AAT3112

500mA High Efficiency Charge Pump

for White LED Flash Applications

Typical Application

3112.2004.12.1.2 1

ChargePump

™

General Description

The AAT3112 is a member of AnalogicTech's Total

Power Management IC™ (TPMIC™) family. It is a

dual voltage doubling charge pump that provides a

regulated output voltage. It operates with an input

voltage range of 2.7 to 5.0 volts. The device can

deliver a constant 200mAoutput load current and up

to 500mA of pulsed current. The 500mA peak current capability of the AAT3112 makes it ideal for

white LED flash applications. A low external parts

count (two 1µF flying capacitors and two small

capacitors at VINand V

OUT

) makes the AAT31 12 ide-

ally suited for small battery-powered applications.

The AAT3112 has a thermal management system

to protect the device in the event of a short-circuit

condition at the output pin. Built-in soft-start circuitry prevents excessive inrush current during startup. A high charge pump switching frequency

enables the use of very small external capacitors.

A low current shutdown feature disconnects the

load from VINand reduces quiescent current to less

than 1µA. The AAT3112 is available in a 16-pin

3x3mm QFN package and is rated over the -40°C

to +85°C temperature range.

Features

• Input Voltage Range:

• AAT3112-5.0: 2.7V to 5.0V

• AAT3112-4.5: 2.7V to 4.5V

• Up to 500mA Peak Output Current

• 200mA Continuous Output Current

•IQ<1µA in Shutdown

• Regulated 4.5V or 5.0V Output

• 26µA of Quiescent Current

• Small Application Circuit

• Automatic Soft Start

• No Inductors

• Short-Circuit/Over-Temperature Protection

• 16-Pin 3x3mm QFN Package

• Temperature Range: -40°C to +85°C

Applications

• General-Purpose High-Current Boost Supply

• White LED Backlighting

• White LED Photo Flash

查询AAT3112供应商查询AAT3112供应商

C1 = 1µF C2 = 1µF

C1+C1-C2+C2

V

IN

C

IN

V

IN

AAT3112

Enable Light

Enable Flash

EN1

EN2

GND

-

V

OUT1

C

V

OUT2

D1 D2 D3 D4

OUT

R

B

Pin Descriptions

Pin Configuration

QFN33-16

(Top View)

Pin # Symbol Function

1 N/C No connect.

2 C2+ Flying capacitor 2 positive terminal. Connect 1µF capacitor between C2+ and C2-.

3 C2- Flying capacitor 2 negative terminal.

4 N/C No connect.

5VINInput voltage. Connect to Pin 11.

6 GND Ground connection.

7 EN2 Enable pin. When connected high, Charge Pump 2 is enabled. When connected low, it

disables the charge pump.

8 N/C No connect.

9 EN1 Enable pin. When connected high, Charge Pump 1 is enabled. When connected low, it

disables the charge pump.

10 GND Ground connection.

11 V

IN

Input voltage. Connect to Pin 5.

12 V

OUT1

Output pin for regulated output voltage. Bypass this pin to ground with a low ESR 10µF

capacitor.

13 N/C No connect.

14 C1+ Flying capacitor 1 positive terminal. Connect 1µF capacitor between C1+ and C1-.

15 C1- Flying capacitor 1 negative terminal.

16 V

OUT2

Regulated output voltage 2. Must be connected to V

OUT1

for higher current applications.

If used separately, bypass this pin to ground with a low ESR 10µF capacitor.

EP Exposed paddle (bottom); connect to GND directly beneath package.

AAT3112

500mA High Efficiency Charge Pump

for White LED Flash Applications

2 3112.2004.12.1.2

N/C

C2+

C2-

N/C

V

OUT2

161514

1

2

3

4

567

V

IN

C1+

C1-

GND

EN2

N/C

13

8

N/C

12

11

10

9

V

OUT1

V

IN

GND

EN1

Absolute Maximum Ratings

1

Note 1: Stresses above those listed in Absolute Maximum Ratings may cause permanent damage to the device. Functional operation at conditions other than the operating conditions specified is not implied. Only one Absolute Maximum Rating should be applied at any one time.

