Monolithic Peak Detector

a

FEATURES

Monolithic Design for Reliability and Low Cost

High Slew Rate: 0.5 V/s

Low Droop Rate

= 25ⴗC: 0.1 mV/ms

T

A

T

= 125ⴗC: 10 mV/ms

A

Low Zero-Scale Error: 4 mV

Digitally Selected Hold and Reset Modes

Reset to Positive or Negative Voltage Levels

Logic Signals TTL and CMOS Compatible

Uncommitted Comparator On-Chip

Available in Die Form

GENERAL DESCRIPTION

The PKD01 tracks an analog input signal until a maximum

amplitude is reached. The maximum value is then retained as a

peak voltage on a hold capacitor. Being a monolithic circuit, the

PKD01 offers significant performance and package density

advantages over hybrid modules and discrete designs without

sacrificing system versatility. The matching characteristics

attained in a monolithic circuit provide inherent advantages

when charge injection and droop rate error reduction are

primary goals.

Innovative design techniques maximize the advantages of monolithic technology. Transconductance (gm) amplifiers were chosen

over conventional voltage amplifier circuit building blocks. The

g

amplifiers simplify internal frequency compensation, minimize

m

acquisition time and maximize circuit accuracy. Their outputs

are easily switched by low glitch current steering circuits. The

steered outputs are clamped to reduce charge injection errors

upon entering the hold mode or exiting the reset mode. The inherently low zero-scale error is further reduced by active Zener-Zap

trimming to optimize overall accuracy.

with Reset-and-Hold Mode

PKD01

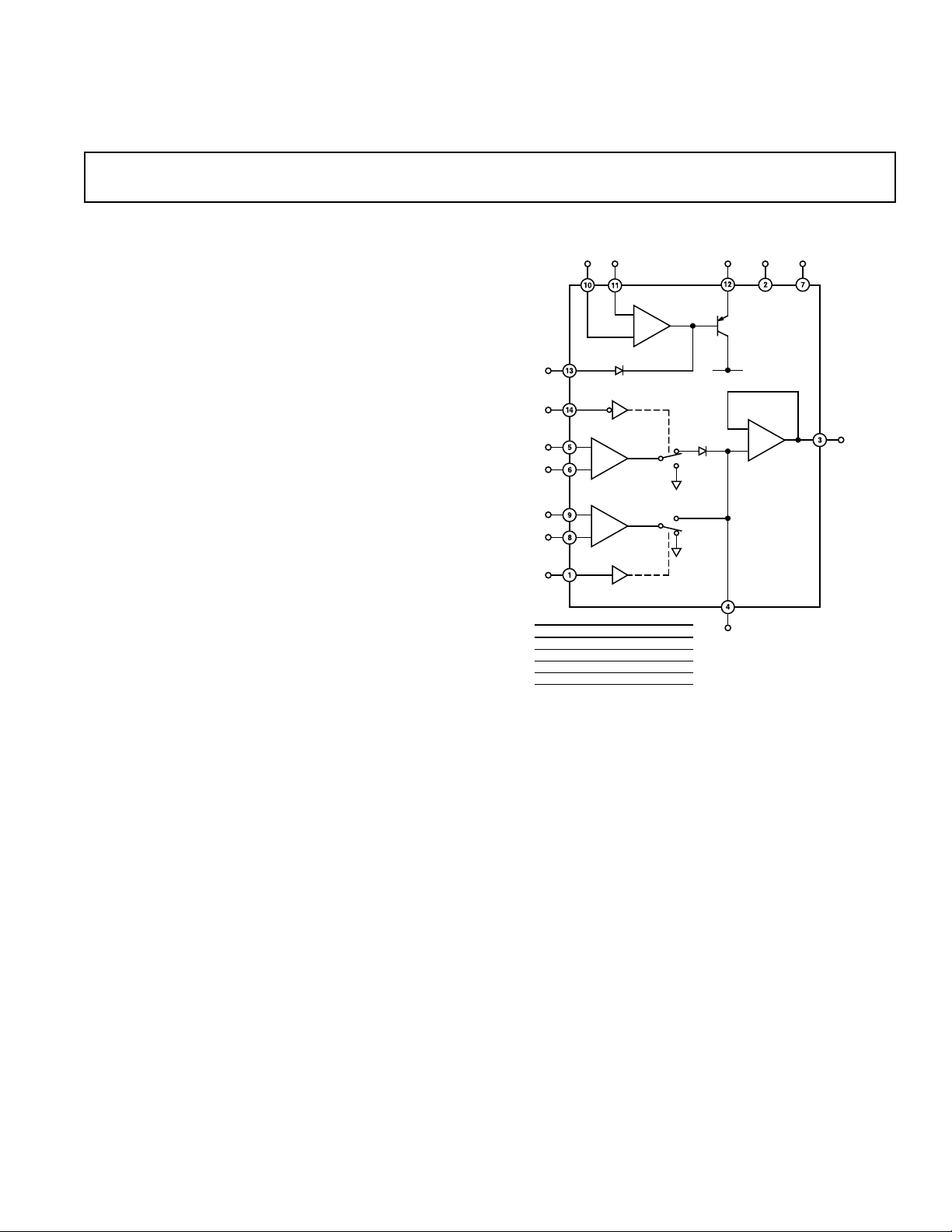

FUNCTIONAL BLOCK DIAGRAM

–IN+IN OUTPUT V+ V–

–

CMP

+

LOGIC

GND

DET

GATED

"

–IN

+IN

–IN

+IN

RST

RST

"g

m

–

AMP

A

+

GATED

"

"g

m

–

AMP

B

+

DET

OPERATIONAL MODE

0

0

0

1

1

PEAK DETECT

1

PEAK HOLD

1

RESET

0

INDETERMINATE

D

The output buffer amplifier features an FET input stage to

reduce droop rate error during lengthy peak hold periods. A bias

current cancellation circuit minimizes droop error at high ambient temperatures.

Through the DET control pin, new peaks may either be detected

or ignored. Detected peaks are presented as positive output

levels. Positive or negative peaks may be detected without

additional active circuits, since Amplifier A can operate as an

inverting or noninverting gain stage.

An uncommitted comparator provides many application options.

Status indication and logic shaping/shifting are typical examples.

V–

OUTPUT

BUFFER

1

–

C

+

PKD01

C

H

SWITCHES SHOWN FOR:

RST = “0,” DET = “0”

OUTPUT

REV. A

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 World Wide Web Site: http://www.analog.com

