Evaluation Board User Guide

UG-437

ADP1614

8

3

9

10

6

2

1

VIN

EN

CLRES

SS

SW

7

SW

FB

COMP

ON

OFF

5

GND

4

GND

11

EP

V

OUT

V

IN

L1

C

IN

C

SS

C

OUT

C

COMP

R

COMP

R

CL

R1

R2

D1

10859-001

One Technology Way • P. O. Box 9106 • Norwood, MA 02062-9106, U.S.A. • Tel: 781.329.4700 • Fax: 781.461.3113 • www.analog.com

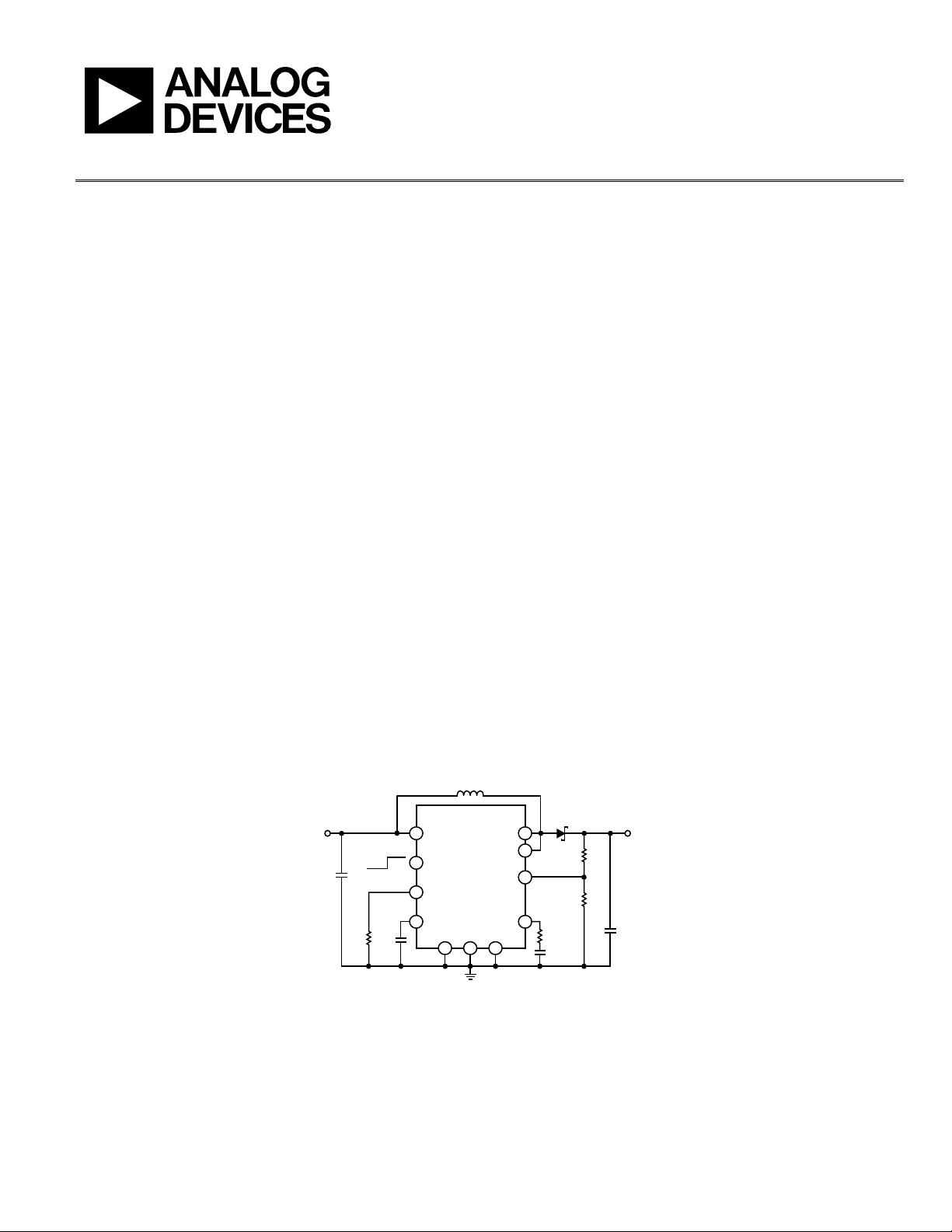

Evaluating the ADP1614 650 kHz/1.3 MHz, 4 A, Step-Up, PWM,

DC-to-DC Switching Converter

FEATURES

2.5 V to 5.5 V input voltage range

650 kHz or 1.3 MHz fixed frequency options

Adjustable current limit up to 4 A

Output voltage

5 V for ADP1614-650-EVALZ

15 V for ADP1614-1.3-EVALZ

Jumper for enable/shutdown control

Components optimized for the indicated output voltages

GENERAL DESCRIPTION

The ADP1614 evaluation board is a complete step-up, dc-to-dc

switching converter application with components selected to allow

operation over the full range of input and load conditions for the

5 V (ADP1614-650-EVALZ) and 15 V (ADP1614-1.3-E VALZ)

output voltages. The boost switching frequency is fixed to either

650 kHz (ADP1614-650-EVALZ) or 1.3 MHz (ADP1614-1.3EVALZ). The evaluation boards can be adjusted for different

output voltages by changing the feedback resistors, R1 and R2.

To ensure stable operation, external components L1, R

R

COMP

, and C

may also need to be recalculated and adjusted

COMP

when the output voltage is changed.

, C

CL

OUT

The ADP1614 evaluation board operates in current mode, pulsewidth modulation (PWM) with up to 94% efficiency. The current

mode PWM architecture allows for excellent transient response,

easy noise filtering, and the use of small, cost-saving external

inductors and capacitors. Other key features include a 47 nF

soft start capacitor, undervoltage lockout (UVLO), thermal

shutdown (TSD), and jumper selected enable. The evaluation

board demonstrates the operation and performance of the

ADP1614.

This user guide includes I/O descriptions, setup instructions,

the schematic, and the PCB layout drawings for the ADP1614

