Evaluation Board User Guide

One Technology Way • P. O . Box 9106 • Norwood, MA 02062-9106, U.S.A. • Tel : 781.329.4700 • Fax : 781.461.3113 • www.analog.com

UG-219

Evaluating the ADP2370/ADP2371 Buck Regulators

FEATURES

Buck regulator input voltage range: 3.2 V to 15 V

Buck regulator output current: 800 mA

Operating temperature range: −40°C to +125°C

EQUIPMENT NEEDED

Voltage meters, current meters, power supply

Resistive or electronic loads

DOCUMENTS NEEDED

ADP2370/ADP2371 data sheet

UG-220 user guide

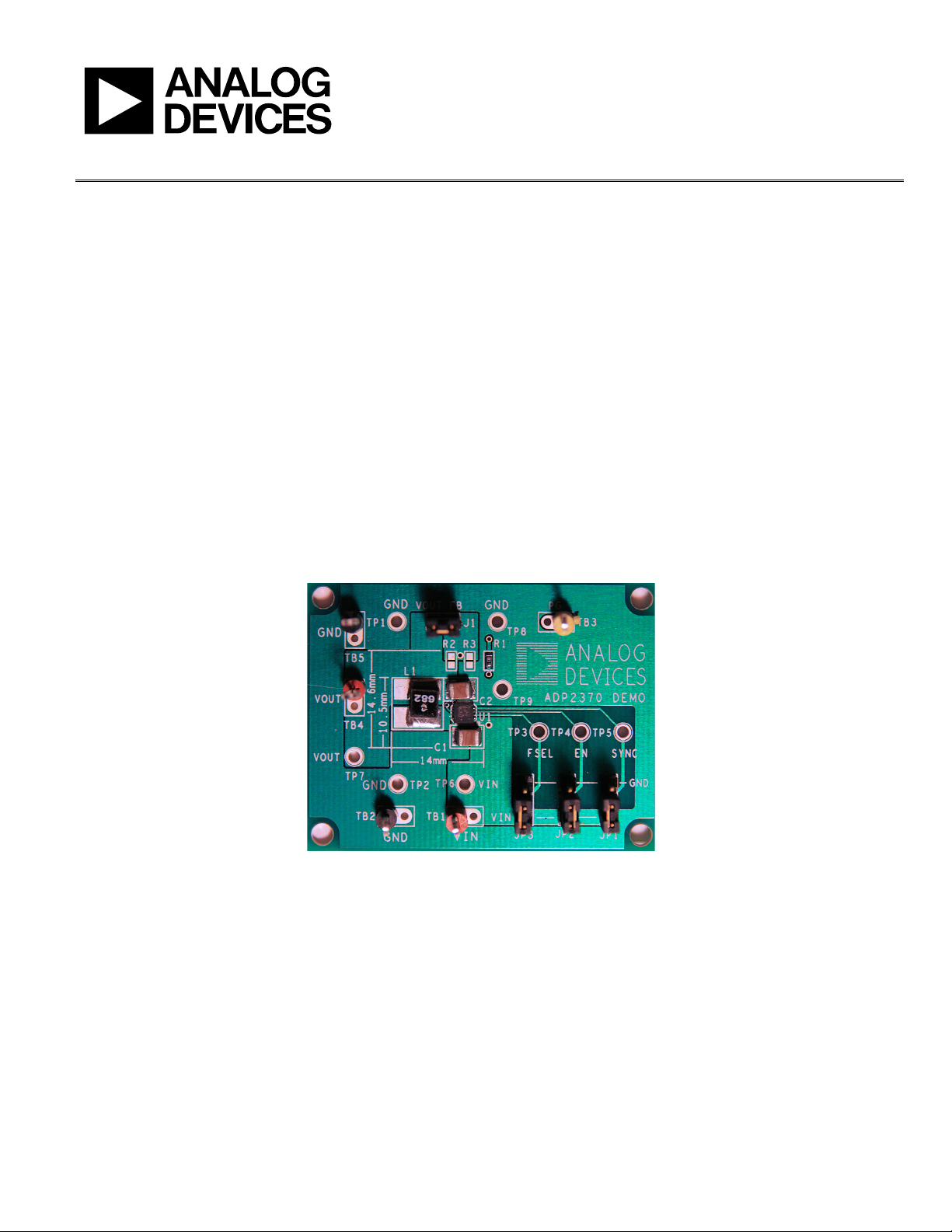

DIGITAL PICTURE OF THE EVALUATION BOARD

GENERAL DESCRIPTION

The ADP2370/ADP2371 evaluation boards (ADP2370CP-EVALZ

and ADP2371CP-EVALZ) are used to demonstrate the functionality of the ADP2370/ADP2371 buck regulators.

Basic electrical performance measurements, such as line and load

regulation, efficiency, and ground current, can be demonstrated

with a few voltage supplies, voltage meters, current meters, and

load resistors.

Complete information about the ADP2370/ADP2371 buck regulators is available in the ADP2370/ADP2371 data sheet, which

should be consulted in conjunction with this user guide when

using the evaluation board.

