Page 1

LT3092

200mA 2-Terminal

Programmable Current Source

FEATURES

n

Programmable 2-Terminal Current Source

n

Maximum Output Current: 200mA

n

Wide Input Voltage Range: 1.2V to 40V

n

Input/Output Capacitors Not Required

n

Resistor Ratio Sets Output Current

n

Initial Set Pin Current Accuracy: 1%

n

Reverse-Voltage Protection

n

Reverse-Current Protection

n

<0.001%/V Line Regulation Typical

n

Current Limit and Thermal Shutdown Protection

n

Available in 8-Lead SOT-23, 3-Lead SOT-223 and

8-Lead 3mm × 3mm DFN Packages

APPLICATIONS

n

2-Terminal Floating Current Source

n

GND Referred Current Source

n

Variable Current Source

n

In-Line Limiter

n

Intrinsic Safety Circuits

DESCRIPTION

The LT®3092 is a programmable 2-terminal current

source. It requires only two resistors to set an output

current between 0.5mA and 200mA. A multitude of analog

techniques lend themselves to actively programming the

output current. The LT3092 is stable without input and

output capacitors, offering high DC and AC impedance. This

feature allows operation in intrinsically safe applications.

The SET pin features 1% initial accuracy and low temperature coeffi cient. Current regulation is better than

10ppm/V from 1.5V to 40V.

The LT3092 can operate in a 2-terminal current source

confi guration in series with signal lines. It is ideal for driving sensors, remote supplies, and as a precision current

limiter for local supplies.

Internal protection circuitry includes reverse-battery and

reverse-current protection, current limiting and thermal

limiting. The LT3092 is offered in the 8-lead TSOT-23,

3-lead SOT-223 and 8-lead 3mm × 3mm DFN packages.

L, LT, LTC, LTM, Linear Technology and the Linear logo are registered trademarks of Linear

Technology Corporation. All other trademarks are the property of their respective owners.

