Page 1

High Speed Converter Evaluation Platform

FEATURES

Xilinx Virtex-4 FPGA-based buffer memory board

Used for capturing digital data from high speed ADC

evaluation boards to simplify evaluation

64 kB FIFO depth

Parallel input at 644 MSPS SDR and 800 MSPS DDR

Supports 1.8 V, 2.5 V, and 3.3 V CMOS and LVDS interfaces

Supports multiple ADC channels up to 18 bits

Measures performance with VisualAnalog

Real-time FFT and time domain analysis

Analyzes SNR, SINAD, SFDR, and harmonics

Simple USB port interface (2.0)

Supports ADCs with serial port interfaces (SPI)

FPGA reconfigurable via JTAG, on-board EPROM, or USB

On-board regulator circuit speeds setup

5 V, 3 A switching power supply included

Compatible with Windows 98 (2nd edition), Windows 2000,

Windows ME, and Windows XP

EQUIPMENT NEEDED

Analog signal source and antialiasing filter

Low jitter clock source

High speed ADC evaluation board and ADC data sheet

PC running Windows 98 (2nd edition), Windows 2000,

Windows ME, or Windows XP

Latest version of VisualAnalog

USB 2.0 port recommended (USB 1.1 compatible)

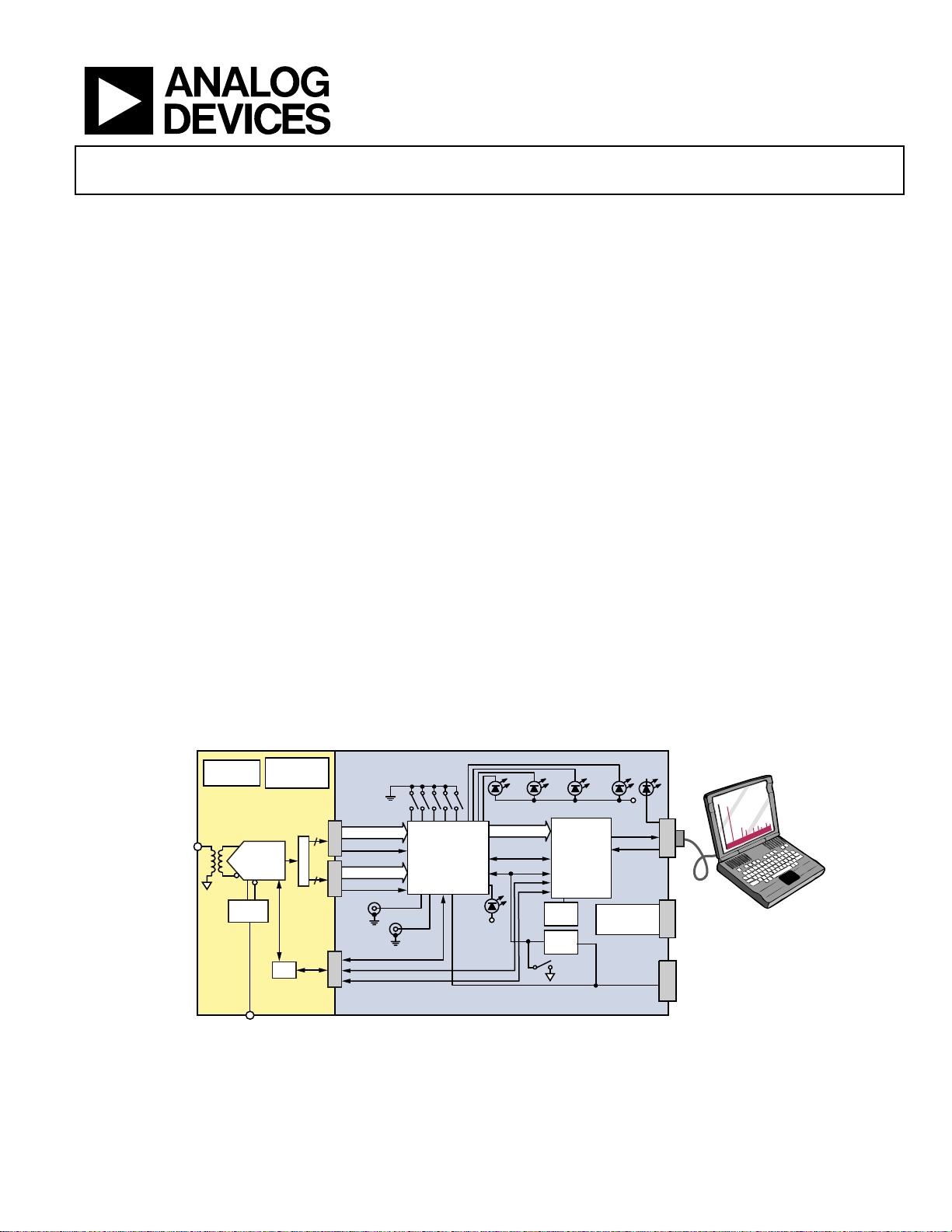

FUNCTIONAL BLOCK DIAGRAM

HSC-ADC-EVALC

PRODUCT HIGHLIGHTS

1. Easy to Set Up. Connect the included power supply along

with the CLK and AIN signal sources to the two evaluation

boards. Then connect to the PC via the USB port and

evaluate the performance instantly.

2. USB Port Connection to PC. PC interface is via a USB 2.0

connection (1.1 compatible) to the PC. A USB cable is

provided in the kit.

3. 64 kB FIFO. The on-board FPGA contains an integrated

FIFO to store data captured from the ADC for subsequent

processing.

4. Up to 644 MSPS SDR/800 MSPS DDR Encode Rates on

Each Channel. Multichannel ADCs with encode rates up

to 644 MSPS SDR and 800 MSPS DDR can be used with

the ADC capture board.

5. Supports ADCs with Serial Port Interface or SPI. Some

ADCs include a feature set that can be changed via the

SPI. The ADC capture board supports these SPI-driven

features through the existing USB connection to the

computer without additional cabling needed.

6. VisualAnalog™. VisualAnalog supports the HSC-ADC-

EVALC hardware platform as well as enabling virtual ADC

evaluation using ADIsimADC™, Analog Devices proprietary

behavioral modeling technology. This allows rapid comparison between multiple ADCs, with or without hardware

evaluation boards. For more information, see AN-737 at

www.analog.com/VisualAnalog.

CLOCK

CIRCUIT

REGULATORS

ADC

ON-BOARD

VOLTAGE

LOGIC

SPI

POWER

CONNECTOR

SINGLE OR MULTICHANNEL

HIGH SPEED ADC

EVALUATION BOARD

FILTERED

ANALOG

INPUT

CLOCK INP UT

Rev. 0

Evaluation boards are only intended for device evaluation and not for production purposes.

Evaluation boards as supplied “as is” and without warranties of any kind, express, implied, or

statutory including, but not limited to, any implied warranty of merchantability or fitness for a

particular purpose. No license is granted by implication or otherwise under any patents or other

intellectual property by application or use of evaluation boards. Information furnished by Analog

Devices is believed to be accurate and reliable. However, no responsibility is assumed by Analog

Devices for its use, nor for any infringements of pate nts or other rights of third parties t hat may result

from its use. Analog Devices reserves the right to change devices or specifications at any time

without notice. Trademarks and registered trademarks are the property of their respective owners.

Evaluation boards are not authorized to be used in life support devices or systems.

HSC-ADC-EVALC

FPGA

CONFIGURATION

MODE

DATA BUS 2(18 )

n

J3*

CLKA(2)

DATA BUS 1(18 )

n

J2*

CLKB(2)

EXT SYNC1

EXT SYNC2

FPGA GPIO(8)

SPI(7)

J1*

USB DIRECT( 5 )

*DATA CONVE RTE R I/O CONNECTORS

FPGA

LED2 LED1

FPGA

DONE

Figure 1.

USB

CAPTUREUPLOAD

DATA(16)

FIFO

CONTROL(9)

PORTB

PORTD

USB

CONTROLLER

PORTC

PORTE

PORTA

USB

CONFIG

PROM

FPGA

CONFIG

PROM

RECONFIG

CONNECTOR

ONBOARD

VOLTAGE

REGULATORS

POWER

CONNECTOR

JTAG

CONNECTOR

USB

J6

J4

J10

STANDARD

USB 2.0

06676-001

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700 www.analog.com

Fax: 781.461.3113 ©2007 Analog Devices, Inc. All rights reserved.

Page 2

HSC-ADC-EVALC

TABLE OF CONTENTS

Features.............................................................................................. 1

Equipment Needed........................................................................... 1

Product Highlights ........................................................................... 1

Functional Block Diagram .............................................................. 1

Revision History ............................................................................... 2

Product Description......................................................................... 3

Evaluation Board Description......................................................... 3

Evaluation Board Hardware............................................................ 4

HSC-ADC-EVALC ADC Capture Board Easy Start ............... 4

Power Supplies .............................................................................. 4

Connection and Setup ................................................................. 4

Jumpers.......................................................................................... 5

HSC-ADC-EVALC ADC Capture Board Features.................. 6

HSC-ADC-EVALC Supported ADC Evaluation Boards........ 7

Theory of Operation .........................................................................8

Configuration ................................................................................8

Input Circuitry...............................................................................8

Data Capture..................................................................................8

Code Description ..........................................................................8

FPGA Configuration and Customization..................................8

Evaluation Board Schematics and Artwork...................................9

HSC-ADC-EVALC Schematics...................................................9

PCB Layout ................................................................................. 23

I/O Connector—J1, J2, and J3 Pin Mapping .......................... 24

Ordering Information.................................................................... 28

Bill of Materials (RoHS Compliant) ........................................ 28

Ordering Guide .......................................................................... 30

ESD Caution................................................................................ 30

REVISION HISTORY

4/07—Revision 0: Initial Version

Rev. 0 | Page 2 of 32

Page 3

HSC-ADC-EVALC

PRODUCT DESCRIPTION

The Analog Devices, Inc. high speed converter evaluation

platform (HSC-ADC-EVALC) includes the latest version of

VisualAnalog and an FPGA-based buffer memory board to capture

blocks of digital data from the Analog Devices high speed

analog-to-digital converter (ADC) evaluation boards. The ADC

capture board is connected to the PC through a USB port and is

used with VisualAnalog to quickly evaluate the performance of

high speed ADCs. Users can view an FFT for a specific analog

input and encode rate to analyze SNR, SINAD, SFDR, and

harmonic information.