PLEASE SEE THE LAST PAGE FOR AN IMPORTANT

WARNING AND LEGAL TERMS AND CONDITIONS.

Figure 1.

Rev. 0 | Page 1 of 12

09532-001

UG-219 Evaluation Board User Guide

TABLE OF CONTENTS

Features .............................................................................................. 1

Equipment Needed ........................................................................... 1

Documents Needed .......................................................................... 1

General Description ......................................................................... 1

Digital Picture of the Evaluation Board ......................................... 1

Revision History ............................................................................... 2

Evaluation Board Hardware and Schematic ................................. 3

Evaluation Board Configuration ................................................ 3

Output Voltage Accuracy Measurements ...................................... 4

REVISION HISTORY

4/12—Revision 0: Initial Version

Line Regulation Measurements ...................................................5

Load Regulation Measurements ..................................................5

Efficiency Measurements .................................................................6

Calculating the Efficiency ............................................................7

Quiescent Current Measurements ..................................................8

Quiescent Current Consumption ...............................................9

Ordering Information .................................................................... 10

Bill of Materials ........................................................................... 10

Related Links ............................................................................... 10

Rev. 0 | Page 2 of 12

Evaluation Board User Guide UG-219

ADJ only (5V )

ADJ only (5V )

PG

SW

VOUT

VIN

FSEL

EN

SYNC

VOUT

TB4

U1

ADP2370/ADP2371

VIN

1

FSEL

2

EN

3

PG

6

SW

7

PGND

8

SYNC

4

FB

5

TP4

1

TP9

1

JP2

EN

1

1

2

2

3

3

TP5

1

GND

TB2

R1

10K

TP6

1

JP3

Freq

1

1

2

2

3

3

TP7

1

R2

422K

JP1

Sync

1

1

2

2

3

3

TP1

1

C2

10UF

VIN

TB1

PG

TB3

GND

TB5

R3

80.6K

TP2

1

L1

6.8uH

J1

1 2

TP8

1

C1

10UF

TP3

1

09532-002

R1

Pull-up resistor

10 kΩ pull-up resistor for power good (PG).

