Analog Microelectronics AME7107Y, AME7107RCPL, AME7107CPL, AME7107ACKW, AME7106Y Datasheet

...

AME, Inc.

AME7106/AME7106A/AME7106R

AME7107/AME7107A/AME7107R

nn

n Key Features

nn

l 100µV Resolution

l High Impedance Differential Inputs

l Differential Reference

l Drive LCD (AME7106) or LED (AME7107)

Directly

l Four New Convenient Features

(AME7106A/AME7107A)

l Display-Hold

l Low-Battery Indication

l Integration Status Indication

l De-Integration Status Indication

nn

n Applications

nn

l Digital multimeter

l pH meter

l Capacitance meter

l Thermometer

l Digital Panel meter

l Photometer

3-1/2 Digit A/D Converter

High Accuracy, Low Power

nn

n General Description

nn

The AME7106 and AME7107 family are high performance, low power, 3-1/2 digit, dual-slope integrating A/

D converters, with on-chip display drivers. The

AME7106 is designed for a single battery operated system, will drive non-multiplexed LCD display directly.

The AME7107 is designed for a dual power supply system, will directly drive common anode LED display.

These A/D converters are inherently versatile and accurate. They are immune to the high noise environments. The true differential high impedance inputs and

differential reference are very useful for making

ratiometric measurement, such as resistance, strain

gauge and bridge transducers. The built-in auto-zero

feature automatically corrects the system offset without any external adjustments.

Display-hold, low-battery flag, integration and de-integration status flags are four additional features which

are available in the 44-pin package, AME7106ACKW

and AME7107ACKW.

nn

n Typical Operating Circuit

nn

* For the operating circuit of the reverse-pins version, please refer

to pin configuration on page 4 and pin description on page 5 & 6

1

AME, Inc.

AME7106/AME7106A/AME7106R

AME7107/AME7107A/AME7107R

nn

n Absolute Maximum Ratings

nn

AME7106

Supply Voltage (V+ to V-) 12V

Analog Input Volt ag e (Either inputs) V+ TO VReference Input Vol tage (Eith er i np uts ) V+ TO VClock Input Test to V+

Power Di ssipation 800mW

Operat ing Tempera ture 0

Storage Temperature -55

Lead Temperature (S ol d eri ng 60 s e c ond s)

AME7107

Supply Voltage

V+ 6V

V- -6V

Analog Input Voltage (Either inputs) V+ to VReference Input Voltage (Either inputs) V+ to VClock Input Gnd to V+

Power Dissipati o n 800mW

Operating Temperature 0

Storage Temperature -55

Lead Temperatur e (Solder ing 60 seconds)

3-1/2 Digit A/D Converter

High Accuracy, Low Power

o

C to 70oC

o

C to 150oC

o

300

C

o

C to 70oC

o

C to 150oC

o

C

300

Static sensitive device. Unused devices must be stored in the conductive material.

Protect device from static discharge and static field. Stresses exceed the above Absolute Maximum

Ratings may cause permanent damage to the device. Exposure to Absolute Maximum Rating Conditions for extended periods may affect the reliability of the device.

2

AME, Inc.