Thermal Information

Note 1: Mounted on an FR4 board.

Symbol Description Value Units

P

D

Maximum Power Dissipation 2.0 W

θ

JA

Maximum Thermal Resistance

1

50 °C/W

Symbol Description Value Units

V

IN

Input Voltage -0.3 to 6 V

V

OUT

Charge Pump Output -0.3 to 6 V

V

EN

EN to GND Voltage -0.3 to 6 V

T

J

Operating Junction Temperature Range -40 to 150 °C

T

LEAD

Maximum Soldering Temperature (at leads, 10 sec) 300 °C

AAT3112

500mA High Efficiency Charge Pump

for White LED Flash Applications

3112.2004.12.1.2 3

Electrical Characteristics

VIN= 3.3V, V

OUT

= 5.0V, CIN= C

OUT

= 10 µF, C1 = C2 = 1.0µF; TA= -40°C to 85°C, unless otherwise noted.

Typical values are TA= 25°C.

Notes:

1. The AAT3112 is guaranteed to meet performance specifications over the -40°C to +85°C operating temperature range and is assured

by design, characterization, and correlation with statistical process controls.

2. V

OUT1

and V

OUT2

are pulled high to prevent switching.

Symbol Description Conditions Min Typ Max Units

AAT3112-4.5

Input Power Supply

V

IN

Operation Range 2.7 4.5 V

I

Q

Quiescent Current

2

2.7 ≤ VIN≤ 4.5, I

OUT

= 0 mA; EN1 = EN2 = V

IN

26 60 µA

I

SHDN

Shutdown Current EN1 = EN2 = 0 1.0 µA

I

OUT

Pulsed Output Current

V

IN

= 3.6V; V

OUT

= 4.0V; T

PULSE

= 50mS 590

mA

VIN= 3.6V; V

OUT

=4.0V; T

PULSE

= 500mS 500

V

OUT

Output Voltage

2.7 ≤ V

IN

≤ 4.5, I

OUT

= 100mA 4.32 4.5 4.68

V

3.0 ≤ VIN≤ 4.5, I

OUT

= 200mA 4.32 4.5 4.68

Charge Pump Section

F

CLK

Clock Frequency 750 KHz

η

CP

Charge Pump Efficiency VIN= 2.7V; I

OUT

= 100mA 80 %

EN

V

EN(L)

Enable Threshold Low 0.3 V

V

EN(H)

Enable Threshold High 1.4 V

I

EN

EN Input Leakage -1.0 1.0 µA

AAT3112-5.0

Input Power Supply

V

IN

Operation Range 2.7 5.0 V

I

Q

Quiescent Current

2

2.7 ≤ VIN≤ 5.0, I

OUT

= 0 mA; EN1 = EN2 = V

IN

26 60 µA

I

SHDN

Shutdown Current EN1 = EN2 = 0 1.0 µA

I

OUT

Pulsed Output Current VIN= 3.6V; V

OUT

= 4.5V; T

PULSE

= 50mS 600

mA

VIN= 3.6V; V

OUT

=4.5V; T

PULSE

= 500mS 500

V

OUT

Output Voltage

2.7 ≤ V

IN

≤ 5.0, I

OUT

= 100mA 4.8 5.0 5.2

V

3.0 ≤ VIN≤ 5.0, I

OUT

= 200mA 4.8 5.0 5.2

Charge Pump Section

F

CLK

Clock Frequency 750 KHz

η

CP

Charge Pump Efficiency VIN= 2.7V; I

OUT

= 100mA 85 %

EN

V

EN(L)

Enable Threshold Low 0.3 V

V

EN(H)

Enable Threshold High 1.4 V

I

EN

EN Input Leakage -1.0 1.0 µA

AAT3112

500mA High Efficiency Charge Pump

for White LED Flash Applications

4 3112.2004.12.1.2

AAT3112

500mA High Efficiency Charge Pump

for White LED Flash Applications

3112.2004.12.1.2 5

Typical Characteristics

VIN=3.5V, CIN=C

OUT

=10µF, C1=C2=1µF, TA=25°C, unless otherwise noted.