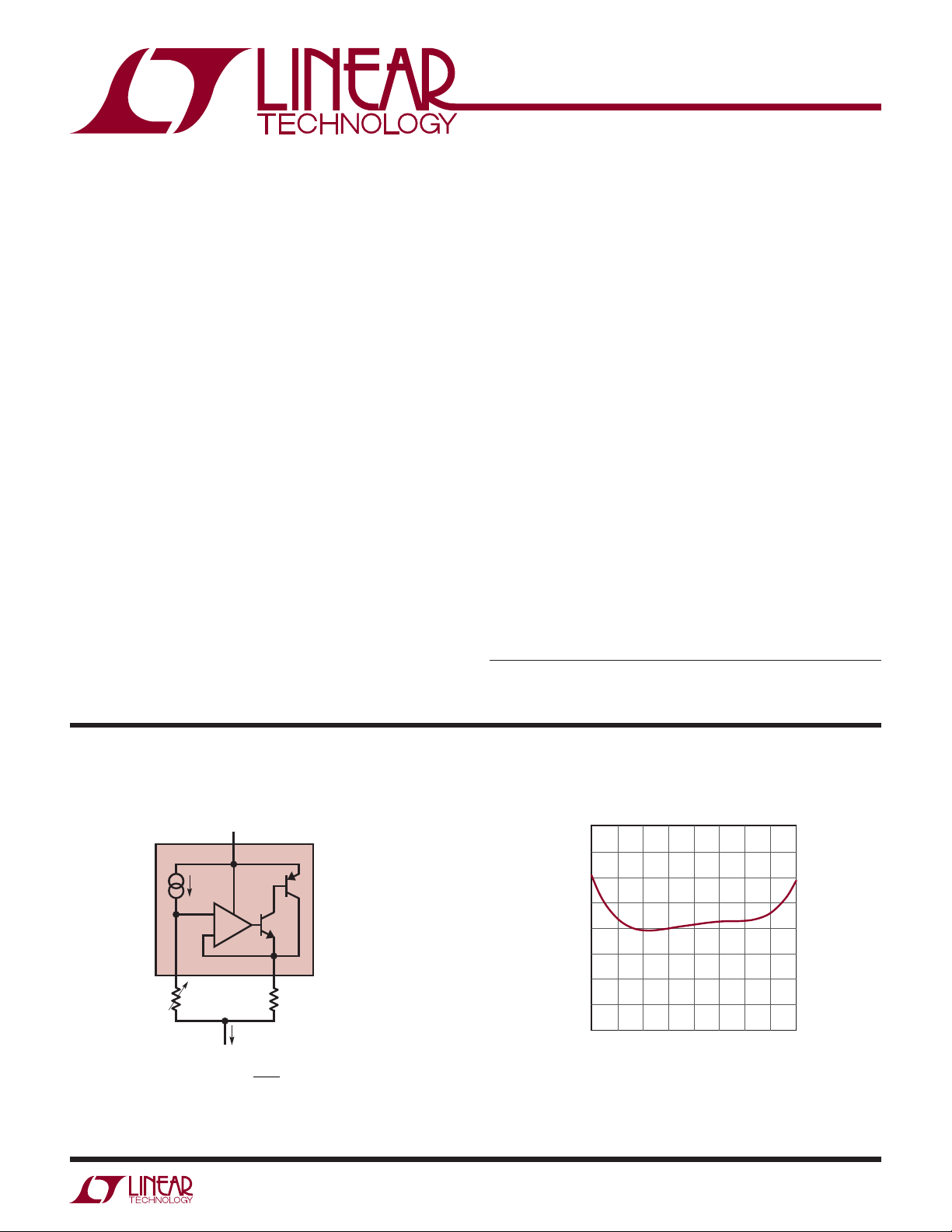

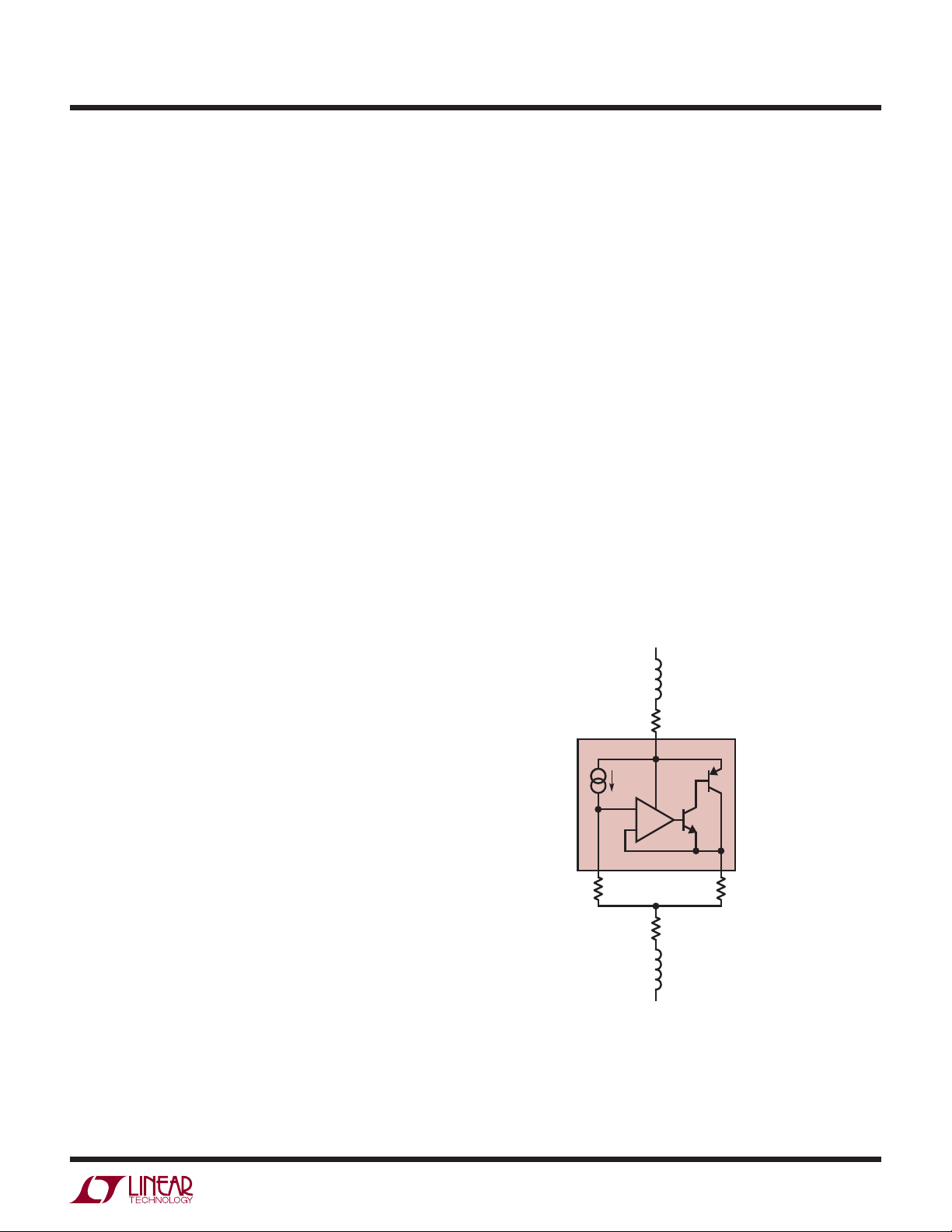

TYPICAL APPLICATION

Adjustable 2-Terminal Current Source

VIN – V

LT3092

IµA

SOURCE

= 1.2V TO 40V

OUT

IN

10µA

+

–

SET OUT

R

SET

= 10 •

R

R

SET

R

OUT

OUT

3092 TA01a

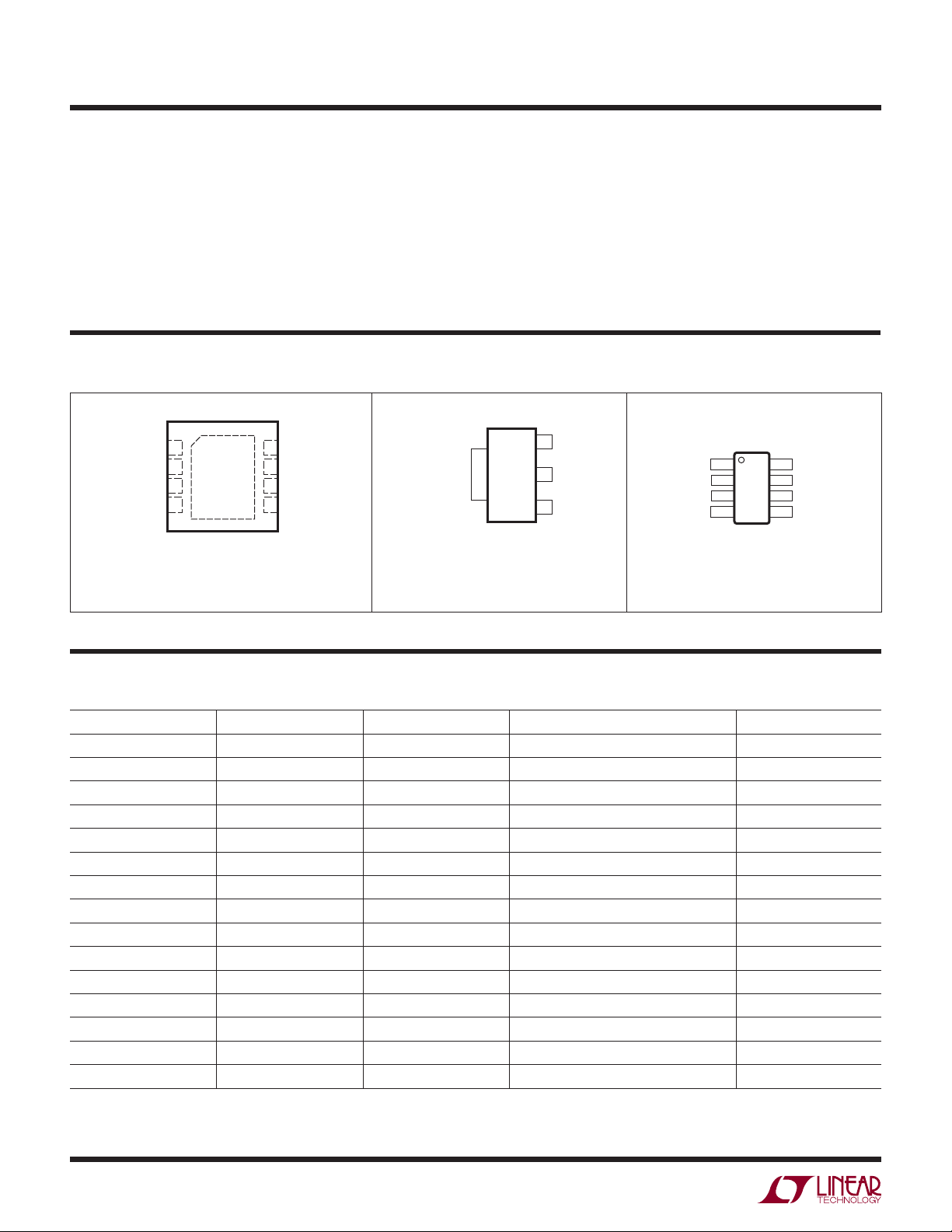

SET Pin Current vs Temperature

10.100

10.075

10.050

10.025

10.000

9.975

SET PIN CURRENT (µA)

9.950

9.925

9.900

–50

–25

25 50 10075 125

0

TEMPERATURE (°C)

