Page 1

FEATURES

LT1372/LT1377

500kHz and 1MHz

High Efficiency

1.5A Switching Regulators

U

DESCRIPTIO

■

Faster Switching with Increased Efficiency

■

Uses Small Inductors: 4.7µH

■

All Surface Mount Components

■

Only 0.5 Square Inch of Board Space

■

Low Minimum Supply Voltage: 2.7V

■

Quiescent Current: 4mA Typ

■

Current Limited Power Switch: 1.5A

■

Regulates Positive or Negative Outputs

■

Shutdown Supply Current: 12µA Typ

■

Easy External Synchronization

■

8-Pin SO or PDIP Packages

U

APPLICATIO S

■

Boost Regulators

■

CCFL Backlight Driver

■

Laptop Computer Supplies

■

Multiple Output Flyback Supplies

■

Inverting Supplies

The LT®1372/LT1377 are monolithic high frequency

switching regulators. They can be operated in all standard

switching configurations including boost, buck, flyback,

forward, inverting and “Cuk.” A 1.5A high efficiency switch

is included on the die, along with all oscillator, control and

protection circuitry. All functions of the LT1372/LT1377

are integrated into 8-pin SO/PDIP packages.

The LT1372/LT1377 typically consumes only 4mA quiescent current and has higher efficiency than previous parts.

High frequency switching allows for very small inductors

to be used. All surface mount components consume less

than 0.5 square inch of board space.

New design techniques increase flexibility and maintain

ease of use. Switching is easily synchronized to an external logic level source. A logic low on the shutdown pin

reduces supply current to 12µA. Unique error amplifier

circuitry can regulate positive or negative output voltage

while maintaining simple frequency compensation techniques. Nonlinear error amplifier transconductance reduces output overshoot on start-up or overload recovery.

Oscillator frequency shifting protects external components during overload conditions.

, LTC and LT are registered trademarks of Linear Technology Corporation.

TYPICAL APPLICATIO

5V-to-12V Boost Converter

5V

L1*

4.7µH

5

V

4

ON

OFF

+ +

C1**

22µF

IN

S/S

LT1372/LT1377

GND

6, 7

C2

0.047µF

V

SW

FB

V

C

1

R3

2k

MBRS120T3

8

2

C3

0.0047µF

D1

U

R1

53.6k

1%

R2

6.19k

1%

†

V

OUT

12V

*FOR LT1372 USE 10µH

COILCRAFT DO1608-472 (4.7µH) OR

COILCRAFT DT3316-103 (10µH) OR

C4**

SUMIDA CD43-4R7 (4.7µH) OR

22µF

SUMIDA CD73-100KC (10µH) OR

**AVX TPSD226M025R0200

†MAX I

OUT

I

OUT

(LT1377)

0.25A

0.35A

L1

4.7µH

10µH

I

OUT

(LT1372)

NA

0.29A

LT1372 • TA01

100

VIN = 5V

90

80

70

EFFICIENCY (%)

60

50

0.01

12V Output Efficiency

0.1 1

OUTPUT CURRENT (A)

