Page 1

ISO 9001:2008, Certificate #485

Copyright © 10/10 All Rights Reserved

Analytical Industries Inc.,

2855 Metropolitan, Pomona, CA 91767 USA.

Tel: 909-392-6900, Fax: 909-392-3665

e-mail: sales-medical@aii1.com, web: www.aii1.com

This manual may not be reproduced in whole or in part without

the prior written consent of Analytical Industries Inc.

AII-3000 AHC

AII-3000 MHC

AII-3000 A

AII-3000 M

Page 2

Table of Contents

1 Introduction 1

1.1 Indications for Use

1.2 Intended Use

1.3 Device Description

2 Quality Control Certification 3

3 Safety Warnings 4

4 Start-up

4.1 Contents of Shipping Container

4.2 Install Batteries

4.3 Install Oxygen Sensor

4.4 Controls

4.5 Start-up Test

4.6 Alarms (AII-3000 M Oxygen Monitor)

4.7 Calibration

4.8 Mounting

5 Operation

5.1 Principle of Operation

5.2 Application Considerations

5.3 Calibration

5.4 Sampling

6 Maintenance

6.1 Service ability

6.2 Battery Replacement

6.3 Oxygen Sensor Replacement

7 Troubleshooting

8 Specifications

8.1 Spare Parts & Accessories

9 Warranty

10 Material Safety Data Sheet (MSDS)

10.1 Disposal

1 Introduction

Congratul a tions o n your p urch ase, t hese Instr ucti o ns fo r Use d escri be th e pr e-

1

2

2

cautions, set-up, operation, maintenance and specifications of the AII-3000

Series Oxygen Analyzers.

This symbol means CAUTION – Failure to read and comply with the

Instructions for Use could damage the device and possibly jeopardize

the well being of the user.

Note: Adva nced Ins trume nts Inc. c annot warra nt any damag e res ulti ng from

the misus e, unauthor ized repair o r imp r o per maintena nce of the device.

1.1 Indications for Use

The AII- 30 00 Seri es Oxygen Analyzers are int en de d to measur e and dis play the

concentration of oxygen in compressed breathing air tanks intended for scuba

diving, for personnel safety, area monitoring, O2 deficiency in confined spaces,

check ing b reathing air tanks and confirming the O2 levels prior to welding.

Users m ust read th e followi ng statements as they ar e essential to reducing the r is k of us e erro r du e to ergo nomi c feat ur es of t he devi ce o r

the environment in which the device is intended to be used.

The devices have been designed and manufactured in such a way that when

used under the conditions and for the purposes intended, they will not compromise the clinical co ndition or t he safety of patients, or safety of the users or

other persons.

Conform ity wi th ess enti al re quir eme nts has been demo nstr ate d by ver if ying th e

perform ance of the device under normal co nditio ns, be nch testi ng and determining that undesirable malfunctions constitute minimal risk to users.

Do not sterilize, autoclave, liquid sterilize, immerse in any liquid or expose the

device or accessories t o st eam, ethylene oxide or radiat ion s t er ilization.

The devic e is inten ded to be re-usabl e. Shoul d the de vice or acc ess ories com e

in conta c t w i t h pat ient bodily f l uids, either di s po se of th e device or c l ean w i t h a

soft cloth dampened with 70% isopropyl alcohol solution in water and allow the

components to air-dry before re-use .

Do not o per ate t he an alyz er ne ar equi pme nt c ap able of em itti n g hi gh le vels of

electromagnetic radiation as the reading may become unstable.

i

1

Page 3

In order to obt ain op ti mum p erforman ce, t he o per ation of the device must be

performed in accordance with th ese Instructions for Us e. Maintenan ce should

be performed only by trained personnel authorized by the manufacturer.

1.2 Intended Use

The AII-3000 Series Oxyge n Analyzers are intended to meas ure and display

the concentration of ox ygen in compressed bre athing air tanks intended for

scuba divi ng, for perso nnel saf ety, ar ea moni toring , O2 defi cienc y in conf ined

spaces, checking breathing air tanks and confirming the O2 levels prior to

welding.

1.3 Device Description

The AII-3000 S eries Oxygen Analyzers can be positioned on a table top or

pole (tri po d wi r e sta nd and V-m o u nt dovetai l attachments ar e m ounted o n t h e

back of the device) and are readily portable from one location to another.

They pro vi de con ti nuous , f ast, rel iabl e a nd ac cur at e oxyg en me asur eme nts of

up to respiratory care systems.

The devices utilize an electrochemical galvanic fuel cell type oxygen sensor of

the type t hat is exte nsivel y used to meas ure o xygen co nce ntratio ns f rom 0%

to 100% in gas streams. O xygen, the fuel f or this electroch emical tr ansducer,

diffus ing into th e sensor thr ough a g as permeabl e membra ne reacts ch emically at the sensi ng electro de to produ ce an elect rical curr ent o utput propo rtional to the ox yg en con ce ntra tio n in the g as p has e. T he s enso r h as an absolute zero meaning that when no oxygen is present to be chemically reacted

the LCD displays 00.0 oxygen.

The sensor’s signal output is linear over the entire range, remains virtually

constant over t he specif ied us eful li fe and dro ps off sharply at the e nd. The

sensor itself requires no maintenance and is simply replaced at the end of its

useful l ife like a ba ttery. In asmuch as t he sensor i s a transdu cer in its own

right, its expected life is not affected by whether the analyzer is ON or OFF.

A batter y pow ered st ate-of -the-ar t mi cro-pro cesso r con verts t he s ensor’ s signal output repr esentin g the partial pr es s ure of ox ygen in t he gas s tream b ei n g

analyzed. The resulting oxygen reading is displayed by a large easy to read

backlit liquid crystal display (LCD) that has a resolution of 0.1% oxygen. The

microprocessor is controlled from a keypad and provides features like system

diagnostics, warning indicators, controls and an alarm capability for continuous monitoring that enhance both safety and effectiveness.

Prior to shipment, every device is thoroughly tested at the factory and documented in the form of a Quality Control Certification that is included in the

Instructions for Use su pplied with ever y device.

2 Quality Control Certification

Customer: ________________________ Order No. _____________ Date: _______

Model: ( ) AII-3000 A Oxygen Analyzer

Sensor: ( ) AII-11-60 or ( ) AII-11-60-HC S/N _______________

Electronics: A-1162 PCB Assembly Main Software Version _______________

Accessories: AII-3000 A / M:

PASS

QC Test: LCD display 3-1/2 digits ……………………………………………………. ______

Battery symbol displays when battery is low ……………………….. ______

Span adjustment +

Following calibration with 99-100% oxygen and flushing with

Span adjustment +

Following calibration with air (20.9% oxygen) and exposing

Qty

Options:

See Sec 8.1 ____________________________________________________ _____

____________________________________________________ _____

____________________________________________________ _____

Delivery: ____________________________________________________

( ) AII-3000 M Oxygen Analyzer

( ) AII-3000 AHC Oxygen Analyzer

( ) AII-3000 MHC Oxygen Analyzer S/N _______________

AII-3000 AHC / MHC: A-3675 Adapter, 5/32” Tube to Sensor

TUBE-1019 7/32” OD Tubing 3 ft.