Fax: 781/326-8703 © Analog Devices, Inc., 2001

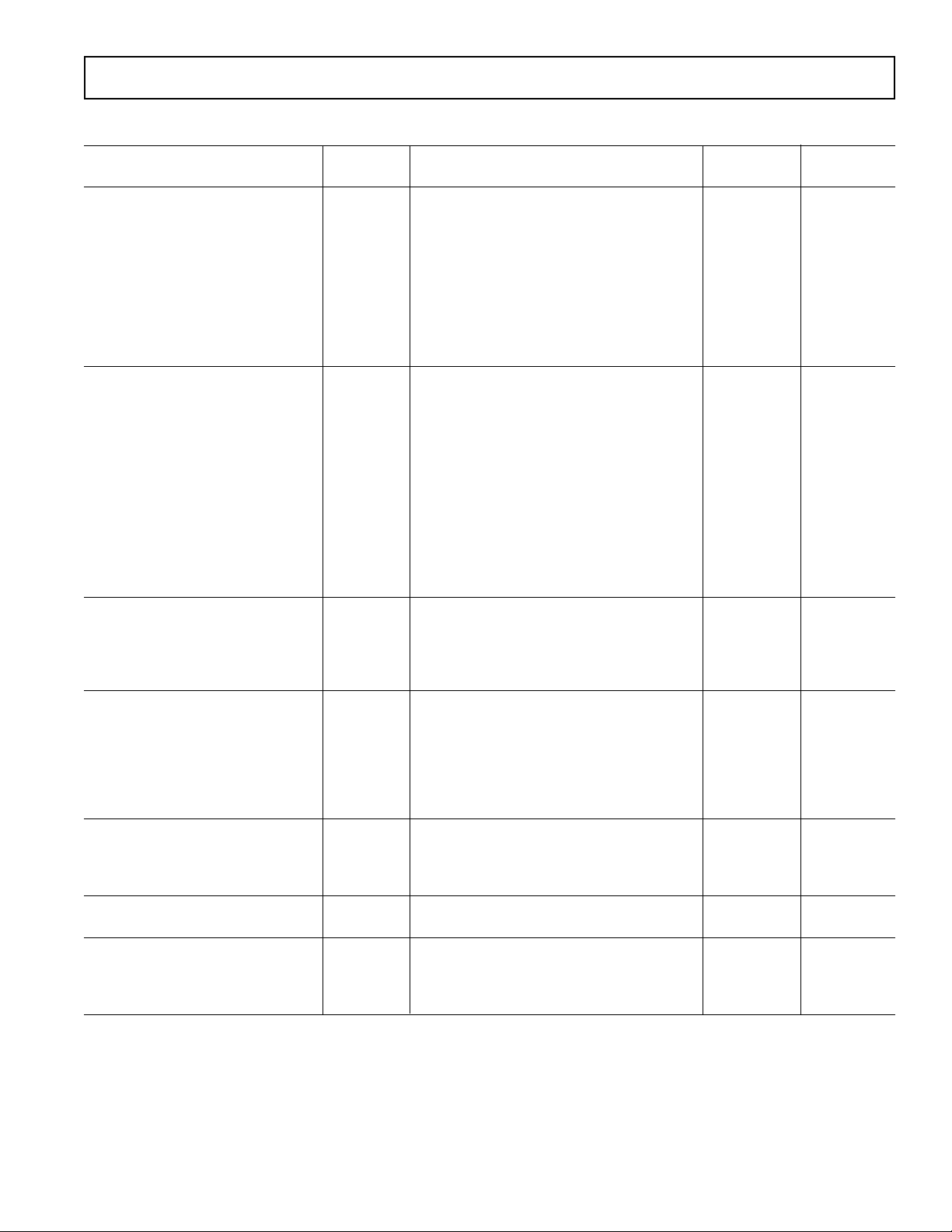

PKD01–SPECIFICATIONS

ELECTRICAL CHARACTERISTICS

Parameter Symbol Conditions Min Typ Max Min Typ Max Unit

AMPLIFIERS A, B

g

m

Zero-Scale Error V

Input Offset Voltage V

Input Bias Current I

Input Offset Current I

Voltage Gain A

Open-Loop Bandwidth BW A

Common-Mode Rejection Ratio CMRR –10 V ≤ V

Power Supply Rejection Ratio PSRR ± 9 V ≤ V

Input Voltage Range

Slew Rate SR 0.5 0.5 V/µs

Feedthrough Error

Acquisition Time to

0.1% Accuracy

Acquisition Time to t

0.01% Accuracy

1

1

1

1

COMPARATOR

Input Offset Voltage V

Input Bias Current I

Input Offset Current I

Voltage Gain A

Common-Mode Rejection Ratio CMRR –10 V ≤ V

Power Supply Rejection Ratio PSRR ± 9 V ≤ V

Input Voltage Range

1

Low Output Voltage V

“OFF” Output Leakage Current I

Output Short-Circuit Current I

Response Time

2

DIGITAL INPUTS – RST, DET

Logic “1” Input Voltage V

Logic “0” Input Voltage V

Logic “1” Input Current I

Logic “0” Input Current I

MISCELLANEOUS

Droop Rate

3

Output Voltage Swing: V

Amplifier C R

Short-Circuit Current:

Amplifier C I

Switch Aperture Time t

Switch Switching Time ts 50 50 ns

Slew Rate: Amplifier C SR R

Power Supply Current I

NOTES

1

Guaranteed by design.

2

DET = 1, RST = 0.

3

Due to limited production test times, the droop current corresponds to junction temperature (TJ). The droop current vs. time (after power-on) curve clarified this point. Since

most devices (in use) are on for more than 1 second, ADI specifies droop rate for ambient temperature (TA) also. The warmed-up (TA) droop current specification is correlated

to the junction temperature (T

are not subject to production testing.

Specifications subject to change without notice.

) value. ADI has a droop current cancellation circuit that minimizes droop current at high temperature. Ambient (T

J

ZS

OS

B

OS

V

V

CM

t

AQ

AQ

OS

B

OS

V

V

CM

OL

L

SC

t

S

2

H

L

INH

INL

V

DR

OP

SC

AP

SY

(@ VS = ⴞ15 V, CH = 1000 pF, TA = 25ⴗC, unless otherwise noted.)

PKD01A/E PKD01F

24 37mV

23 36mV

80 150 80 250 nA

20 40 20 75 nA

RL = 10 kΩ, VO = ±10 V 18 25 10 25 V/mV

= 1 0.4 0.4 MHz

V

≤ +10 V 8090 7490 dB

CM

≤ ±18 V 8696 7696 dB

S

±10 ±11 ± 10 ±11 V

∆VIN = 20 V, DET = 1, RST = 0 66 80 66 80 dB

20 V Step, A

20 V Step, A

= +1 41 70 41 70 µs

VCL

= +1 45 45 µs

VCL

0.5 1.5 1 3 mV

700 1000 700 1000 nA

75 300 75 300 nA

2kΩ Pull-Up Resistor to 5 V 5 7.5 3.5 7.5 V/mV

≤ +10 V 82 106 82 106 dB

CM

≤ ±18 V 7690 7690 dB

S

±11.5 ±12.5 ±11.5 ±12.5 V

I

≤ 5 mA, Logic GND = 0 V –0.2 +0.15 +0.4 –0.2 +0.15 +0.4 V

SINK

V

= 5 V 2580 2580µA

OUT

V

= 5 V 7 12 45 7 12 45 mA

OUT

5 mV Overdrive, 2 kΩ Pull-Up 150 150 ns

Resistor to 5 V

22V

0.8 0.8 V

VH = 3.5 V 0.02 1 0.02 1 µA

VL = 0.4 V 1.6 10 1.6 10 µA

TJ = 25°C 0.01 0.07 0.01 0.1 mV/ms

T

= 25°C 0.02 0.15 0.03 0.20 mV/ms

A

DET = 1

= 2.5 kΩ±11.5 ±12.5 ± 11 ±12 V

L

7 15 40 7 15 40 mA

75 75 ns

= 2.5 kΩ 2.5 2.5 V/µs

L

No Load 57 69mA

) temperature specifications

A

–2–

REV. A

PKD01

(@ VS = ⴞ15 V, CH = 1000 pF, –55ⴗC ≤ TA ≤ +125ⴗC for PKD01AY, –25ⴗC ≤ TA ≤ +85ⴗC for

ELECTRICAL CHARACTERISTICS

Parameter Symbol Conditions Min Typ Max Min Typ Max Unit

” AMPLIFIERS A, B

“g

m

Zero-Scale Error V

Input Offset Voltage V

Average Input Offset Drift

Input Bias Current I

Input Offset Current I

Voltage Gain A

Common-Mode Rejection Ratio CMRR –10 V ≤ V

Power Supply Rejection Ratio PSRR ± 9 V ≤ V

Input Voltage Range

Slew Rate SR 0.4 0.4 V/µs

Acquisition Time to 0.1% Accuracy1t

COMPARATOR

Input Offset Voltage V

Average Input Offset Drift

Input Bias Current I

Input Offset Current I

Voltage Gain A

Common-Mode Rejection Ratio CMRR –10 V ≤ V

Power Supply Rejection Ratio PSRR ± 9 V ≤ V

Input Voltage Range

Low Output Voltage V

OFF Output Leakage Current I

Output Short-Circuit Current I

Response Time t

DIGITAL INPUTS – RST, DET

Logic “1” Input Voltage V

Logic “0” Input Voltage V

Logic “1” Input Current I

Logic “0” Input Current I

MISCELLANEOUS

Droop Rate

3

Output Voltage Swing

Amplifier C V

Short-Circuit Current

Amplifier C I

Switch Aperture Time t

Slew Rate: Amplifier C SR R

Power Supply Current I

NOTES

1

Guaranteed by design.

2

DET = 1, RST = 0.

3

Due to limited production test times, the droop current corresponds to junction temperature (T

point. Since most devices (in use) are on for more than 1 second, ADI specifies droop rate for ambient temperature (T

specification is correlated to the junction temperature (TJ) value. ADI has a droop current cancellation circuit that minimizes droop current at high temperature.

Ambient (TA) temperature specifications are not subject to production testing.