step-up converter evaluation board.

Complete specifications for the ADP1614 are available in the

ADP1614 data sheet and should be consulted in conjunction

with this document when using the evaluation board.

,

TYPICAL APPLICATION CIRCUIT

Figure 1. Step-Up Regulator Configuration

PLEASE SEE THE LAST PAGE FOR AN IMPORTANT

WARNING AND LEGAL TERMS AND CONDITIONS.

Rev. 0 | Page 1 of 8

UG-437 Evaluation Board User Guide

TABLE OF CONTENTS

Features .............................................................................................. 1

General Description ......................................................................... 1

Typical Application Circuit ............................................................. 1

Revision History ............................................................................... 2

Evaluation Board Hardware ............................................................ 3

Input/Output Connectors ........................................................... 3

REVISION HISTORY

7/12—Revision 0: Initial Version

Evaluation Setup ............................................................................3

Performance Evaluation ...............................................................3

Evaluation Board Schematic and Layout........................................4

Layout Guidelines..........................................................................4

Ordering Information .......................................................................5

Bill of Materials ..............................................................................5

Rev. 0 | Page 2 of 8

Evaluation Board User Guide UG-437

PLACE

JUMPER

HERE

10859-002

PLACE

JUMPER

HERE

10859-003

CONNECT

EXTERNAL

DEVICE

HERE

10859-004

ININ

OUTOUT

IVIV×

×

=η

EVALUATION BOARD HARDWARE

The ADP1614 evaluation board is fully assembled and tested.

The following sections describe the various connectors on the

board, the proper evaluation setup, and the testing capabilities

of the evaluation board.

