Page 1

查询AD7899供应商查询AD7899供应商

a

Evaluation Board 400kSPS, 14-Bit ADC

FEATURES

Full-Featured Evaluation Board for the AD7899

Eval-Board Controller Compatible

Stand Alone Capability

On-Board Analog Buffering and Reference

Various Linking Options

PC Software for Control and Data Analysis when used

with Eval-Board Controller

INTRODUCTION

This Technical Note describes the evaluation board for the

AD7899 high speed, low power, 14-bit A/D converter that

operates from a single 5 V supply. Full data on the AD7899

is available in the AD7899 data sheet available from Analog

Devices and should be consulted in conjunction with this

Technical Note when using the Evaluation Board.

On-board components include an AD780 which is a +2.5V

ultra high precision bandgap reference and an op-amp for the

analog inputs. There are various link options which are

explained in detail on page 2.

Interfacing to this board is through a 96-way connector. This

96-way connector is compatible with the EVAL-BOARD

CONTROLLER which is also available from Analog Devices. External sockets are provided for the optional, external, CONVST and CLKIN and V

inputs and the

DRIVE

VIN1-VIN4 inputs.

EVAL-AD7899CB

OPERATING THE AD7899 EVALUATION BOARD

Power Supplies

When using this evaluation board with the EVAL-BOARD

CONTROLLER all supplies are provided from the EVALBOARD CONTROLLER through the 96 way connector.

When using the board as a stand alone unit external supplies

must be provided. This evaluation board has seven power

supply inputs: V

D

. If the evaluation board is used in stand-alone mode

GND

+5V must be connected to the V

AD7899 V

pin and the AD780 voltage reference. +12V and

DD

-12V are used to supply the op-amps. The V

driven by a voltage between +3V and +5V allowing the

evaluation board to be connected to both +3V and +5V

systems. The supplies are decoupled to the relevant ground

plane with 10µF tantalum and 0.1µF multilayer ceramic

capacitors at the point where they enter the board. The supply

pins of all the op-amps and reference are also decoupled to

A

with 10µF tantalum and a 0.1µF ceramic capacitor. The

GND

AD7899 AV

DD

tantalum and 0.1µF multilayer ceramic capacitors.

Extensive ground planes are used on this board to minimize

the effect of high frequency noise interference. There are two

ground planes, A

location close to the AD7899.