AME7106/AME7106A/AME7106R

AME7107/AME7107A/AME7107R

nn

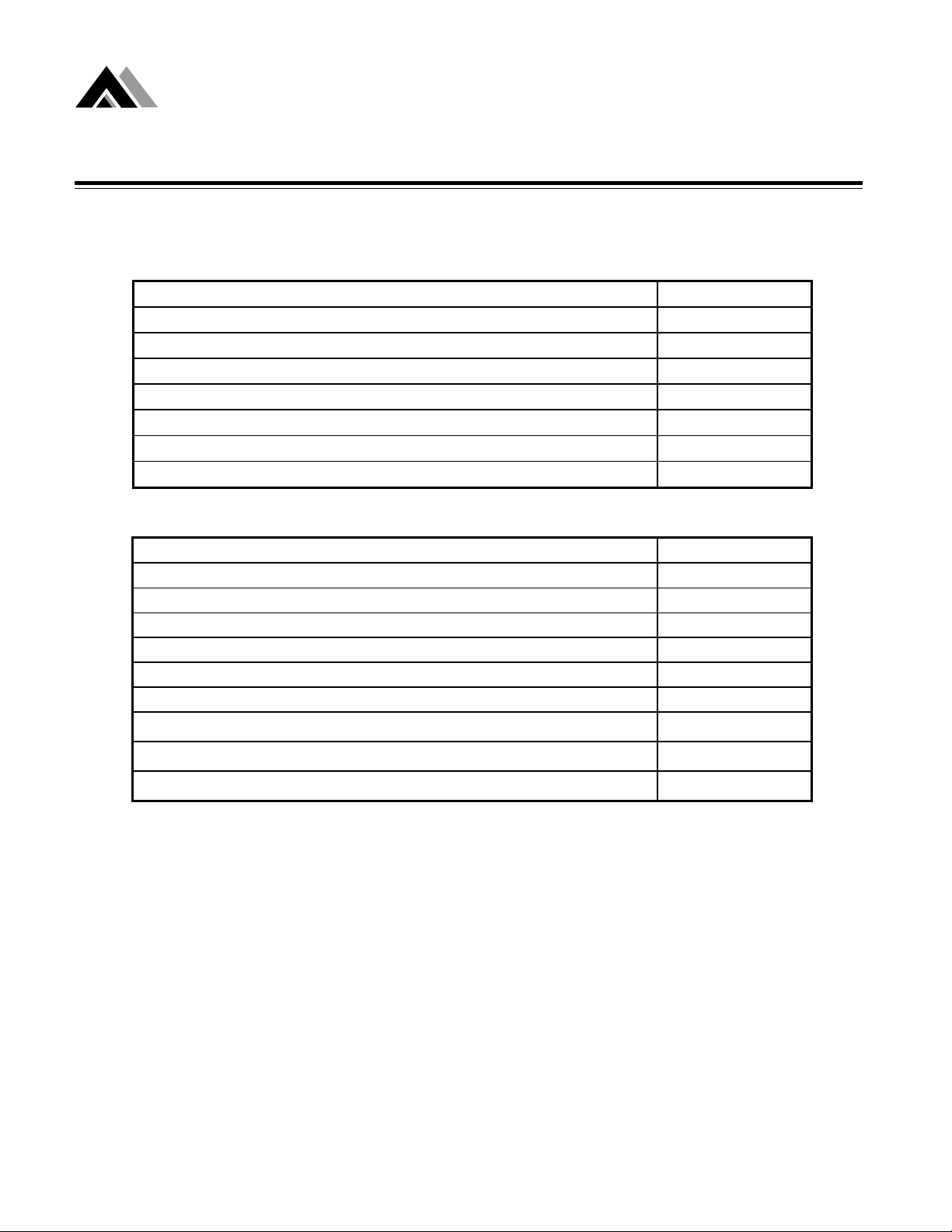

n Ordering Information

nn

Pa rt Numbe r Displa y Marki ng Pa cka ge Pin Layout Tem p. Ra nge

AME7106CPL LCD

AME7106RCPL LCD

AME7106ACKW LCD

AME7106Y LCD

AME7107CPL LED

AME7107RCPL LED

AME7107ACKW LED

AME7107Y LED

AME7106CPL

AME7106RCPL

AME7106ACKW

AME7107CPL

AME7107RCPL

AME7107ACKW

YYWW

YYWW

YYWW

AME7106Y

YYWW

YYWW

YYWW

YYWW

AME7107Y

YYWW

3-1/2 Digit A/D Converter

High Accuracy, Low Power

40 Pin P DIP Normal

40 Pin P DIP Reverse

44 Pin P Q F P Normal

44 Pin Di ce Normal

40 Pin P DIP Normal

40 Pin P DIP Reverse

44 Pin P Q F P Normal

44 Pin Di ce Normal

o

C to 70oC

0

o

0

C to 71oC

o

C to 72oC

0

o

0

C to 73oC

o

0

C to 74oC

o

C to 75oC

0

o

0

C to 76oC

o

0

C to 77oC

3

AME, Inc.

