Page 1

LT1074/LT1076

Step-Down Switching

Regulator

FEATURES

■

5A Onboard Switch (LT1074)

■

Operates Up to 60V Input

■

100kHz Switching Frequency

■

Greatly Improved Dynamic Behavior

■

Available in Low Cost 5 and 7-Lead Packages

■

Only 8.5mA Quiescent Current

■

Programmable Current Limit

■

Micropower Shutdown Mode

U

APPLICATIO S

■

Buck Converter with Output Voltage Range of 2.5V

to 50V

■

Tapped-Inductor Buck Converter with 10A Output

at 5V

■

Positive-to-Negative Converter

■

Negative Boost Converter

■

Multiple Output Buck Converter

U

DESCRIPTIO

The LT®1074 is a 5A (LT1076 is rated at 2A) monolithic

bipolar switching regulator which requires only a few

external parts for normal operation. The power switch, all

oscillator and control circuitry, and all current limit com-

ponents, are included on the chip. The topology is a classic

positive “buck” configuration but several design innovations allow this device to be used as a positive-to-negative

converter, a negative boost converter, and as a flyback

converter. The switch output is specified to swing 40V

below ground, allowing the LT1074 to drive a tappedinductor in the buck mode with output currents up to 10A.

The LT1074 uses a true analog multiplier in the feedback

loop. This makes the device respond nearly instantaneously to input voltage fluctuations and makes loop gain

independent of input voltage. As a result, dynamic behavior of the regulator is significantly improved over previous

designs.

On-chip pulse by pulse current limiting makes the LT1074

nearly bust-proof for output overloads or shorts. The input

voltage range as a buck converter is 8V to 60V, but a selfboot feature allows input voltages as low as 5V in the

inverting and boost configurations.

The LT1074 is available in low cost TO-220 or DD packages

with frequency pre-set at 100kHz and current limit at 6.5A

(LT1076 = 2.6A). A 7-pin TO-220 package is also available

which allows current limit to be adjusted down to zero. In

addition, full micropower shutdown can be programmed.

See Application Note 44 for design details.

A fixed 5V output, 2A version is also available. See LT1076-5.

, LTC and LT are registered trademarks of Linear Technology Corporation.

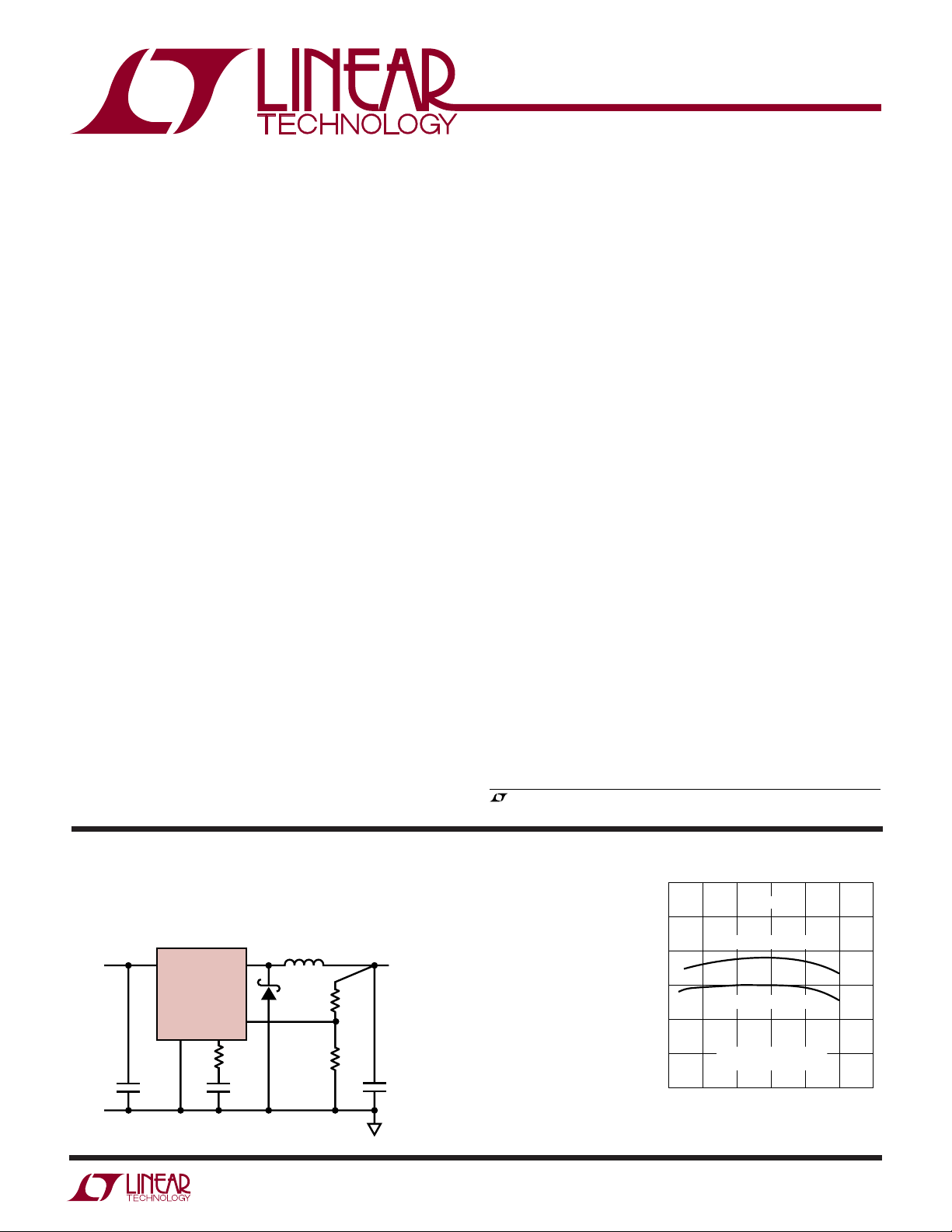

TYPICAL APPLICATIO

Basic Positive Buck Converter

50µH (LT1074)

100

µH (LT1076)

MBR745*

µF

10V TO 40V

LT1074

V

SW

FB

V

C

R3

2.7k

C2

0.01

V

IN

GND

+

†

C3

200µF

L1**

U

R1

2.8k

1%

R2

2.21k

1%

Buck Converter Efficiency

100

5V

USE MBR340 FOR LT1076

*

5A

COILTRONICS #50-2-52 (LT1074)

**

PULSE ENGINEERING, INC.