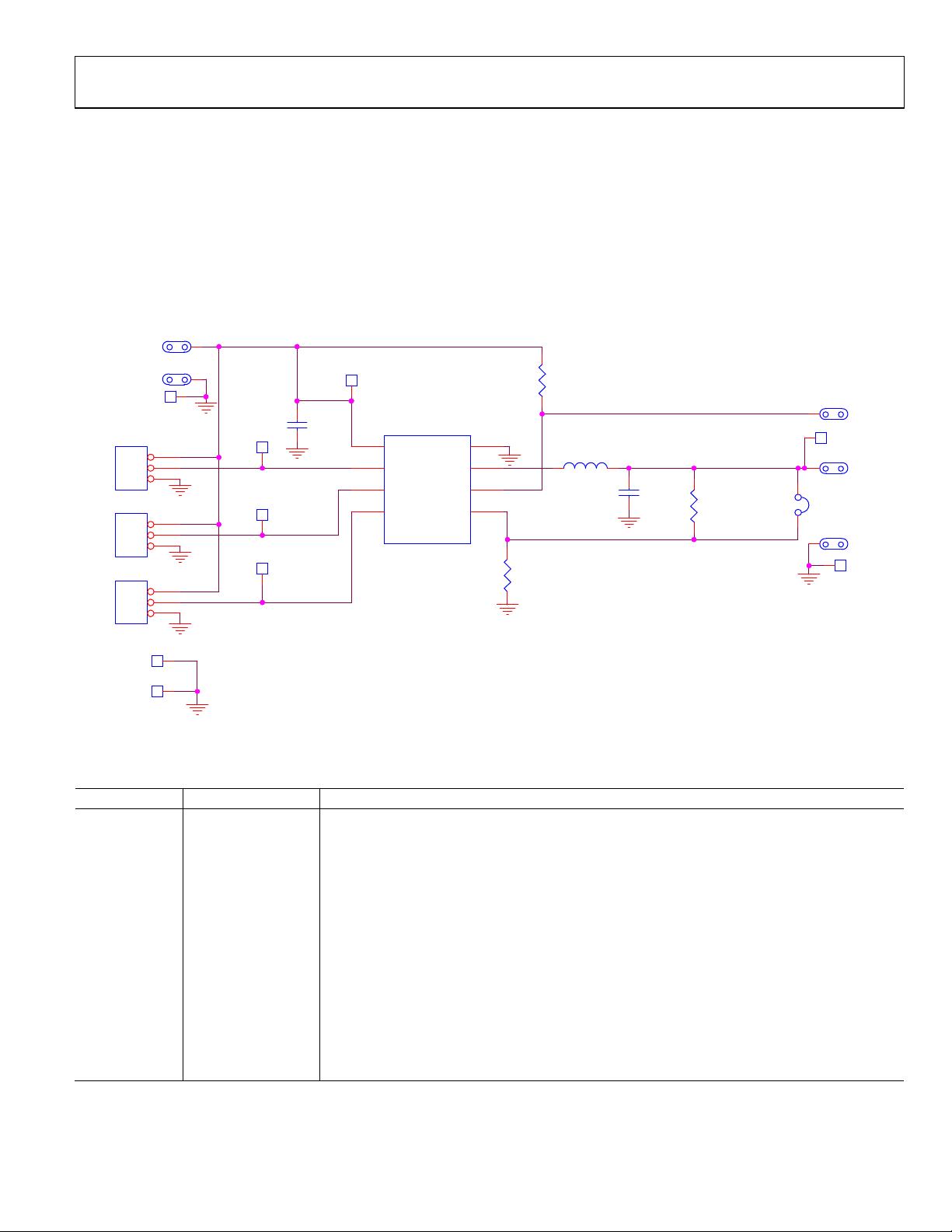

EVALUATION BOARD HARDWARE AND SCHEMATIC

EVALUATION BOARD CONFIGURATION

The ADP2370/ADP2371 evaluation boards ship with all the

components necessary to perform basic electrical performance

measurements, including the input and output capacitors, buck

inductor, and power-good pull-up resistor. The placement of

the critical components for the buck regulator (inductor and

capacitors) has been optimized for low noise and the smallest

possible footprint.

Figure 2 shows the schematic of the evaluation board configuration. Tab le 1 describes the hardware components.

For complete information about the ADP2370/ADP2371 buck

regulators, see the ADP2370/ADP2371 data sheet.

Figure 2. Evaluation Board Schematic

Table 1. Evaluation Board Hardware Components

Component Function Description

U11 Buck regulator ADP2370 or ADP2371 buck regulator.

C1 Input capacitor 10 μF input bypass capacitor required for transient performance.

C2 Output capacitor 10 μF output capacitor required for stability and transient performance.

L12 Inductor 6.8 μH inductor for 3.3 V output at 1.2 MHz.

R2 Resistor 422 kΩ, 1% resistor. With R3, sets the output voltage to 5 V (adjustable version only).

R3 Resistor 80.6 kΩ, 1% resistor. With R2, sets the output voltage to 5 V (adjustable version only).

JP1 Jumper When JP1 is connected to VIN, forced PWM mode is enabled. When JP1 is connected to GND,

JP2 Jumper When JP2 is connected to VIN, the output is enabled. When JP2 is connected to GND, the output

JP3 Jumper When JP3 is connected to VIN, 1.2 MHz operation is selected. When JP3 is connected to GND,

J1 Jumper Connects the FB pin to the buck regulator output (fixed output version only).

1

Component varies depending on the evaluation board model ordered.

2

Inductor value varies depending on the output voltage.

auto mode is enabled. When JP1 is connected to SYNC, an external clock can be used to set the

operating frequency.

is disabled.

600 kHz operation is selected.

