Page 1

Advanced Instruments Inc.

GPR-2600 Series

Oxygen Analyzer

Owner’s Manual

2855 Metropolitan Place, Pomona, California 91767 USA ♦ Tel: 909-392-6900, Fax: 909-392-3665, e-mail: info@aii1.com

Page 2

Table of Contents

Introduction 1

Quality Control Certification 2

Safety & Installation 3

Features & Specifications 4

Operation 5

Maintenance 6

Spare Parts 7

Troubleshooting 8

Warranty 9

Material Safety Data Sheets 10

Advanced Instruments Inc.

1 Introduction

Your new oxygen analyzer is a precision piece of equipment designed to give you years of use in variety of industrial oxygen

applications.

This analyzer is designed to measure the oxygen concentration in inert gases, gaseous hydrocarbons, hydrogen, and a variety

of gas mixtures. In order to derive maximum performance from your new oxygen analyzer, please read and follow the

guidelines provided in this Owner’s Manual.

The serial number of this analyzer may be found on the inside the analyzer. You should note the serial number in the space

provided and retains this Owner’s Manual as a permanent record of your purchase, for future reference and for warranty

considerations.

Serial Number: _______________________

Every effort has been made to select the most reliable state of the art materials and components designed for superior

performance and minimal cost of ownership. This analyzer was tested thoroughly by the manufacturer for best performance.

However, modern electronic devices do require service from time to time. The warranty included herein plus a staff of trained

professional technicians to quickly service your analyzer is your assurance that we stand behind every analyzer sold.

Advanced Instruments Inc. appreciates your business and pledge to make effort to maintain the highest possible quality

standards with respect to product design, manufacturing and service.

2

Page 3

Advanced Instruments Inc.

2 Quality Control Certification

Date:

Model: GPR-2600 ppm Oxygen Analyzer S/N _____________________

Customer: Order No.:

Pass

Sensor: ( ) GPR-12-333 ppm Oxygen Sensor

( ) XLT-12-333 ppm Oxygen Sensor S/N _____________________

Accessories: Owner’s Manual

CABL-1008 Power Cord

TOOL-1001 5/16” Combination Wrench

Configuration: Ranges: 0-1 ppm, 0-10 ppm, 0-100 ppm, 0-1000 ppm

( ) Stainless steel sensor housing, manual flow control and bypass valves, ¼” compression

( ) Temperature controlled heater system 85°F specify: ( ) 110VAC ( ) 220VAC

Power: 100/120/220/250 VAC (universal without temperature controlled heater systems)

Enclosure: ( ) Std. panel mount (“T”) 7.5x10.8x12”; ( ) “TO” option 7.75x 7.75x12”

Test System start-up diagnostics satisfactory

Auto/manual range

Alarm relays activate/deactivate with changes in O2 concentration

Alarm bypass

Analog outputs: Signal output 4-20mA

Range ID: ( ) 4-20mA or ( ) 5x relay contacts plus 1x common

Recovery from air to < 10 ppm in < 15 minutes

Baseline drift on zero gas < ± 2% FS over 24 hour period

Noise level < ± 1.0% FS

Span calibration gas value

Span adjustment within 10-50% FS

Peak to peak over/under shoot < 0.5% FS

Overall inspection for physical defects

Options Label analyzer “Oxygen Service” in accordance with P-1507 Rev-1; see certificate next page.

Notes

A-1146-40 PCB Assembly Main / Display Software V. ______

( ) A-1174-40 PCB Assy Power Supply / Interconnect, 4-20mA Range ID

( ) A-1174-40C PCB Assy Power Supply / Interconnect, 5x Relay Contacts Range ID

type fittings for sample inlet and vent

( ) Delete bypass valve from above (T and TO options)

( ) Sample, span, zero inlet solenoid valves

( ) Bezel for 19” rack mmount 19x12x12” option

( ) GPR-2600-W option general purpose wall mount 12x12x8”

3

Page 4

Advanced Instruments Inc.

Certificate of Cleaning

Oxygen Service

Standard: Manufacturing Procedure No. P-1057 Rev-1,

Compressed Gas Association,

Publication: G-4.1 Edition 4,

Title: Cleaning Equipment for Oxygen Service,

Published 1/1/1996 and related publications

Mfg. Item No.: GPR-2600 Series

Description: Oxygen Analyzer

Serial No.:

Customer:

Purchase Order:

Quantity: 1 of

Warranty Date: 12 months from ______________

The undersigned warrants on behalf of Manufacturer that the product identified above

conforms to the manufacturing, testing and packaging criteria set forth by the ‘Standard’

specified above.

___________________________

___________________________

___________________________

Date:

______________

Place: Pomona, CA

By print name:

Signature:

Title:

4

Page 5

Advanced Instruments Inc.

3 Safety Guidelines

Safety

This section summarizes the basic precautions applicable to all analyzers. Additional precautions specific to individual analyzer

are contained in the following sections of this manual. To operate the analyzer safely and obtain maximum performance follow

the basic guidelines outlined in this Owner’s Manual.

Caution: This symbol is used throughout the Owner’s Manual to Caution and alert the user to recommended safety and/or

operating guidelines.

Danger: This symbol is used throughout the Owner’s Manual to identify sources of immediate Danger such as the presence of

hazardous voltages.

Read Instructions: Before operating the analyzer read the instructions.

Retain Instructions: The safety precautions and operating instructions found in the Owner’s Manual should be retained for

future reference.

Heed Warnings Follow Instructions: Follow all warnings on the analyzer, accessories (if any) and in this Owner’s Manual.

Observe all precautions and operating instructions. Failure to do so may result in personal injury or damage to the analyzer.

Heat: Situate and store the analyzer away from sources of heat.

Liquid and Object Entry: The analyzer should not be immersed in any liquid. Care should be taken so that liquids are not

spilled into and objects do not fall into the inside of the analyzer.

Handling: Do not use force when using the switches and knobs. Before moving your analyzer be sure to disconnect the

wiring/power cord and any cables connected to the output terminals located on the analyzer.

Maintenance

Serviceability: Except for replacing the oxygen sensor, there are no parts inside the analyzer for the operator to service.

Only trained personnel with the authorization of their supervisor should conduct maintenance.

Oxygen Sensor: DO NOT open the sensor. The sensor contains a corrosive liquid electrolyte that could be harmful if touched

or ingested, refer to the Material Safety Data Sheet contained in this Owner’s Manual. Avoid contact with any liquid or crystal

type powder in or around the sensor or sensor housing, as either could be a form of electrolyte. Leaking sensors should be

disposed of in accordance with local regulations.

Troubleshooting: Consult the guidelines in section 8 for advice on the common operating errors before concluding that your

analyzer is faulty. Do not attempt to service the analyzer beyond those means described in this Owner’s Manual.

Do not attempt to make repairs by yourself as this will void the warranty, as detailed by section 9, and may result in electrical

shock, injury or damage. All other servicing should be referred to qualified service personnel.

Cleaning: The analyzer should be cleaned only as recommended by the manufacturer. Wipe off dust and dirt from the outside

of the unit with a soft damp cloth then dry immediately. Do not use solvents or chemicals.

Nonuse Periods: Disconnect the power when the analyzer is left unused for a long period of time.

5

Page 6

Advanced Instruments Inc.

Installation

Gas Sample Stream: Ensure the gas stream composition of the application is consistent with the specifications and review the

application conditions before initiating the installation. Consult the factory to ensure the sample is suitable for analysis.

Contaminant Gases: A gas scrubber and flow indicator with integral metering valve are required upstream of the of the

analyzer to remove interfering gases such as oxides of sulfur and nitrogen or hydrogen sulfide that can produce false readings,

reduce the expected life of the sensor and void the sensor warranty if not identified at time of order placement. Installation of a

suitable scrubber is required to remove the contaminant from the sample gas to prevent erroneous analysis readings and

damage to the sensor or optional components. Consult the factory for recommendations concerning the proper selection and

installation of components.

Expected Sensor Life: With reference to the publish specification located as the last page of this manual, the expected life of

all oxygen sensors is predicated on oxygen concentration (< 1000 ppm or air), temperature (77°F/25°C) and pressure (1

atmosphere) in “normal” applications. As a rule of thumb sensor life is inversely proportional to changes in the parameters.

Deviations are outside the specifications and will affect the life of the sensor. Avoid exposure to oxygen levels near 100% for an

extended period of time.

Accuracy & Calibration: Refer to section 5 Operation. The 0-25% range is provided not only as a measuring range but for

the purpose of air calibration which is the recommended method of calibration. Optionally, the analyzer can be calibrated with a

certified span gas or compressed instrument air at the user’s discretion. Note: The oxygen sensor’s inherent linearity and

absolute zero properties facilitates single point calibration.