HURRICANE #HL-AK147QQ (LT1074)

+

25V

†

C1

RIPPLE CURRENT RATING ≥ I

500

µF

#100-1-52 (LT1076)

#PE-92114 (LT1074)

#PE-92102 (LT1076)

#HL-AG210LL (LT1076)

/2

OUT

LT1074•TA01

90

80

EFFICIENCY (%)

70

60

50

0

1234

OUTPUT LOAD CURRENT (A)

LT1074

V = 12V, V = 20V

OUT IN

V = 5V, V = 15V

OUT IN

L = 50µH TYPE 52 CORE

DIODE = MBR735

5

LT1074•TPC27

sn1074 1074fds

6

1

Page 2

LT1074/LT1076

WW

W

ABSOLUTE AXI U RATI GS

U

(Note 1)

Input Voltage

LT1074/ LT1076 .................................................. 45V

LT1074HV/LT1076HV ......................................... 64V

Switch Voltage with Respect to Input Voltage

LT1074/ LT1076 .................................................. 64V

LT1074HV/LT1076HV ......................................... 75V

Switch Voltage with Respect to Ground Pin (V

Negative)

SW

LT1074/LT1076 (Note 7) ..................................... 35V

LT1074HV/LT1076HV (Note 7) ........................... 45V

Feedback Pin Voltage..................................... – 2V, +10V

Shutdown Pin Voltage (Not to Exceed VIN) .............. 40V

UUW

PACKAGE/ORDER I FOR ATIO

ORDER PART

LT1076CQ

LT1076IQ

LT1076CR

LT1076IR

LT1076HVCR

LT1076HVIR

LT1074CT7

LT1074HVCT7

C

LT1074IT7

LT1074HVIT7

LT1076CT7

SW

IN

LT1076HVCT7

NUMBER

TAB IS

GND

FRONT VIEW

TAB IS

GND

Q PACKAGE

5-LEAD PLASTIC DD

LT1076: θJC = 4°C, θJA = 30°C/W

FRONT VIEW

TAB IS

GND

R PACKAGE

7-LEAD PLASTIC DD

LT1076: θ

= 4°C, θJA = 30°C/W

JC

FRONT VIEW

T7 PACKAGE

7-LEAD PLASTIC TO-220

5

4

3

2

1

7

6

5

4

3

2

1

7

6

5

4

3

2

1

V

IN

V

SW

GND

V

C

FB/SENSE

SHDN

V

C

FB/SENSE

GND

I

LIM

V

SW

V

IN

SHDN

V

FB

GND

I

LIM

V

V

I

Pin Voltage (Forced) ............................................ 5.5V

LIM

Maximum Operating Ambient Temperature Range

Commercial ................................................. 0°C to 70°C

Industrial ................................................ –40°C to 85°C

Military (OBSOLETE) ..................... –55°C to 125°C

Maximum Operating Junction Temperature Range

Commercial ............................................... 0°C to 125°C

Industrial .............................................. –40°C to 125°C

Military (OBSOLETE) .................... –55°C to 150°C

Maximum Storage Temperature ............... –65°C to 150°C

Lead Temperature (Soldering, 10 sec)...................... 300°C

BOTTOM VIEW

V

C

1

2

3

4

V

IN

CASE

IS GND

ORDER PART

NUMBER

LT1074CK

LT1074HVCK

LT1074MK

FB

K PACKAGE

4-LEAD TO-3 METAL CAN

LT1074: θJC = 2.5°C, θJA = 35°C/W

LT1076: θ

OBSOLETE PACKAGE

Consider the T5 Package for Alternate Source

TAB IS

GND

LT1074: θ

LT1076: θ

= 4°C, θJA = 35°C/W

JC

FRONT VIEW

5

4

3

2

1

T PACKAGE

5-LEAD PLASTIC TO-220

LEADS ARE FORMED STANDARD FOR

STRAIGHT LEADS, ORDER FLOW 06

= 2.5°C, θJA = 50°C/W

JC

= 4°C, θJA = 50°C/W

JC

V

SW

LT1074HVMK

LT1076CK

LT1076HVCK

LT1076MK

LT1076HVMK

LT1074CT

LT1074HVCT

V

IN

V

SW

LT1074IT

GND

LT1074HVIT

V

C

LT1076CT

FB

LT1076HVCT

LT1076IT

LT1076HVIT

LT1074: θ

LT1076: θ

= 2.5°C, θJA = 50°C/W

JC

= 4°C, θJA = 50°C/W

JC

*Assumes package is soldered to 0.5 IN2 of 1 oz. copper over internal ground plane or over back side plane.

Consult LTC Marketing for parts specified with wider operating temperature ranges.

2

sn1074 1074fds

Page 3

LT1074/LT1076

ELECTRICAL CHARACTERISTICS

temperature range, otherwise specifications are at T

The ● denotes the specifications which apply over the full operating

= 25°C. Tj = 25°C, VIN = 25V, unless otherwise noted.

A

PARAMETER CONDITIONS MIN TYP MAX UNITS

Switch “On” Voltage (Note 2) LT1074 I

LT1076 I

Switch “Off” Leakage LT1074 V

LT1076 V

Supply Current (Note 3) V

= 2.5V, V

FB

40V < V

V

SHUT

= 1A, Tj ≥ 0°C 1.85 V

SW

= 1A, Tj < 0°C 2.1 V

I

SW

I

= 5A, Tj ≥ 0°C 2.3 V

SW

= 5A, Tj < 0°C 2.5 V

I

SW

= 0.5A ● 1.2 V

SW

= 2A ● 1.7 V

I

SW

≤ 25V, V

IN

= V

V

IN

MAX, VSW

= 25V, V

IN

V

= V

IN

MAX, VSW

≤ 40V ● 8.5 11 mA

IN

< 60V ● 912 mA

IN

= 0 5 300 µA

SW

= 0 (Note 8) 10 500 µA

= 0 150 µA

SW

= 0 (Note 8) 250 µA

= 0.1V (Device Shutdown) (Note 9) ● 140 300 µA

Minimum Supply Voltage Normal Mode ● 7.3 8 V

Startup Mode (Note 4)