All units: BATT-1008 Battery, 1.5V AA (Qty 2)

P-0187 Manual, Instructions for Use ……… Included ______

ambient air, oxygen reading as displayed by LCD 20.9% +

to 99-100% oxygen, LCD displays 100% +

Overall inspection for physical defects ………………………………... ______

CABL-1006 Cable, Coiled Phone Jack

10-30% FS with 100% oxygen calibration ______

2% ____

10-30% FS with air calibration ……………….. ______

2% ……………………. ______

_____________________________________________ ____

____________________________________________________

____

2

3

Page 4

3 Safety Warnings

ALWAYS foll ow the s tatem ents bel ow as t hey ar e ess ential to red ucing the ri s k o f us e err o r due to er gonomi c f eatures of t h e de vi ce or the

environment in which t he device is intended to be use d.

Only trained personnel who have read, understand and agree to follow

the Instructions for Use should operate the device.

Retain the Instructions for Use for future reference.

Refer service needs to trained authorized personnel. Failure to do so may

cause the dev ice to fail and vo id the warran ty .

Inspect the device and accessories before operating and ensure: (a)

there is no evi de nc e of ph ysical dam age; (b) the se nso r ( parti c ularl y t he

sensing s urf ace) a nd el ectrical connecti ons ar e dry; a nd, ( c) the sensor i s

installed and upstream from any humidifying device for accurate calibration and oxygen readings.

Calibrate: (a) with a known source of air or dry 100% oxygen before

using ea ch day or after 8 hour s of conti nuous use; (b) when t he temperature or pressure of the operating environment changes; (c) if the

oxygen sensor has been disconnected and reconnected; (d) after the

battery or oxygen sensor has been replace.

Sampling flowing gas: (a) install the optional flow diverter and tee-

adapter in a vertical position as shown in Section 4.3 and (b) assure

there is a tight fit between the flow diverter and tee adapter.

Sampling static, ambient or controlled atmospheres remove the flow

diverter.

Clean the device and accessories in accordance with Section 6.1.2.

Battery replacement Section 6.2: ( a) replace t he batteries within tw enty-

four (2 4) ho urs of the bat tery symbol appearin g on LC D di s p lay

calibrate the analyzer after repla cing the batter ies.

Oxygen sensor installation or replacement Section 6.3: allow the new

sensor to stabilize for 15-20 minutes in ambient air before attempting to

calibrate.

Store th e de vice b y turni ng t he power O FF an d rem ovin g t he ba tteri es if

the device will not be operat ed for over thir ty (30) days.

Attempt to repeat the procedure that caused a perceived malfunction

and refer to troubleshooting hints in Section 7 before concluding the

device is faulty. If in doubt, contact the manufacturer for assistance.

and (b)

NEVER o perate the d evice in any m anner des cribed belo w doing so

may compromise the clinical condition or the safety of patients, users

or other persons.

If the reading is unstable or a malfunc tion is suspect ed.

After the battery symbol appears in the LCD display.

Near eq uipment capable of emitting high lev els of el ectromag netic radia-

tion (EMI) or radio frequency interference (RFI).

Expose the device; particularly the LCD display or sensor to sources of

extreme heat, cold or excessive sunlight beyond the device’s storage tempe rature range, re fer to S ection 8 for extende d p eriods of ti me.

In a gas stream with a vacuum greater than 14” water column.

Immerse the device, oxygen sensor or coiled cable in any liquid.

Outside of the parameters specified in Section 8 particularly at flow rates

greater t han 10 l iters per minute - t he bac kpressure generat ed produc es

erroneously high oxygen readings.

Calibrate: (a) with 20.9% oxygen or room air with the intent of taking

oxygen measurements at oxyg en levels above 30% oxygen; (b) in a humidified gas stream or atmosphere; (c) without allowing a newly installed

sensor to sta bilize for 15 -20 minutes in ambient air.

Attempt to sterilize, autoclave, liquid sterilize, immerse in any liquid or

expose the device or accessories to steam, ethylene oxide or radiation

sterilization.

In the presence of fl am m abl e gas es .

Open t he main c ompar tme nt of th e devic e, ex cept to c hang e the in tegral

oxygen sensor of the AII-3000 AHC or AII-3000 MHC Oxygen Analyzers.

Open the oxygen sensor or pro be th e s e nsing s urface, r efer to Section 10

in the event the sensor should leak and someo ne comes in co ntact with

the electrolyte from inside the sensor.

Operate with a cable that appears worn, torn o r cracked, or, allow an

excess length of cable nea r t he patie nt’s he ad or neck ; secure it to the bed

rail or ot her suitable object to avoid the possibility of strangulation.

Allow the device or ox ygen sensor to be serviced, repaire d or altered by

anyone except trained personnel – failure to do so may endanger the

patient or damage the device rendering the warranty null and void.