The ADC capture board is easy to set up. Additional equipment

needed includes an Analog Devices high speed ADC evaluation

board, a signal source, and a clock source. Once the kit is

connected and powered, the evaluation is enabled instantly on

the PC.

The ADC capture board enables numerous expansion and

evaluation possibilities by virtue of its powerful reconfigurable

FPGA core.

The system can acquire digital data at speeds up to 644 MSPS

single data rate (SDR) and 800 MSPS double data rate (DDR).

The FPGA contains an integrated FIFO memory that allows

capture of data record lengths up to a total of 64 kB. A USB 2.0

microcontroller communicating with VisualAnalog allows

for easy interfacing to newer computers using the USB 2.0

(USB 1.1 compatible) interface.

EVALUATION BOARD DESCRIPTION

The ADC capture board provides all of the support circuitry

required to accept two 18-bit channels from an ADC’s parallel

CMOS or LVDS outputs. Various functions such as FPGA

configuration load options and I/O logic levels can be selected by

proper connection of various jumpers or switches (see

When using the HSC-ADC-EVALC in conjunction with an

ADC evaluation board, it is critical that the signal sources used

for the ADC board’s analog input and clock have very low phase

noise (<1 ps rms jitter) to achieve the ultimate performance of

the converter.

Proper filtering of the analog input signal to remove harmonics

and lower the integrated or broadband noise at the input is also

necessary to achieve the specified noise performance.

Figure 5 to Figure 20 for complete schematics and layout plots.

See

Tabl e 1).

Rev. 0 | Page 3 of 32

Page 4

HSC-ADC-EVALC

EVALUATION BOARD HARDWARE

HSC-ADC-EVALC ADC CAPTURE BOARD

EASY START

Requirements

• HSC-ADC-EVALC ADC capture board, VisualAnalog, 5 V

wall transformer, and USB cable

• High speed ADC evaluation board and ADC data sheet

• Power supply for ADC evaluation board

• Analog signal source and appropriate filtering

• Low jitter clock source applicable for specific ADC

evaluation, typically <1 ps rms jitter

• PC running Windows® 98 (2nd edition), Windows 2000,

Windows ME, or Windows XP

• PC with a USB 2.0 port recommended (USB 1.1 compatible)

Easy Start Steps

Important Note

Administrative rights for the Windows operating systems are

needed during the entire easy start procedure.

Completion of every step before reverting to a normal user

mode is recommended.

1. Install VisualAnalog from the CD provided in the ADC

capture board kit or download the latest version from the

Web. For the latest updates to the software, check the

Analog Devices website at

2. Connect the ADC capture board to the ADC evaluation

board. If an adapter is required, insert the adapter between

the ADC evaluation board and the ADC capture board.

3. Connect the provided USB cable to the ADC capture board

and to an available USB port on the computer.

4. Refer to

logic level to match the level coming from the ADC evaluation board. 1.8 V is default; 2.5 V and 3.3 V are jumper

selectable. Most evaluation boards can be used with the

default settings.

5. The ADC capture board is supplied with a wall mount

switching power supply. Connect the supply end to an ac

wall outlet rated for 100 Vac to 240 Vac at 47 Hz to 63 Hz.

The other end is a 2.1 mm inner diameter jack that connects

to the PCB at J4.

Table 1 for setting the ADC capture board’s I/O

www.analog.com/FIFO.

6. Once the USB cable is connected to both the computer and

the HSC-ADC-EVALC board, and power is applied, the

USB driver starts to install. The Found New Hardware

Wizard opens and prompts you through the automated

install process.

7. (Optional) Verify in the Windows device manager that

Analog Devices ADC-HSC-EVALC is listed under the

USB hardware.

8. Refer to the instructions included in the respective ADC

data sheet found at

information about connecting the ADC evaluation board’s

power supply and other requirements. After verification of

power supply connections, apply power to the ADC

evaluation board and check the voltage levels on the ADC

board to make sure they are correct.

9. Make sure the evaluation boards are powered on before

connecting the analog input and clock. Connect the

appropriate analog input (which should be filtered with a

band-pass filter) and low jitter clock signal.

10. Refer to the VisualAnalog User Manual at

www.analog.com/FIFO for detailed software operating

instructions.

www.analog.com/FIFO for more

POWER SUPPLIES

The ADC capture board is supplied with a wall mount switching power supply that provides a 5 V, 3 A maximum output.

Connect the supply to the rated 100 Vac to 240 Vac wall outlet at

47 Hz to 63 Hz. The other end is a 2.1 mm inner diameter jack

that connects to the PCB at J4. On the PC board, the supply is

fused and conditioned before connecting to the regulators that

supply the proper bias to the entire ADC capture board.

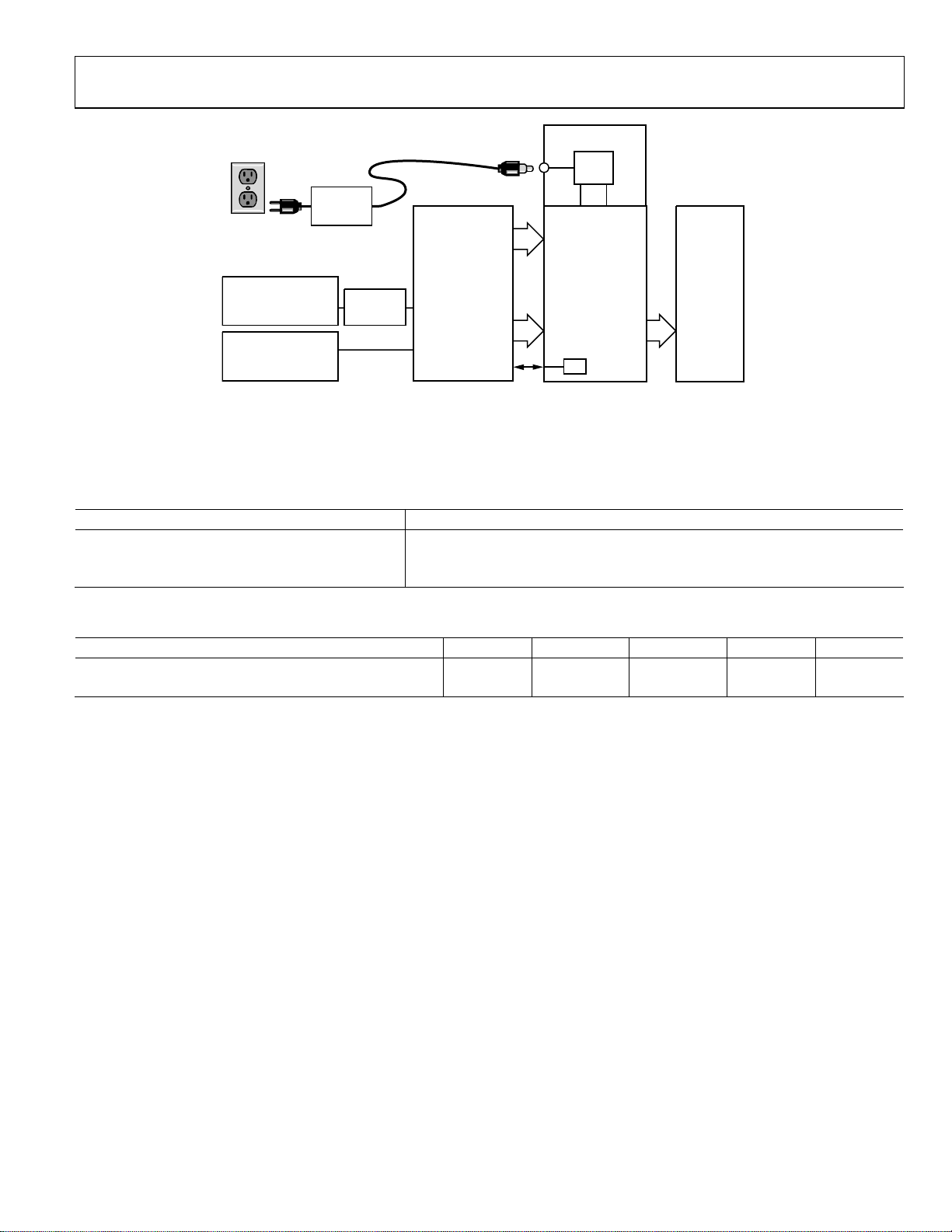

CONNECTION AND SETUP

The ADC capture board has two 40-pin connectors (J2 and J3)

that accept two 18-bit channels of parallel CMOS or LVDS

inputs from the ADC (see

(J1) is used to pass SPI and other USB/FPGA control signals

across to adjacent ADC evaluation boards that support these

features.

Figure 2). The third 40-pin connector

Rev. 0 | Page 4 of 32

Page 5

HSC-ADC-EVALC

T

WALL OUTLE

100V TO 240V AC

47Hz TO 63Hz

ROHDE & SCHWARZ,

SMHU,

2V p-p SIGNAL

SYNTHESIZER

ROHDE & SCHWARZ,

SMHU,

2V p-p SIGNAL

SYNTHESIZER

SWITCHING

POWER

SUPPLY

BAND-PASS

FILTER

EVALUATION

BOARD

XFMR

INPUT

CLK

DATA BUS 2

PARALLEL

LVDS/ CMOS

OUTPUTS

DATA BUS 1

PARALLEL

LVDS/ CMOS

OUTPUTS

SPI

5V DC

3A MAX

ONBOARD POW ER

SUPPLY

PS

–+

REG

GND

V

HSC-ADC-EVALC

DATA CAPTURE

BOARD

USB

CONNECTION

SPI

PC

RUNNING

VisualAnalog

06676-004

Figure 2. Example Setup Using ADC Evaluation Board and HSC-ADC-EVALC ADC Capture Board

JUMPERS

Default Settings

Tabl e 1 lists the default settings for the HSC-ADC-EVALC evaluation kit.

Table 1. Jumper Configurations

Jumper Number Description

J9, Pin 1 to Pin 2 (1.8 V) Default. Sets FPGA I/O voltage to 1.8 V logic (hardwired, do not remove).

J9, Pin 3 to Pin 4 (2.5 V) Install single jumper here to set FPGA I/O voltage to 2.5 V logic.

J9, Pin 5 to Pin 6 (3.3 V) Install single jumper here to set FPGA I/O voltage to 3.3 V logic.