Materials: Assemble the necessary zero, purge and span gases and optional components such as valves, coalescing or

particulate filters, and, pumps as dictated by the application; stainless steel tubing is essential for maintaining the integrity of

the gas stream for ppm and percentage range (above or below ambient air) analysis; hardware for mounting.

Operating Temperature: The sample must be sufficiently cooled before it enters the analyzer and any optional components.

A coiled 10 foot length of ¼” stainless steel tubing is sufficient for cooling sample gases as high as 1,800ºF to ambient. The

maximum operating temperature is 45º C on an intermittent basis unless the user is willing to accept a reduction in expected

sensor life – refer to analyzer specification - where expected sensor life is specified at an oxygen concentration less than 1000

ppm oxygen for ppm analyzers and air (20.9% oxygen) for percent analyzers, but in all instances at 25°C and 1 atmosphere of

pressure. Expected sensor varies inversely with changes in these parameters.

Pressure & Flow

All electrochemical oxygen sensors respond to partial pressure changes in oxygen. The sensors are equally capable of analyzing

the oxygen content of a flowing sample gas stream or monitoring the oxygen concentration in ambient air (such as a confined

space such in a control room or an open area such as a landfill or bio-pond).

Analyzers designed for in-situ ambient or area monitoring have no real inlet and vent pressure because the sensor is exposed

directly to the sample gas and intended to operate at atmospheric pressure, however, slightly positive pressure has minimal

effect on accuracy.

Sample systems and flowing gas samples are generally required for applications involving oxygen measurements at oxygen

concentrations and pressures other than ambient air. In these situations, the use of stainless steel tubing and fittings is critical

to maintaining the integrity of the gas stream to be sampled and the inlet pressure must always be higher than the pressure at

the outlet vent which is normally at atmospheric pressure.

The sensor is exposed to sample gas that must flow or be drawn through metal tubing inside the analyzer. The internal sample

system includes 1/8” compression inlet and vent fittings, a corrosion resistant or stainless steel sensor housing with an o-ring

seal to prevent the leakage of air and stainless steel tubing.

Inlet Pressure: Analyzers designed for flowing samples under positive pressure or pump vacuum (for samples at atmospheric

or slightly negative atmospheres) that does not exceed 14” water co

on the side of the unit (unless otherwise indicated, either fitting can serve as inlet or vent) and are intended to operate at

positive pressure regulated to between 5-30 psig although the rating of the fitting itself is considerably higher. Caution: If the

analyzer is equipped with an optional H2S scrubber, inlet pressure must not exceed 30 psig.

lumn are equipped with bulkhead tube fitting connections

6

Page 7

Advanced Instruments Inc.

Outlet Pressure: In positive pressure applications the vent pressure must be less than the inlet, preferably atmospheric.

Flow Rate: Flow rates of 1-5 SCFH cause no appreciable change in the oxygen reading. However, flow rates above 5 SCFH

generate backpressure and erroneous oxygen readings because the diameter of the integral tubing cannot evacuate the sample

gas at the higher flow rate. The direction the sample gas flows is not important, thus either tube fitting can serve as the inlet or

vent – just not simultaneously.

A flow valve upstream (with flow indicator positioned downstream) of the sensor is recommended as a means of controlling the

flow rate of the sample gas, minimizing air leaks and produce optimum accuracy. A flow rate of 2 SCFH or 1 liter per minute is

recommended for optimum performance.

Caution: Do not place your finger over the vent (it pressurizes the sensor) to test the flow indicator when gas is flowing to the

sensor. Removing your finger (the restriction) generates a vacuum on the sensor and may damage the sensor (voiding the

sensor warranty). To avoid generating a vacuum on the sensor (as described above) during operation, always select and install

the vent fitting first and remove the vent fitting last.

Application Pressure - Positive: A flow indicator with integral metering valve positioned upstream of the sensor is

recommended for controlling the sample flow rate between 1-5 SCFH. To reduce the possibility of leakage for low ppm

measurements, position a metering needle valve upstream of the sensor to control the flow rate and position a flow indicator

downstream of the sensor. If necessary, a pressure regulator (with a metallic diaphragm is recommended for optimum

accuracy, the use of diaphragms of more permeable materials may result in erroneous readings) upstream of the flow control

valve should be used to regulate the inlet pressure between 5-30 psig.

Caution: If the analyzer is equipped with a H2S scrubber as part of an optional sample conditioning system, inlet pressure

must not exceed 30 psig.

Application Pressure - Atmospheric or Slightly Negative: For accurate ppm range oxygen measurements, an optional

external sampling pump should be positioned downstream of the sensor to draw the sample from the process, by the sensor

and out to atmosphere. A flow meter is generally not necessary to obtain the recommended flow rate with most sampling

pumps.

Caution: If the analyzer is equipped with an optional flow indicator with integral metering valve or a metering flow control

valve upstream of the sensor - open the metering valve completely to avoid drawing a vacuum on the sensor and placing an

undue burden on the pump. If pump loading is a consideration, a second throttle valve on the pump’s inlet side may be

necessary to provide a bypass path so the sample flow rate is within the above parameters.

Recommendations to avoid erroneous oxygen readings and damaging the sensor:

¾ Do not place your finger over the vent (it pressurizes the sensor) to test the flow indicator when gas is flowing to the

sensor. Removing your finger (the restriction) generates a vacuum on the sensor and may damage the sensor (thus voiding

the sensor warranty).

¾ Assure there are no restrictions in the sample or vent lines

¾ Avoid drawing a vacuum that exceeds 14” of water column pressure – unless done gradually

¾ Avoid excessive flow rates above 5 SCFH which generate backpressure on the sensor.

¾ Avoid sudden releases of backpressure that can severely damage the sensor.

¾ Avoid the collection of liquids or particulates on the sensor, they block the diffusion of oxygen into the sensor

¾ If the analyzer is equipped with an optional integral sampling pump (positioned downstream of the sensor) and a flow

control metering valve (positioned upstream of the sensor), completely open the flow control metering valve to avoid

drawing a vacuum on the sensor and placing an undue burden on the pump.

Moisture & Particulates: Installation of a suitable coalescing or particulate filter is required to remove condensation, moisture

and/or particulates from the sample gas to prevent erroneous analysis readings and damage to the sensor or optional

components. Moisture and/or particulates do not necessarily damage the sensor, however, collection on the sensing surface can

block or inhibit the diffusion of sample gas into the sensor resulting in a reduction of sensor signal output – and the appearance

of a sensor failure when in fact the problem is easily remedied by blowing on the front of the sensor. Consult the factory for

recommendations concerning the proper selection and installation of components.

Moisture and/or particulates generally can be removed from the sensor by opening the sensor housing and either blowing on

the sensing surface or gently wiping or brushing the sensing surface with damp cloth.

7

- wipe away.

Page 8

Advanced Instruments Inc.

Mounting: The analyzer is approved for indoor use, outdoor use requires optional enclosures, consult factory. Mount as

recommended by the manufacturer.

Gas Connections: Inlet and outlet vent gas lines for ppm analysis require 1/8” or ¼” stainless steel compression fittings; hard

plastic tubing with a low permeability factor can be used percentage range measurements.

Power: Supply power to the analyzer only as rated by the specification or markings on the analyzer enclosure. The wiring that

connects the analyzer to the power source should be installed in accordance with recognized electrical standards. Ensure that is

properly grounded and meets the requirements for area classification. Never yank wiring to remove it from a terminal

connection. AC powered analog analyzers consume 5 watts, digital analyzers 50 watts without optional heaters. Optional 110V

and 220V heaters AC powered heaters consume an additional 100-150 watts; DC powered digital analyzers consume 30 watts,

40 watts with the optional DC powered heater.

8

Page 9

Advanced Instruments Inc.

4 Features & Specifications

9

Page 10

Advanced Instruments Inc.

10

Page 11

Advanced Instruments Inc.

5 Operation

Principle of Operation

The GPR-2600 ppm Oxygen Analyzers incorporates a a variety of ppm range advanced galvanic fuel cell type sensors and is

configured for panel mounting and requires a 7.5x10.8” (T configuration) cutout with 4 holes for the analyzer’s front panel.

Optional configurations include a panel mount (TO configuration) 7.75x7.75” with cutout; 19” bezel for rack mounting either the

T or TO; 12x12x8” wall mount enclosure (GPR-2600W). Contact the factory for additional information on options. All

configurations are tested and calibrated by the manufacturer prior to shipment. The GPR-2600 analyzers and sensors are CE

certified and manufactured under a Quality Assurance System certified by an independent agency to ISO 9001:2000 standards.

