Page 1

LTC3780

High Effi ciency, Synchronoous,

4-Switch Buck-Boost Controller

FEATURES

n

Single Inductor Architecture Allows VIN Above,

Below or Equal to V

n

Wide VIN Range: 4V to 36V Operation

n

Synchronous Rectifi cation: Up to 98% Effi ciency

n

Current Mode Control

n

±1% Output Voltage Accuracy: 0.8V < V

n

Phase-Lockable Fixed Frequency: 200kHz to 400kHz

n

Power Good Output Voltage Monitor

n

Internal LDO for MOSFET Supply

n

Quad N-Channel MOSFET Synchronous Drive

n

V

Disconnected from VIN During Shutdown

OUT

n

Adjustable Soft-Start Current Ramping

n

Foldback Output Current Limiting

n

Selectable Low Current Modes

n

Output Overvoltage Protection

n

Available in 24-Lead SSOP and Exposed Pad

OUT

OUT

< 30V

(5mm × 5mm) 32-Lead QFN Packages

APPLICATIONS

n

Automotive Systems

n

Telecom Systems

n

DC Power Distribution Systems

n

High Power Battery-Operated Devices

n

Industrial Control

DESCRIPTION

The LTC®3780 is a high performance buck-boost switching regulator controller that operates from input voltages

above, below or equal to the output voltage. The constant

frequency current mode architecture allows a phase-lockable frequency of up to 400kHz. With a wide 4V to 30V

(36V maximum) input and output range and seamless

transfers between operating modes, the LTC3780 is ideal

for automotive, telecom and battery-powered systems.

The operating mode of the controller is determined through

the FCB pin. For boost operation, the FCB mode pin can

select among Burst Mode

and forced continuous mode. During buck operation, the

FCB mode pin can select among skip-cycle mode, discontinuous mode and forced continuous mode. Burst Mode

operation and skip-cycle mode provide high effi ciency

operation at light loads while forced continuous mode and

discontinuous mode operate at a constant frequency.

Fault protection is provided by an output overvoltage

comparator and internal foldback current limiting. A power

good output pin indicates when the output is within 7.5%

of its designed set point.

, LT, LTC, LTM and Burst Mode are registered trademarks of Linear Technology

Corporation. All other trademarks are the property of their respective owners.

Protected by U.S. Patents including 5481178, 6304066, 5929620, 5408150, 6580258,

patent pending on current mode architecture and protection

®

operation, discontinuous mode

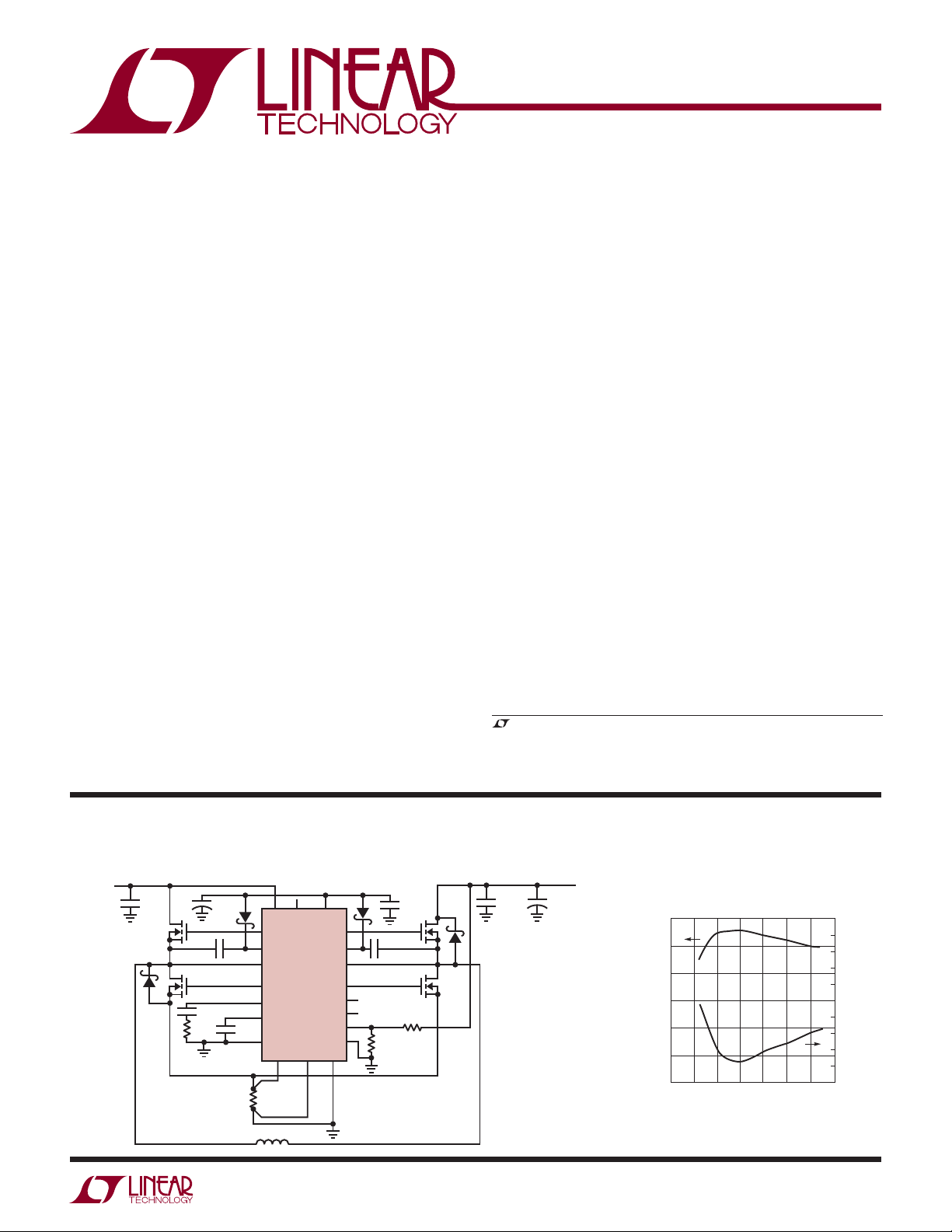

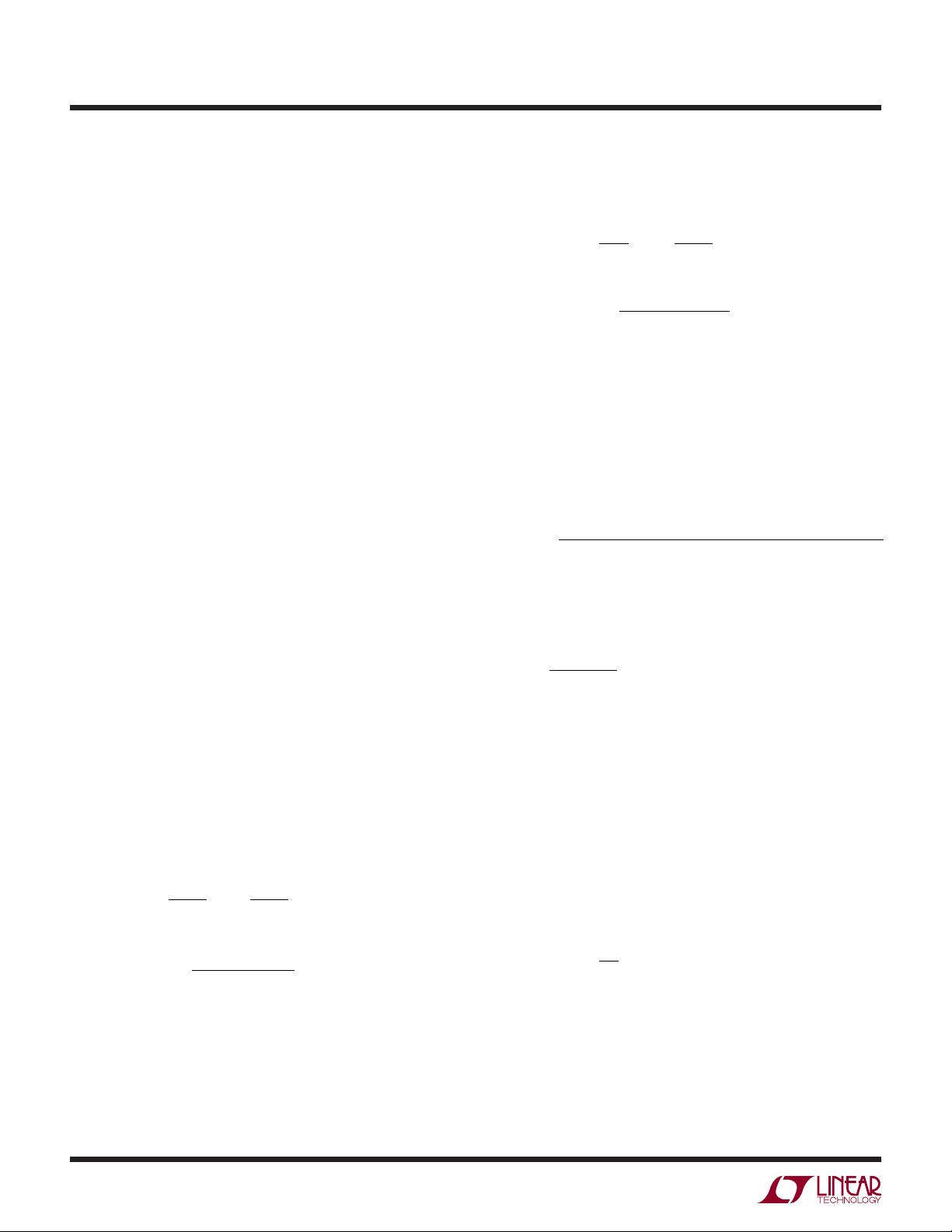

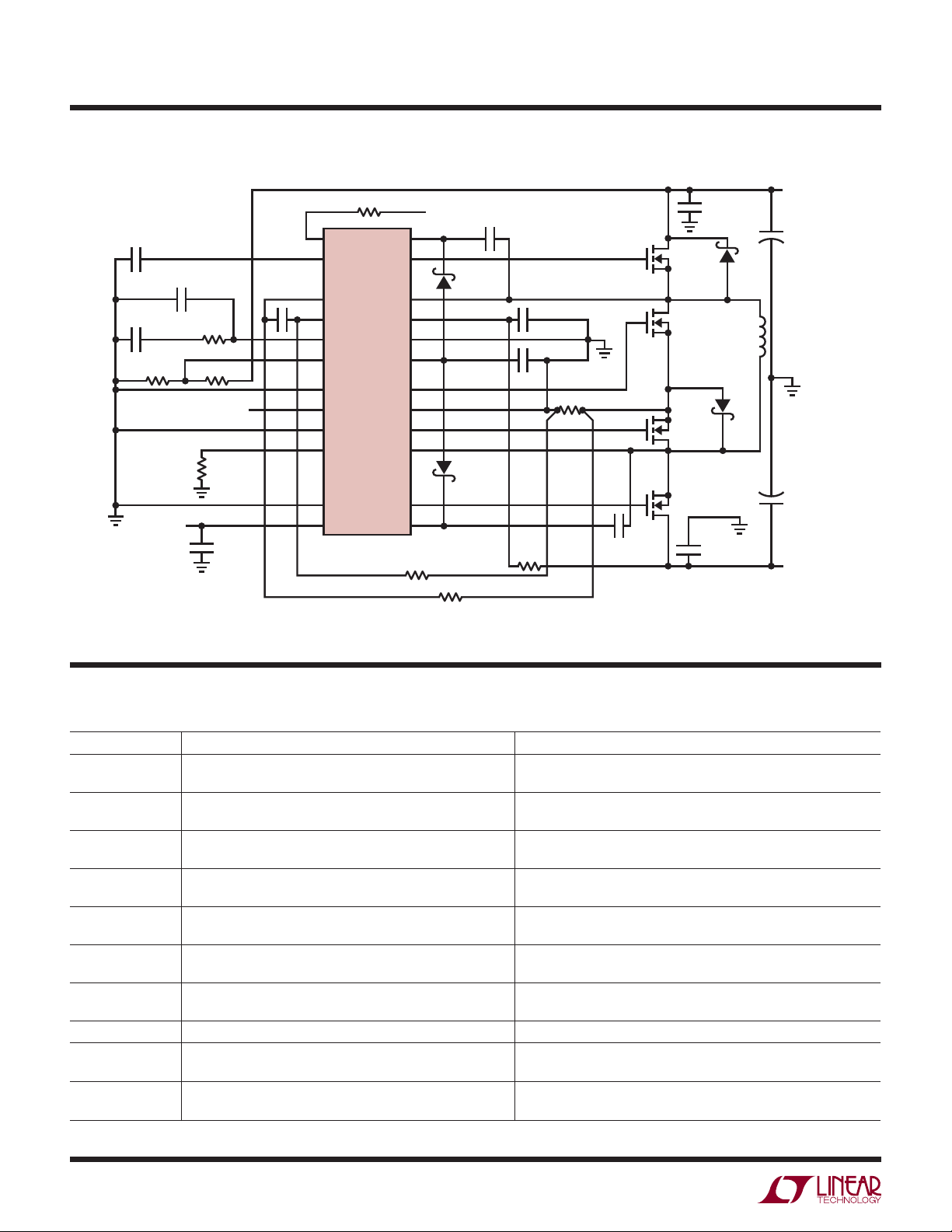

TYPICAL APPLICATION

High Effi ciency Buck-Boost Converter

V

IN

5V TO 32V

22μF

50V

CER

+

4.7μF

A

0.1μF 0.1μF

B

2200pF

20k

V

IN

TG2

BOOST2

SW2

BG2

I

TH

SS

0.1μF

SGND FCB

SENSE+SENSE–PGND

0.010Ω

4.7μH

PGOOD

LTC3780

INTV

BOOST1

SW1

PLLIN

RUN

V

OSENSE

CC

TG1

BG1

ON/OFF

7.5k

1%

1μF

CER

105k

1%

V

OUT

100μF

+

16V

D

C

CER

3780 TA01

330μF

16V

12V

5A

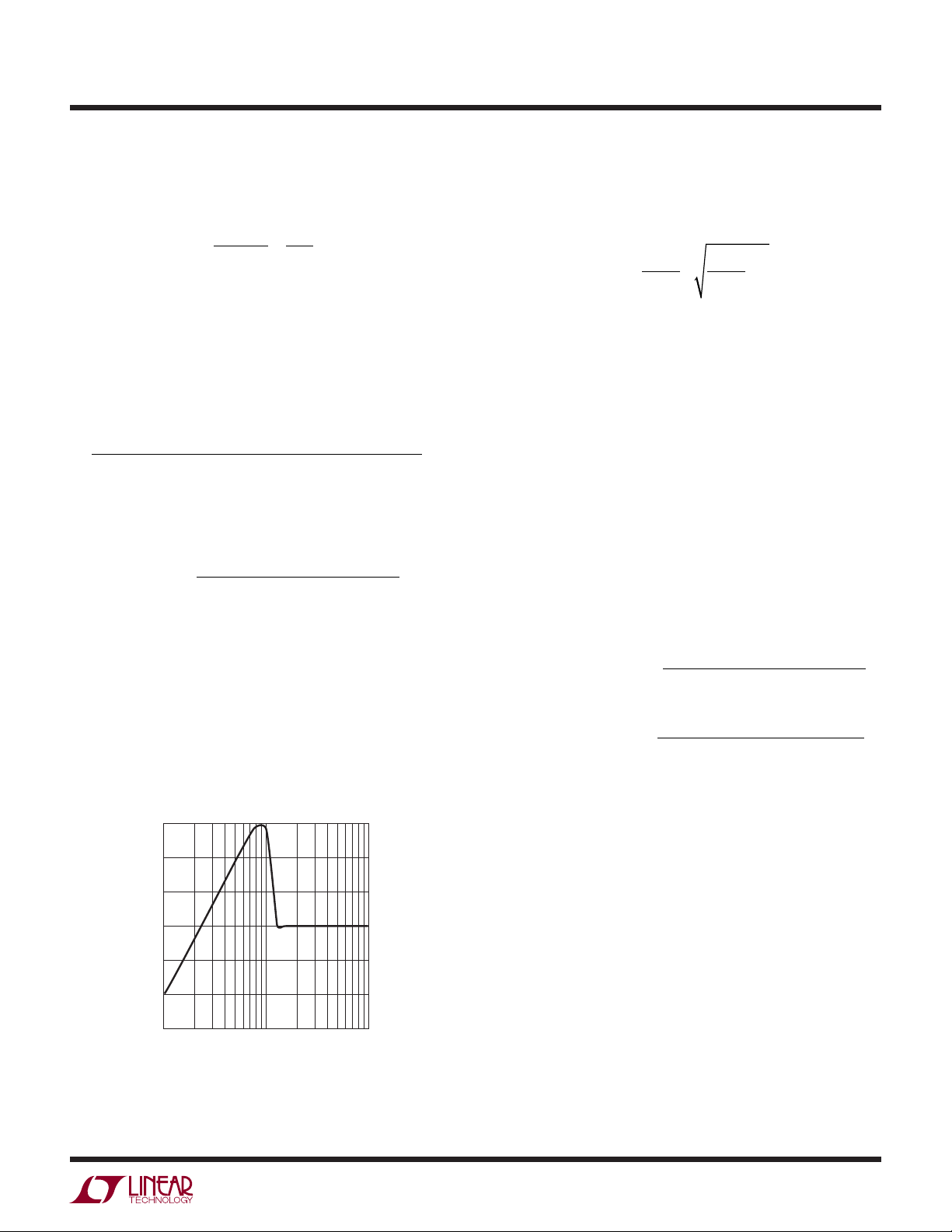

Effi ciency and Power Loss

V

= 12V, I

100

95

90

85

EFFICIENCY (%)