Specifications subject to change without notice.

1

1

1

1

TCV

B

OS

V

AQ

TCV

B

OS

V

L

SC

S

2

INH

INL

V

SC

AP

SY

PKD01EY, PKD01FY and 0ⴗC ≤ TA ≤ +70ⴗC for PKD01EP, PKD01FP, unless otherwise noted.)

PKD01A/E PKD01F

ZS

OS

OS

47 612mV

36 510mV

–9 –24 –9 –24 µV/°C

160 250 160 500 nA

30 100 30 150 nA

V

CM

OS

RL = 10 kΩ, VO = ±10 V 7.5 9 5 9 V/mV

≤ +10 V 74 82 72 80 dB

CM

≤ ±18 V 80 90 70 90 dB

S

±10 ± 11 ±10 ±11 V

20 V Step, A

= +1 60 60 µs

VCL

2 2.5 2 5 mV

OS

–4 –6 –4 –6 µV/°C

1000 2000 1100 2000 nA

100 600 100 600 nA

V

CM

OL

2 kΩ Pull-Up Resistor to 5 V 4 6.5 2.5 6.5 V/mV

≤ +10 V 80 100 80 92 dB

CM

≤ ±18 V 72 82 72 86 dB

S

±11 ±11 V

I

≤ 5 mA, Logic GND = 0 V –0.2 +0.15 +0.4 –0.2 +0.15 +0.4 V

SINK

V

= 5 V 25 100 100 180 µA

OUT

V

= 5 V 6 10 45 6 10 45 mA

OUT

5 mV Overdrive, 2 kΩ Pull-Up

Resistor to 5 V 200 200 ns

H

L

22 V

0.8 0.8 V

VH = 3.5 V 0.02 1 0.02 1 µA

VL = 0.4 V 2.5 15 2.5 15 µA

DR

TJ = Max Operating Temp. 1.2 10 3 15 mV/ms

T

= Max Operating Temp.

A

DET = 1 2.4 20 6 20 mV/ms

OP

RL = 2.5 kΩ±11 ± 12 ± 10.5 ±12 V

6 12406 1240 mA

75 75 ns

= 2.5 kΩ 22V/µs

L

No Load 5.5 8 6.5 10 mA

). The droop current vs. time (after power-on) curve clarifies this

J

) also. The warmed-up (TA) droop current

A

REV. A

–3–

PKD01

WARNING!

ESD SENSITIVE DEVICE

ABSOLUTE MAXIMUM RATINGS

1, 2

Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ±18 V

Input Voltage . . . . . . . . . . . . . . . . . . . Equal to Supply Voltage

Logic and Logic Ground

Voltage . . . . . . . . . . . . . . . . . . . . . . Equal to Supply Voltage

Output Short-Circuit Duration . . . . . . . . . . . . . . . . Indefinite

Amplifier A or B Differential Input Voltage . . . . . . . . . . ±24 V

Comparator Differential Input Voltage . . . . . . . . . . . . . ±24 V

Comparator Output Voltage

. . . . . . . . . . . . . . . . . . . . . . Equal to Positive Supply Voltage

Hold Capacitor Short-Circuit Duration . . . . . . . . . . Indefinite

Lead Temperature (Soldering, 60 sec) . . . . . . . . . . . . . 300°C

Storage Temperature Range

PKD01AY, PKD01EY, PKD01FY . . . . . –65°C to +150°C

PKD01EP, PKD01FP . . . . . . . . . . . . . . . –65°C to +125°C

Operating Temperature Range

PKD01AY . . . . . . . . . . . . . . . . . . . . . . . . –55°C to +125°C

PKD01EY, PKD01FY . . . . . . . . . . . . . . . . –25°C to +85°C

PKD01EP, PKD01FP . . . . . . . . . . . . . . . . . . . 0°C to 70°C

Junction Temperature . . . . . . . . . . . . . . . . . –65°C to +150°C

NOTES

1

Absolute maximum ratings apply to both DICE and packaged parts, unless

otherwise noted.

2

Stresses above those listed under Absolute Maximum Ratings may cause permanent damage to the device. This is a stress rating only; functional operation of the

device at these or any other conditions above those listed in the operational

sections of this specification is not implied. Exposure to absolute maximum rating

conditions for extended periods may affect device reliability.

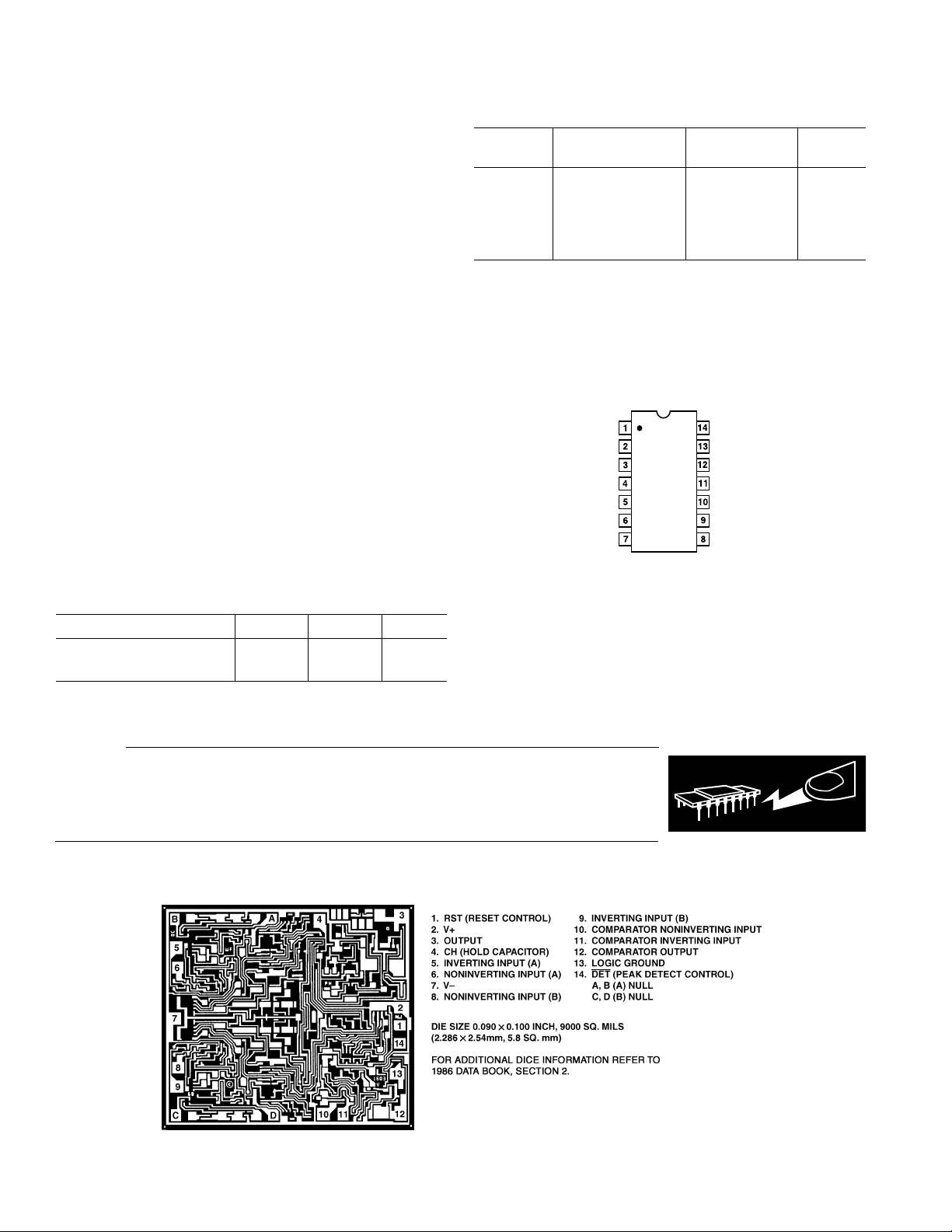

1

Model

ORDERING GUIDE

2

Temperature Package Package

Range Description Option

PKD01AY –55°C to +85°C Cerdip Q-14

PKD01EY –25°C to +85°C Cerdip Q-14

PKD01FY –25°C to +85°C Cerdip Q-14

PKD01EP 0°C to 70°C Plastic DIP N-14

PKD01FP 0°C to 70°C Plastic DIP N-14

NOTES

1

Burn-in is available on commercial and industrial temperature range parts in

cerdip, plastic DIP, and TO-can packages.