INPUT/OUTPUT CONNECTORS

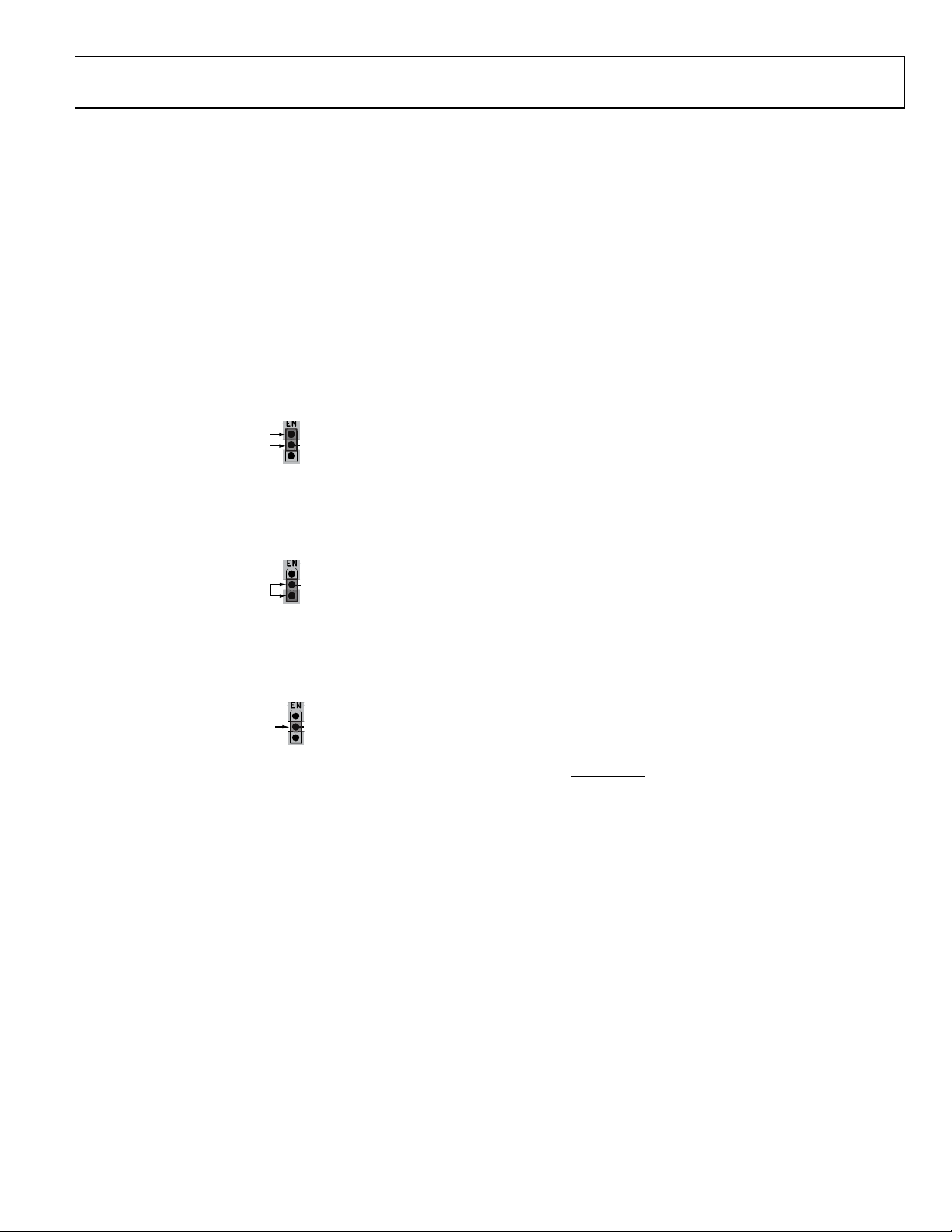

EN Test Bus

The EN connector is used to enable/disable the converter via

the EN pin. Use one of the following methods to enable the

converter. Do not leave the EN pin floating.

• Use a jumper to connect the top two pins of the EN test

bus. This connects EN to VIN and enables the converter

(see Figure 2).

Figure 2. Enabled Jumper Position

• Use a jumper to connect the bottom two pins of the EN test

bus. This connects EN to GND and disables the converter

(see Figure 3).