LT1372 • TA02

1

Page 2

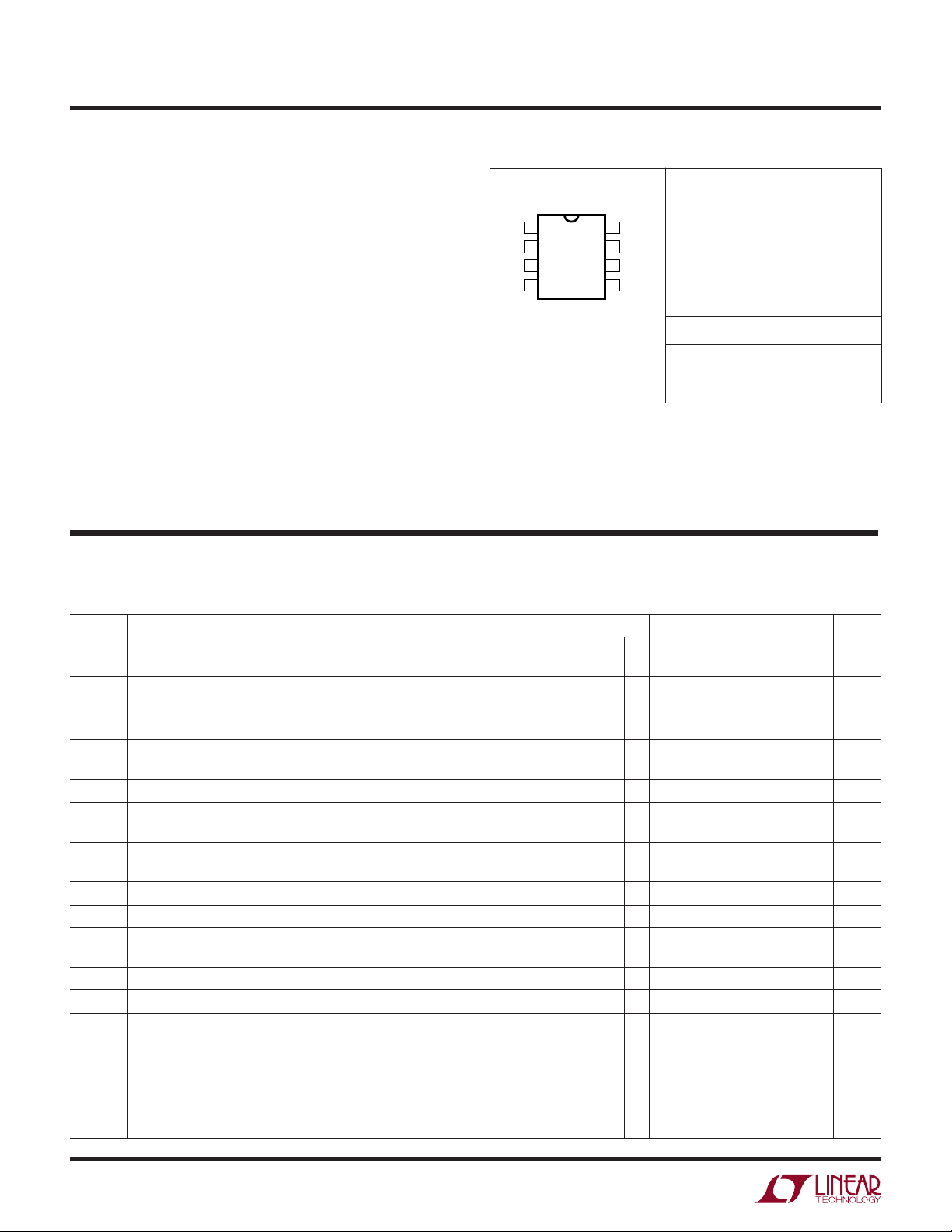

LT1372/LT1377

PACKAGE/ORDER I FOR ATIO

UU

W

WWWU

ABSOLUTE AXI U RATI GS

(Note 1)

Supply Voltage ....................................................... 30V

Switch Voltage

LT1372/LT1377 .................................................. 35V

LT1372HV .......................................................... 42V

S/S Pin Voltage....................................................... 30V

Feedback Pin Voltage (Transient, 10ms) .............. ±10V

Feedback Pin Current........................................... 10mA

Negative Feedback Pin Voltage

(Transient, 10ms)............................................. ±10V

Operating Junction Temperature Range

Commercial ........................................ 0°C to 125°C*

Industrial ......................................... – 40°C to 125°C

Short Circuit ......................................... 0°C to 150°C

Storage Temperature Range ................ –65°C to 150°C

Lead Temperature (Soldering, 10 sec)................. 300°C

ORDER PART NUMBER

TOP VIEW

V

1

C

FB

2

NFB

3

S/S

4

N8 PACKAGE

8-LEAD PDIP

T

= 125°C, θ

JMAX

T

JMAX

Consult factory for parts specified with wider operating temperature ranges.

*Units shipped prior to Date Code 9552 are rated at 100°C maximum

operating temperature.

= 125°C, θ

JA

JA

V

8

GND

7

GND S

6

V

5

S8 PACKAGE

8-LEAD PLASTIC SO

= 100°C/ W (N8)

= 120°C/ W (S8)

LT1372CN8

SW

LT1372HVCN8

LT1372CS8

LT1372HVCS8

IN

LT1372IN8

LT1372HVIN8

LT1372IS8

LT1372HVIS8

LT1377CS8

LT1377IS8

S8 PART MARKING

1372

1372I

1372H

1372HI

1377

1377I

ELECTRICAL CHARACTERISTICS

The ● denotes specifcatons which appy over the full operating temperature range, otherwise specifications are at TA = 25°C.

VIN = 5V, VC = 0.6V, VFB = V

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

V

REF

I

FB

V

NFB

I

NFB

g

m

A

V

f Switching Frequency 2.7V ≤ VIN ≤ 25V

Reference Voltage Measured at Feedback Pin 1.230 1.245 1.260 V

Feedback Input Current VFB = V

Reference Voltage Line Regulation 2.7V ≤ VIN ≤ 25V, VC = 0.8V ● 0.01 0.03 %/V

Negative Feedback Reference Voltage Measured at Negative Feedback Pin –2.540 – 2.490 –2.440 V

Negative Feedback Input Current V

Negative Feedback Reference Voltage 2.7V ≤ VIN ≤ 25V, VC = 0.8V ● 0.01 0.05 %/V

Line Regulation

Error Amplifier Transconductance ∆IC = ±25µA 1100 1500 1900 µmho

Error Amplifier Source Current VFB = V

Error Amplifier Sink Current VFB = V

Error Amplifier Clamp Voltage High Clamp, VFB = 1V 1.70 1.95 2.30 V

Error Amplifier Voltage Gain 500 V/V

VC Pin Threshold Duty Cycle = 0% 0.8 1 1.25 V

, VSW, S/S and NFB pins open, unless otherwise noted.

REF

V

= 0.8V ● 1.225 1.245 1.265 V

C

REF

Feedback Pin Open, V

= V

NFB

NFR

– 150mV, VC = 1.5V ● 120 200 350 µA

REF

+ 150mV, VC = 1.5V ● 1400 2400 µA

REF

Low Clamp, V

LT1372 450 500 550 kHz

0°C ≤ TJ ≤ 125°C ● 430 500 580 kHz

–40°C ≤ T

LT1377 0.90 1 1.10 MHz

0°C ≤ TJ ≤ 125°C ● 0.86 1 1.16 MHz

–40°C ≤ T

FB

< 0°C (I Grade) 400 580 kHz

J

< 0°C (I Grade) 0.80 1.16 MHz

J

= 0.8V ● –2.570 – 2.490 –2.410 V

C

= 1.5V 0.25 0.40 0.52 V

250 550 nA

● 900 nA

● –45 –30 –15 µA

● 700 2300 µmho

2

Page 3

LT1372/LT1377

TEMPERATURE (°C)

–50

1.8

INPUT VOLTAGE (V)

2.0

2.2

2.4

2.6

050

100

150

LT1372 • G03

2.8

3.0

–25 25

75

125

ELECTRICAL CHARACTERISTICS

The ● denotes specifcatons which appy over the full operating temperature range, otherwise specifications are at TA = 25°C.