4

5

Page 5

4 Start-Up

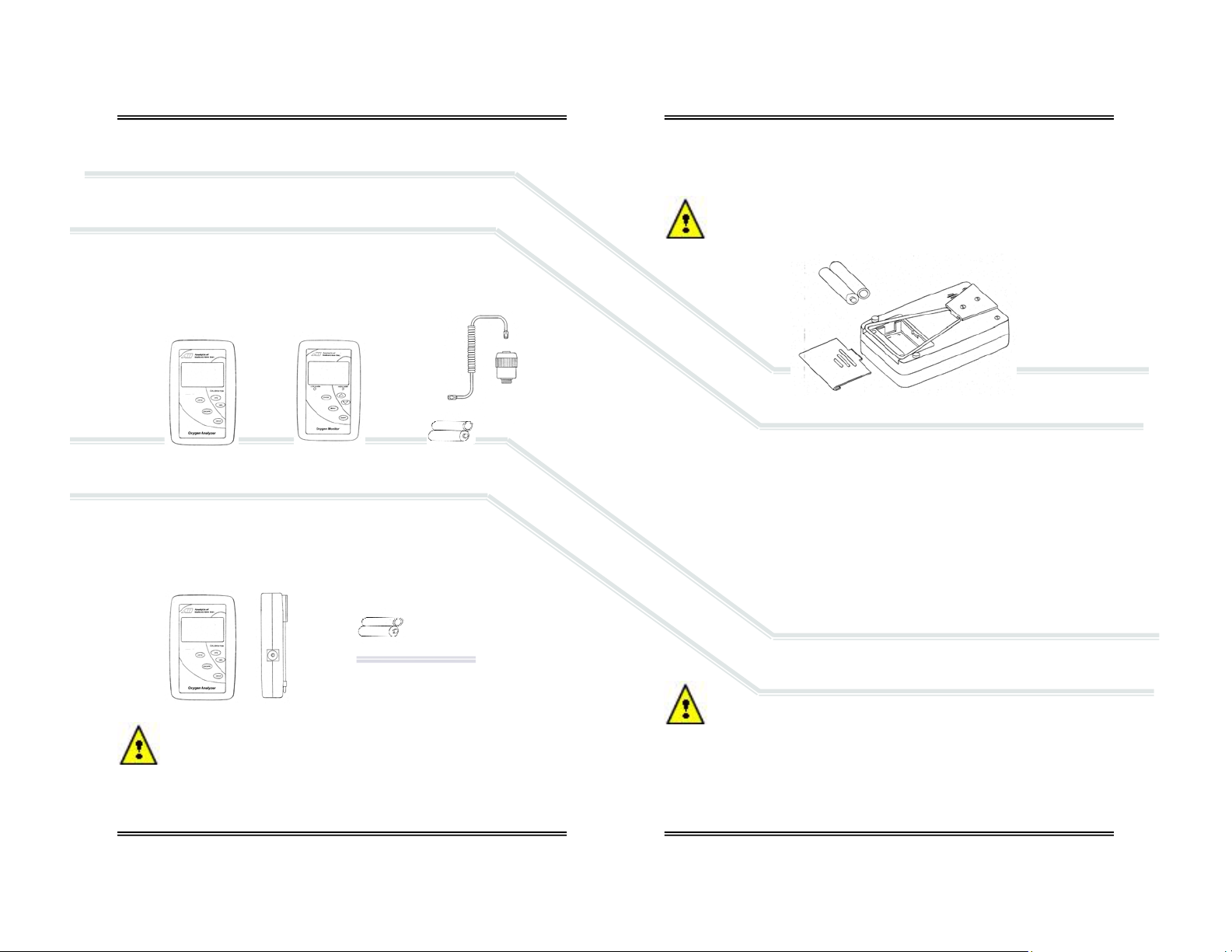

4.1 Contents of Shipp ing Containe r:

4.1.1 AII-3000 A, AII-3000 M:

ENCL-1061 V-mount retainer (attached)

ENCL-1066 Tripod wire stand (attached)

AII-11-60 Oxygen Sensor

BATT-1008 Battery, AA 1.5V Alkaline (Qty 2)

CABL-1006 Cable, Coiled Phone Jack

P-1087 Instructions for Use

4.1.1 AII-3000 AHC, AII-3000 MHC:

ENCL-1061 V-mount retainer (attached)

ENCL-1066 Tripod wire stand (attached)

AII-11-60-HC Oxygen Sensor (installed inside analyzer)

BATT-1008 Battery, AA 1.5V Alkaline (Qty 2)

TUBE-1019 Tubing, 7/32” OD Tubing 3 ft.

P-1087 Instructions for Use

Inspect t he box and cont ents for shippi ng damage. If t he device or

compone nts app ear dam age d, do not a ttem pt to oper ate t he devi ce -

contact the manufacturer immediately, refer to section 9.

OR

AND

AND

4.2 Install Batteries

All devices are powered by two 1.5V AA alkaline batteries which must be installed before the device can be operated.

The battery compartment is located at the rear of all devices. Initially

this proc edure c an be som ewhat dif ficult. C are sho uld be take n not to

damage the case when removing the battery compartment cover.

4.2.1 Procedure:

1. Remove the device and the (2) AA 1.5V Alkaline batteries from the foam

shipping container.

2. Turn t he devi ce over so the shortest raised line on the batt ery co mpartment cover is pointing away from you.

3. Lift the tripod wire stand up and away from the case.

4. Grasp the c ase wit h both hands, use y our thum bs pres s dow n firm ly on

the raised lines and push the battery compartment cover away from you.

5. Locate the positive (+) and negative (-) terminals on the battery.

6. Assure the battery contacts are clean.

7. Ali gn one batt ery’s posi tive (+) termin al with t he corr espondin g (+) battery sy mbo l m o lded into the cas e.

8. Insert the battery into the compartment.

9. Repeat with the remaining battery.

10. Replace the battery compartm ent cover, make sure it snaps into p osition

and is secured flush against the case. Replace the wire stand as required.

Replac e the bat teri es w ithi n t we nty- four (24) ho ur s of th e batt ery sym bol appearing on LCD display because batteries decline at different

rates. Calibrate the device afte r rep lacing the bat te r ies.

6

7

Page 6

4.3 Install Oxygen Sensor

The device cannot function until the oxygen sensor is installed. Once installed,

allow the sensor to stabilize for 15-20 minutes in ambient air before attempting to calibr ate the device.

NEVER - Attempt to open, repair or service the oxygen sensor.

Refer to Sect ion 3 f or hi nts an d warni ngs co ncer nin g th e han dli ng an d

environmental considerations of the oxygen sensor and the device.

4.3.1 AII-3000 A/M:

1. Remov e the contents from the shipping conta iner as shown in section 4.1

and check for damage .

2. The coiled cable uses a common RJ11 phone jack at both ends, making a

bad connection impossible.

3. Inst all the sensor awa y from any humidifyin g device to pr event moi sture

from condensing on the sensing surface and assure accurate calibration

and oxygen readings.

4. Connect one end of the cable to the device in the same manner you

would co nnect a t elephon e. Simply f i n d and re gi s t er the male pl ug at the

end of the coiled cable and insert it into the mating female jack on the

side of the device.

5. Connect the other end of the cable to the sensor in the same manner.

6. For diffusion sampling of static, ambient or controlled atmospheres –

simply expose the oxygen sensor to the atmosphere to be sampled.

7. For sampling breathing circuits with flowing gas, position the sensor

vertically for optimum results. Avoid letting the gas stagnate and facilitates the flow of g as across t he sensing ar ea of t he sensor to produ ce a

more accurate measurement of the gas stream to be measured.

8. Install the tee-adap ter in the breathing circuit.

9. Screw the flow diverter to the sensor.

10. Ensure the o-ring is lightly lubricated for ease of entry and a tight seal

between the flow diverter and tee adapter.

11. Insert the assembled flow diverter/sensor into the tee allowing air or

100% oxygen (dry, no n-humidif ied) to f low p ast t he se nsor at a r at e l ess

than 10 liters per minute.

4.3.2 AII-3000 AHC/ MHC:

When the HC (hose connection) version is ordered, the device is shipped with

the sensor installed.

4.4 Controls

4.4.1 AII-3000 A/AHC Oxygen Analyzers

These analyzers employ a micro-processor that is controlled by five (5)

pushbuttons located on the keypad attached to front cover.

1. ON/OFF provides power to the electronics

2. ESCAPE abo r ts a previous selected option

3. ENTER se lects a menu op tion

4. 100% initi ates t he routine for CA LIBRATI ON with 100 % oxygen. T he sensor must be exposed to 100% oxygen.

5. 21% initiates the routine for CALIBRATION with air or 21% oxygen. The

sensor must be exposed to air or 21% oxygen.

4.4.2 AII 3000 M/MHC Oxyge n A nalyzers

The mo nitor emplo ys a menu drive n micr o-proces sor that i s cont rol led by five

(5) pushbuttons located on the keypad attached to front cover.

1. ON/OFF provides power to the electronics

2. MENU accesses the MAIN MENU

3. ENTER s elects a menu option, and, en ables the user to si l en ce the a udi bl e

alarm quickl y wit hout havi n g to navigate through the menu(s)

4. DOWN ARROW scrolls down the menu options

5. UP ARROW sc rolls up the menu op tions

Note: The monitor is equipped with visual and audible HIGH and LOW

(minimum set point of 15%) alarms which are controlled through the MAIN

MENU a nd are activat ed when the ox ygen val ue is 0. 1% b elow the LO alarm

set point or 0.1% above the HI alarm set point, refer to section 4.6 below.