AME7106/AME7106A/AME7106R

AME7107/AME7107A/AME7107R

nn

n Electrical Characteristics

nn

Unless otherwise noted, AME7106 & AME7107 are specified at TA = 25

O

C, fclock = 48KHz. Supply voltage = 9V (V+ to V-)

3-1/2 Digit A/D Converter

High Accuracy, Low Power

Parameter Conditions Min Typ Max Unit

Zero Input Reading

Ratiometric Reading Vi n = Vref = 100.0mV 999 999/1000 1000 Digi tal Reading

Roll-Over Error -1 –0.2 +1 Counts

(Difference in Reading for

Equal Positive and Negative

Reading Near Full-Sc ale)

Linearity (Max. Deviation Full-Scale = 200.0mV -1 –0.2 +1 Counts

From B est Straight Li ne Fit)

Common-Mode Vcm = –1V, Vin =0V 50

Rejection Ratio Full-Sc ale = 200.0mV

Noise (Pk-Pk V alue Not Vi n = 0V 15

Exceeded 95% of Tim e) Full-Scale = 200.0mV

Leakage Current at Input Vi n = 0V 1 10 pA

Zero Reading Drift Vi n = 0V, 0

Suppl y Current Vi n = 0V 0.8 1.2 mA

(Excluding LED current

for 7107)

Anal og Com m on Voltage 25KΩ Between 2.8 3.0 3.2 V

(With respect to V+) Common and V+

Temp. Coeff. of Analog 25KΩ Between 50 75 ppm/

Common (With respect to V+) Common and V+

Low Bat tery Flag V+ to V- 6.3 7.0 7.7 V

Test Pin Voltage With respect to V+ 4 5 6 V

(AME7106 only)

LCD Segment Drive Voltage V+ to V- = 9V 4 5 6 V

(AME7106 only)

Backplane Drive Voltage V+ to V- = 9V 4 5 6 V

(AME7106 only)

Segment Si nking Current V+ = 5.0V 5 8.0 mA

(Except Segment AB4) Segment Voltage = 3V

(AME7107 only)

Segment Si nking Current V+ = 5.0V 10 16 mA

(Segment AB4) Segment Voltage = 3V

(AME7107 only)

Vi n = 0V 0 Digi tal Reading

Full-Scale = 200.0mV

-Vin=+Vin ≈200.0mV

O

C to 70OC0.21

O

0

C ≤TA ≤70OC

µ

µ

V/OC

µ

V/V

V

O

C

Notes: 1.Input voltage may exceed the supply voltages provided the input current is limited to ±100µA.

2.Dissipation rating assumes a device is mounted with all leads soldered to printed circuit board.

4

AME, Inc.

AME7106/AME7106A/AME7106R

AME7107/AME7107A/AME7107R

Pin Configurations

n

3-1/2 Digit A/D Converter

High Accuracy, Low Power

5

AME, Inc.

AME7106/AME7106A/AME7106R

AME7107/AME7107A/AME7107R

nn

n Pin Description

nn

40-pin DIP 40-pin DIP 44-pin P QF P

Pin Number (Reverse) Pin Number

1 (40) 8 V+ Posi t ive supply voltage

2 (39) 9 D1 Unit s -digit D-s egm ent driver

3 (38) 10 C1 Units -digit C-s egment driver

4 (37) 11 B1 Unit s -digit B -s egm ent driver

5 (36) 12 A1 Unit s -digit A -s egm ent driver

6 (35) 13 F1 Unit s -digit F-s egm ent driver

7 (34) 14 G1 Units -digit G -segm ent driver

8 (33) 15 E1 Unit s -digit E -s egm ent driver

9 (32) 16 D2 Tens-digit D-s egm ent driver

10 (31) 17 C2 Tens-digit C-s egm ent driver

11 (30) 18 B 2 Tens-digi t B -s egm ent driver

12 (29) 19 A 2 Tens-digi t A -s egm ent driver

13 (28) 20 F 2 Tens-digit F-s egm ent driver

14 (27) 21 E 2 Tens-digi t E -s egm ent driver

15 (26) 22 D3 Hundreds -digit D-segm ent driver

16 (25) 23 B 3 Hundreds -digit B -s egm ent driver

17 (24) 24 F 3 Hundreds -digit F -s egm ent driver

18 (23) 25 E 3 Hundreds -digit E -s egm ent driver

19 (22) 26 AB4 Thousands-digit , B& C segment s driver

20 (21) 27 POL Negative-polarity driver

21 (20) 28 B P / LCD back plane driver (AM E 7106)

22 (19) 29 G 3 Hundreds-digit G-s egm ent driver

23 (18) 30 A 3 Hundreds -digit A -s egm ent driver

24 (17) 31 C3 Hundreds -digit C-segm ent driver

25 (16) 32 G 2 Tens-digit G -segment driver

¢w 33 LB Low-batt ery flag segm ent driver

26 (15) 34 V- Negative power suppl y voltage

27 (14) 35 INT Integrator output . Connec t ion point for

28 (13) 36 BUF Integrator resistor c onnec ti on-point .