Rev. 0 | Page 3 of 12

UG-219 Evaluation Board User Guide

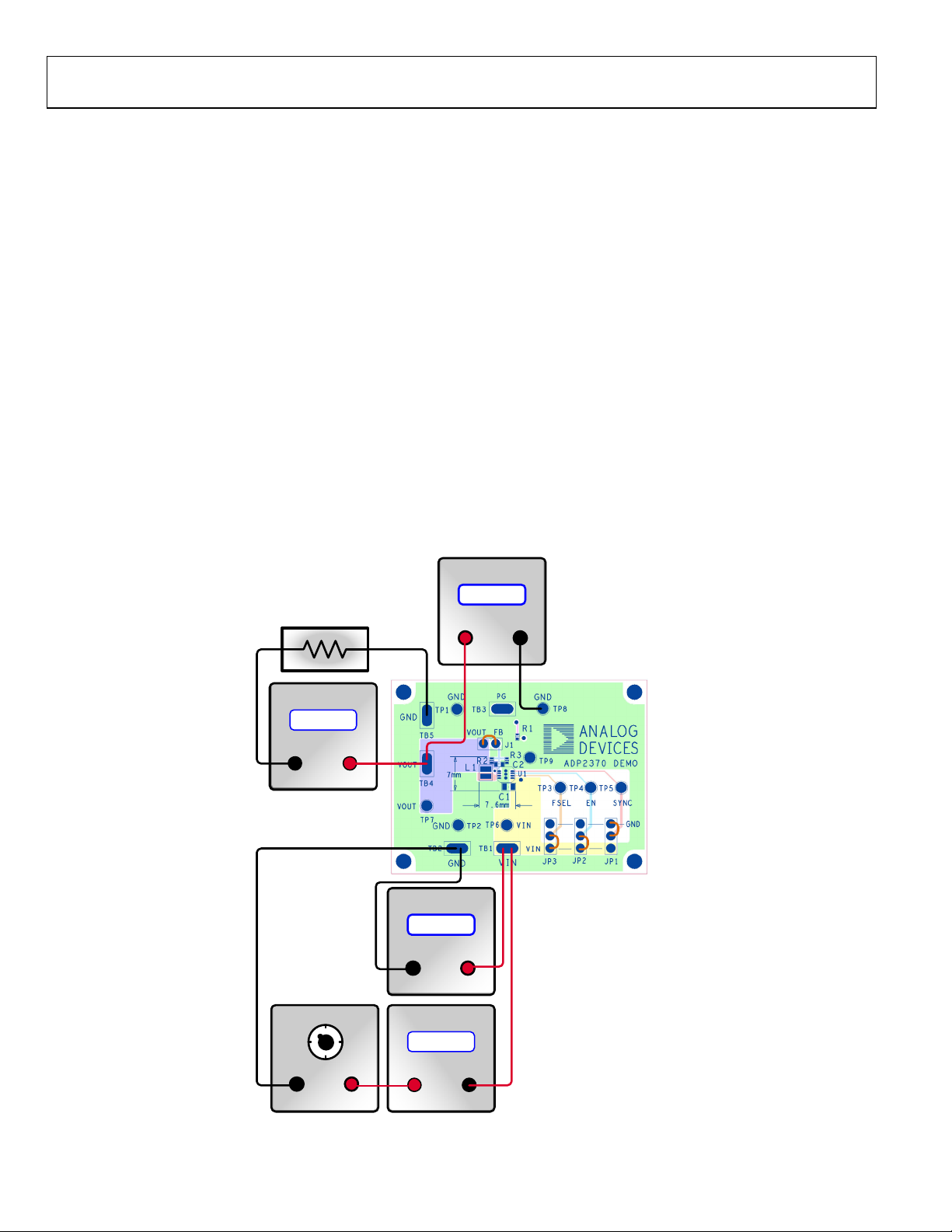

OUTPUT VOLTAGE ACCURACY MEASUREMENTS

Figure 3 shows how to connect the evaluation board to a voltage

source and a voltage meter (voltmeter) for basic output voltage

accuracy measurements. A resistor can be used as the load for the

buck regulator. Ensure that the resistor has a power rating adequate

to handle the power that is expected to be dissipated across it. An

electronic load can be used as an alternative. In addition, ensure

that the voltage source can supply enough current for the expected

load levels.

Follow these steps to connect the evaluation board to a voltage

source and voltage meter:

1. Connect the negative terminal (−) of the voltage source

to the GND pad (TB2) on the evaluation board.

2. Connect the positive terminal (+) of the voltage source

to the VIN pad (TB1) on the evaluation board.

3. Connect a load between the VOUT pad (TB4) and one

of the GND pads on the evaluation board.

4. Connect the negative terminal (−) of the voltmeter to one

of the GND pads on the evaluation board.

5. Connect the positive terminal (+) of the voltmeter to the

VOUT pad (TP7) on the evaluation board.

6. Connect a jumper between Pin 1 and Pin 2 of JP2 to enable

the buck regulator.

7. Connect a jumper between Pin 3 and Pin 2 of JP1 to enable

auto mode.

8. Connect a jumper between Pin 1 and Pin 2 of JP3 to enable

1.2 MHz operation.

9. Turn on the voltage source.

If the load current is large, connect the voltage meter as close to

TB4 as possible to reduce the effects of IR drops.

LOAD

VOLTMETER

1.99711

–

+

VOLTAGE SOURCE

–

Figure 3. Buck Regulator Output Voltage Regulation Measurement Setup

Rev. 0 | Page 4 of 12

+

09532-004

Evaluation Board User Guide UG-219

3.10

3.15

3.20

3.25

3.30

3.35

3.40

3 5 7 9 11 13 15

OUTPUT VOLTAGE (V)

INPUT VOLTAGE (V)

I

LOAD

= 0.1mA

I

LOAD

= 1mA

I

LOAD

= 5mA

I

LOAD

= 10mA

I

LOAD

= 50mA

I

LOAD

= 100mA

I

LOAD

= 300mA

I

LOAD

= 800mA

09532-011

3.10

3.15

3.20

3.25

3.30

3.35

3.40

0.1 1 10 100 1000

OUTPUT VOLTAGE (V)

LOAD CURRENT ( mA)

V

IN

= 3.8V

V

IN

= 4.55V

V

IN

= 6.05V

V

IN

= 7.30V

V

IN

= 10.55V

V

IN

= 12

.05V

VIN = 15.05V

09532-012

LINE REGULATION MEASUREMENTS

For line regulation measurements, the output of the buck

regulator is monitored while the input is varied. For good line

regulation, the output must change as little as possible with

varying input levels.

For example, for an ADP2370/ADP2371 with a fixed 3.3 V

output, V

can be repeated under different load conditions. Figure 4 shows

the typical line regulation performance of an ADP2370/ADP2371

with a fixed 3.3 V output.

must be varied from 3.8 V to 15 V. This measurement

IN

LOAD REGULATION MEASUREMENTS

For load regulation measurements, the output of the buck

regulator is monitored while the load is varied. For good load

regulation, the output must change as little as possible with

varying loads.

