Page 1

510(k) K952736 O2 Sensor

510(k) K053407 O2 Analyzers

EN 12598:1999 / ISO 7767: 1997

(Oxygen monitors for patient breathing

mixtures – Particular requirements).

EC: Medical Device Directive: 93/42/EEC,

Annex II as Amended by 2007/47/EC,

Certificate #485CE

ISO 9001:2008, Certificate #485

Authorized EC Representative:

RGV Lda.

Rua Jose Joaquim de Freitas, 247

2750-4 04 Cas ca is-Portu ga l

Health Canada: Medical Device Regulations, F-27/ SOR-98-282

ISO 13485:2003, Certificate #485B

AII-2000 A

AII-2000 HC

Copyright © 10/10 All Rights Reserved

Analytical Industries Inc.,

2855 Metropolitan, Pomona, CA 91767 U SA.

Tel: 909-39 2-6900, Fax: 909-392-3665

e-mail: sales-medical@aii1.com, web: www.aii1.com

This manual may not be reproduced in whole or in part without

the prior written consent of Analytical Industries Inc.

AII-2000 M

Page 2

Table of Contents

1 Introduction

1.1 Indications for Use

1.2 Intended Use

1.3 Device Description

1.4 Declaration of Conformity

2 Quality Control Certification

3 Safety Warnings

4 Start-up

4.1 Contents of Shipping Container

4.2 Install Batteries

4.3 Install Oxygen Sensor

4.4 Controls

4.5 Start-up Test

4.6 Alarms (AII-2000 M Oxygen Monitor)

4.7 Calibration

4.8 Mounting

5 Operation

5.1 Principle of Operation

5.2 Application Conside ra t io ns

5.3 Calibration

5.4 Sampling

6 Maintenance

6.1 Service ability

6.2 Battery Replacement

6.3 Oxygen Sensor Replacement

7 Troubleshooting

8 Specifications

8.1 Spare Parts & Accessories

9 Warranty

10 Material Safety Data Sheet (MSDS)

10.1 Disposal

1 Introduction

Congratul a tions o n your p urch ase, t hese Ins tr ucti ons fo r U se des cri be th e pr ecautions, set-up, operation, maintenance and specifications of the AII 2000

Series Oxygen Analyzers & Monitors.

This symbol means CAUTION – Failure to read and comply with the

Instructions for Use could damage the device and possibly jeopardize

the well being of the patient and/or health care professional.

Note: Analytical Industries Inc. cannot warrant any damage resulting from the

misuse, unauthorize d repair or improper maintenanc e o f th e device.

1.1 Indications for Use

The AII 2000 S eries Oxygen Analyzers & Monitor are int ended to m easure a nd

display the concentration of oxygen in breathing gas mixtures. The intended

use is only to v er i fy, spot chec k or continuously monit or , oxyge n conce nt rat i ons

in circumstances where the oxygen concentration is controlled and set by other

medical device such as oxygen/air blenders, flow m eters or other control device.

Users m ust read th e followi ng statements as they are es sential to reducing the r is k of us e erro r du e to ergo nomi c f eat ur es of th e devi ce o r

the environment in which the device is intended to be used.

The de vices as ide ntified i n Section 1 .4 Declar ation of Co nformity have been

designed and man uf actured i n s uch a way that w h en used u nder the co ndi tions

and for the purposes intended, they will not compromise the clinical condition

or the safety of patients, or safety of the users or other persons.

Federal law restrict s this device to sale by or on the order of a physician.

Conform ity wi th ess enti al re quir eme nts has been demo nstr ate d by ver if ying th e

performance of the device under normal conditions, bench testing, pre-clinical

and simulated clinical evaluations and determining that undesirable malfunctions constitute minimal risk to patients and users.

Particular requirements for sterilization do not apply to these devices. Do not

sterilize, autoclave, liquid sterilize, immerse in any liquid or expose the device

or acce ss o r ies to steam, ethylene oxide or ra diation sterilization.

i

1

Page 3

The device is i ntended t o be re - usable. S ho ul d t h e device o r access o ri es co m e

in contact w ith p atien t bo dil y fl uids , eit her di spos e o f th e devi c e or clea n wi th

a soft cloth dampened with 70% isopropyl alcohol solution in water and allow

the components to air-dry before re-use .

The device and accessories are not intended to transport or store any medicines, bo dy l iquids or ot her s ubstan ces th at ca n be adminis tered or rem oved

from the body, and, do not contain any latex, human blood derivatives, phthalates, carcinogens or other reproductive toxics.

Calibrate the device with 100 % o xygen b efore using each da y or aft er 8 hours

of continuous use. In the event the device fails to calibrate or if the reading

becomes, do not attempt to use the device. Contact the manufacturer for

assistance.

Do not operate the a nalyzer near eq ui pm ent cap abl e of emittin g hi gh level s o f

electromagnetic radiation as the reading may become unstable.

In order to obt ain op ti mum p erforman ce, t he o peration of th e d evice m ust b e

performed in accordance with th ese Instructions for Us e. Maintenan ce should

be performed only by trained personnel authorized by the manufacturer.

Additional operating pointers are provided in Section 3.

1.2 Intended Use

The AII 2000 S eries Oxygen Analyzers & Monitors are intended to measure

and displ ay the conce ntration of o xygen in breat hing gas mi xtures. The intended use i s o nly to veri fy, s pot ch eck or co nti nuous l y mo ni tor , o xyg en co ncentrations in circumstances where the oxygen concentration is controlled and

set by other me dical d evice s uc h as o x ygen/air ble nders, f low me ter s or other

contr o l device found in the fo llo wing medical applications:

Anesthesia (refer to Section 5.2)

Respira t o ry Therapy – Ventilators, Respir ators

Neonatal & Pediatric Incubators & Hoods

Oxygen Therapy - Intensive Care

Spot Checking Concentrator

1.3 Device Description

The AII 2000 Seri es Oxygen Anal yzers and Mo nitor can be pos itioned on a

table to p or pole ( tripod wire stand and V-moun t dovetail attach ments are

mounted on the back of the device) and are readily portable from one location

to another. They provide continuous, fast, reliable and accurate oxygen measurements of up to respiratory care systems.

The devices utilize an electrochemical galvanic fuel cell type oxygen sensor of

the type t hat is extens ivel y used to meas ure o xygen co nce ntratio ns f rom 0%

to 100% in gas streams. O xygen, the fuel f or this electroch emical transduc er,

diffus ing into the s ensor thr ough a g as permeabl e membra ne reacts ch emically at the sensi ng electro de to produ ce an elect rical curr ent o utput propo rtional to the ox yg en con ce ntra tio n in the g as phas e. T he s enso r h as an absolute zero meaning that when no oxygen is present to be chemically reacted

the LCD displays 00.0 oxygen.

The sensor’s signal output is linear over the entire range, rem ains virtually

constant over t he specif ied us eful li fe and drop s off sharply at the e nd. The

sensor itself requires no maintenance and is simply replaced at the end of its

useful l ife like a ba ttery. In asmuch as t he sensor i s a transdu cer in its own

right, its expected life is not affected by whether the analyzer is ON or OFF.

A batter y pow ered st ate-of -the-ar t mi cro-pr ocess or con verts t he s ensor’ s signal output representin g t he partial pressure of ox ygen in the gas stream bei ng

analyzed. The resulting oxygen reading is displayed by a large easy to read

backlit liquid crystal display (LCD) that has a resolution of 0.1% oxygen. The

microprocessor is controlled from a keypad and provides features like system

diagnostics, warning indicators, controls and an alarm capability for continuous monitoring that enhance both safety and effectivene ss.

Prior to shipment, every device is thoroughly tested at the factory and documented in the form of a Quality Control Certification that is included in the

Instructions for Use supp lied with every device.

The manuf acturer ’s cont act info rmation and serial number o f this d evice c an

be found above the ba ttery compar tment cov er on the r ear of the d evice and

in Sect ion 2 Qu ality Control C ertificat io n.