VIN vs. V

1.00

0.95

-40°C

0.90

0.85

0.80

0.75

(V)

IH

0.70

V

0.65

0.60

0.55

0.50

2.0 2.5 3.0 3.5 4.0 4.5 5.0 5.5

25°C

85°C

IH

Input Voltage (V)

V

Threshold vs. Supply Voltage

SHDN

1.00

0.95

0.90

Thre shold (V)

SHDN

V

0.85

0.80

0.75

0.70

0.65

0.60

0.55

0.50

V

IH

V

IL

2.0 2.5 3.0 3.5 4.0 4.5 5.0 5.5

Input Voltage (V)

VIN vs. V

1.00

0.95

0.90

-40°C

25°C

2.0 2.5 3.0 3.5 4.0 4.5 5.0 5.5

(V)

IL

V

0.85

0.80

0.75

0.70

0.65

0.60

0.55

0.50

IL

85°C

Input Voltage (V)

AAT3112

500mA High Efficiency Charge Pump

for White LED Flash Applications

6 3112.2004.12.1.2

Typical Characteristics-AAT3112-4.5V

VIN=3.5V, CIN=C

OUT

=10µF, C1=C2=1µF, TA=25°C, unless otherwise noted.

µ

Output Voltage vs. Output Current

5.0

4.9

4.8

4.7

4.6

4.5

VIN = 4.2V

4.4

4.3

4.2

Output Voltage (V)

4.1

4.0

0 50 100 150 200 250 300

Startup Time with 100mA Load

EN

(2V/div)

V

OUT

(1V/div)

VIN = 3.9VVIN = 3.6V

Output Current (mA)

Supply Current vs. Supply Voltage

(No Load, No Switching)

30

25

A)

20

15

10

5

Supply Current (µ

0

2.5 3.0 3.5 4.0 4.5

Supply Voltage (V)

Startup Time with 200mA Load

EN

(2V/div)

V

OUT

(1V/div)

50µµs/div

Maximum Current Pulse (50ms pulse)

vs. Input Voltage, V

800

700

600

500

400

300

Maximum Current Pulse (mA)

3 3.2 3.4 3.6 3.8 4 4.2

OUT

> 4.0V

85

80

75

70

65

60

55

Efficiency (%)

50

45

40

Efficiency vs. Supply Voltage

50mA

200mA

2.7

2.9 3.1 3.3 3.5 3.7 3.9 4.1 4.3 4.5

Input Voltage (V)

50µµs/div

100mA

Input Voltage (V)