Table 2. FPGA Configuration Mode

U4 DIP Switch Setting M0 M1 M2 M3 M4

FPGA Configured via EEPROM On On On Reserved Reserved

FPGA Configured via USB (Default) On Off Off Reserved Reserved

Rev. 0 | Page 5 of 32

Page 6

HSC-ADC-EVALC

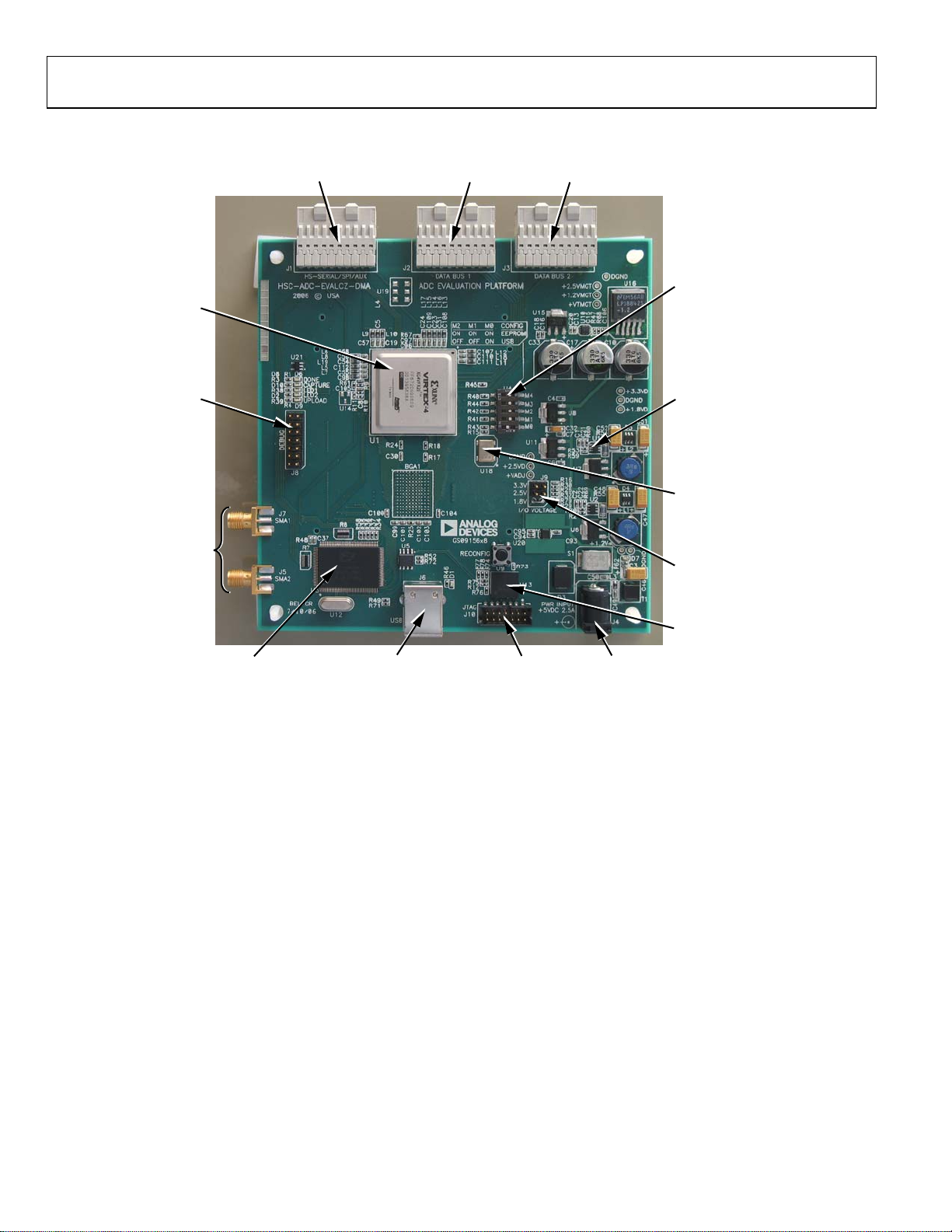

HSC-ADC-EVALC ADC CAPTURE BOARD FEATURES

GENERAL PURPOSE I/O,

USB/SPI CONTROL DATA BUS 1 DATA BUS 2

FPGA LOAD

XILINX

VIRTEX-4

FPGA

SELECT

DEBUG

PINS

EXTERNAL

SYNC I/O

CYPRESS USB

CONTROLLER

USB CONNECTOR FPGA JTAG

CONNECTOR

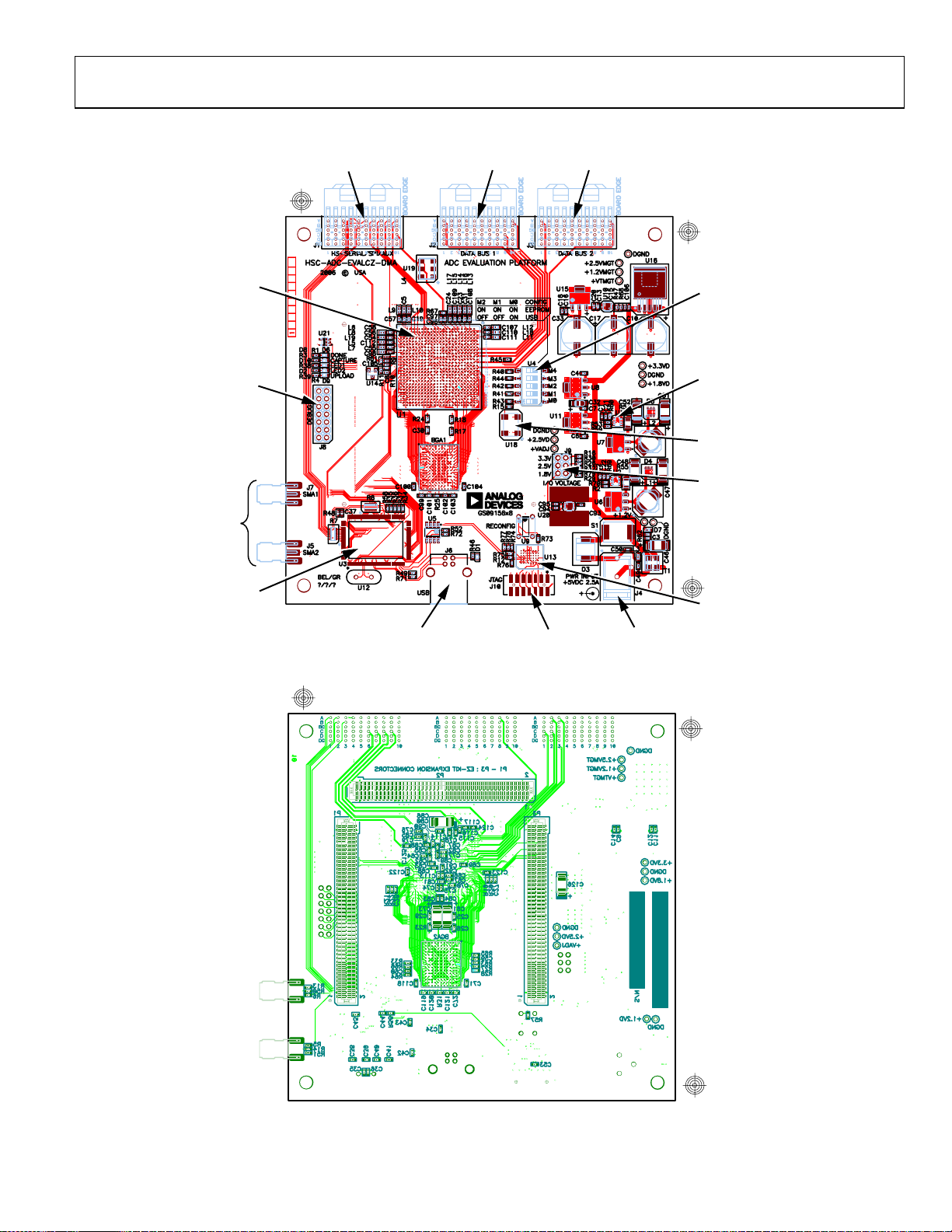

Figure 3. HSC-ADC-EVALC Components (Top View)