150

3092 TA01b

3092fb

1

Page 2

LT3092

ABSOLUTE MAXIMUM RATINGS

(Note 1) All Voltages Relative to V

IN Pin Voltage Relative to SET, OUT ........................±40V

SET Pin Current (Note 6) .....................................±15mA

SET Pin Voltage (Relative to OUT, Note 6) ...............±10V

Output Short-Circuit Duration .......................... Indefi nite

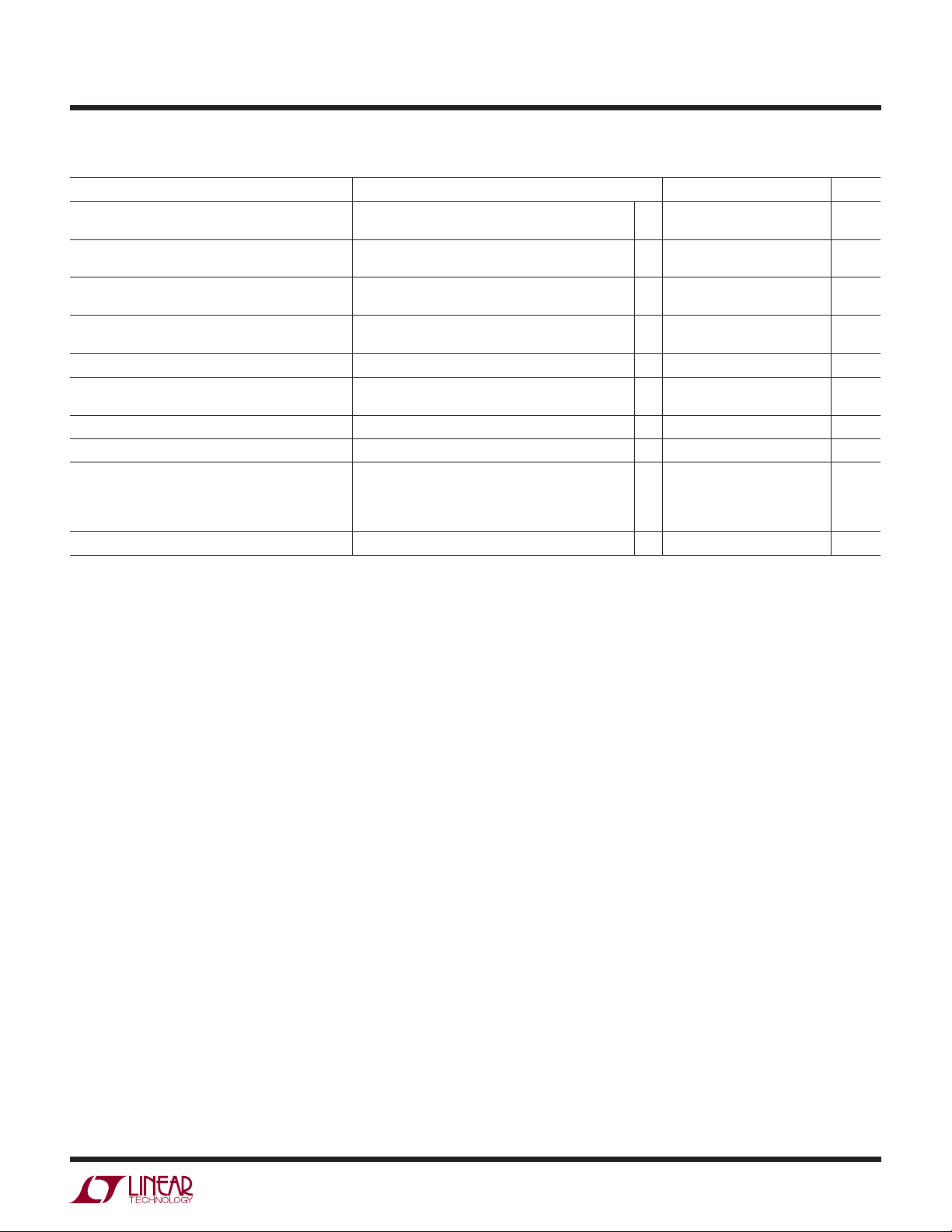

PIN CONFIGURATION

TOP VIEW

1OUT

OUT

2

NC

3

SET

4

8-LEAD (3mm s 3mm) PLASTIC DFN

T

= 125°C, θJA = 28°C/W, θJC = 10°C/W

JMAX

EXPOSED PAD (PIN 9) IS OUT, MUST BE SOLDERED TO OUT

ON THE PCB. SEE THE APPLICATIONS INFORMATION SECTION.

9

DD PACKAGE

8

IN

IN

7

NC

6

NC

5

TAB IS OUT

T

= 125°C, θJA = 24°C/W, θJC = 15°C/W

JMAX

TAB IS OUT, MUST BE SOLDERED TO OUT ON THE PCB.

SEE THE APPLICATIONS INFORMATION SECTION.

OUT

Operating Junction Temperature Range (Notes 2, 8)

E, I Grades ......................................... –40°C to 125°C

MP Grade ........................................... –55°C to 125°C

Storage Temperature Range ................... –65°C to 150°C

Lead Temperature (ST, TS8 Packages Only)

Soldering, 10 sec .............................................. 300°C

TOP VIEW

3

2

1

ST PACKAGE

3-LEAD PLASTIC SOT-223

IN

OUT

SET

T

OUT 2

OUT 3

OUT 4

JMAX

TOP VIEW

NC 1

TS8 PACKAGE

8-LEAD PLASTIC TSOT-23

= 125°C, θJA = 57°C/W, θJC = 15°C/W

8 IN

7 IN

6 NC

5 SET

ORDER INFORMATION

LEAD FREE FINISH TAPE AND REEL PART MARKING* PACKAGE DESCRIPTION TEMPERATURE RANGE

LT3092EDD#PBF LT3092EDD#TRPBF LFJD

LT3092IDD#PBF LT3092IDD#TRPBF LFJD

8-Lead (3mm × 3mm) Plastic DFN

8-Lead (3mm × 3mm) Plastic DFN

LT3092EST#PBF LT3092EST#TRPBF 3092 3-Lead Plastic SOT-223 –40°C to 125°C

LT3092IST#PBF LT3092IST#TRPBF 3092 3-Lead Plastic SOT-223 –40°C to 125°C

LT3092MPST#PBF LT3092MPST#TRPBF 3092MP 3-Lead Plastic SOT-223 –55°C to 125°C

LT3092ETS8#PBF LT3092ETS8#TRPBF LTFJW 8-Lead Plastic SOT-23 –40°C to 125°C

LT3092ITS8#PBF LT3092ITS8#TRPBF LTFJW 8-Lead Plastic SOT-23 –40°C to 125°C

LEAD BASED FINISH TAPE AND REEL PART MARKING* PACKAGE DESCRIPTION TEMPERATURE RANGE

LT3092EDD LT3092EDD#TR LFJD

LT3092IDD LT3092IDD#TR LFJD

8-Lead (3mm × 3mm) Plastic DFN

8-Lead (3mm × 3mm) Plastic DFN

LT3092EST LT3092EST#TR 3092 3-Lead Plastic SOT-223 –40°C to 125°C

LT3092IST LT3092IST#TR 3092 3-Lead Plastic SOT-223 –40°C to 125°C

LT3092MPST LT3092MPST#TR 3092MP 3-Lead Plastic SOT-223 –55°C to 125°C

LT3092ETS8 LT3092ETS8#TR LTFJW 8-Lead Plastic SOT-23 –40°C to 125°C

LT3092ITS8 LT3092ITS8#TR LTFJW 8-Lead Plastic SOT-23 –40°C to 125°C

Consult LTC Marketing for parts specifi ed with wider operating temperature ranges. *The temperature grade is identifi ed by a label on the shipping container.

For more information on lead free part marking, go to:

For more information on tape and reel specifi cations, go to:

http://www.linear.com/leadfree/

http://www.linear.com/tapeandreel/

–40°C to 125°C

–40°C to 125°C

–40°C to 125°C

–40°C to 125°C

3092fb

2

Page 3

LT3092

ELECTRICAL CHARACTERISTICS

The l denotes the specifi cations which apply over the full operating

temperature range, otherwise specifi cations are at T

PARAMETER CONDITIONS MIN TYP MAX UNITS

SET Pin Current I

Offset Voltage (V

OUT

– V

) V

SET

Current Regulation (Note 7) ∆I

∆V

Line Regulation ∆I

∆V

Minimum Load Current (Note 3) 2V ≤ V

Dropout Voltage (Note 4) I

Current Limit VIN = 5V, V

Reference Current RMS Output Noise (Note 5) 10Hz ≤ f ≤ 100kHz 0.7 nA

Ripple Rejection f = 120Hz, V

Thermal Regulation I

SET

OS

SET

OS

SET

OS

SET

= 25°C. (Note 2)

J

VIN = 2V, I

2V ≤ V

VIN = 2V, I

V

= 2V, I

IN

∆I

LOAD

∆I

LOAD

∆VIN = 2V to 40V, I

∆V

= 2V to 40V, I

IN

= 10mA

LOAD

I

= 200mA

LOAD

C

= 0.1µF, C

SET

f = 10kHz

f = 1MHz

= 1mA

LOAD

≤ 40V, 1mA ≤ I

IN

= 1mA

LOAD

= 1mA

LOAD

= 1mA to 200mA

= 1mA to 200mA

LOAD

LOAD

≤ 40V

IN

= 0V, V

SET

RIPPLE

OUT

OUT

= 0.5V

= 2.2µF

LOAD

= 1mA

= 1mA

= –0.1V

, I

P-P

≤ 200mA

= 0.1A,

LOAD

9.9

l

9.8

10

10

10.1

10.2

–2

l

–4

–0.1

l

l

l

l

l

200 300 mA

–0.5 –2

0.03

0.003

0.2

0.010

300 500 µA

1.22

1.3

1.45

1.65

90

75

20

µA

µA

2

4

mV

mV

nA

mV

nA/V

mV/V

RMS

dB

dB

dB

10ms Pulse 0.003 %/ W

V

V

Note 1: Stresses beyond those listed under Absolute Maximum Ratings

may cause permanent damage to the device. Exposure to any Absolute

Maximum Rating condition for extended periods may affect device

reliability and lifetime.

Note 2: Unless otherwise specifi ed, all voltages are with respect to V

OUT

.

The LT3092E is tested and specifi ed under pulse load conditions such

that T

≅ TA. The LT3092E is 100% tested at TA = 25°C. Performance at

J

–40°C and 125°C is assured by design, characterization, and correlation

with statistical process controls. The LT3092I is guaranteed to meet all

data sheet specifi cations over the full –40°C to 125°C operating junction

temperature range. The LT3092MP is 100% tested and guaranteed over

the –55°C to 125°C operating junction temperature range.

Note 3: Minimum load current is equivalent to the quiescent current of

the part. Since all quiescent and drive current is delivered to the output

of the part, the minimum load current is the minimum current required to

maintain regulation.

Note 4: For the LT3092, dropout is specifi ed as the minimum input-tooutput voltage differential required supplying a given output current.

Note 5: Adding a small capacitor across the reference current resistor

lowers output noise. Adding this capacitor bypasses the resistor shot noise

and reference current noise (see the Applications Information section).