29 (12) 37 A/Z Aut o-zero c apac i t or connection-point

30 (11) 38 INLO Analog-input l ow

31 (10) 39 INHI Analog-input high

32 (9) 40 COM Analog-c ommon

3-1/2 Digit A/D Converter

High Accuracy, Low Power

Symbol Description

GND Digital ground (A ME7107)

integrati on c apac i tor.

6

AME, Inc.

AME7106/AME7106A/AME7106R

AME7107/AME7107A/AME7107R

nn

n Pin Description (Cont.)

nn

40-pin DIP 40-pin DIP 44-pin PQFP

Pin Number (Reverse) Pin Number

33 (8) 41 CREF- Referenc e capacitor, negative terminal

34 (7) 42 CREF+ Reference c apacitor, pos it ive t erm inal

35 (6) 43 VREF+ Analog-referenc e input , negative termi nal

36 (5) 44 VREF- Analog-reference input, positive terminal

37 (4) 3 TES T Display -test pin, When pulled to V+,

38 (3) 4 OSC3 S ee OSC1

39 (2) 6 OCS2 S ee OSC1

40 (1) 7 OCS1 Pin OS C1, OSC2, OSC3 make up the

3-1/2 Digit A/D Converter

High Accuracy, Low Power

Symbol Description

1 DEEN De-integration status flag

2 INTEN Integration st atus flag

displ ay s hould read -1888.

5 HOLD Hold pin, Logic 1 holds display

osci lla tor. See Clock sec ti on for detai ls

nn

n Function Description

nn

7

AME, Inc.

AME7106/AME7106A/AME7106R

AME7107/AME7107A/AME7107R

The A/D conversion has the following three phases:

1. Auto-Zero Phase

2. Integration Phase

3. De-integration Phase

Auto-Zero Phase

The INHI and INLO are shorted to analog common internally . The reference capacitor is charged to the reference voltage. A feedback loop is closed around the

system to cancel the offset voltage of buffer, integrator

and comparator.

Signal Integration phase

The converter integrates the differential voltage across

the INHI and INLO for a fixed time, 1000 system clocks.

The polarity of the signal is determined at the end of

this phase.

Reference Integration Phase

INLO is internally connected to the Analog Common,

INHI is connected across the reference capacitor with

appropriate polarity determined by the control circuit.

The integrator output will then return to zero. The time

it takes to return to zero, 1000 X VIN /VREF, is the

digital representation of the analog signal.

Differential Signal Inputs (INHI & INLO)

The AME7106/AME7107 has true differential inputs and

accepts input signals within the input common mode

voltage range (Vcm). Typical range is from 1V above

the V- to 1V below the V+. The integrator output can

swing within 0.3 V of V+ or V- without increasing

3-1/2 Digit A/D Converter

High Accuracy, Low Power

linearity errors. Care must be exercised to make sure

the integrator output does not saturate. In a typical

application, the common mode is eliminated by connecting the INLO to COM, Analog Common.

Differential Reference (VREF+ & VREF-)

The reference voltage can be generated anywhere

within the V+ to V-. Under a large common mode voltage, reference capacitor can gain charge during the

de-integration of a positive signal. The reference capacitor will lose charge when de-integrating a negative

input signal. The difference in reference voltage for

positive or negative input voltages can cause the

rollover error. To prevent rollover error from being induced by large common-mode voltages, reference capacitor should be large compared to stray node capacitance.

Analog Common (COM)

The Analog Common is to set a common mode voltage for the analog signal. The analog common is typically 3.0V below V+, set primary for the battery operated application. Analog common is capable to sink 20

mA. It’s source current is limited to 10 µA. Analog

common is therefore easily pulled to a more negative

voltage to override the internal reference. When supply voltage is greater than 7V, analog common can be

used as reference source with temperature coefficient

of typically 50 ppm/OC. The internal heating by the LED

display drivers of the AME7107 may degrade the stability of the Analog Common. An external reference is

recommended.