Advanced Galvanic Sensor Technology

The sensors function on the same principle and are specific for oxygen. They measure the partial pressure of oxygen from low

ppm to 100% levels in inert gases, gaseous hydrocarbons, helium, hydrogen, mixed gases, acid gas streams and ambient air.

Oxygen, the fuel for this electrochemical transducer, diffusing into the sensor reacts chemically at the sensing electrode to

produce an electrical current output proportional to the oxygen concentration in the gas phase. The sensor’s signal output is

linear over all ranges and remains virtually constant over its useful life. The sensor requires no maintenance and is easily and

safely replaced at the end of its useful life.

Proprietary advancements in design and chemistry add significant advantages to an extremely versatile oxygen sensing

technology. Extending the expected life of our new generation of percentage range sensors now range to five and ten years

with faster response times and greater stability. Another significant development involves the first galvanic oxygen sensor

capability of continuous oxygen purity measurements and expanding the operating temperature range from -40°C to 50°C,

excellent compatibility with CO

competition.

Oxygen, the fuel for this electrochemical transducer, reacts chemically at the sensing electrode to produce an electrical current

output proportional to the oxygen concentration in the gas phase. The sensor’s signal output is linear over all four ranges and

remains virtually constant over its useful life. The sensor requires no maintenance or electrolyte addition and is easily and safely

replaced at the end of its useful life.

and acid gases (XLT series) and reliable quality giving them a significant advantage over the

2

11

Page 12

Advanced Instruments Inc.

Electronics

The signal generated by the sensor is processed by state of the art low power micro-processor based digital circuitry. The first

stage amplifies the signal. The second stage eliminates the low frequency noise. The third stage employs a high frequency filter

and compensates for signal output variations caused by ambient temperature changes. The result is a very stable signal.

Sample oxygen is analyzed very accurately. Response time of 90% of full scale is less than 10 seconds (actual experience may

vary due to the integrity of sample line connections, dead volume and flow rate selected) on all ranges under ambient

monitoring conditions. Sensitivity is typically 0.5% of full scale low range.

Additional features of the micro-processor based electronics include manual or auto ranging, auto-zero and auto-cal, isolated 420mA signal for signal output and range ID, separate relay contacts rated 30VDC max @ 1A are provided for the alarm feature

and an optional range ID feature (auto-zero/auto-cal with relay contacts for Range ID is special order, so . Whenever the

analyzer is calibrated, a unique algorithm predicts and displays a message indicating a ‘weak sensor’ suggesting the sensor be

replaced in the near future.

Sample System

The sample must be properly presented to the sensor to ensure an accurate measurement. In standard form the GPR-2600 is

designed with a sample system that enables the user to control the flow rate via a flow meter positioned upstream of the

sensor. The sensor is exposed to sample gas that must flow or be drawn through the analyzer’s internal sample system.

Advanced Instruments Inc. offers a full line of sample handling, conditioning and expertise to meet your application

requirements. Contact us at 909-392-6900 or e-mail us at info@aii1.com

12

Page 13

Advanced Instruments Inc.

Accuracy Overview

Single Point Calibration: As previously described

the galvanic oxygen sensor generates an electrical

current proportional to the oxygen concentration in

the sample gas. In the absence of oxygen the sensor

exhibits an absolute zero, e.g. the sensor does not

generate a current output in the absence of oxygen.

Given these linearity and absolute zero properties,

single point calibration is possible.

Pressure: Because sensors are sensitive to the

partial pressure of oxygen in the sample gas their

output is a function of the number of molecules of

oxygen 'per unit volume'. Readouts in percent are

permissible only when the total pressure of the

sample gas being analyzed remains constant. The

pressure of the sample gas and that of the calibration

gas(es) must be the same (reality < 1-2 psi).

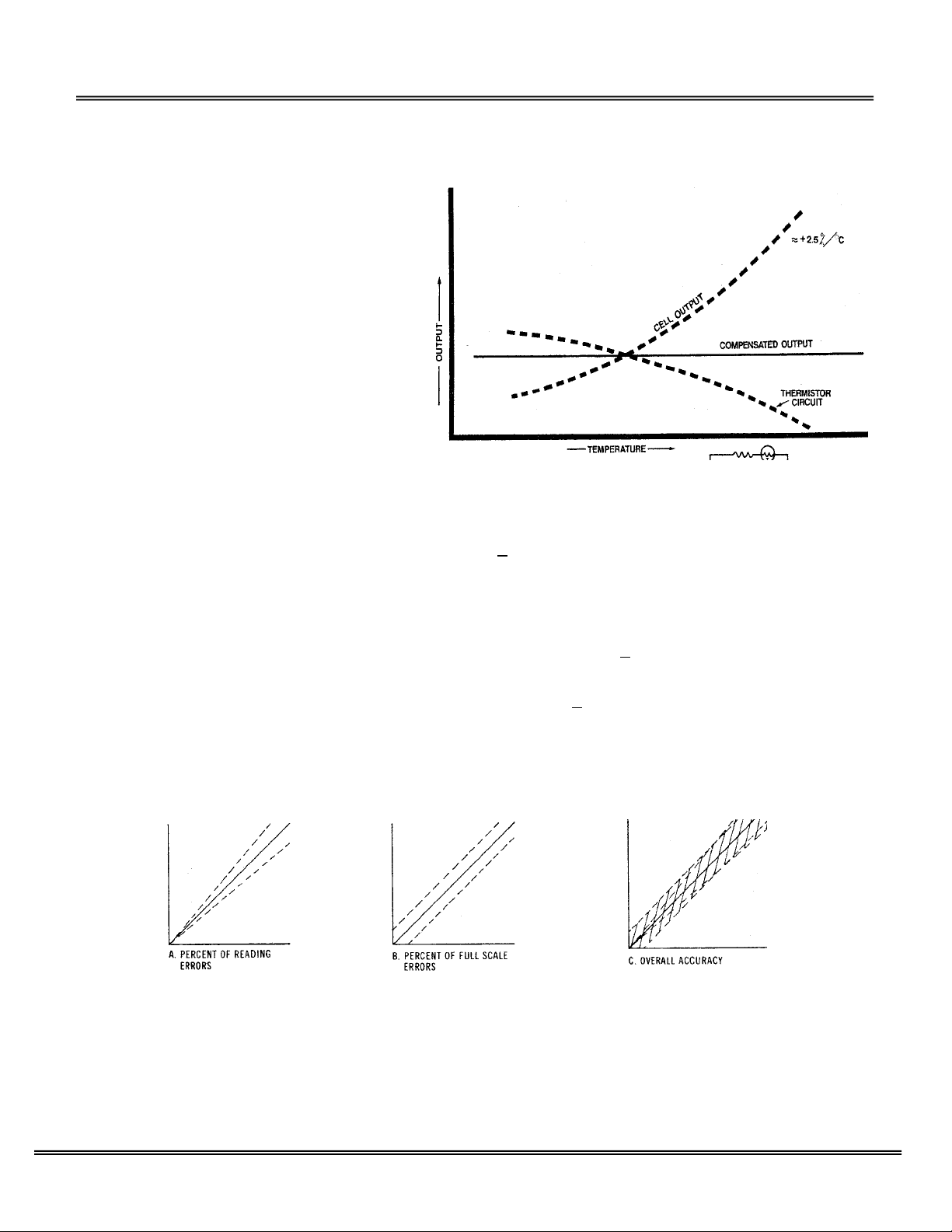

Temperature: The rate oxygen molecules diffuse into the sensor is controlled by a Teflon membrane otherwise known as an

'oxygen diffusion limiting barrier' and all diffusion processes are temperature sensitive, the fact the sensor's electrical output

will vary with temperature is normal. This variation is relatively constant 2.5% per ºC. A temperature compensation circuit

employing a thermistor offsets this effect with an accuracy of +

independent of temperature. There is no error if the calibration and sampling are performed at the same temperature or if the

measurement is made immediately after calibration. Lastly, small temperature variations of 10-15º produce < 1% error.

Accuracy:

1) those producing 'percent of reading errors', illustrated by Graph A below, such as +

tolerances of range resistors and the 'play' in the potentiometer used to make span adjustments and

2) those producing 'percent of full scale errors', illustrated by Graph B, such as +

are really minimal due to today's technology and the fact that other errors are 'spanned out' during calibration.

Graph C illustrates these 'worse case' specifications that are typically used to develop an analyzer's overall accuracy statement

of < 1% of full scale at constant temperature or < 5% over the operating temperature range. QC testing is typically < 0.5%

prior to shipment.

Example 1: As illustrated by Graph A any error, play in the multi-turn span pot or the temperature compensation circuit,

during a span adjustment at 20.9% (air) of full scale range would be multiplied by a factor of 4.78 (100/20.9) if used for

measurements of 95-100% oxygen concentrations. Conversely, an error during a span adjustment at 100% of full scale range is

reduced proportionately for measurements of lower oxygen concentrations.