80

75

70

0

510

OUT

LOAD

20 30 35

15 25

VIN (V)

= 5A

3780 TA01b

10

9

8

POWER LOSS (W)

7

6

5

4

3

2

1

0

3780fe

1

Page 2

LTC3780

ABSOLUTE MAXIMUM RATINGS

(Note 1)

Input Supply Voltage (VIN) ........................ –0.3V to 36V

Topside Driver Voltages

(BOOST1, BOOST2) .................................. –0.3V to 42V

Switch Voltage (SW1, SW2) ........................ –5V to 36V

INTV

, EXTVCC, (BOOST – SW1),

CC

(BOOST2 – SW2), PGOOD .......................... –0.3V to 7V

RUN, SS ....................................................... –0.3V to 6V

PLLIN Voltage .......................................... –0.3V to 5.5V

PLLFLTR Voltage ....................................... –0.3V to 2.7V

FCB, STBYMD Voltages ........................ –0.3V to INTV

ITH, V

OSENSE

Voltages .............................. –0.3V to 2.4V

CC

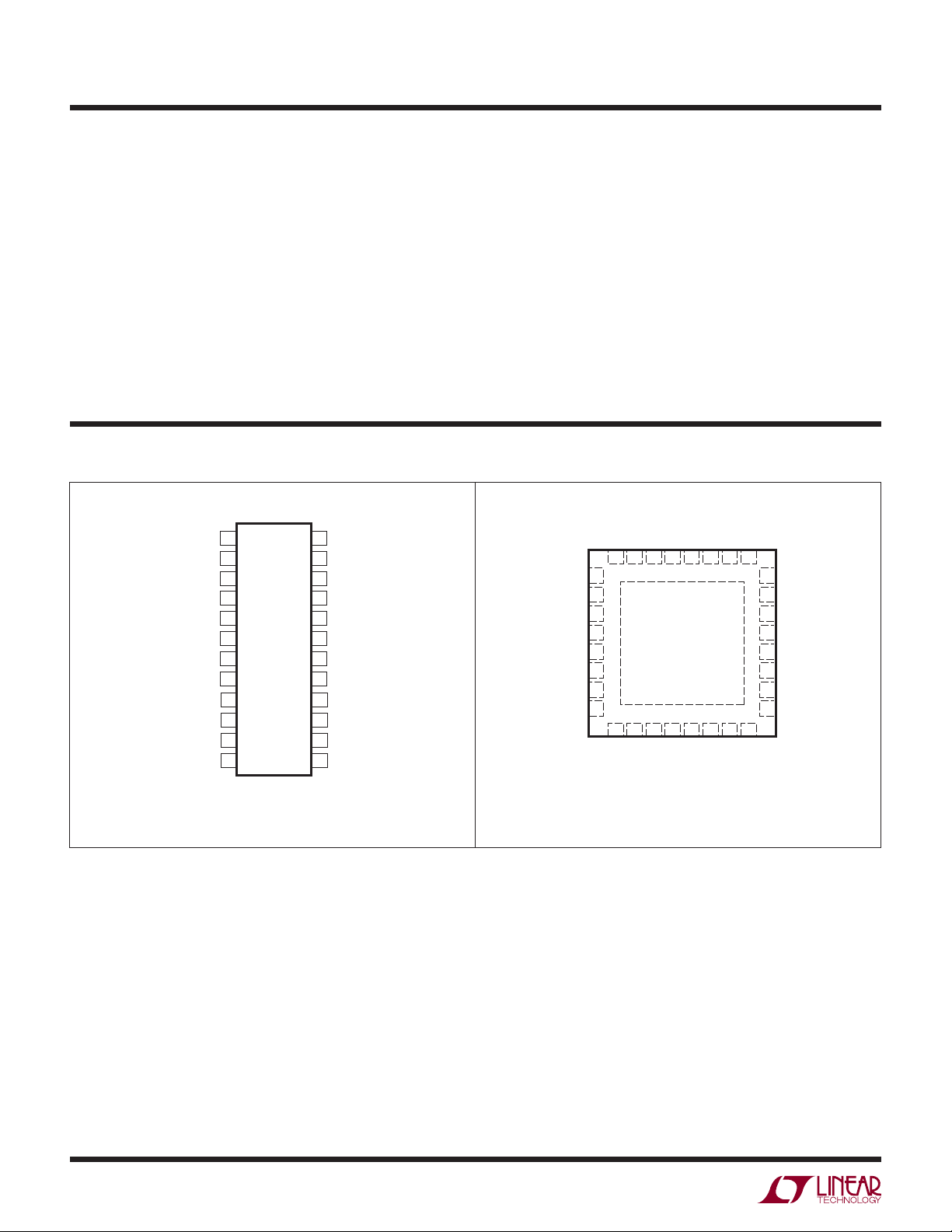

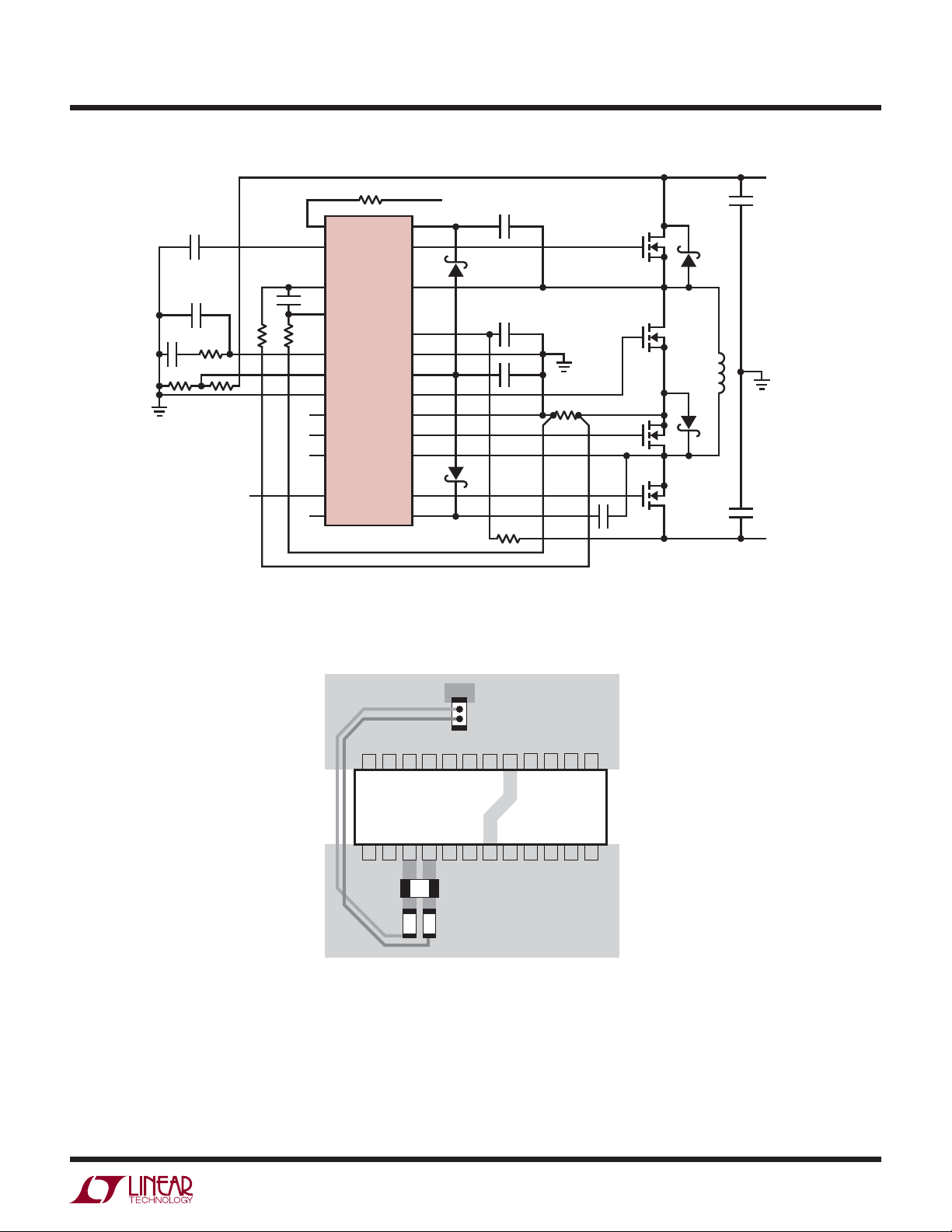

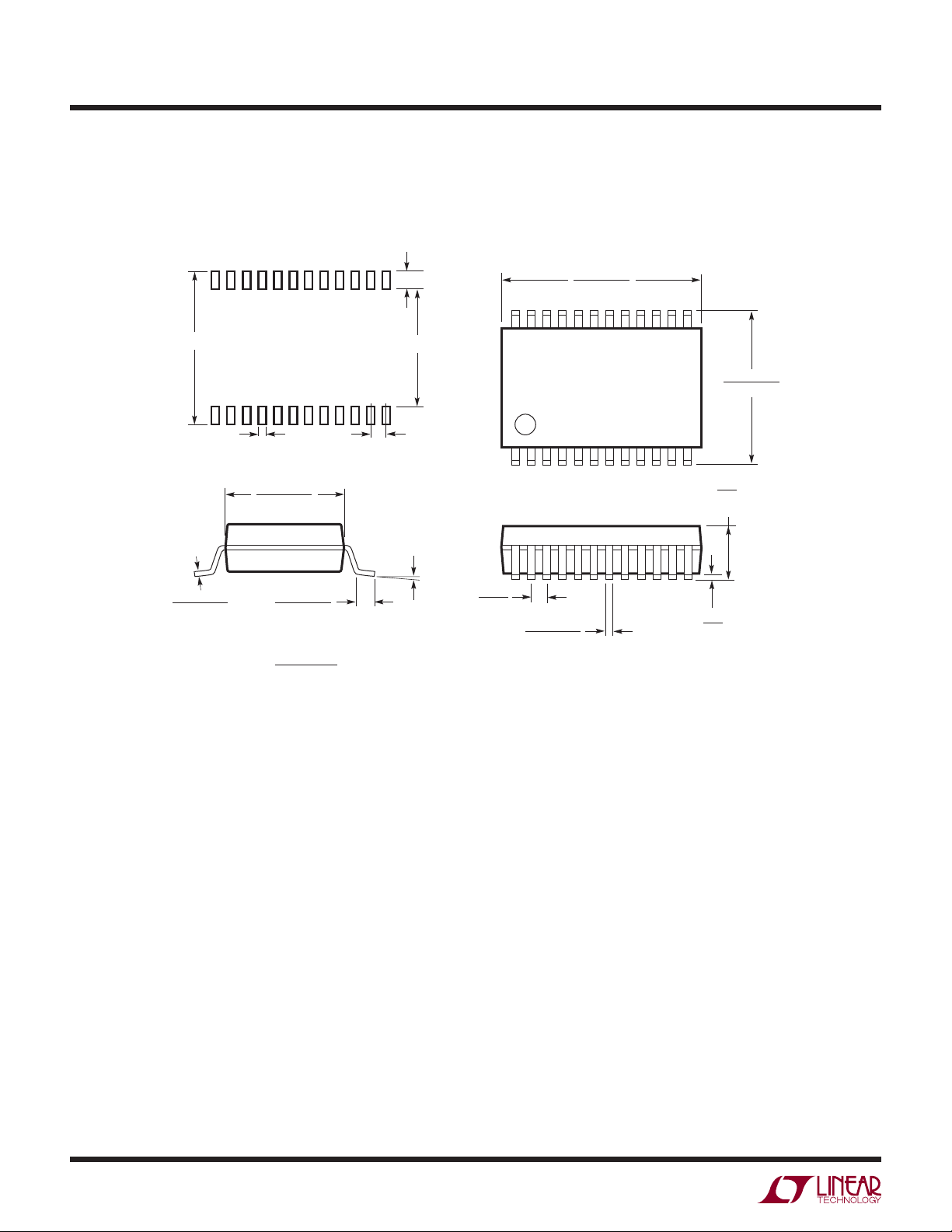

PIN CONFIGURATION

TOP VIEW

PGOOD

SENSE

SENSE

I

V

OSENSE

SGND

RUN

FCB

PLLFLTR

PLLIN

STBYMD

1

2

SS

+

3

–

4

5

TH

6

7

8

9

10

11

12

G PACKAGE

24-LEAD PLASTIC SSOP

T

= 125°C, θJA = 130°C/W

JMAX

24

23

22

21

20

19

18

17

16

15

14

13

BOOST1

TG1

SW1

V

IN

EXTV

CC

INTV

CC

BG1

PGND

BG2

SW2

TG2

BOOST2

Peak Output Current <10μs (TG1, TG2, BG1, BG2) .....3A

INTV

Peak Output Current ................................. 40mA

CC

Operating Junction Temperature Range (Notes 5, 2, 7)

LTC3780E ............................................. –40°C to 85°C

LTC3780I............................................ –40°C to 125°C

LTC3780MP ....................................... –55°C to 125°C

Junction Temperature (Note 2) ............................ 125°C

Storage Temperature Range ................... –65°C to 125°C

Lead Temperature (Soldering, 10 sec)