Switch Current Limit (Note 5) LT1074 I

LT1076 I

Open ● 5.5 6.5 8.5 A

LIM

= 10k (Note 6) 4.5 A

R

LIM

R

= 7k (Note 6) 3 A

LIM

Open ● 2 2.6 3.2 A

LIM

R

= 10k (Note 6) 1.8 A

LIM

R

= 7k (Note 6) 1.2 A

LIM

● 3.5 4.8 V

Maximum Duty Cycle ● 85 90 %

Switching Frequency 90 100 110 kHz

≤ 125°C ● 85 120 kHz

T

j

T

> 125°C ● 85 125 kHz

j

= 0V through 2kΩ (Note 5) 20 kHz

V

FB

Switching Frequency Line Regulation 8V ≤ V

IN

≤ V

(Note 8) ● 0.03 0.1 %/V

MAX

Error Amplifier Voltage Gain (Note 7) 1V ≤ VC ≤ 4V 2000 V/V

Error Amplifier Transconductance 3700 5000 8000 µmho

Error Amplifier Source and Sink Current Source (V

Sink (V

Feedback Pin Bias Current V

FB

= 2V) 100 140 225 µA

FB

= 2.5V) 0.7 1 1.6 mA

FB

= V

REF

● 0.5 2 µA

Reference Voltage VC = 2V ● 2.155 2.21 2.265 V

Reference Voltage Tolerance V

(Nominal) = 2.21V ±0.5 ±1.5 %

REF

All Conditions of Input Voltage, Output

● ± 1 ± 2.5 %

Voltage, Temperature and Load Current

Reference Voltage Line Regulation 8V ≤ VIN ≤ V

(Note 8) ● 0.005 0.02 %/V

MAX

VC Voltage at 0% Duty Cycle 1.5 V

Over Temperature

● – 4 mV/°C

Multiplier Reference Voltage 24 V

Shutdown Pin Current V

= 5V ● 51020 µA

SH

V

SH

≤ V

THRESHOLD

(≅2.5V) ● 50 µA

Shutdown Thresholds Switch Duty Cycle = 0 ● 2.2 2.45 2.7 V

Fully Shut Down

● 0.1 0.3 0.6 V

Thermal Resistance Junction to Case LT1074 2.5 °C/W

LT1076 4.0 °C/W

sn1074 1074fds

3

Page 4

LT1074/LT1076

ELECTRICAL CHARACTERISTICS

Note 1: Absolute Maximum Ratings are those values beyond which the life

of a device may be impaired.

Note 2: To calculate maximum switch “on” voltage at currents between

low and high conditions, a linear interpolation may be used.

Note 3: A feedback pin voltage (V

) of 2.5V forces the VC pin to its low

FB

clamp level and the switch duty cycle to zero. This approximates the zero

load condition where duty cycle approaches zero.

Note 4: Total voltage from V

pin to ground pin must be ≥ 8V after start-

IN

up for proper regulation.

W

BLOCK DIAGRA

INPUT SUPPLY

10 Aµ

SHUTDOWN*

0.3V

2.35V

+

-POWER

µ

SHUTDOWN

–

+

–

CURRENT

LIMIT

SHUTDOWN

6V

REGULATOR

AND BIAS

I *

LIM

320 Aµ

6V TO ALL

CIRCUITRY

Note 5: Switch frequency is internally scaled down when the feedback pin

voltage is less than 1.3V to avoid extremely short switch on times. During

testing, V

Note 6: I

is adjusted to give a minimum switch on time of 1µs.

FB

R

LIM

2k

– 1k

LIM

≈ (LT1074), I

R

– 1k

LIM

≈ (LT1076).

LIM

5.5k

Note 7: Switch to input voltage limitation must also be observed.

Note 8: V

= 40V for the LT1074/76 and 60V for the LT1074HV/76HV.

MAX

Note 9: Does not include switch leakage.

LT1074

500

Ω

CURRENT

4.5V

10k

LIMIT

COMP

+

C2

–

250

Ω

0.04

+

A1

ERROR

2.21V

*AVAILABLE ON PACKAGES WITH PIN

COUNTS GREATER THAN 5.

AMP

–

FB V

X

C

FREQ SHIFT

100kHz

OSCILLATOR

SYNC

V

IN

Z

ANALOG

MULTIPLIER

XY

Z

Y

24V (EQUIVALENT)

3V(p-p)

+

–

C1

PULSE WIDTH

COMPARATOR

S

R

R/S

LATCH

R

Q

LT1076

100

Ω

SWITCH

OUTPUT (V )

G1

Ω

15

400

Ω

SWITCH

OUTPUT

(V )

SW

0.1

Ω

SW

LT1074 • BD01

sn1074 1074fds

4

Page 5

BLOCK DIAGRAWDESCRIPTIO

LT1074/LT1076

U

A switch cycle in the LT1074 is initiated by the oscillator

setting the R/S latch. The pulse that sets the latch also

locks out the switch via gate G1. The effective width of this

pulse is approximately 700ns, which sets the maximum

switch duty cycle to approximately 93% at 100kHz switching frequency. The switch is turned off by comparator C1,

which resets the latch. C1 has a sawtooth waveform as one

input and the output of an analog multiplier as the other

input. The multiplier output is the product of an internal

reference voltage, and the output of the error amplifier, A1,

divided by the regulator input voltage. In standard buck

regulators, this means that the output voltage of A1

required to keep a constant regulated output is independent of regulator input voltage. This greatly improves line

transient response, and makes loop gain independent of

input voltage. The error amplifier is a transconductance

type with a GM at null of approximately 5000µmho. Slew

current going positive is 140µA, while negative slew

current is about 1.1mA. This asymmetry helps prevent

overshoot on start-up. Overall loop frequency compensation is accomplished with a series RC network from VC to

ground.

Switch current is continuously monitored by C2, which

resets the R/S latch to turn the switch off if an overcurrent

condition occurs. The time required for detection and

switch turn off is approximately 600ns. So minimum

switch “on” time in current limit is 600ns. Under dead

shorted output conditions, switch duty cycle may have to

be as low as 2% to maintain control of output current. This

would require switch on time of 200ns at 100kHz switching frequency, so frequency is reduced at very low output

voltages by feeding the FB signal into the oscillator and

creating a linear frequency downshift when the FB signal

drops below 1.3V. Current trip level is set by the voltage on

the I

source. When this pin is left open, it self-clamps at about

4.5V and sets current limit at 6.5A for the LT1074 and 2.6A

for the LT1076. In the 7-pin package an external resistor

can be connected from the I

current limit. A capacitor in parallel with this resistor will

soft-start the current limit. A slight offset in C2 guarantees

that when the I

C2 output will stay high and force switch duty cycle to zero.