In conclusion, Analytical Industries Inc. appreciates the opportunity to supply

this device and anticipates many years of useful service.

2

3

Page 4

1.4 Declaration of Conformity

Manufacturer:

Analytical Industries Inc.

2855 Metropolitan Place, Pomona, California 91767 USA

Tel: 909-392-6900, Fax: 909-392-3665

e-mail: sales-medical@aii1.com , www.aii1.com

Authorized EC

Repres entativ e:

RGV Lda.

Rua Jose Joaquim de Freitas, 247

2750-404 Cascais-Portugal

Product:

AII 2000, AII 2000A, AII 2000 HC, A I I 2000 TruO2 Ox ygen

Analyzers; AII 2000M Oxygen Monitor

PSR Series Oxygen Senso rs

Classification:

Directives:

IIb

Medical De vice Direct iv e 93/4 2/E EC, Annex II as am ended

by 2007/47/EC

Standards &

Certificates:

510(k) K952736 O2 Sensors

510(k) K053407 O2 Analyzers

EN 12598:1999 (ISO 7767: 1997) Oxygen devices for

patient breathing mixtures – Safety requirements

Medical De vice Direct iv e 93/4 2/E EC, Annex II as am ended

by 2007/47/EC, Certificate 485CE

ISO 9001:2008, Certificate 485

ISO 13485:2003, Cert 485A

Medical Device Regulations, F-27/ SO R-98- 282 (Cana da)

Notified Body:

AMTAC Ce r tification Services Limit ed

Davy Ave nue, Knowhill

Milton Keynes MK5 8NL

United Kingdom

CE mark affixed: February 21, 2006

We hereby declare the above product meets the provisions of the directives

and standards specified. All supporting documents are retained on the premises of the manufacturer.

Patrick Prindible, QA Ma na ger

2 Quality Control Certification

Customer: ________________________ Order No. _____________ Date: _______

Model: ( ) AII-2000 A Oxygen Analyzer

Sensor: ( ) AII-11-60 or ( ) AII-11-60-HC S/N _______________

Electronics: A-1162 PCB Assembly Main Software Version _______________

Accessories: AII-2000 A / M:

PASS

QC Test: LCD display 3-1/2 digits ……………………………………………………. ______

Battery symbol displays when battery is low ……………………….. ______

Span adjustment +

Following calibration with 99-100% oxygen and flushing with

Span adjustment +

Following calibration with air (20.9% oxygen) and exposing

Options: Item No.

FITN-1009 Tee Adapter ……………………………………………………….. _____

ENCL-1072 Carrying Case ……………………………………………………. _____

Other: _____

Delivery:

( ) AII-2000 M Oxygen Monitor

( ) AII-2000 HC Oxygen Analyzer S/N _______________

FITN-1112-1 Flow Diverter

AII-2000 HC: A-3675 Adapter, 5/32” Tube to Sensor

TUBE-1007 1/4” Tubing 7 ft. with Adapter

All units: BATT-1008 Battery, 1.5V AA (Qty 2)

P-0187 Manual, Instructions for Use ……… Included ______

ambient air, oxygen reading as displayed by LCD 20.9% +

to 99-100% oxygen, LCD displays 100% +

Overall inspection for physical defects ………………………………... ______

HRWR-1075 Dovetail Female Clamp Pole/Shelf ………………………

CABL-1006 Cable, Coiled Phone Jack

10-30% FS with 100% oxygen calibration ______

2% ____

10-30% FS with air calibration ……………….. ______

2% ……………………. ______

Qty

____

4

5

Page 5

3 Safety Warnings

ALWAYS foll ow the st atem ents bel ow as t hey ar e ess ential to redu cing the ri s k o f us e err o r due to er gonomic f eatures of t h e device o r t he

environment in which the device is inte nded to be used.

Only trained personnel who have read, understand and agree to follow

the Instructions for Use should operate the device.

Retain the Instructions for Use for future reference.

Refer service needs to trained authorized personnel. Failure to do so may

cause the dev ice to fail and void the warranty .

Inspect the device and accessories before operating and ensure: (a)

there is no evi de nc e of ph ysical dama ge; (b) the se nsor ( parti cul arl y t he

sensing s urf ace) and elect ri cal conn ecti ons ar e dry; and, ( c) the sensor is

installed and upstream from any humidifying device for accurate calibration and oxygen readings.

Calibrate: (a) with a known source of dry 100% oxygen before using

each da y or after 8 hour s of conti nuo us use; (b) when the temper atur e

or pressure of the operating environment changes; (c) if the oxygen

sensor has b een di sconne cted and r econnect ed; (d) af ter t he batt ery o r

oxygen sensor ha s been repla ce.

Sampling flowing gas: (a) install the flow diverter and the tee-adapter in

a vertical position as shown in Section 4.3 and (b) assure there is a tight

fit between the flow diverter and tee adapter.

Sampling static, ambient or controlled atmospheres such as incubators,

oxygen hoods, tents, etc.: remove the flow diverter.

Clean the device and accessories in accordance with Section 6.1.2.

Battery replacement Section 6.2: ( a) replace t he batteries within tw enty-

four (2 4) hour s of the battery symbol appearin g o n LCD di s play

calibrate the analyze r aft er replacing th e ba tteries.

Oxygen sensor installation or replacement Section 6.3: allow the new

sensor to stabilize for 15-20 minutes in ambient air before attempting to

calibrate.

Store th e de vice b y turni ng t he po wer OFF an d rem ovin g t he ba tteri es i f

the device will not be operated for over thirty (3 0) days.

Attempt to repeat the procedure that caused a perceived malfunction

and refer to troubleshooting hints in Section 7 before concluding the

device is faulty. If in doubt, contact the manufacturer for assistance.

and (b)

NEVER o perate the d evice in any m anner des cribed below doing so

may compromise the clinical condition or the safety of patients, users

or other persons.

If the reading is unstable or a malfunct io n is suspected.

After the battery symbol appears in the LCD display.

Near eq uipment capable of emitting high lev els of el ectromag netic radia-

tion (EMI) or radio frequency interference (RFI).

Expose the device; particularly the LCD display or sensor to sources of

extreme heat, cold or excessive sunlight beyond the device’s storage temperature ra n ge, r efer to Sectio n 8 for e xtended periods o f time .

In a gas stream with a vacuum greater than 14” water column.

Immerse the device, oxyg en sensor or coile d cable in any liq uid.

Outside of the parameters specified in Section 8 particularly at flow rates

greater t han 10 l iters per minute - t he bac kpressure generat ed produc es

erroneously high oxygen readings.

Calibrate: (a) with 20.9% oxygen or room air with the intent of taking

oxygen measurements at oxyg en levels above 30% oxygen; (b) i n a humidified gas stream or atmosphere; (c) without allowing a newly installed

sensor to sta bilize for 15- 20 m inutes in ambient air.

Attempt to sterilize, autoclave, liquid sterilize, immerse in any liquid or

expose the device or accessories to steam, ethylene oxide or radiation

sterilization.

In the presence of fl am m abl e anes theti c gas es.

Open t he main c ompar tment of th e devic e, ex cept to c hange t he in tegral

oxygen sensor of the AII-2000 HC Oxygen Analyzer.

Open the oxygen sensor or pro be th e se nsing surfa ce, refer to S ecti on 10

in the event the sensor should leak and someo ne comes in co ntact with

the electrolyte from inside the sensor.

Operate with a cable that appears worn, torn or cracked, or, allow an

excess length of cabl e near the patient’s head o r neck; secure it to the bed

rail or ot her suitable object to avoid the p o s s ibility of strangulation.

Allow the device or ox ygen sensor to be serviced, repaire d or altered by

anyone except trained personnel – failure to do so may endanger the

patient or damage the device rendering the warranty null and void.