SSOP Only ........................................................ 300°C

TOP VIEW

NCSSPGOODNCNC

32 31 30 29 28 27 26 25

+

1SENSE

–

SENSE

2

I

3

TH

V

4

OSENSE

SGND

5

RUN

6

FCB

7

PLLFTR

8

9 10 11 12

NC

PLLIN

STBYMD

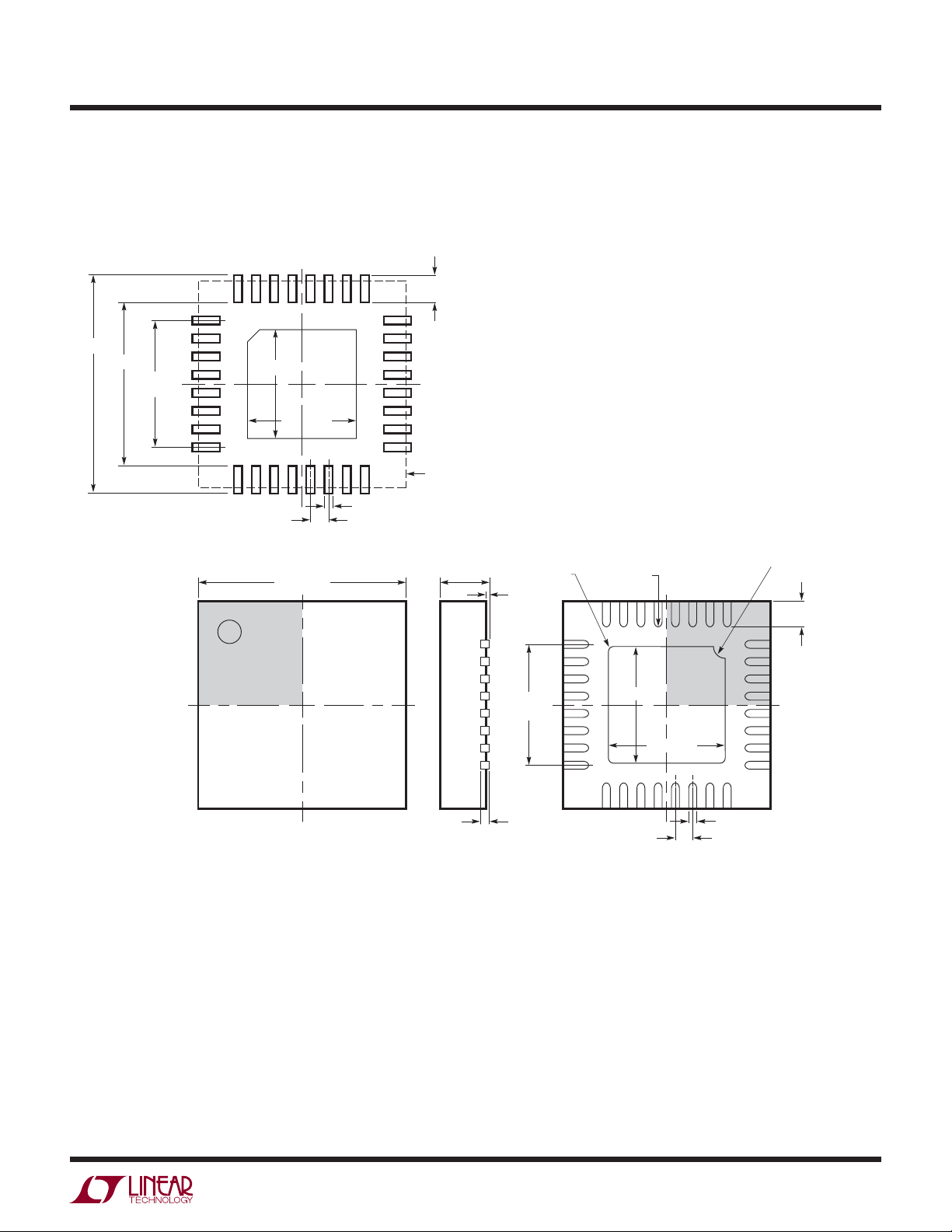

32-LEAD (5mm s 5mm) PLASTIC QFN

EXPOSED PAD (PIN 33) IS GND, MUST BE SOLDERED TO PCB

UH PACKAGE

T

= 125°C, θJA = 34°C/W

JMAX

BOOST1

33

13 14 15 16

NC

NC

BOOST2

TG1

TG2

NC

NC

24

SW1

V

23

IN

EXTV

22

CC

INTV

21

CC

BG1

20

PGND

19

BG2

18

SW2

17

2

3780fe

Page 3

LTC3780

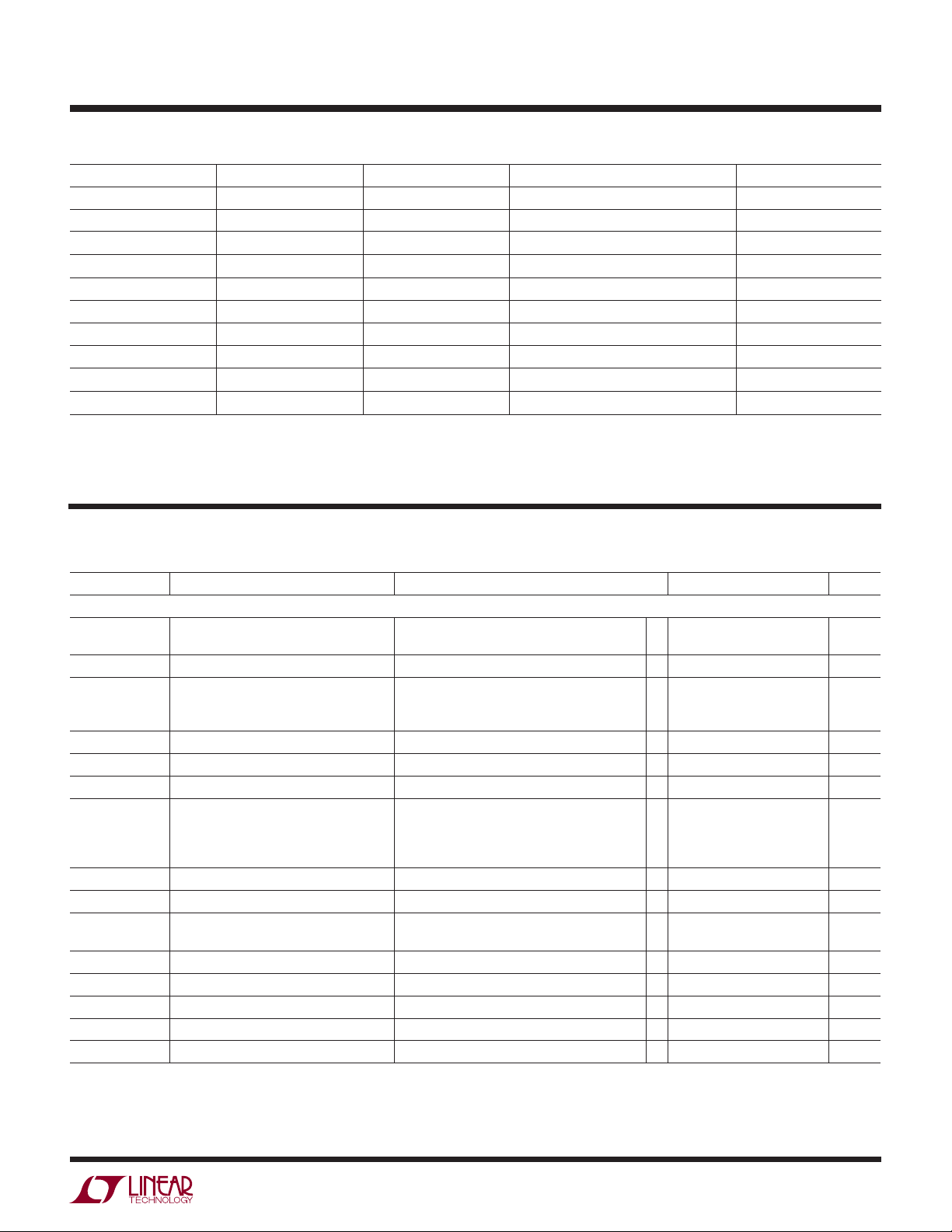

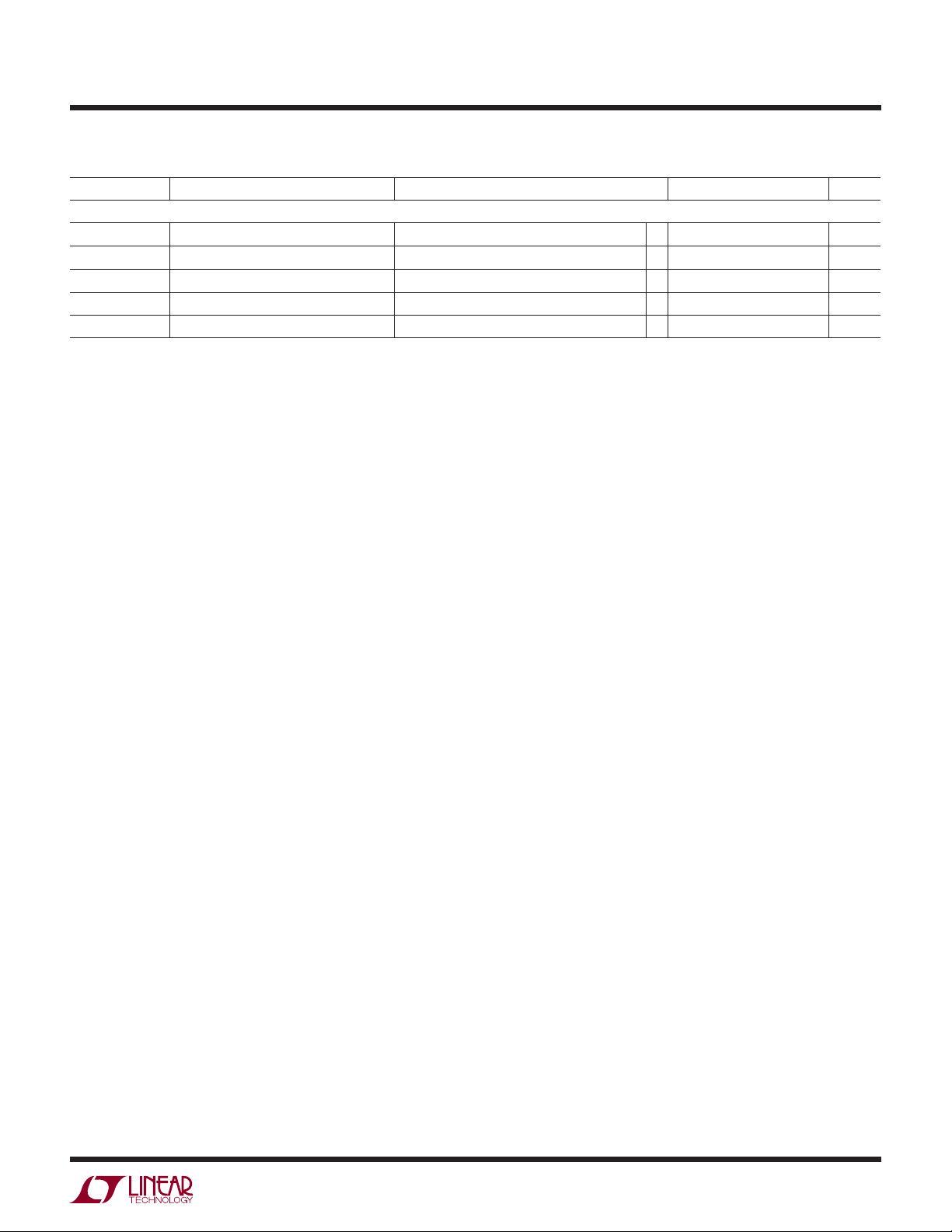

ORDER INFORMATION

LEAD FREE FINISH TAPE AND REEL PART MARKING PACKAGE DESCRIPTION TEMPERATURE RANGE

LTC3780EG#PBF LTC3780EG#TRPBF LTC3780EG 24-Lead Plastic SSOP –40°C to 85°C

LTC3780IG#PBF LTC3780IG#TRPBF LTC3780IG 24-Lead Plastic SSOP –40°C to 125°C

LTC3780EUH#PBF LTC3780EUH#TRPBF 3780

LTC3780IUH#PBF LTC3780IUH#TRPBF 3780I

32-Lead (5mm × 5mm) Plastic QFN

32-Lead (5mm × 5mm) Plastic QFN

LEAD BASED FINISH TAPE AND REEL PART MARKING PACKAGE DESCRIPTION TEMPERATURE RANGE

LTC3780EG LTC3780EG#TR LTC3780EG 24-Lead Plastic SSOP –40°C to 85°C

LTC3780IG LTC3780IG#TR LTC3780IG 24-Lead Plastic SSOP –40°C to 125°C

LTC3780MPG LTC3780MPG#TR LTC3780MPG 24-Lead Plastic SSOP –55°C to 125°C

LTC3780EUH LTC3780EUH#TR 3780

LTC3780IUH LTC3780IUH#TR 3780I

32-Lead (5mm × 5mm) Plastic QFN

32-Lead (5mm × 5mm) Plastic QFN

Consult LTC Marketing for parts specifi ed with wider operating temperature ranges.

For more information on lead free part marking, go to:

For more information on tape and reel specifi cations, go to:

ELECTRICAL CHARACTERISTICS

The l denotes the specifi cations which apply over the full operating

http://www.linear.com/leadfree/

http://www.linear.com/tapeandreel/

junction temperature range, otherwise specifi cations are at TA = 25°C. VIN = 15V unless otherwise noted.

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

Main Control Loop

V

OSENSE

Feedback Reference Voltage ITH = 1.2V, –40°C ≤ T ≤ 85°C (Note 3)

–55°C ≤ T ≤ 125°C

I

VOSENSE

V

LOADREG

V

REF(LINEREG)

g

m(EA)

g

m(GBW)

I

Q

Feedback Pin Input Current (Note 3) –5 –50 nA

Output Voltage Load Regulation (Note 3)

ΔI

= 1.2V to 0.7V

TH

ΔI

= 1.2V to 1.8V

TH

Reference Voltage Line Regulation VIN = 4V to 30V, ITH = 1.2V (Note 3) 0.002 0.02 %/V

Error Amplifi er Transconductance ITH = 1.2V, Sink/Source = 3μA (Note 3) 0.32 mS

Error Amplifi er GBW (Note 8) 0.6 MHz

Input DC Supply Current

(Note 4)

Normal

V

FCB

I

FCB

V

BINHIBIT

Standby

Shutdown Supply Current

Forced Continuous Threshold 0.76 0.800 0.84 V

Forced Continuous Pin Current V

Burst Inhibit (Constant Frequency)

V

= 0V, V

RUN

V

= 0V, V

RUN

= 0.85V –0.30 –0.18 –0.1 μA

FCB

Measured at FCB Pin 5.3 5.5 V

Threshold

UVLO Undervoltage Reset VIN Falling

V

OVL

I

SENSE

V

STBYMD(START)

V

STBYMD(KA)

Feedback Overvoltage Lockout Measured at V

Sense Pins Total Source Current V

Start-Up Threshold V

Keep-Alive Power-On Threshold V

SENSE

STBYMD

STBYMD

–

= V

> 2V

STBYMD

= Open

STBYMD

Pin 0.84 0.86 0.88 V

OSENSE

+

= 0V –380 μA

SENSE

Rising 0.4 0.7 V

Rising, V

= 0V 1.25 V

RUN

l

0.792

l

0.792

l

l

l

–40°C to 85°C

–40°C to 125°C

–40°C to 85°C

–40°C to 125°C

0.800

0.800

0.1

–0.1

0.808

0.811

0.5

–0.5

2400

1500

55 70

3.8 4 V

μA

μA

μA

V

V

%

%

3780fe

3

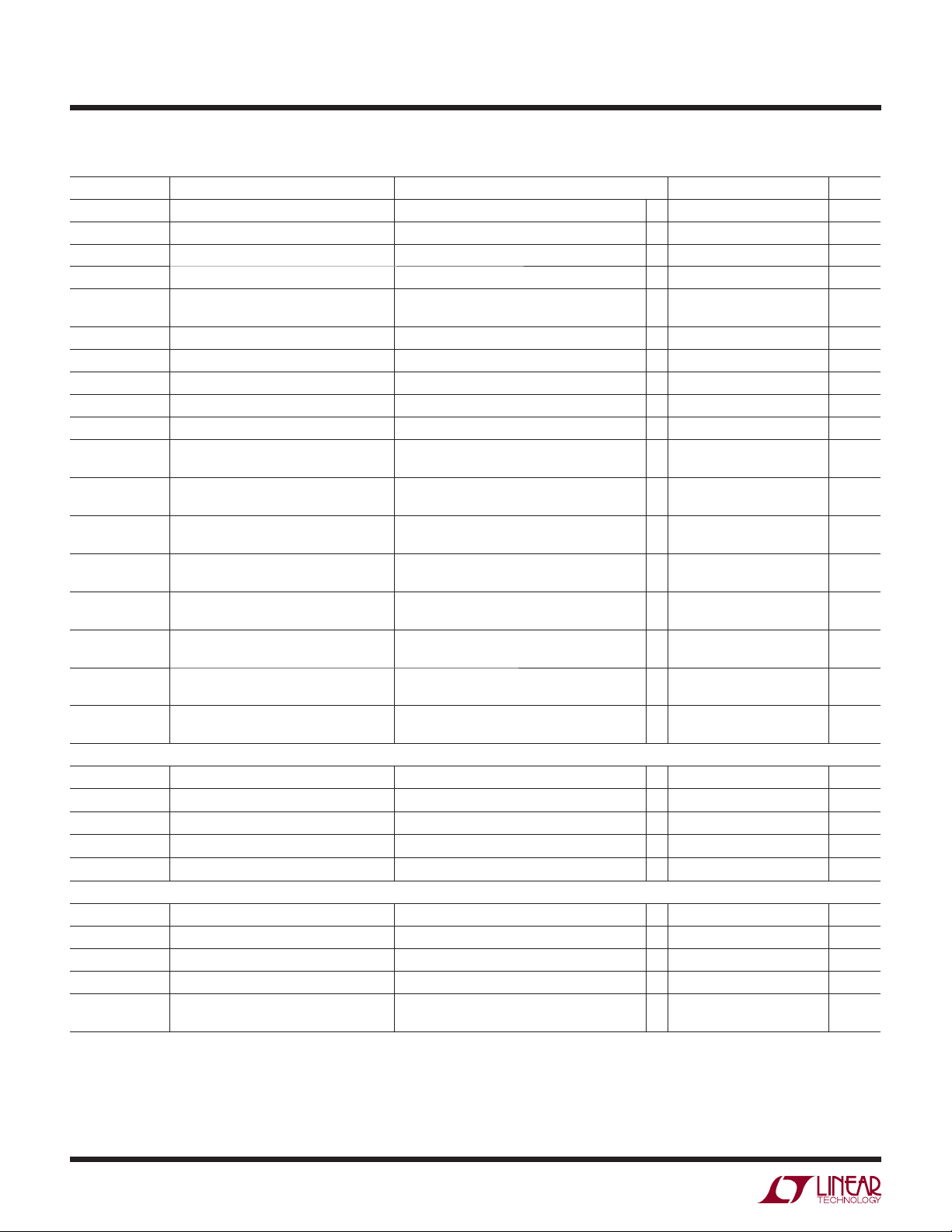

Page 4

LTC3780

ELECTRICAL CHARACTERISTICS

The l denotes the specifi cations which apply over the full operating

junction temperature range, otherwise specifi cations are at T

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

DF MAX, Boost Maximum Duty Factor % Switch C On 99 %

DF MAX, Buck Maximum Duty Factor % Switch A On (in Dropout) 99 %

V

RUN(ON)

I

SS

V

SENSE(MAX)

V

SENSE(MIN,BUCK)

TG1, TG2 t

TG1, TG2 t

r

f

BG1, BG2 t

BG1, BG2 t

TG1/BG1 t

BG1/TG1 t

TG2/BG2 t

BG2/TG2 t

1D

2D

3D

4D

Mode

Transition 1

Mode

Transition 2

t

ON(MIN,BOOST)

t

ON(MIN,BUCK)

Internal VCC Regulator

V

INTVCC

ΔV

LDO(LOADREG)

V

EXTVCC

ΔV

EXTVCC(HYS)

ΔV

EXTVCC

Oscillator and Phase-Locked Loop

f

NOM

f

LOW

f

HIGH

R

PLLIN

I

PLLLPF

RUN Pin On Threshold V

Soft-Start Charge Current V

Maximum Current Sense Threshold Boost: V

Buck: V

Minimum Current Sense Threshold Discontinuous Mode –6 mV

TG Rise Time C

TG Fall Time C

BG Rise Time C

r

BG Fall Time C

f

TG1 Off to BG1 On Delay,

C

Switch C On Delay

BG1 Off to TG1 On Delay,

C

Synchronous Switch D On Delay

TG2 Off to BG2 On Delay,

C

Synchronous Switch B On Delay

BG2 Off to TG2 On Delay,

C

Switch A On Delay

BG1 Off to BG2 On Delay,

C

Switch A On Delay

BG2 Off to BG1 On Delay,

C

Synchronous Switch D On Delay

Minimum On-Time for Main Switch in

Switch C (Note 6) 200 ns

Boost Operation

Minimum On-Time for Synchronous

Switch B (Note 6) 180 ns

Switch in Buck Operation

Internal VCC Voltage 7V < VIN < 30V, V

Internal VCC Load Regulation ICC = 0mA to 20mA, V

EXTVCC Switchover Voltage ICC = 20mA, V

EXTVCC Switchover Hysteresis 300 mV

EXTVCC Switch Drop Voltage ICC = 20mA, V

Nominal Frequency V

Lowest Frequency V

Highest Frequency V

PLLIN Input Resistance 50 kΩ

Phase Detector Output Current f

f

= 25°C. VIN = 15V unless otherwise noted.