4.4.3 Instructions and Warnings displayed by LCD

START-UP TEST – diagnostic tests of the electronics, alarm circuit

(monitors only), battery voltage and the sensor’s signal output.

SERVICE DEVICE – non-sensor failures during the start-up test.

CHECK SAMPLE GAS, CHECK CA BLE, CHECK SENSOR – sensor fails the

start-up test or becomes disconnected during operation, or if an alarms is

activated (monitor).

SAMPLING – oxygen concentration from 0-100% in the sample gas during

the normal operation.

BAT LOW – battery voltage is not adequate, replace batteries.

ALARM SET POINTS, CONDITION (set point reverses color and red LED

indicator turns on) for monitor only.

8

9

Page 7

4.5 Start-Up Test

Press the ON/OFF key o n the front panel to apply power to th e device and

initiate a complete diagnostic test of all system functions: the electronics,

feeds voltage and tests the alarm circuit (monitor only below right) internally,

confirms the battery voltage is ad equate to power the circuit, and, the sensor’s signal output is within specifications.

START-UP TEST

ELECTRONICS - PASS

ALARMS - N/A

BATTERY - PASS

SENSOR - PASS

Following successful Start-Up Test the devices default to the SAMPLING mode.

20.9 %

SAMPLING

With the exception of the ALARMS for the AII-3000 M/MHC (above left) the

tests and resulting displays are the same.

Note: Any START-UP TEST failure requires the user to take corrective

action before continuing or attempting to use any device.

4.5.1 Electronics, Alarms (AII-3000 M/MHC) o r Ba t t e ry Failure

If any of these START-UP TESTs ar e unsuccess ful, the follow ing display instructs th e user to SE RVIC E DEVIC E. The f oll owing di splay i s the same f or all

models.

ELECTRONICS - FAILED

SENSOR - FAILED LOW

20.9 %

LO 15% HI 50%

START-UP TEST

ALARMS - FAILED

BATTERY - FAILED

SERVICE DEVICE

START-UP TEST

ELECTRONICS - PASS

ALARMS - PASS

BATTERY - PASS

SENSOR - PASS

SAMPLING

4.5.2 Sensor Failure

Sensor failure can result from multiple causes; the user’s failure to connect a

sensor or sensor cable, a defectiv e sensor cable or a sensor with an output

outside specification.

SENSOR - FA ILED LOW is one of the po ss ible unsucces s ful START-UP TESTs as

illustrated previo usly and displays additional warning s as follows .

4.5.2.1 AII-3000 A/AHC Oxyge n A nalyzers

The LCD alternately displays the fo llo wing until the problem is corrected.

Corrective action:

1. Expose the sensor to air or a gas containing approximately 20.9% oxygen

2. Connect or replace the cable connecting the sensor to the analyzer

3. Connect or replace the oxygen sensor

4.5.2.2 AII-3000 M/MHC Oxygen Analyzers

Perform s th e sam e rou ti ne an d requi r es th e sam e cor r ectiv e acti on as th e analyzers above with additional indicators related to the monitor’s alarm feature.

In addition to the alternating LCD display, the LO ALARM becomes active and:

0.0 %

ALARM

0.0 %

ALARM

LO 15% HI 50%

CHECK SAMP LE GAS

CHECK SAMP LE GAS

LO 15% HI 50%

CHECK CABLE

CHECK SEN SO R

ALARM

CHECK CABLE

CHECK SEN SO R

ALARM

LO ALARM value and background alternately reverse colors on the LCD

RED LED bel o w th e LO ALARM value light s up and begins fl as hing

Audible alarm begins beeping

The audible alarm can be disabled for two (2) minutes (unlimited times) by:

1. Press the MENU key on th e fr ont panel

2. Press the UP/DOWN arrow to select ALARMS AUDIBLE

3. Press the ENTER key to toggle to ALARMS SILENT mode

10

11

Page 8

4.6 Alarms AII-3000 M/M HC Ox yg e n A nalyzers

The monitor is equipped with user selectable HI and LO alarm set points

which are displayed at th e bottom of the LCD. The default alarm set points

are 15% LO an d 50% HI. The L O alarm set point c an be set betw een 15%

and 99% and the HI alarm set point can be set between 16% and 100%.

Alarm s et points may be adj usted in 1% i ncrements by pressing a nd holding

the UP/ D OWN A R ROW keys, see below . T he A RROW k e ys are dis abl ed wh en

the alarm set points are within 1% of e ac h other to pre ve nt the HI a larm f rom

being set below th e LO alarm. T he HI alar m may be disable d by atte m pti ng t o

select a HI alarm set point above 100% to facilitate flushing patients after

anesthe s ia. In this mode the LCD continua lly displays HI O FF.

The AII-3000 M/MHC Ox ygen Analyzers are equip ped with four (4) indicators

that activate when oxygen conc entrations are 0.1% below the LO alarm set

point or 0.1% above the HI alarm set point.

1. LCD alternat es between the ALA RM mode with an oxy gen reading 0.0%

and reco mm endation as illus trated in sections 4.5.2.1 and 4.5. 2.2

2. Alarm value and background alternately reverse color on LCD

3. Red LED below the alarm value lights up and begins flashing

4. Audible alarm begins beeping

4.6.1 Setting Alarm Set Points

1. Fr om the SA MPLING mode pr ess MENU

to display the MAIN MENU

2. Press the UP/DOWN arrow keys to

highlight SET ALARMS

3. Press ENTER to select SET ALARMS

4. LO alarm value is highlig hted by default

5. Press ENTER to skip the LO alarm (and

proceed to t he HI alarm) or pres s the

UP/DOWN arrow keys to change the

alarm set point

6. Press ENTER to save LO alarm set point

and move to select the HI alarm

7. Pres s ENTE R to s kip t he HI al arm ( and

return to SAMPLING mode) or press the

UP/DOWN arrow keys to change the

alarm set point

8. Press ENTER to save HI alarm set point

and return to SAMPLING mode

9. If no key is pressed within 5 seconds,

the LCD returns to the SAMPLING mode

20.9 %

SAMPLING

LO 15% HI 50%

MAIN MENU

CALIBRATE

SET ALARMS

ALARMS AUDI BL E

LO 15% HI 50%

SET LOW/HIGH ALARM

USE UP/DOWN ARROWS

TO ADJUST VALUE

TO SKIP - PRESS ENTER

LO 15% HI 50%

4.7 Calibration

Electro chem ical oxy ge n s ensors ge ner at e sli ghtl y di ff erent sign al out puts under

identical conditions due to variations in the thickness of the sensing membrane

and manufac turing process.

Simulate the application for optimum accuracy: Review Sections 3

Safety Warnings and 5.2 Application Considerations before proceeding.

The de vices are d esigned to meet th e requireme nts for bo th ambi ent

and el evated oxyge n measurements b ut should NEVER be calibrated

with air or 21% oxygen with the intent of taking oxygen me asurements

at oxyge n levels above 30% oxygen.

Accordin gly, the d evices may be calibr ated with ei ther air (20.9%) or

100% oxygen which r equires the user to m ake a conscious decision to

bypass or skip the recommended 100% oxygen calibration.