Refer to the Calibration section for additional details.

In light of the above parameters, the overall accuracy of an analyzer is affected by two types of errors:

5% or better and generates an output function that is

5% temperature compensation circuit,

1-2% linearity errors in readout devices, which

13

Page 14

Advanced Instruments Inc.

Mounting the Analyzer

The standard GPR-2600 is designed to be panel mounted and requires a cutout that accommodates the enclosure and 4

mounting bolts. The design also lends itself to 19” rack mounting with an optional bezel or wall mount enclosures as illustrated

below.

Procedure:

1. The GPR-2600 is designed for panel mounting directly to any flat vertical surface, wall or bulkhead plate with the

appropriate cut out and four ¼” diameter holes for insertion of the mounting studs located on the back side of the front

panel.

2. When mounting the analyzer position it approximately 5 feet off the floor for viewing purposes and allow sufficient room for

access to the terminal connections at the rear of the enclosure.

3. Note: The proximity of the analyzer to the sample point and use of optional sample conditioning components have an

impact on sample lag time.

Mounting GPR-2600:

14

Page 15

Mounting GPR-2600-W Option:

Advanced Instruments Inc.

15

Page 16

Advanced Instruments Inc.

Gas Connections

The GPR-2600 with its standard flow through configuration is designed for positive pressure samples

and requires connections for incoming sample and outgoing vent lines, see illustrations above.

The user is responsible for calibration gases and the components described below. Flow rates of 1-5

SCFH cause no appreciable change in the oxygen reading. A flow valve upstream (flow indicator

downstream) of the sensor is recommended as a means of controlling the flow rate of the sample

gas. A flow rate of 2 SCFH is recommended for optimum performance.

Caution: Do not place your finger over the fitting designated as the vent (it pressurizes the sensor)

or to test the flow indicator when gas is flowing to the sensor. Removing your finger (the restriction)

generates a vacuum on the sensor and may damage the sensor (voiding the sensor warranty).

Procedure:

1. Caution: Do not change the factory setting until instructed.

2. Regulate the pressure and flow as described in Pressure & Flow above.

3. Install the sample out or vent line connection to the 1/8” dia. fitting labeled SAMPLE VENT.

4. Install the incoming sample or span gas line to the 1/8” dia. fitting labeled SAMPLE IN.

5. Set the flow rate to 1 SCFH (open the flow control valve completely if using an external sampling pump positioned

downstream of the sensor).

6. Allow gas to flow through the analyzer for 3-5 minutes and proceed to Calibration or Sampling.

16

Page 17

Advanced Instruments Inc.

Electrical Connections:

Incoming power for the 100-250V AC powered analyzers is supplied through a universal power entry module. A standard

computer type power cord (P/N A-1008) is required for the universal power entry module. A well grounded insulated power

cable is recommended to avoid noise resulting from unwanted interference.

The appropriate AC power supply (110V or 220V) must specified be specified at order placement if the analyzer is to be

equipped with proper the temperature control heater system.

Power consumption is approximately 150-200 watts with the temperature control heater system and 30 watts without.

Caution: Integral 4-20mA converters are internally powered and do not require external power. DO NOT supply any voltage to

any of the terminals for 4-20mA signal output and range ID or the 4-20mA converters will be damaged.

Caution: To assure proper grounding, connect the 4-20mA signal output to the external device (PLC, DCS, etc.) before

attempting any zero or span adjustments.

Optional Range ID:

The standard 4-20mA output used for range identification, as described below, can be replaced by eliminating the alarms

feature and using the relay contacts associated with the alarms to provide a single common and four (4) normally open relay

contacts that close when the related range is active. The dry contacts are rated at 30VDC @ 1A and powering them is not

required if the PLC can distinguish contact closure via continuity check.

17

Page 18

Advanced Instruments Inc.

Procedure:

1. As illustrated above the sensor, power and alarm relays and signal output connections are hard wired to screw type

terminal blocks located at the rear of the analyzer.

2. Use a small bladed screwdriver to loosen the appropriate terminal screws as illustrated above.

3. Strip the wires of the cable no more than 3/16 inch.

4. To connect to an active relay or “fail safe”, connect the live cable to the common terminal C and the secondary cable to the

normally open NO terminal.

5. To break the connection upon relay activation, connect the secondary cable to the normally closed NC terminal.

6. Insert the stripped end of the cables into the appropriate terminal slots assuring no bare wire remains exposed that could

come in contact with the back panel of the analyzer enclosure.

7. Tighten the terminal screws to secure the wires of the cable.

Danger: While connecting the cables to the relay terminals, ensure there is no voltage on the cables to prevent electric shock

and possible damage to the analyzer. Caution: Assure the stripped wire ends of the cable are fully inserted into the terminal

slots and do not touch each other or the back panel of the analyzer enclosure.

Interconnections for the optional wall mount enclosure pictured below.

18

Page 19

Advanced Instruments Inc.

Alarms

The analyzer is configured with two user adjustable threshold type alarm relays that can be configured in the field from the

ALARM option on the MAIN MENU as follows:

¾ Establish independent set points

¾ Either Hi or Lo

¾ Either On or Off (enabled or disabled)

¾ Both temporarily defeated using a user entered ‘timeout’ period (normally minutes)

The alarm set point represents a value. When the oxygen reading exceeds (high alarm) or falls below (low alarm) the alarm set

point, the relay is activated and the LCD displays the alarm condition.

When activated the alarms trigger SPDT Form C non-latching relays @ 5A, 30VDC or 240VAC resistive. To prevent chattering of

the relays, a 2% hysteresis is added to the alarm set point. This means that the alarm will remain active until the oxygen

reading has fallen 2% below the alarm set point (high alarm) or risen 2% above the alarm set point (low alarm) after the alarm

was activated. The timeout feature is useful while replacing the oxygen sensor or during calibration when the oxygen reading

might well rise above the alarm set point and trigger a false alarm.

Note: When making connections the user must decide whether to configure/connect Alarm 1 and Alarm 2 in failsafe mode

(Normally Open – NO – where the alarm relay de-energizes and closes in an alarm condition) or non-failsafe mode (Normally

Closed – NC – where alarm relay energizes and opens in an alarm condition).

Power Failure Alarm

A dry contact rated at 30VDC @ 1A is provided as a power failure alarm that activates when power supplied to the analyzer’s

circuits is unacceptable. The contact is normally closed but opens when the power to the analyzer is switched off or interrupted

and cannot be disabled.

4-20mA Signal Output

The analyzer provides a 4-20mA full scale fully isolated ground signals for external recording devices. The integral IC on the

main PCB provides 4-20mA fully isolated signals for output and range ID. The 4-20mA current output is obtained by connecting

the current measuring device between the positive and negative terminals labeled OUTPUT 4-20mA. To check the signal output

of the 4-20mA E/I integrated circuit connect an ammeter as the measuring device and confirm the output is within +

4mA. A finer adjustment of the zero offset of the 4-20mA converter can be provided by a potentiometer mounted on the main

PCB Assembly. Consult factory for instructions

Range ID

For range ID the output of 4mA, 8mA, 12mA, 16mA, 20mA correspond to the most sensitive to least sensitive analysis range.

The standard 4-20mA output used for range indentification, as described below, can be replaced by eliminating the alarms

feature and using the relay contacts associated with the alarms to provide a single common and four (4) normally open relay

contacts that close when the related range is active. The dry contacts are rated at 30VDC @ 1A and powering them is optional

as some PLCs can distinguish contact closure via continuity check.

Caution:

voltage to any of the two terminals of the 4-20mA converter.

The integral 4-20mA converters are internally powered and do not require external power. DO NOT supply any

0.1mA of

19

Page 20

Advanced Instruments Inc.

Optional - Temperature Controlled Heater System with Runaway Protection Circuit

The standard GPR-2600 Series analyzer is not equipped with the heater system. However, in anticipation of very low ppm (high

ppb) oxygen analysis, the user may elect to add the heater system. If the analyzer is equipped with an optional temperature

controlled heater system, open the front door of the analyzer to access it. This unit is a PID controller which operates between

0-99°F. The controller is programmed to maintain the temperature at 85°F.

Caution: Do not change this setting. A higher temperature

setting may drastically reduce sensor life and possibly cause

damage to the electronic circuitry of both the controller and the

analyzer.

Warning:

the temperature controller is ON.

When power is applied to the temperature controller, the controller

tunes itself to eliminate and/or minimize the over/under shoot of

temperature from the set point. It is recommended that at initial

start-up, when replacing the oxygen sensor or when trouble

shooting, turn off the power to the heater or set the temperature

set point at 60°F (to turn the heater off) to prevent overheating

the analyzer. When operating the analyzer under normal

conditions, set the temperature controller at 85⁰F.