AAT3112

500mA High Efficiency Charge Pump

for White LED Flash Applications

3112.2004.12.1.2 7

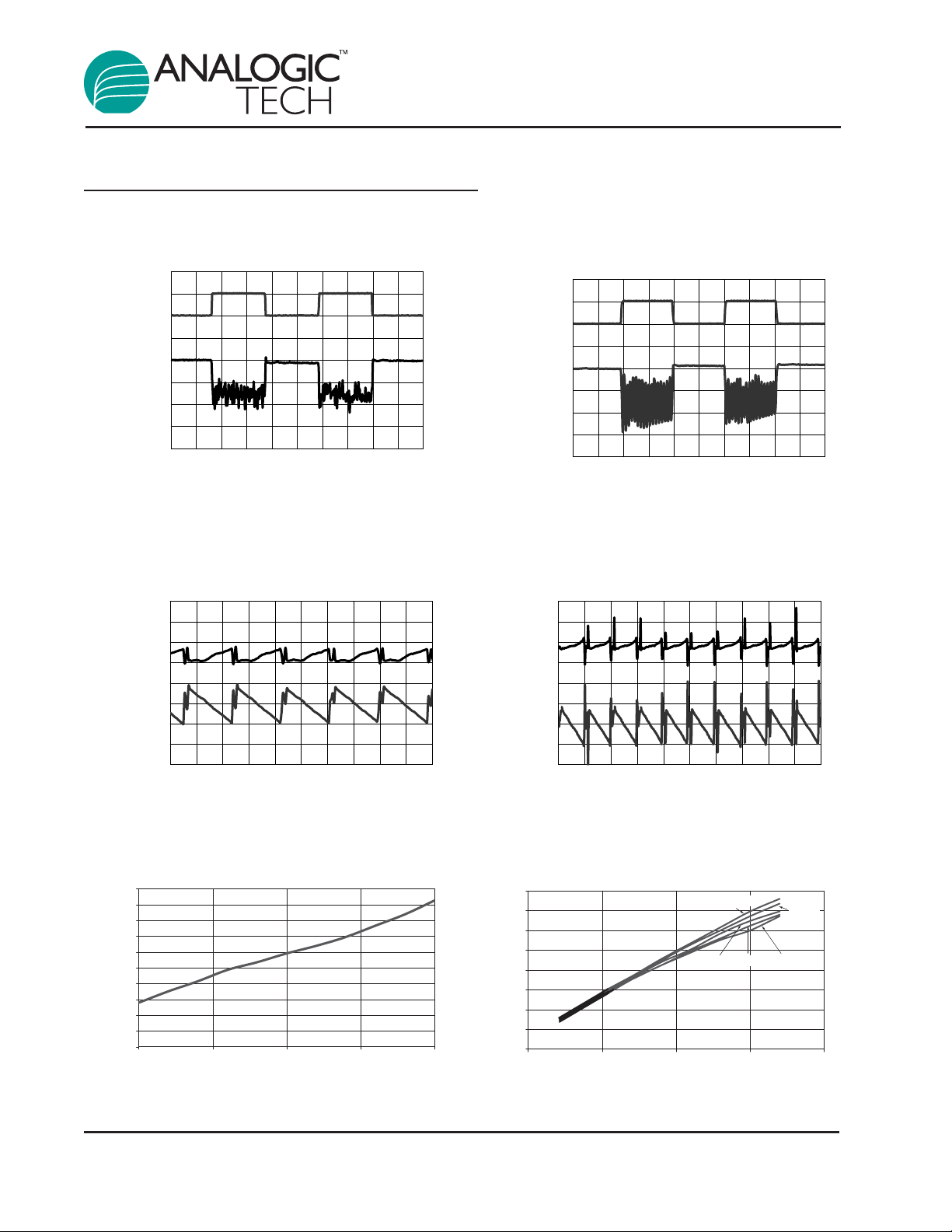

Typical Characteristics-AAT3112-4.5V

VIN=3.5V, CIN=C

OUT

=10µF, C1=C2=1µF, TA=25°C, unless otherwise noted.

A

A

I

OUT

(200mA/div)

V

OUT

(20mV/div)

V

IN

C Coupled

(20mV/div)

V

OUT

C Coupled

(20mV/div)

Load Transient Response

(VIN = 3.0V)

50µs/div

Input and Output Ripples

(I

= 50mA @ VIN = 3.5V)

OUT

I

OUT

(200mA/div)

V

OUT

(20mV/div)

AC Coupled

(20mV/div)

V

AC Coupled

(20mV/div)

V

OUT

Load Transient Response

(VIN = 4.2V)

50µs/div

Input and Output Ripples

(I

= 100mA @ VIN = 3.5V)

OUT

IN

5µs/div

Output Current vs. Input Voltage

(500ms Pulse Time; V

800

700

600

500

400

300

200

100

Output Current (mA)

0

2.5 3 3.5 4 4.5

Input Voltage (V)

OUT

> 4.0V)

Output Current vs. Input Voltage (70°C)

800

700

600

500

400

300

200

Output Current (mA)

100

0

2.5 3.0 3.5 4.0 4.5

5µs/div

(V

> 4.0V)

OUT

50ms

200ms 300ms 500ms

Input Voltage (V)

100ms

AAT3112

500mA High Efficiency Charge Pump

for White LED Flash Applications

8 3112.2004.12.1.2

Typical Characteristics-AAT3112-4.5V

VIN=3.5V, CIN=C

OUT

=10µF, C1=C2=1µF, TA=25°C, unless otherwise noted.