A

Rising 1 1.5 2 V

RUN

= 2V 0.5 1.2 μA

RUN

= V

OSENSE

OSENSE

= 3300pF (Note 5) 50 ns

LOAD

= 3300pF (Note 5) 45 ns

LOAD

= 3300pF (Note 5) 45 ns

LOAD

= 3300pF (Note 5) 55 ns

LOAD

= 3300pF Each Driver 80 ns

LOAD

= 3300pF Each Driver 80 ns

LOAD

= 3300pF Each Driver 80 ns

LOAD

= 3300pF Each Driver 80 ns

LOAD

= 3300pF Each Driver 250 ns

LOAD

= 3300pF Each Driver 250 ns

LOAD

= 1.2V 260 300 330 kHz

PLLFLTR

= 0V 170 200 220 kHz

PLLFLTR

= 2.4V 340 400 440 kHz

PLLFLTR

< f

PLLIN

OSC

> f

OSC

(Note 9)

PLLIN

– 50mV

REF

= V

– 50mV

REF

= 5V

EXTVCC

= 5V 0.2 2 %

EXTVCC

Rising

EXTVCC

= 6V 150 300 mV

EXTVCC

l

l

–95

l

5.7 6 6.3 V

l

5.4 5.7 V

160

–110

185

–150

–15

15

mV

mV

μA

μA

4

3780fe

Page 5

LTC3780

ELECTRICAL CHARACTERISTICS

The l denotes the specifi cations which apply over the full operating

junction temperature range, otherwise specifi cations are at T

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

PGOOD Output

ΔV

FBH

ΔV

FBL

ΔV

FB(HYST)

V

PGL

I

PGOOD

Note 1: Stresses beyond those listed under Absolute Maximum Ratings

may cause permanent damage to the device. Exposure to any Absolute

Maximum Rating condition for extended periods may affect device

reliability and lifetime.

Note 2: T

power dissipation P

T

Note 3: The IC is tested in a feedback loop that servos V

voltage and measures the resultant V

Note 4: Dynamic supply current is higher due to the gate charge being

delivered at the switching frequency.

Note 5: Rise and fall times are measured using 10% and 90% levels. Delay

times are measured using 50% levels.

for the QFN package is calculated from the temperature TA and

J

= TA + (PD • 34°C/W)

J

PGOOD Upper Threshold V

PGOOD Lower Threshold V

PGOOD Hysteresis V

PGOOD Low Voltage I

PGOOD Leakage Current V

according to the following formula:

D

to a specifi ed

ITH

OSENSE

.

= 25°C. VIN = 15V unless otherwise noted.

A

Rising 5.5 7.5 10 %

OSENSE

Falling –5.5 –7.5 –10 %

OSENSE

Returning 2.5 %

OSENSE

= 2mA 0.1 0.3 V

PGOOD

= 5V ±1 μA

PGOOD

Note 6: The minimum on-time condition is specifi ed for an inductor

peak-to-peak ripple current ≥ 40% of I

considerations in the Applications Information section).

Note 7: The LTC3780E is guaranteed to meet performance specifi cations

from 0°C to 85°C. Performance over the –40°C to 85°C operating junction

temperature range is assured by design, characterization and correlation

with statistical process controls. The LTC3780I is guaranteed over the

–40°C to 125°C operating junction temperature range. The LTC3780MP

is guaranteed and tested over the full –55 to 125°C operating junction

temperature range.

Note 8: This parameter is guaranteed by design.

Note 9: f

is the running frequency for the application.

OSC

(see minimum on-time

MAX

3780fe

5

Page 6

LTC3780

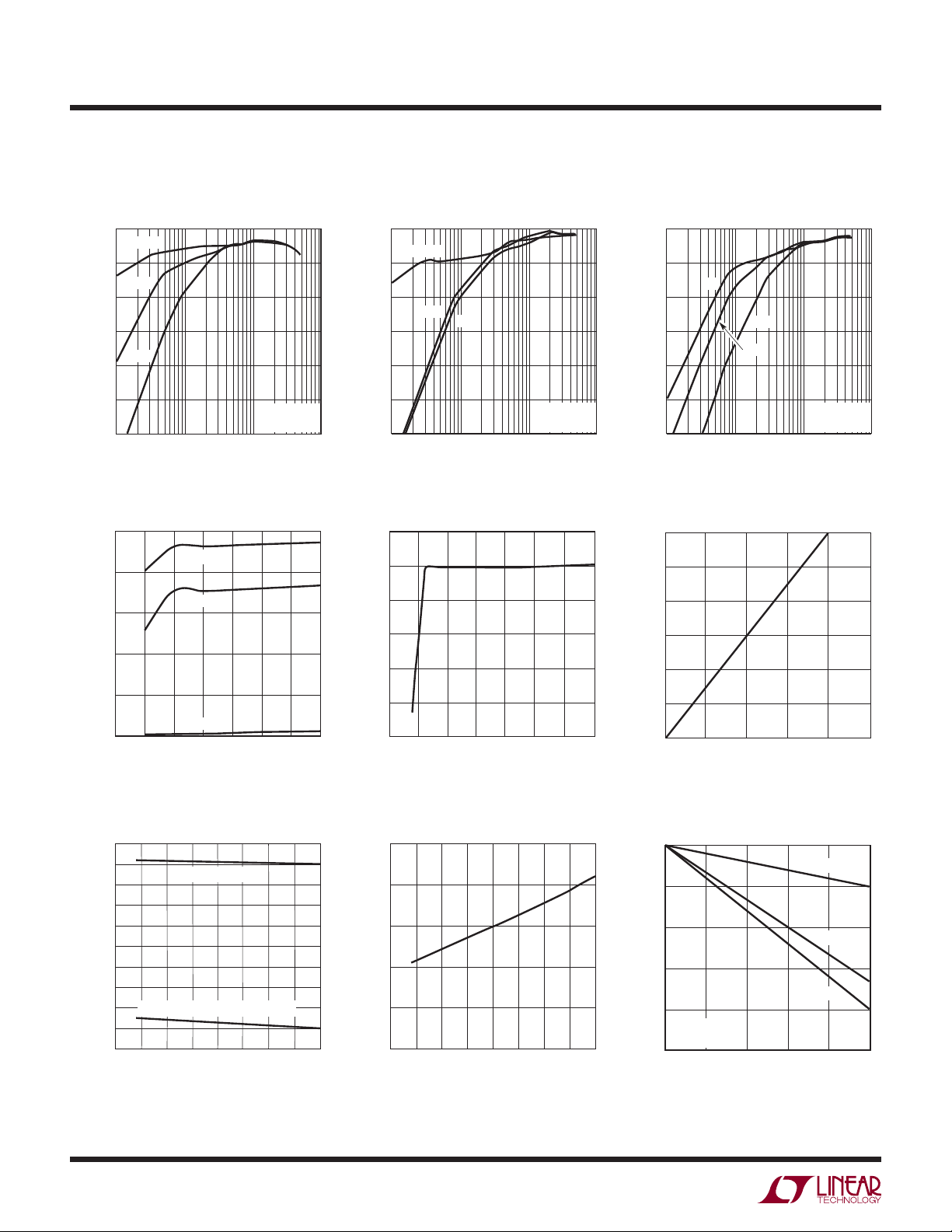

TYPICAL PERFORMANCE CHARACTERISTICS

Effi ciency vs Output Current

(Boost Operation)

100

BURST

90

DCM

80

70

CCM

EFFICIENCY (%)

60

50

40

0.01

VIN = 6V

= 12V

V

OUT

0.1 1 10

I

(A)

LOAD

3780 G01

Effi ciency vs Output Current

100

BURST

90

80

DCM

70

EFFICIENCY (%)

60

50

40

0.01

CCM

0.1 1 10

I

LOAD

(A)

T

= 25°C unless othewise noted.

A

Effi ciency vs Output Current

(Buck Operation)

100

90

80

70

EFFICIENCY (%)

60

VIN = 12V

= 12V

V

OUT

3780 G02

50

40

0.01

Supply Current vs Input Voltage Internal 6V LDO Line Regulation EXTVCC Voltage Drop

2500

2000

V

= 0V

FCB

6.5

6.0

120

100

SC

CCM

DCM

VIN = 18V

V

0.1 1 10

I

(A)

LOAD

OUT

= 12V

3780 G03

1500

1000

SUPPLY CURRENT (μA)

500

0

05

INTV

STANDBY

SHUTDOWN

10

INPUT VOLTAGE (V)

and EXTVCC Switch

CC

Voltage vs Temperature

6.05

6.00

5.95

5.90

5.85

5.80

SWITCH VOLTAGE (V)

CC

5.75

5.70

AND EXTV

5.65

CC

5.60

INTV

5.55

–75 –50

INTVCC VOLTAGE

EXTVCC SWITCHOVER THRESHOLD

–25

TEMPERATURE (°C)

5.5

5.0

VOLTAGE (V)

CC

4.5

INTV

4.0

20

15

25

30

35

3780 G04

3.5

0

510

INPUT VOLTAGE (V)

20 30 35

15 25

3780 G05

80

60

VOLTAGE DROP (mV)

40

CC

EXTV

20

0

0

10 20 30 40

CURRENT (mA)

50

3780 G06

EXTVCC Switch Resistance

vs Temperature

5

4

3

2

SWITCH RESISTANCE (Ω)

CC

1

EXTV

0

75

50

25

100

125

3780 G07

0

–75 –50 –25

50

25

0

TEMPERATURE (°C)

100

125

3780 G08

75

Load Regulation

0

–0.1

(%)

OUT

–0.2

–0.3

NORMALIZED V

–0.4

FCB = 0V

= 12V

V

OUT

–0.5

0

1

2

LOAD CURRENT (A)

3

VIN = 18V

VIN = 12V

VIN = 6V

4

5

3780 G09

6

3780fe

Page 7

LTC3780

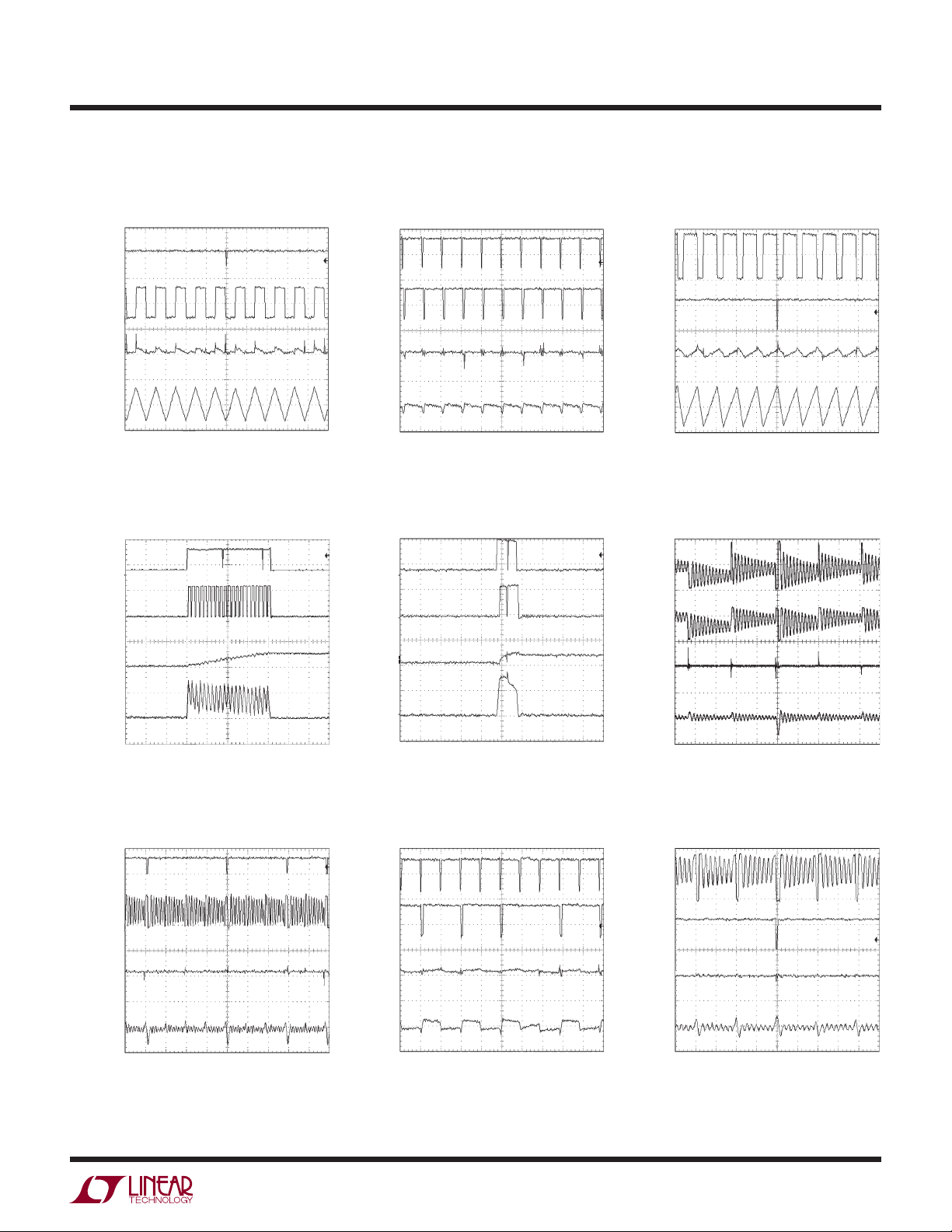

TYPICAL PERFORMANCE CHARACTERISTICS

SW2

10V/DIV

SW1

10V/DIV

V

OUT

100mV/DIV

2A/DIV

SW2

10V/DIV

SW1

10V/DIV

V

OUT

500mV/DIV

2A/DIV

Continuous Current Mode

(CCM, VIN = 6V, V

I

L

= 6V

IN

= 12V

V

OUT

= 12V)

OUT

5μs/DIVV

Burst Mode Operation

(VIN = 6V, V

I

L

OUT

= 12V)

100mV/DIV

3780 G10

200mV/DIV

Continuous Current Mode

(CCM, VIN = 12V, V

SW2

10V/DIV

SW1

10V/DIV

V

OUT

I

L

2A/DIV

= 12V

IN

= 12V

V

OUT

Burst Mode Operation

(VIN = 12V, V

SW2

10V/DIV

SW1

10V/DIV

V

OUT

I

L

2A/DIV

5μs/DIVV

OUT

OUT

= 12V)

= 12V)

TA = 25°C unless othewise noted.

Continuous Current Mode

(CCM, VIN = 18V, V

SW2

10V/DIV

SW1

10V/DIV

V

OUT

100mV/DIV

I

L

2A/DIV

3780 G11

= 18V

IN

= 12V

V

OUT

5μs/DIVV

Skip-Cycle Mode

SW2

10V/DIV

SW1

10V/DIV

V

OUT

100mV/DIV

1A/DIV

(VIN = 18V, V

I

L

OUT

OUT

= 12V)

= 12V)

3780 G12

SW2

10V/DIV

SW1

10V/DIV

V

OUT

100mV/DIV

1A/DIV

= 6V

IN

= 12V

V

OUT

25μs/DIVV

Discontinuous Current Mode

(DCM, VIN = 6V, V

I

L

= 6V

IN

= 12V

V

OUT

= 12V)

OUT

5μs/DIVV

3780 G13

3780 G16

SW2

10V/DIV

SW1

10V/DIV

V

OUT

100mV/DIV

2A/DIV

= 12V

IN

= 12V

V

OUT

10μs/DIVV

Discontinuous Current Mode

(DCM, VIN = 12V, V

I

L

= 12V

IN

= 12V

V

OUT

5μs/DIVV

OUT

= 12V)

3780 G14

3780 G17

SW2

10V/DIV

SW1

10V/DIV

V

OUT

100mV/DIV

1A/DIV

V

IN

OUT

= 18V

= 12V

2.5μs/DIVV

Discontinuous Current Mode

(DCM, VIN = 18V, V

I

L

= 18V

IN

= 12V

V

OUT

2.5μs/DIVV

OUT

= 12V)

3780 G15

3780 G18

3780fe

7

Page 8

LTC3780

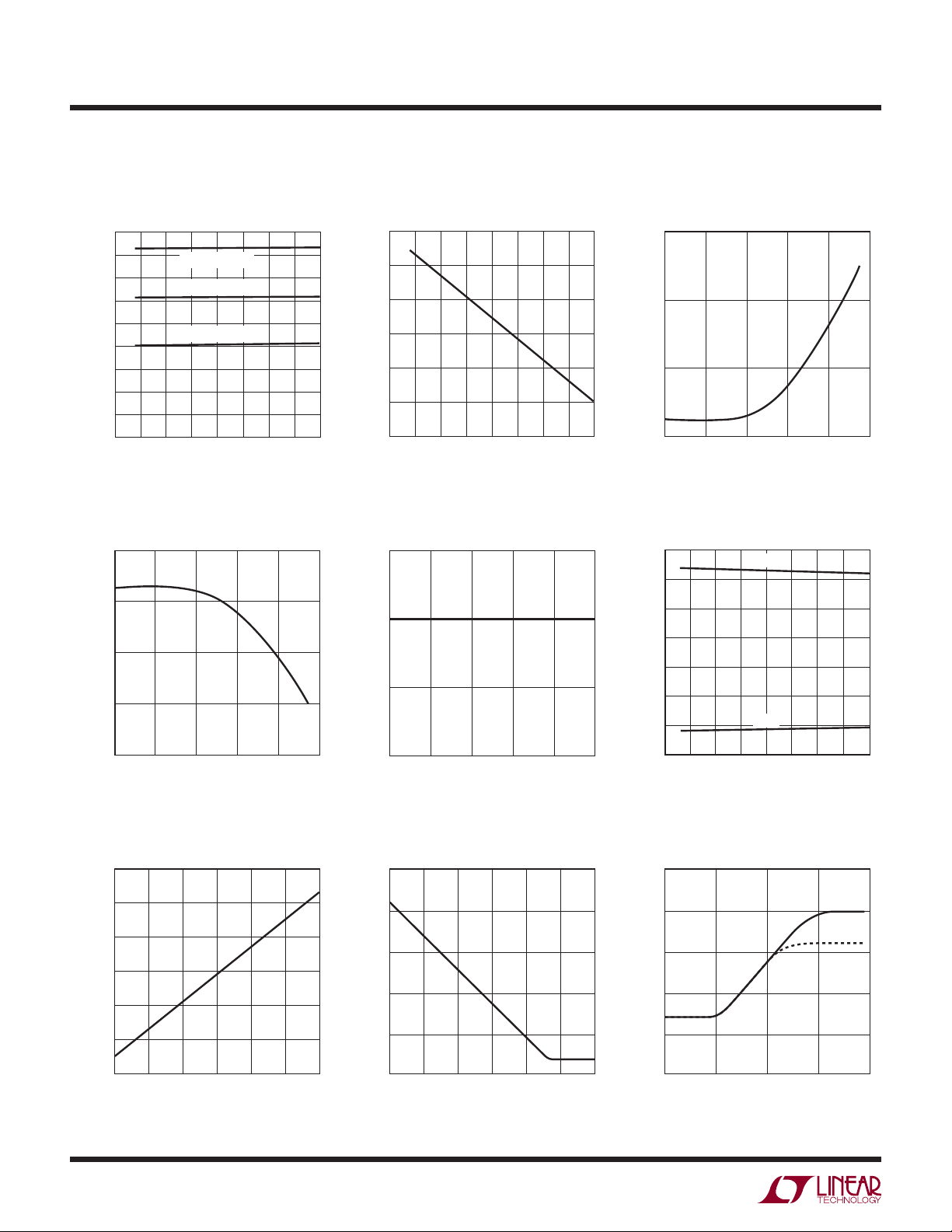

TYPICAL PERFORMANCE CHARACTERISTICS

Oscillator Frequency

vs Temperature

450

400

350

300

250

200

150

FREQUENCY (kHz)