Pictured with optional stainless steel sensor housing

Changing the display value from °F to °C:

1. Push the UP ARROW and ENTER buttons down for 5 seconds to access the SECURE MENU

2. Press INDEX to advance to the F-C MENU

3. Select °C or °F by pressing the UP ARROW key

4. Press the ENTER key when F-C starts flashing on the display

5. Press INDEX to exit the SECURE MENU

Heater Runaway Protection

Part of the optional temperature controlled heater system is a heater runaway protection circuit that protects the electronics in

the event the temperature controller should fail and thereby allowing the heater to runaway damaging the components inside

the analyzer.

The runaway protection is provided by a J2 type device positioned between the temperature controller and the heater. This

device cuts-off power to the heater if the temperature inside the analyzer exceeds 70°C. Should the J2 device cut power to the

heater, correct the problem and reset the runaway protector device by exposing it to 0°C for a few minutes (a refrigerator

freezer will do).

Keep the front door securely fastened and closed when

20

Page 21

Advanced Instruments Inc.

Span Gas Preparation

The analyzer must be calibrated periodically. See the Calibration section below for recommendations. Caution: Do not

contaminate the span gas cylinder when connecting the regulator. Bleed the air filled regulator (faster and more reliable than

simply flowing the span gas) before attempting the initial calibration of the instrument.

Required components:

¾ Certified span gas cylinder with an oxygen concentration, balance nitrogen, approximating 80% of the full scale range

above the intended measuring range.

¾ Regulator to reduce pressure to 30 psig.

¾ Flow meter to set the flow between 1 SCFH,

¾ Suitable fittings and 1/8” dia. 4-6 ft. in length of metal tubing to connect the regulator to the flow meter inlet

¾ Suitable fitting and 1/8” dia. 4-6 ft. in length of metal tubing to connect from the flow meter vent to tube fitting designated

SAMPLE IN on the GPR-2600.

Procedure:

1. With the span gas cylinder valve closed, install the regulator on the cylinder.

2. Open the regulator’s exit valve and partially open the pressure regulator’s control knob.

3. Open slightly the cylinder valve.

4. Loosen the nut connecting the regulator to the cylinder and bleed the pressure regulator.

5. Retighten the nut connecting the regulator to the cylinder

6. Adjust the regulator exit valve and slowly bleed the pressure regulator.

7. Open the cylinder valve completely.

8. Set the pressure between 5-30 psig using the pressure regulator’s control knob.

9. Caution: Do not exceed the recommended flow rate. Excessive flow rate could cause the backpressure on the sensor

and may result in erroneous readings and permanent damage to the sensor.

Establishing Power to the Electronics:

Once the power to the electronics is established, the digital display responds instantaneously. When power is applied, the

analyzer performs several diagnostic system status checks termed “SYSTEM SELF TEST” as illustrated below:

System Self Test

CPU

Memory

RTC

Analog

GPR Series Oxygen Analyzer

Software Version X.XX

Advanced Instruments

2855 Metropolitan Place

Pomona, CA 91767

Tel: 909-392-6900

Fax: 909-392-3665

e-mail: info@aii1.com

OK

OK

OK

OK

21

Page 22

Advanced Instruments Inc.

After 3 seconds the system defaults to the STANDBY mode and the LCD displays the following:

* MAIN MENU

Sample

Span

Zero

Alarm

System

Standby

Auto Range

85⁰F 100Kpa

Standby

12/31/07 12:00:00

Menu Format

Menu displayed – displayed on the top line in the upper left corner of the display.

Menu options available - displayed in the upper left corner of the display under the current menu on the top line.

Menu option selected - indicated by the cursor (*) positioned to the left of the menu option selected.

System mode - indicated at the top center of the display.

Range mode and current auto or fixed manual range - displayed on the first line at the bottom of the display.

Temperature inside the analyzer and ambient pressure - displayed on the second line at the bottom of the display.

Note:

In the event power to the analyzer is interrupted, the system defaults to the “Standby” mode when power is

restored. To resume sampling, advance the cursor (*) to “Sample” mode, press ENTER to select and select the

range mode as described below.

Menu Navigation

The four (4) pushbuttons located on the front of the analyzer control the system’s micro-processor:

1. Green - ENTER (select)

2. Yellow UP ARROW – advance cursor up

3. Yellow DOWN ARROW – advance cursor down

4. Red – ESC (menu)

Select menu option by advancing cursor (*) by repeatedly pressing the yellow UP/DOWN ARROW keys.

Accept the menu option selected with cursor (*) by pressing the green ENTER key.

Abort the menu option selected with cursor (*) and return to the previous menu by pressing the red ESC key.

Note: If a selection is not made within 30 seconds, the system returns to the MAIN MENU.

22

Page 23

Advanced Instruments Inc.

Range Mode Selection

Advance the cursor (*) to the “Sample” option as illustrated and press the green ENTER key to accept the selection.

MAIN MENU

* Sample

Span

Zero

Alarm

System

Standby

Auto Range

85⁰F 100Kpa

The following menu appears:

* SAMPLE

Auto Range

Manual Range

Bypass

Standby

Auto Range

85⁰F 100Kpa

The analyzer is equipped with five (5) standard measuring ranges (see specification) and provides users with a choice of

sampling modes. By accessing the MAIN MENU, users may select either the Auto Range or a fixed Manual Range) mode.

Note: For calibration purposes, use of the Auto Range mode is recommended. However, the user can select a fixed Manual

Range (full scale) as dictated by the oxygen content of the calibration gas.

Standby

12/31/07 12:00:00

Standby

12/31/07 12:00:00

23

Page 24

Advanced Instruments Inc.

Auto Range Sampling

The display will shift to the next higher range when the oxygen reading exceeds 99.9% of the current range. The display will

shift to the next lower range when the oxygen reading drops to 85% of the next lower range.

For example, if the analyzer is reading 1 ppm on the 0-10 ppm range and an upset occurs, the display will shift to the 0-100

ppm range when the oxygen reading exceeds 9.99 ppm. Conversely, once the upset condition is corrected, the display will shift

back to the 0-10 ppm range when the oxygen reading drops to 8.5 ppm.

Procedure: From the SAMPLE menu, advance the cursor (*) to the “Auto Range” option and press ENTER:

SAMPLE

* Auto Range

Manual Range

Bypass

Standby

Auto Range

85⁰F 100Kpa

Note: To provide for the possibility of an optional automated sample system, the system displays the message “Opening

Sample Valves” at this time. This message does not apply to analyzers equipped with the standard manually operated

sample system.

Similarly, the Bypass and Standby options do not apply to analyzers equipped with manual sample systems.

Within seconds the system assesses the oxygen concentration, selects the appropriate range (as described above) and returns

to the MAIN MENU in the “Sample” mode. On the top line at the bottom of the menu, the Auto Range mode is indicated as is

the current full scale range.

* MAIN MENU

Sample

Span

Zero

Alarm

System

Standby

Auto Range

85⁰F 100Kpa

Standby

12/31/07 12:00:00

Sample

5.00 %

0 to 10 %

12/31/07 12:00:00

24

Page 25

Advanced Instruments Inc.

Manual Range Sampling

The display will not shift automatically. Instead, when the oxygen reading exceeds 125% of the upper limit of the current range

an OVER RANGE warning will be displayed. Once the OVER RANGE warning appears the user must advance the analyzer to the

next higher range.

Procedure: From the SAMPLE menu, advance the cursor (*) to the “Manual Range” option and press ENTER:

SAMPLE

Auto Range

* Manual Range

Bypass

Standby

Auto Range

85⁰F 100Kpa

The following display appears:

MANUAL RANGE

0 to 25%

0 to 1%

0 to 1000 PPM

0 to 100 PPM

* 0 to 10 PPM

Auto Range

85⁰F 100Kpa

Advance the cursor (*) to the desired fixed manual range, e.g. 0 to 10 ppm and press ENTER.

Within seconds the system assesses the oxygen concentration and returns to the MAIN MENU in the “Sample” mode. On the top

line at the bottom of the menu, the Manual Range mode is indicated as is the fixed full scale range selected.

Standby

12/31/07 12:00:00

Standby

12/31/07 12:00:00

* MAIN MENU

Sample

Span

Zero

Alarm

System

Standby

Manual Range

85⁰F 100Kpa

Sample

5.00 %

0 to 10 %

12/31/07 12:00:00

25

Page 26

Advanced Instruments Inc.