Figure 3. Disabled Jumper Position

• Alternatively, connect a voltage between VIN and GND to the

center pin of the EN test bus for independent control of the

EN pin voltage (see Figure 4).

Figure 4. EN Pin Direct Connection

VIN Test Bus

The VIN test bus connects the positive input supply voltage to

the VIN pin. Connect the power supply to this bus and keep the

wires as short as possible to minimize the EMI transmission.

SW Test Point

The SW test point is for monitoring the switch node (SW pin)

behavior and switching frequency. Connect a BNC cable to this

test point to measure the ADP1614 switching frequency.

VOUT Test Bus

The output voltage at the VOUT test bus is set by the resistive

voltage divider network, R1 and R2. A load can be attached

from the VOUT test bus to the GND test bus.

GND Test Bus

The GND test bus is the power ground connection for the part

via the GND pin as well as the bypass capacitors. Connect ground

connections from external equipment to this bus.

Rev. 0 | Page 3 of 8

EVALUATION SETUP

To ensure proper operation of the ADP1614 evaluation board:

1. Connect the input supply ground to GND.

2. Connect the positive input supply to VIN.

3. Connect the desired load between VOUT and GND. The

maximum continuous output current of the ADP1614 is

dependent upon the input and output voltage conditions.

4. Apply a voltage between 2.5 V and 5.5 V to the VIN test bus.

5. Move the jumper on the EN test bus to the enabled position.

If the feedback resistors, R1 and R2, are adjusted to change the

output voltage, recalculate the recommended values for the external

components (L1, R

, C

, R

CL

OUT

COMP

, and C

) using the applications

COMP

information from the ADP1614 data sheet.

PERFORMANCE EVALUATION

The following sections discuss tests and the resulting oscilloscope

waveforms. Oscilloscope waveforms and typical performance

characteristics are provided in the ADP1614 data sheet.

Line Regulation

The line regulation is observed and measured by monitoring

the output voltage (VOUT) while varying the input voltage (VIN).

Load Regulation

The load regulation is observed and measured by monitoring the

output voltage (VOUT) while sweeping the applied load between

VOUT and GND. To minimize voltage drop, use short low

resistance wires, especially for heavy loads.

Efficiency

The efficiency, η, is measured by comparing the input power to

the output power

Line Transient

The line transient performance is evaluated by generating a high

speed voltage transient on the input (VIN) and observing the

behavior of the evaluation board at the output (VOUT.)

Load Transient

The load transient performance is evaluated by generating a fast

current transient on the output (VOUT) and observing the

behavior of the evaluation board at the output (VOUT.)

Oscillator Frequency

The oscillator frequency can be measured by connecting an

oscilloscope to the SW pin.

Inductor Current

The inductor current is made accessible by removing one side

of the inductor from its pad and connecting a current loop in

series. Place an oscilloscope current probe on the loop to view

the current waveform.

UG-437 Evaluation Board User Guide

8

3

9

10

6

2

1

5

VIN

EN

CLRES

SS

SW

SW

FB

COMP

L1 SW

VIN

R1

R2

D1

VOUT

GND

EN

4

GND GND EP

11

7

ADP1614

(U1)

ADP1614ACPZ-650-R7

ADP1614ACPZ-1.3-R7

C

IN3

(C6)

C

IN2

(C5)

C

IN1

(C4)

R

CL

(R4)

C

SS

(C1)

R

COMP

(R3)

C

COMP1

(C3)

C

COMP2

(C2)

C

OUT1

(C7)

C

OUT2

(C8)

C

OUT9

(C9)

10859-005

10859-006

10859-007

EVALUATION BOARD SCHEMATIC AND LAYOUT

Figure 5. ADP1614 Boost Application Evaluation Board Schematic

Figure 6. ADP1614 Boost Application Printed Circuit Board (PCB) Top Layer

Figure 7. ADP1614 Boost Application PCB Bottom Layer

Rev. 0 | Page 4 of 8

LAYOUT GUIDELINES

For high efficiency, good regulation, and stability, a well-designed

PCB layout is required.