6

7

Page 6

4 Start-Up

4.1 Contents of Shipp ing Container:

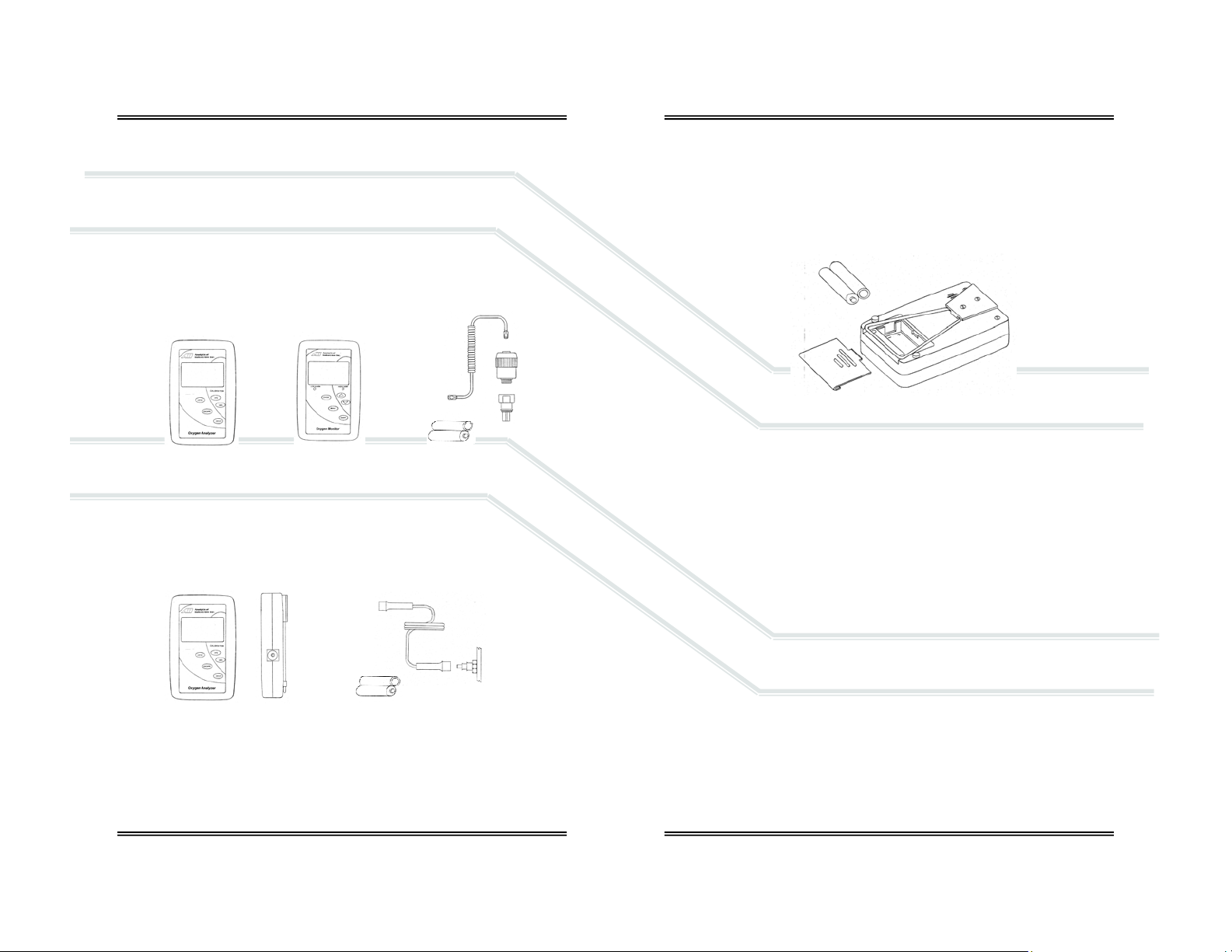

4.1.1 AII 2000 A Oxygen Analy zer, and AI I 2000 M Oxygen Monitor:

ENCL-1061 V-mount retainer (attached)

ENCL-1066 Tripod wire stand (attached)

AII-11-60 Oxygen Sensor

BATT-1008 Battery, AA 1.5V Alkaline (Qty 2)

CABL-1006 Cable, Coiled Phone Jack

FITN-1065 Flow diverter

P-1087 Instructions for Use

4.1.1 AII 2000 HC Oxygen Analyzer, Home Care:

ENCL-1061 V-mount retainer (attached)

ENCL-1066 Tripod wire stand (attached)

AII-11-60-HC Oxygen Sensor (installed inside analyzer)

BATT-1008 Battery, AA 1.5V Alkaline (Qty 2)

TUBE-1007 Tubing, 1/4” Tubing 7 ft. with Adapter

P-1087 Instructions for Use

Inspect t he box and cont ents for shippi ng damage. If t he device or

compone nts app ear dam age d, do not a ttem pt to oper ate t he devi ce -

contact the manufacturer immediately, refer to section 9.

OR

AND

AND

4.2 Install Batteries

All devices are powered by two 1.5V AA alkaline batteries which must be installed before the device can be operated.

The battery compartment is located at the rear of all devices. Initially

this proc edure c an be som ewhat dif ficult. C are sho uld be take n not to

damage the case when removing the battery compartment cover.

4.2.1 Procedure:

1. Remove the device and the (2) AA 1.5V Alkaline batteries from the foam

shipping container.

2. Turn t he devi ce over so the s hortest r aised line on the batt ery co mpartment cover is pointing away from you.

3. Lift the tripod wire stand up and away from the case.

4. Grasp the c ase wit h both hands, use y our thum bs pres s dow n firm ly on

the raised lines and push the battery compartment cover away from you.

5. Locate the positive (+) and negative (-) terminals on the battery.

6. Assure the battery contacts are clean.

7. Ali gn one batt ery’s posi tive (+) termin al with t he corr espondin g (+) battery sy mbo l m o lded into the case.

8. Insert the battery into the compartment.

9. Repeat with the remaining battery.

10. Replace the battery comp artment cover, make sure it snaps into p osition

and is secured flush against the case. Replace the wire stand as required.

Replac e the bat teri es w ithi n tw e nty- four (24) ho ur s of the b att ery sym bol appearing on LCD display because batteries decline at different

rates. Calibrate the dev ice after repla cing the batteries.

8

9

Page 7

4.3 Install Oxygen Sensor

The device cannot function until the oxygen sensor is installed. Once installed,

allow the sensor to stabilize for 15-20 minutes in ambient air before attempting to calibr ate the device.

NEVER - Attempt to open, repair or service the oxygen sensor.

Refer to Sect ion 3 f or hi nts an d war nin gs co ncer nin g th e han dli ng an d

environmental considerations of the oxygen sensor and the device.

4.3.1 AII 2000 A Oxygen Analyzer, AII-2000 M Oxyge n M onitor:

1. Remov e the content s fro m the shipping co ntainer as sho wn in s ection 4.1

and check for damage.

2. The coiled cable uses a common RJ11 phone jack at both ends, making a

bad connection impossible.

3. Inst all the sensor awa y from any humidifyin g device to pr event moi sture

from condensing on the sensing surface and assure accurate calibration

and oxygen readings.

4. Connect one end of the cable to the device in the same manner you

would co nnect a telepho n e. Si m pl y f ind and regis t er the male pl ug at th e

end of the coiled cable and insert it into the mating female jack on the

side of the device.

5. Connect the other end of the cable to the sensor in the same manner.

6. For diffusion sampling of static, ambient or controlled atmospheres –

incubators, infant hoods, tents, etc., the flow diverter and tee are not

required as shown above.

7. For sampli ng breathing ci rcuits with f lowing gas, use the flow di verter

and tee adapter accessories supplied with the device, and, position the

sensor vertically for optimum results, as shown right. The flow div erter

avoids stagnation and facilitates the movement of gas to and from the

sensing ar ea of t he s ens or th ereby pro du cing a mor e accur ate me a surement of the gas stream to be measured.

8. Install the tee-a dapter in the breathin g circuit.

9. Screw the flow diverter to the sensor.

10. Ensure the o-ring is lightly lubricated for ease of entry and a tight seal

between the flow diverter and tee adapter.

11. Insert the assembled flow diverter/sensor into the tee allowing 100%

oxygen ( dry, no n-hum idif ied) to f low pas t th e sens or at a r ate les s tha n

10 liters per minute.