If the oxygen reading exceeds 99.9% of the full scale fixed range manually selected, the system displays the following:

* MAIN MENU

Sample

Span

Zero

Alarm

System

Standby

Manual Range

85⁰F 100Kpa

Sample

5.00 %

OVER RANGE

0 to 10 %

12/31/07 12:00:00

Alarms

The analyzer is configured with two user adjustable threshold type alarm relays that can be configured in the field from the

ALARM option on the MAIN MENU as follows:

¾ Establish independent set points

¾ Either Hi or Lo

¾ Either On or Off (enabled or disabled)

¾ Both temporarily defeated using a user entered ‘timeout’ period (normally minutes)

The alarm set point represents a value. When the oxygen reading exceeds (high alarm) or falls below (low alarm) the alarm set

point, the relay is activated and the LCD displays the alarm condition.

When activated the alarms trigger SPDT Form C non-latching relays @ 5A, 30VDC or 240VAC resistive. To prevent chattering of

the relays, a 2% hysteresis is added to the alarm set point. This means that the alarm will remain active until the oxygen

reading has fallen 2% below the alarm set point (high alarm) or risen 2% above the alarm set point (low alarm) after the alarm

was activated. The timeout feature is useful while replacing the oxygen sensor or during calibration when the oxygen reading

might well rise above the alarm set point and trigger a false alarm.

Note: When making connections the user must decide whether to configure/connect Alarm 1 and Alarm 2 in failsafe mode

(Normally Open – NO – where the alarm relay de-energizes and closes in an alarm condition) or non-failsafe mode (Normally

Closed – NC – where alarm relay energizes and opens in an alarm condition).

Procedure: Advance the cursor (*) to the “Alarm” option and press the green ENTER key to accept the selection.

MAIN MENU

Sample

Span

Zero

* Alarm

System

Standby

Auto Range

85⁰F 100Kpa

Sample

5.00 %

0 to 10 %

12/31/07 12:00:00

26

Page 27

Advanced Instruments Inc.

The following menu appears:

ALARM Sample

* Set Alarm 1

Set Alarm 2

Alarm 1 HI

Alarm 2 HI

Alarm 1 ON

Alarm 2 ON

Alarm Timeout

Auto Range 0 to 10 %

85⁰F 100Kpa 12/31/07 12:00:00

Advance the cursor (*) to the “Set Alarm 1” option and press the green ENTER key to accept the selection.

The following menu appears:

Sample

20%

Press UP or DOWN

to change value

ENTER to Save

ESC to Return

Auto Range 0 to 10 %

85⁰F 100Kpa 12/31/07 12:00:00

Follow the prompt above and press the ENTER key to save the alarm value (% full scale) or ESC to return to the MAIN MENU.

Within a few seconds after pressing the ENTER key, the system returns to the MAIN MENU.

Repeat the above steps for “Set Alarm 2”.

Configure Alarm 1 and Alarm 2 by advancing the cursor (*) to the desired feature as illustrated below.

ALARM Sample

Set Alarm 1

Set Alarm 2

* Alarm 1 HI / LO

* Alarm 2 HI / LO

* Alarm 1 ON / OFF

* Alarm 2 ON / OFF

Alarm Timeout

Auto Range 0 to 10 %

85⁰F 100Kpa 12/31/07 12:00:00

Press the ENTER key to toggle between the settings: HI and LO and/or ON and OFF.

After toggling, the system returns to the MAIN MENU. To confirm selection, re-access the ALARM menu above.

27

Page 28

Advanced Instruments Inc.

Advance the cursor (*) to the “Alarm” option and press the green ENTER key to accept the selection.

MAIN MENU

Sample

Span

Zero

* Alarm

System

Standby

Auto Range

85⁰F 100Kpa

The following menu appears:

ALARM Sample

Set Alarm 1

Set Alarm 2

Alarm 1 HI

Alarm 2 HI

Alarm 1 ON

Alarm 2 ON

* Alarm Timeout

Auto Range 0 to 10 %

85⁰F 100Kpa 12/31/07 12:00:00

Advance the cursor (*) to the “Alarm Timeout” option and press the green ENTER key to accept the selection.

The following menu appears:

Sample

5.00 %

0 to 10 %

12/31/07 12:00:00

Sample

20 Minutes

Press UP or DOWN

to change value

ENTER to Save

ESC to Return

Auto Range 0 to 10 %

85⁰F 100Kpa 12/31/07 12:00:00

Follow the prompt above and press the ENTER key to save the alarm timeout value or ESC to return to the MAIN MENU.

Within a few seconds after pressing the ENTER key, the system returns to the MAIN MENU.

28

Page 29

Advanced Instruments Inc.

System Menu

The analyzer is equipped with a wide range of features that enables users to enhance performance and tailor their interface

with the analyzer. The SYSTEM menu shown below lists the features available and is followed by a description of each function.

Most of the functions are initiated by toggling between options using the ENTER key as previously described.

Advance the cursor (*) to the “Alarm” option and press the green ENTER key to accept the selection.

MAIN MENU

Sample

Span

Zero

Alarm

* System

Standby

Auto Range

85⁰F 100Kpa

The following menu appears:

* SYSTEM

Enable Low Flow Alarm

Disable Alarm During Cal

Signal Average

Range

Logging Interval

Temp Coefficient

View Data Graph

Set Clock (and Date)

Logging ON

Show Text

Display Negative (Reading) ON

Advance the cursor (*) to the desired option and press follow the instructions below.

Enable Low Flow Alarm If the analyzer is equipped with a low flow alarm, press ENTER key to toggle between

Disable Alarm During Cal Press ENTER key to toggle between ENABLE and DISABLE.

Signal Average Press ENTER key to select and choose Low, Medium (default) or High – functions allows

Range Same as Manual Range option found on SAMPLE menu.

Logging Interval Press ENTER key and a display appears similar to Alarm Timeout above for the user to

Temp Coefficient Not operable at this time.

Sample

5.00 %

0 to 10 %

12/31/07 12:00:00

ENABLE and DISABLE.

users to select their preference regarding the trade-off of response time vs. noise

filtering.

enter the interval in minutes for capturing data points for logging purposes.

29

Page 30

Advanced Instruments Inc.

View Data Graph Provided “Logging” feature below is toggled ON, selecting this feature provides a

fullscreen display or graph of the data points.

Set Clock (and Date) Selecting this option generates a display for selecting Time or Date with each followed

by a detailed display for setting hour, minute, second or year, month, day.

Logging Press ENTER key to toggle between ON and OFF.

Show Text Press ENTER key to toggle between MAIN MENU display options:

1.) Menu text with large numbers (as illustrated herein)

2.) Menu text with small numbers and a small graph of O2 reading.

Display Negative (Reading) Press the ENTER key to toggle between ON and OFF.

Installation & Start-up is now complete . . .

30

Page 31

Advanced Instruments Inc.

Calibration

The electrochemical oxygen sensors manufactured by Analytical Industries Inc. (dba Advanced Instruments) generate an

electrical current that is linear or proportional to the oxygen concentration in the sample gas. In the absence of oxygen the

sensor exhibits an absolute zero, e.g. the sensor does not generate a current output in the absence of oxygen. Given the

properties of linearity and an absolute zero, single point calibration is possible.

As described below, zero calibration is recommended only when the application (or user) demands optimum accuracy for

analysis below 5% of the most sensitive or lowest range available on the analyzer. Span calibration in one of the forms

described below is sufficient for all other measurements. When employed zero calibration should precede span calibration.

Zero Calibration

Despite the absolute zero inherent in electrochemical oxygen sensors, the reality is that analyzers display an oxygen reading

when sampling a zero gas due to:

¾ Contamination or quality of the zero gas

¾ Minor leakage in the sample line connections

¾ Residual oxygen dissolved in the sensor’s electrolyte

¾ Tolerances of the electronic components

The zero capability (low end sensitivity) of every analyzer is qualified prior to shipment. However, because the factory sample

system conditions differ from that of the user, no ZERO OFFSET adjustment is made to the analyzer by the factory

Span Calibration

Involves periodically, see Intervals section below, checking and/or adjusting the electronics to the sensor’s signal output at a

given oxygen standard or span. Maximum drift from calibration temperature is approximately 0.11% of reading per °C. The

frequency of calibration varies with the application conditions (potential for contamination), the degree of accuracy required by

the application and the quality requirements of the user. However, the interval between span calibrations should not exceed

three (3) months.

Note: Regardless of the oxygen concentration of the standard used, the span calibration process takes approximately 10

minutes, however, the time required to bring a ppm analyzer back on-line can vary, see Online Recovery Time below.

Considerations

When it comes to the calibration of oxygen analyzers utilizing an electrochemical oxygen sensor circumstances vary widely from

the ideal conditions that exist at the factory to a variety of differing circumstances users encounter in the field. The following

describes the most common factors and reasons that they influence the calibration procedures.