Output Voltage vs. Input Voltage for

Pulsed High Current, I

5

4.5

50ms Pulse

4

3.5

3

2.5

2

1.5

1

Output Voltage (V)

0.5

0

343.2 3.4 3.6 3.8 4.2

= 500mA

OUT

500ms Pulse

Input Voltage (V)

AAT3112

500mA High Efficiency Charge Pump

for White LED Flash Applications

3112.2004.12.1.2 9

Typical Characteristics-AAT3112-5.0V

VIN=3.5V, CIN=C

OUT

=10µF, C1=C2=1µF, TA=25°C, unless otherwise noted.

µ

O

(

)

Output Voltage vs. Output Current

5.5

5.4

V

5.3

5.2

5.1

5.0

4.9

4.8

utput Voltage

4.7

4.6

4.5

0 50 100 150 200 250 300

VIN = 4.2V

VIN = 3.6V

Output Current (mA)

Startup Time with 100mA Load

EN

(2V/div)

V

OUT

(1V/div)

VIN = 3.9V

Supply Current vs. Supply Voltage

(No Load, No Switching)

30

25

A)

20

15

10

5

Supply Current (µ

0

2.5 3.0 3.5 4.0 4.5 5.0

Supply Voltage (V)

Startup Time with 200mA Load

EN

(2V/div)

V

OUT

(1V/div)

50µµs/div

Maximum Current Pulse (50ms pulse)

vs. Input Voltage, V

1000

900

800

700

600

500

400

300

Maximum Current Pulse (mA)

3.0 3.2 3.4 3.6 3.8 4.0 4.2

OUT

> 4.5V

95

90

85

80

75

70

65

60

Efficiency (%)

55

50

45

40

Efficiency vs. Supply Voltage

100mA

200mA

50mA

2.7 3.0 3.3 3.5 3.8 4.1 4.4 4.7 4.9

Input Voltage (V)

50µµs/div

Input Voltage (V)

AAT3112

500mA High Efficiency Charge Pump

for White LED Flash Applications

10 3112.2004.12.1.2

Typical Characteristics-AAT3112-5.0V

VIN=3.5V, CIN=C

OUT

=10µF, C1=C2=1µF, TA=25°C, unless otherwise noted.

I

OUT

(200mA/div)

V

OUT

(20mV/div)

AC Coupled

(20mV/div)

V

AC Coupled

(20mV/div)

V

OUT

Load Transient Response

(VIN = 3.0V)

I

OUT

Load Transient Response

(VIN = 4.2V)

(200mA/div)

V

50µs/div

Input and Output Ripples

(I

= 50mA @ VIN = 3.5V)

OUT

IN

OUT

(20mV/div)

V

IN

50µs/div

Input and Output Ripples

(I

= 100mA @ VIN = 3.5V)

OUT

AC Coupled

(20mV/div)

V

OUT

AC Coupled

(20mV/div)

5µs/div

Output Current vs. Input Voltage

(500ms Pulse Time; V

1000

900

800

700

600

500

400

300

200

Output Current (mA)

100

0

3.0 3.5 4.0 4.5 5.0

Input Voltage (V)

OUT

> 4.5V)

Output Current vs. Input Voltage (70°C)

800

700

600

500

400

300

200

Output Current (mA)

100

0

2.5 3.0 3.5 4.0 4.5

5µs/div

(V

> 4.5V)

OUT

200ms 300ms 500ms

Input Voltage (V)

50ms

100ms

AAT3112

500mA High Efficiency Charge Pump

for White LED Flash Applications

3112.2004.12.1.2 11

Typical Characteristics-AAT3112-5.0V

VIN=3.5V, CIN=C

OUT

=10µF, C1=C2=1µF, TA=25°C, unless otherwise noted.