VIN = 5V, VC = 0.6V, VFB = V

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

Maximum Switch Duty Cycle ● 85 95 %

Switch Current Limit Blanking Time 130 260 ns

BV Output Switch Breakdown Voltage LT1372/LT1377 ● 35 47 V

V

I

∆I

∆I

I

SAT

LIM

IN

SW

Q

Output Switch “On” Resistance ISW = 1A ● 0.5 0.8 Ω

Switch Current Limit Duty Cycle = 50% ● 1.5 1.9 2.7 A

Supply Current Increase During Switch On-Time 15 25 mA/A

Control Voltage to Switch Current 2A/V

Transconductance

Minimum Input Voltage ● 2.4 2.7 V

Supply Current 2.7V ≤ VIN ≤ 25V ● 4 5.5 mA

Shutdown Supply Current 2.7V ≤ VIN ≤ 25V, V

Shutdown Threshold 2.7V ≤ VIN ≤ 25V ● 0.6 1.3 2 V

Shutdown Delay ● 51225µs

S/S Pin Input Current 0V ≤ V

Synchronization Frequency Range LT1372 ● 600 800 kHz

, VSW, S/S and NFB pins open, unless otherwise noted.

REF

LT1372HV

0°C ≤ TJ ≤ 125°C ● 42 47 V

–40°C ≤ T

< 0°C (I Grade) 40 V

J

Duty Cycle = 80% (Note 2)

≤ 0.6V

0°C ≤ T

J

–40°C ≤ T

≤ 5V ● –10 15 µA

S/S

≤ 125°C ● 12 30 µA

S/S

< 0°C (I Grade) 50 µA

J

LT1377

● 1.3 1.7 2.5 A

● 1.2 1.6 MHz

Note 1: Absolute Maximum Ratings are those values beyond which the life

of the device may be impaired.

TYPICAL PERFORMANCE CHARACTERISTICS

SWITCH SATURATION VOLTAGE (V)

Switch Saturation Voltage

vs Switch Current

1.0

0.9

0.8

0.7

0.2

0.1

0.6

0.5

0.4

0.3

0

0.2

0.4

0

0.6

SWITCH CURRENT (A)

0.8

100°C

1.0

1.2

150°C

–55°C

1.4

1.6

W

25°C

1.8

LT1372 • G01

2.0

U

3.0

2.5

2.0

1.5

1.0

SWITCH CURRENT LIMIT (A)

0.5

0

Note 2: For duty cycles (DC) between 50% and 90%, minimum

guaranteed switch current is given by I

Switch Current Limit

vs Duty Cycle

20 40 60 80

DUTY CYCLE (%)

–55°C

25°C AND

125°C

LT1372 • G02

= 0.667 (2.75 – DC).

LIM

Minimum Input Voltage

vs Temperature

10010030 50 70 90

3

Page 4

LT1372/LT1377

FEEDBACK PIN VOLTAGE (V)

400

ERROR AMPLIFIER OUTPUT CURRENT (µA)

–300

–200

–100

300

100

–0.1 0.1

200

0

–0.3 –0.2

V

REF

–55°C

125°C

25°C

LT1372 • G06

TEMPERATURE (°C)

–50

0

TRANSCONDUCTANCE (µmho)

200

600

800

1000

2000

1400

0

50

75

LT1372 • G09

400

1600

1800

1200

–25 25

100

125

150

gm =

∆I (V

C

)

∆V (FB)

UW

TYPICAL PERFOR A CE CHARACTERISTICS

Shutdown Delay and Threshold

vs Temperature

20

18

16

14

12

10

8

6

SHUTDOWN DELAY (µs)

4

2

0

–50

SHUTDOWN THRESHOLD

SHUTDOWN DELAY

–25 25

0

TEMPERATURE (°C)

50

75

S/S Pin Input Current

vs Voltage

5

VIN = 5V

4

3

2

1

0

–1

–2

–3

S/S PIN INPUT CURRENT (µA)

–4

–5

1

2

08

–1

S/S PIN VOLTAGE (V)

5

3

4

100

6

125

LT1372 • G04

7

LT1372 • G07

)

3.0

P-P

SHUTDOWN THRESHOLD (V)

2.5

2.0

1.5

1.0

0.5

MINIMUM SYNCHRONIZATION VOLTAGE (V

110

100

90

80

70

60

50

40

30

20

SWITCHING FREQUENCY (% OF TYPICAL)

10

150

2.0

1.8

1.6

1.4

1.2

1.0

0.8

0.6

0.4

0.2

0

9

Minimum Synchronization

Voltage vs Temperature

f

= 700kHz (LT1372)

SYNC

= 1.4MHz (LT1377)

f

SYNC

LT1377

LT1372

0

–50

050

–25 25

TEMPERATURE (°C)

75

Switching Frequency

vs Feedback Pin Voltage

0.2

0

0.3

0.1 0.9

FEEDBACK PIN VOLTAGE (V)

0.4

0.5

0.6

0.7

100

0.8

125

LT1372 • G05

LT1372 • G08

Error Amplifier Output Current

vs Feedback Pin Voltage

150

Error Amplifier Transconductance

vs Temperature

1.0

VC Pin Threshold and High

Clamp Voltage vs Temperature

2.4

2.2

2.0

1.8

1.6

1.4

1.2

PIN VOLTAGE (V)

C

1.0

V

0.8

0.6

0.4

4

–50

–25 25

VC HIGH CLAMP

VC THRESHOLD

0

TEMPERATURE (°C)

50

75

100

125

LT1372 • G10

150

Feedback Input Current

vs Temperature

800

VFB =V

0

–50

–25

REF

0

50

25

TEMPERATURE (°C)

700

600

500

400

300

200

FEEDBACK INPUT CURRENT (nA)

100

Negative Feedback Input Current

vs Temperature

0

V

=V

NFB

NFR

–10

–20

–30

–40

NEGATIVE FEEDBACK INPUT CURRENT (µA)

–50

–50

–25 25

75

100

125

LT1372 • G11

150

0

50

TEMPERATURE (°C)

75

100

125

LT1372 • G12

150

Page 5

LT1372/LT1377

U

UU

PI FU CTIO S

VC (Pin 1): The compensation pin is used for frequency

compensation, current limiting and soft start. It is the

output of the error amplifier and the input of the current

comparator. Loop frequency compensation can be performed with an RC network connected from the V

ground.