The input voltage must be held constant during this measurement. The load current can be varied from 0 mA to 800 mA.

Figure 5 shows the typical load regulation performance of an

ADP2370/ADP2371 with a fixed 3.3 V output for various input

voltages.

Figure 4. Output Voltage (V

) vs. Input Voltage (VIN)

OUT

Figure 5. Output Voltage (V

) vs. Load Current (I

OUT

OUT

)

Rev. 0 | Page 5 of 12

UG-219 Evaluation Board User Guide

EFFICIENCY MEASUREMENTS

Figure 6 shows how to connect the evaluation board to a voltage

source, two voltage meters, and two current meters (ammeters)

for basic efficiency measurements. A resistor can be used as the

load for the buck regulator. Ensure that the resistor has a power

rating adequate to handle the power that is expected to be dissipated across it. An electronic load can be used as an alternative.

In addition, ensure that the voltage source can supply enough

current for the expected load levels.

Follow these steps to connect the evaluation board to a voltage

source and to the voltage and current meters:

1. Connect a jumper between Pin 1 and Pin 2 of JP2 to enable

the buck regulator.

2. Connect a jumper between Pin 3 and Pin 2 of JP1 to enable

auto mode.

3. Connect a jumper between Pin 1 and Pin 2 of JP3 to enable

1.2 MHz operation.

4. Connect the negative terminal (−) of the voltage source to

the GND pad (TB2) on the evaluation board.

5. Connect the positive terminal (+) of the voltage source to

the positive terminal (+) of the input ammeter.

6. Connect the negative terminal (−) of the input ammeter to

the VIN pad (TB1) on the evaluation board.

7. Connect the positive terminal (+) of the input voltmeter to

the VIN pad (TB1) on the evaluation board.

8. Connect the negative terminal (−) of the input voltmeter to

the GND pad (TB2) on the evaluation board.

9. Connect the positive terminal (+) of the output ammeter to

the VOUT pad (TB4) on the evaluation board.

10. Connect a load between the negative terminal (−) of the

output ammeter and the GND pad (TB5) on the evaluation

board.

11. Connect the positive terminal (+) of the output voltmeter

to the VOUT pad (TB4) on the evaluation board.

12. Connect the negative terminal (−) of the output voltmeter

to the GND pad (TP8) on the evaluation board.

13. Turn on the voltage source.

If the load current is large, connect the voltage meters as close

as possible to the VIN and VOUT pads to reduce the effects of

IR drops.

LOAD

AMMETER

0.00112

–

VOLTAGE SOURCE

+

VOLTMETER

1.99711

–

AMMETER

VOLTMETER

1.99711

+

+

–

0.00112

–

+

Figure 6. Buck Regulator Efficiency Measurement Setup

+

Rev. 0 | Page 6 of 12

–

09532-006

Evaluation Board User Guide UG-219

0

10

20

30

40

50

60

70

80

90

100

0.01 0.1 1.0 10 100 1000

EFFICIENCY (%)

LOAD CURRENT ( mA)