When designing PCBs, use the following guidelines:

• Keep the low ESR input capacitor (C

GND pins. This minimizes noise injected into the part

from the board parasitic inductance.

• Keep the high current path from C

to the SW and GND pins as short as possible.

• Keep the high current path from the VIN pin through L1,

the rectifier (D1), and the output capacitor (C

as possible.

• Keep high current traces as short and as wide as possible.

• Place the feedback resistors, R1 and R2, as close to the FB

pin as possible to prevent noise pickup. Connect the ground of

the feedback network directly to an AGND plane to make a

Kelvin connection to the GND pin.

• Place the compensation components as close as possible to

the COMP pin. Connect the ground of the compensation

network directly to an AGND plane that makes a Kelvin

connection to the GND pin.

• Avoid routing high impedance traces from the compensation

and feedback resistors near any node connected to SW or

near the inductor to prevent radiated noise injection.

• Connect the soft start capacitor (C

possible. Connect the ground of the soft start capacitor to an

AGND plane that makes a Kelvin connection to the GND pin.

• Connect the current limit set resistor (R

to the device. Connect the ground of R

that makes a Kelvin connection to the GND pin.

• The PCB must be properly designed to conduct the heat away

from the package. This is achieved by adding thermal vias to

the PCB that provide a thermal path to the inner or bottom

layers. Place thermal vias on the PCB under the exposed

pad of the LFCSP and in the GND plane around the ADP1614

package to improve thermal performance of the application.

) close to the VIN and

IN

through the L1 inductor

IN

) as short

OUT

) as close to the device as

SS

) as close as possible

CL

to an AGND plane

CL

Evaluation Board User Guide UG-437

Qty

C5, C6

Input capacitors

Open

ORDERING INFORMATION

BILL OF MATERIALS

Table 1. ADP1614-650-EVALZ (fSW = 650 kHz, V

Reference

Designator

1 U1 ADP1614 step-up converter with fSW = 650 kHz Analog Devices, Inc. ADP1614ACPZ-650-R7

1 L1 Inductor, 4.7 µH, 4.3 A Coilcraft XAL5030-472MEB

1 D1 Schottky rectifier, 30 V, 5 A Toshiba CMS05(TE12L,Q,M)

1 C1 Soft start capacitor, 47000 pF, 50 V, 0805, ±10% Kemet C0805C473K5RACTU

1 C2 Compensation capacitor, 33 pF, 50 V, 0805, ±5% Panasonic Electronic Components ECJ-2VC1H330J

1 C3 Compensation capacitor, 22000 pF, 50 V, 0805, ±10% TDK Corporation C2012X7R1H223K/0.60

1 C4 Input capacitor, 10 µF, 16 V, 0805, ±10% Murata Electronics GRM21BR61C106KE15L

2 C7, C8 Output capacitors, 10 µF, 25 V, 0805, ±10% Murata Electronics GRM21BR61E106KA73L

C9 Output capacitor Open

1 R1 Output voltage divider resistor, 30.9 kΩ, 0805, ±1% Vishay Dale CRCW080530K9FKEA

1 R2 Output voltage divider resistor, 10.0 kΩ, 0805, ±1% Panasonic Electronic Components ERJ-6ENF1002V

1 R3 Compensation resistor, 2 kΩ, 0805, ±1% Yageo 9C08052A2001FKHFT

1 R4 Current limit set resistor, 66.5 kΩ, 0805, ±1% Vishay Dale CRCW080566K5FKEA

1 EN Headers, 0.100 in, single, straight, 3-pin Sullins Connector Solutions PBC03SAAN2

1 SW Headers, 0.100 in, single, straight, 1-pin Sullins Connector Solutions PBC01SAAN2

4 VIN, VOUT, GNDx2 Test point loop connectors Aavid Thermalloy 125800D00000G

1

Equivalent substitutions may be made for all resistors and capacitors.

