest version. Issue No: Industrial Oxygen Analyzers__partnumber_V2_UK_1018

Loading...

Loading...