The “Shutdown” pin is used to force switch duty cycle to

zero by pulling the I

the regulator. Threshold for the former is approximately

2.35V, and for complete shutdown, approximately 0.3V.

Total supply current in shutdown is about 150µA. A 10µA

pull-up current forces the shutdown pin high when left

open. A capacitor can be used to generate delayed startup. A resistor divider will program “undervoltage lockout”

if the divider voltage is set at 2.35V when the input is at the

desired trip point.

The switch used in the LT1074 is a Darlington NPN (single

NPN for LT1076) driven by a saturated PNP. Special

patented circuitry is used to drive the PNP on and off very

quickly even from the saturation state. This particular

switch arrangement has no “isolation tubs” connected to

the switch output, which can therefore swing to 40V below

ground.

pin which is driven by an internal 320µA current

LIM

pin to ground to set a lower

LIM

pin is pulled to within 200mV of ground,

LIM

pin low, or to completely shut down

LIM

sn1074 1074fds

5

Page 6

LT1074/LT1076

UW

TYPICAL PERFOR A CE CHARACTERISTICS

VC Pin Characteristics VC Pin Characteristics Feedback Pin Characteristics

200

150

100

50

0

–50

CURRENT (mA)

–100

–150

–200

0

1234

V ADJUSTED FOR

FB

I = 0 AT V = 2V

CC

SLOPE ≈ 400kΩ

V ≤ 2V

FB

VOLTAGE (V)

5

789

6

LT1074•TPC01

2.0

1.5

1.0

0.5

0

–0.5

CURRENT (mA)

–1.0

–1.5

–2.0

1234

0

V ≥ 2.5V

FB

VOLTAGE (V)

5

789

6

LT1074•TPC02

–100

CURRENT (µA)

–200

–300

–400

–500

500

400

300

200

100

0

START OF

FREQUENCY SHIFTING

1

0

234

VOLTAGE (V)

5

78 109

6

LT1074•TPC03

Shutdown Pin Characteristics

40

30

20

V

= 50V

DETAILS OF THIS

AREA SHOWN IN

OTHER GRAPH

10

20 40

IN

WITH V

30

VOLTAGE (V)

IN

CURRENT (µA)

–10

–20

–30

–40

10

0

0

THIS POINT MOVES

50 60 70 80

LT1074•TPC04

Shutdown Pin Characteristics I

0

–5

–10

–15

–20

–25

CURRENT (µA)

–30

–35

–40

= 25°CT

j

CURRENT FLOWS OUT

OF SHUTDOWN PIN

SHUTDOWN

THRESHOLD

0

1.0 2.0

0.5

1.5

VOLTAGE (V)

2.5 3.0 3.5 4.0

LT1074•PC05

Supply Current

20

18

16

14

12

10

8

6

INPUT CURRENT (mA)

4

2

0

DEVICE NOT SWITCHING

V

C

0

20 30 60

10 40 50

INPUT VOLTAGE (V)

= 1V

LT1074•TPC11

–100

–150

–200

CURRENT (µA)

–250

–300

–350

–400

Pin Characteristics

LIM

100

50

0

–50

0

–1

–2

T = 25°C

j

12

VOLTAGE (V)

3

7

5

8

LT1074•TPC06

6

4

6

sn1074 1074fds

Page 7

UW

TYPICAL PERFOR A CE CHARACTERISTICS

Reference Voltage vs

Supply Current (Shutdown)

300

250

200

150

100

INPUT CURRENT (µA)

50

0

0

10 20 40

30 50 60

INPUT VOLTAGE (V)

Reference Shift with Ripple

Voltage

20

10

0

–10

–20

–30

–40

–50

–60

–70

CHANGE IN REFERENCE VOLTAGE (mV)

–80

0

SQUARE

WAVE

20 40 60 80

PEAK-TO-PEAK RIPPLE AT FB PIN (mV)

100 120

TRI WAVE

140

LT1074•TPC13

160 180 200

LT1074•TPC16

Temperature Switch “On” Voltage

2.25

2.24

2.23

2.22

2.21

VOLTAGE (V)

2.20

2.19

2.18

2.17

–25 0 25 50

–50

JUNCTION TEMPERATURE (°C)

75 100 125 150

Error Amplifier Phase and G

8k

7k

6k

(µmho)

5k

4k

3k

2k

TRANSCONDUCTANCE

1k

0

1k 100k 1M 10M

10k

FREQUENCY (Hz)

LT1074•TPC14

M

θ

G

M

LT1074•TPC17

200

150

100

50

0

–50

–100

–150

–200

PHASE (°)

LT1074/LT1076

3.0

2.5

2.0

1.5

“ON” VOLTAGE (V)

1.0

0.5

0

Switching Frequency vs

Temperature

120

115

110

105

100

95

FREQUENCY (kHz)

90

85

80

–50

–25 0 25 50

LT1074

LT1076

123

SWITCH CURRENT (A)

JUNCTION TEMPERATURE (°C)

T = 25°C

j

4 56

LT1074•TPC28

75

100

125

LT1074•TPC18

150

Feedback Pin Frequency Shift

160

140

120

100

80

60

40

SWITCHING FREQUENCY (kHz)

20

–55°C

0

0

0.5 2.0 2.5

FEEDBACK PIN VOLTAGE (V)

150°C

25°C

1.0 1.5 3.0

LT1074•TPC19

Current Limit vs Temperature*

8

7

I PIN OPEN

LIM

6

5

4

3

R = 5kΩ

2

OUTPUT CURRENT LIMIT (A)

1

*MULTIPLY CURRENTS BY 0.4 FOR LT1076

0

–50 –25 0 25 50

LIM

JUNCTION TEMPERATURE (°C)

R = 10kΩ

LIM

75

100

125

LT1074•TPC22

150

sn1074 1074fds

7

Page 8

LT1074/LT1076

∆∆V

VV

OUT

GND OUT

=

()()

221.