5VDC POWER

INPUT

ON BOARD

POWER SUPPLY

100MHz

OSCILLATOR

FPGA I/O

VOLTAGE MODE

FPGA CONFIG

PROM

06676-002

Rev. 0 | Page 6 of 32

Page 7

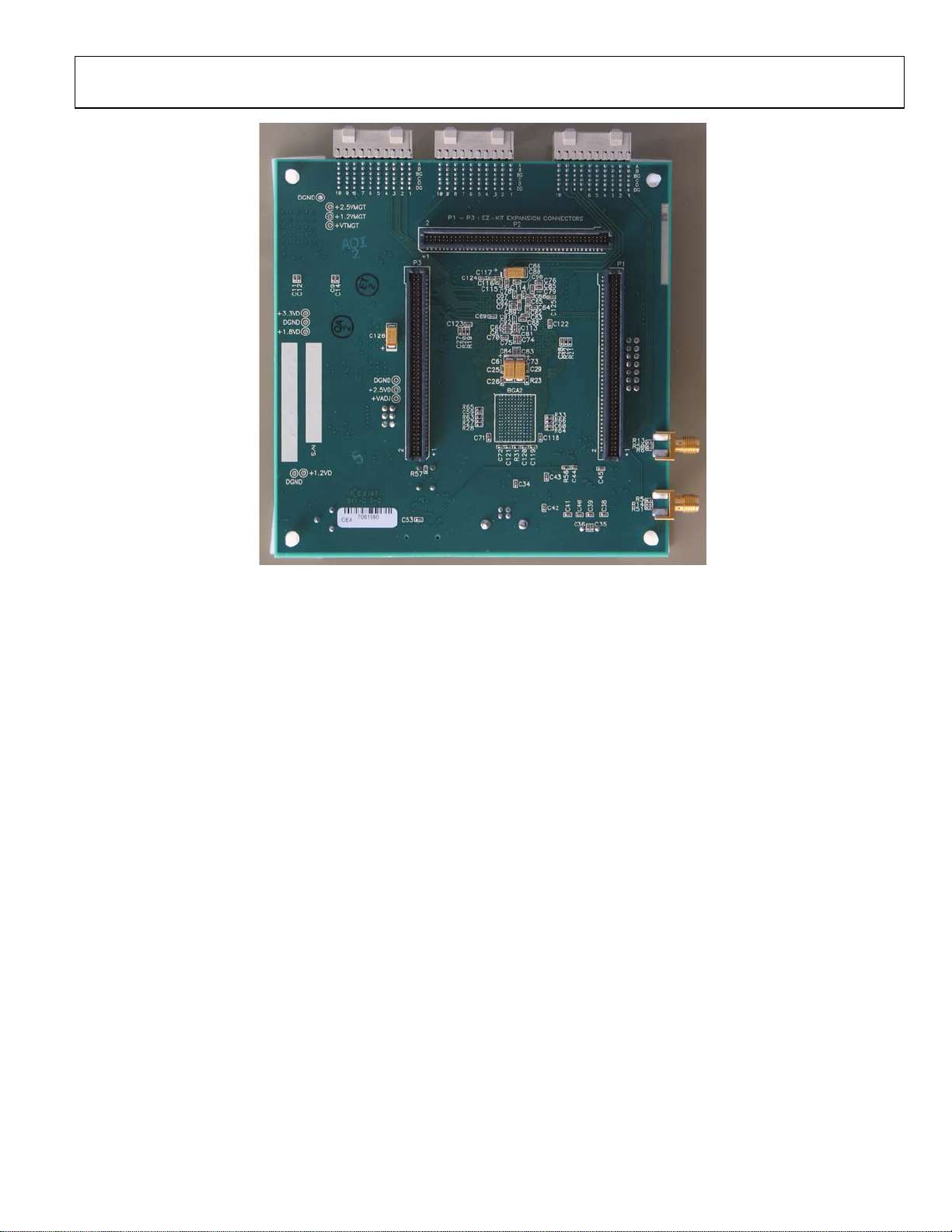

HSC-ADC-EVALC

06676-003

Figure 4. HSC-ADC-EVALC Components (Bottom View)

HSC-ADC-EVALC SUPPORTED ADC EVALUATION BOARDS

Refer to the Analog Devices ADC capture board product page at www.analog.com/FIFO for a list of HSC-ADC-EVALC-compatible ADC

evaluation boards. Some legacy ADC boards may require interposer cards to facilitate proper pin mapping to the ADC capture board. If

needed, the interposer part number is noted in the compatibility table at

www.analog.com/FIFO for the respective data converter.

Rev. 0 | Page 7 of 32

Page 8

HSC-ADC-EVALC

THEORY OF OPERATION

The HSC-ADC-EVALC evaluation platform is based around

the Virtex-4 FPGA (XC4VFX20-10FFG672C) from Xilinx®,

which can be programmed through VisualAnalog to operate

with a variety of data converters. Another key component, the

Cypress USB device (U3), communicates with a host PC and

provides the SPI interface used for configuration.

CONFIGURATION

Some converter devices require programming for mode or

feature selection, which the SPI controller accomplishes using

SPI-accessible register maps. U3 drives the 4-wire SPI (SCLK,

SDI, SDO, CSB

(J1). For more information on serial port interface (SPI) functions, consult the user manual titled Interfacing to High Speed

ADCs via SPI at

The SPI interface designed on the Cypress IC can communicate

with up to five different SPI-enabled devices including the

FPGA. The CLK and SDI/SDO data lines are common to all SPI

devices. The desired SPI-enabled device is selected for control

by using one of the five active low chip select (CS) pins. This

functionality is controlled by selecting a SPI channel in the SPI

Controller software.

At power-up, VisualAnalog attempts to autodetect the converter

that is attached to the ADC capture board using the SPI

interface. If a recognized device is found, VisualAnalog selects

the appropriate FPGA configuration; otherwise, the user is

prompted to make the device selection. In either case,

VisualAnalog then programs the FPGA using the SPI interface

of U3. The configurations typically program a FIFO data capture

function within the FPGA.

1

) signals to the converter board via connector

www.analog.com/FIFO.

INPUT CIRCUITRY

The parallel data input pins of the FPGA, which interface to the

converter, are configurable. They can operate with 1.8 V, 2.5 V,

or 3.3 V logic levels and can accept LVDS or CMOS inputs.

Each channel of the ADC capture board requires a clock signal

to capture data. These clock signals are normally provided by

the attached ADC evaluation board and are passed along with

the data through one or more pins on Connector J2 and/or

Connector J3. Refer to the HSC-ADC-EVALC I/O connector

pin mappings shown in

Figure 21 and Figure 22.

DATA CAPTURE

The process of filling the FIFO and reading the data back

requires several steps.

1. VisualAnalog initiates the FIFO fill process by resetting

the FIFOs.

2. The 48 MHz USB read clock (RCLK) is then suspended to

ensure that it does not add noise to the ADC input.

3. VisualAnalog waits approximately 30 ms to allow for data

capture before beginning the readback process. This wait

time is an adjustable parameter in VisualAnalog.

4. VisualAnalog reads the data from the FIFO through the

USB interface to the PC.

CODE DESCRIPTION

FPGA configuration files are provided by ADI for all ADCs

supported by the HSC-ADC-EVALC evaluation platform.

These files are designed and tested to facilitate quick

performance evaluations of Analog Devices data converters. No

additional FPGA programming is required from the user for

typical operation.

FPGA CONFIGURATION AND CUSTOMIZATION

Users can manually customize or update the FPGA code

through a JTAG connector (J10) provided on the ADC capture

board, as shown in

provides no support or guarantee of performance if the

provided code is customized by the user.

The HSC-ADC-EVALC hardware platform may contain additional circuit functions to support future developments and

capabilities. These functions are not supported beyond the

scope of this data sheet and the Analog Devices supplied datacapture FPGA routines at this time.

Additional FPGA programming support may be available

through the user’s local Xilinx representative or distributor.

1

Note that CSB1 is the default CSB line used.

Figure 17. However, Analog Devices

Rev. 0 | Page 8 of 32

Page 9

HSC-ADC-EVALC

EVALUATION BOARD SCHEMATICS AND ARTWORK

HSC-ADC-EVALC SCHEMATICS

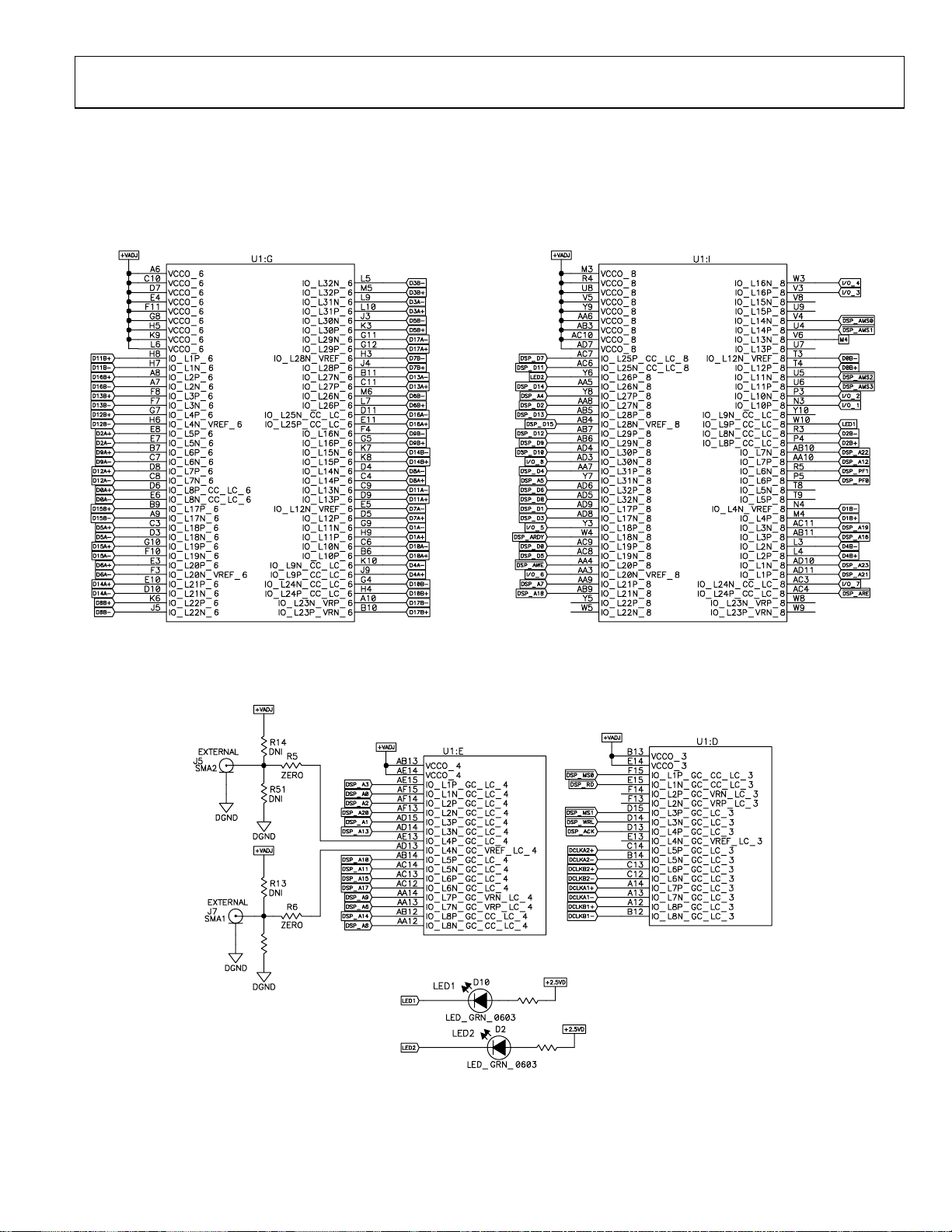

TYCO AND DSP EZ–KIT CONNECTOR TO FPGA

XC4VFX20-10F FG672C XC4VFX20-10F FG672C

R50

51.1Ω

XC4VFX20-10F FG672C

R38

100Ω

Figure 5.