8

AME, Inc.

AME7106/AME7106A/AME7106R

AME7107/AME7107A/AME7107R

nn

n Digital Block Diagrams

nn

3-1/2 Digit A/D Converter

High Accuracy, Low Power

9

AME, Inc.

AME7106/AME7106A/AME7106R

AME7107/AME7107A/AME7107R

nn

n Digital Section

nn

Digital Ground

AME7106 generates an internal digital ground, typically

5V below the V+. The digital ground of AME7107 is

supplied externally.

Clock Circuit

The clock can be generated in either of the following

three methods.

1. An external oscillator connected to“OSC1”

2. A crystal between pins” OSC1” and “OOSC2”

3. A R-C oscillator using “OOSC1”, “OOSC2” and

“OSC3”

Notes: There is no on-chip feedback resister across osc1

and osc2.

Systems Timing

The oscillator frequency is divided by 4 prior to clocking the internal decade counters. Each conversion takes

4000 counts or 16000 oscillator clock pulses. The timing of each phase are as follows:

3-1/2 Digit A/D Converter

High Accuracy, Low Power

Auto-Zero Phase: 1000 to 3000 Counts

Signal Integration Phase: 1000 Counts (Fixed)

Reference Integration Phase : 0 to 2000 Counts

For signals less than full-The A/D conversion has the

following three phases:scale, the unused reference

integration time is assigned to the autozero phase.

Segment Drivers (AME7106)

The backplane frequency is 1/800 of the oscillator clock

frequency. For example if the oscillator frequency is

48 KHz (3 conversions per second) the backplane frequency will be 60 Hz. The segment and backplane are

at the same frequency with a nominal 5 volt amplitude.

The segment is visible (ON) when the segment and the

backplane are out of phase, otherwise it is invisible

(OFF). The polarity segment is “ON” for negative analog inputs. When the TEST pin on the AME7106 is

pulled to V+, all segments are turned “ON”. The display reads -1888. During this mode the LCD segments

have a constant DC voltage impressed. DO NOT LEA VE

THE DISPLAY IN THIS MODE FOR MORE THAN

SEVERAL MINUTES! LCD displays may be destroyed

if operated with DC levels for extended periods.

10

AME, Inc.

AME7106/AME7106A/AME7106R

AME7107/AME7107A/AME7107R

Segment Drivers (AME7107)

The AME7107 is designed to drive common anode

LEDs. All segment drivers are N-channel transistors

with a typically 8 mA current driving capability. The

1000’s segment AB4 sinks current from two LED segments, and has a 16 mA driving capability. The polarity indication is “on” when the analog input voltage is

negative.

Test

When the TEST is pulled to V+ all segments and the

minus sign will be activated. The TEST pin is tied to

the internally generated digital ground through a 500Ω

resistor in the AME7106. It is typically 5V lower than

V+. TEST pin may be used as the negative power supply for external CMOS logic at the maximum current of

1 mA.

Data Hold

When the Hold pin is connected to V+ the conversion

result will not be updated. The conversion is still free

running during the hold mode. It is available in 44 pin

package.