2

Alternatively, PBC36SAAN can be purchased and cut as necessary.

Description Manufacturer

OUT

= 5 V)

1

Part Number

Rev. 0 | Page 5 of 8

UG-437 Evaluation Board User Guide

1

R3

Compensation resistor, 1 kΩ, 0805, ±1%

Vishay Dale

CRCW08051K00FKEA

Table 2. ADP1614-1.3-EVALZ (fSW = 1.3 MHz, V

Reference

Qty

Designator

Description Manufacturer

1 U1 ADP1614 step-up converter with fSW = 1.3 MHz Analog Devices, Inc. ADP1614ACPZ-1.3-R7

1 L1 Inductor, 10 µH, 5A Coilcraft XAL6060-103MEB

1 D1 Schottky rectifier, 30V, 5A Toshiba CMS05(TE12L,Q,M)

1 C1 Soft start capacitor, 47000 pF, 50 V, 0805, ±10% Kemet C0805C473K5RACTU

1 C2 Compensation capacitor, 18 pF, 50V, 0805, ±5% Yageo CC0805JRNPO9BN180

1 C3 Compensation capacitor, 47000 pF, 50 V, 0805, ±10% Kemet C0805C473K5RACTU

1 C4 Input capacitor, 10 µF, 16 V, 0805, ±10% Murata Electronics GRM21BR61C106KE15L

C5, C6 Input capacitors Open

2 C7, C8 Output capacitors, 10 µF, 25 V, 0805, ±10% Murata Electronics GRM21BR61E106KA73L

C9 Output capacitor Open

1 R1 Output voltage divider resistor, 110.0 kΩ, 0805, ±1% Panasonic, ECG ERJ-6ENF1103V

1 R2 Output voltage divider resistor, 10.0 kΩ, 0805, ±1% Panasonic, ECG ERJ-6ENF1002V

1 R4 Current limit set resistor, 60.4 kΩ, 0805, ±1% Yageo RC0805FR-0760K4L

1 EN Headers, 0.100 in, single, straight, 3-pin Sullins Connector Solutions PBC03SAAN2

1 SW Headers, 0.100 in, single, straight, 1-pin Sullins Connector Solutions PBC01SAAN2

4 VIN, VOUT, GNDx2 Test point loop connectors Aavid Thermalloy 125800D00000G

1

Equivalent substitutions may be made for all resistors and capacitors.

2

Alternatively, PBC36SAAN can be purchased and cut as necessary.

= 15 V)

OUT

1

Part Number

Rev. 0 | Page 6 of 8

Evaluation Board User Guide UG-437

NOTES

Rev. 0 | Page 7 of 8

UG-437 Evaluation Board User Guide

Evaluation Board for any other purpose. Furthermore, the license granted is expressly made subject to the following additiona

NOTES

ESD Caution

ESD Caution

ESD (electrostatic discharge) sensitive device. Charged devices and circuit boards can discharge without detection. Although this product features patented or proprietary protection

ESD (electrostatic discharge) sensitive device. Charged devices and circuit boards can discharge without detection. Although this product features patented or proprietary protection

circuitry, damage may occur on devices subjected to high e nergy ESD. Therefore, proper ESD precaution s should be taken to avoid per forma nce degra dation or loss of functionality.

circuitry, damage may occur on devices subjected to high energy ESD. Therefore, proper ESD precautions should be taken to avoid performance degradation or loss of functionality.

Legal Terms and Conditions

By using the evaluation board discussed herein (together with any tools, components documentation or suppor t materials, the “Evaluation Board”), you are agreei ng to be bound by the terms and conditions

set forth below (“Agreement”) unless you have purchased the Evaluation Board, in which case the Analog Devices Standard Terms and Conditions of Sale shall govern. Do not use the Evaluation Board until you

have read and agreed to the Agreement. Your use of the Evaluation Board shall signify your acceptance of the Agreement. This Agreement is made by and between you (“Customer”) an d Analog Devices, In c.