100

50

0

–75 –50

V

PLLFLTR

V

PLLFLTR

V

PLLFLTR

0

–25

25 125

TEMPERATURE (°C)

= 2.4V

= 1.2V

= 0V

50

Maximum Current Sense

Threshold vs Duty Factor (Boost)

180

160

(mV)

+

140

SENSE

I

120

100

20

0

DUTY FACTOR (%)

60

40

75 100

80

3780 G19

100

3780 G22

Undervoltage Reset

vs Temperature

4.2

4.0

3.8

3.6

3.4

UNDERVOLTAGE RESET (V)

3.2

3.0

–75 –50 –25

0

TEMPERATURE (°C)

50

25

Maximum Current Sense

Threshold vs Duty Factor (Buck)

140

130

(mV)

+

SNESE

I

120

110

20 40 60 80

DUTY FACTOR (%)

75

TA = 25°C unless othewise noted.

Minimum Current Sense

Threshold vs Duty Factor (Buck)

–20

–40

(mV)

+

SENSE

I

–60

100

125

3780 G20

–80

80 60 40 20

DUTY FACTOR (%)

Minimum Current Sense

Threshold vs Temperature

3780 G23

200

150

100

50

THRESHOLD (mV)

+

0

SNESE

–50

–100

MAXIMUM I

–150

1000

–75 –50

BOOST

BUCK

–25 0

TEMPERATURE (°C)

50 100 125

25 75

0100

3780 G21

3780 G24

Peak Current Threshold

vs V

(Boost)

ITH

50

0

0

0.4

(mV)

+

SENSE

I

–100

200

150

100

–50

8

0.8 1.2 1.6

V

(V)

ITH

1.8 2.4

3780 G25

Valley Current Threshold

vs V

(Buck)

ITH

50

0

0

0.8 1.2 1.6

0.4

(mV)

+

SENSE

I

–100

–150

100

–50

Current Foldback Limit

200

160

120

(mV)

+

SENSE

80

I

40

V

(V)

ITH

2.0 2.4

3780 G26

0

0

0.2 0.4 0.6

V

(V)

OSENSE

BOOST

BUCK

0.8

3780 G32

3780fe

Page 9

LTC3780

TYPICAL PERFORMANCE CHARACTERISTICS

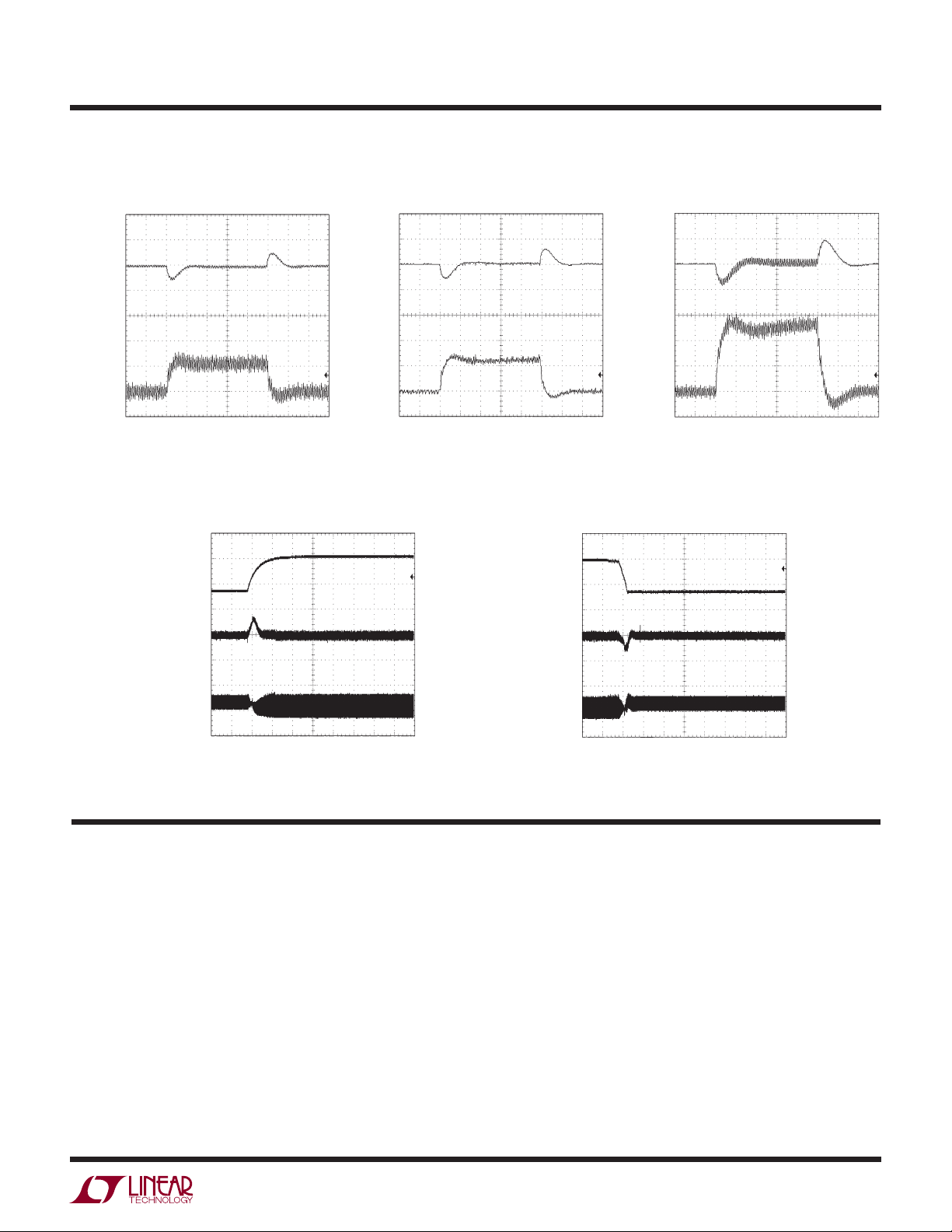

Load Step Load Step Load Step

V

OUT

500mV/DIV

5A/DIV

I

L

= 12V

V

OUT

LOAD STEP: 0A TO 5A

CONTINUOUS MODE

10V/DIV

200μs/DIVVIN = 18V

3780 G27

Line Transient Line Transient

V

IN

V

OUT

500mV/DIV

5A/DIV

I

L

= 12V

IN

= 12V

V

OUT

LOAD STEP: 0A TO 5A

CONTINUOUS MODE

200μs/DIVV

10V/DIV

TA = 25°C unless othewise noted.

V

OUT

500mV/DIV

I

L

5A/DIV

3780 G28

V

IN

= 6V

IN

= 12V

V

OUT

LOAD STEP: 0A TO 5A

CONTINUOUS MODE

200μs/DIVV

3780 G29

V

OUT

500mV/DIV

I

L

1A/DIV

OUT

I

LOAD

STEP: 7V TO 20V

V

IN

CONTINUOUS MODE

PIN FUNCTIONS

= 12V

= 1A

(SSOP/QFN)

500μs/DIVV

3780 G30

PGOOD (Pin 1/Pin 30): Open-Drain Logic Output. PGOOD

is pulled to ground when the output voltage is not within

±7.5% of the regulation point.

SS (Pin 2/Pin 31): Soft-start reduces the input power

sources’ surge currents by gradually increasing the

controller’s current limit. A minimum value of 6.8nF is

recommended on this pin.

+

SENSE

and Reverse Current Detect Comparators. The I

(Pin 3/Pin 1): The (+) Input to the Current Sense

pin

TH

V

OUT

500mV/DIV

I

L

1A/DIV

= 12V

OUT

= 1A

I

LOAD

STEP: 20V TO 7V

V

IN

CONTINUOUS MODE

500μs/DIVV

voltage and built-in offsets between SENSE

pins, in conjunction with R

SENSE

3780 G31

–

and SENSE+

, set the current trip

threshold.

–

SENSE

(Pin 4/Pin 2): The (–) Input to the Current Sense

and Reverse Current Detect Comparators.

(Pin 5/Pin 3): Current Control Threshold and Error

I

TH

Amplifi er Compensation Point. The current comparator

threshold increases with this control voltage. The voltage

ranges from 0V to 2.4V.

3780fe

9

Page 10

LTC3780

PIN FUNCTIONS

V

OSENSE

(Pin 6/Pin 4): Error Amplifi er Feedback Input.

(SSOP/QFN)

This pin connects the error amplifi er input to an external

resistor divider from V

OUT

.

SGND (Pin 7/Pin 5): Signal Ground. All small-signal components and compensation components should connect

to this ground, which should be connected to PGND at a

single point.

RUN (Pin 8/Pin 6): Run Control Input. Forcing the RUN

pin below 1.5V causes the IC to shut down the switching

regulator circuitry. There is a 100k resistor between the RUN

pin and SGND in the IC. Do not apply >6V to this pin.

FCB (Pin 9/Pin 7): Forced Continuous Control Input. The

voltage applied to this pin sets the operating mode of the

controller. When the applied voltage is less than 0.8V, the

forced continuous current mode is active. When this pin

is allowed to fl oat, the Burst Mode operation is active in

boost operation and the skip-cycle mode is active in buck

operation. When the pin is tied to INTV

, the constant

CC

frequency discontinuous current mode is active in buck

or boost operation.

PLLFLTR (Pin 10/Pin 8): The phase-locked loop’s

lowpass fi lter is tied to this pin. Alternatively, this pin can

be driven with an AC or DC voltage source to vary the

frequency of the internal oscillator.

PLLIN (Pin 11/Pin 10): External Synchronization Input to

Phase Detector. This pin is internally terminated to SGND

with 50kΩ. The phase-locked loop will force the rising

bottom gate signal of the controller to be synchronized

with the rising edge of the PLLIN signal.

STBYMD (Pin 12/Pin 11): LDO Control Pin. Determines

whether the internal LDO remains active when the controller is shut down. See Operation section for details. If the

STBYMD pin is pulled to ground, the SS pin is internally

pulled to ground, preventing start-up and thereby providing a single control pin for turning off the controller. To

keep the LDO active when RUN is low, for example to

power a “wake up” circuit which controls the state of the

RUN pin, bypass STBYMD to signal ground with a 0.1μF

capacitor, or use a resistor divider from V

to keep the

IN

pin within 2V to 5V.

BOOST2, BOOST1 (Pins 13, 24/Pins 14, 27): Boosted

Floating Driver Supply. The (+) terminal of the bootstrap

capacitor C

pin swings from a diode voltage below INTV

+ INTV

below INTV

and CB (Figure 11) connects here. The BOOST2

A

up to VIN

CC

. The BOOST1 pin swings from a diode voltage

CC

up to V

CC

+ INTVCC.

OUT

TG2, TG1 (Pins 14, 23/Pins 15, 26): Top Gate Drive. Drives

the top N-channel MOSFET with a voltage swing equal to

INTV

superimposed on the switch node voltage SW.

CC

SW2, SW1 (Pins 15, 22/Pins 17, 24): Switch Node. The (–)

terminal of the bootstrap capacitor C

and CB (Figure 11)

A

connects here. The SW2 pin swings from a Schottky diode

(external) voltage drop below ground up to V

. The SW1

IN

pin swings from a Schottky diode (external) voltage drop

below ground up to V

OUT

.

BG2, BG1 (Pins 16, 18/Pins 18, 20): Bottom Gate Drive.

Drives the gate of the bottom N-channel MOSFET between

ground and INTV

CC

.

PGND (Pin 17/Pin 19): Power Ground. Connect this pin

closely to the source of the bottom N-channel MOSFET, the

(–) terminal of C

INTV

(Pin 19/Pin 21): Internal 6V Regulator Output. The

CC

and the (–) terminal of CIN (Figure 11).

VCC

driver and control circuits are powered from this voltage.

Bypass this pin to ground with a minimum of 4.7μF low

ESR tantalum or ceramic capacitor.

EXTV

exceeds 5.7V, an internal switch connects this pin to INTV

(Pin 20/Pin 22): External VCC Input. When EXTVCC

CC

CC

and shuts down the internal regulator so that the controller

and gate drive power is drawn from EXTV

7V at this pin and ensure that EXTV

(Pin 21/Pin 23): Main Input Supply. Bypass this pin

V

IN

. Do not exceed

CC

< VIN.

CC

to SGND with an RC fi lter (1Ω, 0.1μF).

Exposed Pad (Pin 33, QFN Only): This pin is SGND and

must be soldered to PCB ground.

10

3780fe

Page 11

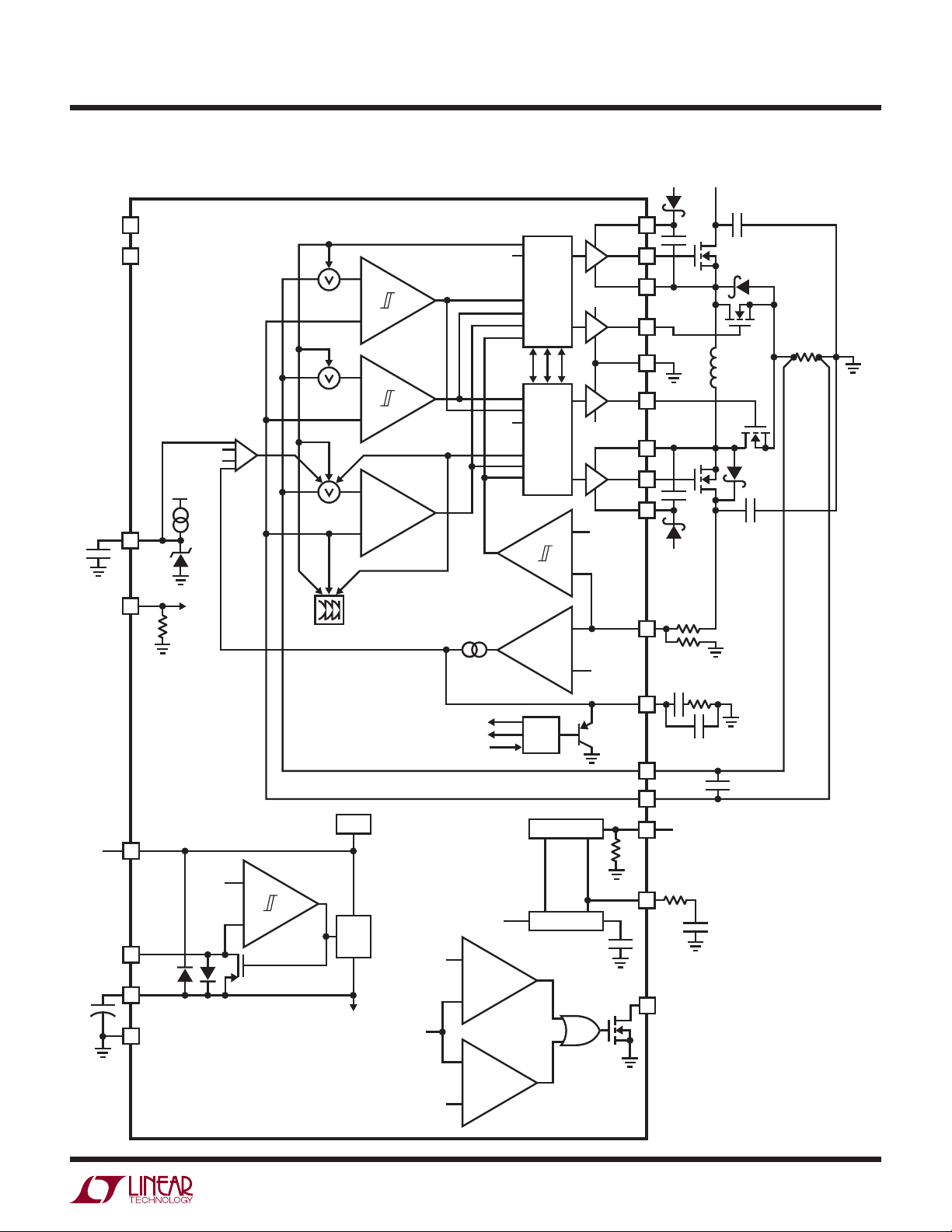

BLOCK DIAGRAM

INTV

LTC3780

CCVIN

STBYMD

FCB

SS

RUN

100k

1.2V

4(V

1.2μA

BOOST2

INTV

CC

TG2

SW2

BG2

PGND

R

SENSE

I

LIM

+

FCB

BUCK

LOGIC

–

I

REV

+

BG1

–

)

FB

I

CMP

+

–

SLOPE

FCB

OV

EA

BOOST

LOGIC

INTV

CC

SW1

TG1

BOOST1

0.86V

–

INTV

CC

V

+

V

OSENSE

–

V

FB

OUT

0.80V

+

I

TH

SHDN

RST

4(V

FB

V

V

V

IN

IN

5.7V

+

–

EXTV

CC

INTV

6V

+

CC

SGND

REF

6V

LDO

REG

INTERNAL

SUPPLY

V

OSENSE

0.86V

–

+

RUN/

CLK

SS

PHASE DET

OSCILLATOR

SENSE

SENSE

PLLIN

PLLFLTR

PGOOD

50k

+

–

F

IN

R

LP

C

LP

)

–

0.74V

+

3780 BD

3780fe

11

Page 12

LTC3780

OPERATION

MAIN CONTROL LOOP

The LTC3780 is a current mode controller that provides an

output voltage above, equal to or below the input voltage.