Set-Up:

AII-3000 A and AII-3000 M refer to section 5.4.1 Flowing Gas

Streams or 5.4.2 Static Atmospheres (shown with optional flow

diverter and tee).

AII-3000 AHC and AII-3000 MHC refer to section 5.4.3.

12

13

Page 9

Procedure

AII-300 0 Ser ies O xy gen A nal yz ers em plo y th e id entic al cali bra tion r o utine and

displays but they differ slightly in the way they arrive at the display that initiates calibration routine. Refer to Set-Up illustration and references above for

gas connections.

1. AII-3000 A/AHC - Press the 21% key under

the word CALIBRATION on the front panel.

1a. AII-3000 M/MHC - Requires navigating its menu to reach the

display that initiates the calib ra t ion routine .

a. From the SAMPLING menu, press

MENU to display the MAIN MENU

b. Press the UP/DOWN arrow keys to

highlight CALIBRATE

c. Press ENTER to select CALIBRATE (the

four (4) alarm indicators are disabled

during the calibration routine)

Both of the above produce the following display which initiates the

calibration routine.

3. The above prompt remains on the display until:

a. The operator presses ENTER to proceed or

b. The ESCAPE key on the AII-3000 A / A HC or the MENU key on the

AII-3000 M/MHC to abort and return to the SAMPLING mode.

4. Expose the sensor to a known source of fresh ambient air or certified 21%

(dry, non-humidified) oxygen nitrogen mix bu t not the oxygen enriched

room air commonly found in hospitals.

5. Once a suitab le calibra t ion gas is intro-

duced, press ENTER to initiate calibration

as displayed right and disable the key

pad (to prevent the calibration routine

from being interrupted).

6. This display appears for sixty (60) seconds

to allow the sensor to s tabilize before

the microprocessor takes the final reading.

20.9 %

INTRODUCE AIR/21% OXYGEN

OBSERVE TREND

PRESS ENTER TO CAL

14

LO 15% HI 50%

MAIN MENU

CALIBRATE

SET ALARMS

ALARMS AUDI BL E

20.9 %

AIR CALIBRATION

IN PROCESS

7. If the calibration is successfu l, the display below left appea r s fo r

three (3) seconds before defaulting to the display below right:

20.9 %

8. The display above right requires a decision by the user (refer to

warnings at the beginning of section 4.7) to press ENTER and

skip the 100% O2 calibration and return to the SAMPLING mode;

or, wait ten (10) se conds for the following display:

9. Repeat steps #3 through #6 using a certified source of 100% oxygen.

10. If the calibration is successful, the display

at right appears for five (5) seconds before

defaulting to the SAMPLING mode.

Calibration Fails

An unsuccessful calibration can be caused by

several problems as displayed at right:

If after three (3) unsuccessful attempts to

calibrate: review section 7 for poss ible causes

and corrective action or co ntact Advance d Instruments Inc. at 909-392-6900.

To abort the RETRY press ESCAPE (analyzer) or MENU (monitor). Do

not proceed until the ana lyzer is calibration successfully.

AIR CALIBRATION

SUCCESSFUL

20.9 %

INTRODUCE 100% O2

OBSERVE TREND

PRESS ENTER TO CAL

15

TO SKIP 100% O2 CAL

PRESS ENTER

FOR 100% O2 CAL

WAIT FOR NEXT

DISPLAY

100 %

OXYGEN CALIBRATION

SUCCESSFUL

AIR / 100% O2 CALIBRATION

FAILED

- CHECK CAL GAS

- CHECK CABLE

- CHECK SENSOR

RETRY - PRESS ENTER

Page 10

4.8 Mounting

Every analyzer and monitor is equipped with a male dove tail bracket and

triangular shaped th ick metal wire s tand secured to the rear of the enclo s ure.

Tripod W i re Stand

Secured b etwe en b ump er f eet o n eith er s id e o f t he b atter y com part m ent i s a

triangular shaped thick metal wire stand that is hinged under the dove tail

bracket secured at the opposite end of enclosure.

Unsnap the triangular thick metal wire stand from between the bumper feet

and pull it away from the enclo s ure to form a tripod which allows the dev ice to

sit upright on any flat surface

Dove Tail Bracket

The male dove t ail bracket is s ecured to th e rear of the enclosure with two

screws. The 1” female dove tail pole bracket (HRWR-1075) is an optional accessory that is commonly found in medical applications. The v-shaped male

componen t simply slide s into and out of the pole mounted female section.

5 Operation

5.1 Principle of Operati on

The AII-3000 Series Oxygen A nalyzers utilize an electrochemical galvanic fuel

cell type oxygen sensor of the type that is extensively used to measure oxygen

concentrations from 0% to 100% in gas streams. Oxygen, the fuel for this

electro chemical tra nsduc er, di ffus ing i nto t he s ensor t hrou gh a gas p ermeabl e

membra ne react s chemi cally a t the s ensing electrod e to produce an elec trical

current output pr oportio nal to the ox ygen concentration in t he gas phase. T he

sensor has an absolute zero meaning that when no oxygen is present to be

chemically reacted th e LCD displays 00 .0 oxygen.

The sens o r’ s s i gnal o utput i s l i near over the e nti r e r a nge, r em ai ns vi rt ual l y constant over th e specified us ef ul li fe and drops of f s harpl y at the end. Th e sensor

itself re quires no mainte nance and is simply r eplaced at the end of its useful life

like a battery. Inasmuch as the sensor is a transducer in its own right, its expected life is not affected by whether the analyzer is ON or OFF.

The relationship between the sensor’s signal and changes with the oxygen

concentration is both proportional and linear, thus allowing single point calibration. Ot her factor s t hat can af f ect the si gn al o utput are descr i be d i n Secti on 5 .2

Application Considerations and Section 3 Safety Warnings which should be read

before use.

Historic ally, the expected life of galvan ic fuel type sensors has been specifie d as

“in air (20.9% O

type s ens or i s inv ersel y aff ect ed b y c ha nges i n t he aver ag e o xyg en conc e ntration, t em p er ature and pressure it i s expos ed t o duri n g its useful l i fe. For ex am ple, the AII-11-60 sensor has a 60 m onths e xpected life i n air (20.9 % oxygen)

at 25°C a nd ambient pres sure, howe ver, in a 100 % oxygen atmo sphere the

expected life is 12.6 months [60mo/(100%/20.9%)].

AII-300 0 Series Oxyg en An alyzer s are batter y pow ered b y (2) AA alkal ine ba tteries a nd controll ed by a state-of- th e- art micr opr ocessor . The batt eries pr ovi de

enough power to operate the analyzer continuo usly for approximately 1,200

hours. Both devices utilize a membrane type keypad for users to communicate

commands to the microprocessor. The monitor is menu driven to accommodate

the alarm functions. The digital electronics provide features such as system

diagnostics, warning indicators, controls and an alarm capability for continuous

monitoring that enhance both safety and effectiveness. The design criteria,

quality pr ogr am a nd per for ma nce f eatur es ensur e rel iabl e a nd a ccur ate o xy gen

measurements.