U

PI

U

DESCRIPTIO S

VIN PIN

The VIN pin is both the supply voltage for internal control

circuitry and one end of the high current switch. It is

important,

especially at low input voltages

, that this pin be

bypassed with a low ESR, and low inductance capacitor to

prevent transient steps or spikes from causing erratic

operation. At full switch current of 5A, the switching

transients at the regulator input can get very large as

shown in Figure 1. Place the input capacitor very close to

the regulator and connect it with wide traces to avoid extra

inductance. Use radial lead capacitors.

dl

L

()

P

()

dt

STEP =

I

ESR

()

()

SW

RAMP =

I

T

()

()

SW

ON

C

LT1074•PD01

To ensure good load regulation, the ground pin must be

connected directly to the proper output node, so that no

high currents flow in this path. The output divider resistor

should also be connected to this low current connection

line as shown in Figure 2.

LT1074

FB

GND

R2

HIGH CURRENT

RETURN PATH

NEGATIVE OUTPUT NODE

WHERE LOAD REGULATION

WILL BE MEASURED

LT1074•PD02

Figure 1. Input Capacitor Ripple Figure 2. Proper Ground Pin Connection

LP = Total inductance in input bypass connections

and capacitor.

“Spike” height (dI/dt • LP) is approximately 2V per

inch of lead length for LT1074 and 0.8V per inch for

LT1076.

“Step” for ESR = 0.05Ω and I

“Ramp” for C = 200µF, T

ON

= 5A is 0.25V.

SW

= 5µs, and I

SW

= 5A,

is 0.12V.

Input current on the VIN Pin in shutdown mode is the sum

of actual supply current (≈140µA, with a maximum of

300µA), and switch leakage current. Consult factory for

special testing if shutdown mode input current is critical.

GROUND PIN

It might seem unusual to describe a ground pin, but in the

case of regulators, the ground pin must be connected

properly to ensure good load regulation. The internal

reference voltage is referenced to the ground pin; so any

error in ground pin voltage will be multiplied at the output;

FEEDBACK PIN

The feedback pin is the inverting input of an error amplifier

which controls the regulator output by adjusting duty

cycle. The noninverting input is internally connected to a

trimmed 2.21V reference. Input bias current is typically

0.5µA when the error amplifier is balanced (I

OUT

= 0). The

error amplifier has asymmetrical GM for large input signals to reduce startup overshoot. This makes the amplifier

more sensitive to large ripple voltages at the feedback pin.

100mVp-p ripple at the feedback pin will create a 14mV

offset in the amplifier, equivalent to a 0.7% output voltage

shift. To avoid output errors, output ripple (P-P) should be

less than 4% of DC output voltage at the point where the

output divider is connected.

See the “Error Amplifier” section for more details.

Frequency Shifting at the Feedback Pin

The error amplifier feedback pin (FB) is used to downshift

the oscillator frequency when the regulator output voltage

is low. This is done to guarantee that output short-circuit

8

sn1074 1074fds

Page 9

LT1074/LT1076

U

PI

U

DESCRIPTIO S

current is well controlled even when switch duty cycle

must be extremely low. Theoretical switch “on” time for a

buck converter in continuous mode is:

VV

+

t

ON

OUT D

=

Vf

•

IN

VD = Catch diode forward voltage ( ≈ 0.5V)

f = Switching frequency

At f = 100kHz, t

must drop to 0.2µs when V

ON

and the output is shorted (V

= 0V). In current limit,

OUT

IN

= 25V

the LT1074 can reduce tON to a minimum value of

≈0.6µs, much too long to control current correctly for

V

= 0. To correct this problem, switching frequency

OUT

is lowered from 100kHz to 20kHz as the FB pin drops

from 1.3V to 0.5V. This is accomplished by the circuitry

TO

OSCILLATOR

V

OUT

2.21V

Q1

R3

3k

R1

EXTERNAL

DIVIDER

FB

R2

2.21k

LT1074•PD03

+2V

+

ERROR

V

AMPLIFIER

C

–

Figure 3. Frequency Shifting

shown in Figure 3.

Q1 is off when the output is regulating (VFB = 2.21V). As

the output is pulled down by an overload, VFB will eventually reach 1.3V, turning on Q1. As the output continues to

drop, Q1 current increases proportionately and lowers the

frequency of the oscillator. Frequency shifting starts when

the output is ≈ 60% of normal value, and is down to its

minimum value of ≅ 20kHz when the output is ≅ 20% of

normal value. The rate at which frequency is shifted is

determined by both the internal 3k resistor R3 and the

external divider resistors. For this reason, R2 should not

be increased to more than 4kΩ, if the LT1074 will be

subjected to the simultaneous conditions of high input

voltage and output short-circuit.

SHUTDOWN PIN

The shutdown pin is used for undervoltage lockout, micropower shutdown, soft-start, delayed start, or as a general

purpose on/off control of the regulator output. It controls

switching action by pulling the I

pin low, which forces

LIM

the switch to a continuous “off” state. Full micropower

shutdown is initiated when the shutdown pin drops below

0.3V.

The V/I characteristics of the shutdown pin are shown in

Figure 4. For voltages between 2.5V and ≈VIN, a current of

10µA flows

out

of the shutdown pin. This current in-

creases to ≈25µA as the shutdown pin moves through the

2.35V threshold. The current increases further to ≈30µA at

the 0.3V threshold, then drops to ≈15µA as the shutdown

voltage fall below 0.3V. The 10µA current source is in-

cluded to pull the shutdown pin to its high or default state

when left open. It also provides a convenient pull-up for

delayed start applications with a capacitor on the shutdown pin.

When activated, the typical collector current of Q1 in

Figure 5, is ≈2mA. A soft-start capacitor on the I

LIM

pin will

delay regulator shutdown in response to C1, by

≈(5V)(C

)/2mA. Soft-start after full micropower shut-

LIM

down is ensured by coupling C2 to Q1.

0

–5

–10

–15

–20

–25

CURRENT (µA)

–30

–35

–40

Figure 4. Shutdown Pin Characteristics

= 25°CT

j

CURRENT FLOWS OUT

OF SHUTDOWN PIN

SHUTDOWN

THRESHOLD

0

1.0 2.0

0.5

1.5

VOLTAGE (V)

2.5 3.0 3.5 4.0

LT1074•PC05

sn1074 1074fds

9

Page 10

LT1074/LT1076

R

VVR

VV

R

R

SH

UTP SH

3

08 1

1

1

2

=

−

()()

− +

⎛

⎝

⎜

⎞

⎠

⎟

.