4.3.2 AII 2000 HC Oxygen Analyzer:

When the Home Care version with its integral oxygen sensor is ordered, the

device is shipped with the sensor installe d.

4.4 Controls

4.4.1 AII 2000 A and AII 2000 HC Oxyge n Ana lyzers

These analyzers employ a micro-processor that is controlled by five (5)

pushbuttons located on the keypad attached to front cover.

1. ON/OFF provides power to the electronics

2. ESCAPE abo r ts a previous sele cted option

3. ENTER selec ts a me nu opti o n

4. 100% initi ates t he routine for CA LIBRATI ON with 100 % oxygen. T he sensor must be exposed to 100% oxygen.

5. 21% initiates the routine for CALIBRATION with air or 21% oxygen. The

sensor must be exposed to air or 21% oxygen.

4.4.2 AII 2000 M Oxygen Monit or

The mo nitor emplo ys a menu driven micro -proces sor that i s cont roll ed by f ive

(5) pushbuttons located on the keypad attached to front cover.

1. ON/OFF provides power to the electronics

2. MENU accesses the MAIN MENU

3. ENTER s elects a menu o p ti o n, and, en abl es the us er t o s i l ence th e a udi bl e

alarm qu ickly without ha ving to navigate through th e menu (s)

4. DOWN ARROW scrolls down the menu options

5. UP ARROW scrolls up the menu op tions

Note: The monitor is equipped with visual and audible HIGH and LOW

(minimum set point of 15%) alarms which are controlled through the MAIN

MENU a nd are activat ed when the ox ygen val ue is 0. 1% bel ow the LO alarm

set point or 0.1% above the HI alarm set point, refer to section 4.6 below.

4.4.3 Instructions and Warnings displayed by LCD

START-UP TEST – diagnostic tests of the electronics, alarm circuit

(monitors only), battery voltage and the sensor’s signal output.

SERVICE DEVICE – non-sensor failures during the start-up test.

CHECK SAMPLE GAS, CHECK CA BLE, CHECK SENSOR – se nsor fails the

start-up test or becomes disconnected during operation, or if an alarms is

activated (monitor).

SAMPLING – oxygen concentration from 0-100% in the sample gas during

the normal operation.

BAT LOW – battery voltage is not adequate, replace batteries.

ALARM SET POINTS, CONDITION (set point reverses color and red LED

indicator turns on) for monitor only.

10

11

Page 8

4.5 Start-Up Test

Press the ON/OFF key o n the front panel to apply power to th e device and

initiate a complete diagnostic test of all system functions: the electronics,

feeds voltage and tests the alarm circuit (monitor only below right) internally,

confirms the battery voltage is ad equate to power the circuit, and, the sensor’s signal output is with in specificatio ns.

START-UP TEST

ELECTRONICS - PASS

ALARMS - N/A

BATTERY - PASS

SENSOR - PASS

Following successful Start-Up Test the devices default to the SAMPLING mode.

20.9 %

SAMPLING

With t he excepti on of th e ALARM S for th e AII-20 00 M (a bove lef t) the t ests

and result ing displays are t he same.

Note: Any START-UP TEST failure requires the user to take corrective

action before continuing or attempting to use any device.

4.5.1 Electronics, Alarms (AII-2000 M Monitor) or Batt e ry Failure

If any of these START-UP TESTs ar e unsuccessf ul, the follow ing display instructs th e user to SE RVIC E DEVIC E. The f oll owing di splay is the same f or all

models.

ELECTRONICS - FAILED

SENSOR - FAILED LOW

20.9 %

LO 15% HI 50%

START-UP TEST

ALARMS - FAILED

BATTERY - FAILED

SERVICE DEVICE

START-UP TEST

ELECTRONICS - PASS

ALARMS - PASS

BATTERY - PASS

SENSOR - PASS

SAMPLING

4.5.2 Sensor Failure

Sensor failure can result from multiple causes; the user’s failure to connect a

sensor or sensor cable, a defectiv e sensor cable or a se nsor with an output

outside specificatio n.

SENSOR - FAILED LOW is one of the po ss ible unsuccess ful START-UP TEST s as

illustrated previously and displays additiona l warnings as follows.

4.5.2.1 AII 2000 A and AII 2000 HC Ox yg e n A nalyzers

The LCD alternately d is plays the followin g until the problem is corrected.

Corrective action:

1. Expose the sensor to air or a gas containing approximately 20.9% oxygen

2. Connect or replace the cable connecting the sensor to the analyzer

3. Connect or replace the oxygen sensor

4.5.2.2 AII 2000 M Oxygen M onitor

Performs th e sam e rou ti ne an d requi r es th e sam e cor rect iv e acti on as th e analyzers above with additional indicators related to the monitor’s alarm feature.

In addition to the alternating LCD display, the LO ALARM becomes active and:

0.0 %

ALARM

0.0 %

ALARM

LO 15% HI 50%

CHECK SAMP LE GAS

CHECK SAMP LE GAS

LO 15% HI 50%

CHECK CABLE

CHECK SEN SO R

ALARM

CHECK CABLE

CHECK SEN SO R

ALARM

LO ALARM value and background alternately reverse colors on the LCD

RED LED bel o w th e LO ALARM valu e li ghts up a nd be gi ns fl as hing

Audible alarm begins beeping

The audible alarm can be disabled for two (2) minutes (unlimited times) by:

1. Press the MENU key on the fr ont panel

2. Press the UP/DOWN arrow to select ALARMS AUDIBLE

3. Press the ENTER key to toggle to ALARMS SILENT mode

12

13

Page 9

4.6 Alarms AII 2000M Oxyge n M onitor

The monitor is equipped with user selectable HI and LO alarm set points

which are displayed at th e bottom of the LCD. The default alarm set points

are 15% LO an d 50% HI. The L O alarm set point c an be set between 15 %

and 99% and the HI alarm set point can be set between 16% and 100%.

Alarm set points may be adj usted in 1% i ncrements by pressing a nd holding

the UP/ D OWN A R ROW keys, see below . T he A RROW k e ys are dis abl ed wh en

the alarm set points are within 1% of e ach ot her to pre vent th e HI a larm f rom

being set below th e LO alarm. T h e HI alarm may be di s abl e d by atte m pti ng t o

select a HI alarm set point above 100% to facilitate flushing patients after

anesthe s ia. In this mode the LCD continually displays HI OFF.

The AII-2000 M Oxygen Monitor i s equipped with four (4) indicators that activate wh en oxyge n concent rations are 0.1% below the LO alarm s et poi nt or

0.1% above the HI alarm set point.

1. LCD alternates b etween the ALAR M mode with an oxyge n reading 0.0%

and reco mm endation as illustrated in sec tions 4.5.2.1 and 4.5.2.2

2. Alarm value and background alternately reverse color on LCD

3. Red LED below the alarm value lights up and begins flashing

4. Audible alarm begins beeping

4.6.1 Setting Alarm Set Points

1. Fr om the SA MPLING mode pres s MENU

to display the MAIN MENU

2. Press the UP/DOWN arrow keys to

highlight SET ALARMS

3. Press ENTER to select SET ALARMS

4. LO alarm value is highlighted by default

5. Press ENTER to skip the LO alarm (and

proceed to t he HI alarm) or pres s the

UP/DOWN arrow keys to change the

alarm set point

6. Press ENTER to save LO alarm set point

and move to select the HI alarm

7. Pres s ENTE R to s kip t he HI al arm ( and

return to SAMPLING mode) or press the

UP/DOWN arrow keys to change the

alarm set point

8. Press ENTER to save HI alarm set point

and return to SAMPLING mode

9. If no key is pressed within 5 seconds,

the LCD returns to the SAMPLING mode

20.9 %

SAMPLING

LO 15% HI 50%

MAIN MENU

CALIBRATE

SET ALARMS

ALARMS AUDI BL E

LO 15% HI 50%

SET LOW/HIGH ALARM

USE UP/DOWN ARROWS

TO ADJUST VALUE

TO SKIP - PRESS ENTER

LO 15% HI 50%

4.7 Calibration

Electro chem ical oxy ge n sens ors ge ner at e sli ghtl y di ff erent sign al o utput s under

identical conditions due to variations in the thickness of the sensing membrane

and manufacturing p r ocess.