2

For devices processed in total compliance to MIL-STD-883, add /883 after

part number. Consult factory for 883 data sheet.

PIN CONFIGURATION

RST

OUTPUT

–IN A

+IN A

V+

PKD01

C

H

V–

DET

LOGIC GND

COMP OUT

–IN C

+IN C

–IN B

+IN B

THERMAL CHARACTERISTICS

Package Type JA*

JC

Unit

14-Lead Hermetic DIP (Y) 99 12 °C/W

14-Lead Plastic DIP (P) 76 33 °C/W

*θJA is specified for worst-case mounting conditions, i.e., θJA is specified for device

in socket for cerdip and PDIP packages.

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection. Although

the PKD01 features proprietary ESD protection circuitry, permanent damage may occur on devices

subjected to high-energy electrostatic discharges. Therefore, proper ESD precautions are

recommended to avoid performance degradation or loss of functionality.

DICE CHARACTERISTICS

–4–

REV. A

PKD01

WAFER TEST LIMITS

(@ VS = ⴞ15 V, CH = 1000 pF, TA = 25ⴗC, unless otherwise noted.)

PKD01N

Parameter Symbol Conditions Limit Unit

“g

” AMPLIFIERS A, B

m

Zero-Scale Error V

Input Offset Voltage V

Input Bias Current I

Input Offset Current I

Voltage Gain A

B

OS

ZS

OS

V

RL = 10 kΩ, VO = ±10 V 10 V/mV min

Common-Mode Rejection Ratio CMRR –10 V ≤ V

Power Supply Rejection Ratio PSRR ±9 V ≤ V

Input Voltage Range

1

V

CM

≤ +10 V 74 dB min

CM

≤ ±18 V 76 dB min

S

7mV max

6mV max

250 nA max

75 nA max

±11.5 V min

Feedthrough Error ∆VIN = 20 V, DET = 1, RST = 0 66 dB min

COMPARATOR

Input Offset Voltage V

Input Bias Current I

Input Offset Current I

Voltage Gain

1

OS

B

OS

A

V

2 kΩ Pull-Up Resistor to 5 V 3.5 V/mV min

Common-Mode Rejection Ratio CMRR –10 V ≤ V

Power Supply Rejection Ratio PSRR ±9 V ≤ V

Input Voltage Range

Low Output Voltage V

1

V

CM

OL

I

≤ 5 mA, Logic GND = 5 V 0.4 V max

SINK

≤ +10 V 82 dB min

CM

≤ ±18 V 76 dB min

S

3mV max

1000 nA max

300 nA max

±11.5 V min

–0.2 V min

“OFF” Output Leakage Current I

Output Short-Circuit Current I

L

SC

V

= 5 V 80 µA max

OUT

V

= 5 V 45 mA min

OUT

7 mA min

DIGITAL INPUTS–RST, DET

Logic “1” Input Voltage V

Logic “0” Input Voltage V

Logic “1” Input Current I

Logic “0” Input Current I

MISCELLANEOUS

Droop Rate

3

Output Voltage Swing Amplifier C V

Short-Circuit Current Amplifier C I

2

2V min

0.8 V max

40 mA max

V

H

L

INH

INL

DR

OP

SC

VH = 3.5 V 1 µA max

VL = 0.4 V 10 µA max

TJ = 25°C, 0.1 mV/ms max

= 25°C 0.20 mV/ms max

T

A

RL = 2.5 kΩ±11 V min

7 mA min

Power Supply Current I

AMPLIFIERS A, B

g

m

Slew Rate SR 0.5 V/µs

Acquisition Time

1

SY

t

A

t

A

No Load 9 mA max

0.1% Accuracy, 20 V Step, A

0.01% Accuracy, 20 V Step, A

= 1 41 µs

VCL

= 1 45 µs

VCL

COMPARATOR

Response Time 5 mV Overdrive, 2 kΩ Pull-Up Resistor to 5 V 150 ns

MISCELLANEOUS

Switch Aperture Time t

Switching Time t

AP

S

75 ns

50 ns

Buffer Slew Rate SR RL = 2.5 kΩ 2.5 V/µs

NOTES

1

Guaranteed by design.

2

DET = 1, RST = 0.

3

Due to limited production test times, the droop current corresponds to junction temperature (T

point. Since most devices (in use) are on for more than 1 second, ADI specifies droop rate for ambient temperature (T

specification is correlated to the junction temperature (TJ) value. ADI has a droop current cancellation circuit that minimizes droop current at high temperature.

Ambient (TA) temperature specifications are not subject to production testing.

). The droop current vs. time (after power-on) curve clarifies this

J

) also. The warmed-up (TA) droop current

A

REV. A

–5–

PKD01

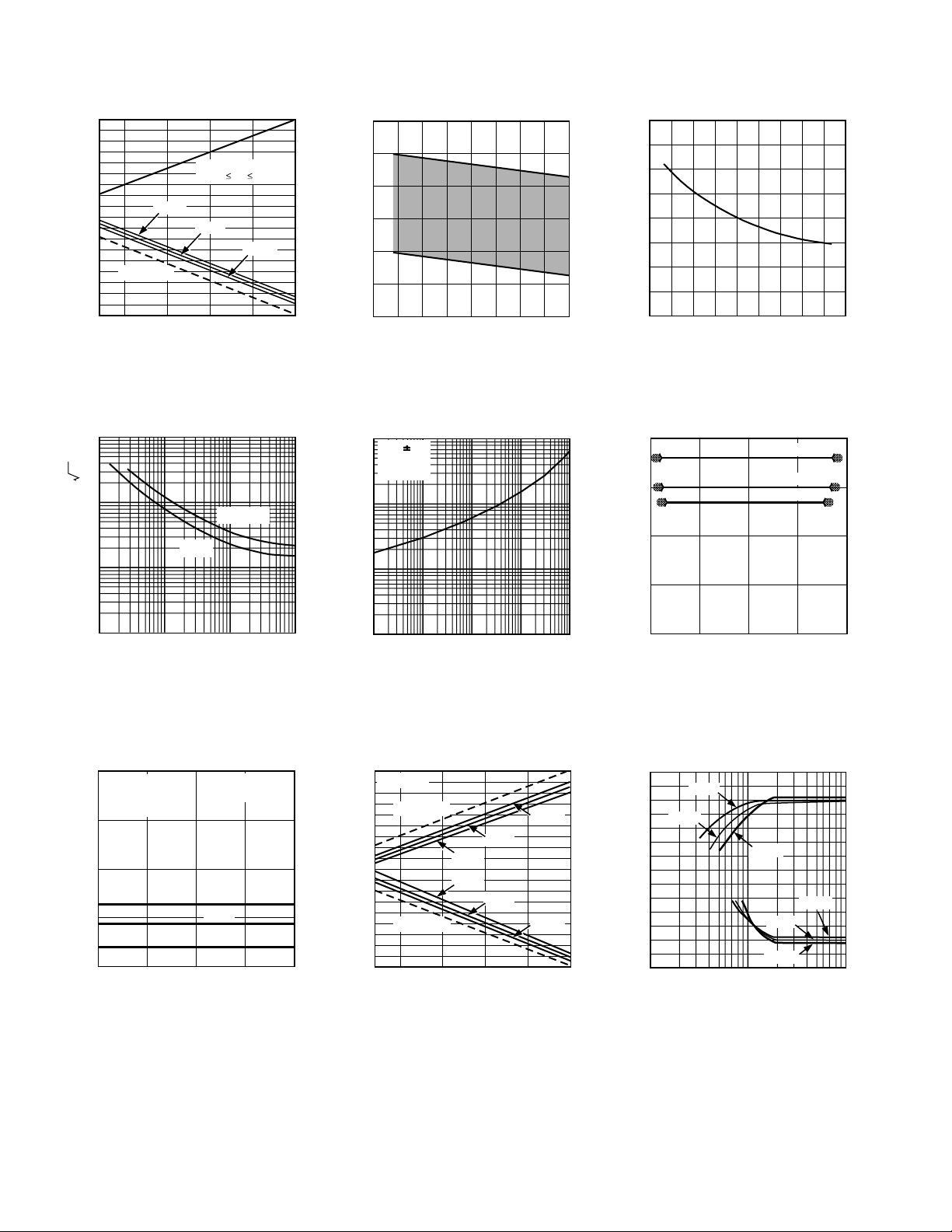

–Typical Performance Characteristics

18

14

10

6

2

–2

–6

–10

INPUT RANGE OF AMPLIFIER – V

V– SUPPLY

–14

–18

46 18

SUPPLY VOLTAGE +V AND –V –V

INPUT + RANGE = V+

–55ⴗC

TA +125ⴗC

–55ⴗC

+25ⴗC

+125ⴗC

91215

TPC 1. A and B Input Range vs.