R39

100Ω

XC4VFX20-10F FG672C

6676-005

Rev. 0 | Page 9 of 32

Page 10

HSC-ADC-EVALC

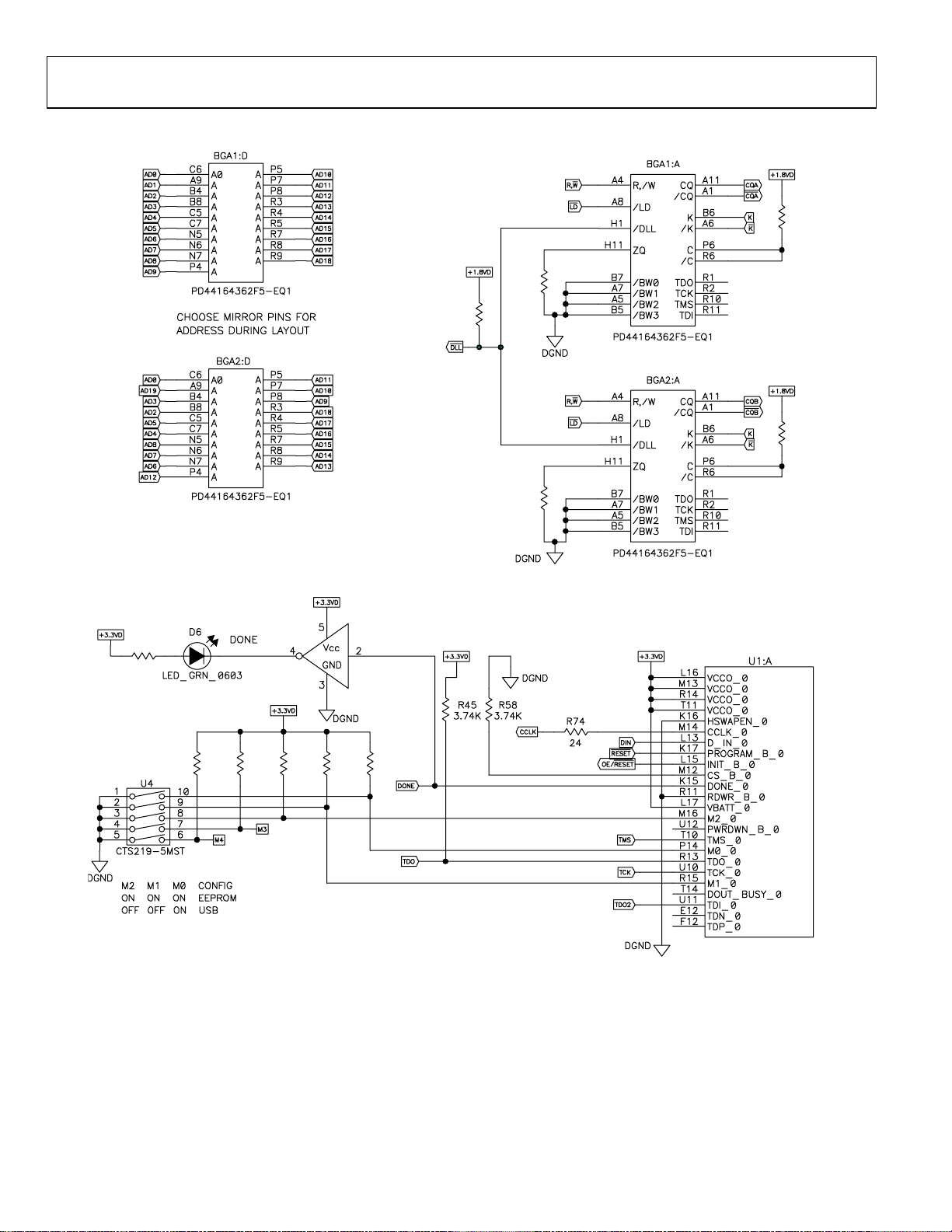

SRAM ADDRESS AND CONTROL

R25

3.74KΩ

R27

249Ω

R28

3.74KΩ

R31

3.74KΩ

R33

249Ω

R1

100Ω

R40

3.74KΩ

R44

3.74KΩ

R42

3.74KΩ

R41

3.74KΩ

R43

3.74KΩ

U21

NC7SZ05M5X

Figure 6.

FPGA CONTROLS

XC4VFX20-10F FG672C

6676-006

Rev. 0 | Page 10 of 32

Page 11

HSC-ADC-EVALC

A

FPGA TO SRAM DAT

XC4VFX20-10F FG672C

XC4VFX20-10F FG672C

06676-007

Figure 7.

Rev. 0 | Page 11 of 32

Page 12

HSC-ADC-EVALC

A

D19 TOBE USED WITH HIGHER

DENSITY SRAM DEVICES

06676-008

Figure 8.

Rev. 0 | Page 12 of 32

Page 13

HSC-ADC-EVALC

R

SRAM AND FPGA POWE

XC4VFX20-10F FG672C

R63

499Ω

R65

499Ω

Figure 9.

R64

499Ω

R66

499Ω

XC4VFX20-10F FG672C

06676-009

Rev. 0 | Page 13 of 32

Page 14

HSC-ADC-EVALC

SRAM A BYPASS CAP

REFCLK Oscillator for IDELAYCTRL

R15

24Ω

SRAM B BYPASS CAP

FPGA BYPASS CAP

+

+

+

+

Figure 10.

06676-010

Rev. 0 | Page 14 of 32

Page 15

HSC-ADC-EVALC

UNUSED ROCKET I/0 CONNECTIONS

XC4VFX20-10F FG672C

DEBUG PINS

Figure 11.

XC4VFX20-10F FG672C

06676-011

Rev. 0 | Page 15 of 32

Page 16

HSC-ADC-EVALC

ROCKET I/0 CONNECTIONS

Figure 12.

Rev. 0 | Page 16 of 32

06676-012

Page 17

HSC-ADC-EVALC

USB CONNECTIONS

R49

R71

3.74Ω

3.74Ω

R48

100KΩ

SDI & SDO DI RECTIONS ARE WIT H

RESPECT TO T HE DEVICE UNDER

CONTROL .

Figure 13.

Rev. 0 | Page 17 of 32

(3.3V)

USB Direct I/O

06676-013

Page 18

HSC-ADC-EVALC

USB CONNECTIONS (CONTINUED)

R46

1

2

3

4

5

6

499Ω

J6

R52

3.74KΩ

R72

3.74KΩ

XC4VFX20-10F FG672C

Rev. 0 | Page 18 of 32

Figure 14.

XC4VFX20-10F FG672C

06676-014

Page 19

HSC-ADC-EVALC

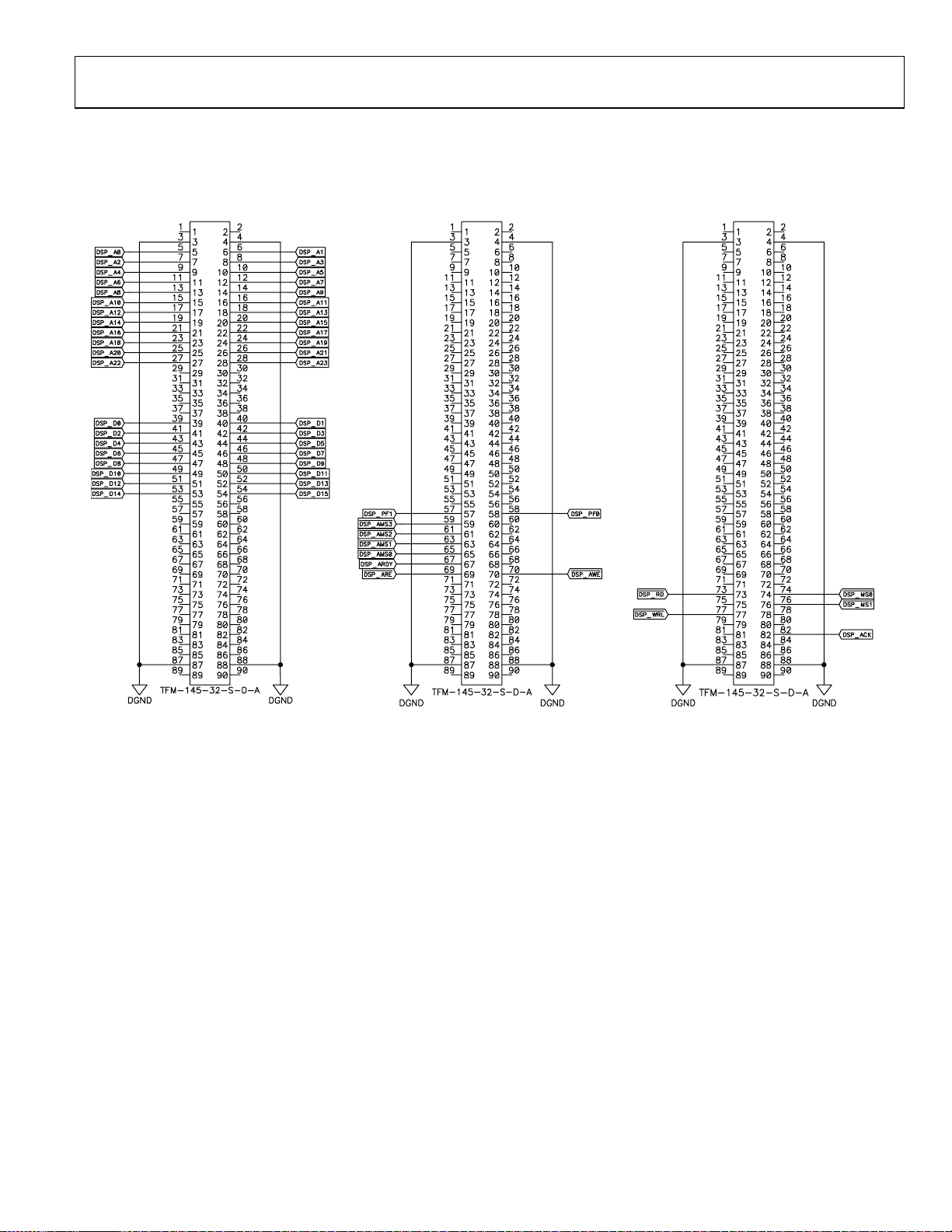

EZ–KIT EXPANSION INTERFACE – FOR DSPs

P1 P2 P3

Figure 15.

06676-015

Rev. 0 | Page 19 of 32

Page 20

HSC-ADC-EVALC

J1

HS-SERIAL/SPI/AUX

06676-016

J2

DATA BUS 1

TYCO HM – Zd CONNECTORS

J3

DATA BUS 2

,

Figure 16.