Note 6: Diodes with series 1k resistors clamp the SET pin to the OUT pin.

These diodes and resistors only carry current under transient overloads.

Note 7: Current regulation is Kelvin-sensed at the package.

Note 8: This IC includes overtemperature protection that protects the

device during momentary overload conditions. Junction temperature

exceeds the maximum operating junction temperature when

overtemperature protection is active. Continuous operation above the

specifi ed maximum operating junction temperature may impair device

reliability.

3092fb

3

Page 4

LT3092

TYPICAL PERFORMANCE CHARACTERISTICS

SET Pin Current SET Pin Current Distribution

10.100

10.075

10.050

10.025

10.000

9.975

SET PIN CURRENT (μA)

9.950

9.925

9.900

–50

–25 25

0

50

TEMPERATURE (°C)

75

100

125

150

3092 G01

N = 1326

9.80

9.90

SET PIN CURRENT DISTRIBUTION (µA)

Offset Voltage Distribution

N = 1326

–2

–1

VOS DISTRIBUTION (mV)

0

1

2

3092 G04

10

10.10

Offset Voltage

1.00

I

OUT

0.75

0.50

0.25

0

–0.25

OFFSET VOLTAGE (mV)

–0.50

–0.75

–1.00

0

Offset Voltage (V

2.0

1.5

1.0

0.5

0.0

–0.5

OFFSET VOLTAGE (mV)

–1.0

–1.5

10.20

3092 G02

= 1mA

5

10

INPUT-TO-OUTPUT VOLTAGE (V)

–2.0

–50

–25

15 20 3025 35

– V

OUT

25 50 10075 125

0

TEMPERATURE (°C)

40

3092 G05

SET

)

150

3092 G03

4

Offset Voltage

100

50

0

–50

–100

–150

–200

–250

OFFSET VOLTAGE (μV)

–300

–350

–400

0

50 150 200

100

LOAD CURRENT (mA)

3092 G06

Current Regulation

20

∆I

= 1mA TO 200mA

OUT

10

– V

V

0

–10

–20

–30

–40

WITH LOAD (nA)

–50

–60

CHANGE IN REFERENCE CURRENT

–70

–80

–50

= 3V

IN

OUT

–25 25

0

TEMPERATURE (oC)

50

125

100

75

150

3092 G07

3092fb

Page 5

TYPICAL PERFORMANCE CHARACTERISTICS

LT3092

Minimum Output Current

600

500

400

300

200

100

MINIMUM OUTPUT CURRENT (μA)

0

–50

–25 25

0

50

TEMPERATURE (°C)

Current Limit

400

350

300

250

200

150

CURRENT LIMIT (mA)

100

50

0

0

INPUT-TO-OUTPUT DIFFERENTIAL VOLTAGE (V)

Dropout Voltage Dropout Voltage

1.6

1.4

) (V)

OUT

– V

IN

DROPOUT VOLTAGE (V

125

100

75

150

3092 G08

1.2

1.0

0.8

0.6

0.4

0.2

0

0

TJ = –55°C

TJ = 25°C

TJ = 125°C

25

50

LOAD CURRENT (mA)

75 100 150125 175

200

3092 G09

1.4

1.2

) (V)

OUT

1.0

– V

IN

0.8

0.6

0.4

0.2

DROPOUT VOLTAGE (V

0

–50

–25 25

0

I

LOAD

I

LOAD

50

TEMPERATURE (°C)

75

= 200mA

= 100mA

100

125

150

3092 G10

Current Limit

500

450

400

350

300

250

200

150

CURRENT LIMIT (mA)

100

VIN = 7V

50

= 0V

V

TJ = 25°C

2

6810

4

3092 G11

OUT

0

–50

–25 25

0

TEMPERATURE (°C)

125

50

100

75

150

3092 G12

Line Transient Response Line Transient Response

8

6

4

2

INPUT VOLTAGE (V)

0

20

0

10

1mA CURRENT SOURCE

CONFIGURATION

40

30

50

TIME (µs)

1.5

1.0

OUTPUT CURRENT

0.5

DEVIATION (mA)

0

–0.5

–1.0

100

60

90

80

70

3092 G13

10

8

6

4

INPUT VOLTAGE (V)

2

0

20

10

10mA CURRENT SOURCE

CONFIGURATION

40

30

50

TIME (µs)

10

OUTPUT CURRENT

5

DEVIATION (mA)

0

–5

–10

100

60

90

80

70

3092 G14

3092fb

5

Page 6

LT3092

TYPICAL PERFORMANCE CHARACTERISTICS

8

6

4

2

INPUT VOLTAGE (V)

0

0

10

5

1mA CURRENT SOURCE

CONFIGURATION

20

15

25

TIME (µs)

Residual Output for Less Than

Minimum Output Current

800

SET PIN = 0V

700

600

500

400

300

OUTPUT VOLTAGE (mV)

200

100

0

0

V

IN

V

OUT

R

TEST

R

()

TEST

CURRENT (mA)

1.0

OUTPUT

0.5

0

50

35

VIN = 36V

VIN = 5V

45

40

3092 G15

20001000

3092 G17

30

8

6

4

2

INPUT VOLTAGE (V)

0

0

1G

100M

10M

1M

100k

10k

1k

OUTPUT IMPEDANCE ()

100

10

1

Turn-On ResponseTurn-On Response

10mA CURRENT SOURCE

CONFIGURATION

20

15

10

5

25

TIME (µs)

Output Impedance

I

= 1mA

SOURCE

I

=

SOURCE

10mA

I

= 100mA

SOURCE

100 1k 10k 100k 1M 10M10

FREQUENCY (Hz)

15

CURRENT (mA)

10

OUTPUT

5

0

50

30

45

40

35

3092 G16

3092 G18

6

Noise Spectral Density

100

10

1

REFERENCE CURRENT

0.1

NOISE SPECTRAL DENSITY (pA/√Hz)

0.01

FREQUENCY (Hz)

10k 100k10010 1k

3092 G19

3092fb

Page 7

LT3092

PIN FUNCTIONS

(DD/ST/TS8)

IN (Pins 7, 8/Pin 3/Pins 7, 8): Input. This pin supplies

power to bias internal circuitry and supply output load

current. For the device to operate properly and regulate,

the voltage on this pin must be 1.2V to 1.4V above the

OUT pin (depending on output load current—see the

dropout voltage specifi cations in the Electrical Characteristics table).

NC (Pins 3, 5, 6/NA/Pins 1, 6): No Connection. These

pins have no connection to internal circuitry and may be

tied to IN, OUT, GND or fl oated.

OUT (Pins 1, 2/Pin 2/Pins 2, 3, 4): Output. This is the

power output of the device. The minimum current source

value to which the LT3092 can be set is 0.5mA or the

device will not regulate.

BLOCK DIAGRAM

SET (Pin 4/Pin 1/Pin 5): Set. This pin is the error amplifi er’s noninverting input and also sets the operating bias

point of the circuit. A fi xed 10A current source fl ows out

of this pin. Two resistors program I

as a function of

OUT

the resistor ratio relative to 10A. Output current range

is 0.5mA to the maximum rated 200mA level.

Exposed Pad/Tab (Pin 9/Tab/NA): Output. The Exposed

Pad of the DFN package and the Tab of the SOT-223

package are tied internally to OUT. Tie them directly to

the OUT pins (Pins 1, 2/Pin 2) at the PCB. The amount

of copper area and planes connected to OUT determine

the effective thermal resistance of the packages (see the

Applications Information section).

SET

IN

10µA

+

–

OUT

3092 BD

3092fb

7

Page 8

LT3092

APPLICATIONS INFORMATION

Introduction

The LT3092 is a versatile IC that operates as a 2-terminal

programmable current source with the addition of only

two external resistors; no external bypass capacitors are

needed for stability.

The LT3092 is easy to use and has all the protection features expected in high performance products. Included

are reverse-voltage protection, reverse-current protection, short-circuit protection and thermal shutdown with

hysteresis.

The LT3092 operates with or without input and output

capacitors. The simplest current source application

requires only two discrete resistors to set a constant

output current up to 200mA. A variety of analog techniques lend themselves to regulating and varying the

current source value.

The device utilizes a precision “0” TC 10A reference current source to program output current. This 10µA current

source connects to the noninverting input of a power

operational amplifi er. The power operational amplifi er

provides a low impedance buffered output of the voltage

on the noninverting input.