Supply Voltage

1000

100

10

INPUT NOISE VOLTAGE – nV/ Hz

RS = 10k⍀

RS = 0

6

4

2

0

–2

OFFSET VOLTAGE – mV

–4

–6

–75 –50 125–25 0 25 50 75 100

TEMPERATURE – ⴗC

TPC 2. A and B Amplifiers Offset

Voltage vs. Temperature

100

VS = 15V

T

= 25ⴗC

A

A

= +1

V

10

1

RMS NOISE – V

40

35

30

25

– nA

20

OS

A,B I

15

10

5

0

–25 0 25 75 100 12550

–75 –50 150

TEMPERATURE – ⴗC

TPC 3. A, B IOS vs. Temperature

1.0

0.5

0

ERROR – mV

–0.5

+125ⴗC

+25ⴗC

–55ⴗC

0

110 1k100

FREQUENCY – Hz

TPC 4. Input Spot Noise vs.

Frequency

1.0

POLARITY OF

ERROR MAY BE

POSITIVE OR

NEGATIVE

0.5

0

ERROR – mV

–0.5

–1.0

–10 –50510

V

IN

+125ⴗC

– V

+25ⴗC

–55ⴗC

CH = 1000pF

T

= 25ⴗC

A

TPC 7. Amplifier A Charge Injection Error vs. Input Voltage and

Temperature

0

0.1 1 10010

BANDWIDTH – kHz

1000

TPC 5. Wideband Noise vs.

Bandwidth

18

RL = 10k⍀

14

V+ SUPPLY

10

6

2

–2

–6

OUTPUT SWING – V

–10

V– SUPPLY

–14

–18

46 18

SUPPLY VOLTAGE +V AND –V – V

–55ⴗC

–55ⴗC

91215

+125ⴗC

+25ⴗC

+25ⴗC

+125ⴗC

TPC 8. Output Voltage Swing vs.

Supply Voltage (Dual Supply

Operation)

–1.0

–10 –50 510

– V

V

IN

TPC 6. Amplifier B Charge Injection Error vs. Input Voltage and

Temperature

OUTPUT SWING – Volts

–10.0

–12.5

15

12.5

10.0

7.5

5.0

2.5

0

–2.5

–5.0

–7.5

–15

+25ⴗC

–55ⴗC

+125ⴗC

–55ⴗC

+25ⴗC

+125ⴗC

1.0 10.0

LOAD RESISTOR TO GROUND – k⍀

0.1

TPC 9. Output Voltage vs. Load

Resistance

–6–

REV. A

PKD01

10

0%

100

90

TIME – 20s/DIV

OUTPUT VOLTAGE – 5mV/DIV

TA = 25ⴗC

0V

12

10

8

2mV ERROR

6

4

PK OF SINEWAVE – V

20mV ERROR

2

0

100 1k 1M

FREQUENCY – Hz

200mV ERROR

10k 100k

TPC 10. Output Error vs.

Frequency and Input Voltage

TA = 25ⴗC

100

90

10

0%

OUTPUT VOLTAGE – 5V/DIV

CH = 1000pF

100

90

10

0%

PEAK

OUTPUT

2s10mV

TPC 11. Settling Response

TA = 25ⴗC

100

90

0V

10

0%

OUTPUT VOLTAGE – 5V/DIV

0V

10mV

CH = 1000pF

100

90

10

0%

10mV

3kHz

SINEWAVE

INPUT

TPC 12. Settling Response

2s

DETECTED

PEAK

10V

TIME – 20s/DIV

TPC 13. Large-Signal Inverting

Response

100

90

TA = 25ⴗC

TA = 25ⴗC

10

0%

OUTPUT VOLTAGE – 5mV/DIV

TIME – 20s/DIV

TPC 16. Settling Time for +10 V to

0 V Step Input

TPC 14. Large-Signal Noninverting

Response

90

60

CH = 1000pF

30

GAIN – dB

0V

0

–30

1 10 10M

TPC 17. Small-Signal Open-Loop

Gain/Phase vs. Frequency

TIME – 20s/DIV

GAIN

CH = 1000pF

PHASE

100 1k 10k 100k 1M

FREQUENCY – Hz

TA = 25ⴗC

R

= 10k⍀

L

C

= 30pF

L

C

= 1000pF

H

0

45

90

135

180

TPC 15. Settling Time for –10 V to

0 V Step Input

120

100

80

60

TEST CONDITION:

40

PHASE LAG – Degrees

CH = 1000pF

AMPLIFIER A AND B CONNECTED IN +1 GAIN

20

AMPLIFIER A(B) OFF, INPUT = 20V p-p

AMPLIFIER B(B) ON, INPUT = 0V

CHANNEL-TO-CHANNEL ISOLATION – dB

0

1 10 10M

100 1k 10k 100k 1M

FREQUENCY – Hz

TPC 18. Channel-to-Channel

Isolation vs. Frequency

TA = 25ⴗC

REV. A

–7–

PKD01

HOLD CAPACITANCE – pF

ACQUISITION TIME TO 0.1% ACCURACY – s

500

200

400

300

2000 4000 6000 8000 100000

100

80

60

40

20

0

20V STEP TO 20mV (0.1%)

10V STEP TO 10mV (0.1%)

5V STEP TO 5mV (0.1%)

1V STEP TO 1mV (0.1%)

100

A, AV = +1

B, A

= ⴞ1

80

60

40

OFF ISOLATION – dB

20

0

V

A, AV = –1

1 10 10M

100 1k 10k 100k 1M

FREQUENCY – Hz

TPC 19. Off Isolation vs. Frequency

50

TA = 25ⴗC

= 1000pF

C

H

40

30

20

SETTLING TIME – s

10

0

TO 2mV

51015200

TO 20mV

TO 200mV

INPUT STEP – V

TPC 22. Acquisition Time vs. Input

Voltage Step Size

3

TA = 125ⴗC

= 1000pF

C

H

2

1

DROOP RATE – mV/ms

0

23456789100

1

TIME AFTER POWER APPLIED – Minutes

TPC 20. Droop Rate vs. Time after

Power On

10000

1000

= 1000pF

H

100

10

DROOP RATE (mV/sec), C

1

–100 –50 500

TEMPERATURE – ⴗC

AMBIENT

TEMPERATURE

JUNCTION

TEMPERATURE

100 500

TPC 23. Droop Rate vs. Temperature

TPC 21. Acquisition Time vs.

External Hold Capacitor and

Acquisition Step

5V

RESET

100

90

10

0%

10V

INPUT

10V

PEAK

DETECT

50s

RESET

PEAK

OUTPUT

TPC 24. Acquisition of Step Input

+10V

0V

–10V

+10V

0V

–10V

1V 5mV

1V 5mV

COMPARATOR OUTPUT

COMPARATOR OUTPUT

100

90

5

4

3

2

10

1

OUTPUT VOLTAGE – V

0%

0

TIME – 50ns/DIV

TPC 26. Comparator Output

Response Time (2 k

Resistor, T

= 25°C)

A

–8–

CH = 1000pF

100

90

10

0%

5V

5V

3kHz

SINEWAVE

INPUT

DETECTED

PEAK

RESET

50s

+10V

0V

–10V

TPC 25. Acquisition of Sine

Wave Peak

50ns

50ns

Ω

Pull-Up

1V 5mV

1V 5mV

COMPARATOR OUTPUT

100

90

5

+5

–5

4

0

3

2

10

1

INPUT VOLTAGE – mV

OUTPUT VOLTAGE – V

0%

0

COMPARATOR OUTPUT

TIME – 50ns/DIV

TPC 27. Comparator Output

Response Time (2 k

Resistor, T

= 25°C)

A

50ns

50ns

Ω

Pull-Up

+5

0

–5

INPUT VOLTAGE – mV

REV. A

PKD01

18

14

10

6

2

–2

–6

INPUT LOGIC RANGE – V

–10

–14

–18

–55ⴗC

V–

46

SUPPLY VOLTAGE +V AND –V – V

+VIN V+ FOR

TA +125ⴗC

–55ⴗC

+25ⴗC

+125ⴗC

9121518

TPC 28. Input Logic Range vs.