Simulate the application for optimum accuracy: Review Sections 3

Safety Warnings and 5.2 Application Considerations before proceeding.

The de vices are d esigned to meet th e requireme nts for bo th ambi ent

and el evated oxyge n measurements b ut should NEVER be calibrated

with air or 21% oxygen with the intent of taking oxygen measur ements

at oxygen levels a bove 30% oxygen.

Accordin gly, the d evices may be calibr ated with ei ther air (20.9%) or

100% oxygen which req uires the user to m ake a conscious de cision to

bypass or skip the recommended 100% oxygen calibration.

Set-Up:

AII-2000 A and AII-2000 M refer to section 5.4.1 Flowing Gas

Streams or 5.4.2 Static Atmospheres.

AII-2000 HC refer to section 5.4.3.

14

15

Page 10

Procedure

AII 2000 Seri es A nal yzers an d Mo nito r em ploy t he i de ntical c ali brati on r outi ne

and displays but they differ slightly in the way they arrive at the display that

initiates calibration routine. Refer to Set-Up illustration and references above

for gas connections.

1. AII-2000 A and AII-2000 HC Oxygen Analyzers - Press the 21% key under

the word CALIBRATION on the front panel.

1a. AII-2000 M Oxygen Monitor - Requires navigating its menu to reach the

display that initiates the calibra t io n routine.

a. From the SAMPLING menu, press

MENU to display the MAIN MENU

b. Press the UP/DOWN arrow keys to

highlight CALIBRATE

c. Press ENTER to select CALIBRATE (the

four (4) alarm indicators are disabled

during the calibration routine)

Both of the above produce the following display which initiates th e

calibration routine.

3. The above pr o mpt re mains on the display until:

a. The operator presses ENTER to proceed or

b. The ESCAPE key on the AII-2000 A and AII-2000 HC or the MENU key

on the AII-2000 M to abort and return to the SAMPLING mode.

4. Expose the sensor to a known source of fresh ambient air or certified 21%

(dry, non-humidifie d) oxygen ni trogen m ix but not the oxygen enriched

room air commonly found in hospitals.

5. Once a suitable calibra t ion gas is intro-

duced, press ENTER to initiate calib r ation

as displayed right and disable the key

pad (to prevent the calibra tion rout i ne

from being interrupted).

6. This display appears for sixty (60) seconds

to allow the sensor to s ta bilize before

the microprocessor takes the final reading.

20.9 %

INTRODUCE AIR/21% OXYGEN

OBSERVE TREND

PRESS ENTER TO CAL

16

LO 15% HI 50%

MAIN MENU

CALIBRATE

SET ALARMS

ALARMS AUDI BL E

20.9 %

AIR CALIBRATION

IN PROCESS

7. If the calibration is su ccessful, the display below left appears for

three (3) seconds before defaulting to the display below right:

20.9 %

8. The display above right requires a decision by the user (refer to

warnings at the beginning of section 4.7) to press ENTER and

skip the 100% O2 calibration and return to the SAMPLING mode;

or, wait ten (10) se conds for the followin g display:

9. Repeat steps #3 through #6 using a certified source of 100% oxygen.

10. If the calibration is successful, the display

at right appears for five (5) seconds before

defaulting to the SAMPLING mode.

Calibration Fails

An unsuccessful calibration can be caused by

several problems as displayed at right:

If after three (3) unsuccessful attempts to

calibrate: review section 7 for pos sible causes

and corr ective acti on or contact Analytical Industries Inc. at 909-392-6900.

To abort the RETRY press ESCAPE (analyzer) or MENU (monitor). Do

not proceed until the analyzer is calibra tion successfully.

AIR CALIBRATION

SUCCESSFUL

20.9 %

INTRODUCE 100% O2

OBSERVE TREND

PRESS ENTER TO CAL

17

TO SKIP 100% O2 CAL

PRESS ENTER

FOR 100% O2 CAL

WAIT FOR NEXT

DISPLAY

100 %

OXYGEN CALIBRATION

SUCCESSFUL

AIR / 100% O2 CALIBRATION

FAILED

- CHECK CAL GAS

- CHECK CABLE

- CHECK SENSOR

RETRY - PRESS ENTER

Page 11

4.8 Mounting

Every analyzer and monitor is equipped with a male dove tail bracket and

triangular shaped thick metal wire stan d secured to the rear o f the enclosure.

Tripod W i re Stand

Secured b etwe en b ump er f eet o n eith er s id e of t he b atter y com part ment i s a

triangular shaped thick metal wire stand that is hinged under the dove tail

bracket secured at the opposite end of enclosure.

Unsnap the triangular thick metal wire stand from between the bumper feet

and pull it away from the enclos ure to form a tripod which allows the devi ce to

sit upright on any flat surface

Dove Tail Bracket

The male dove t ail bracket is s ecured to the rear of the enclosure with two

screws. The 1” female dove tail pole bracket (HRWR-1075) is an optional accessory that is commonly found in medical applications. The v-shaped male

componen t simply slides into and out of the po le mou nted female section.

5 Operation

5.1 Principle of Operation

The AII 2000 Series O xygen Analyzers and Monitor u tilize an electrochemical

galvanic f uel cell type ox ygen sensor of the type t hat is exte nsively used to

measure oxygen concentrations from 0% to 100% in gas streams. Oxygen, the

fuel fo r this electr o chemi cal t rans du cer, di ff using i nto t he se nso r t hro ugh a gas

permeabl e mem br ane r e acts c hem ical ly at t he s ensin g electro de to prod uce an

electrical current output proportional to t he oxygen concentration in the gas

phase. The sensor has an absolute zero meaning that when no oxygen is present to be chemically reac te d the LCD displays 00. 0 oxygen.

The sens o r’ s s i gnal o utput i s l i near over the e nti r e rang e, remains vir t ual l y co n stant over th e speci f i ed useful life and dr ops of f s h ar ply at the end. Th e sensor

itself re quires no maintenance and is simply replaced at the end of its u s eful life

like a battery. Inasmuch as the sensor is a transducer in its own right, its expected life is not affected by whether the analyzer is ON or OFF.

The relationship between the sensor’s signal and changes with the oxygen

concentration is both proportional and linear, thus allowing single point calibration. Ot her factors that c an affect the si gn al output are describe d i n Section 5.2

Application Considerations and Section 3 Safety Warnings which should be read

before use.

Historic ally, the expect ed life of galvanic fue l type sensors has been spe cified as

“in air (20.9% O

type s ens or i s inv ersel y aff ect ed b y c ha nges i n t he aver ag e o xyg en conc e ntration, t em p er ature and pr es s ure it i s exposed t o duri n g its useful l i f e. For ex am ple, the AII-11-60 sensor has a 60 mo nths e xpected life in air (20.9 % oxygen)

at 25°C a nd ambient pres sure, howe ver, in a 100 % oxygen atmo sphere the

expected life is 12.6 months [60mo/(100%/20.9%)].

AII 2000 Seri es Oxyg en Anal yzer s and M onit ors are batt er y pow ere d b y (2) AA

alkaline batteries and controlled by a state-of-the-art micro processor. The batteries p rovid e eno ugh pow er to oper ate th e anal yzer co ntin uously for ap proximately 1,200 hours. Both devices utilize a membrane type keypad for users to

communicate commands to the microprocessor. The monitor is menu driven to

accommo date th e alar m f uncti o ns. Th e digit al el ectr oni cs pro vid e fe atur es suc h

as system diagnostics, warning indicators, controls and an alarm capability for

continuo us mo nitori ng tha t en hance bo th s afet y and ef fecti veness. The d esign

criteria, quality program and performance features ensure reliable and accurate

oxygen measurements.