3-1/2 Digit A/D Converter

High Accuracy, Low Power

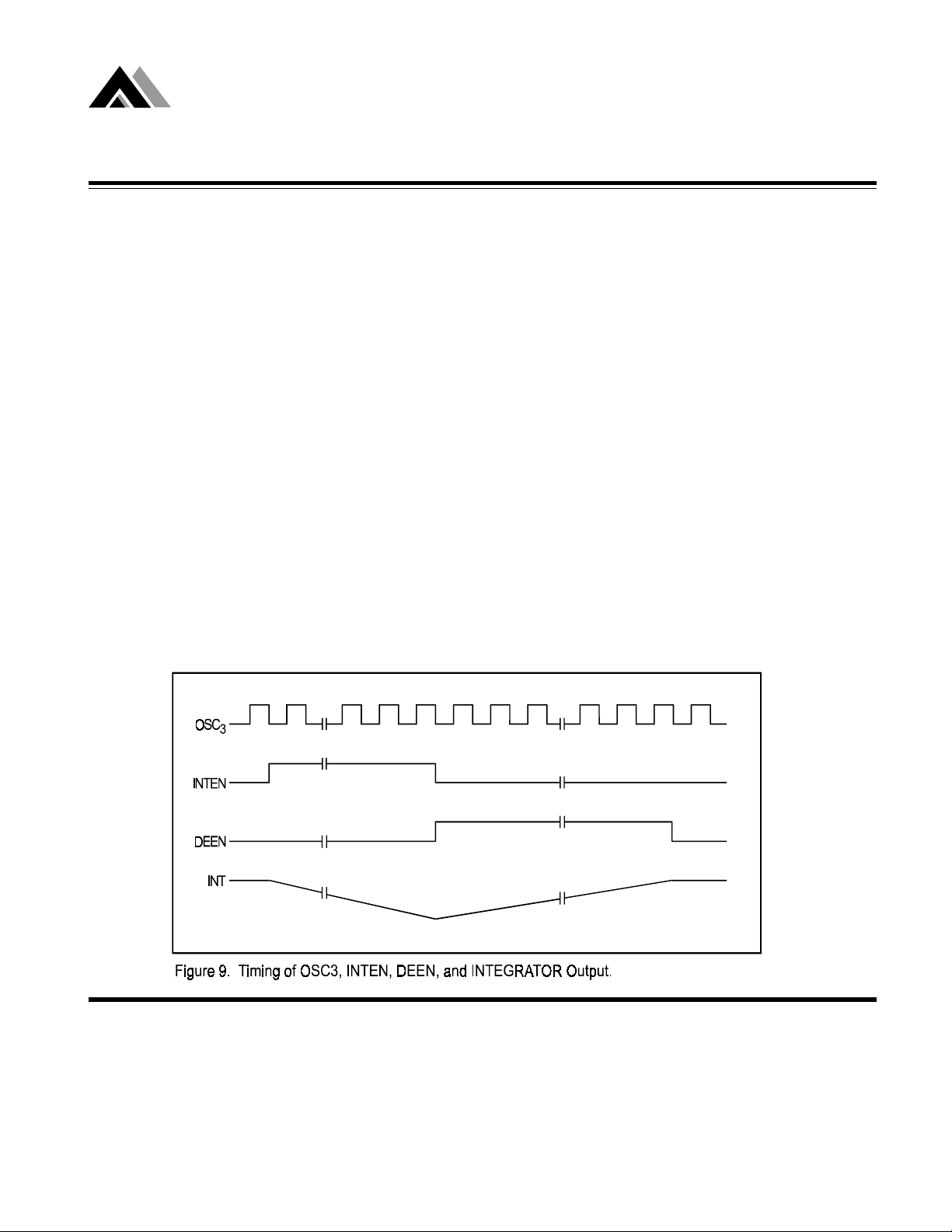

Integration Status (INTEN)

The INTEN is an output signal of the converter, it is

“high” during the signal integration phase. This signal

can be used as a status indicator or a control to connect the analog signal to the converter for processing.

It is available in 44 pin package.

De-integration Status (DEEN)

The DEEN is an output signal of the converter, it is

“high” during the reference de-integration phase. The

period of the DEEN is proportional to the conversion

result. Users may calculate the conversion result by

counting the number of clock pulse on the OSC3 pin

when DEEN is “high”. The conversion result is equal

to (N/4) - 1/2 where N is the number of the pulse at the

OSC3 pin. It is available in 44 pin package.

nn

n Component Value Selection

nn

Auto-Zero Capacitor (Caz)

The Caz capacitor size has some influence on system

noise. A 0.47µF capacitor is recommended for 200

mV full-scale applications. A 0.047µF capacitor is

recommended for 2.0V full-scale applications. A mylar

dielectric capacitor is adequate.

Reference Capacitor (Cref)

A 0.1µF capacitor is acceptable when “INLO” is tied

to analog common. If a large common-mode voltage

11

AME, Inc.

AME7106/AME7106A/AME7106R

AME7107/AME7107A/AME7107R

nn

n Component Value Selection

nn

Auto-Zero Capacitor (Caz)

The Caz capacitor size has some influence on system

noise. A 0.47µF capacitor is recommended for 200 mV

full-scale applications. A 0.047µF capacitor is recommended for 2.0V full-scale applications. A mylar dielectric capacitor is adequate.