Many application areas exist in which operation without

input and output capacitors is advantageous. A few of

these applications include sensitive circuits that cannot

endure surge currents under fault or overload conditions

and intrinsic safety applications in which safety regulations

limit energy storage devices that may spark or arc.

Programming Output Current in 2-Terminal

Current Source Mode

With a 10A current source generating the reference that

gains up to set output current, leakage paths to or from

the SET pin can create errors in the reference and output

currents. High quality insulation should be used (e.g.,

Tefl on, Kel-F). The cleaning of all insulating surfaces to

remove fl uxes and other residues may be required. Surface

coating may be necessary to provide a moisture barrier

in high humidity environments.

Minimize board leakage by encircling the SET pin and

circuitry with a guard ring operated at a potential close

to itself; tie the guard ring to the OUT pin. Guarding

both sides of the circuit board is required. Bulk leakage

reduction depends on the guard ring width. Ten nanoamperes of leakage into or out of the SET pin and its associated circuitry creates a 0.1% reference current error.

Leakages of this magnitude, coupled with other sources

of leakage, can cause signifi cant offset voltage and reference current drift, especially over the possible operating

temperature range.

10µA

and R

IN

ImA

≥

05

.

+

–

I

OUT

OUT

OUT

VµAR

SET SET

I

OUT

R

OUT

3092 F01

=

10

•

V

==

R

SET

OUT

10

µA

R

•

OUT

RR

SET

LT3092

+

V

SET

–

Figure 1. Using the LT3092 as a Current Source

Selecting R

SET OUT

R

SET

SET

Setting the LT3092 to operate as a 2-terminal current

source is a simple matter. The 10µA reference current from

the SET pin is used with one resistor to generate a small

voltage, usually in the range of 100mV to 1V (200mV is

a level that will help reject offset voltage, line regulation,

and other errors without being excessively large). This

voltage is then applied across a second resistor that

connects from OUT to the fi rst resistor. Figure 1 shows

connections and formulas to calculate a basic current

source confi guration.

8

In Figure 1, both resistors R

SET

and R

program the

OUT

value of the output current. The question now arises: the

ratio of these resistors is known, but what value should

each resistor be?

The fi rst resistor to select is R

. The value selected should

SET

generate enough voltage to minimize the error caused by

the offset between the SET and OUT pins. A reasonable

(R

starting level is 200mV of voltage across R

SET

SET

equal

to 20k). Resultant errors due to offset voltage are a few

percent. The lower the voltage across R

becomes, the

SET

higher the error term due to the offset.

3092fb

Page 9

APPLICATIONS INFORMATION

LT3092

From this point, selecting R

forward calculation from R

is easy, as it is a straight-

OUT

. Take note, however, resistor

SET

errors must be accounted for as well. While larger voltage

drops across R

minimize the error due to offset, they

SET

also increase the required operating headroom.

Obtaining the best temperature coeffi cient does not require

the use of expensive resistors with low ppm temperature

coeffi cients. Instead, since the output current of the LT3092

is determined by the ratio of R

SET

to R

, those resistors

OUT

should have matching temperature characteristics. Less

expensive resistors made from the same material will

provide matching temperature coeffi cients. See resistor

manufacturers’ data sheets for more details.

Stability and Frequency Compensation

The LT3092 does not require input or output capacitors

for stability in many current-source applications. Clean,

tight PCB layouts provide a low reactance, well controlled

operating environment for the LT3092 without requiring

capacitors to frequency-compensate the circuit. The front

page Typical Application circuit illustrates the simplicity

of using the LT3092.

Some current source applications will use a capacitor

connected in parallel with the SET pin resistor to lower

the current source’s noise. This capacitor also provides a

soft-start function for the current source. This capacitor

connection is depicted in Figure 7 (see the Quieting the

Noise section).

When operating with a capacitor across the SET pin resistor, external compensation is usually required to maintain

stability and compensate for the introduced pole. The

following paragraphs discuss methods for stabilizing

the LT3092 for either this capacitance or other complex

impedances that may be presented to the device. Linear

Technology strongly recommends testing stability in situ

with fi nal components before beginning production.

inductive components and may be complex distributed

networks. In addition, the current source’s value will differ between applications and its connection may be GND

referenced, power supply referenced or fl oating in a signal

line path. Linear Technology strongly recommends that

stability be tested in situ for any LT3092 application.

In LT3092 applications with long wires or PCB traces, the

inductive reactance may cause instability. In some cases,

adding series resistance to the input and output lines (as

shown in Figure 2) may suffi ciently dampen these possible

high-Q lines and provide stability. The user must evaluate

the required resistor values against the design’s headroom

constraints. In general, operation at low output current

levels (< 5mA) automatically requires higher values of

programming resistors and may provide the necessary

damping without additional series impedance.

If the line impedances in series with the LT3092 are

complex enough such that series damping resistors are

not suffi cient, a frequency compensation network may be

necessary. Several options may be considered.

LONG LINE

REACTANCE/INDUCTANCE

R

SERIES

10µA

SET

IN

+

–

R

SERIES

LONG LINE

REACTANCE/INDUCTANCE

R

OUT

3092 F02

LT3092

SET OUT

R

Although the LT3092’s design strives to be stable without

any capacitors over a wide variety of operating conditions,

it is not possible to test for all possible combinations of

input and output impedances that the LT3092 will encounter.

These impedances may include resistive, capacitive and

Figure 2. Adding Series Resistor Decouples

and Dampens Long Line Reactances

3092fb

9

Page 10

LT3092

APPLICATIONS INFORMATION

Figure 3 depicts the simplest frequency compensation

network as a single capacitor connected across the two

terminals of the current source. In this case, either a

capacitor with a value less than 1000pF, or greater than

1µF (ESR < 0.5), may stabilize the circuit. Some applications may use the small value capacitor to stand

off DC voltage, but allow the transfer of data down a

signal line.

For some applications, this capacitance range may be

unacceptable or present a design constraint. One circuit

example typifying this is an “intrinsically-safe” circuit in

which an overload or fault condition potentially allows

the capacitor’s stored energy to create a spark or arc.

For applications in which a single capacitor is unacceptable,

Figure 3 alternately shows a series RC network connected

across the two terminals of the current source. This network

has two benefi ts. First, it limits the potential discharge

current of the capacitor under a fault condition, preventing

sparks or arcs. Second, it bridges the gap between the

upper bound of 1000pF for small capacitors to the lower

bound of 1µF for large capacitors such that almost any

value capacitor can be used. This allows the user greater

fl exibility for frequency compensating the loop and fi ne

tuning the RC network for complex impedance networks.

In many instances, a series RC network is the best solution

for stabilizing the application circuit. Typical resistor values

will range from 100 to about 5k, especially for capacitor

values in between 1000pF and 1µF. Once again, Linear

Technology strongly recommends testing stability in situ

for any LT3092 application across all operating conditions,

especially ones that present complex impedance networks

at the input and output of the current source.

If an application refers the bottom of the LT3092 current

source to GND, it may be necessary to bypass the top

of the current source with a capacitor to GND. In some

cases, this capacitor may already exist and no additional

capacitance is required. For example, if the LT3092 was

used as a variable current source on the output of a power

supply, the output bypass capacitance would suffi ce to

provide LT3092 stability. Other applications may require

the addition of a bypass capacitor. Once again, the same

capacitor value requirements previously mentioned apply

in that an upper bound of 1000pF exists for small values

of capacitance, and a lower bound of 1µF (ESR < 0.5)

exists for large value capacitors. A series RC network may

also be used as necessary, and depends on the application

requirements.

In some extreme cases, capacitors or series RC networks

may be required on both the LT3092’s input and output to

stabilize the circuit. Figure 4 depicts a general application

using input and output capacitor networks, rather than

an input-to-output capacitor. As the input of the current

source tends to be high impedance, placing a capacitor

on the input does not have the same effect as placing a

10

10µA

SET

IN

C

COMP

+

–

R

OUT

3092 F03

R

OR

LT3092

SET OUT

R

Figure 3. Compensation From Input to

Output of Current Source Provides Stability

COMP

C

COMP

V

IN

R

LT3092

IN

C

IN

SET OUT

3092 F04

Figure 4. Input and/or Output Capacitors May

Be Used for Compensation

IN

10µA

+

–

R

SET

R

OUT

I

OUT

C

OR

OUT

R

OUT

C

OUT

3092fb

Page 11

APPLICATIONS INFORMATION

LT3092

capacitor on the lower impedance output, and the same

restrictions do not apply. Capacitors in the range of 0.1µF

to 1µF usually provide suffi cient bypassing on the input,

and the value of input capacitance may be increased

without limit.