The LTC proprietary topology and control architecture employs a current-sensing resistor in buck or boost modes.

The sensed inductor current is controlled by the voltage

on the I

V

OSENSE

pin, which is the output of the amplifi er EA. The

TH

pin receives the voltage feedback signal, which is

compared to the internal reference voltage by the EA.

The top MOSFET drivers are biased from fl oating booststrap capacitors C

and CB (Figure 11), which are normally

A

recharged through an external diode when the top MOSFET

is turned off. Schottky diodes across the synchronous

switch D and synchronous switch B are not required, but

provide a lower drop during the dead time. The addition of

the Schottky diodes will typically improve peak effi ciency

by 1% to 2% at 400kHz.

The main control loop is shut down by pulling the RUN

pin low. When the RUN pin voltage is higher than 1.5V, an

internal 1.2μA current source charges soft-start capacitor

at the SS pin. The ITH voltage is then clamped to the

C

SS

SS voltage while C

is slowly charged during start-up.

SS

This “soft-start” clamping prevents abrupt current from

being drawn from the input power supply.

POWER SWITCH CONTROL

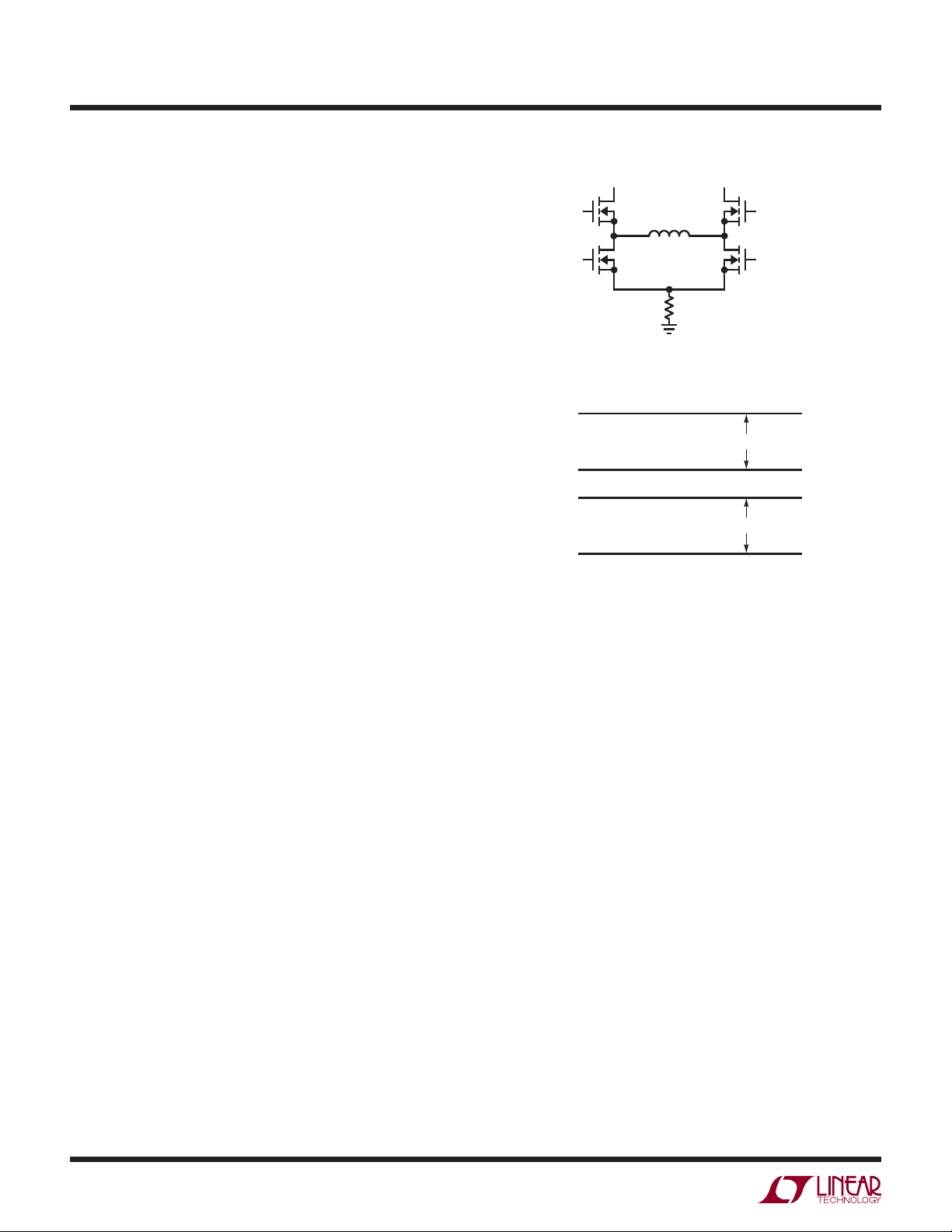

Figure 1 shows a simplifi ed diagram of how the four

, V

power switches are connected to the inductor, V

IN

OUT

and GND. Figure 2 shows the regions of operation for the

LTC3780 as a function of duty cycle D. The power switches

are properly controlled so the transfer between modes is

continuous. When V

approaches V

IN

, the buck-boost

OUT

region is reached; the mode-to-mode transition time is

typically 200ns.

V

IN

TG2

BG2

Figure 1. Simplifi ed Diagram of the Output Switches

98%

D

MAX

BOOST

D

MIN

BOOST

D

MAX

BUCK

3%

D

MIN

BUCK

Figure 2. Operating Mode vs Duty Cycle

A

B

A ON, B OFF

PWM C, D SWITCHES

FOUR SWITCH PWM

D ON, C OFF

PWM A, B SWITCHES

L

SW2 SW1

V

OUT

D

C

R

SENSE

3780 F01

BOOST REGION

BUCK/BOOST REGION

BUCK REGION

TG1

BG1

3780 F02

and switch A is turned on for the remainder of the cycle.

switches A and B will alternate, behaving like a typical

synchronous buck regulator. The duty cycle of switch A

increases until the maximum duty cycle of the converter

in buck mode reaches D

D

MAX_BUCK

where D

= 100% – D

BUCK-BOOST

= duty cycle of the buck-boost switch

MAX_BUCK

BUCK-BOOST

, given by:

range:

D

BUCK-BOOST

= (200ns • f) • 100%

and f is the operating frequency in Hz.

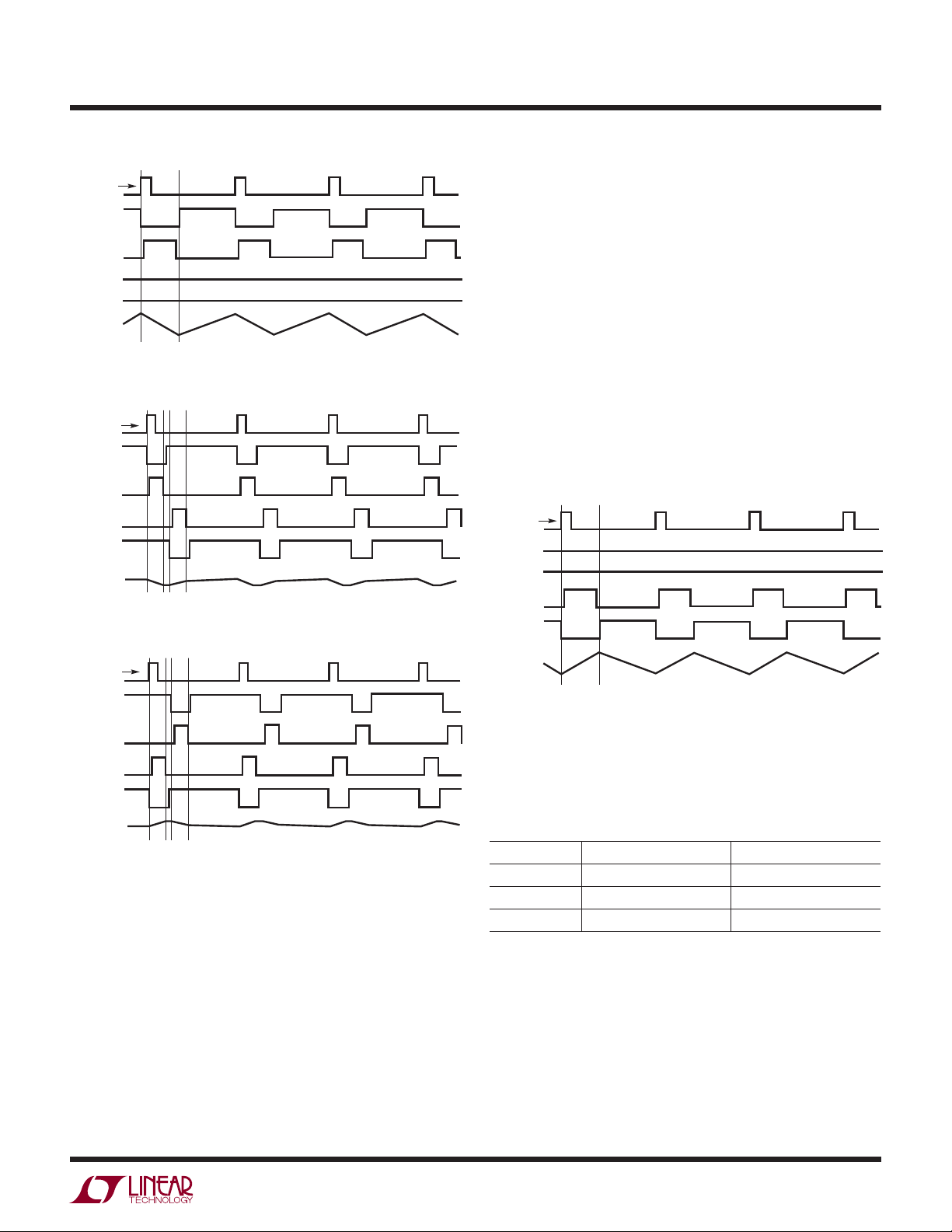

Figure 3 shows typical buck mode waveforms. If V

approaches V

, the buck-boost region is reached.

OUT

IN

Buck Region (V

IN

> V

OUT

)

Switch D is always on and switch C is always off during

this mode. At the start of every cycle, synchronous switch

B is turned on fi rst. Inductor current is sensed when

synchronous switch B is turned on. After the sensed inductor current falls below the reference voltage, which is

proportional to V

, synchronous switch B is turned off

ITH

12

Buck-Boost (V

When V

is close to V

IN

IN

≅ V

)

OUT

, the controller is in buck-boost

OUT

mode. Figure 4 shows typical waveforms in this mode.

Every cycle, if the controller starts with switches B and D

turned on, switches A and C are then turned on. Finally,

switches A and D are turned on for the remainder of the

time. If the controller starts with switches A and C turned

3780fe

Page 13

OPERATION

LTC3780

CLOCK

SWITCH A

SWITCH B

SWITCH C

SWITCH D

CLOCK

SWITCH A

SWITCH B

SWITCH C

SWITCH D

the remainder of the cycle. switches C and D will alternate,

behaving like a typical synchronous boost regulator.

The duty cycle of switch C decreases until the minimum duty

cycle of the converter in boost mode reaches D

0V

given by:

HIGH

I

L

Figure 3. Buck Mode (VIN > V

OUT

)

3780 F03

D

MIN_BOOST

where D

switch range:

D

BUCK-BOOST

= D

BUCK-BOOST

= (200ns • f) • 100%

BUCK-BOOST

is the duty cycle of the buck-boost

MIN_BOOST

,

and f is the operating frequency in Hz.

Figure 5 shows typical boost mode waveforms. If V

proaches V

CLOCK

SWITCH A

I

L

3780 F04a

(4a) Buck-Boost Mode (VIN ≥ V

OUT

)

SWITCH B

SWITCH C

SWITCH D

, the buck-boost region is reached.

OUT

IN

ap-

HIGH

0V

CLOCK

SWITCH A

SWITCH B

SWITCH C

SWITCH D

I

L

(4b) Buck-Boost Mode (VIN ≤ V

OUT

)

3780 F04b

Figure 4. Buck-Boost Mode

on, switches B and D are then turned on. Finally, switches

A and D are turned on for the remainder of the time.

Boost Region (V

IN

< V

OUT

)

Switch A is always on and synchronous switch B is always

off in boost mode. Every cycle, switch C is turned on fi rst.

Inductor current is sensed when synchronous switch C is

turned on. After the sensed inductor current exceeds the

reference voltage which is proportional to V

, switch C

ITH

is turned off and synchronous switch D is turned on for

I

L

Figure 5. Boost Mode (VIN < V

OUT

)

3780 F05

LOW CURRENT OPERATION

The FCB pin is used to select among three modes for both

buck and boost operations by accepting a logic input.

Figure 6 shows the different modes.

FCB PIN BUCK MODE BOOST MODE

0V to 0.75V Force Continuous Mode Force Continuous Mode

0.85V to 5V Skip-Cycle Mode Burst Mode Operation

>5.3V DCM with Constant Freq DCM with Constant Freq

Figure 6. Different Operating Modes

When the FCB pin voltage is lower than 0.8V, the controller

behaves as a continuous, PWM current mode synchronous

switching regulator. In boost mode, switch A is always on.

switch C and synchronous switch D are alternately turned

on to maintain the output voltage independent of direction

of inductor current. Every ten cycles, switch A is forced off

for about 300ns to allow boost capacitor C

(Figure 13) to

A

recharge. In buck mode, synchronous switch D is always

3780fe

13

Page 14

LTC3780

OPERATION

on. switch A and synchronous switch B are alternately

turned on to maintain the output voltage independent of

direction of inductor current. Every ten cycles, synchronous switch D is forced off for about 300ns to allow C

B

to recharge. This is the least effi cient operating mode at

light load, but may be desirable in certain applications. In

this mode, the output can source or sink current.

When the FCB pin voltage is below V

– 1V, but greater

INTVCC

than 0.8V, the controller enters Burst Mode operation in

boost operation or enters skip-cycle mode in buck operation. During boost operation, Burst Mode operation sets a

minimum output current level before inhibiting the switch

C and turns off synchronous switch D when the inductor

current goes negative. This combination of requirements

will, at low currents, force the I

pin below a voltage

TH

threshold that will temporarily inhibit turn-on of power

switches C and D until the output voltage drops. There is

100mV of hysteresis in the burst comparator tied to the

pin. This hysteresis produces output signals to the

I

TH

MOSFETs C and D that turn them on for several cycles,

followed by a variable “sleep” interval depending upon the

load current. The maximum output voltage ripple is limited

to 3% of the nominal DC output voltage as determined

by a resistive feedback divider. During buck operation at

no load, switch A is turned on for its minimum on-time.

This will not occur every clock cycle when the output load

current drops below 1% of the maximum designed load.

The body diode of synchronous switch B or the Schottky

diode, which is in parallel with switch B, is used to discharge the inductor current; switch B only turns on every

ten clock cycles to allow C

to recharge. As load current

B

is applied, switch A turns on every cycle, and its on-time

begins to increase. At higher current, switch B turns on

briefl y after each turn-off of switch A. switches C and D

remain off at light load, except to refresh CA (Figure 11)

every 10 clock cycles. In Burst Mode operation/skip-cycle

mode, the output is prevented from sinking current.

When the FCB pin voltage is tied to the INTV

pin, the

CC

controller enters constant frequency discontinuous current

mode (DCM). For boost operation, synchronous switch D

is held off whenever the I

pin is below a threshold volt-

TH

age. In every cycle, switch C is used to charge inductor

current. After the output voltage is high enough, the

controller will enter continuous current buck mode for

one cycle to discharge inductor current. In the following

cycle, the controller will resume DCM boost operation. For

buck operation, constant frequency discontinuous current

mode sets a minimum negative inductor current level.

synchronous switch B is turned off whenever inductor

current is lower than this level. At very light loads, this

constant frequency operation is not as effi cient as Burst

Mode operation or skip-cycle, but does provide lower

noise, constant frequency operation.

FREQUENCY SYNCHRONIZATION AND

FREQUENCY SETUP

The phase-locked loop allows the internal oscillator to be

synchronized to an external source via the PLLIN pin. The

phase detector output at the PLLFLTR pin is also the DC

frequency control input of the oscillator. The frequency

ranges from 200kHz to 400kHz, corresponding to a DC

voltage input from 0V to 2.4V at PLLFLTR. When locked,

the PLL aligns the turn on of the top MOSFET to the rising edge of the synchronizing signal. When PLLIN is left

open, the PLLFLTR pin goes low, forcing the oscillator to

its minimum frequency.