Supply Voltage

6

+25ⴗC

+125ⴗC

96

SUPPLY CURRENT – mA

–55ⴗC

5

4

31215180

SUPPLY +V AND –V – V

TPC 31. Supply Current vs. Supply

Voltage

18

14

10

6

2

0

–55ⴗC

–2

–6

–10

–14

INPUT RANGE OF LOGIC GROUND – V

–18

46 9 12 1815

SUPPLY VOLTAGE +V AND –V – V

V+

+125ⴗC

+25ⴗC

ACCEPTABLE GROUND PIN

POTENTIAL IS BETWEEN

SLIDE LINES.

+25ⴗC

+125ⴗC

V–

TPC 29. Input Range of Logic

Ground vs. Supply Voltage

100

REJECTION RATIO – dB

80

60

40

20

0

POSITIVE SUPPLY

(+15V +1V SIN T)

NEGATIVE SUPPLY

(–15V +1V SIN )

CHANNEL A = 1

CHANNEL B = 0

10 100 1M

1k 10k 100k

FREQUENCY – Hz

TA = 25ⴗC

= 0V

V

IN

= 1000pF

C

H

TPC 32. Hold Mode Power Supply

Rejection vs. Frequency

1

LOGIC 1

0

–1

LOGIC CURRENT – A

–2

–3

+125ⴗC

LOGIC 0

–2 –15

01234

LOGIC INPUT VOLTAGE – V

–55ⴗC

+25ⴗC

LOGIC GROUND = 0V

TPC 30. Logic Input Current vs.

Logic Input Voltage

3

VS = ⴞ15V

= 25ⴗC

T

A

2

1

0

–1

INPUT BIAS CURRENT (EITHER INPUT) – A

–15 –10 15

INPUT CURRENT

MUST BE LIMITED

TO LESS THAN 1mA

OTHER

INPUT

AT –10V

–50 510

INPUT VOLTAGE – V

OTHER

INPUT

AT 0V

OTHER

INPUT

AT +10V

TPC 33. Comparator Input Bias

Current vs. Differential Input Voltage

3

2

1

0

–1

OFFSET VOLTAGE – mV

–2

–3

–75 –50 125–25 0 25 50 75 100

TEMPERATURE – ⴗC

TPC 34. Comparator Offset Voltage

vs. Temperature

REV. A

110

100

90

– nA

OS

80

70

COMPARATOR I

60

50

–25 0 25 75 100 12550

–75 –50 150

TEMPERATURE – ⴗC

TPC 35. Comparator IOS vs.

Temperature

–9–

1200

1000

– nA

B

800

600

COMPARATOR I

400

200

–25 0 25 75 100 12550

–75 –50 150

TEMPERATURE – ⴗC

TPC 36. Comparator IB vs.

Temperature

PKD01

18

14

10

6

2

–55ⴗC

–2

–6

–10

–14

OUTPUT RANGE OF COMPARATOR – V

–18

46 9121518

SUPPLY VOLTAGE +V AND –V – V

V+

+125ⴗC

+25ⴗC

+25ⴗC

+125ⴗC

V–

TPC 37. Output Swing of Com parator vs. Supply Voltage

1.0

0.8

DC

0.6

0.4

0.2

0

– VOLTAGE OUTPUT – V

O

V

–0.2

014

IO – OUTPUT SINK CURRENT – mA

+125ⴗC

+25ⴗC

–55ⴗC

42 6 10 128

5

PULL-UP

RESISTOR = 2k⍀

4

3

2

TA = –55ⴗC

OUTPUT VOLTAGE – V

1

0

+5

0

–5

INPUT VOLTAGE – mV

–50 300

TPC 38. Comparator Response

Time vs. Temperature

5

4

3

TA = –55ⴗC

2

OUTPUT VOLTAGE – V

1

0

+5

0

–5

INPUT VOLTAGE – mV

–50 300

TA = +25ⴗC

500 100 200 250150

TA = +25ⴗC

500 100 200 250150

TIME – ns

TIME – ns

TA = +125ⴗC

PULL-UP

RESISTOR = 2k⍀

TA = +125ⴗC

6

INVERTING INPUT = V

NONINVERTING INPUT = 0V

5

4

3

RL = 2k⍀

TO 5V

2

OUTPUT VOLTAGE – V

1

0

–1.5 2.0

–0.5–1.0 0 1.0 1.50.5

INPUT VOLTAGE – mV

IN

R

= 1k⍀

L

TO 5V

VS = ⴞ15V

= 25ⴗC

T

A

TPC 39. Comparator Transfer

Characteristic

TPC 40. Comparator Output

Voltage vs. Output Current and

Temperature

TPC 41. Comparator Response

Time vs. Temperature

–10–

REV. A

PKD01

THEORY OF OPERATION

The typical peak detector uses voltage amplifiers and a diode or

an emitter follower to charge the hold capacitor, C

ionally (see Figure 1). The output impedance of A plus D

dynamic impedance, r

, make up the resistance which deter-

d

, indirect-

H

’s

1

mines the feedback loop pole. The dynamic impedance is

kT

r

=

d

The pole moves toward the origin of the S plane as I

, where Id is the capacitor charging current.

qI

d

goes to

d

zero. The pole movement in itself will not significantly lengthen

the acquisition time since the pole is enclosed in the system

feedback loop.

V

(A) = VIN (A) ⴛ AV (A)

OUT

A

V

V

IN

INPUT

OUT

R

OUT

+

D

1

V

r

d

C

H

C

H

OUTPUT

Figure 1. Conventional Voltage Amplifier Peak Detector

When the moving pole is considered with the typical frequency

compensation of voltage amplifiers however, there is a loop stability

problem. The necessary compensation can increase the required

acquisition time. ADI’s approach replaces the input voltage amplifier with a transconductance amplifier (see Figure 2).

The PKD01 transfer function can be reduced to:

V

OUT

=

V

IN

++

1

where: gm ⬇ 1 µA/mV, R

1

sC

H

ggR

mm

⬇ 20 MΩ.

OUT

1

OUT

1

≈

sC

H

+

1

g

m

The diode in series with A’s output (see Figure 2) has no effect

because it is a resistance in series with a current source. In

addition to simplifying the system compensation, the input

transconductance amplifier output current is switched by current steering. The steered output is clamped to reduce and match

any charge injection.

I

(A) = VIN (A) ⴛ gm (A)

OUT

A

I

V

IN

INPUT

OUT

R

OUT

D

1

V

H

C

C

H

OUTPUT

V

OUT

Figure 2. Transconductance Amplifier Peak Detector

Figure 3 shows a simplified schematic of the reset gm amplifier,

B. In the track mode, Q

OFF. A current of 2I passes through D

passes through Q

1

can absorb only 3I, thus the current passing through D

and Q4 are ON and Q2 and Q3 are

1

, I is summed at B and

1

, and is summed with gmVIN. The current sink

can

2

only be: 2K – g

node then, is g

Q

and Q3 are ON while Q1 and Q4 are OFF. The net current

2

into the top of D

bottom of D

thus, D

is pulled up with a current I until D4 turns ON,

2

and D2 are reverse biased by <0.6 V, and charge injec-

1

. The net current into the hold capacitor

m VIN

mVIN [IH

= 2I – (2I – gmVIN)]. In the hold mode,

is –I until D3 turns ON. With Q1 OFF, the

1

tion is independent of input level.

The monolithic layout results in points A and B having equal

nodal capacitance. In addition, matched diodes D

and D2 have

1

equal diffusion capacitance. When the transconductance amplifier outputs are switched open, points A and B are ramped

equally, but in opposite phase. Diode clamps D

and D4 cause

3

the swings to have equal amplitudes. The net charge injection

(voltage change) at node C is therefore zero.