If an application uses GND referred capacitors on the input

or output (particularly the input), pay attention to the length

of the lines powering and returning ground from the circuit.

In the case where long power supply and return lines are

coupled with low ESR input capacitors, application-specifi c

voltage spikes, oscillations and reliability concerns may

be seen. This is not an issue with LT3092 stability, but

rather the low ESR capacitor forming a high-Q resonant

tank circuit with the inductance of the input wires. Adding

series resistance with the input of the LT3092, or with the

input capacitor, often solves this. Resistor values of 0.1

to 1 are often suffi cient to dampen this resonance.

Give extra consideration to the use of ceramic capacitors.

Ceramic capacitors are manufactured with a variety of dielectrics, each with different behavior across temperature

and applied voltage. The most common dielectrics used

are specifi ed with EIA temperature characteristic codes of

Z5U, Y5V, X5R and X7R. The Z5U and Y5V dielectrics are

good for providing high capacitances in a small package,

but they tend to have strong voltage and temperature

coeffi cients as shown in Figures 5 and 6. When used with

a 5V regulator, a 16V 10F Y5V capacitor can exhibit an

effective value as low as 1F to 2F for the DC bias voltage

applied and over the operating temperature range. The X5R

and X7R dielectrics result in more stable characteristics

and are more suitable for use as the output capacitor.

The X7R type has better stability across temperature,

while the X5R is less expensive and is available in higher

values. Care still must be exercised when using X5R and

X7R capacitors; the X5R and X7R codes only specify

operating temperature range and maximum capacitance

change over temperature. Capacitance change due to DC

bias with X5R and X7R capacitors is better than Y5V and

Z5U capacitors, but can still be signifi cant enough to drop

capacitor values below appropriate levels. Capacitor DC

bias characteristics tend to improve as component case

size increases, but expected capacitance at operating

voltage should be verifi ed.

Voltage and temperature coeffi cients are not the only

sources of problems. Some ceramic capacitors have a

piezoelectric response. A piezoelectric device generates

voltage across its terminals due to mechanical stress. In a

ceramic capacitor the stress can be induced by vibrations

in the system or thermal transients.

20

0

–20

–40

–60

CHANGE IN VALUE (%)

–80

–100

0

26

Figure 5. Ceramic Capacitor DC Bias Characteristics

BOTH CAPACITORS ARE 16V,

1210 CASE SIZE, 10µF

X5R

Y5V

4

8

DC BIAS VOLTAGE (V)

10

14

12

16

3092 F05

40

20

0

–20

–40

–60

CHANGE IN VALUE (%)

–80

BOTH CAPACITORS ARE 16V,

1210 CASE SIZE, 10µF

–100

–50

–25 0

Figure 6. Ceramic Capacitor Temperature Characteristics

25 75

TEMPERATURE (°C)

X5R

Y5V

50 100 125

3092 F06

3092fb

11

Page 12

LT3092

APPLICATIONS INFORMATION

Quieting the Noise

When a reduction in the noise of the current source is

(C

desired, a small capacitor can be placed across R

SET

SET

in Figure 7). Normally, the 10µA reference current source

generates noise current levels of 2.7pA/√Hz (0.7nA

RMS

over the 10Hz to 100kHz bandwidth). The SET pin resistor

generates a spot noise equal to i

–23

constant, 1.38 • 10

J/°K, and T is absolute temperature)

= √4kT/R (k = Boltzmann’s

n

which is RMS-summed with the noise generated by the

10µA reference current source. Placing a C

across R

(as shown in Figure 7) bypasses this noise

SET

capacitor

SET

current. Note that this noise reduction capacitor increases

start-up time as a factor of the time constant formed by

• C

R

SET

. When using a capacitor across the SET pin

SET

resistor, the external pole introduced usually requires

compensation to maintain stability. See the Stability and

Frequency Compensation section for detailed descriptions

on compensating LT3092 circuits.

A curve in the Typical Performance Characteristics section

depicts noise spectral density for the reference current

over a 10Hz to 100kHz bandwidth.

Paralleling Devices

Obtain higher output current by paralleling multiple

LT3092’s together. The simplest application is to run

two current sources side by side and tie their inputs

together and their outputs together, as shown in Figure

8. This allows the sum of the current sources to deliver

more output current than a single device is capable of

delivering.

Another method of paralleling devices requires fewer

components and helps to share power between devices.

Tie the individual SET pins together and tie the individual

IN pins together. Connect the outputs in common using

small pieces of PC trace as ballast resistors to promote

equal current sharing. PC trace resistance in milliohms/

inch is shown in Table 1. Ballasting requires only a tiny

area on the PCB.

Table 1. PC Board Trace Resistance

WEIGHT (oz) 10mil WIDTH 20mil WIDTH

1 54.3 27.1

2 27.1 13.6

Trace resistance is measured in m/in

10µA

IN

+

–

C

SET

LT3092

SET OUT

R

SET

Figure 7. Adding C

C

COMP

R

OUT

3092 F07

Lowers Current Noise

SET

OR

R

COMP

C

COMP

The worst-case room temperature offset, only ±2mV between the SET pin and the OUT pin, allows the use of very

small ballast resistors.

As shown in Figure 9, each LT3092 has a small 40m

ballast resistor, which at full output current gives better

than 80% equalized sharing of the current. The external

resistance of 40m (20m for the two devices in parallel) only adds about 8mV of output voltage compliance at

an output of 0.4A. Of course, paralleling more than two

LT3092’s yields even higher output current. Spreading the

device on the PC board also spreads the heat. Series input

resistors can further spread the heat if the input-to-output

difference is high.

Thermal Considerations

The LT3092’s internal power and thermal limiting circuitry

protects itself under overload conditions. For continuous

normal load conditions, do not exceed the 125°C maximum

junction temperature. Carefully consider all sources of

thermal resistance from junction-to-ambient. This includes

(but is not limited to) junction-to-case, case-to-heat sink

3092fb

12

Page 13

APPLICATIONS INFORMATION

LT3092

I

OUT

LT3092

IN IN

10µA 10µA

300 300

LT3092

+

–

SET SETOUTOUTOUTOUT

1.33 1.33

I

, 300mA

OUT

Figure 8. Connect Two LT3092s for Higher Current

I

OUT

LT3092

IN IN

10µA

+

–

SET SET

LT3092

10µA

+

–

40m*

+

–

3092 F08

40m*

20k20k

R

x

R

=

x

VR

•

IN MAX

()

%90

50k

1V

3092 F09

I

, 400mA

OUT

Figure 9. Parallel Devices

interface, heat sink resistance or circuit board-to-ambient

as the application dictates. Consider all additional, adjacent

heat generating sources in proximity on the PCB.

Surface mount packages provide the necessary heat

sinking by using the heat spreading capabilities of the

PC board, copper traces and planes. Surface mount heat

sinks, plated through-holes and solder fi lled vias can also

spread the heat generated by power devices.

Junction-to-case thermal resistance is specifi ed from the

IC junction to the bottom of the case directly, or the bottom

of the pin most directly, in the heat path. This is the lowest

thermal resistance path for heat fl ow. Only proper device

mounting ensures the best possible thermal fl ow from this

area of the package to the heat sinking material.

R

2.5

*40m PC BOARD TRACE

Note that the Exposed Pad of the DFN package and the

Tab of the SOT-223 package are electrically connected

to the output (V

OUT

).

The following tables list thermal resistance as a function

of copper areas in a fi xed board size. All measurements

were taken in still air on a four-layer FR-4 board with 1oz

solid internal planes and 2oz external trace planes with a

total fi nished board thickness of 1.6mm.

PCB layers, copper weight, board layout and thermal vias

affect the resultant thermal resistance. Please reference

JEDEC standard JESD51-7 for further information on high

thermal conductivity test boards. Achieving low thermal

resistance necessitates attention to detail and careful layout.