U

PI

SHUTDOWN

PIN

DESCRIPTIO S

10 Aµ

–

2.3V

+

–

0.3V

+

Figure 5. Shutdown Circuitry

U

V

IN

300 Aµ

I

LIM

Q1

TO TOTAL

REGULATOR

SHUTDOWN

PIN

6V

LT1074•PD07

EXTERNAL

C

LIM

C1

C2

Undervoltage Lockout

Undervoltage lockout point is set by R1 and R2 in Figure 6.

To avoid errors due to the 10µA shutdown pin current, R2

is usually set at 5k, and R1 is found from:

VV

−

TP SH

RR

12=

()

V

SH

VTP = Desired undervoltage lockout voltage

Hysteresis in undervoltage lockout may be accomplished

by connecting a resistor (R3) from the I

pin to the

LIM

shutdown pin as shown in Figure 7. D1 prevents the

shutdown divider from altering current limit.

V

R1

D1*

R3

R2

*1N4148

Figure 7. Adding Hysteresis

Trip Po V V

int .== +

TP

235 1

IN

SHUT

LT1074

I

LIM

OPTIONAL CURRENT

LIMIT RESISTOR

⎛

R

1

⎜

R

2

⎝

LT1074•PD09

⎞

⎟

⎠

If R3 is added, the lower trip point (VIN descending) will be

the same. The upper trip point (V

⎛

RRR

VV

=+

UTP SH

1

⎜

⎝

121

⎞

−

08

⎟

R

3

⎠

.

UTP

⎛

V

⎜

⎝

R

R

) will be:

⎞

1

⎟

3

⎠

If R1 and R2 are chosen, R3 is given by:

VSH = Threshold for lockout on the

shutdown pin = 2.45V

If quiescent supply current is critical, R2 may be increased

up to 15kΩ, but the denominator in the formula for R2

should replace VSH with VSH – (10µA)(R2).

R1

R2

5k

Figure 6. Undervoltage Lockout

10

SHUT

V

IN

LT1074

GND

LT1074•PD08

Example: An undervoltage lockout is required such that

the output will not start until VIN = 20V, but will continue

to operate until VIN drops to 15V. Let R2 = 2.32k.

15 2 35

1234

=

Rk

()

3

Rk

=

20 2 35 1

()

.

235 08 125

...

−

()()

.

− +

.

VV

−

=

235

.

V

39

⎛

12 5

⎜

232

⎝

=

⎞

.

⎟

.

⎠

12 5

.

.

k

sn1074 1074fds

Page 11

LT1074/LT1076

U

PI

I

LIM

The I

U

DESCRIPTIO S

PIN

pin is used to reduce current limit below the

LIM

preset value of 6.5A. The equivalent circuit for this pin is

shown in Figure 8.

When I

TO LIMIT

CIRCUIT

R1

8K

is left open, the voltage at Q1 base clamps at 5V

LIM

V

Q1

I

LIM

Figure 8. I

IN

320 Aµ

D1

LIM

D2

4.3V

D3

6V

LT1047•PD12

Pin Circuit

through D2. Internal current limit is determined by the

current through Q1. If an external resistor is connected

between I

and ground, the voltage at Q1 base can be

LIM

reduced for lower current limit. The resistor will have a

voltage across it equal to (320µA)(R), limited to ≈5V when

clamped by D2. Resistance required for a given current

limit is:

R

= I

(2kΩ) + 1kΩ (LT1074)

LIM

= I

(5.5kΩ) + 1kΩ (LT1076)

LIM

R

LIM

LIM

As an example, a 3A current limit would require

3A(2k) + 1k = 7kΩ for the LT1074. The accuracy of these

formulas is ± 25% for 2A ≤ I

7A ≤ I

25% above the

≤ 1.8A (LT1076), so I

LIM

peak

switch current required.

≤ 5A (LT1074) and

LIM

should be set at least

LIM

Foldback current limiting can be easily implemented by

adding a resistor from the output to the I

pin as shown

LIM

in Figure 9. This allows full desired current limit (with or

without R

) when the output is regulating, but reduces

LIM

current limit under short-circuit conditions. A typical value

for RFB is 5kΩ, but this may be adjusted up or down to set

the amount of foldback. D2 prevents the output voltage

from forcing current back into the I

value for RFB, first calculate R

IR

−

044

.*

SC L

R

FB

()()

=

−Ω

Rk I

05 1

.*

LSC

()

LIM

−

pin. To calculate a

LIM

, the RFB:

Rink

()

Ω

L

*Change 0.44 to 0.16, and 0.5 to 0.18 for LT1076.

Example: I

R

FB

= 4A, ISC = 1.5A, R

LIM

−

15 044 9

..

()

=

kk

059 1 15

..

()

R

LIM

Figure 9. Foldback Current Limit

k

Ω

()

−

−

LT1074

I

LIM

R

FB

38

()

FB

D2

1N4148

= (4)(2k) + 1k = 9k

LIM

Ω

k

.

V

OUT

LT1074•PD13

Error Amplifier

The error amplifier in Figure 10 is a single stage design

with added inverters to allow the output to swing above

and below the common mode input voltage. One side of

the amplifier is tied to a trimmed internal reference voltage

of 2.21V. The other input is brought out as the FB (feedback) pin. This amplifier has a GM (voltage “in” to current

“out”) transfer function of ≈5000µmho. Voltage gain is

determined by multiplying GM times the total equivalent

output loading, consisting of the output resistance of Q4

and Q6 in parallel with the series RC external frequency

compensation network. At DC, the external RC is ignored,

and with a parallel output impedance for Q4 and Q6 of

400kΩ, voltage gain is ≈2000. At frequencies above a few

hertz, voltage gain is determined by the external compensation, RC and CC.

sn1074 1074fds

11

Page 12

LT1074/LT1076

PI

U

DESCRIPTIO S

U

90 Aµ

Q3

50 Aµ

Q2

Q1

X1.8

2.21V

140 Aµ

ALL CURRENTS SHOWN ARE AT NULL CONDITION

FB

Figure 10. Error Amplifier

300

50 Aµ

D2

5.8V

Q4

µ

90 A

D1

Ω

V

C

90 Aµ

Q6

EXTERNAL

FREQUENCY

COMPENSATION

R

C

C

C

LT1074 • PD11

G

2π

m

fC

••

at mid frequencies

C

A

=

V

A G R at high frequencies

=•

VmC

Phase shift from the FB pin to the VC pin is 90° at mid

frequencies where the external CC is controlling gain, then

drops back to 0° (actually 180° since FB is an inverting

input) when the reactance of CC is small compared to RC.