V+

I

2I

A

D

1

C

D

2

B

Q

Q

2

1

gm V

V

IN

IN

3I

D

3

C

D

4

C

H

6

Q

Q

4

3

3I

A

B

A > B = PEAK DETECT

V–

A < B = PEAK HOLD

LOGIC

CONTROL

Figure 3. Transconductance Amplifier with Low Glitch

Current Switch

The peak transconductance amplifier, A is shown in Figure 4.

Unidirectional hold capacitor charging requires diode D

to be

1

connected in series with the output. Upon entering the peak

hold mode D

is reverse-biased. The voltage clamp limits charge

1

injection to approximately 1 pC and the hold step to 0.6 mV.

Minimizing acquisition time dictates a small C

capacitance. A

H

1000 pF value was selected. Droop rate was also minimized by

providing the output buffer with an FET input stage. A current cancellation circuit further reduces droop current and

minimizes the gate current’s tendency to double for every 10°

temperature change.

V+

I

2I

D

2

Q

Q

2

1

gm V

V

IN

IN

3I

D

3

D

1

r

D

d

4

6

Q

Q

3

3I

C

C

H

4

A > B = PEAK DETECT

V–

A < B = PEAK HOLD

A

B

LOGIC

CONTROL

Figure 4. Peak Detecting Transconductance Amplifier

with Switched Output

REV. A

–11–

PKD01

APPLICATIONS INFORMATION

Optional Offset Voltage Adjustment

Offset voltage is the primary zero scale error component since a

variable voltage clamp limits voltage excursions at D

’s anode

1

and reduces charge injection. The PKD01 circuit gain and operational mode (positive or negative peak detection) determine the

applicable null circuit. Figures 5 through 8 are suggested circuits.

Each circuit also corrects amplifier C offset voltage error.

100k⍀

+

V

S

0.1F

VIN+

NOTES:

1. NULL RANGE = ⴞV

2. DISCONNECT RC FROM CH AFTER AMPLIFIER A ADJUSTMENT.

3. REPEAT NULL CIRCUIT FOR RESET BUFFER AMPLIFIER B IF REQUIRED.

R

A

VS–

R2

2M⍀

DET

R1

1k⍀

, RB AND RC NOT NECESSARY FOR AMPLIFIER B ADJUSTMENT.

A

B

RST

R1

(

)

S

R2

R1

1k⍀

D

1

C

R

2M⍀

–15V

C

C

H

1000pF

PKD01

V

OUT

R

A

200k⍀

R

B

1k⍀

Figure 5. VOS Null Circuit for Unity Gain Positive Peak

Detector

R2 = R3 + R4

DET

IN

VS–

V

R1

R1

+

R3

R5

20k⍀

R4

0.1F

+

S

20⍀

R5

(

S

R4

)( )

R1 + R3

VIN–

V

25k⍀

NOTES:

1. NULL RANGE = ⴞV

2. DISCONNECT RC FROM CH AFTER AMPLIFIER A ADJUSTMENT.

3. REPEAT NULL CIRCUIT FOR RESET BUFFER AMPLIFIER B IF REQUIRED.

A

B

RST

R1

D

1

R

2M⍀

V

OUT

–15V

R

A

C

200k⍀

R

B

1k⍀

C

H

1000pF

C

PKD01

Figure 6. VOS Null Circuit for Differential Peak Detector

A. Nulling Gated Output g

Amplifier A. Diode D1 must

m

be conducting to close the feedback circuit during amplifier A

adjustment. Resistor network RA – RC cause D1 to conduct

V

OS

slightly. With DET = 0 and V

output. Adjust the null potentiometer until V

adjustment, disconnect R

B. Nulling Gated g

input to V

= 0 V and monitor the PKD01 output. Set DET =

IN

Amplifier B. Set Amplifier B signal

m

1, RST = 1 and adjust the null potentiometer for V

= 0 V, monitor the PKD01

IN

from CH.

C

OUT

= 0 V. After

= 0 V.

OUT

The circuit gain—inverting or noninverting—will determine which

null circuit illustrated in Figures 5 through 8 is applicable.

V

IN

VS–

25k⍀

V

NOTES:

1. NULL RANGE = ⴞV

2. DISCONNECT RC FROM CH AFTER AMPLIFIER A ADJUSTMENT.

3. REPEAT NULL CIRCUIT FOR RESET BUFFER AMPLIFIER B IF REQUIRED.

R1

DET

R3

20k⍀

R4

0.1F

+

S

20⍀

S

A

B

RST

R4

(

)

R3

R2

D

1

R

2M⍀

V

OUT

–15V

R

A

C

200k⍀

R

B

1k⍀

C

H

1000pF

C

PKD01

Figure 7. VOS Null Circuit for Negative Peak Detector

VS–

25k⍀

V

V

IN

NOTES:

1. NULL RANGE = ⴞV

2. DISCONNECT RC FROM CH AFTER AMPLIFIER A ADJUSTMENT.

3. REPEAT NULL CIRCUIT FOR RESET BUFFER AMPLIFIER B IF REQUIRED.

R5

R1

20k⍀

R3

0.1F

R4 =

20⍀

R4

R2 R1

R1 + R2

S

+

S

DET

A

B

RST

R3

(

)

R5

R2

D

1

C

H

1000pF

GAIN = 1 +

C

PKD01

R

2M⍀

C

R1 + R3

–15V

R2

V

OUT

R

A

200k⍀

R

B

1k⍀

Figure 8. VOS Null Circuit for Positive Peak Detector with

Gain

–12–

REV. A

PKD01

PEAK HOLD CAPACITOR RECOMMENDATIONS

The hold capacitor (CH) serves as the peak memory element

and compensating capacitor. Stable operation requires a minimum value of 1000 pF. Larger capacitors may be used to lower

droop rate errors, but acquisition time will increase.

Zero scale error is internally trimmed for C

C

values will cause a zero scale shift which can be approxi-

H

= 1000 pF. Other

H

mated with the following equation.

pC

×

110

∆VmV

()

ZS

=

()

CnF

()

H

mV

−

063.

The peak hold capacitor should have very high insulation resistance and low dielectric absorption. For temperatures below

85°C, a polystyrene capacitor is recommended, while a Teflon

capacitor is recommended for high temperature environments.

CAPACITOR GUARDING AND GROUND LAYOUT

Ground planes are recommended to minimize ground path

resistance. Separate analog and digital grounds should be used.

The two ground systems are tied together only at the common

system ground. This avoids digital currents returning to the

system ground through the analog ground path.

PKD01

1

2

3

4

5

6

7

C

H

REPEAT ON

“COMPONENT SIDE”

OF PC BOARD IF POSSIBLE

14

13

12

11

10

9

8

BOTTOM VIEW

Figure 9. CH Terminal (Pin 4) Guarding. See Text.

The CH terminal (Pin 4) is a high impedance point. To minimize

gain errors and maintain the PKD01’s inherently low droop rate,

guarding Pin 4 as shown in Figure 9 is recommended.

COMPARATOR

The comparator output high level (VOH) is set by external resistors. It is possible to optimize noise immunity while interfacing

to all standard logic families—TTL, DTL, and CMOS. Figure

10 shows the comparator output with external level-setting

resistors. Table I gives typical R1 and R2 values for common

circuit conditions.

The maximum comparator high output voltage (V

) should be

OH

limited to:

V

(maximum) < V+ –2.0 V

OH

With the comparator in the low state (V

will be required to sink a current approximately equal to V

), the output stage

OL

C

/R1.

COMPARATOR

INPUT

CMP

INVERTING

COMPARATOR

INPUT

PKD01

DIGITAL

GND

V–

V

R1 = R2

C

R1

R2

V

(

V

V

OH

C

–1

)

OH

Figure 10. Comparator Output with External Level-Setting

Resistors

Table I.

V

VCV

OH

R1 R2

R

1 ≈

I

C

SINK

5 3.5 2.7 kΩ 6.2 kΩ

5 5.0 2.7 kΩ ⬁

15 3.5 4.7 kΩ 1.5 kΩ

15 5.0 4.7 kΩ 2.4 kΩ

15 7.5 7.5 kΩ 7.5 kΩ

15 10.0 7.5 kΩ 15 kΩ

R

2

V

1

V

C

1≈−

OH

PEAK DETECTOR LOGIC CONTROL (RST, DET)

The transconductance amplifier outputs are controlled by the

digital logic signals RST and DET. The PKD01 operational

mode is selected by steering the current (I

) through Q1 and Q2,

1

thus providing high-speed switching and a predictable logic

threshold. The logic threshold voltage is 1.4 V when digital

ground is at zero volts.