FB (Pin 2): T

he feedback pin is used for positive output

voltage sensing and oscillator frequency shifting. It is the

inverting input to the error amplifier. The noninverting

input of this amplifier is internally tied to a 1.245V

reference. Load on the FB pin should not exceed 250µA

when the NFB pin is used. See Applications Information.

NFB (Pin 3): The negative feedback pin is used for negative

output voltage sensing. It is connected to the inverting

input of the negative feedback amplifier through a 100k

source resistor.

S/S (Pin 4): Shutdown and Synchronization Pin. The S/S

pin is logic level compatible. Shutdown is active low and

the shutdown threshold is typically 1.3V. For normal

operation, pull the S/S pin high, tie it to V

floating. To synchronize switching, drive the S/S pin between 600kHz and 800kHz (LT1372) or 1.2MHz to 1.6MHz

(LT1377).

pin to

C

or leave it

IN

V

(Pin 5): Bypass input supply pin with 10µF or more. The

IN

part goes into undervoltage lockout when V

drops below

IN

2.5V. Undervoltage lockout stops switching and pulls the

V

pin low.

C

GND S (Pin 6): The ground sense pin is a “clean” ground.

The internal reference, error amplifier and negative feedback amplifier are referred to the ground sense pin. Connect it to ground. Keep the ground path connection to the

output resistor divider and the V

compensation network

C

free of large ground currents.

GND (Pin 7): The ground pin is the emitter connection of

the power switch and has large currents flowing through it.

It should be connected directly to a good quality ground

plane.

V

(Pin 8): The switch pin is the collector of the power

SW

switch and has large currents flowing through it. Keep the

traces to the switching components as short as possible to

minimize radiation and voltage spikes.

BLOCK DIAGRA

S/S

100k

NFB

50k

FB

1.245V

REF

GND SENSE

W

SHUTDOWN

DELAY AND RESET

+

NFBA

–

–

EA

+

OSCSYNC

5:1 FREQUENCY

SHIFT

V

IN

LOW DROPOUT

2.3V REG

LOGIC DRIVER

COMP

IA

≈ 6

A

V

C

V

SW

ANTI-SAT

SWITCH

+

0.08Ω

–

GND LT1372 • BD

5

Page 6

LT1372/LT1377

U

OPERATIO

The LT1372/LT1377 are current mode switchers. This

means that switch duty cycle is directly controlled by

switch current rather than by output voltage. Referring to

the block diagram, the switch is turned “On” at the start of

each oscillator cycle. It is turned “Off” when switch current

reaches a predetermined level. Control of output voltage is

obtained by using the output of a voltage sensing error

amplifier to set current trip level. This technique has

several advantages. First, it has immediate response to

input voltage variations, unlike voltage mode switchers

which have notoriously poor line transient response.

Second, it reduces the 90° phase shift at mid-frequencies

in the energy storage inductor. This greatly simplifies

closed-loop frequency compensation under widely varying input voltage or output load conditions. Finally, it

allows simple pulse-by-pulse current limiting to provide

maximum switch protection under output overload or

short conditions. A low dropout internal regulator provides a 2.3V supply for all internal circuitry. This low

dropout design allows input voltage to vary from 2.7V to

25V with virtually no change in device performance. A

500kHz (LT1372) or 1MHz (LT1377) oscillator is the basic

clock for all internal timing. It turns “On” the output switch

via the logic and driver circuitry. Special adaptive anti-sat

circuitry detects onset of saturation in the power switch

and adjusts driver current instantaneously to limit switch

saturation. This minimizes driver dissipation and provides

very rapid turn-off of the switch.

A 1.245V bandgap reference biases the positive input of

the error amplifier. The negative input of the amplifier is

brought out for positive output voltage sensing. The error

amplifier has nonlinear transconductance to reduce out-

put overshoot on start-up or overload recovery. When

the feedback voltage exceeds the reference by 40mV,

error amplifier transconductance increases ten times,

which reduces output overshoot. The feedback input also

invokes oscillator frequency shifting, which helps protect components during overload conditions. When the

feedback voltage drops below 0.6V, the oscillator frequency is reduced 5:1. Lower switching frequency allows

full control of switch current limit by reducing minimum

switch duty cycle.

Unique error amplifier circuitry allows the LT1372/LT1377

to directly regulate negative output voltages. The negative

feedback amplifier’s 100k source resistor is brought out

for negative output voltage sensing. The NFB pin regulates

at –2.49V while the amplifier output internally drives the

FB pin to 1.245V. This architecture, which uses the same

main error amplifier, prevents duplicating functions and

maintains ease of use. Consult Linear Technology Marketing for units that can regulate down to –1.25V.