V

IN

=

3.80V

V

IN

=

4.55V

V

IN

=

6.05V

V

IN

=

7.30V

V

IN

=

10.55V

V

IN

=

12.05V

V

IN

=

15.05V

09532-019

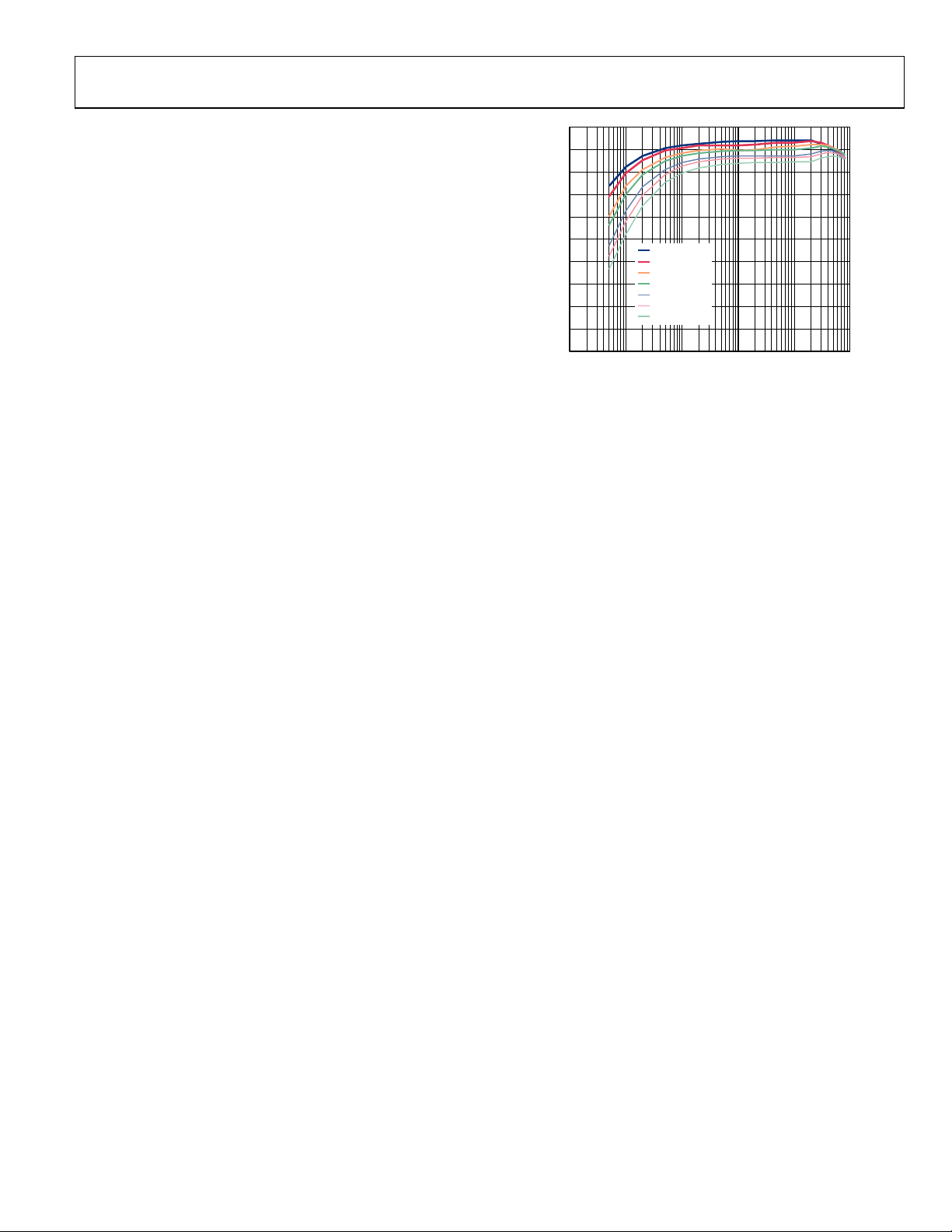

CALCULATING THE EFFICIENCY

The efficiency is calculated as follows:

× I

Efficiency = 100% × (V

OUT

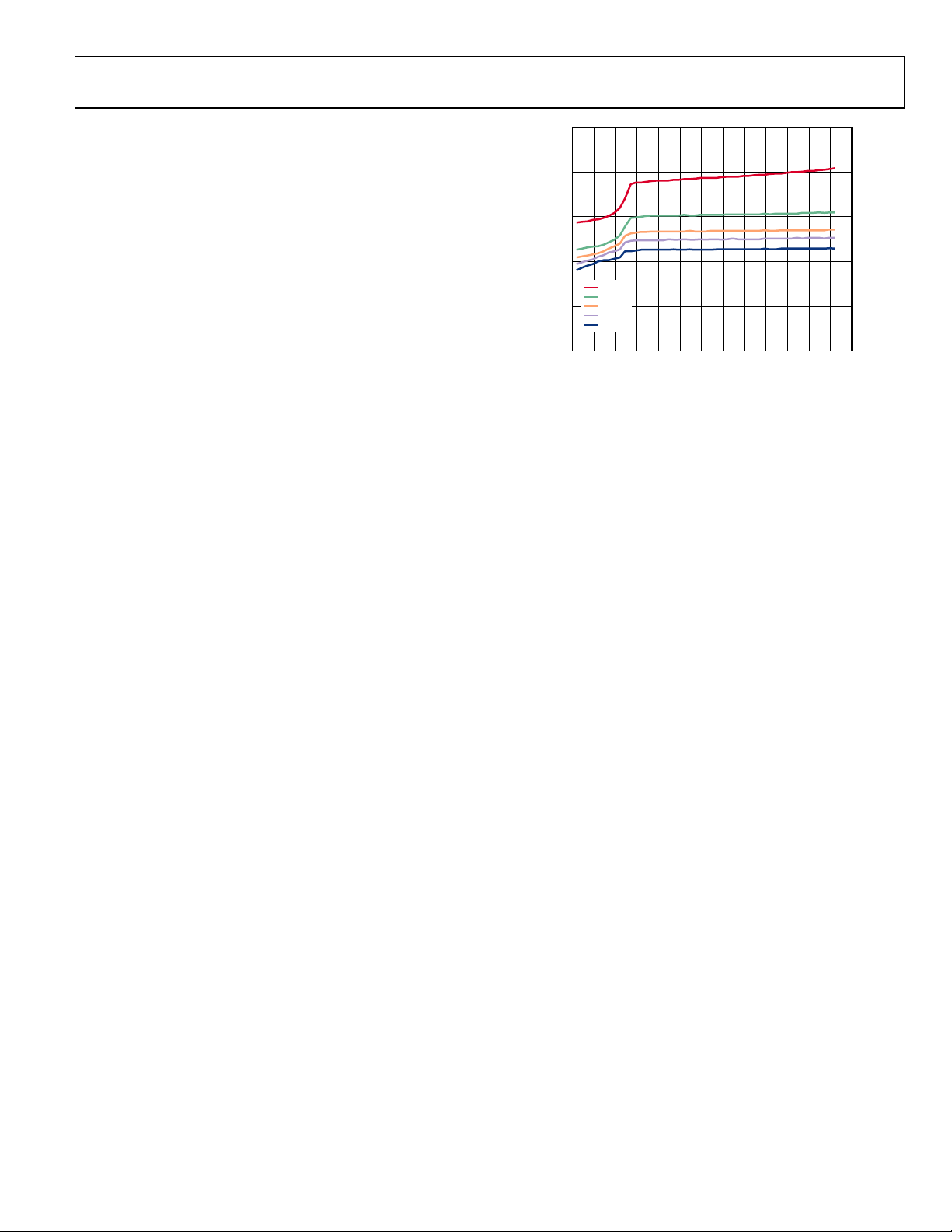

The efficiency of the buck regulator can be measured over several

combinations of input voltage and load current. Figure 7 shows

the efficiency of a 3.3 V output buck regulator over input voltage

and load current.

)/(VIN × IIN)

OUT

Figure 7. Efficiency vs. Input Voltage and Load Current

Rev. 0 | Page 7 of 12

UG-219 Evaluation Board User Guide

QUIESCENT CURRENT MEASUREMENTS

Figure 8 shows how to connect the evaluation board to two

voltage sources and a current meter for quiescent current

measurements.

Follow these steps to connect the evaluation board to the

voltage sources and to the current meter:

1. Connect a jumper between Pin 1 and Pin 2 of JP2 to enable

the buck regulator.

2. Connect a jumper between Pin 3 and Pin 2 of JP1 to enable

auto mode.

3. Connect a jumper between Pin 1 and Pin 2 of JP3 to enable

1.2 MHz operation.

4. Connect the positive terminal (+) of the input voltage

source to the positive terminal (+) of the ammeter.

5. Connect the negative terminal (−) of the ammeter to the

VIN pad (TB1) on the evaluation board.

VOLTAGE SOURCE

6. Connect the negative terminal (−) of the input voltage

source to the GND pad (TB2) on the evaluation board.

7. Remove R1. (R1 can remain in circuit, but it increases the

quiescent current by 10 kΩ/V

8. Connect the positive terminal (+) of the output voltage

source to the VOUT pad (TB4) on the evaluation board.

9. Connect the negative terminal (−) of the output voltage

source to the GND pad (TB5) on the evaluation board.

10. If the output voltage source has a current limit function,

set the current limit to 10 mA or less.

11. Set the output voltage source output voltage to ~500 mV

above the normal output voltage of the ADP2370/ADP2371

evaluation board.

12. Turn on the voltage source.

.)

IN

+

VOLTAGE SOURCE

Figure 8. Quiescent Current Measurement Setup

–

AMMETER

++

––

09532-008

Rev. 0 | Page 8 of 12

Evaluation Board User Guide UG-219

0

5

10

15

20

25

3 4 5 6 7 8 9 10 11 12 13 14 15 16

QUIESCENT CURRENT (µA)

INPUT VOLTAGE (V)

–40°C

–5°C

+25°C

+85°C

+125°C

09532-003

QUIESCENT CURRENT CONSUMPTION

Quiescent current measurements can determine how much

current the internal circuits of the buck regulator consume under

no load conditions. To be efficient, the regulator must consume

as little current as possible. Figure 9 shows the typical quiescent

current consumption at no load for various input voltages. When

the device is disabled (EN = PGND), quiescent current drops to

less than 2 µA.

Figure 9. Quiescent Current vs. Input Voltage, No Load

Rev. 0 | Page 9 of 12

UG-219 Evaluation Board User Guide

ORDERING INFORMATION

BILL OF MATERIALS

Table 2.

Qty Reference Designator Description Manufacturer/Vendor Vendor Part No.

2 C1, C2 Capacitor, MLCC, 10 μF, 25 V, 1210, X5R Murata or equivalent

3 JP1, JP2, JP3 Header, single, STR, three pins Digi-Key Corp. S1012E-03-ND

1 J1 Header, single, STR, two pins Digi-Key Corp. S1012E-02-ND

1 L1 Inductor, 6.8 μH, 4 mm × 4 mm × 3 mm Coilcraft XAL4030-682ME

1 R1 Resistor, 10 kΩ, 0.10 W, 0603 Vishay or equivalent

1 U1 IC, ADP2370/ADP2371 buck regulator Analog Devices, Inc. ADP2370ACPZ-3.3-R7

ADP2371ACPZ-3.3-R7

RELATED LINKS

Resource Description

ADP2370/ADP2371 Product Page

UG-220 ADP2370/ADP2371 RedyKit™ User Guide

Rev. 0 | Page 10 of 12

Evaluation Board User Guide UG-219

NOTES

Rev. 0 | Page 11 of 12

UG-219 Evaluation Board User Guide

and between you (“Customer”) and Analog Devices, Inc.