) at 25°C and 760mm Hg”. The actual life of any galvanic fuel

2

16

17

Page 11

5.2 Application Consideratio ns

Effect of Temperature

All mem bra ne clad electro ch emi cal se nsor s are t em perat ur e depe ndent d ue t o

the expa ns i o n and contr action o f the Teflon sens i ng mem br a ne. A s result m o re

or less of the sample gas including oxygen to be reacted diffuses into the sensor. The oxygen s ensor’s electrical current signal output varies linearly with

oxygen concen tr ati o n . T he s i gnal als o varies with changes in am bi en t tem perature. The temperature coefficient is typically 2.54% of the signal or reading per

degree C change in temperature.

The tem peratur e depe ndent cur rent si gnal ou tput is compens ated by us ing a

resistor-thermistor network. With a proper resistor-thermistor network, the

signal can b e compens ated to w ithin +

5% of the oxygen reading over the 545°C tem p er a t ure range. Thi s i s the wors e case s i tuat i on when goin g f r o m o n e

extreme of the operating temperature range to the other. The error will be

elimi nated wh en t he ther mis tor in the t em per atur e com pe nsa ti on netw ork a nd

the elec t r olyte inside the sensor reach therma l equ ilibrium in appro ximately 4560 minutes.

Erroneous oxygen readings can result if the gases flowing over the

sensing area of the sens or are not at am bient t em perature. This occ urs

because the sens or is expos ed to dif ferent tem peratur es. The s ensi ng

area of the sensor is o-ri ng seal ed in t h e heat ed breathi ng circ ui t and the temperature compensation network at the rear of the sensor is exposed to ambient

temperature.

Effect of Pressure

Electrochemical sensors a ctu all y m eas ure th e par tial pressure, not th e p ercen tage, of o xy ge n in the gas s t ream they are e xpo sed to. Th es e sensors are a cc urate at any press ure provid ed the press ure is cons tant and the analyz er has

been calibrated at the same pressure as the sample gas measured.

For example, when moving an analyzer calibrated at sea level into the mountains caus es the anal yzer to display an decre ase in the ox ygen readin g displayed. When if fact, the decrease in the reading displayed is not related to a

change in the oxygen percentage but to the decrease in partial pressure

(corresponding to the increase in total pressure) at altitude.

Calibrat e at th e temper ature a nd pres sure ( altitu de) at w hich t he ana-

lyzer will be operated.

Effect of Humidity

The an alyzer is no t affect ed by non -condensi ng relativ e humidit y (RH). Ho wever, the use of a humidifier to introduce water vapor and increase the moisture level of the gas mixture does affect the oxygen concentration and the

resultant reading dis played by t he anal yzer. The addition of water vapor increases the total pr es s ure thereby di l uting or decre as i ng the oxygen conce ntr ation of the ga s mi xture resulting in a lower oxygen reading.

Effect of Condensati on

Excessiv e co nde nsati on col lecti ng on t he sens ing ar ea or t he el ect ri cal con nections at the rear of the sensors can a dversely imp act the performan ce of electrochemical sensors. Conde nsation blocks the di ffusion pat h of oxyg en into th e

sensor a nd ca n re duce t he oxy gen r eading to 00 .0 if the cond ensat ion cov ers

the entire s ensing ar ea. Co ndensation o n t he el ectrical c onnections at the re ar

of the sensor can affect oxygen readings. Remedy either situation by shaking

out the condensation and allowing the sensor to air dry.

Erroneously characterized in many instances as a sensor f ailure, exc essive condensatio n i s r emedied by gentl y w i pi ng away t he condensati on wit h a s oft cloth

or simply allo wing the sensor to air dry.

Effect of Electromagnetic Radiation

Tested over a 26 MHz to 100 0 MHz elect rom agnetic fiel d, th e anal yzer i s susceptibl e at al l fr equ e nci es t ested exce pt t hose between 930 an d 99 0 MHz .

Never operate the analyzer near equipment capable of emitting high

levels of electromagneti c radi at i o n. Do no t continue t o oper ate th e analyzer if the reading becomes unstable.

5.3 Calibration

Calibrating the analyzer or monitor during normal operation involves the same

precautions and procedures as thos e descri b ed in Sections 4 . 7 Start- up Cali bration with the same cautio ns to review Sections 3 S afety Warnings a nd 5.2 Applicatio n Considera t ions.

5.4 Sampling

Assuming the START-UP instructions are followed and the tests are completed

successfully the devices de fault t o the SAMPLIN G mode.

Never operate the analyzer if the reading is unstable or if a malfunction

is suspected. If calibration is required as indicated herein, do not proceed until the analyzer is c alibration succ essfully.

18

19

Page 12

5.4.1 Flowing Gas Stream s

1. Place the sens ing are a of the s ensor i nto the g as str eam to b e analyzed

upstream of any humidification equipment.

2. Assure that the flow rate of the gas stream does not exceed ten (10) liters

per minute. Exceeding ten (10) liters per minute generates backpressure.

3. Check the gas stream and particularly the mechanical connection for leaks

that dilute the gas stream with a mbien t air.

4. Assure there are no restrictions in the circuit downstream of the sensor

that could generate backpressure on the sensor.

5. Use the optional flow diverter along with the op-

tional tee adapter and positi on the s ensor v ertically

for optimum results, as s hown right. The flow diverter avoids stagnation and facilitates the movement of gas to and from the s ensing area of the

sensor thereby producing a more accurate measuremen t of the g as stream to be measured.

6. Install the tee-adapter in the breath ing c i rcuit.

7. Screw the flow diverter to the sensor.

8. Ensure the o-ring is lightly lubricated for ease of

entry and a tight seal between the flow diverter and

tee adapter.

9. Insert the assembled flow diverter/sensor into the tee allowing air or

100% oxygen (dry, non-humidified) to fl ow past the sensor at a rate of 58 liters per minute.

10. Once th e sensin g area of the se nsor is expose d to the gas stre am allo w

approximately sixty (60) seconds for the reading to stabilize and observe

the reading displayed by the LCD.

11. Refer to Section 8.1 for a variety of accessories that provide a several

methods of sampling flowing gas streams.

5.4.2 Static Atmospheres

Remove the flow diverter, not needed. Failure to remove the flow diverter will

dramatically slow the response time of the sensor.

Expose the sensing area of the sensor to the atmosphere allowing appro xi-

mately sixty (60) seconds for the reading to stabilize and observe the

reading displayed by the LCD.

If placing the entire sensor inside the controlled atmosphere review

Section 5.2 Application Consideration, Effect o f Temperature.

5.4.3 AII-3000 AHC and M HC (Inte g ral Oxygen Sensor)

AII-300 0 AHC and MHC wit h thei r in tegral oxyg en s ensor req uires conne cting

the ¼” tubing su pplied (section 4.2.1 a bove) with the device to a ¼” hose

barb attac hed to a pressure regulator controlling a source of gas flowing at less

than 10 liters per minute.

5.5 Alarms (AII-3000 M/MHC):

The mo ni to r i s eq ui pped w i th user s electable HI a nd LO alar m s e t p o i nts w hi c h

are displayed at the bottom of the LCD. Section 4.6 describes the operation

and procedure for setting the alarms in detail.

6 Maintenance

Review Section 3 Safety Warnings and Section 7 Troubleshooting for

guidelin es on servicing the devices.