The error signal developed at the amplifier output is

brought out externally. This pin (VC) has three different

functions. It is used for frequency compensation, current

limit adjustment and soft starting. During normal regulator operation this pin sits at a voltage between 1V (low

output current) and 1.9V (high output current). The error

amplifier is a current output (gm) type, so this voltage can

be externally clamped for lowering current limit. Likewise, a capacitor coupled external clamp will provide soft

start. Switch duty cycle goes to zero if the VC pin is pulled

below the control pin threshold, placing the LT1372/

LT1377 in an idle mode.

WUUU

APPLICATIO S I FOR ATIO

Positive Output Voltage Setting

The LT1372/LT1377 develops a 1.245V reference (V

REF

)

from the FB pin to ground. Output voltage is set by

connecting the FB pin to an output resistor divider

(Figure 1). The FB pin bias current represents a small

error and can usually be ignored for values of R2 up to 7k.

The suggested value for R2 is 6.19k. The NFB pin is

normally left open for positive output applications.

6

V

OUT

R1

FB

PIN

V

REF

Figure 1. Positive Output Resistor Divider

R2

V

OUT

R1 = R2

= V

R1

1 +

REF

()

R2

V

OUT

– 1

()

1.245

LT1372 • F01

Page 7

WUUU

APPLICATIO S I FOR ATIO

LT1372/LT1377

Positive fixed voltage versions are available (consult

Linear Technology marketing).

Negative Output Voltage Setting

The LT1372/LT1377 develops a –2.49V reference (V

NFR

)

from the NFB pin to ground. Output voltage is set by

connecting the NFB pin to an output resistor divider

(Figure 2). The –30µA NFB pin bias current (I

NFB

) can

cause output voltage errors and should not be ignored.

This has been accounted for in the formula in Figure 2. The

suggested value for R2 is 2.49k. The FB pin is normally left

open for negative output application. See Dual Polarity

Output Voltage Sensing for limitatins on FB pin loading

when using the NFB pin.

–V

OUT

NFB

R1

R1 =

R2

2.49

( ) ( )

R2

NFB

I

PIN

V

NFR

Figure 2. Negative Output Resistor Divider

= V

–V

OUT

R1

+ I

NFB

()

V

– 2.49

OUT

+ 30 × 10

(R1)1 +

NFB

R2

–

6

LT1372 • F02

Dual Polarity Output Voltage Sensing

Shutdown and Synchronization

The dual function S/S pin provides easy shutdown and

synchronization. It is logic level compatible and can be

pulled high, tied to VIN or left floating for normal operation.

A logic low on the S/S pin activates shutdown, reducing

the part’s supply current to 12µA. Typical synchronization

range is from 1.05 to 1.8 times the part’s natural switching

frequency, but is only guaranteed between 600kHz and

800kHz (LT1372) or 1.2MHz and 1.6MHz (LT1377). At

start-up, the synchronization signal should not be applied

until the feedback pin is above the frequency shift voltage

of 0.7V. If the NFB pin is used, synchronization should not

be applied until the NFB pin is more negative than –1.4V.

A 12µs resetable shutdown delay network guarantees the

part will not go into shutdown while receiving a synchronization signal.

Caution should be used when synchronizing above 700kHz

(LT1372) or 1.4MHz (LT1377) because at higher sync

frequencies the amplitude of the internal slope compensation used to prevent subharmonic switching is reduced.

This type of subharmonic switching only occurs when the

duty cycle of the switch is above 50%. Higher inductor

values will tend to eliminate problems.

Certain applications benefit from sensing both positive

and negative output voltages. One example is the “Dual

Output Flyback Converter with Overvoltage Protection”

circuit shown in the Typical Applications section. Each

output voltage resistor divider is individually set as described above. When both the FB and NFB pins are used,

the LT1372/LT1377 acts to prevent either output from

going beyond its set output voltage. For example in this

application, if the positive output were more heavily loaded

than the negative, the negative output would be greater

and would regulate at the desired set-point voltage. The

positive output would sag slightly below its set-point

voltage. This technique prevents either output from going

unregulated high at no load. Please note that the load on

the FB pin should not exceed 250µA when the NFB pin is

used. This situation occurs when the resistor dividers are

used at

both

FB and NFB. True load on FB is not the full

divider current unless the positive output is shorted to

ground. See Dual Output Flyback Converter application.

Thermal Considerations

Care should be taken to ensure that the worst-case input

voltage and load current conditions do not cause excessive die temperatures. The packages are rated at 120°C/W

for SO (S8) and 130°C/W for PDIP (N8).

Average supply current (including driver current) is:

IIN = 4mA + DC (ISW/60 + ISW × 0.004)

ISW = switch current

DC = switch duty cycle

Switch power dissipation is given by:

PSW = (ISW)2 × RSW × DC

RSW = output switch “On” resistance

Total power dissipation of the die is the sum of supply

current times supply voltage plus switch power:

P

D(TOTAL)

= (IIN × VIN) + P

SW

7

Page 8

LT1372/LT1377

WUUU

APPLICATIO S I FOR ATIO

Choosing the Inductor

For most applications the inductor will fall in the range of

2.2µH to 22µH. Lower values are chosen to reduce physi-

cal size of the inductor. Higher values allow more output

current because they reduce peak current seen by the

power switch, which has a 1.5A limit. Higher values also

reduce input ripple voltage and reduce core loss.

When choosing an inductor you might have to consider

maximum load current, core and copper losses, allowable

component height, output voltage ripple, EMI, fault

current in the inductor, saturation, and of course, cost.

The following procedure is suggested as a way of handling

these somewhat complicated and conflicting requirements.

1. Assume that the average inductor current for a boost

converter is equal to load current times V

decide whether or not the inductor must withstand

continuous overload conditions. If average inductor

current at maximum load current is 0.5A, for instance,

a 0.5A inductor may not survive a continuous 1.5A

overload condition. Also be aware that boost converters are not short circuit protected, and that under

output short conditions, inductor current is limited only

by the available current of the input supply.