Factor Reasons

Intervals:

Conditions:

Analysis Level Required:

All electrochemical sensor based analyzers require periodic, e.g. weekly intervals to a 3

month maximum, calibration to ensure accuracy and ascertain whether the sensor has been

contaminated or otherwise damaged while in service.

Calibrate at the temperature and pressure of the sample.

Continuous analysis below 5% of the most sensitive or lowest range available:

ZERO CALIBRATION followed by SPAN CALIBRATION with good quality gases is

recommended (for optimum accuracy) when:

- the analyzer and/or O2 sensor is initially installed,

- the sample system connections are modified,

- the O2 sensor is replaced.

Note: It is not necessary to repeat the ZERO CALIBRATION with subsequent periodic

SPAN CALIBRATION unless desired or one of the above events occurs.

All other analysis: SPAN CALIBRATION is sufficient. Procedure varies with factors.

31

Page 32

Zero Calibration Offset

Adjustment Capability:

Type of Analyzer:

Online Recovery Time:

Advanced Instruments Inc.

Designed to facilitate precise analysis below 5% of the most sensitive or lowest range

available on the analyzer, this feature enables users’ to compensate for background offsets,

as defined above, of up to 50% of the most sensitive or lowest full scale range available on

the analyzer and bring analyzers online faster.

As described below, accomplishing either objective places a degree of responsibility on the

user. Determining the true offset requires the user to wait, see Online Recovery Time

section, until the analyzer reading is no longer trending downward (best evidenced by a

constant horizontal trend on an external recording device). Bringing the analyzer online

faster, basically the same as choosing not to wait for the stable horizontal trend reading,

requires the user to repeat the ZERO CALIBRATION function. The frequency of which is at

the user’s discretion, hourly is recommended but at least when the reading goes negative.

Advanced Instruments’ oxygen analyzers are capable of zero offset adjustments of 50% of

the most sensitive or lowest range available on the analyzer. Since every analyzer is QC

tested to 1% of the most sensitive or lowest range available, exercise CAUTION when

initiating the ZERO CALIBRATION function at 50% (prematurely) of the most sensitive or

lowest range available on the analyzer. If the anticipated O2 analysis level is less than the

offset value or if adequate time is not allowed for the analyzer to establish the true offset,

the analyzer will in all probability display a negative reading.

Note: From the SYSTEM menu option “Display Negative (Reading)” users can toggle

between ON and OFF choose by pressing the ENTER key and control whether

analyzer displays negative readings.

Online ppb or ppm process analyzers: Analysis below 5% of the most sensitive or

lowest range is normally limited to these analyzers. However, such analysis is possible with

portable analyzers from Advanced Instruments due to their 60 day duty cycle and/or ability

to operate during battery charging.

Portable analyzers: Typically used intermittently moving between different sample

points/systems for trend analysis above 5% of the most sensitive range and, therefore, they

fall into the “all other analysis” category requiring only span calibration.

Percentage analyzers: Generally used above 5% of the most sensitive range and,

therefore, fall into the “all other analysis” category requiring only span calibration.

The priority users place on getting or keeping an analyzer online is “the” most significant

factor involved in calibration and troubleshooting issues. The time it takes an analyzer to

come down to a specific level after exposure to high O2 concentrations or air is significantly

different if a sensor is being installed than if the sensor had been in-service at low oxygen

levels for more than 1 week.

Sensor Calibration at Install In-service Calibration

% Fuel Cell

The above times assume the introduction of a purge gas, the lower of the available zero or

sample (if known and constant) gas, with a ppm level O2 concentration less than 0.5 ppm is

introduced to the analyzer following span calibration to purge (accelerate the reaction of)

the O2 that has dissolved into the electrolyte inside the sensor. If zero gas is not available,

substitute the sample gas and expect slightly longer recovery time.

Air to .1% < 1 min

Air to .05% < 3 min

Air to < .01% < 1-2 hrs

32

Similar

Page 33

Span Gas Selection:

Type of Sensor:

Span Gas vs. Air

(Fuel Cell Sensors only):

Span Calibration

Adjustments:

Advanced Instruments Inc.

The O2 concentration of a span gas should approximate 70-90% of the full scale range

dictated by the span gas, e.g. 20.9% O2 on the 0-25% range. For optimum accuracy, the

full scale range dictated by the span gas should be at least one range higher than the

intended analysis range. Both of the aforementioned recommendations reduce the error

induced by the tolerance of the electronic components; also, span gases with higher O2

concentrations are more reliable and less expensive.

Conversely, if the recommended span gas is not available and air calibration is not an

option, a span gas of the same full scale range and near the anticipated analysis level

(approximately 10% of full scale) is acceptable with the understanding the accuracy will

suffer slightly.

Use of span gas near 10% of the same full scale range for measurements at the higher end

of the range has the effect of “expanding the error” by moving upscale as illustrated by

Graph A and Example 1 in the Accuracy section above and is not recommended. Of course

the user can always elect at his discretion to accept an accuracy error of +

range if no other span gas is available.

Galvanic Fuel Cell Sensors: Analyzers utilizing these sensors can be calibrated with

ambient air (20.9% or 209,000 ppm O2) and have been proven capable of precise analysis

below 0.5 ppm (500 ppb).

Note: As described above, these oxygen sensors are capable of one point calibration.

Span gas calibration: Recommended for calibration of in-service analyzers, if the priority

is the fastest online recovery time.

Air calibration: Recommended for calibration an analyzer if a new oxygen sensor is being

installed or if the availability of span gas, the cost of span gas or the accuracy of a span gas

is an issue. An air calibrated analyzer can be used to reliably verify a “certified” span gas,

which has frequently been found to be inaccurate. For best results, select a recognized

name supplier.

Note: Galvanic Fuel Cell sensors can be calibrated (using air) and brought online (using

sample gas) without “purchased calibration gases” and without sacrificing accuracy provided the analyzer is given enough time to come down to the O2 concentration of the

sample gas.

Prematurely initiating the SPAN CALIBRATION function (when there is no intention of

performing a ZERO CALIBRATION) before the analyzer reading has stabilized can result in

erroneous readings as follows:

When purging an analyzer to lower ranges for span gas calibration: If the oxygen

reading reaches less than 2% of the intended calibration range, enter the value of the span

gas. If the oxygen reading is greater than 2% of the calibration range, add the O2 reading

to the value of the span gas (the impact of the offset on accuracy is minor but the addition

allows the oxygen sensor to continue to purge down and avoid negative readings).

Note: If ZERO CALIBRATION has been performed or the analyzer has been in service, the

analyzer reading should already be stable and below 2% of the calibration range.

When installing a new oxygen sensor and calibrating with air: Allow 5-10 minutes

for the sensor to equilibrate in ambient air from storage packaging. Failure to do so can

introduce a positive offset (electronic gain) that prevents the analyzer from displaying low

ppm O2 readings.

33

2-3% of full scale

Page 34

Advanced Instruments Inc.

Menu Functions – Zero Calibration

Factory Default Zero: The system eliminates any previous zero calibration offset adjustment stored in

memory and displays the unadjusted oxygen reading of the gas currently flowing

through the analyzer.

This function is recommended before performing a manual ZERO CALIBRATION or

when troubleshooting an analyzer. This function is not recommended for subsequent

periodic SPAN CALIBRATION - see Analysis Level Required above.

Auto Zero: Applicable only to analyzers equipped with an optional automated sample system. The

system automatically closes the sample inlet valve and opens the zero inlet valve at a

predetermined interval in time, see System Menu section above. It also trends the

downward slope of the oxygen reading. When the slope of the oxygen reading trend

approaches the factory set value, the system initiates a ZERO CALIBRATION offset

adjustment and displays an oxygen reading of 0.000 or 00.00 ppm.

Manual Zero: Recommended for optimum accuracy. The user must ascertain that the oxygen reading

has reached a stable value, see Zero Calibration Offset Adjustment Capability above,

below 50% of the most sensitive or lowest range available on the analyzer before the

system will accept and make a ZERO CALIBRATION offset adjustment.

If the user attempts to initiate the ZERO CALIBRATION function while the oxygen

reading is above 50% of the most sensitive or lowest range, the system displays the

message “CALIBRATION FAILED” and returns to the “Sample” mode.

Timed Zero Cal: Subtitle only, this function represented by the following menu options are applicable

only to analyzers equipped with an optional automated sample system.

Timed Zero Cal in ___ days:

Calibration will occur at ____: Requires the user to enter a “military time in hours and minutes” representing the time

Menu Functions – Span Calibration

Factory Default Span: The system eliminates any previous span calibration adjustment stored in memory and

Span Gas Units/Value:

Requires the user to enter a “number” representing the interval in days before the next

ZERO CALIBRATION.

of day at which the next ZERO CALIBRATION will be initiated.

displays an oxygen reading +

analyzer.