Output Voltage vs. Input Voltage for

Pulsed High Current, I

6

5

50ms Pulse

4

3

2

Output Voltage (V)

1

0

3.0 3.2 3.4 3.6 3.8 4.0 4.2

= 500mA

OUT

500ms Pulse

Input Voltage (V)

AAT3112

500mA High Efficiency Charge Pump

for White LED Flash Applications

12 3112.2004.12.1.2

Functional Block Diagram

2

Functional Description

The AAT3112 is a dual charge pump intended for

high-current applications. This device boosts an

input voltage to a regulated output voltage.

Regulation is achieved by sensing the output voltage through an internal resistor divider network.

The AAT3112 requires only four external components: two 1.0µF ceramic capacitors for the charge

pump (C1 and C2), one 10µF ceramic capacitor for

CIN, and one 10µF ceramic capacitor for C

OUT

.

The AAT3112 is designed to deliver 200mA of continuous current and up to 500mA of pulsed current.

Each charge pump engine has an independent

enable pin to extend battery life. The charge pump

switching frequency is approximately 750kHz,

enabling the use of small external flying capacitors.

The AAT31 12 has complete output short-circuit and

thermal protection to safeguard the device under

extreme operating conditions. An internal thermal

protection circuit senses die temperature and will

shut down the device if the internal junction temperature exceeds approximately 145°C.

V

IN

EN1

Con tro l

Circuit

S2 S1

+

C1

-

C1

S4

S3

V

OUT1

EN2

C2

C2

+

-

Con tro l

Circuit

S3

S2S1

S4

GND

V

OUT

AAT3112

500mA High Efficiency Charge Pump

for White LED Flash Applications

3112.2004.12.1.2 13

Applications Information

Charge Pump Efficiency

The AAT3112 is a regulated output voltage doubling charge pump. The efficiency (η) can simply

be defined as a linear voltage regulator with an

effective output voltage that is equal to two times

the input voltage. Efficiency (η) for an ideal voltage

doubler can typically be expressed as the output

power divided by the input power:

In addition, with an ideal voltage doubling charge

pump, the output current may be expressed as half

the input current. The expression to define the

ideal efficiency (η) can be rewritten as:

-or-

For a charge pump with an output of 4.5 volts and

a nominal input of 2.8 volts, the theoretical efficiency is 80.4%. Due to internal switching losses and

IC quiescent current consumption, the actual efficiency can be measured at 79.6%. These figures

are in close agreement across a wide range of output load conditions. Efficiency will decrease as

load current drops below 0.05mAor when the level

of VINapproaches V

OUT

.

Capacitor Selection

Careful selection of the four external capacitors

CIN, C1, C2, and C

OUT

is important because they

will affect turn-on time, output ripple, and transient

performance. Optimum performance will be

obtained when low equivalent series resistance

(ESR) ceramic capacitors are used. In general,

low ESR may be defined as less than 100mΩ.

Capacitor Characteristics

Ceramic composition capacitors are highly recommended over all other types of capacitors for use with

the AAT31 12. Ceramic capacitors of fer many advantages over their tantalum and aluminum electrolytic

counterparts. A ceramic capacitor typically has very

low ESR, is lowest cost, has a smaller PCB footprint,

and is non-polarized. Low ESR ceramic capacitors

help to maximize charge pump transient response.

Since ceramic capacitors are non-polarized, they are

not prone to incorrect connection damage.

Equivalent Series Resistance: ESR is an important characteristic to consider when selecting a

capacitor. ESR is a resistance internal to a capacitor that is caused by the leads, internal connections, size or area, material composition, and ambient temperature. Capacitor ESR is typically measured in milliohms for ceramic capacitors and can

range to more than several ohms for tantalum or

aluminum electrolytic capacitors.