2. Calculate peak inductor current at full load current to

ensure that the inductor will not saturate. Peak current

can be significantly higher than output current, especially with smaller inductors and lighter loads, so don’t

omit this step. Powdered iron cores are forgiving because they saturate softly, whereas ferrite cores saturate abruptly. Other core materials fall in between

somewhere. The following formula assumes continuous mode operation but it errors only slightly on the

high side for discontinuous mode, so it can be used for

all conditions.

+

VIN(V

OUT – VIN

2(f)(L)(V

V

I

= I

PEAK

V

IN

f = 500kHz Switching Frequency (LT1372) or

1MHz Switching Frequency (LT1377)

3. Decide if the design can tolerate an “open” core geom-

etry like a rod or barrel, which have high magnetic field

OUT

= Minimum Input Voltage

×

OUT

V

IN

OUT

OUT/VIN

)

)

and

radiation, or whether it needs a closed core like a toroid

to prevent EMI problems. One would not want an open

core next to a magnetic storage media for instance!

This is a tough decision because the rods or barrels are

temptingly cheap and small, and there are no helpful

guidelines to calculate when the magnetic field radiation will be a problem.

4. Start shopping for an inductor which meets the requirements of core shape, peak current (to avoid

saturation), average current (to limit heating) and fault

current. If the inductor gets too hot, wire insulation will

melt and cause turn-to-turn shorts. Keep in mind that

all good things like high efficiency, low profile and high

temperature operation will increase cost, sometimes

dramatically.

5. After making an initial choice, consider the secondary

things like output voltage ripple, second sourcing, etc.

Use the experts in the Linear Technology application

department if you feel uncertain about the final choice.

They have experience with a wide range of inductor

types and can tell you about the latest developments in

low profile, surface mounting, etc.

Output Capacitor

The output capacitor is normally chosen by its effective

series resistance, (ESR), because this is what determines

output ripple voltage. At 500kHz, any polarized capacitor

is essentially resistive. To get low ESR takes

physically smaller capacitors have high ESR. The ESR

range for typical LT1372 and LT1377 applications is

0.05Ω to 0.5Ω. A typical output capacitor is an AVX type

TPS, 22µF at 25V, with a guaranteed ESR less than 0.2Ω.

This is a “D” size surface mount solid tantalum capacitor.

TPS capacitors are specially constructed and tested for

low ESR, so they give the lowest ESR for a given volume.

To further reduce ESR, multiple output capacitors can be

used in parallel. The value in microfarads is not particularly critical, and values from 22µF to greater than 500µF

work well, but you cannot cheat mother nature on ESR.

If you find a tiny 22µF solid tantalum capacitor, it will have

high ESR, and output ripple voltage will be terrible. Table

1 shows some typical solid tantalum surface mount

capacitors.

volume

, so

8

Page 9

WUUU

APPLICATIO S I FOR ATIO

LT1372/LT1377

Table 1. Surface Mount Solid Tantalum Capacitor

ESR and Ripple Current

E CASE SIZE ESR (MAX Ω) RIPPLE CURRENT (A)

AVX TPS, Sprague 593D 0.1 to 0.3 0.7 to 1.1

AVX TAJ 0.7 to 0.9 0.4

D CASE SIZE

AVX TPS, Sprague 593D 0.1 to 0.3 0.7 to 1.1

AVX TAJ 0.9 to 2.0 0.36 to 0.24

C CASE SIZE

AVX TPS 0.2 (Typ) 0.5 (Typ)

AVX TAJ 1.8 to 3.0 0.22 to 0.17

B CASE SIZE

AVX TAJ 2.5 to 10 0.16 to 0.08

Many engineers have heard that solid tantalum capacitors

are prone to failure if they undergo high surge currents.

This is historically true and type TPS capacitors are

specially tested for surge capability, but surge ruggedness

is not a critical issue with the

tantalum capacitors fail during very high

output

capacitor. Solid

turn-on

surges,

which do not occur at the output of regulators. High

discharge

surges, such as when the regulator output is

dead shorted, do not harm the capacitors.

Single inductor boost regulators have large RMS ripple

current in the output capacitor, which must be rated to

handle the current. The formula to calculate this is:

Output Capacitor Ripple Current (RMS)

DC

I

RIPPLE

(RMS) = I

= I

OUT

OUT

1 – DC

V

OUT – VIN

V

IN

Input Capacitors

The input capacitor of a boost converter is less critical due

to the fact that the input current waveform is triangular and

does not contain large squarewave currents as is found in

the output capacitor. Capacitors in the range of 10µF to

100µF with an ESR of 0.3Ω or less work well up to full 1.5A

switch current. Higher ESR capacitors may be acceptable

at low switch currents. Input capacitor ripple current for

boost converter is :

I

RIPPLE

=

0.3(V

)(V

IN

(f)(L)(V

OUT

OUT

– VIN)

)

f = 500kHz Switching frequency (LT1372) or,

1MHz Switching frequency (LT1377)

The input capacitor can see a very high surge current when

a battery or high capacitance source is connected “live”

and solid tantalum capacitors can fail under this condition.

Several manufacturers have developed a line of solid

tantalum capacitors specially tested for surge capability

(AVX TPS series, for instance), but even these units may

fail if the input voltage approaches the maximum voltage

rating of the capacitor. AVX recommends derating capacitor voltage by 2:1 for high surge applications. Ceramic and

aluminum electrolytic capacitors may also be used and

have a high tolerance to turn-on surges.