If the oxygen reading is outside +

message “CALIBRATION FAILED” and returns to the “Sample” mode. This feature

allows the user to test the sensor’s signal output without removing it from the sensor

housing.

This function is recommended before performing a SPAN CALIBRATION or when

troubleshooting an analyzer.

After initiating either Auto or Manual Span from the SPAN CALIBRATION menu, the

system produces a display prompting the user to select span gas in ppb, ppm or %

units, which is followed by a second display prompting the user to enter a numerical

span gas value.

50% of the span gas value currently flowing through the

50% of the span gas value, the system displays the

34

Page 35

Advanced Instruments Inc.

Auto Span: Applicable only to analyzers equipped with an optional automated sample system. The

system automatically closes the sample inlet valve and opens the span inlet valve at a

predetermined interval in time, see System Menu section above. It also trends the

downward slope of the oxygen reading vs. time curve. When the slope of the oxygen

reading reaches “0”, the system initiates a SPAN CALIBRATION adjustment and

displays an oxygen reading corresponding to the span gas value entered.

Manual Span: The user must ascertain that the oxygen reading has reached a stable value, see Span

Calibration Adjustment above, before the system will accept and make a SPAN

CALIBRATION adjustment.

Timed Span Cal: Subtitle only, this function represented by the following menu options are applicable

only to analyzers equipped with an optional automated sample system.

Timed Span Cal in ___ days: Requires the user to enter a “number” representing the interval in days before the next

SPAN CALIBRATION.

Calibration will occur at ____: Requires the user to enter a “military time in hours and minutes” representing the time

of day at which the next SPAN CALIBRATION will be initiated.

Timed Span Gas Value:

Procedure – Zero Calibration

Note: Not necessary and thus not recommended for most percentage range measurements see Analysis Level Required section

above.

The analyzer is online in the Auto Range mode as described above.

Review the Analysis Level Required, Online Recovery Time, Zero Calibration Offset Adjustment and Menu Functions – Zero

Calibration above before proceeding.

Assure there are no restrictions in vent line.

Regulate the pressure between 5-30 psig and set the flow rate to 2 SCFH for Fuel Cell sensors.

Allow the analyzer reading to stabilize below 50% of the most sensitive or lowest range available on the analyzer.

Advance the cursor (*) to the “Zero” option as illustrated and press the green ENTER key to accept the selection.

MAIN MENU

Sample

Span

* Zero

Alarm

System

Standby

Auto Range

85⁰F 100Kpa

The following menu appears:

Displays the numerical span gas value and units entered when the Auto Span option

was initiated.

Sample

0.500 %

0 to 1 %

12/31/07 12:00:00

35

Page 36

Advanced Instruments Inc.

ZERO Sample

* Factory Default

Calibrate

Auto Range 0 to 1 %

85⁰F 100Kpa 12/31/07 12:00:00

Advance the cursor (*) to the Factory Default Zero option and press ENTER.

Within seconds the system returns to the MAIN MENU in the “Sample” mode.

MAIN MENU

Sample

Span

* Zero

Alarm

System

Standby

Auto Range

85⁰F 100Kpa

Advance the cursor (*) to the “Zero” option and press the green ENTER key to accept the selection.

The following menu appears:

ZERO Sample

Factory Default

* Calibrate

Auto Range 0 to 1 %

85⁰F 100Kpa 12/31/07 12:00:00

Advance the cursor (*) to the “Manual Zero” option and press the green ENTER key to accept the selection.

The following menu appears:

Sample

0.500 %

0 to 1 %

12/31/07 12:00:00

36

Page 37

Advanced Instruments Inc.

CALIBRATION

IN PROGRESS . . .

0.500 %

After the oxygen reading has stabilized, press ENTER to complete the Zero Calibration. If the user attempts to initiate the ZERO

CALIBRATION function while the oxygen reading is above 50% of the most sensitive or lowest range, the system displays the

message “CALIBRATION FAILED” and returns to the “Sample” mode.

CALIBRATION

FAILED

CALIBRATION

COMPLETE

37

Page 38

Advanced Instruments Inc.

Procedure – Span Calibration

The analyzer is online in the Auto Range mode as described above.

Review the Intervals, Online Recovery Time, Span Gas Selection, Type of Sensor, Span Calibration Adjustment and Menu

sections above, before proceeding.

Allow the analyzer reading to stabilize, Advance the cursor (*) to the “Span” option as illustrated and press the green ENTER

key to accept the selection.

MAIN MENU

Sample

* Span

Zero

Alarm

System

Standby

Auto Range

85⁰F 100Kpa

The following menu appears:

SPAN Sample

* Factory Default

Calibrate

Auto Range 0 to 1 %

85⁰F 100Kpa 12/31/07 12:00:00

Advance the cursor (*) to the Factory Default Span option and press ENTER.

Within seconds the system returns to the MAIN MENU in the “Sample” mode.

Sample

0.500 %

0 to 1 %

12/31/07 12:00:00

MAIN MENU

Sample

* Span

Zero

Alarm

System

Standby

Auto Range

85⁰F 100Kpa

At this point, the user must decide whether to perform a Span Gas or Air Calibration, see above.

Note: If the analyzer is to calibrated with instrument or compressed air follow the Span Gas Calibration procedure below.

Sample

0.500 %

0 to 1 %

12/31/07 12:00:00

38

Page 39

Advanced Instruments Inc.

Span Gas Calibration: Assure there are no restrictions in vent line.

Regulate the pressure between 5-30 psig and set the flow rate to 2 SCFH for Fuel Cell sensors.

Air Calibration –

Standard Sensor

and Flow Housing:

Air Calibration –

Optional Sensor

and Sensor Housing:

Caution: Allow the reading to stabilize before proceeding. A premature SPAN CALIBRATION adjustment can result in erroneous

readings, see the Span Calibration Adjustment section above.

It is highly recommended that the analyzer be connected to an external recording device, if practical, to ensure that the

analyzer reading reaches a stable value (10-20 minutes) before accepting the span calibration.

Advance the cursor (*) to the “Span” option as illustrated and press the green ENTER key to accept the selection.

Access the interior of the analyzer by opening the front door of the analyzer.

With the left hand hold the gas connections of the housing and unscrew the

oxygen sensor from the flow housing with the right hand.

The sensor is now exposed to ambient air, connected to the analyzer

electronics and ready for calibration.

Allow the sample gas to continue to flow if possible, otherwise close the FLOW

valve but do not disconnect the sample gas line.

Access the interior of the analyzer by opening the front door of the

analyzer.

Using the 5/16 wrench supplied loosen but do not remove the clamp bolt

located in the center of the bracket attached to bottom section with the

elbow fittings.

Rotate the upper section of the sensor housing 90º to disengage from the

clamp.

Remove the upper section by pulling it straight

up and let it rest on your 1

With your other hand remove the oxygen sensor,

place it in the upper section of the sensor

housing ensuring the PCB contacts the two gold

pins and use your thumb to hold the sensor and

upper section of the sensor housing together.

The sensor is now exposed to ambient air,

connected to the analyzer electronics and ready

for calibration.

Allow the sample gas to continue to flow if possible, otherwise close the FLOW valve but do not

disconnect the sample gas line.

st

and 2nd fingers.

39

Page 40

Advanced Instruments Inc.

MAIN MENU

Sample

* Span

Zero

Alarm

System

Standby

Auto Range

85⁰F 100Kpa

The following menu appears:

SPAN Sample

Factory Default

* Calibrate

Auto Range 0 to 1 %

85⁰F 100Kpa 12/31/07 12:00:00

Advance the cursor (*) to the “Manual Span” option and press the green ENTER key to accept the selection.

The following menu appears:

Sample

20.5 %

0 to 1 %

12/31/07 12:00:00

SPAN GAS Standby

Enter as PPM

Enter as PPB

* Enter as %

Auto Range 0 to 1 %

85⁰F 100Kpa 12/31/07 12:00:00

Enter span gas units appropriate to the numerical span gas value and press ENTER key.

Note: Select “Enter as %” for air calibration.

40

Page 41

Advanced Instruments Inc.

The following display appears:

Sample

0.90 %

02

Press UP or DOWN keys to change values

Select ENTER to save, ESC to return

Auto Range 0 to 1 %

85⁰F 100Kpa 12/31/07 12:00:00

Press the ENTER key to move the cursor (underscore) to the right to the digit to be changed.

Press the UP or DOWN key until the desired number appears in digit field.

Repeat as necessary to enter the numerical span value.

Press the ENTER key to accept and save the span gas value.

The system then initiates the SPAN CALIBRATION function and the following menu appears:

CALIBRATION

IN PROGRESS . . .