INTV

/EXTVCC Power

CC

Power for all power MOSFET drivers and most internal circuitry is derived from the INTV

EXTV

regulator supplies INTV

pin is left open, an internal 6V low dropout linear

CC

power. If EXTVCC is taken above

CC

pin. When the

CC

5.7V, the 6V regulator is turned off and an internal switch

is turned on, connecting EXTV

the INTV

power to be derived from a high effi ciency

CC

to INTVCC. This allows

CC

external source.

POWER GOOD (PGOOD) PIN

The PGOOD pin is connected to an open drain of an internal

MOSFET. The MOSFET turns on and pulls the pin low when

the output is not within ±7.5% of the nominal output level

as determined by the resistive feedback divider. When

the output meets the ±7.5% requirement, the MOSFET

is turned off and the pin is allowed to be pulled up by an

external resistor to a source of up to 7V.

14

3780fe

Page 15

OPERATION

LTC3780

FOLDBACK CURRENT

Foldback current limiting is activated when the output

voltage falls below 70% of its nominal level, reducing

power waste. During start-up, foldback current limiting

is disabled.

INPUT UNDERVOLTAGE RESET

The SS capacitor will be reset if the input voltage is allowed to fall below approximately 4V. The SS capacitor

will attempt to charge through a normal soft-start ramp

after the input voltage rises above 4V.

OUTPUT OVERVOLTAGE PROTECTION

An overvoltage comparator guards against transient overshoots (>7.5%) as well as other more serious conditions

that may overvoltage the output. In this case, synchronous

switch B and synchronous switch D are turned on until the

overvoltage condition is cleared or the maximum negative

current limit is reached. When inductor current is lower

than the maximum negative current limit, synchronous

switch B and synchronous switch D are turned off, and

switch A and switch C are turned on until the inductor

current reaches another negative current limit. If the

comparator still detects an overvoltage condition, switch

A and switch C are turned off, and synchronous switch B

and synchronous switch D are turned on again.

SHORT-CIRCUIT PROTECTION AND CURRENT LIMIT

Switch A on-time is limited by output voltage. When output

voltage is reduced and is lower than its nominal level,

switch A on-time will be reduced.

In every boost mode cycle, current is limited by a voltage

reference, which is proportional to the I

maximum sensed current is limited to 160mV. In every

buck mode cycle, the maximum sensed current is limited

to 130mV.

STANDBY MODE PIN

The STBYMD pin is a three-state input that controls circuitry

within the IC as follows: When the STBYMD pin is held at

ground, the SS pin is pulled to ground. When the pin is

left open, the internal SS current source charges the SS

capacitor, allowing turn-on of the controller and activating necessary internal biasing. When the STBYMD pin is

taken above 2V, the internal linear regulator is turned on

independent of the state on the RUN and SS pins, providing

an output power source for “wake-up” circuitry. Bypass

the pin with a small capacitor (0.1μF) to ground if the pin

is not connected to a DC potential.

pin voltage. The

TH

3780fe

15

Page 16

LTC3780

APPLICATIONS INFORMATION

Figure 11 is a basic LTC3780 application circuit. External

component selection is driven by the load requirement,

and begins with the selection of R

value. Next, the power MOSFETs are selected. Finally, C

and C

are selected. This circuit can be confi gured for

OUT

and the inductor

SENSE

IN

operation up to an input voltage of 36V.

Selection of Operation Frequency

The LTC3780 uses a constant frequency architecture and

has an internal voltage controlled oscillator. The switching

frequency is determined by the internal oscillator capacitor.

This internal capacitor is charged by a fi xed current plus

an additional current that is proportional to the voltage

applied to the PLLFLTR pin. The frequency of this oscillator

can be varied over a 2-to-1 range. The PLLFLTR pin can

be grounded to lower the frequency to 200kHz or tied to

2.4V to yield approximately 400kHz. When PLLIN is left

open, the PLLFLTR pin goes low, forcing the oscillator to

minimum frequency.

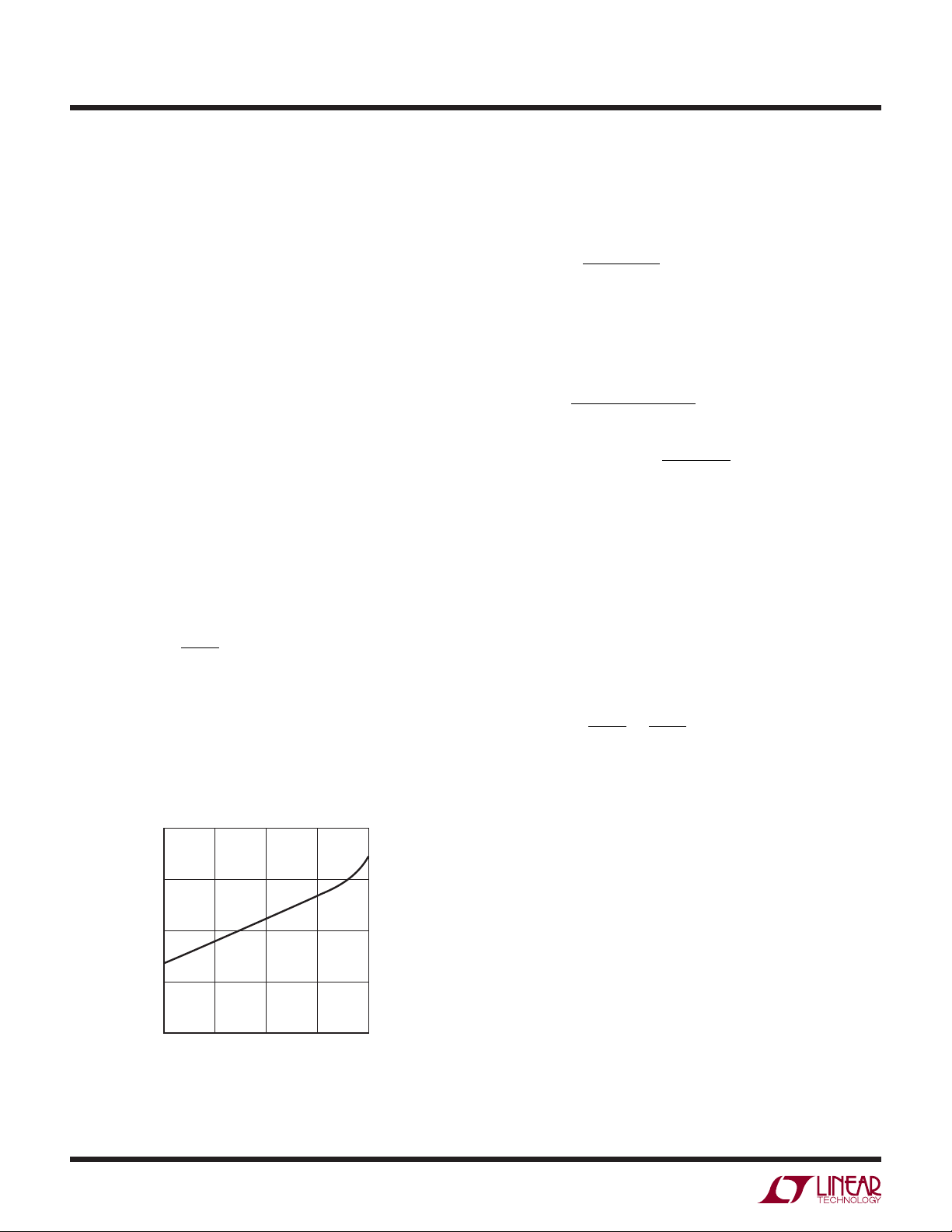

A graph for the voltage applied to the PLLFLTR pin vs

frequency is given in Figure 7. As the operating frequency

is increased the gate charge losses will be higher, reducing

effi ciency. The maximum switching frequency is approximately 400kHz.

450

400

350

300

250

200

150

100

OPERATING FREQUENCY (kHz)

50

0

0

0.5 1.5

1

PLLFLTR PIN VOLTAGE (V)

Figure 7. Frequency vs PLLFLTR Pin Voltage

2.5

2

3780 F07

Inductor Selection

The operating frequency and inductor selection are interrelated in that higher operating frequencies allow the use

of smaller inductor and capacitor values. The inductor

value has a direct effect on ripple current. The inductor

current ripple ΔI

maximum inductor current at boost mode V

is typically set to 20% to 40% of the

L

. For

IN(MIN)

a given ripple the inductance terms in continuous mode

are as follows:

2

•– •

IN MIN OUT IN MIN

() ()

•

ƒ

OUT IN MAX O

I Ripple V

OUT MAX IN MAX

()

I

MMAX OUT

OUT

(

•–

()

() ()

Ripple V

•% •

)

()

UUT

•

100

100

2

H

,

H

L

BOOST

L

BUCK

VVV

>

VV V

>

••%•

ƒ

where:

f is operating frequency, Hz

% Ripple is allowable inductor current ripple, %

V

V

V

I

OUT(MAX)

is minimum input voltage, V

IN(MIN)

IN(MAX)

OUT

is maximum input voltage, V

is output voltage, V

is maximum output load current

For high effi ciency, choose an inductor with low core loss,

such as ferrite and molypermalloy (from Magnetics, Inc.).

Also, the inductor should have low DC resistance to reduce

2

R losses, and must be able to handle the peak inductor

the I

current without saturating. To minimize radiated noise,

use a toroid, pot core or shielded bobbin inductor.

R

R

Selection and Maximum Output Current

SENSE

is chosen based on the required output current.

SENSE

The current comparator threshold sets the peak of the

inductor current in boost mode and the maximum inductor

valley current in buck mode. In boost mode, the maximum

average load current at V

IN(MIN)

is:

16

I

OUT MAX BOOST

(, )

⎛

⎜

⎝

160

R

SENSE

mV

Δ

L

–•=

⎟

2

⎠

IN

V

MMIN

(

OUT

)

3780fe

V

⎞

I

Page 17

APPLICATIONS INFORMATION

LTC3780

where ΔIL is peak-to-peak inductor ripple current. In buck

mode, the maximum average load current is:

I

OUT MAX BUCK

(, )

130

=+

R

SENSE

Figure 8 shows how the load current (I

L

2

MAXLOAD

• R

SENSE

)

I

Δ

mV

varies with input and output voltage

The maximum current sensing R

value for the boost

SENSE

mode is:

R

SENSE MAX

•

2

I

OUT MAX BOOS

The maximum current sensing R

=

()

2 160

(,

••

mV V

IN MIN

()

VI V

••+Δ

TT OUT L BOOST IN MIN

),()

value for the buck

SENSE

mode is:

R

SENSE MAX

The fi nal R

R

SENSE(MAX)

=

()

SENSE

•–

2 Δ

value should be lower than the calculated

2 130

II

OUT MAX BUCK L BUC

(, ) ,

in both the boost and buck modes. A 20% to

mV

KK

•

30% margin is usually recommended.

input square wave current. Use a low ESR capacitor sized

to handle the maximum RMS current. For buck operation,

the input RMS current is given by:

V

II

≈

RMS OUT MAX

()

OUT

•• –1

V

IN

This formula has a maximum at VIN = 2V

I

RMS

= I

OUT(MAX)

/2. This simple worst-case condition

V

V

IN

OUT

OUT

, where

is commonly used for design because even signifi cant

deviations do not offer much relief. Note that ripple current ratings from capacitor manufacturers are often based

on only 2000 hours of life which makes it advisable to

derate the capacitor.

In boost mode, the discontinuous current shifts from the

input to the output, so C

must be capable of reducing

OUT

the output voltage ripple. The effects of ESR (equivalent

series resistance) and the bulk capacitance must be

considered when choosing the right capacitor for a given

output ripple voltage. The steady ripple due to charging

and discharging the bulk capacitance is given by:

Ripple Boost Cap

(,)

IVV

OUT MAX OUT IN MIN

=

•–

() ()

()

CVf

••

OUT OUT

V

C

IN

and C

Selection

OUT

In boost mode, input current is continuous. In buck mode,

input current is discontinuous. In buck mode, the selection

of input capacitor C

160

150

(mV)

140

SENSE

130

• R

120

MAX(LOAD)

I

110

100

0.1

Figure 8. Load Current vs VIN/V

is driven by the need to fi lter the

IN

110

VIN/V

(V)

OUT

3780 F08

OUT

Ripple Buck Cap

(,)

where C

is the output fi lter capacitor.

OUT

IVV

OUT MAX IN MAX OUT

=

•–

() ()

()

CV f

••

OUT IN MAX

()

V

The steady ripple due to the voltage drop across the ESR

is given by:

ΔV

ΔV

BOOST,ESR

BUCK,ESR

= I

L(MAX,BOOST)

= I

L(MAX,BUCK)

• ESR

• ESR

Multiple capacitors placed in parallel may be needed to

meet the ESR and RMS current handling requirements.

Dry tantalum, special polymer, aluminum electrolytic and

ceramic capacitors are all available in surface mount

packages. Ceramic capacitors have excellent low ESR

characteristics but can have a high voltage coeffi cient.

Capacitors are now available with low ESR and high ripple

current ratings, such as OS-CON and POSCAP.

3780fe

17

Page 18

LTC3780

APPLICATIONS INFORMATION

Power MOSFET Selection and

Effi ciency Considerations

The LTC3780 requires four external N-channel power

MOSFETs, two for the top switches (switch A and D, shown

in Figure 1) and two for the bottom switches (switch B and C

shown in Figure 1). Important parameters for the power

MOSFETs are the breakdown voltage V

voltage V

GS,TH

capacitance C

, on-resistance R

and maximum current I

RSS

, reverse transfer

DS(ON)

BR,DSS

DS(MAX)

, threshold

.

The drive voltage is set by the 6V INTVCC supply. Consequently, logic-level threshold MOSFETs must be used

in LTC3780 applications. If the input voltage is expected

to drop below 5V, then the sub-logic threshold MOSFETs

should be considered.

In order to select the power MOSFETs, the power dissipated by the device must be known. For switch A, the

maximum power dissipation happens in boost mode, when

it remains on all the time. Its maximum power dissipation

at maximum output current is given by:

2

⎞

ρ

⎟

⎠

P

A BOOST

⎛

V

OUT

IR

⎜

⎝

•••=

OUT MAX T DS ON,()()

V

IN

Switch B operates in buck mode as the synchronous

rectifi er. Its power dissipation at maximum output current

is given by:

–

P

BBUCK

VV

IN OUT

V

IN

•••=

IR

OUT MAX T DS ON,()()

2

ρ

Switch C operates in boost mode as the control switch. Its

power dissipation at maximum current is given by:

–

VVV

()

OUT IN OUT

P

CBOOST

,()()

where C

=

+

kV

is usually specifi ed by the MOSFET manufactur-

RSS

2

V

IN

3

•• ••

OUT

•••

IR

OUT MAX T DS ON

I

OUT MAX

()

V

IN

2

ρ

Cf

RSS

ers. The constant k, which accounts for the loss caused

by reverse recovery current, is inversely proportional to

the gate drive current and has an empirical value of 1.7.

For switch D, the maximum power dissipation happens in

boost mode, when its duty cycle is higher than 50%. Its

maximum power dissipation at maximum output current

is given by:

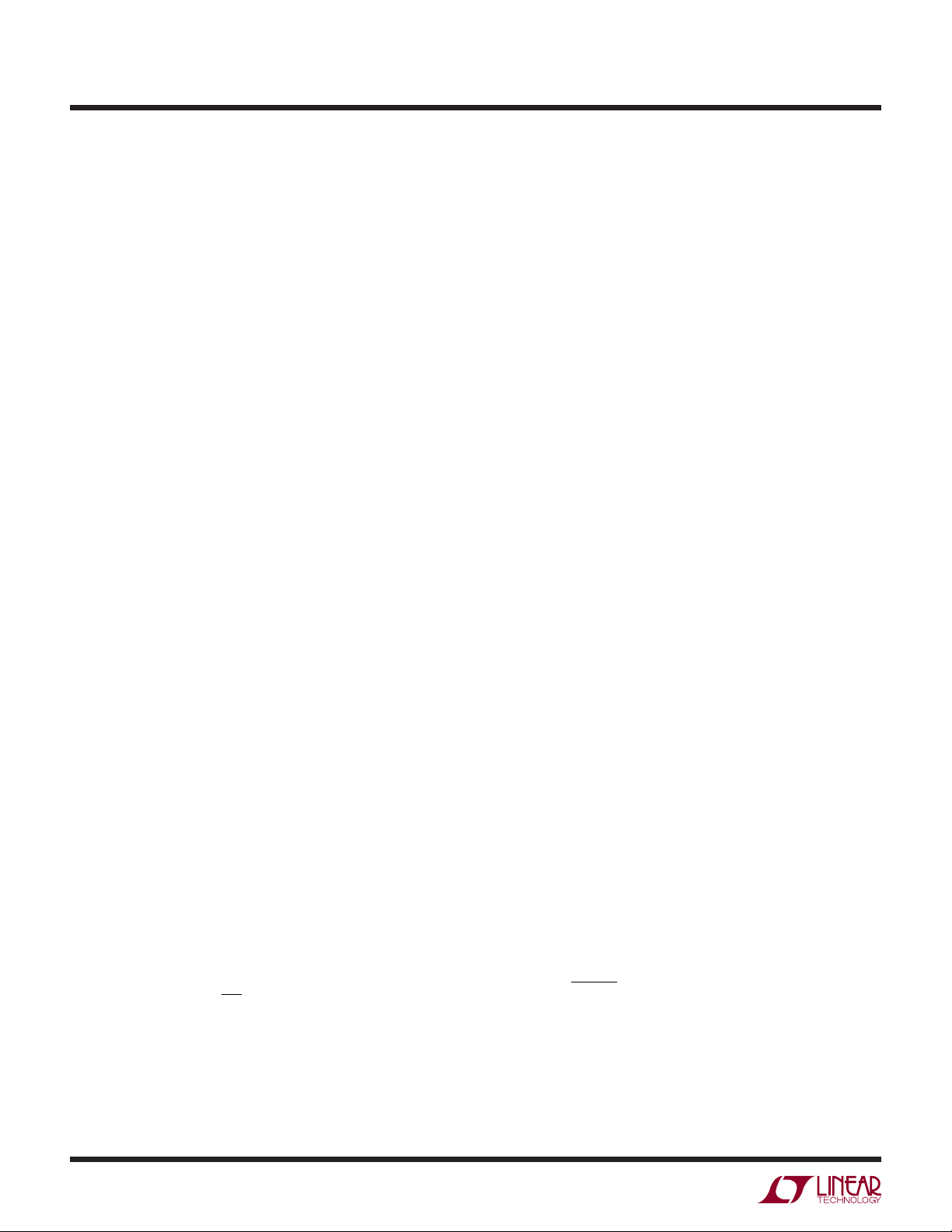

where ρT is a normalization factor (unity at 25°C) accounting for the signifi cant variation in on-resistance with

temperature, typically about 0.4%/°C as shown in Figure 9.