Other threshold voltages (V

) may be selected by applying

TH

the formula:

V

≈ 1.4 V + Digital Ground Potential.

TH

For proper operation, digital ground must always be at least

3.5 V below the positive supply and 2.5 V above the negative

supply. The RST or DET signal must always be at least 2.8 V

above the negative supply.

Operating the digital ground at other than zero volts does influence

the comparator output low voltage. The V

level is referenced

OL

to digital ground and will follow any changes in digital ground

potential:

V

≈ 0.2 V + Digital Ground Potential.

OL

REV. A

–13–

PKD01

DET OR RST

I

1

Q

Q

CURRENT TO

CONTROL MODES

2

1

I

2

D

Q

3

V–

Figure 11. Logic Control

Typical Circuit Configurations

INPUT

OUTPUT

V+

DIGITAL

GROUND

+10V

0V

+10V

0V

DET/RST

INPUT

RESET

VO LTAG E

+18V

56k⍀

5%

1

2

3

PKD01

4

5

6

7

36k⍀

5%

–18V

18k⍀

5%

Figure 12. Burn-In Circuit

V+ V–

D

1

A

PKD01

B

C

A GAIN = +1

B GAIN = +1

14

13

12

11

10

9

8

OUTPUT

INPUT

OUTPUT

TIME – 50s/DIV

TIME – 50s/DIV

Figure 13. Unity Gain Positive Peak Detector

DET

10k⍀

+5V

0V

–2V

+10V

0V

–4V

–10V

INPUT

(GAIN = +2)

VOLTAGE = +1V

(RESETS TO –4V)

40.2k⍀

RESET

5.1k⍀

5%

1%

10k⍀

1%

10k⍀

8.2k⍀

RST

1%

5%

5%

Figure 14. Positive Peak Detector with Gain

A

PKD01

B

C

H

1000pF

V+ V–

D

1

C

A GAIN = +2

B GAIN = –4

C

H

1000pF

OUTPUT

–14–

REV. A

PKD01

INPUT

OUTPUT

INPUT

OUTPUT

TIME – 50s/DIV

DET/RST

20k⍀

10k⍀

1%

30.1k⍀

RESET

1%

1%

10k⍀

1%

8.2k⍀

5%

7.5k⍀

5%

RST

+2V

0V

–5V

+10V

0V

–4V

–10V

INPUT

(GAIN = –2)

VOLTAGE = –1V

(RESETS TO –4V)

Figure 15. Negative Peak Detector with Gain

DET

10k⍀

1%

10k⍀

5%

0V

–10V

+10V

0V

V

IN

10k⍀

1%

RESET

VO LTAG E

A

PKD01

B

A

PKD01

B

V+ V–

D

1

V+ V–

D

1

C

A GAIN = –2

B GAIN = +4

C

H

1000pF

C

A GAIN = –1

B GAIN = +1

OUTPUT

OUTPUT

INPUT

RESET

VO LTAG E

R3

R4

R1

TIME – 50s/DIV

A

B

Figure 16. Unity Gain Negative Peak Detector

R2

OUTPUT

INPUT AMPLIFIER GAIN

RESET AMPLIFIER GAIN

R3 = R4 =

1

1R11

+

R2

= 1 +

R1

R2

PKD01

C

H

1000pF

C

Figure 17. Alternate Gain Configuration

C

H

1000pF

IF BOTH INPUT SIGNAL (AMPLIFIER A INPUT) AND THE RESET

VOLTAGE (AMPLIFIER B INPUT) HAVE THE SAME POSITIVE

VOLTAGE GAIN, THE GAIN CAN BE SET BY A SINGLE VOLTAGE

DIVIDER FOR BOTH INPUT AMPLIFIERS.

NOTE:

R1, R2, R3 AND R4 > 5k

⍀

REV. A

–15–

PKD01

V

PEAK DETECTOR

INPUT

IN

POS/NEG

R

VPK+

PKD01

POSITIVE

PEAK

DETECTOR

V

IN

PKD01

–

V

PK

NEGATIVE

PEAK

DETECTOR

VPK+

VPK–

10k⍀

10k⍀

10k⍀

OP27

VPK– + VPK+

10k⍀

V

OUT

Figure 18. Peak-to-Peak Detector

+15V

10.5k⍀

S2

SW-02

S1

S3

S4

R

+15V –15V

PKD01

1000pF

C

H

POLYSTYRENE

OUTPUT

PEAK DETECTOR

RESET

Figure 19. Logic Selectable Positive or Negative Peak Detector

PORT 0

PROCESSOR

PORT 1

0

1

2

3

4

5

6

7

0

1

2

3

4

5

6

7

BIT 1

BIT 10

–15V

DAC10

NOTES:

1. DEVICE IS RESET TO 0 VOLTS.

2. DETECTED PEAKS ARE PRESENTED AS POSITIVE OUTPUT LEVELS.

3. R = 10k⍀.

5V

2.7k⍀

RESET

VO LTAG E

INPUT

SIGNAL

DET

RST

CMP

D

1

A

B

C

PKD01

C

H

R

R

Figure 20. Peak Reading A/D Converter

–16–

REV. A

V

V

RS

V

RS

V

RS

VRS4

A1

A2

A3

A4

PK DET/RST

IN

1

2

3

–15V +15V

SW-201

5V

A

B

ANALOG

–15V+15V

GND

C

PKD01

LOGIC

GND

V

OUT

INPUT

PEAK

DETECT

OUTPUT

NOTES:

RESET VOLTAGE = –1.0V

TRACE 1 = 2V/DIV

TRACE 2 = 5V/DIV

TRACE 3 = 2V/DIV

Figure 21. Positive Peak Detector with Selectable Reset Voltage

PKD01

RESET

1ms2V

AMPLITUDE

SELECTION

LOGIC

RAMP

AMPLITUDE

DET

D

A0 A1 A2

CH1

CH2

CH3

CH4

MUX-08

CH5

CH6

CH7

CH8

RAMP

AMPLITUDE

RAMP

START

PULSE

0

RAMP START

PULSE

SLOPE =

~0.5V/s

NOTES:

1. NEGATIVE SLOPE OF RAMP IS SET BY DAC08 OUTPUT CURRENT.

2. DAC08 IS A DIGITALLY CONTROLLED CURRENT GENERATOR.

THE MAXIMUM FULL-SCALE CURRENT MUST BE LESS THAN 0.5mA.

1

A

B

RST

I

0

C

~0.5V/s

C

PKD01

I

C

H

I

SLOPE =

1

C

Figure 22. Programmable Low Frequency Ramp Generator

BUFFERED

RAMP

OUTPUT

RAMP SLOPE

SELECTION

B1 B8

DAC08

R > 20k⍀

15V

REF-01

REV. A

–17–

PKD01

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).

14-Lead Plastic DIP (PDIP)

0.795 (20.19)

0.725 (18.42)

14

17

PIN 1

0.210 (5.33)

MAX

0.160 (4.06)

0.115 (2.93)

0.005 (0.13) MIN 0.098 (2.49) MAX

0.200 (5.08)

0.200 (5.08)

0.125 (3.18)

0.100 (2.54)

0.022 (0.558)

0.014 (0.356)

14

PIN 1

17

0.100 (2.54) BSC

0.785 (19.94) MAX

MAX

0.023 (0.58)

0.014 (0.36)

(N-14)

8

0.280 (7.11)

0.240 (6.10)

0.070 (1.77)

0.045 (1.15)

0.060 (1.52)

0.015 (0.38)

SEATING

PLANE

BSC

14-Lead Cerdip

(Q-14)

8

0.310 (7.87)

0.220 (5.59)

0.060 (1.52)

0.015 (0.38)

0.070 (1.78)

0.030 (0.76)

SEATING

PLANE

0.130

(3.30)

MIN

0.150

(3.81)

MIN

0.325 (8.25)

0.300 (7.62)

0.015 (0.381)

0.008 (0.204)

0.320 (8.13)

0.290 (7.37)

15°

0°

0.195 (4.95)

0.115 (2.93)

0.015 (0.38)

0.008 (0.20)

C00481-0-2/01 (rev. A)

–18–

PRINTED IN U.S.A.

REV. A

Loading...

Loading...