6.1 Serviceability

Do not op en t h e m ain com partm en t of t he anal yz er, as it cont ai ns no s er vic eable parts inside. Never attempt to repair the analyzer or sensor by yourself as

you may damage the analyzer which could void the warranty.

6.1.2 Cleaning / Reuse Inst ructions

Clean th e devic e, oxyge n sens or and accessori es with a soft cloth dam pened

with either water or mild isopropyl alcohol solution (70% isopropyl alcohol

solution in water), if necessary, before re-use. Allow the components to air-dry

after cleaning .

Note: The Home Care Kit is not intended for patient use, it is intended solely

for conf irming t he O

cleaning instructions apply.

6.2 Battery Replacement

The an alyzers an d moni tor are po wered b y two A A alkali ne batt eries wi th an

approximate life of 1,200 hours. A low battery indicator circuit m onitors the

battery suppl y vo l ta ge and sends a sign al di rectly t o the LC D when the bat t er y

voltage reaches a preset level that activates the battery symbol in the LCD.

The bat t eri es ar e h o used i n a separate co m p ar tment l ocated at the rear o f the

device and are accessible by sliding the removable cover.

concentration in Oxygen Concentrators. Accordingly, no

2

20

21

Page 13

Initially this procedure can be somewhat difficult. Care should be taken

not to damage the case when removing the battery compartment cover.

6.2.1 Procedure:

1. Turn the device over so the

shortest raised line on the bat tery

compartment cover is pointing

away from you.

2. Lift the tripo d wire stand up and

away from the case.

3. Grasp the case with both hands

and using your thumbs press

down fir mly on the rai sed li nes and push t he battery compart ment cover

away from you.

4. Locate the positive (+) and negative (-) terminals on the battery.

5. Assure the battery contacts are clean.

6. Ali gn one batt ery’s posi tive (+) termin al with t he corr espondin g (+) bat-

tery sy mbo l m o lded into the cas e.

7. Insert the battery into the compartment.

8. Repeat with the remaining battery.

9. Replace the batter y compartment cover, make sure it snaps into position

and is secured flush against the case. Replace the wire stand as required.

10. Calibrat e the device after re placing the ba tteries.

6.3 Oxygen Sensor Replacement

The desi gn of th e electr onics is int ended f or only t he An alytical Ind ustries Inc.

AII-11-60 or AI I-11-60-HC Oxygen Sensors. Use of a different o xygen sensor

may result in an erroneous oxygen reading.

NEVER - Open th e oxygen s ensor or probe t he sensin g surfa ce, refer

to Section 10 in the event the sensor should leak and someone comes

in contact with the electrolyte from inside the sensor.

6.3.1 Procedure AII-3000 A a nd AII-3000 M - External Sensor

1. Disconnect the cable from the old sensor just as you disconnect a tele-

phone jack from a wall plug.

2. To connect the new sensor simply fi nd and register the male plug at the

end of the coiled cable and insert it into the mating female jack at the rear

of the senso r unt il it m ates or snaps into place.

3. Calibrate the device after replacing the oxygen sensor.

6.3.2 Procedure AII-3000 AHC and AII-3000 MH C - Int e g ral Sensor

1. Tools required: small bladed screwdriver.

2. Plac e the device face down on a flat surface.

3. Remove the two (2) screws from the upper cor ners of the rear of the

device.

4. Move th e tripod up, rem ove the batt ery compartment co ver (see Battery

Replacement) and remove the two (2) screws located on either side.

5. Pull the rear section up ¼”-½”, turn it over and lay it next to the other

section.

6. Loc ate the w hite co nnecto r at the e nd of the f our (4) wires runnin g fr om

the sensor (the cylinder with the white label) to the top of the PCB.

7. With your left for finger and thumb, grasp the sides of the back end of the

white connector where it is soldered to the PCB.

8. With yo ur rig ht fore f inger and thumb, grasp t he sides of the sec tion of

the white connector where the four (4) wires from the sensor terminate.

9. Separate the connector - hold the white connector section your left hand

while gently pulling and wiggling the white connector section with your

right hand until it un lo cks.

10. The oxygen sensor inserts into an adaptor (identified by a round recess

with a cylindrical hose adapter in the center) that slides into grooves

molded into the side of the case.

11. Hold the r ear section of the cas e down, gr asp the sq uare edges of the

adaptor, lift up (lift straight up so as not to strip the grooves molded into

the adaptor and case) and remove the adaptor and oxygen sensor as a

single component.

22

23

Page 14

12. Once th e adapt er and ol d sensor h ave bee n removed f rom the c ase, ho ld

the label of the s ensor , agai n grasp t he s quare ed ges of the ada ptor and

pull – to separate the old sensor from the adaptor.

13. Remove the new oxygen sensor from the plastic shipping container.

14. Install the new oxygen sensor by reversing steps 12 through 3.

15. Calibrate the device after replacing the oxygen sensor.

7 Troubleshooting

If the recom men ded corr ectiv e action does no t resol ve the probl em retur n the

device to the factory for service.

Symptom Corrective Action

Device appears to be physically dam age d

No digital display when analyzer is turned ON

Battery symbol on LCD display

LCD display reads 00.0

No response to keypad command

Cannot turn device OFF

Turn device ON – if it successful passes

START-UP TEST and calibrates – proceed.

Install b attery

Replace bat tery

Check battery polarity

Check and/ or cl ean battery contact s

Replace battery and calibrate device

Install sensor

Check electrical conn ections

Assure electrical connections are dry

Replace bat tery

Calibration routine in process – escape or

wait until completed

Symptom Corrective Action

Reading displayed by LCD

drifts during calib r ation

Analyzer reading climbs after

calibration in 100% dry oxygen when exposed to air

20.9%

After calibration in 100% dry

oxygen, analyzer reading

drifts more than 2% over 8

hours

Reading displayed by LCD

does not change when oxygen leve l cha nges

Reading does not stabilize or

fluctuates erratically

Wait 5 minutes and repeat calibration with

sensor placed on flat surface (not in your

hand)

Check integrity of gas delivery system

Check sensor’s front o-ring seal

Verify calibration g as in not humidified

Remove moisture covering sensor

Replace sensor, repeat calibration

Allow the sensor to stabilize for 5 minutes in

100% dry oxygen and recalibrate

Check p r im ary oxygen delivery de vice

Replac e se nsor t ha t is near i ng th e e nd of it s

useful life

Replace sensor

Relocat e analyz er aw ay sour ce of radio f requency or electromagnetic radiation emissions. Tested over a 26 MHz to 1000 MHz

electromagne ti c f ield, th e a nalyzer i s sus ceptible at all frequencies tested except those

between 930 and 990 MHz.

Check sensor connection

Check cable connection

Wait 5 minu te s and re peat calibration

Replace sensor, repeat calibration

Do not attempt to use the analyzer and

return the analyzer for service.