Rev. 0 | Page 20 of 32

Page 21

HSC-ADC-EVALC

M

CONFIGURATION EEPRO

R77

100Ω

R78

R75

3.74KΩ

100Ω

R76

3.74KΩ

R73

ZERO

JTAG CONNECTOR EEPROM HARDWARE

RECONFIGURATION

PUSHBUTTON

R57

3.74KΩ

Figure 17.

Rev. 0 | Page 21 of 32

6676-017

Page 22

HSC-ADC-EVALC

++

+

R68

147k

+

06676-018

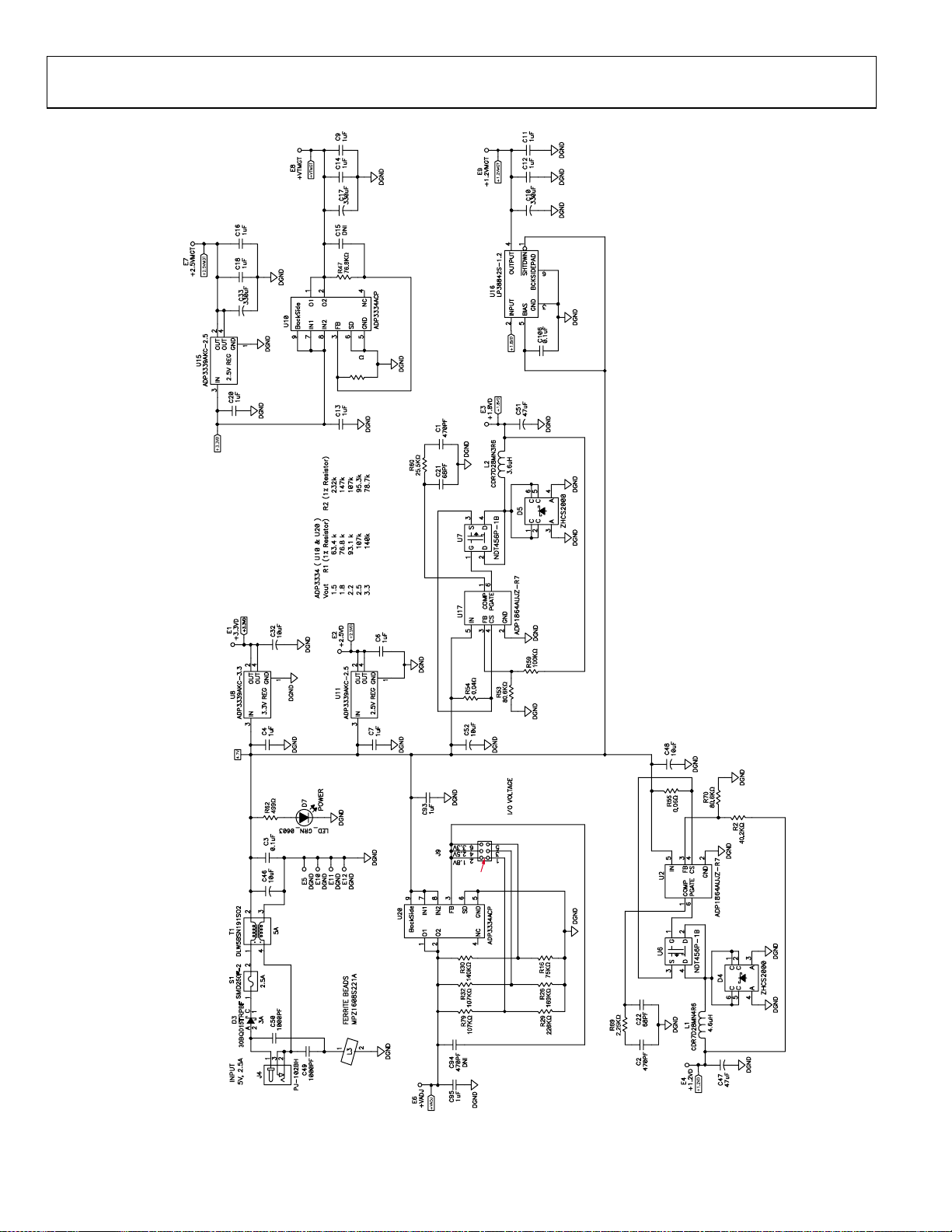

POWER AND VOLTAGE REGULATORS

+

+

REMOVE

DO NOT

+

TSW–102–08–G–D

+

+

Figure 18.