) at 25°C and 760mm Hg”. The actual life of any galvanic fuel

2

18

19

Page 12

5.2 Application Consideratio ns

Effect of Anesthetic Agents

The AII 2000 Series Oxygen Analyzers and Monitors utilize an electrochemical

galvanic fuel cell type sensor, model AII-11-60, that has been characterized by

its gas permeable sensing membrane that allows the gas to be analyzed to

diffus e into the sensor w here oxyg en can be reacted. The dis played oxyg en

concentr atio n of al l s ensors of t his d esign d ecreas es i n th e pres ence o f a nesthesia gases. EN 1259 8:1999/I SO 776 7:1997 ( E) establ ished sta ndards f or the

maximum error allow able over a given durati on. Th e anesth etic a gents l isted

(Halothane, Enflurane, Isoflurane, Sevoflurane and Desflurance) were vaporized into a gas stream of 30% oxygen / 70% nitrous oxide.

Gas Test Level Decrease in O

Helium 50%, Balance O

Nitrous Oxide 80%, Balance O

Carbon Dioxide 10%, Balance O

0%

2

0%

2

0%

2

Reading

2

Halothane 4% <-1.5%

Enflurane 5% <-1.5%

Isoflurane 5% <-1.5%

Sevoflurane 5% <-1.5%

Desflurane 15% <-1.5%

The errors listed were observed after a two (2) hour exposure period. The

table above summ arizes the performance of the AII 2000 Series electronics

and AII- 11 -60 Oxygen Sensor. The above p er f o rm ances al l m eet or exc eed the

requirements established by EN 12598:1999/ISO 7767:1997 (E).

Do not operate any device in the presence of flammable anesthetic

agents such as Diethal Ether or Cyclpropane.

Note: The AII-11-60 Oxygen Sensor has been specifically designed and tested

to be compatible with nitrous o xide. For optimum results, mount the oxyge n

sensor w ith the s ensing ar ea facin g down tow ard the fl oor and be flushed or

calibrated with 100% oxygen every eight (8) hours.

Effect of Temperature

All mem bra ne clad electro ch emi cal se nsor s are t emp erat ur e depe ndent d ue t o

the expa ns i o n and contr a c ti o n of the Tef l o n sensin g m embrane. A s result m or e

or less of the sample gas including oxygen to be reacted diffuses into the sensor. The oxygen s ensor’s electrical current signal output varies linearly with

oxygen concen tr ati o n . T he s i gnal also var i es w i t h changes in ambi ent temp erature. The temperature coefficient is typically 2.54% of the signal or reading per

degree C change in temperature.

The tem perature de pendent c urrent sig nal output i s compensat ed by us ing a

resistor-thermistor network. With a proper resistor-thermistor network, the

signal can be compensated to within +

5% of the oxyg en reading over the 545°C temperature range. This is the worse case situation when going from one

extreme of the operating temperature range to the other. The error will be

elimi nated wh en th e therm istor in th e temper at ure comp ensat ion n etwor k and

the electrolyte inside the sensor reach thermal equilibrium in approximately 4560 minutes.

Erroneous oxygen readings can result if the gases flowing over the

sensing area o f th e se nso r ar e no t at am bie nt t emper at ure. This oc cur s

because t he sensor i s exposed to different tem peratur es. The sens ing

area of t he se nso r is o-ri ng se aled i n th e hea ted bre athi ng ci rcuit an d the t emperature compensation network at the rear of the s ensor is e xpos ed to ambie nt

temperature.

Effect of Pressure

Electrochemical sensors actually measure the partial pressure, not the percentage, of oxygen in the gas stream they are exposed to. These sensors are accurate at a ny pressure pro vided the press ure is consta nt and the analyzer h as

been calibrated at the same pressure as the sample gas measured.

For exam ple, when connect ed to a ve ntilator circ uit, the si x (6) second T90

respons e time of the AI I-11-60 Oxygen S ensor ca uses th e analyz er to dis play

an increase in the oxygen reading displayed when in fact the alternating

breathing pressure cycles generated by the ventilator is increasing the total

pressure.

The increase in the reading displayed is not related to a change in the oxygen

percentage but to the increase in partial pressure (corresponding to the increase in total pressure).

Calibrat e at the tem perat ure and press ure (alti tude) at which th e ana-

lyzer will be operated.

Effect of Humidity

The an alyzer is no t affect ed by non -condensin g relativ e humidit y (RH). Ho wever, the use of a humidifier to introduce water vapor and increase the moisture level of the gas mixture does affect the oxygen concentration and the

resultant reading dis played by the anal yzer. The addi tion of wate r vapor increases the total pr es s ure ther eby dil ut i ng o r decreasi ng the o xygen co nc entration of the ga s m ixture resulting in a lower oxygen r eading.

20

21

Page 13

Calibrate at the temperature and pressure (altitude) at which the analyzer will b e operated, hum idified gases cannot be 100% oxygen.

Effect of Condens ation

Excessiv e co ndens at ion c oll ecting on t he s ensi ng ar ea or th e el ectri cal con nections at th e rear o f t he s ensor s can adve rs ely i m pact t he per for man ce of el ectrochemical sensors. Cond e nsation bl ocks the diffusion p ath of oxygen into the

sensor an d can r educe the ox ygen r eading t o 00.0 i f the cond ensat ion covers

the entire sensing area. Condensation on the electrical connections at the rear

of the s ensor can aff ect ox ygen re adings . R emedy either situ ation by sh aking

out the condensation and allowing the sensor to air dry.

Erroneously characterized in many instances as a sensor failure, excessive

condensation is rem edied by gently wi ping away the condensation with a soft

cloth or simply allowing the sensor to air dry.

Effect of Electromagnetic Radiation

Tested o ver a 26 MHz t o 1000 MHz ele ctrom agneti c fiel d, the a nalyz er is s usceptibl e at al l frequencies tes ted except tho se betw ee n 93 0 and 990 MHz.

Never o perate the a nalyzer near equipment c apable of emi tting hig h

levels of electromagnetic radiation. Do not continue to operate the

analyzer if the reading becomes unstable.

Calibration

Calibrating t he analyz er or moni tor durin g normal o peration invol ves

the same pr ecautions a nd proc edures as thos e described in S ections

4.7 Start-up Calibration with t he same cautions to review Sections 3

Safety Warn ings and 5.2 Applic ation Conside ra t io ns.

5.4 Sampling

Assuming the START-UP instructions are followed and the tests are completed

successfully the devices de fault t o the SAMPLIN G mode.

Never ope r ate the analyzer if the r eading is unstab le o r if a ma lfunction

is suspected. If calibration is required as indicated herein, do not proceed until the analyzer is calibration succ essfully.

5.4.1 Flowing Gas Stream s (B re a thing Circuits)

1. Place the sensi ng are a of the s ensor i nto the g as stream to be analyzed

upstream of any humidification equipment.

2. Assure that the flow rate of the gas stream does not exceed ten (10) liters

per minute. Exceeding ten (10) liters per minute generates backpressure.

3. Check the gas stream and particularly the mechanical connection for leaks

that dilute the gas stream with ambient ai r.

4. Assure there are no restrictions in the circuit downstream of the sensor

that could generate backpressure on the sensor.

5. Use th e f l o w di ver ter supplied wi th the d e vi ce along

with the optional tee adap ter and position the s ensor vertically for optimum results, as shown right.

The flow diverter avoids stagnation and facilitates

the movement of gas to and from the sensing area

of the sensor thereby producing a more accurate

measurement of the gas stream to be measured.

6. Install the tee-a dapter in the breathin g circuit.

7. Screw the flow diverter to the sensor.

8. Ensure the o-ring is lightly lubricated for ease of

entry and a tight seal between the flow diverter and

tee adapter.

9. Insert the assembled flow diverter/sensor into the tee allowing 100%

oxygen (dry, non-humidi fi ed) to f low past t he se nsor at a r ate of 5-8 l i ters

per minute.

10. Once th e sensin g area of the se nsor is expose d to the gas stre am all ow

approximately sixty (60) seconds for the reading to stabilize and observe

the reading displayed by the LCD.