Ceramic Capacitors

Higher value, lower cost ceramic capacitors are now

becoming available in smaller case sizes. These are tempting for switching regulator use because of their very low

ESR. Unfortunately, the ESR is so low that it can cause

loop stability problems. Solid tantalum capacitor ESR

generates a loop “zero” at 5kHz to 50kHz that is instrumental in giving acceptable loop phase margin. Ceramic capacitors remain capacitive to beyond 300kHz and usually

resonate with their ESL before ESR becomes effective.

They are appropriate for input bypassing because of their

high ripple current ratings and tolerance of turn-on surges.

Linear Technology plans to issue a Design Note on the use

of ceramic capacitors in the near future.

Output Diode

The suggested output diode (D1) is a 1N5818 Schottky or

its Motorola equivalent, MBR130. It is rated at 1A average

forward current and 30V reverse voltage. Typical forward

voltage is 0.42V at 1A. The diode conducts current only

during switch off time. Peak reverse voltage for boost

converters is equal to regulator output voltage. Average

forward current in normal operation is equal to output

current.

9

Page 10

LT1372/LT1377

WUUU

APPLICATIO S I FOR ATIO

Frequency Compensation

Loop frequency compensation is performed on the output

of the error amplifier (VC pin) with a series RC network.

The main pole is formed by the series capacitor and the

output impedance (≈500kΩ) of the error amplifier. The

pole falls in the range of 2Hz to 20Hz. The series resistor

creates a “zero” at 1kHz to 5kHz, which improves loop

stability and transient response. A second capacitor,

typically one-tenth the size of the main compensation

capacitor, is sometimes used to reduce the switching

frequency ripple on the VC pin. VC pin ripple is caused by

output voltage ripple attenuated by the output divider and

multiplied by the error amplifier. Without the second

capacitor, VC pin ripple is:

(V

OUT

P–P

)(gm)(RC)

)

)

VC Pin Ripple =

V

RIPPLE

g

m

= Output ripple (V

= Error amplifier transconductance

1.245(V

RIPPLE

(≈1500µmho)

= Series resistor on VC pin

R

C

= DC output voltage

V

OUT

(magnetic) radiation is minimized by keeping output diode, switch pin, and output bypass capacitor leads as

short as possible. E field radiation is kept low by minimizing the length and area of all traces connected to the switch

pin. A ground plane should always be used under the

switcher circuitry to prevent interplane coupling.

The high speed switching current path is shown schematically in Figure 3. Minimum lead length in this path is

essential to ensure clean switching and low EMI. The path

including the switch, output diode, and output capacitor is

the only one containing nanosecond rise and fall times.

Keep this path as short as possible.

SWITCH

L1

NODE

HIGH

V

IN

FREQUENCY

CIRCULATING

PATH

Figure 3

LOAD

V

OUT

LT1372 • F03

More Help

To prevent irregular switching, VC pin ripple should be

kept below 50mV

Worst-case VC pin ripple occurs at

P–P.

maximum output load current and will also be increased

if poor quality (high ESR) output capacitors are used. The

addition of a 0.0047µF capacitor on the VC pin reduces

switching frequency ripple to only a few millivolts. A low

value for RC will also reduce VC pin ripple, but loop phase

margin may be inadequate.

Switch Node Considerations

For maximum efficiency, switch rise and fall time are

made as short as possible. To prevent radiation and high

frequency resonance problems, proper layout of the components connected to the switch node is essential. B field

For more detailed information on switching regulator

circuits, please see Application Note 19. Linear Technology also offers a computer software program, SwitcherCAD,

to assist in designing switching converters. In addition,

our applications department is always ready to lend a

helping hand.

10

Page 11

U

D2

1N4148

Q2

1N5818

D1

1N4148

562Ω*

20k

DIMMING

10k

330Ω

10

12345

Q1

10µF

C1

0.1µF

V

IN

4.5V

TO 30V

V

IN

V

SW

V

FB

V

C

GND

S/S

5

84

2

16, 7

LT1372/LT1377

2µF

0.1µF

L1

33µH

T1

LT1372 • TA06

C1 = WIMA MKP-20

L1 = COILCRAFT DT3316-333

T1 = COILTRONICS CTX 110609

* = 1% FILM RESISTOR

DO NOT SUBSTITUTE COMPONENTS

Q1, Q2 = ZETEX ZTX849 OR ROHM 2SC5001

LAMP

C2

27pF

5mA MAX

2.2µF

2.7V TO

5.5V

22k

1N4148

OPTIONAL REMOTE

DIMMING

COILTRONICS (407) 241-7876

COILCRAFT (708) 639-6400

ON

OFF

CCFL BACKLIGHT APPLICATION CIRCUITS

CONTAINED IN THIS DATA SHEET ARE

COVERED BY U.S. PATENT NUMBER 5408162

AND OTHER PATENTS PENDING

+

+

+

TYPICAL APPLICATIONS N

V

IN

OFF

0.0047µF

2.7V TO 16V

+

C1

22µF

4

ON

C3

5

V

IN

S/S

LT1372/LT1377

V

C

1

C2

0.047µF

R1

2k

V

NFB

GND

SW

6, 7

D2

P6KE-15A

D3

1N4148

8

3

*COILTRONICS CTX10-2 (407) 241-7876

†

MAX I

OUT

I

OUT

0.3A

0.5A

0.75A

T1*

214

•

MBRS130LT3

V

IN

3V

5V

9V

•

3

D1

LT1372/LT1377

Dual Output Flyback Converter with Overvoltage ProtectionPositive-to-Negative Converter with Direct Feedback