Rev. 0 | Page 22 of 32

Page 23

HSC-ADC-EVALC

PCB LAYOUT

GENERAL PURPOSE I/O,

USB/SPI CONTROL DATA BUS 1 DATA BUS 2

XILINX

VIRTEX-4

FPGA

FPGA LOAD

SELECT

DEBUG

PINS

EXTERNAL

SYNC I/O

CYPRESS USB

CONTROLLER

USB CONNECTO R FPGA JTAG

CONNECTOR

Figure 19. Top Silkscreen

5VDC POWER

INPUT

ON BOARD

POWER SUPPLY

100MHz

OSCILLATOR

FPGA I/O

VOLTAGE MODE

FPGA CONFIG

PROM

06676-019

Figure 20. Bottom Silkscreen

Rev. 0 | Page 23 of 32

06676-020

Page 24

HSC-ADC-EVALC

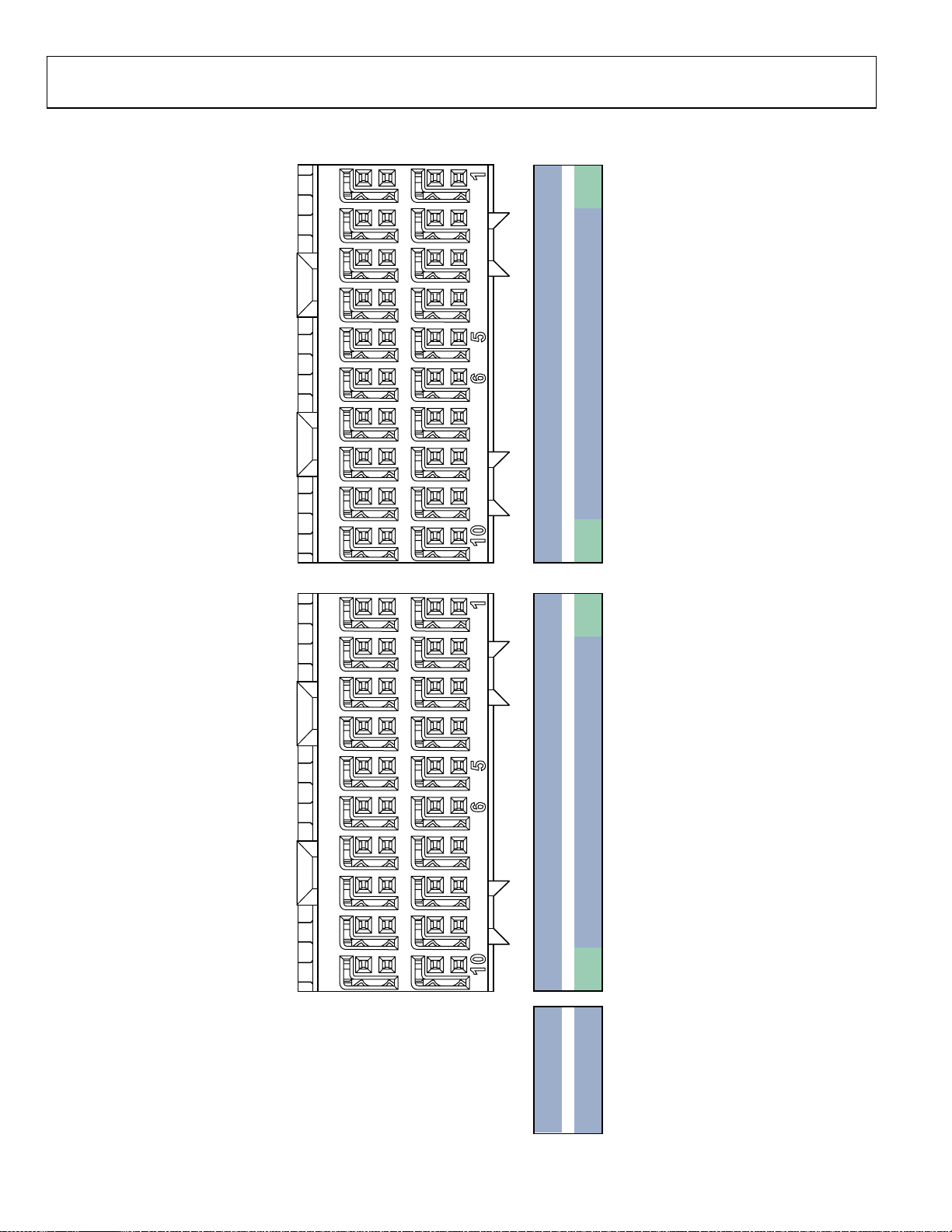

I/O CONNECTOR—J1, J2, AND J3 PIN MAPPING

D

C

B

A

DCLKB2–

D15B– D13B– D11B– D9B– D7B– D5B– D3B– D1B–

06676-021

DCLKB2+

(J2) DATA BUS 1(J3) DATA BUS 2

D15B+ D13B+ D11B+ D9B+ D7B+ D5B+ D3B+ D1B+

D17B– D16B– D14B– D12B– D10B– D8B– D6B– D4B– D2B– D0B–

D17B+ D16B+ D14B+ D12B+ D10B+ D8B+ D6B+ D4B+ D2B+ D0B+

DCLKB1–

DCLKB1+

D

C

B

A

DCLKA2–

DCLKA2+

D15A– D13A– D11A– D9A– D7A– D5A– D3A– D1A–

D15A+ D13A+ D11A+ D9A+ D7A+ D5A+ D3A+ D1A+

D17A– D16A– D14A– D12A– D10A– D8A– D6A– D4A– D2A– D0A–

D17A+ D16A+ D14A+ D12A+ D10A+ D8A+ D6A+ D4A+ D2A+ D0A+

DCLKA1–

D

C

B

A

DCLKA1+

Figure 21. J2 and J3 Pin Mapping

Rev. 0 | Page 24 of 32

LVDS DATA PATH >

CMOS/LV DS DATA PATH >

LVDS DATA PATH >

CMOS/LV DS DATA PATH >

Page 25

HSC-ADC-EVALC

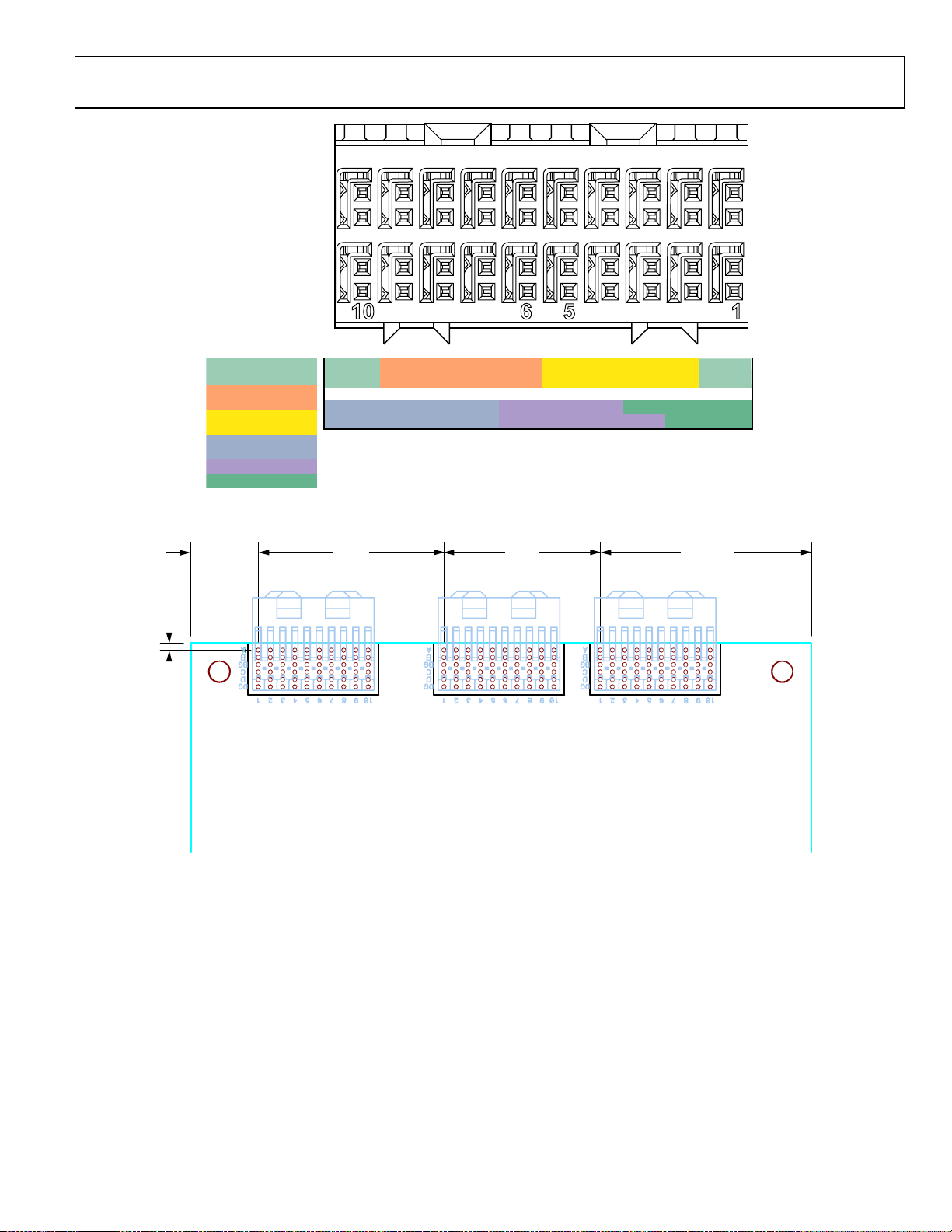

m

D

C

B

A

06676-022

HIGH SPEED SE RIAL

REFERENCE CLK

HIGH SPEED SE RIAL

DATA INPUTS

FUTURE HIG H S PEED

SERIAL DATA I NP UTS

FPGA GENERAL

PURPOSE I/ O

SPI CONTRO L (3.3V)

USB DIRECT I/ O (3.3V)

D

C

B

A

MGTCLK1– SD1– SD2– SD3– SD4– SD5– SD6– SD7– SD8– MGTCLK2–

MGTCLK1+ SD1+ SD2+ SD3+ SD4+ SD5+ SD6+ SD7+ SD8+ MGTCLK2+

I/O_1 I/O_3 I/ O_5 I/O_7 SCLK SDI SDO USB_1 USB_2 USB_4

I/O_2 I/O_4 I/ O_6 I/O_8 CSB_1 CSB_2 CSB_3 CSB_4 USB_3 USB_5

(J1) HS-SERIAL/SPI/ AU X

Figure 22. J1 Pin Mapping

13.843mm 38mm 32mm 43.155mm

1.4m

J1 J2

HS-SERIAL/SPI/AUX

DATA BUS 1

J3

DATA BUS 2

06676-023

Figure 23. Data Converter I/O Connector Placement (Top View)

Rev. 0 | Page 25 of 32

Page 26

HSC-ADC-EVALC

Table 3. HSC-ADC-EVALC J1 I/O Connections to FPGA (U1)

Connector J1

(HS-Serial, SPI, AUX)

A1 USB_5 none

B1 USB_4 none

C1 MGTCLK2+ AF10

D1 MGTCLK2− AF11

A2 USB_3 none

B2 USB_2 none

C2 none none

D2 none none

A3 CSB_4 none

B3 USB_1 none

C3 none none

D3 none none

A4 CSB_3 none

B4 SDO H12

C4 none none

D4 none none

A5 CSB_2 none

B5 SDI K12

C5 none none

D5 none none

A6 CSB_1 none

B6 SCLK H13

C6 SD4+ AF7

D6 SD4− AF8

A7 I/O_8 AD3

B7 I/O_7 AC3

C7 SD3+ AC1

D7 SD3− AD1

A8 I/O_6 AA3

B8 I/O_5 Y3

C8 SD2+ G1

D8 SD2− H1

A9 I/O_4 W3

B9 I/O_3 V3

C9 SD1+ A4

D9 SD1− A3

A10 I/O_2 P3

B10 I/O_1 N3

C10 MGTCLK1+ K1

D10 MGTCLK1− L1

Schematic Net Name FPGA Pin

Table 4. HSC-ADC-EVALC J2 I/O Connections to FPGA (U1)

Connector J2

(DATA BUS 1)

A1 DCLKB2+ C13

B1 DCLKB2− C12

C1 D0B+ T4

D1 D0B− T3

A2 D1B+ M4

B2 D1B− N4

C2 D2B+ P4

D2 D2B− R3

A3 D3B+ M5

B3 D3B− L5

C3 D4B+ L4

D3 D4B− L3

A4 D5B+ K3

B4 D5B− J3

C4 D6B+ L7

D4 D6B− M6

A5 D7B+ J4

B5 D7B− H3

C5 D8B+ K6

D5 D8B− J5

A6 D9B+ G5

B6 D9B− F4

C6 D10B+ H4

D6 D10B− G4

A7 D11B+ H8

B7 D11B− H7

C7 D12B+ G7

D7 D12B− H6

A8 D13B+ F8

B8 D13B− F7

C8 D14B+ K8

D8 D14B− K7

A9 D15B+ B9

B9 D15B− A9

C9 D16B+ A8

D9 D16B− A7

A10 DCLKB1+ A12

B10 DCLKB1− B12

C10 D17B+ B10

D10 D17B− A10

Schematic Net Name FPGA Pin

Rev. 0 | Page 26 of 32

Page 27

HSC-ADC-EVALC

Table 5. HSC-ADC-EVALC J3 I/O Connections to FPGA (U1)

Connector J3

(DATA BUS 2)

A1 DCLKA2+ C14

B1 DCLKA2− B14

C1 D0A+ D6

D1 D0A− E6

A2 D1A+ H9

B2 D1A− G9

C2 D2A+ E8

D2 D2A− E7

A3 D3A+ L10

B3 D3A− L9

C3 D4A+ J9

D3 D4A− K10

A4 D5A+ C3

B4 D5A− D3

C4 D6A+ E3

D4 D6A− F3

A5 D7A+ D5

B5 D7A− E5

C5 D8A+ C4

D5 D8A− D4

A6 D9A+ B7

B6 D9A− C7

C6 D10A+ B6

D6 D10A− C6

A7 D11A+ D9

B7 D11A− C9

C7 D12A+ D8

D7 D12A− C8

A8 D13A+ C11

B8 D13A− B11

C8 D14A+ E10

D8 D14A− D10

A9 D15A+ G10

B9 D15A− F10

C9 D16A+ E11

D9 D16A− D11

A10 DCLKA1+ A14

B10 DCLKA1− A13

C10 D17A+ G12

D10 D17A− G11

Schematic Net Name FPGA Pin

Rev. 0 | Page 27 of 32

Page 28

HSC-ADC-EVALC

ORDERING INFORMATION

BILL OF MATERIALS (RoHS COMPLIANT)

Table 6.