5.4.2 Static Atmospheres (Incubators, Hoods, Oxyge n Tents)

Remove the flow diverter, not needed. Failure to remove the flow diverter will

dramatically slow the response time of the sensor.

Expose the sensing area of the sensor to the atmosphere allowing approximately sixty (60) seconds for the reading to stabilize and observe the reading

displayed by the LCD.

If placing the entire sensor inside the controlled atmosphere review

Section 5.2 Applicat ion C on s ideration, Effe ct of Temperature.

22

23

Page 14

5.4.3 AII 2000HC Oxygen Analyzer (Integral Oxygen Sensor)

AII 2000HC w ith its integr al oxy gen sensor req uires co nnecting the ¼” tu bing

supplied (section 4.2.1 abo ve) with th e d evice to a ¼” hose bar b attached to a

pressure regulator controlling a source of gas flowing at less than 10 liters per

minute.

5.5 Alarms (AII 2000M Oxyge n M onito r):

The mo ni to r i s eq ui pped w i th us er select able HI a nd LO alarm se t points w hi ch

are displayed at the bottom of the LCD. Section 4.6 describes the operation

and procedure for setting the alarms in detail.

6 Maintenance

Review Section 3 Safety Warnings and Section 7 Troubleshooting for

guidelin es on servicing the dev ices.

6.1 Serviceability

Do not op en t h e m ain com partm en t of t he anal yz er, as it cont ai ns no s er vic eable parts inside. Never attempt to repair the analyzer or sensor by yourself as

you may damage the analyzer which could void the warranty.

6.1.2 Cleaning / Reuse Instructions

Clean th e devic e, oxyge n sens or and accessori es with a soft cl oth dam pened

with either water or mild isopropyl alcohol solution (70% isopropyl alcohol

solution in water), if necessary, before re-use. Allow the components to air-dry

after cleaning.

Note: The Home Care Kit is not intended for patient use, it is intended solely

for conf irming t he O

cleaning instructions apply.

6.2 Battery Replacement

The an alyzers an d monit or are po wered b y two A A alkali ne batt eries wi th an

approximate life of 1,200 hours. A low b attery indicator circ uit monitors th e

battery suppl y vol t a ge and s en ds a si gn al di rectly t o the LCD when the bat t er y

voltage reaches a preset level that activates the battery symbol in the LCD.

The bat t eri es are housed in a s eparate co m p ar tment l o c at e d at t he rear o f the

device and are accessible by sliding the removable cover.

concentration in Oxygen Concentrators. Accordingly, no

2

Initially this procedure can be somewhat difficult. Care should be taken

not to damage the case when removing the battery compartment cover.

6.2.1 Procedure:

1. Turn the device over so the

shortest raised l ine o n t he battery

compartment cover is pointing

away from you.

2. Lift the tripod wire stand up and

away from the case.

3. Grasp the case with both hands

and using your thumbs press

down fir mly on the rai sed li nes and push t he battery compart ment cover

away from you.

4. Locate the positive (+) and negative (-) terminals on the battery.

5. Assure the battery contacts are clean.

6. Ali gn one batt ery’s posi tive (+) termin al with t he corr espondin g (+) bat-

tery sy mbo l m o lded into the case.

7. Insert the battery into the compartment.

8. Repeat with the remaining battery.

9. Replace the batter y compartment cover, make sure it snaps into position

and is secured flush against the case. Replace the wire stand as required.

10. Calibrate the device after replacing the batteries.

6.3 Oxygen Sensor Replacement

The desi gn of th e electr onics is int ended f or only t he An alytical Indus tries I nc.

AII-11-60 or AI I-11-60-HC Oxygen Sensors. Use of a different o xygen sensor

may result in an erroneous oxygen reading.

NEVER - Open th e oxygen s ensor or probe t he sensin g surfac e, refer

to Section 10 in the event the sensor should leak and someone comes

in contact with the electrolyte from inside the sensor.

6.3.1 Procedure AII 2000 M and A II 2000A - External Sensor

1. Disconnect the cable from the old sensor just as you disconnect a tele-

phone jack from a wall plug.

2. To connect the new sensor simply fi nd and register the male plug at the

end of the coiled cable and insert it into the mating female jack at the rear

of the senso r unt il it mates or snaps into place.

3. Calibrate the device after replacing the oxygen sensor.

24

25

Page 15

6.3.2 Procedure AII 2000 HC - Integ ral Se nsor

1. Tools required: small bladed screwdriver.

2. Plac e the device face down on a flat surface.

3. Remove the two (2) screws from the upper corners of the rear of the

device.

4. Move the tri pod up, rem ove the batt ery compartment co ver (see B attery

Replacement) and remove the two (2) screws located on either side.

5. Pull the rear section up ¼”-½”, turn it over and lay it next to the other

section.

6. Loc ate the w hite co nnecto r at the e nd of the f our (4) wires runnin g fro m

the sensor (the cylinder with the white label) to the top of the PCB.

7. With your left for finger and thumb, grasp the sides of the back end of the

white connector where it is soldered to the PCB.

8. With yo ur rig ht fore f inger and thumb, grasp t he sides of the sec tion of

the white connector where the four (4) wires from the sensor terminate.

9. Separate the connector - hold the white connector section your left hand

while gently pulling and wiggling the white connector section with your

right hand until it unlo cks.

10. The oxygen sensor inserts into an adaptor (identified by a round recess

with a cylindrical hose adapter in the center) that slides into grooves

molded into the side of the case .

11. Hold the r ear section of the cas e down, gr asp the sq uare edges of the

adaptor, lift up (lift straight up so as not to strip the grooves molded into

the adaptor and case) and remove the adaptor and oxygen sensor as a

single component.

12. Once th e adapt er and ol d sensor h ave bee n removed f rom the c ase, ho ld

the label of the s ensor , agai n grasp t he s quare ed ges of the ada ptor and

pull – to separate the old sensor from the adaptor.

13. Remove the new oxygen sensor from the plastic shipping container.

14. Install the new oxygen sensor by reversing s teps 12 through 3.

15. Calibrate the device after replacing the oxygen sensor.

7 Troubleshooting

If the recom men ded corr ective a ction does no t resol ve the probl em retur n the

device to the factory for service.

Symptom Corrective Action

Device appears to be physically dam age d

No digital display when analyzer is turned ON

Battery symbol on LCD display

LCD display reads 00.0

No response to keypad command

Cannot turn device OFF

Turn device ON – if it successful passes

START-UP TEST and calibrates – proceed.

Install b attery

Replace bat tery

Check battery polarity

Check and/ or cl ean battery contacts

Replace battery and calibrate device

Install sensor

Check electric al connections

Assure el ec t ri c al connecti ons are dry

Replace bat tery

Calibration routine in process – escape or

wait until completed

26

27

Page 16

Symptom Corrective Action

Reading displayed by LCD

drifts during calibr ation

Analyzer reading climbs after

calibration in 100% dry oxygen when exposed to air

20.9%

After calibration in 100% dry

oxygen, analyzer reading

drifts more than 2% over 8

hours

Reading displayed by LCD

does not change when oxygen leve l cha nges

Reading does not stabilize or

fluctuates erratically

Wait 5 minutes and repeat calibration with

sensor placed on flat surface (not in your

hand)

Check integrity of gas delivery system

Check sensor’s front o-ring seal

Verify calibration gas in not humidified

Remove moisture covering sensor

Replace sensor, repeat calibration

Allow the sensor to stabilize for 5 minutes in

100% dry oxygen and recalibrate

Check p r im ary oxygen delivery device

Replac e sens or t ha t is near i ng th e e nd of its

useful life

Replace sensor

Relocat e analyz er aw ay sour ce of radio f requency or electromagnetic radiation emissions. Tested o ver a 26 MHz to 1000 MHz

electromagnet i c f i el d, the anal yz er i s s us c eptible at all frequencies tested except those

between 930 and 990 MHz.