R2

1.21k

1%

+

C4

47µF

R2

2.49k

1%

R3

2.49k

1%

–V

OUT

–5V

LT1372 • TA03

†

+

OFF

0.0047µF

C1

22µF

FB

4

ON

S/S

LT1372/LT1377

V

C

C3

V

IN

2.7V TO 13V

52

V

IN

V

SW

NFB

GND

1

R3

2k

6, 7

C2

0.047µF

*DALE LPE-4841-100MB (605) 665-9301

R1

13k

1%

MBRS140T3

T1*

2, 3

5

6, 7

•

•

•

MBRS140T3

4

8

1

P6KE-20A

1N4148

8

3

V

OUT

15V

+

C4

47µF

+

C5

47µF

–V

OUT

–15V

R4

12.1k

1%

R5

2.49k

1%

LT1372 • TA04

Low Ripple 5V to –3V “Cuk”† Converter

V

IN

5V

5

+

C1

22µF

10V

4

7

6

0.0047µF

SUMIDA CLS62-100L

*

MOTOROLA MBR0520LT3

**

†

PATENTS MAY APPLY

L1*

3

2

••

41

C2

47µF

LT1372/LT1377

V

IN

S/S

GND

GND S

V

SW

NFB

V

C5

16V

8

+

3

1

C

D1**

R4

2k

C4

0.047µF

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of circuits as described herein will not infringe on existing patent rights.

R1

1k

1%

R2

4.99k

1%

90% Efficient CCFL Supply

V

OUT

–3V

250mA

C6

0.1µF

C3

47µF

16V

+

LT1372 • TA05

11

Page 12

LT1372/LT1377

U

TYPICAL APPLICATIONS N

V

IN

4V TO 9V

2 Li-Ion Cell to 5V SEPIC Converter

5

V

IN

4

ON

OFF

+

C1

33µF

20V

S/S

LT1372/LT1377

GND

6, 7

8

V

SW

2

FB

V

C

1

R1

2k

C4

0.047µF

PACKAGE DESCRIPTION

N8 Package

8-Lead PDIP (Narrow 0.300)

(LTC DWG # 05-08-1510)

0.400*

(10.160)

MAX

876

0.255 ± 0.015*

(6.477 ± 0.381)

L1A*

•

10µH

C2

1µF

C5

0.0047µF

MBRS130LT3

•

L1B*

10µH

R2

18.7k

1%

R3

6.19k

1%

†

V

OUT

C1 = AVX TPSD 336M020R0200

5V

C2 = TOKIN 1E105ZY5U-C103-F

+

C3 = AVX TPSD107M010R0100

C3

*SINGLE INDUCTOR WITH TWO WINDINGS

100µF

COILTRONICS CTX10-1

10V

†

MAX I

OUT

V

I

IN

OUT

4V

0.45A

5V

0.55A

7V

0.65A

9V

0.72A

U

Dimensions in inches (millimeters) unless otherwise noted.

S8 Package

8-Lead Plastic Small Outline (Narrow 0.150)

(LTC DWG # 05-08-1610)

5

0.228 – 0.244

(5.791 – 6.197)

LT1372 • TA07

0.189 – 0.197*

(4.801 – 5.004)

8

7

6

5

0.150 – 0.157**

(3.810 – 3.988)

1234

0.300 – 0.325

(7.620 – 8.255)

0.065

(1.651)

0.009 – 0.015

(0.229 – 0.381)

+0.035

0.325

–0.015

+0.889

8.255

()

–0.381

*THESE DIMENSIONS DO NOT INCLUDE MOLD FLASH OR PROTRUSIONS.

MOLD FLASH OR PROTRUSIONS SHALL NOT EXCEED 0.010 INCH (0.254mm)

TYP

0.045 – 0.065

(1.143 – 1.651)

0.100

(2.54)

BSC

0.130 ± 0.005

(3.302 ± 0.127)

0.125

(3.175)

MIN

0.018 ± 0.003

(0.457 ± 0.076)

0.020

(0.508)

MIN

N8 1098

0.010 – 0.020

(0.254 – 0.508)

0.008 – 0.010

(0.203 – 0.254)

*

DIMENSION DOES NOT INCLUDE MOLD FLASH. MOLD FLASH

SHALL NOT EXCEED 0.006" (0.152mm) PER SIDE

**

DIMENSION DOES NOT INCLUDE INTERLEAD FLASH. INTERLEAD

FLASH SHALL NOT EXCEED 0.010" (0.254mm) PER SIDE

× 45°

0.016 – 0.050

(0.406 – 1.270)

0°– 8° TYP

0.053 – 0.069

(1.346 – 1.752)

0.014 – 0.019

(0.355 – 0.483)

TYP

1

3

2

4

0.050

(1.270)

BSC

RELATED PARTS

PART NUMBER DESCRIPTION COMMENTS

LT1370 High Efficiency DC/DC Converter 42V, 6A, 500kHz Switch

LT1767 1.5A, 1.25MHz Step-Down Switching Regulator 3V to 25V Input, V

LT1374 High Efficiency Step-Down Switching Regulator 25V, 4.5A, 500kHz Switch

LTC1735-1 High Efficiency Step-Down Controller with Power Good Output Fault Protection, 16-Pin SSOP and SO-8

LTC®3402 Single Cell, High Current (2A), Micropower, Synchronous VIN = 0.7V to 5V, Up to 95% Efficiency Synchronizable Oscillator

3MHz Step-Up DC/DC Converter from 100kHz to 3MHz

= 1.2V, Synchronizable Up to 2MHz, MSOP Package

REF

0.004 – 0.010

(0.101 – 0.254)

SO8 1298

12

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ● FAX: (408) 434-0507

●

www.linear-tech.com

sn13727 13727fbs LT/TP 0401 2K REV B • PRINTED IN THE USA

LINEAR TECHNOLOGY CORPORATION 1995

Loading...

Loading...