(“ADI”), with its principal place of business at One Technology Way, Norwood, MA 02062, USA. S ubject to the terms and conditions of the Agreement, ADI hereby grants to Customer a free, limited, personal,

temporary, non-exclu sive, non-sublicensable, non-transferable license to use the Evaluation Board FOR EVALUATION PURPOSES ONLY. Customer understands and agrees that the Evaluation Board is provided

for the sole and exclusive purpose referenced above, and agrees not to use the

limitations: Customer shall not (i) rent, lease, display, sell, transfer, assign, sublicense, or distribute the Evaluation Board; and (ii) permit any Third Party to access the Evaluation Board. As used herein, the term

“Third Party” includes any entity other than ADI, Customer, their employees, affiliates and in-house consultants. The Evaluation Board is NOT sold to Customer; all rights not expressly granted herein, including

ownership of the Evaluation Board, are reserved by ADI. CONFIDENTIALIT Y. This Agreement and the Evaluation Board shall all be considered the confidential and proprietary information of ADI. Customer may

not disclose or transfer any portion of the Evaluation Board to any other party for any reason. Upon discontinuation of use of the Evaluation Board or termination of this Agreement, Customer agrees to

promptly return the Evaluation Board to ADI. ADDITIONAL RESTRICTIONS. Customer may not disassemble, decompile or reverse engineer chips on the Evaluation Board. Customer shall inform ADI of any

occurred damages or any modifications or alterations it makes to the Evaluation Board, including but not limited to soldering or any other activity that affects the material content of the Evaluation Board.

Modifications to the Evaluation Board must comply with applicable law, including but not limited to the RoHS Directive. TERMINATION. ADI may terminate this Agreement at any time upon gi ving written notice

to Customer. Customer agrees to return to ADI the Evaluation Board at that time. LIMITATION OF LIABILITY. THE EVALUATION BOARD PROVIDED HEREUNDER IS PROVIDED “AS IS” AND ADI MAKES NO

WARRANTIES OR REPRES ENTATIONS OF ANY KIND WITH RESPECT TO IT. AD I SPE CIFICALLY DISCLAIMS AN Y RE PRESENTATIONS, ENDORSEMENTS, GUARANTEES, OR WARRANTIES, EXPRESS OR IM PLIED, RELATED

TO THE EVALUATION BOARD INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTY OF MERCHANTABILITY, TITLE, FITNESS FOR A PARTICULAR PURPOSE OR NONINFRINGEMENT OF INTELLECTUAL

PROPERTY RIGHTS. IN NO EVENT WILL ADI AND ITS LICENSORS BE LIABLE FOR ANY INCIDENTAL, SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES RESULTING FROM CUSTOMER’S POSSESSION OR USE OF

THE EVALUATION BOARD, INCLUDING BUT NOT LIMITED TO LOST PROFITS, DELAY COSTS, LABOR COSTS OR LOSS OF GOODWILL. ADI’S TOTAL LIABILITY FROM ANY AND ALL CAUSES SHALL BE LIMITED TO THE

AMOUNT OF ONE HUNDRED US DOLLARS ($100.00). EXPORT. Customer agrees that it will not directly or indirectly export the Evaluation Board to another country, and that it will comply with all applicable

United States federal laws and regulations relating to exports. GOVERNING LAW. This Agreement shall be governed by and construed in accordance with the substantive laws of the Commonwealth of

Massachusetts (excluding conflict of law rules). Any legal action regarding this Ag re ement will be heard in the state or federal cour ts having jurisdicti on in Suffolk County, Mass achusetts, and Customer h ereby

submits to the personal jurisdiction and venue of such courts. The United Nations Convention on Contracts for the Int ernational Sale of Goods shall not ap ply to this Agreement and is expre ssly disclaimed.

©2012 Analog Devices, Inc. All rights reserved. Trademarks and

registered trademarks are the property of their respective owners.

UG10859-0-7/12(0)

Rev. 0 | Page 8 of 8

l

Loading...

Loading...