For a maximum junction temperature of 125°C, using a

value ρ

= 1.5 is reasonable.

T

2.0

1.5

1.0

0.5

NORMALIZED ON-RESISTANCE (Ω)

T

R

0

–50

Figure 9. Normalized R

0

JUNCTION TEMPERATURE (°C)

50

DS(ON)

100

vs Temperature

150

3780 F09

2

⎞

ρ

TTDSON

⎟

⎠

R•

()

P

D BOOST

V

V

IN

OUT

⎛

V

OUT

•• •=

⎜

⎝

I

OUT MAX,()

V

IN

For the same output voltage and current, switch A has the

highest power dissipation and switch B has the lowest

power dissipation unless a short occurs at the output.

From a known power dissipated in the power MOSFET, its

junction temperature can be obtained using the following

formula:

= TA + P • R

T

J

The R

TH(JA)

the R

TH(JC)

the case to the ambient temperature (R

can then be compared to the original, assumed value

of T

J

TH(JA)

to be used in the equation normally includes

for the device plus the thermal resistance from

). This value

TH(JC)

used in the iterative calculation process.

3780fe

18

Page 19

APPLICATIONS INFORMATION

LTC3780

Schottky Diode (D1, D2) Selection

and Light Load Operation

The Schottky diodes D1 and D2 shown in Figure 1 conduct

during the dead time between the conduction of the power

MOSFET switches. They are intended to prevent the body

diode of synchronous switches B and D from turning on

and storing charge during the dead time. In particular, D2

signifi cantly reduces reverse recovery current between

switch D turn-off and switch C turn-on, which improves

converter effi ciency and reduces switch C voltage stress.

In order for the diode to be effective, the inductance

between it and the synchronous switch must be as small

as possible, mandating that these components be placed

adjacently.

In buck mode, when the FCB pin voltage is 0.85 < V

FCB

< 5V, the converter operates in skip-cycle mode. In this

mode, synchronous switch B remains off until the inductor peak current exceeds one-fi fth of its maximum peak

current. As a result, D1 should be rated for about one-half

to one-third of the full load current.

In boost mode, when the FCB pin voltage is higher than

5.3V, the converter operates in discontinuous current mode.

In this mode, synchronous switch D remains off until the

inductor peak current exceeds one-fi fth of its maximum

peak current. As a result, D2 should be rated for about

one-third to one-fourth of the full load current.

In buck mode, when the FCB pin voltage is higher than 5.3V,

the converter operates in constant frequency discontinuous current mode. In this mode, synchronous switch B

remains on until the inductor valley current is lower than

the sense voltage representing the minimum negative

inductor current level (V

= –5mV). Both switch A

SENSE

and B are off until next clock signal.

In boost mode, when the FCB pin voltage is 0.85 < V

FCB

< 5.3V, the converter operates in Burst Mode operation.

In this mode, the controller clamps the peak inductor

current to approximately 20% of the maximum inductor

current. The output voltage ripple can increase during

Burst Mode operation.

INTV

Regulator

CC

An internal P-channel low dropout regulator produces 6V

at the INTV

pin from the VIN supply pin. INTVCC powers

CC

the drivers and internal circuitry within the LTC3780. The

INTV

pin regulator can supply a peak current of 40mA

CC

and must be bypassed to ground with a minimum of 4.7μF

tantalum, 10μF special polymer or low ESR type electrolytic

capacitor. A 1μF ceramic capacitor placed directly adjacent

to the INTV

and PGND IC pins is highly recommended.

CC

Good bypassing is necessary to supply the high transient

current required by MOSFET gate drivers.

Higher input voltage applications in which large MOSFETs

are being driven at high frequencies may cause the maximum junction temperature rating for the LTC3780 to be

exceeded. The system supply current is normally dominated

by the gate charge current. Additional external loading of

the INTV

power dissipation calculations. The total INTV

also needs to be taken into account for the

CC

current

CC

can be supplied by either the 6V internal linear regulator

or by the EXTV

the EXTV

CC

input pin. When the voltage applied to

CC

pin is less than 5.7V, all of the INTVCC current

is supplied by the internal 6V linear regulator. Power dissipation for the IC in this case is V

IN

• I

INTVCC

, and overall

effi ciency is lowered. The junction temperature can be

estimated by using the equations given in Note 2 of the

Electrical Characteristics. For example, a typical application

operating in continuous current mode might draw 24mA

from a 24V supply when not using the EXTV

= 70°C + 24mA • 24V • 34°C/W = 90°C

T

J

Use of the EXTV

input pin reduces the junction tem-

CC

CC

pin:

perature to:

= 70°C + 24mA • 6V • 34°C/W = 75°C

T

J

To prevent maximum junction temperature from being

exceeded, the input supply current must be checked

operating in continuous mode at maximum V

IN

.

3780fe

19

Page 20

LTC3780

APPLICATIONS INFORMATION

EXTVCC Connection

The LTC3780 contains an internal P-channel MOSFET

switch connected between the EXTV

When the voltage applied to EXTV

and INTVCC pins.

CC

rises above 5.7V, the

CC

internal regulator is turned off and a switch connects the

EXTV

pin to the INTVCC pin thereby supplying internal

CC

power. The switch remains closed as long as the voltage

applied to EXTV

remains above 5.5V. This allows the

CC

MOSFET driver and control power to be derived from the

output when (5.7V < V

< 7V) and from the internal

OUT

regulator when the output is out of regulation (start-up,

short-circuit). If more current is required through the

EXTV

diode can be interposed between the EXTV

pins. Ensure that EXTV

switch than is specifi ed, an external Schottky

CC

and INTVCC

CC

≤ VIN.

CC

The following list summarizes the three possible connections for EXTV

1. EXTV

CC

:

CC

left open (or grounded). This will cause INTVCC

to be powered from the internal 6V regulator at the cost

of a small effi ciency penalty.

2. EXTV

connected directly to V

CC

(5.7V < V

OUT

OUT

< 7V).

This is the normal connection for a 6V regulator and

provides the highest effi ciency.

3. EXTV

connected to an external supply. If an external

CC

supply is available in the 5.5V to 7V range, it may be

used to power EXTV

provided it is compatible with

CC

the MOSFET gate drive requirements.

Output Voltage

The LTC3780 output voltage is set by an external feedback

resistive divider carefully placed across the output capacitor.

The resultant feedback signal is compared with the internal

precision 0.800V voltage reference by the error amplifi er.

The output voltage is given by the equation:

VV

=+

08 1

OUT

.•

⎛

⎜

⎝

⎞

⎟

⎠

R

1

R

2

Topside MOSFET Driver Supply (CA, DA, CB, DB)

Referring to Figure 11, the external bootstrap capacitors

and CB connected to the BOOST1 and BOOST2 pins

C

A

supply the gate drive voltage for the topside MOSFET

switches A and D. When the top MOSFET switch A turns

on, the switch node SW2 rises to V

pin rises to approximately V

+ INTVCC. When the bottom

IN

and the BOOST2

IN

MOSFET switch B turns on, the switch node SW2 drops

to low and the boost capacitor C

from INTV

. When the top MOSFET switch D turns on,

CC

the switch node SW1 rises to V

rises to approximately V

OUT

is charged through DB

B

and the BOOST1 pin

OUT

+ INTVCC. When the bottom

MOSFET switch C turns on, the switch node SW1 drops

to low and the boost capacitor C

from INTV

. The boost capacitors CA and CB need to

CC

is charged through DA

A

store about 100 times the gate charge required by the top

MOSFET switch A and D. In most applications a 0.1μF to

0.47μF, X5R or X7R dielectric capacitor is adequate.

Run Function

The RUN pin provides simple ON/OFF control for the

LTC3780. Driving the RUN pin above 1.5V permits the

controller to start operating. Pulling RUN below 1.5V puts

the LTC3780 into low current shutdown. Do not apply more

than 6V to the RUN pin.

Soft-Start Function

Soft-start reduces the input power sources’ surge currents by gradually increasing the controller’s current

limit (proportional to an internally buffered and clamped

equivalent of V

An internal 1.2μA current source charges up the C

ITH

).

SS

capacitor. As the voltage on SS increases from 0V to

2.4V, the internal current limit rises from 0V/R

150mV/R

. The output current limit ramps up slowly,

SENSE

SENSE

to

taking 1.5s/μF to reach full current. The output current thus

ramps up slowly, eliminating the starting surge current

required from the input power supply.

24

.

V

T

=

IRMP SS SS

12

•./•

.

CsFC

A

μ

15

=μ

()

Do not apply more than 6V to the SS pin.

Current foldback is disabled during soft-start until the

voltage on C

reaches 2V. Make sure CSS is large enough

SS

when there is loading during start-up.

20

3780fe

Page 21

APPLICATIONS INFORMATION

LTC3780

The Standby Mode (STBYMD) Pin Function

The standby mode (STBYMD) pin provides several choices

for start-up and standby operational modes. If the pin is

pulled to ground, the SS pin is internally pulled to ground,

preventing start-up and thereby providing a single control

pin for turning off the controller. If the pin is left open or

bypassed to ground with a capacitor, the SS pin is internally

provided with a starting current, permitting external control

for turning on the controller. If the pin is connected to a

voltage greater than 1.25V, the internal regulator (INTV

CC

)

will be on even when the controller is shut down (RUN

pin voltage < 1.5V). In this mode, the onboard 6V linear

regulator can provide power to keep-alive functions such

as a keyboard controller.

Fault Conditions: Current Limit and Current Foldback

The maximum inductor current is inherently limited in a

current mode controller by the maximum sense voltage.

In boost mode, maximum sense voltage and the sense

resistance determines the maximum allowed inductor

peak current, which is:

mV

I

L MAX BOOST

(, )

=

160

R

SENSE

In buck mode, maximum sense voltage and the sense

resistance determines the maximum allowed inductor

valley current, which is:

Fault Conditions: Overvoltage Protection

A comparator monitors the output for overvoltage conditions. The comparator (OV) detects overvoltage faults

greater than 7.5% above the nominal output voltage.

When the condition is sensed, switches A and C are

turned off, and switches B and D are turned on until the

overvoltage condition is cleared. During an overvoltage

condition, a negative current limit (V

= –60mV) is

SENSE

set to limit negative inductor current. When the sensed

current inductor current is lower than –60mV, switch A and

C are turned on, and switch B and D are turned off until

the sensed current is higher than –20mV. If the output is

still in overvoltage condition, switch A and C are turned

off, and switch B and D are turned on again.

Effi ciency Considerations

The percent effi ciency of a switching regulator is equal to

the output power divided by the input power times 100%.

It is often useful to analyze individual losses to determine

what is limiting the effi ciency and which change would

produce the most improvement. Although all dissipative

elements in circuit produce losses, four main sources

account for most of the losses in LTC3780 circuits:

2

1. DC I

R losses. These arise from the resistances of the

MOSFETs, sensing resistor, inductor and PC board

traces and cause the effi ciency to drop at high output

currents.

mV

I

L MAX BUCK

(, )

=

130

R

SENSE

To further limit current in the event of a short circuit to

ground, the LTC3780 includes foldback current limiting.

If the output falls by more than 30%, then the maximum

sense voltage is progressively lowered to about one third

of its full value.

2. Transition loss. This loss arises from the brief amount

of time switch A or switch C spends in the saturated

region during switch node transitions. It depends upon

the input voltage, load current, driver strength and

MOSFET capacitance, among other factors. The loss

is signifi cant at input voltages above 20V and can be

estimated from:

Transition Loss ≈ 1.7A

where C

is the reverse transfer capacitance.

RSS

IN2

OUT

• C

RSS

• f

3780fe

–1

• V

• I

21

Page 22

LTC3780

APPLICATIONS INFORMATION

3. INTVCC current. This is the sum of the MOSFET driver

and control currents. This loss can be reduced by supplying INTV

current through the EXTVCC pin from a

CC

high effi ciency source, such as an output derived boost

network or alternate supply if available.

4. C

and C

IN

loss. The input capacitor has the diffi cult

OUT

job of fi ltering the large RMS input current to the regulator in buck mode. The output capacitor has the more

diffi cult job of fi ltering the large RMS output current

in boost mode. Both C

and C

IN

low ESR to minimize the AC I

are required to have

OUT

2

R loss and suffi cient

capacitance to prevent the RMS current from causing

additional upstream losses in fuses or batteries.

5. Other losses. Schottky diode D1 and D2 are responsible for conduction losses during dead time and light

load conduction periods. Inductor core loss occurs

predominately at light loads. Switch C causes reverse

recovery current loss in boost mode.

When making adjustments to improve effi ciency, the input

current is the best indicator of changes in effi ciency. If you

make a change and the input current decreases, then the

effi ciency has increased. If there is no change in input

current, then there is no change in effi ciency.

The highest value of ripple current occurs at the maximum

input voltage. In boost mode, the ripple current is:

⎛

V

Δ=

I

L BOOST

,

I

RIPPLE BOOST

,

IN IN

•–1

⎜

⎝

fL

•

Δ 100

I

L BOOST

,

I

The highest value of ripple current occurs at VIN = V

⎞

V

⎟

⎠

V

OUT

•

%=

IN

/2.

OUT

A 6.8μH inductor will produce 11% ripple in boost mode

= 6V) and 29% ripple in buck mode (VIN = 18V).

(V

IN

The R

resistor value can be calculated by using the

SENSE

maximum current sense voltage specifi cation with some

accommodation for tolerances.

R

SENSE

=

2

Select an R

••

IV

••

(, )

OUT MAX BOOST O

of 10mΩ.

SENSE

()

IN MIN

IV+Δ

UUT L BOOST IN MIN

,()

•

mV V

2 160

Output voltage is 12V. Select R1 as 20k. R2 is:

VR

R

OUT

2

08

.

1

•

R

1=

–

Design Example

As a design example, assume V

= 12V (5%), I

V

OUT

OUT(MAX)

= 5V to 18V (12V nominal),

IN

= 5A and f = 400kHz.

Set the PLLFLTR pin at 2.4V for 400kHz operation. The

inductance value is chosen fi rst based on a 30% ripple

current assumption. In buck mode, the ripple current is:

Δ=

I

LBUCK

,

I

RIPPLE BUCK

,

V

⎛

OUT OUT

•–1

⎜

fL

•

⎝

Δ 100

I

LBUCK

,

I

OUT

⎞

V

⎟

V

⎠

IN

•

%=

Select R2 as 280k. Both R1 and R2 should have a tolerance of no more than 1%.

Next, choose the MOSFET switches. A suitable choice is

the Siliconix Si4840 (R

= 150pF, θJA = 40°C/W).

C

RSS

= 0.009Ω (at VGS = 6V),

DS(ON)

The maximum power dissipation of switch A occurs in

boost mode when switch A stays on all the time. Assuming a junction temperature of T

1.5, the power dissipation at V

12

PW

A BOOST,

⎛

⎜

⎝

2

⎞

••.•. .=

5 1 5 0 009 1 94

⎟

⎠

5

= 150°C with ρ

J

= 5V is:

IN

=

150°C

3780fe

=

22

Page 23

APPLICATIONS INFORMATION

LTC3780

Double-check the TJ in the MOSFET with 70°C ambient

temperature:

= 70°C + 1.94W • 40°C/W = 147.6°C

T

J

The maximum power dissipation of switch B occurs in buck

mode. Assuming a junction temperature of T

= 1.2, the power dissipation at VIN = 18V is:

ρ

80°C

–

PmW

BBUCK,

18 12

18

2

••.•.==

5 1 2 0 009 90

= 80°C with

J

Double-check the TJ in the MOSFET at 70°C ambient

temperature:

= 70°C + 0.09W • 40°C/W = 73.6°C

T

J

The maximum power dissipation of switch C occurs in boost

mode. Assuming a junction temperature of T

= 1.4, the power dissipation at VIN = 5V is:

ρ

110°C

12 5 12

–•

()

P

C BOOST,

=

+

212

•••

2

5

3

2

5 1 4 0 009

••.•.

5

1150 400 1 27pk W•.=

5

= 110°C with

J

Double-check the TJ in the MOSFET at 70°C ambient

temperature:

C

is chosen to fi lter the square current in buck mode. In

IN

this mode, the maximum input current peak is:

IA

IN PEAK MAX BUCK,(, )

⎛

•

⎜

⎝

A low ESR (10mΩ) capacitor is selected. Input voltage

ripple is 57mV (assuming ESR dominate ripple).

is chosen to fi lter the square current in boost mode.

C

OUT

In this mode, the maximum output current peak is:

I

OUT PEAK MAX BOOST,(, )