The low frequency “pole” where the reactance of CC is

equal to the output impedance of Q4 and Q6 (rO), is:

f

POLE

Although f

=

1

rk

≈Ω

400

rC

••

2

π

varies as much as 3:1 due to rO variations,

POLE

O

O

mid-frequency gain is dependent only on Gm, which is

specified much tighter on the data sheet. The higher

frequency “zero” is determined solely by RC and CC.

RC

••

2π

1

CC

f

ZERO

=

The error amplifier has asymmetrical peak output current.

Q3 and Q4 current mirrors are unity-gain, but the Q6

mirror has a gain of 1.8 at output null and a gain of 8 when

the FB pin is high (Q1 current = 0). This results in a

maximum positive output current of 140µA and a maxi-

mum negative (sink) output current of ≅1.1mA. The asymmetry is deliberate—it results in much less regulator

output overshoot during rapid start-up or following the

release of an output overload. Amplifier offset is kept low

by area scaling Q1 and Q2 at 1.8:1.

Amplifier swing is limited by the internal 5.8V supply for

positive outputs and by D1 and D2 when the output goes

low. Low clamp voltage is approximately one diode drop

(≈0.7V – 2mV/°C).

Note that both the FB pin and the VC pin have other internal

connections. Refer to the frequency shifting and synchronizing discussions.

12

sn1074 1074fds

Page 13

U

TYPICAL APPLICATIO S

LT1074/LT1076

Tapped-Inductor Buck Converter

V

20V† TO 35V

IN

+

**

* = 1% FILM RESISTORS

D1 = MOTOROLA-MBR745

C1 = NICHICON-UPL1C221MRH6

C2 = NICHICON-UPL1A102MRH6

L1 = COILTRONICS-CTX25-5-52

L2

µ

H

5

C1

+

4400

(2 EA

2200

16V)

µ

F

µ

F,

+

V

IN

LT1074HV

GND

C3

µ

F

200

50V

PULSE ENGINEERING #PE±65282*

MOTOROLA MBR2030CTL

†

IF INPUT VOLTAGE IS BELOW 20V,

MAXIMUM OUTPUT CURRENT WILL BE REDUCED. SEE AN44

V

SW

FB

V

C

R3

1k

C2

µ

F

0.2

31

D2

35V

5W

D3

1N5819

L1*

D1**

0.01µF

R1

2.8k

R2

2.21k

Positive-to-Negative Converter with 5V Output

V

IN

4.5V to

40V

+

LT1074

GND

†

LOWER REVERSE VOLTAGE RATING MAY BE USED FOR LOWER INPUT VOLTAGES.

LOWER CURRENT RATING IS ALLOWED FOR LOWER OUTPUT CURRENT. SEE AN44.

††

LOWER CURRENT RATING MAY BE USED FOR LOWER OUTPUT CURRENT. SEE AN44.

R1, R2, AND C4 ARE USED FOR LOOP FREQUENCY COMPENSATION WITH LOW INPUT VOLTAGE,

**

BUT R1 AND R2 MUST BE INCLUDED IN THE CALCULATION FOR OUTPUT VOLTAGE DIVIDER VALUES.

FOR HIGHER OUTPUT VOLTAGES, INCREASE R1, R2, AND R3 PROPORTIONATELY.

FOR INPUT VOLTAGE > 10V, R1, R2, AND C4 CAN BE ELIMINATED, AND COMPENSATION IS

DONE TOTALLY ON THE V PIN.

R3 = –2.37 (KΩ)

V

R1 = (R3) (1.86)

R2 = (R3) (3.65)

MAXIMUM OUTPUT CURRENT OF 1A IS DETERMINED BY MINIMUM INPUT

**

VOLTAGE OF 4.5V. HIGHER MINIMUM INPUT VOLTAGE WILL ALLOW MUCH HIGHER

OUTPUT CURRENTS. SEE AN44.

V

OUT

+

C1

µF

220

50V

L1

µH

25

††

5A

IN

V

SW

V

FB

V

C

C3

µF

0.1

C

R1**

5.1k

R2**

10k

†

D1

MBR745

C4**

0.01

R3*

2.74k

+

C2

µF

1000

10V

R4

1.82k*

µF

LT1074 • TA03

V

OUT

†

5V, 10A

C4

µ

F

390

16V

LT1074 •TA02

OPTIONAL FILTER

µH

5

–

+

–5V,1A***

200µF

10V

sn1074 1074fds

13

Page 14

LT1074/LT1076

PACKAGE DESCRIPTIO

0.320 – 0.350

(8.13 – 8.89)

0.420 – 0.480

(10.67 – 12.19)

U

K Package

4-Lead TO-3 Metal Can

(Reference LTC DWG # 05-08-1311)

0.760 – 0.775

(19.30 – 19.69)

0.038 – 0.043

(0.965 – 1.09)

1.177 – 1.197

(29.90 – 30.40)

0.470 TP

0.060 – 0.135

(1.524 – 3.429)

0.655 – 0.675

(16.64 – 19.05)

P.C.D.