3092fb

13

Page 14

LT3092

APPLICATIONS INFORMATION

Demo circuit 1531A’s board layout using multiple inner

planes and multiple thermal vias achieves 28°C/W

V

OUT

performance for the DFN package.

Table 2. DD Package, 8-Lead DFN

COPPER AREA

TOPSIDE* BACKSIDE BOARD AREA

2

2500mm

1000mm

225mm

100mm

*Device is mounted on topside

Table 3. TS8 Package, 8-Lead SOT-23

COPPER AREA

TOPSIDE* BACKSIDE BOARD AREA

2500mm

1000mm

225mm

100mm

*Device is mounted on topside

2500mm22500mm

2

2500mm22500mm

2

2500mm22500mm

2

2500mm22500mm

2

2500mm22500mm

2

2500mm22500mm

2

2500mm22500mm

2

2500mm22500mm

THERMAL RESISTANCE

(JUNCTION-TO-AMBIENT)

2

2

2

2

(JUNCTION-TO-AMBIENT)

2

2

2

2

25°C/W

25°C/W

28°C/W

32°C/W

THERMAL RESISTANCE

54°C/W

54°C/W

57°C/W

63°C/W

V

IN(MAX CONTINUOUS)

V

OUT(MIN CONTINUOUS)

= 200mA

I

OUT

= 16.5 (15V + 10%)

= 11.4V (12V – 5%)

Power dissipation under these conditions equals:

P

= (16.5 – 11.4V)(200mA) = 1.02W

TOTAL

Junction temperature equals:

T

J

= TA + P

TOTAL

• θ

JA

TJ = 50°C + (1.02W • 30°C/W) = 80.6°C

In this example, the junction temperature is below the

maximum rating, ensuring reliable operation.

Protection Features

The LT3092 incorporates several protection features ideal

for battery-powered circuits, among other applications.

In addition to normal circuit protection features such as

current limiting and thermal limiting, the LT3092 protects

itself against reverse-input voltages, reverse-output voltages, and reverse OUT-to-SET pin voltages.

Table 4. ST Package, 3-Lead SOT-223

COPPER AREA

TOPSIDE* BACKSIDE BOARD AREA

2

2500mm

1000mm

225mm

100mm22500mm22500mm

*Device is mounted on topside

For further information on thermal resistance and using thermal information,

refer to JEDEC standard JESD51, notably JESD51-12.

2500mm22500mm

2

2500mm22500mm

2

2500mm22500mm

THERMAL RESISTANCE

(JUNCTION-TO-AMBIENT)

2

2

2

2

20°C/W

20°C/W

24°C/W

29°C/W

Calculating Junction Temperature

Example: Given an industrial factory application with an

input voltage of 15V ±10%, an output voltage of 12V ±5%,

an output current of 200mA and a maximum ambient

temperature of 50°C, what would be the maximum junction temperature for a DFN package?

The total circuit power equals:

P

TOTAL

= (VIN – V

OUT

)(I

OUT

)

Current limit protection and thermal overload protection

protect the IC against output current overload conditions. For normal operation, do not exceed a junction

temperature of 125°C. The thermal shutdown circuit’s

typical temperature threshold is 165°C and has about

5°C of hysteresis.

The LT3092’s IN pin withstands ±40V voltages with respect

to the SET and OUT pins. Reverse-current fl ow, if OUT is

greater than IN, is less than 1mA (typically under 100µA),

protecting the LT3092 and sensitive loads.

Clamping diodes and 1k limiting resistors protect the

LT3092’s SET pin relative to the OUT pin voltage. These

protection components typically only carry current under

transient overload conditions. These devices are sized to

handle ±10V differential voltages and ±15mA crosspin

current fl ow without concern.

The SET pin current is negligible and can be ignored.

14

3092fb

Page 15

TYPICAL APPLICATIONS

LT3092

Paralleling Current Sources for Higher Current

LT3092

IN

10µA

+

–

SET OUT

⎛

RRR

IµA

=+

10

OUT

214

•

⎜

⎝

LT3092

SET OUT

R1R2

I

⎞

OUT

⎟

R

3

⎠

IN

10µA

+

–

3092 TA02

High Voltage Current Source

10µA

IN

D1

+

35V

LT3092

–

SET OUT

R4

20k

LT3092

10µA

+

R3

2

IN

ImA

≥=05

OUT

I

OUT

D2

35V

–

R3R4

.

200

Paralleling LT3092s with Ballast Resistor

LT3092

IN

10µA

+

–

SET OUT

R2

40.2k

LT3092

SET OUT

R1

40m

400mA

IN

10µA

+

–

R3

40m

R4

2

3092 TA03

Decreasing Power Dissipation in LT3092 100mA Current Source

10µA

IN

R

OUT

3092 TA05

x

VVV

==(– )

MAX IN OUT MAX

R

x

mV

200

R

1

R1

2

V

MAX

•%

90

+

–

I

OUT

100mA

LT3092

SET

R2

20k

mV

R

1

Capacitor Adds Stability, But Limits Slew Rate

SET OUT

+

200mV

–

R2

20k

I

OUT

100mA

R1

2

3092 TA04

LT3092

SET

R2

20k

10µA

IN

C1

+

–

OUT

R1

2

3092 TA06

I

OUT

100mA

LIMIT

dV

dt

≤ 901%•

I

OUT

C

3092fb

15

Page 16

LT3092

TYPICAL APPLICATIONS

Remote Temperature Sensor

LT3092

10µA

SET OUT

49.9k 49.9

MURATA

NCP15WF104F03RC

1% 100k

Pulsed Current Source, Load to Ground

DAC Controlled Current Source

I

= 0.5mA TO

+

–

OUT

100mA

IN

10

3092 TA08

INPUT

+

V

V

IN

IN

LT3092

10µA

+

–

SET OUT

DAC OUTPUT

0V TO 1V

I

OUT

LOAD

3092 TA07

Active Load

LT3092

IN

10µA

+

–

SET OUT

1mA

10010k

OUTPUT

3092 TA09

Fully Floating Current Source Switches

From 200mA to Quiescent Current

ON

OFF

V

IN

LT3092

IN

10µA

+

–

SET OUT

20k

VN2222LL

1

I

OUT

200mA

LOAD

3092 TA10

OPTO-FET

NEC PS 7801-1A

V

IN

LT3092

IN

10µA

+

–

SET OUT

100k 4.99

200mA

3092 TA11

16

3092fb

Page 17

TYPICAL APPLICATIONS

LT3092

Pulsed Current Source, Load to V

V

IN

LOAD

I

OUT

LT3092

IN

10µA

+

–

OFF

SET

ON

OUT

120k

3092 TA12

Voltage Clamp

IN

I

OUT

2-Terminal AC Current Limiter

LT3092

10µA

+

I

OUT

–

20k

I

OUT

3092 TA13

I

OUT

I

SET

.

V

02

R

High Accuracy Current Source

V

IN

2N3906

10k

10k

10k

IN

LT3092

2N3904

SET

10µA

10µA

IN

+

–

124

0.1%

10mA

I

OUT

3092 TA15

3092fb

LT3092

+

–

100k

10V

VIN – V

OUT

4.99

3092 TA14

OUT

V

OUT

= 11V TRIP POINT

SET OUT

LT1634-1.25

17

Page 18

LT3092

TYPICAL APPLICATIONS

V

IN

2-Level Current Source

LT3092

IN

10µA

+

–

SET OUT

100k

100k*

VN2222LL*

10V*

*CURRENT FOLDBACK CIRCUIT LIMITS

THE LT3092 POWER DISSIPATION

10k*

= 200mA, IF VIN – V

I

OUT

= 100mA, IF V

4.99

V

OUT

< 12V

OUT

– V

> 12V

IN

OUT

3092 TA16

More Effi cient Current Source

V

IN

+

36V

–

V

IN

SHDN

LT3470A

GND

BOOST

SW

BIAS

0.22µF

33µH

10µA

+

–

20k

IN

1

I

OUT

C3

47µF

1nF

ZVP3306F

1k

3092 TA17

FB

LT3092

100

SET OUT

18

3092fb

Page 19

PACKAGE DESCRIPTION

DD Package

8-Lead Plastic DFN (3mm × 3mm)

(Reference LTC DWG # 05-08-1698)

0.675 ±0.05

R = 0.115

TYP

LT3092

0.38 ± 0.10

85

3.5 ±0.05

NOTE:

1. DRAWING TO BE MADE A JEDEC PACKAGE OUTLINE M0-229 VARIATION OF (WEED-1)

2. DRAWING NOT TO SCALE

3. ALL DIMENSIONS ARE IN MILLIMETERS

4. DIMENSIONS OF EXPOSED PAD ON BOTTOM OF PACKAGE DO NOT INCLUDE

MOLD FLASH. MOLD FLASH, IF PRESENT, SHALL NOT EXCEED 0.15mm ON ANY SIDE

1.65 ±0.05

(2 SIDES)2.15 ±0.05

PACKAGE

OUTLINE

0.25 ± 0.05

RECOMMENDED SOLDER PAD PITCH AND DIMENSIONS

0.50 BSC

2.38 ±0.05

(2 SIDES)

PIN 1

TOP MARK

(NOTE 6)

0.200 REF

ST Package

3-Lead Plastic SOT-223

(Reference LTC DWG # 05-08-1630)

.248 – .264

(6.30 – 6.71)

.114 – .124

(2.90 – 3.15)

3.00 ±0.10

(4 SIDES)

0.75 ±0.05

5. EXPOSED PAD SHALL BE SOLDER PLATED

6. SHADED AREA IS ONLY A REFERENCE FOR PIN 1 LOCATION

ON TOP AND BOTTOM OF PACKAGE

.059 MAX

1.65 ± 0.10

0.00 – 0.05

.129 MAX

(2 SIDES)

0.25 ± 0.05

2.38 ±0.10

(2 SIDES)

BOTTOM VIEW—EXPOSED PAD

14

0.50 BSC

(DD) DFN 1203

.264 – .287

(6.70 – 7.30)

.130 – .146

(3.30 – 3.71)

.071

(1.80)

MAX

.0905

(2.30)

BSC

.024 – .033

(0.60 – 0.84)

.181

(4.60)

BSC

.033 – .041

(0.84 – 1.04)

.012

(0.31)

MIN

.059 MAX

10o

MAX

.181 MAX

RECOMMENDED SOLDER PAD LAYOUT

10o – 16o

.0008 – .0040

(0.0203 – 0.1016)

.248 BSC

.039 MAX

.090

BSC

.010 – .014

(0.25 – 0.36)

10o – 16o

ST3 (SOT-233) 0502

3092fb

19

Page 20

LT3092

PACKAGE DESCRIPTION

TS8 Package

8-Lead Plastic TSOT-23

(Reference LTC DWG # 05-08-1637)

3.85 MAX

0.20 BSC

0.52

MAX

2.62 REF

RECOMMENDED SOLDER PAD LAYOUT

PER IPC CALCULATOR

DATUM ‘A’

NOTE:

1. DIMENSIONS ARE IN MILLIMETERS

2. DRAWING NOT TO SCALE

3. DIMENSIONS ARE INCLUSIVE OF PLATING

4. DIMENSIONS ARE EXCLUSIVE OF MOLD FLASH AND METAL BURR

0.65

REF

0.30 – 0.50 REF

1.22 REF

1.4 MIN

2.80 BSC

0.09 – 0.20

(NOTE 3)

1.50 – 1.75

(NOTE 4)

PIN ONE ID

0.65 BSC

0.80 – 0.90

1.00 MAX

5. MOLD FLASH SHALL NOT EXCEED 0.254mm

6. JEDEC PACKAGE REFERENCE IS MO-193

2.90 BSC

(NOTE 4)

0.22 – 0.36

8 PLCS (NOTE 3)

0.01 – 0.10

1.95 BSC

TS8 TSOT-23 0802

20

3092fb

Page 21

LT3092

REVISION HISTORY

REV DATE DESCRIPTION PAGE NUMBER

B 12/09 Update Order Information 2

(Revision history begins at Rev B)

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

3092fb

21

Page 22

LT3092

TYPICAL APPLICATIONS

USB LED Driver

LT3092

IN

10µA

+

–

SET OUT

20k

3092 TA18

USB

1

ADJUST LIMIT

200mA LED

Current Limiter for Remote Power

V

IN

LT3092

IN

10µA

+

–

SET OUT

100k

3092 TA19

RELATED PARTS

PART NUMBER DESCRIPTION COMMENTS

LDO

LT1761 100mA, Low Noise LDO 300mV Dropout Voltage, Low Noise: 20µV

LT1762 150mA, Low Noise LDO 300mV Dropout Voltage, Low Noise: 20µV

LTC1844 150mA, Very Low Dropout LDO 80mV Dropout Voltage, Low Noise <30µV

Capacitors, ThinSOT Package

LT1962 300mA, Low Noise LDO 270mV Dropout Voltage, Low Noise: 20µV

LT1964 200mA, Low Noise, Negative LDO 340mV Dropout Voltage, Low Noise 30µV

LT3008 20mA, 45V, 3µA I

Micropower LDO 280mV Dropout Voltage, Low IQ: 3µA, VIN = 2V to 45V, V

Q

ThinSOT and 2mm × 2mm DFN-6 Packages

LT3009 20mA, 20V, 3µA IQ Micropower LDO 280mV Dropout Voltage, Low IQ: 3µA, VIN = 1.6V to 20V, V

ThinSOT and SC70 Packages

LT3020 100mA, Low Voltage VLDO Linear

Regulator

LTC3025 300mA Micropower VLDO Linear

Regulator

LTC3035 300mA VLDO Linear Regulator with

Charge Pump Bias Generator

LT3080/

LT3080-1

1.1A, Parallelable, Low Noise,

Low Dropout Linear Regulator

VIN: 0.9V to 10V, V

: 0.2V to 5V (Min), VDO = 0.15V, IQ = 120µA, Noise: <250µV

OUT

Stable with 2.2µF Ceramic Capacitors, DFN-8, MS8 Packages

VIN = 0.9V to 5.5V, Dropout Voltage: 45mV, Low Noise 80µV

2mm × 2mm DFN Package

V

= 1.7V to 5.5V, V

IN

: 0.4V to 3.6V, Dropout Voltage: 45mV, IQ: 100µA, 3mm × 2mm DFN-8

OUT

300mV Dropout Voltage (2-Supply Operation), Low Noise: 40µV

V

: 0V to 35.7V, Current-Based Reference with 1-Resistor V

OUT

(No Op Amp Required), Stable with Ceramic Caps, TO-220, SOT-223, MSOP-8 and

3mm × 3mm DFN-8 Packages; LT3080-1 Version Has Integrated Internal Ballast Resistor

LT3085 500mA, Parallelable, Low Noise, Low

Dropout Linear Regulator

275mV Dropout Voltage (2-Supply Operation), Low Noise: 40µV

V

: 0V to 35.7V, Current-based Reference with 1-Resistor V

OUT

(No Op Amp Required), Stable with Ceramic Caps, MSOP-8 and 2mm × 3mm DFN-6 Packages

Current Sense Amplifi ers

LT6106 Low Cost, 36V High Side Current

36V (44V Max) Current Sense, Dynamic Range of 2000:1, 106dB of PSRR

Sense Amplifi er

LT6107 High Temperature High Side Current

Sense Amp in SOT-23

36V (44V Max) Current Sense, Dynamic Range of 2000:1, 106dB of PSRR, –55 to 150°C

(MP-Grade)

ThinSOT is a trademark of Linear Technology Corporation.

Linear Technology Corporation

22

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ● FAX: (408) 434-0507

●

www.linear.com

, VIN = 1.8V to 20V, ThinSOT™ Package

RMS

, VIN = 1.8V to 20V, MS8 Package

RMS

, VIN = 1.6V to 6.5V, Stable with 1µF Output

RMS

, VIN = 1.8V to 20V, MS8 Package

RMS

, VIN = –1.8V to –20V, ThinSOT Package

RMS

4.99

LDO

= 0.6V to 39.5V;

OUT

= 0.6V to 19.5V;

OUT

, Low IQ: 54µA, 6-Lead

RMS

, VIN: 1.2V to 36V,

RMS

Set; Directly Parallelable

OUT

, VIN: 1.2V to 36V,

RMS

Set; Directly Parallelable

OUT

LT 1209 REV B • PRINTED IN USA

© LINEAR TECHNOLOGY CORPORATION 2009

RMS

V

OUT

,

3092fb

Loading...

Loading...