Ceramic Capacitor Materials: Ceramic capacitors

less than 0.1µF are typically made from NPO or

COG materials. NPO and COG materials typically

have tight tolerance and are stable over temperature. Large capacitor values are typically composed of X7R, X5R, Z5U, or Y5V dielectric materials. Large ceramic capacitors, typically greater

than 2.2µF, are often available in low-cost Y5V and

Z5U dielectrics, but large capacitors are not

required in AAT3112 applications.

Capacitor area is another contributor to ESR.

Capacitors that are physically large will have a lower

ESR when compared to an equivalent material

smaller capacitor . These larger devices can improve

circuit transient response when compared to an

equal value capacitor in a smaller package size.

Layout Considerations

High charge pump switching frequencies and large

peak transient currents mandate careful printed circuit board layout. As a general rule for charge pump

boost converters, all external capacitors should be

located as closely as possible to the device package with minimum length trace connections.

Maximize the ground plane around the AAT3112

charge pump and make sure all external capacitors

are connected to the immediate ground plane. Alocal

component side ground plane is recommended.

T

P

OU

η =

P

IN

P

= V

OUT

η =

PIN VIN × 2I

η(%) = 100

× I

OUT

OUT

OUT

V

⎛⎞

OUT

2V

⎝⎠

IN

= V

2V

OUT

IN

AAT3112

500mA High Efficiency Charge Pump

for White LED Flash Applications

14 3112.2004.12.1.2

Application Circuits

Figure 1: Flash Application.

Figure 2: Movie Mode Light with Flash Function.

C1 = 1µF C2 = 1µF

T

PULSE

100ms - 500ms

V

IN

Light/Movie

Mode Enable

V

IN

CIN=10µF

CIN=10µF

C1+C1-C2+C2

V

IN

EN1

EN2

GND

-

V

OUT

V

OUT

D1 D2 D3 D4

C1 = 1µF C2 = 1µF

C1+C1-C2+C2

V

IN

EN1

EN2

GND

-

V

OUT

V

OUT

D1 D2 D3 D4

R

Q1

C

=10µF

OUT

Flash LED

=10

2

C

=10µF

OUT

Flash LED

R3=60 - 100

R

=10

2

Q1

T

PULSE

Flash Enable

LL4148

R

1

2K

C3

0.1µF

AAT3112

500mA High Efficiency Charge Pump

for White LED Flash Applications

3112.2004.12.1.2 15

Ordering Information

Note 1: XYY = assembly and date code.

Sample stock is held on part numbers listed in bold.

Package Information

All dimensions in millimeters.

Package Marking

1

Part Number (Tape and Reel)

QFN33-16 LGXYY AAT3112IVN-4.5-T1

QFN33-16 MNXYY AAT3112IVN-5.0-T1

Pin 1 Dot By Marking

3.000 ± 0.050

Top View

Pin 1 Identification

3.000 ± 0.050

0.400 ± 0.100

0.240 ± 0.060

1

5

13

9

0.500 ± 0.050

0.975 ± 0.725

Bottom View

0.850 ± 0.150

0.025 ± 0.025

0.213 ± 0.036

Side View

AAT3112

500mA High Efficiency Charge Pump

for White LED Flash Applications

16 3112.2004.12.1.2

Advanced Analogic Technologies, Inc.

830 E. Arques Avenue, Sunnyvale, CA 94085

Phone (408) 737-4600

Fax (408) 737-4611

AnalogicTech cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in an AnalogicTech product. No circuit patent licenses, copyrights, mask work

rights, or other intellectual property rights are implied.

AnalogicTech reserves the right to make changes to their products or specifications or to discontinue any product or service without notice, and advise customers to obtain the latest

version of relevant information to verify, before placing orders, that information being relied on is current and complete. All products are sold subject to the terms and conditions of sale

supplied at the time of order acknowledgement, including those pertaining to warranty, patent infringement, and limitation of l iability.

AnalogicTech warrants performance of its semiconductor products to the specifications applicable at the time of sale in accordance with AnalogicTech’s standard warranty. Testing and

other quality control techniques are utilized to the extent AnalogicTech deems necessary to support this warranty. Specific testing of all parameters of each device is not necessarily

performed.

Loading...

Loading...