Check sensor connection

Check cable connection

Wait 5 minu te s and repeat calib ration

Replace sensor, repeat calibration

Do not attempt to use the analyzer and

return the analyzer for service.

Symptom Corrective Action

Reading displayed by LCD

does not change when calibratio n control is adju s ted

Reading displayed by LCD is

very low

Alarms continuously activated

Replace sensor

Check sensor connection

Check cable connection

Replace sensor

None – Normal operation, confirm set points

Abnormal Adjust alarm set points

Remove moisture covering sensor

Check sensor connection

Check cable connection

Check integrity of gas delivery system

Check sensor’s front o-ring seal

Verify calibration gas in not humidified

Verify flow rate is 4-5 liters per minute

Replace sensor

Replace cable

28

29

Page 17

8 Specifications

Accuracy: +

Analysis: 0-100% oxygen

Area Classification: Ge nera l purpose

Alarms:

Calibration: 100% oxygen before using each day or aft er 8 hours of

Compensation: Temperature compensated

Connections: (M, A) 1x16mm thread or o-ring diverter; (HC) tubing

Controls: Soft touch keypad for ON/OFF and menu function

Dimensions: 3.6 x 5.9 x 1.6”; weight 10 oz. (280 grams)

Display: 3-1/2 digit backlit LCD 2.5” x 1.5”; resolution 0.1% O

Flow Sen sitivity: None between 0.2 to 10 liters per minut e

Humidity: Non-condensing 0-95% RH

LED Indicators: Analyzer - none; Monitor - upon activation of alarms

Linearity: +

Pressure: In let – (M, A) a mbient, (HC) regulate; v ent - atmo spheric

Power: 2 AA Alkaline batter i es ; 1, 20 0 hours co n t i nuous use

Respon se Time: 90% of final FS read ing in 9 seconds

Sensitivity: < 0.5% of FS range

Sensor: (M, A) AII-11-60 or (HC) AII-11-60-HC

Expected Life: 60 months in air at 25ºC and 1 atmosphere

Storage Temp.: -20º to 60ºC (-4ºF to 140ºF) on intermittent basis

Temp. Range: 5º to 45ºC (41ºF to 113ºF)

Warm-up Time: None

Warranty: 24 months analyzer; 18 months sensor (any application)

2% of FS range under constant conditions

Analyz er – non e; Moni tor - U s er adjust abl e H I 1 6-10 0%,

LO 15-99 %, 120 seco nd alarm si lence, HI alarm defe at

for flushing patients with 100% O

2

contin uous use.

2

1% under constant conditions

Expected Sensor Life

Consider s t he ful l ra ng e of t he se nso r’s signal , exam ple 7- 13 mV. M os t medi cal

oxygen sensors are configured to meet the published, see opposite page, specification which distrib utes the overall sensor life as fo llo ws :

- 60 months Expected Service Life (915,420 oxygen % hours)

- 6 months Recommended Storage Life period (91,542 % oxygen hours)

- 2 months margin of error

Therefor e, the Recommend ed Storag e life p eriod should not be co nsidered a

perishabl e shelf life. Op erating at the spe cified par ameters of oxyg en concentration (air 20.9%), temperature (25⁰C/77⁰F) and pressure (1 atm/bar), the

sensor will o perate for appr o ximately 68 m onths whether in storage or in use.

The purpo se of the Storage Li fe period i s to ensur e the user derives th e Expected Life of 60 mo nths (915,420 % oxygen ho urs) and does not lose the

benefit of the warranty.

Warranty

The 18 month (274,626 % oxygen hours) w arranty period (b egins with shipment from the factory and is limit ed to the first claim submitted) is ba s ed on:

- 60 months Expected Service Life (915,420 % oxygen hours)

- Estimated exposure (24/7) to 60-70% oxygen concentration

- Marginal of error of 2 months

8.1 Spare Parts & Accessories

AII-2000 A, AII-2000 M

Spare Parts: Spare Parts:

AII-11-60 Oxygen Sensor A II-11-60-HC Oxygen Sensor

BATT-1008 Battery (2x) 1.5V AA BATT-1008 Battery (2x) 1.5V AA

P-1087 Instructions for Use P-1087 Instructions for Use

A--1162 PCB Assy Main A-1162 PCB Assy Main

CABL-1006 Coil Cable TUBE-1007 1/4” Tubing 7’

FITN-1112-1 Flow Diverter

AII-2000 HC

Optional Accessories : Optional Accessories :

FITN-1009 Tee Adapter FITN-1066 Nipple Universal

HRWR-1075 Dovetail Clamp H RWR-1074 Doveta il C lamp

CC-1072 Carrying Case CC-1072 Carrying Case

30

31

Page 18

9 Warranty

Coverage

Under nor mal o perati ng co nditions , th e anal yzer an d sens ors ar e war rante d to

be free of defects in materials and workm anship for the period s pecif ied in the

current published specification s . To make a warranty claim, you must retur n th e

item properly packaged and postage prepaid to:

Analytical Industries in their sole discretion shall determine the nature of the

defect. If the item is determined to be eligible for warranty we will repair it or,

at our option, replace it at no charge to you. If w e choose to r epair your item,

we may us e new or reco ndition ed repl acem ent par ts of t he same o r upgr aded

design. This is the only warranty we will give and it sets forth all our responsibilities, there are no other express or imp lied warranties.

The war ra nty begi ns w ith t he date of ship me nt f rom An alyti c al Indu stri es I nc.,

is limited to the first customer who submits a claim for a given serial number

which must be in place and readable to be eligible for warranty and will not

extend to more than one customer or beyond the warranty period under any

conditions.

Exclusions

This warranty does not cover normal wear and tear; corrosion; damage while in

transit; damage resulting from misuse or abuse; lack of proper maintenance;

unauthorized repair or modification of the analyzer; fire; flood; explosion or

other fa ilure to follow the Owner’s Manual.

Limitations

Analytical Industries Inc. shall not liable for losses or damages of any kind; loss

of use of the a nalyzer; i n ci dental or cons e quenti al l o ss es o r d am ages; dam a ges

resulting from alterations, misuse, abuse, lack of proper maintenance; unauthorized repair or modification of the analyzer.

Service

Contact us between 8:00am and 5:00pm PST Mon day thru Thursday or before

12:00pm on Friday. Trained technicians will assist you in diagnosing the problem and determ i ning the appropriate cours e of action.

Analytical Industries Inc.

2855 Metropolitan Place

Pomona, Ca 91767 USA

T: 909-392-6900, F: 909-392-3665

E: sales-medical@aii1.com

, W: www.aii1.com

10 Material Safety Data Sheet (MSDS)

Product name Electrochemic al Galvanic Fu el Cell Oxygen Sensor

Exposure Sealed device with protective coverings, normally no hazard

Ingredients Carcinogens - none; Potassium Hydroxide (KOH), Lead (Pb)

Properties

Flash Points Not applicable, non-flammable

React ivity Stable; avo i d st r o ng acids, emits fumes when heated

Health Hazard KOH entry via ingestion - harmful or fatal if swallowed;

Symptom s Eye con ta ct - burning sensat io n; skin contact - slick feeling

Protection Ventilation - none; eye - safety glasses; hands - gloves

Precautions Do not remove Teflon and PCB coverings; do not probe wi th

Action KOH

Leak

10.1 Disposal

Oxygen sensors and batteries should be disposed of in accordance with local

regulations for batteries.

Completely soluble in H

eye - corrosive, possible loss of vision;

skin con ta ct - corrosive, p o s s ible chemical burn.

Liquid inhalation is unlikely.

Lead - known to caus e bir th defect s , co ntact unl i kely

sharp objects; avoid contact with eyes, skin and clothing.

Use rubber gloves, safety glasses and H

surfaces repeatedly with liberal amounts of H

WEEE regulations prohibit electronic products including the Helium a nd enviro nmental s ensors fr om being placed in househol d

trash bins.

Electronic products should be disposed of in accordance with local

regulations.

2O; ev aporation simi lar to H2O

2O and flush all

2O

32

33

Loading...

Loading...