0.151 – 0.161

(3.84 – 4.09)

DIA 2 PLC

0.256

(6.502)

0.060

(1.524)

0.300

(7.620)

BOTTOM VIEW OF DD PAK

HATCHED AREA IS SOLDER PLATED

COPPER HEAT SINK

0.060

(1.524)

0.075

(1.905)

0.183

(4.648)

0.167 – 0.177

(4.24 – 4.49)

R

72°

18°

0.490 – 0.510

(12.45 – 12.95)

R

K4(TO-3) 1098

OBSOLETE PACKAGE

Q Package

5-Lead Plastic DD Pak

(Reference LTC DWG # 05-08-1461)

0.060

(1.524)

TYP

0.330 – 0.370

(8.382 – 9.398)

+0.012

0.143

–0.020

+0.305

3.632

()

–0.508

0.028 – 0.038

(0.711 – 0.965)

0.390 – 0.415

(9.906 – 10.541)

15° TYP

0.067

(1.70)

BSC

0.165 – 0.180

(4.191 – 4.572)

0.059

(1.499)

TYP

0.013 – 0.023

(0.330 – 0.584)

0.045 – 0.055

(1.143 – 1.397)

+0.008

0.004

–0.004

+0.203

0.102

()

–0.102

0.095 – 0.115

(2.413 – 2.921)

0.050 ± 0.012

(1.270 ± 0.305)

Q(DD5) 1098

14

sn1074 1074fds

Page 15

PACKAGE DESCRIPTIO

LT1074/LT1076

U

R Package

7-Lead Plastic DD Pak

(Reference LTC DWG # 05-08-1462)

0.256

(6.502)

0.060

(1.524)

0.300

(7.620)

BOTTOM VIEW OF DD PAK

HATCHED AREA IS SOLDER PLATED

COPPER HEAT SINK

(1.524)

(1.905)

0.060

0.075

0.183

(4.648)

0.060

(1.524)

TYP

0.330 – 0.370

(8.382 – 9.398)

+0.012

0.143

–0.020

+0.305

3.632

()

–0.508

0.026 – 0.036

(0.660 – 0.914)

0.390 – 0.415

(9.906 – 10.541)

15° TYP

0.050

(1.27)

BSC

0.165 – 0.180

(4.191 – 4.572)

T Package

5-Lead Plastic TO-220 (Standard)

(Reference LTC DWG # 05-08-1421)

0.059

(1.499)

TYP

0.013 – 0.023

(0.330 – 0.584)

0.045 – 0.055

(1.143 – 1.397)

+0.008

0.004

–0.004

+0.203

0.102

()

–0.102

0.095 – 0.115

(2.413 – 2.921)

0.050 ± 0.012

(1.270 ± 0.305)

R (DD7) 1098

0.390 – 0.415

(9.906 – 10.541)

0.460 – 0.500

(11.684 – 12.700)

0.067

BSC

(1.70)

0.147 – 0.155

(3.734 – 3.937)

DIA

0.230 – 0.270

(5.842 – 6.858)

0.570 – 0.620

(14.478 – 15.748)

0.330 – 0.370

(8.382 – 9.398)

SEATING PLANE

0.152 – 0.202

0.260 – 0.320

(6.60 – 8.13)

0.028 – 0.038

(0.711 – 0.965)

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

(3.861 – 5.131)

0.165 – 0.180

(4.191 – 4.572)

0.700 – 0.728

(17.78 – 18.491)

0.135 – 0.165

(3.429 – 4.191)

0.620

(15.75)

TYP

* MEASURED AT THE SEATING PLANE

0.045 – 0.055

(1.143 – 1.397)

0.095 – 0.115

(2.413 – 2.921)

0.155 – 0.195*

(3.937 – 4.953)

0.013 – 0.023

(0.330 – 0.584)

T5 (TO-220) 0399

sn1074 1074fds

15

Page 16

LT1074/LT1076

TYPICAL APPLICATIO

U

Negative Boost Converter

200µF

V

–5V TO –15V

PACKAGE DESCRIPTIO

0.390 – 0.415

(9.906 – 10.541)

LT1074

GND

C3

+

15V

IN

MBR735

*

**

I

(MAX) = 1A TO 3A DEPENDING

OUT

ON INPUT VOLTAGE. SEE AN44

U

7-Lead Plastic TO-220 (Standard)

(Reference LTC DWG # 05-08-1422)

(3.734 – 3.937)

V

IN

V

FB

V

V

C

0.01µF

0.147 – 0.155

DIA

SW

R3

750Ω

T7 Package

C2

1nF

100pF

L1

D1*

25

µ

H

+

µ

H

5

OPTIONAL OUTPUT FILTER

0.165 – 0.180

(4.191 – 4.572)

R1

12.7k

R2

2.21k

100µF

+

C1

µ

F

1000

25V

V

OUT

–15V**

LT1074 • TA04

0.045 – 0.055

(1.143 – 1.397)

0.230 – 0.270

(5.842 – 6.858)

0.460 – 0.500

(11.684 – 12.700)

0.050

BSC

(1.27)

0.330 – 0.370

(8.382 – 9.398)

0.026 – 0.036

(0.660 – 0.914)

0.570 – 0.620

(14.478 – 15.748)

0.260 – 0.320

(6.604 – 8.128)

SEATING PLANE

0.152 – 0.202

(3.860 – 5.130)

0.700 – 0.728

(17.780 – 18.491)

0.135 – 0.165

(3.429 – 4.191)

0.620

(15.75)

TYP

*MEASURED AT THE SEATING PLANE

0.095 – 0.115

(2.413 – 2.921)

0.155 – 0.195*

(3.937 – 4.953)

0.013 – 0.023

(0.330 – 0.584)

T7 (TO-220) 0399

RELATED PARTS

PART NUMBER DESCRIPTION COMMENTS

LT1375/LT1376 1.5A, 500kHz Step-Down Switching Regulators VIN Up to 25V, I

LT1374/LT1374HV 4.5A, 500kHz Step-Down Switching Regulators VIN Up to 25V (32V for HV), I

LT1370 6A, 500kHz High Efficiency Switching Regulator 6A/42V Internal Switch, 7-Lead DD/TO-220

LT1676 Wide Input Range, High Efficiency Step-Down Regulator VIN from 7.4V to 60V, I

LT1339 High Power Synchronous DC/DC Controller VIN Up to 60V, I

LT1765 3A, 1.25MHz, Step-Down Regulator VIN = 3V to 25V, VµF =1.2V, TSSOP-16E, SO8 Package

Linear Technology Corporation

16

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ● FAX: (408) 434-0507

●

www.linear.com

Up to 1.25A, SO-8

OUT

Up to 4.25A, SO-8/DD

OUT

Up to 0.5A, SO-8

OUT

Up to 50A, Current Mode

OUT

LT/CPI 0202 1.5K REV D • PRINTED IN USA

© LINEAR TECHNOLOGY CORPORATION 1994

sn1074 1074fds

Loading...

Loading...