24

25

Page 15

Symptom Corrective Action

Reading displayed by LCD

does not change when calibratio n control is adjusted

Reading displayed by LCD is

very low

Alarms continuously activated

Replace sensor

Check sensor connection

Check cable connection

Replace sensor

None – Normal operation, confirm set points

Abnormal Adjust alarm set points

Remove moisture covering sensor

Check sensor connection

Check cable connection

Check integrity of gas delivery system

Check sensor’s front o-ring seal

Verify calibration g as in not humidified

Verify flow rate is 4-5 liters per minute

Replace sensor

Replace cable

8 Specifications

Accuracy: +2% of FS range under constant conditions

Analysis: 0-100% oxygen

Area Classification: General purpose

Alarms:

Calibration: Air or 100% oxygen after 8 hours of continuous use.

Compensation: Temperature compensated

Connections: A/M models: 1x16mm thread; HC models: Tubin g 1/4”

Controls: Soft touch keypad for ON/OFF and menu function

Dimensions: 3.6 x 5.9 x 1.6”; weight 10 oz. (280 grams)

Display: 3-1/2 digit backlit LCD 2.5” x 1.5”; resolution 0.1% O

Flow Sen sitivity: None bet ween 0.2 to 10 liters per minute

Humidity: Non-condensing 0-95% RH

LED Indicators: A models - none; M models - upon activation of alarms

Linearity: +

Pressure: Inlet – (A/M) ambient, (HC) regulate; Vent - atmosphe r ic

Power: 2 AA Alkaline batter i es ; 1, 2 00 hours co ntinuo us us e

Respon se Time: 90% of fina l FS reading in 9 seco nds

Sensitivity: < 0.5% of FS range

Sensor: A/M models: AII-11-60 or HC models: AII-11-60-HC

Expected Life: 60 months in air at 25ºC and 1 atmosphere

Storage Temp.: -20º to 60ºC (-4ºF to 140ºF) on intermittent basis

Temp. Range: 5º to 45ºC (41ºF to 113ºF)

Warm-up Time: None

Warranty: 12 months analyzer; 12 months sensor

A models – none; M model s - Us er adjus tabl e HI 1-100%

and LO 0-99% alarms; 120 second alarm silence; HI

alarm defeat for 100% O

1% under constant conditions

measurements

2

2

26

27

Page 16

Expected Sensor Life

Consider s the f ul l r ang e of th e s enso r’s si gnal , exam ple 7-13 m V. Oxy ge n s ensors are co nfigured to meet th e published, s ee preceding pa ge, specificati on

which dist r ibutes the overall sensor life as follows:

- 60 months Expected Service Life (915,420 oxygen % hours)

- 6 months Recommended Storage Life period (91,542 % oxygen hours)

- 2 months margin of error

Therefor e, the Recommend ed Storag e life per iod should not be co nsidered a

perishabl e shelf life. Op erating at the spe cified par ameters of oxyg en conce ntration (air 20.9%), temperature (25⁰C/77⁰F) and pressure (1 atm/bar), the

sensor will o perate for app r o ximately 68 m onths whether in s torage or in use .

The purpo se of the Rec ommended Storage Life p eriod is to ensure the user

derives the E xpected Life of 60 months (9 15,420 % oxyg en hours) a nd does

not lose the benefit of the warranty.

Warranty

The 12 month (183,084 % oxygen hours) w arranty period (b egins with shipment from the factory and is limited to the first claim submitt ed) is based on :

8.1 Spare Parts & Accessories

AII-3000 A, AII-3000 M

Spare Parts: Spare Parts:

AII-11-60 Oxygen Sensor AII-11-60-HC Oxygen Sensor

BATT-1008 Battery (2x) 1.5V AA BATT-1008 Battery (2x) 1.5V AA

P-1087 Instructions for Use P-1087 Instructions for Use

A-1162 PCB Assy Main A-1162 PCB Assy Main

CABL-1006 Coil Cable TUBE-1019 7/32” OD Tubing 3’

AII-3000 AHC, AII-3000 MHC

Optional Acces sories - See opposing page

CC-1072 Carrying Case

28

29

Page 17

9 Warranty

Coverage

Under nor mal o perati ng co nditions , th e anal yzer an d sens ors ar e war rante d to

be free of defects in materials and workm anship for the p eriod speci fied in the

current published specificat ion s . To make a warrant y claim, you must return the

item properly packaged and postage prepaid to:

Advanced Instruments in their sole discretion shall determine the nature of the

defect. If the item is determined to be eligible for warranty we will repair it or,

at our option, replace it at no charg e to you. If we choos e to repair your item,

we may us e new or reco ndition ed repl acem ent par ts of t he same o r upgr aded

design. This is the only warranty we will give and it sets forth all our responsibilities, there are n o other express or implied warran ties.

The w arra nty b egi ns wi th t he dat e of shi pm ent fro m A dv ance d Ins tr ume nts, is

limited to the first customer who submits a claim for a given serial number

which must be in place and readable to be eligible for warranty and will not

extend to more than one customer or beyond the warranty period under any

conditions.

Exclusions

This warranty does not cover normal wear and tear; corrosion; damage while in

transit; damage resulting from misuse or abuse; lack of proper maintenance;

unauthorized repair or modification of the analyzer; fire; flood; explosion or

other fa ilure to follow t he Owner’s Manual.

Limitations

Advanced Instruments shall not liable for losses or damages of any kind; loss of

use of t he analyz er; incide ntal or co nsequenti al losses o r damages ; damages

resulting from alterations, misuse, abuse, lack of proper maintenance; unauthorized repair or modification of the analyzer.

Service

Contact us between 8:00am and 5:00pm PST Mon day thru Thursday or before

12:00pm on Friday. Trained technicians will assist you in diagnosing the problem and determ i ning the appropriate course of action .

Advanced Instruments Inc.

2855 Metropolitan Place

Pomona, Ca 91767 USA

T: 909-392-6900, F: 909-392-3665

E: sales-industrial@aii1.com

, W: www.aii1.com

10 Material Safety Data Sheet (MSDS)

Product name Electrochemical Galvanic Fuel Cell Oxygen Sensor

Exposure Sealed device with protective coverings, normally no hazard

Ingredients Carcinogens - none; Potassium Hydroxide (KOH), Lead (Pb)

Properties

Flash Points Not applicable, non-flammable

React ivity Stable; avoid strong ac ids, emits fumes when heated

Health Hazard KOH entry via ingestion - harmful or fatal if swallowed;

Symptom s Eye con ta ct - burning sens at io n; skin conta ct - slick feelin g

Protection Ventilation - none; eye - safety glasses; hands - gloves

Precautions Do not remove Teflon and PCB coverings; do not probe wi th

Action KOH

Leak

10.1 Disposal

Oxygen sensors and batteries should be disposed of in accordance with local

regulations for batteries.

Completely soluble in H

eye - corrosive, possible loss of vision;

skin con ta ct - corrosive, possible che mical burn.

Liquid inhalation is unlikely.

Lead - known to caus e bir th defec ts , contact unl ikely

sharp objects; avoid contact with eyes, skin and clothing.

Use rubber gloves, safety glasses and H

surfaces repeatedly with liberal amounts of H

WEEE regulations prohibit electronic products including the Helium a nd enviro nmental s ensors fr om being placed i n househol d

trash bins.

Electronic products should be disposed of in accordance with local

regulations.

2O; ev aporation similar to H2O

2O and flush all

2O

30

31

Loading...

Loading...