Reference Capacitor (Cref)

A 0.1µF capacitor is acceptable when “INLO” is tied

to analog common. If a large common-mode voltage

exists and the application requires 200 mV full-scale,

increase Cref to 1.0 µF. A mylar dielectric capacitor is

adequate.

Integrating Capacitor (Cint)

Cint should be selected to maximize the integrator output voltage swing without causing output saturation. A

±2V full-scale integrator output swing is recommended

if “ANALOG COMMON” is used as signal reference.

For 3 readings/second (fosc = 48 KHz) a 0.22 µF value

is suggested. If a different oscillator frequency is used,

Cint must be changed in inverse proportion to maintain

the nominal 2V integrator swing. An exact expression

for Cint is:

Cint = [(4000)(1/fosc)(Vfs/Rint)] / Vint

where:

fosc= Oscillator clock frequency

Vfs = Full-scale input voltage

Rint = Integrating resistor

Vint = Desired full-scale integrator output swing

Cint must have low dielectric absorption to minimize

rollover error. A polypropylene capacitor is recommended.

Integrating Resistor (Rint)

The input buffer amplifier and integrator both have a

class A output stage with 100 µA quiescent current.

The integrator and buffer can supply 20 µA drive currents with negligible linearity errors. Rint is chosen to

keep the output stage in the linear region. For a 200mV

full-scale, it is 47KΩ; 2.0V full-scale requires 470KΩ.

3-1/2 Digit A/D Converter

High Accuracy, Low Power

Oscillator Components

R-C Oscillator

A 100 KΩ Rosc is recommended for all frequencies.

Cosc is selected by using the equation:

fosc = 0.45/(RC)

For fosc of 48KHz, Cosc is 100pF nominally.

To achieve maximum line noise rejection, the signal-

integrate period should be a multiple of line period. The

optimum oscillator frequencies for 60 Hz and 50 Hz

rejection are listed as follows:

For 60 Hz rejection:

40KHz, 48KHz, 60KHz etc.

For 50 Hz rejection:

40KHz, 50KHz, 66-2/3KHz etc.

Reference Voltage Selection

A full-scale reading (2000 counts) requires the input

signal be twice the reference voltage.

F u ll-S c a le Vo lta g e V re f

200.0 m V 100.0 m V

2.000 V 1.000 V

In some applications a scale factor other than unity may

exist between a transducer output voltage and the required digital reading. Assume, for example, a pressure transducer output is 600 mV for 2000 Ib/in2. Rather

than dividing the input voltage by three the reference

voltage should be set to 300 mV . This permits the transducer input to be used directly. The integrator resistor

would be 120KΩ. In some temperature and weighting

system with variable tare, the offset reading can be

generated by connecting the voltage transducer between INHI and COMMON and the variable offset voltage between COMMON and INLO.

Summary of component selection:

Full scale 200.0m V 2.000V

Caz 0.47µF0.047µF

R int 47 K

Cint 0.22µF0.22

Vref 100.0mV 1.000V

Note: fosc = 48 KHz

12

Ω

470 K

Ω

F

µ

AME, Inc.

AME7106/AME7106A/AME7106R

AME7107/AME7107A/AME7107R

Power Supplies

The AME7107 is designed to work from ±5V supplies.

However, if a negative supply is not available, it can be

generated from the clock output with two diodes, two

capacitors, and an inexpensive IC. The 7660 DC to DC

converter may also be used to generate -5V from +5V.

Low Battery Flag (LB)

The low battery flag is set when the supply voltage (V+

to V-) is lower than seven volts, typical. Once the LB is

set, the waveform of the LB will be out of phase with

the BP (Back Plane) to turn on a low battery annunciator for AME7106; LB pin will be low (Ground)

3-1/2 Digit A/D Converter

High Accuracy, Low Power

for AME7107 and is capable to sink 8 mA to turn on a

LED indicator.

AME7107 Power Dissipation Reduction

The AME7107 sinks the LED display current and this

generates heat in the IC package. If the internal voltage reference is used, the fluctuating chip temperature

can cause the display to change reading. The AME7107

package power dissipation can be reduced by reducing

the LED common anode voltage.