Directive. TERMINATION. ADI may terminate this Agreement at any time upon giving written notice

, THE IMPLIED WARRANTY OF MERCHANTABILITY, TITLE, FITNESS FOR A PARTICULAR PURPOSE OR NONINFRINGEMENT OF INTELLECTUAL

NOTES

ESD Caution

ESD (electrostatic discharge) sensitive device. Charged devices and circuit boards can discharge without detection. Although this product features patented or proprietary protection

circuitry, damage may occur on devices subjected to high e nergy ESD. Therefore, proper ES D precautions should be taken t o avoid performance degradation or loss of functionality.

Legal Terms and Conditions

By using the evaluation board discussed herein (together with any tools, components documentation or support materials, the “Evaluation Board”), you are agreeing to be bound by the terms and conditions

set forth below (“Agreement”) unless you have purchased the Evaluation Board, in which case the Analog Devices Standard Terms and Conditions of Sale shall govern. Do not use t he Evaluation Board until you

have read and agreed to the Agreement. Your use of the Evaluation Board shall signify your acceptance of the Agreement. This Agreement is made by

(“ADI”), with its principal place of business at One Technology Way, Norwood, MA 02062, USA. Subject to the terms and conditions of the Agreement, ADI hereby grants to Customer a free, limited, personal,

temporary, non-exclusive, non-sublicensable, non-transferable license to use the Evaluation Board FOR EVALUATION PURPOSES ONLY. Customer understands and agrees that the Evaluation Board is provided

for the sole and exclusive purpose referenced above, and agrees not to use the Evaluation Board for any other purpose. Furthermore, the license granted is expressly made subject to the following additional

limitations: Customer shall not (i) rent, lease, display, sell, transfer, assign, sublicense, or distribute the Evaluation Board; and (ii) permit any Third Party to access the Evaluation Board. As used herein, the term

“Third Party” includes any entity other than ADI, Customer, their employees, affiliates and in-house consultants. The Evaluation Board is NOT sold to Customer ; all rights not expressly granted herein, including

ownership of the Evaluation Board, are reserved by ADI. CONFIDENTIALITY. This Agreement and the Evaluation Board shall all be considered the confidential and proprietar y information of ADI . Customer may

not disclose or transfer any portion of the Evaluation Board to any other party for any reason. Upon discontinuation of use of the Evaluation Board or termination of this Agreement, Customer agrees to

promptly return the Evaluation Board to ADI. ADDITIONAL RESTRICTIONS. Customer may not disassemble, decompile or reverse engineer chips on the Evaluation Board. Customer shall inform ADI of any

occurred damages or any modifications or alterations it makes to the Evaluation Board, including but not limited to soldering or any other activity that affects the material content of the Evaluation Board.

Modifications to the Evaluation Board must comply with applicable law, inclu ding but not limited to the RoHS

to Customer. Customer agrees to return to ADI the Evaluation Board at that time. LIMITATION OF LIABILITY. THE EVALUATION BOARD PROVIDED HEREUNDER IS PROVIDED “AS IS” AND ADI MAKES NO

WARRANTIES OR REPRES ENTATIONS OF ANY KIND WITH RESPECT TO IT. ADI SPECIFICALLY DISCLAIMS ANY REPRESENTATIONS, END ORSEMENTS, GUARANTEES, OR WARRANTIES, EXPRESS OR IMPLIED, RELATED

TO THE EVALUATION BOARD INCLUDING, BUT NOT LIMITED TO

PROPERTY RIGHTS. IN NO EVENT WILL ADI AND ITS LICENSORS BE LIABLE FOR ANY INCIDENTAL, SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES RESULTING FROM CUSTOMER’S POSSESSION OR USE OF

THE EVALUATION BOARD, INCLUDING BUT NOT LIMITED TO LOST PROFITS, D ELAY COSTS, LAB OR COSTS OR LOSS OF GOODWILL . ADI’S TOTAL LIABILIT Y FROM ANY AND ALL CAUSES SHALL B E LIMITED TO THE

AMOUNT OF ONE HUNDRED US DOLLARS ($100.00). EXPORT. Customer agrees that it will not directly or indirectly export the Evaluation Board to another country, and that it will comply with all applicable

United States federal laws and regulations relating to exports. GOVERNING LAW. This Agreement shall be governed by and construed in accordance with the substantive laws of the Commonwealth of

Massachusetts (excluding conflict of law rules). Any legal action regarding this Agreement will be heard in the state or federal courts having jurisdiction in Suffolk County, Massachusetts, and Customer hereby

submits to the personal jurisdiction and venue of such courts. The United Nations Convention on Contracts for the International Sale of Goods shall no t apply to this Agreement and is exp ressly disclaimed.

©2012 Analog Devices, Inc. All rights reserved. Trademarks and

registered trademarks are the property of their respective owners.

UG09532-0-4/12(0)

Rev. 0 | Page 12 of 12

Loading...

Loading...