Qty Reference Designator Description Manufacturer Part Number

1 PCB PCB, ADC evaluation platform MOOG/PCSM GS09156x8

0 BGA1, BGA2

2 C1, C2

3 C10, C17, C33 Capacitor, 330 μF, 10 V TG SMD Panasonic/ECG EEETG1A331P

2 C21, C22

67

C3, C25 to C30, C34,

C37 to C45, C59, C60,

C63 to C72, C74 to

C76, C78 to C85, C88

to C92, C96 to C98,

C100 to C106, C113 to

C118, C120 to C125

1 C32

2 C35, C36

18

C4, C6, C7, C9, C11 to

C14, C16, C18, C20,

C62, C77, C87, C93,

C95, C99, C119

7

C46, C48, C52, C61,

C73, C86, C126

2 C47, C51 Capacitor, 47 μF, 10 V, tantalum TEL SMD Epcos, Inc. B45197A2476K309

2 C49, C50

17

C5, C19, C23, C24, C31,

C53 to C58, C107 to

C112

1 C94

7 D1, D2, D6 to D10 LED green, clear lens SMD Panasonic LNJ308G8TRA

1 D3 PolySwitch surface-mount (PTC devices) International IRF Rectifiers 30BQ015TRPBF

2 D4, D5

1 J1, J2, J3

1 J10

1 J4 Connector, DC power jack CUI Inc. PJ-102AH

1 J6 Connector, USB Type B Mill-Max 897-43-004-90-000000

2 J5,J7

1 J8

1 J9 (2.5 V and 3.3 V) Connector, 2 × 2 header, 100 mil Samtec, Inc. TSW-102-08-G-D

1

J9 (Jumper Pin 1 to

Jumper Pin 2)

1 L1 Inductor, 4.6 μH SMD, Code 0004 Sumida CDR7D28MN4R6

1 L2 Inductor, 3.6 μH SMD, Code 0003 Sumida CDR7D28MN3R6

IC, 18-bit DDRII SRAM 2-word burst

operation (MOS integrated circuit),

do not install

Capacitor, 470 pF, 50 V ceramic

X7R 0402

Capacitor, 68 pF, 50 V, ceramic

0402 SMD

Capacitor, 0.1 μF, 10 V, ceramic

X5R 0402

Capacitor, 10 μF, 6.3 V, tantalum

TE series

Capacitor, 12 pF, 50 V, ceramic

0402 SMD

Capacitor, 0402 chip, X5R, 6.3 V,

1 μF, ± 20%

Capacitor, 10 μF, 20 V, tantalum TEL SMD AVX TPSC106K025R0500

Capacitor, 1000 pF, 50 V, ceramic Y5V

0402

Capacitor, 0402 chip, X5R, 6.3 V,

0.22 μF, ±10%

Capacitor, 470 pF, 25 V, ceramic

0402 SMD

40 V silicon high current Schottky

barrier diode

Connector, 2-pair 10 column high speed

HM-Zd PCB mount

Connector, 2 mm, 2 × 7 pin SMT vertical

male, with shroud

Connector, end launch jack/PCB, 62 mil,

gold

Connector, 25 mil square postheader,

100 mil, 2 × 7

Solder wire jumper (Pin 1 indicator to

1.8 V on silkscreen)

Rev. 0 | Page 28 of 32

NEC PD44164362F5-EQ1

Panasonic/ECG ECJ-0EB1H471K

Panasonic/ECG ECU-E1H680JCQ

Panasonic/ECG ECJ-0EB1A104K

Kemet T491A106M006AT

Panasonic/ECG ECJ-0EC1H120J

Panasonic ECJ-0EB0J105M

Panasonic/ECG ECJ-0EF1H102Z

Panasonic ECJ-0EB0J224K

Panasonic/ECG ECJ-0EB1E471K

Zetex Semiconductors ZHCS2000

Tyco 6469028-1

Molex 87832-1420-TB32

Emerson 142-0701-801

Samtec, Inc. TSW-107-08-G-D

Page 29

HSC-ADC-EVALC

Qty Reference Designator Description Manufacturer Part Number

17 L3 to L19 Ferrite chip, 220 Ω, 2 A, 0603, 100 MHz TDK MPZ1608S221A

3 P1 to P3

13

R1, R3, R4, R34 to R39,

R61, R67, R77, R78

3 R15, R56, R74 Resistor, 24 Ω, 1/16 W, 5%, 0402 SMD Panasonic/ECG ERJ-2GEJ240X

1 R16 Resistor, 75 kΩ, 1/16 W, 1%, 0402 SMD Panasonic/ECG ERJ-2RKF7502X

5 R17, R18, R23, R24, R50 Resistor, 51.1 Ω, 1/16 W, 1%, 0402 SMD Panasonic/ECG ERJ-2RKF51R1X

10

R19 to R22, R46, R62 to

R66

1 R2 Resistor, 40.2 kΩ, 1/16 W, 1%, 0402 SMD Panasonic/ECG ERJ-2RKF4022X

17

R25, R28, R31, R40 to

R45, R49, R52, R57,

R58, R71, R72, R75, R76

1 R26 Resistor, 169 kΩ, 1/16 W, 1%, 0402 SMD Panasonic/ECG ERJ-2RKF1693X

2 R27, R33 Resistor, 249 Ω, 1/16 W, 1%, 0402 SMD Panasonic/ECG ERJ-2RKF2490X

1 R68 Resistor, 147 kΩ, 1/16 W, 1%, 0402 SMD Panasonic/ECG ERJ-2RKF1473X

1 R29 Resistor, 226 kΩ, 1/16 W, 1%, 0402 SMD Panasonic/ECG ERJ-2RKF2263X

0 R30

1 (R32), R79

1 R47 Resistor, 76.8 kΩ, 1/16 W, 1%, 0402 SMD Panasonic/ECG ERJ-2RKF7682X

2 R48, R59 Resistor, 100 kΩ, 1/16 W, 1%, 0402 SMD Panasonic/ECG ERJ-2RKF1003X

3 R5, R6, R73 Resistor 0 Ω, 1/16 W, 5%, 0402 SMD Panasonic/ECG ERJ-2GE0R00X

2 R53, R70 Resistor 80.6 kΩ, 1/16 W, 1%, 0402 SMD Panasonic/ECG ERJ-2RKF8062X

1 R54 Resistor, low value, 1206 SMD, 0.04 Ω TT Electronics LRC-LR1206LF-01-R040-F

1 R55 Resistor, low value, 1206 SMD, 0.06 Ω TT Electronics LRC-LR1206LF-01-R060-F

2 R60, R69 Resistor, 25.5K Ω, 1/16 W, 1%, 0402 SMD Panasonic/ECG ERJ-2RKF2552X

2 R7, R8 Resistor array network, 8 Ω to 22 Ω chip Panasonic EXB-2HV220JV

1 S1 Fuse, PolySwitch SMT (PTC devices) Tyco SMD250F-2

1 T1

1 U1 Virtex-4 FPGA Xilinx XC4VFX20-10FFG672C

2 U10, U20

2 U11, U15

1 U12 Crystal oscillator, 24 Mhz, 12 pF, SMD ECS ECS-240-12-4X

1 U13 1.8 V, 8 Mb, platform flash-in system Xilinx XCF08PFSG48C

1 U16

1 U18

0 U19

2 U2, U17

1 U21

1 U3 IC, EZ-USB FX2LP USB microcontroller Cypress Semiconductor Corp. CY7C68013A-128AXC

1 U4 Switch, 5-position, SMT, DIP CTS 219-5MST

1 U5 IC, 128-bit I2C bus serial EEPROM Microchip 24LC00-I/SN

Connector, 0.050 in × 0.050 in, Samtec

TFM series, 2R

Resistor, 100 Ω, 1/16 W, 1%, 0402 SMD Panasonic/ECG ERJ-2RKF1000X

Resistor, 499 Ω, 1/16 W, 1%, 0402 SMD Panasonic/ECG ERJ-2RKF4990X

Resistor, 3.74 kΩ, 1/16 W, 1%, 0402 SMD Panasonic/ECG ERJ-2RKF3741X

Resistor, 140 kΩ, 1/16 W, 1%, 0402 SMD,

do not install

Resistor, 107 kΩ, 1/16 W, 1%, 0402 SMD,

do not install R32

Choke, common-mode coils, wirewound type for large current

DLW5AH/DLW5BS series

(2014/2020 Size)

Voltage regulator, high accuracy, low IQ,

adjustable

Voltage regulator, high accuracy

ultralow IQ, 1.5 A

Voltage regulator, 1.5 A ultralow

dropout linear regulator

Crystal controlled oscillator (100 MHz

fixed frequency oscillator)

156.25 MHz low jitter saw crystal

oscillator, do not install

IC, constant frequency current-mode,

step-down, dc-to-dc controller in TSOT

IC, single inverter buffer/driver with

open-drain output

Samtec, Inc. TFM-145-32-S-D-A

Panasonic/ECG ERJ-2RKF1403X

Panasonic/ECG ERJ-2RKF1073X

Murata DLW5BSN191SQ2

Analog Devices ADP3334ACPZ-REEL7

Analog Devices ADP3339AKCZ-2.5R7

National Semiconductor LP38842S-1.2

Connor-Winfield Corp. CWX823-100.0M

Epson Electronics America EG-2121CA 156.2500M-PHPAL3

Analog Devices ADP1864AUJZ-R7

Fairchild Semiconductor NC7SZ05M5X

Rev. 0 | Page 29 of 32

Page 30

HSC-ADC-EVALC

Qty Reference Designator Description Manufacturer Part Number

2 U6, U7

1 U8

1 U9 Switch, 6 mm light touch SW, N.O. Alps SKHHAKA010

4 H1, H2, H3, H4 Circuit board support on base Richco, Inc. CBSB-14-01

1 Packed with PCB Transformer 5 V, 3 A switcher P5 CUI, Inc. DPS050300U-P5P-TK

0 U14

0 R9

0 R12, R13, R14, R51

0 R11

0 R10

0 C8

0 C15

IC, P-channel enhancement mode field

effect transistor

Voltage regulator, high accuracy

ultralow IQ, 1.5 A

1.2 V precision low noise shunt voltage

references, SOT-23 (RT-3), do not install

Resistor, 6.2 kΩ, 1/16 W, 5%, 0402 SMD,

do not install

Resistor, 0 Ω, 1/16 W, 5%, 0402 SMD,

do not install

Resistor 13 k Ω, 1/16 W, 5%, 0402 SMD,

do not install

Resistor 1.0 kΩ, 1/16 W, 5%, 0402 SMD,

do not install

Capacitor, 0402 SMD, X5R, 6.3 V, 0.22 μF,

±10%, do not install

0402 chip capacitor, X5R, 6.3 V, 1 μF,

±20%, do not install

Fairchild Semiconductor NDT456P

Analog Devices ADP3339AKCZ-3.3

Analog Devices ADR512ART

Panasonic/ECG ERJ-2GEJ622X

Panasonic/ECG ERJ-2GE0R00X

Panasonic/ECG ERJ-2GEJ133X

Panasonic/ECG ERJ-2GEJ102X

Panasonic ECJ-0EB0J224K

Panasonic ECJ-0EB0J105M

ORDERING GUIDE

Model Description

HSC-ADC-EVALC Data Converter Evaluation Platform

HSC-ADC-EVALCZ1 Data Converter Evaluation Platform

1

Z = RoHS Compliant Part.

ESD CAUTION

Rev. 0 | Page 30 of 32

Page 31

HSC-ADC-EVALC

NOTES

Rev. 0 | Page 31 of 32

Page 32

HSC-ADC-EVALC

NOTES

©2007 Analog Devices, Inc. All rights reserved. Trademarks and

registered trademarks are the property of their respective owners.

EB06676-0-4/07(0)

Rev. 0 | Page 32 of 32

Loading...

Loading...