A typical LED has 1.8 volts across it, at 7mA. When its

common anode is connected to +5V, the AME7107

13

AME, Inc.

AME7106/AME7106A/AME7106R

AME7107/AME7107A/AME7107R

output is at 3.2V . Maximum power dissipation is 8.1 mA

X 3.2 V X 24 segments = 622mW. However, once the

AME7107 output voltage is above two volts, the LED current is essentially constant as output voltage increases.

Reducing the output voltage by 0.7V , results in 7.7mA of

LED current, only a 5 percent reduction. Maximum power

dissipation is only 7.7mA X 2.5V X 24 = 462 mW, a reduction of 26%. An output voltage reduction of 1 volt

reduces LED current by 10% (7.3mA) power dissipation

by 38%. (7.3mA X 2.2V X 24 = 385mW).

There are two ways to reduce the power dissipation:

either a 5.1 ohm resistor or a 1 Amp diode placed in

series with the display (but not in series with the

AME7107). The resistor will reduce the AME7107 output voltage, when all 24 segments are “ON”. When

segments turn off, the output voltage will increase. The

3-1/2 Digit A/D Converter

High Accuracy, Low Power

diode, on the other hand, will result in a relatively steady

output voltage.

In addition to limiting maximum power dissipation, the

resistor reduces the change in power dissipation as the

display changes. As fewer segments are “ON,” each

“ON” output drops more voltage and current. For the

best case of six segments (a “111” display) to worst

case (a “1888” display) the resistor will change about

230 mW. While a circuit without the resistor will change

about 470 mW. Therefore, the resistor will reduce the

variation of power dissipation by about 50%.

The change in LED brightness caused by the resistor is

almost unnoticeable as more segments turn off. If steady

display brightness is very important, a diode is recommended.

nn

n T ypical Applications

nn

14

AME, Inc.

AME7106/AME7106A/AME7106R

AME7107/AME7107A/AME7107R

3-1/2 Digit A/D Converter

High Accuracy, Low Power

15

AME, Inc.

AME7106/AME7106A/AME7106R

AME7107/AME7107A/AME7107R

3-1/2 Digit A/D Converter

High Accuracy, Low Power

16

AME, Inc.

AME7106/AME7106A/AME7106R

AME7107/AME7107A/AME7107R

3-1/2 Digit A/D Converter

High Accuracy, Low Power

17

AME, Inc.

AME7106/AME7106A/AME7106R

AME7107/AME7107A/AME7107R

3-1/2 Digit A/D Converter

High Accuracy, Low Power

18

AME, Inc.

AME7106/AME7106A/AME7106R

AME7107/AME7107A/AME7107R

nn

n Package Dimension

nn

PDIP-40

SYMBOLS

A

A

B

B

D

E

F

e

E

θθθθ

3-1/2 Digit A/D Converter

High Accuracy, Low Power

MILLIMETERS INCHES

MIN MAX MIN MAX

0.150 0.165 0.0059 0.0065

1

1

1

B

0.072 (TYP) 0.0028

0.018(TYP) 0.0007

0.050(TY P) 0.0020

2.049 2.074 0.0807 0.0817

0.540 0.555 0.0213 0.0219

0.600(TY P) 0.0236

0.100(TY P) 0.0039

0.600 0.700 0.0236 0.0276

o

0

15

o

o

0

15

o

19

www.ame.com.tw

E-Mail: info@ame.com.tw

Life Support Policy:

These products of AME, Inc. are not authorized for use as critical components in life-support devices or

systems, without the express written approval of the president

of AME, Inc.

AME, Inc. reserves the right to make changes in the circuitry and specifications of its devices and

advises its customers to obtain the latest version of relevant information.

ã AME, Inc. , February 2002

Document: 1021-DS7106/7107-C

U.S. Headquarter Corporate Headquarter

Analog Microelectronics, Inc. AME, Inc.

3100 De La Cruz Blvd. Suite 201 2F , 189 Kang-Chien Road, Nei-Hu District

Santa Clara, CA. 95054-2046 Taipei 114, Taiwan, R.O.C.

Tel : (408) 988-2388 Tel : 886 2 2627-8687

Fax: (408) 988-2489 Fax: 886 2 2659-2989

Loading...

Loading...