, A

DD

supply pin is decoupled to A

GND

, +12V, -12V, A

GND

and D

GND

GND

input to supply the

DD

DRIVE

GND

. These are connected at one

, V

DRIVE

and

pin can be

with 47uF

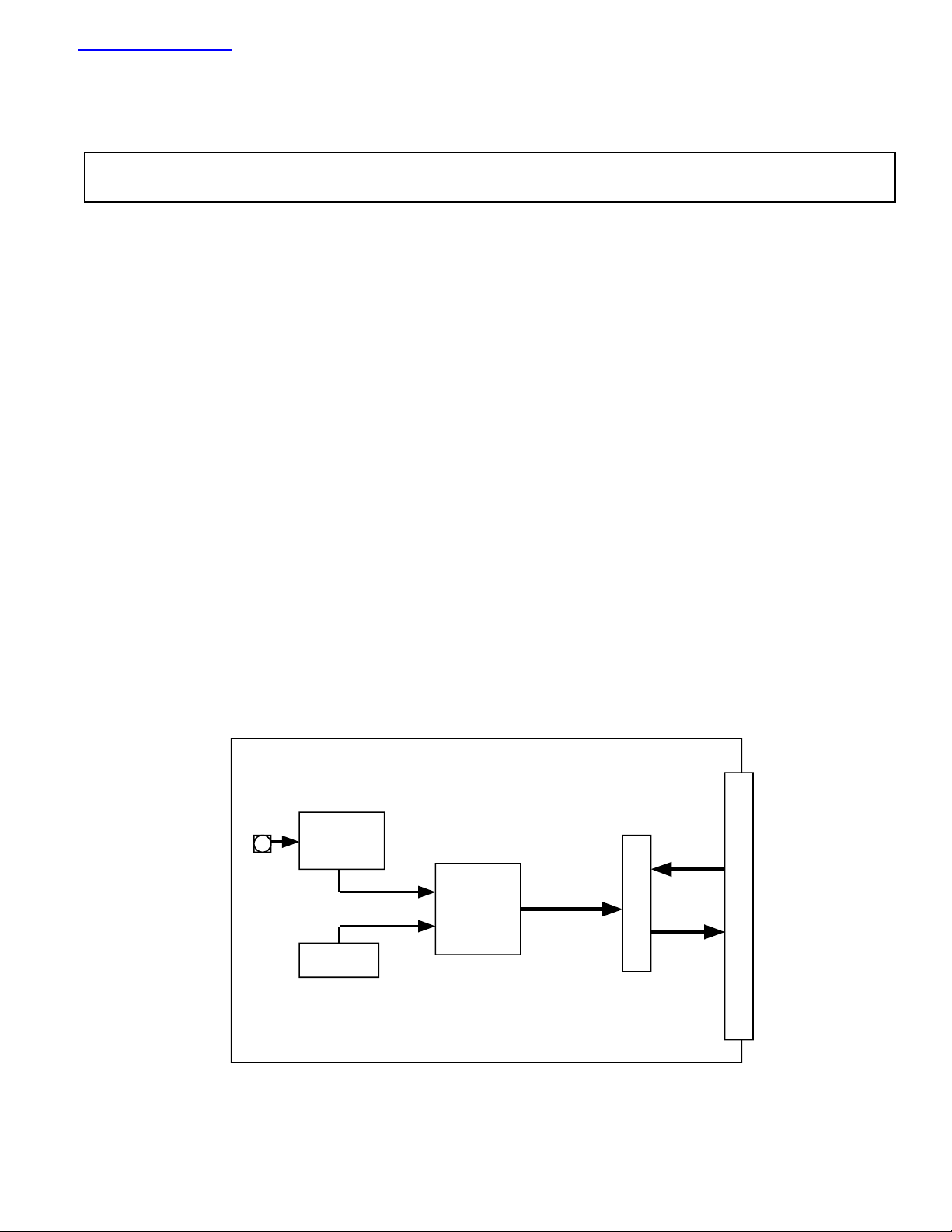

Fig. 1: FUNCTIONAL BLOCK DIAGRAM

ANALOG

INP UT

ANALOG

SIGNAL

CONDITIONING

EXTERNAL

REFERENCE

AD7899

REV. 0

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for

its use, nor for any infringements of patents or other rights of third

parties which may result from its use. No license is granted by

implication or otherwise under any patent or patent rights of Analog

Devices.

OR

RS

FE

F

BU

O

I/

L

TA

GI

DI

One Technology Way, P.O. Box 9106, Norwood. MA 02062-9106, U.S.A.

Tel: 617/329-4700 Fax: 617/326-8703

T

EC

NN

O

C

GE

ED

AY

W

96

Page 2

EV AL-AD7899CB

Link and Switch Options

There are 9 link options which must be set for the required operating setup before using the evaluation board. The

functions of these options are outlined below.

Link No. Function.

LK1 This link option selects the input range of the ADC. The position of this link is determined by the input

range required by the user. Please refer to the AD7899 data sheet for more information.

When this link is in position "A" V

When this link is in position "B" V

LK2 This link selects the reference source for the AD7899.

When a link is in position "A" the AD780 is selected as the reference source.

When a link is in position "B" an external voltage applied to SK7 is selected as the reference source.

When the link is removed completly the internal reference of the AD7899 is used as the reference source.

LK3 This link selects the source of the +12V supply.

When this link is in position "A" an external +12V must be connected to J2-1.

When this link is in position "B" the EVAL-BOARD CONTROLLER will provide the +12V supply

LK4 This link selects the source of the VDD supply.

When this link is in position "A" an external +5V must be connected to J2-2.

When this link is in position "B" the EVAL-BOARD CONTROLLER will provide the +5V supply

LK5 This link selects the source of the -12V supply.

When this link is in position "A" an external -12V must be connected to J2-4.

When this link is in position "B" the EVAL-BOARD CONTROLLER will provide the -12V supply

is connected to V

INB

is connected toAGND.

INB

INA

.

LK6 This link selects the source of the V

When this link is in position A the VDD supply is used as the V

DRIVE

supply.

DRIVE

supply.

When this link is in position B the DVDD supply of the EVAL-BOARD CONTROLLER is used as the

V

supply.

DRIVE

When this link is in position C an external supply on SK6 is used as the V

LK7 This link is used to select the source of the Conversion Start signal.

When this link is in position "A" the CONVST signal is generated by the EVAL-BOARD CONTROLLER.

When this link is in position "B" the CONVST signal is generated by an external signal connected to SK2.

LK8 This link selects the source of the CLKIN signal for the AD7899.

When this link is in position "A" the CLKIN signal is provided by the EVAL-BOARD CONTROLLER.

When this link is in position "B" the CLKIN signal can be provided by a signal applied to SK3. If no

signal is applied to SK3 the pin is pulled low and the internal oscillator is is used to control the conversion.

LK9 This link sets the logic level of the STBY pin.

When a link is in position "A" the STBY pin is controlled by the FL1 flag pin of the EVAL-BOARD

CONTROLLER.

When a link is in position "B" the STBY pin is tied to VDD and the part is in normal operating mode.

When a link is in position "C" the STBY pin is tied to DGND and the part is in standby mode.

DRIVE

supply.

–2–

REV. 0

Page 3

EV AL-AD7899CB

SET-UP CONDITIONS

Care should be taken before applying power and signals to the evaluation board to ensure that all link positions are as

per the required operating mode. Table I shows the position in which all the links are set when the evaluation board is

shipped. The board is compatible with the EVAL-BOARD CONTROLLER when shipped.

Table I. Initial Link and Switch Positions

Link No. Position Function.

LK1 B The largest voltage range for the part is selected.

LK2 A The AD780 is selected as the reference source for the AD7899.

LK3-5 B The EVAL-BOARD CONTROLLER is used to provide the supply voltages for the

evaluation board.

LK6 A The V

LK7 B The CONVST signal is provided by the EVAL-BOARD CONTROLLER.

LK8 B The CLKIN can be supplied either by an external signal connected to SK3 or by the

AD7899s internal oscillator.

LK9 B The STBY pin is tied to VDD

pin is connected to the VDD supply.

DRIVE

REV. 0

–3–

Page 4

EV AL-AD7899CB

EVALUATION BOARD INTERFACING

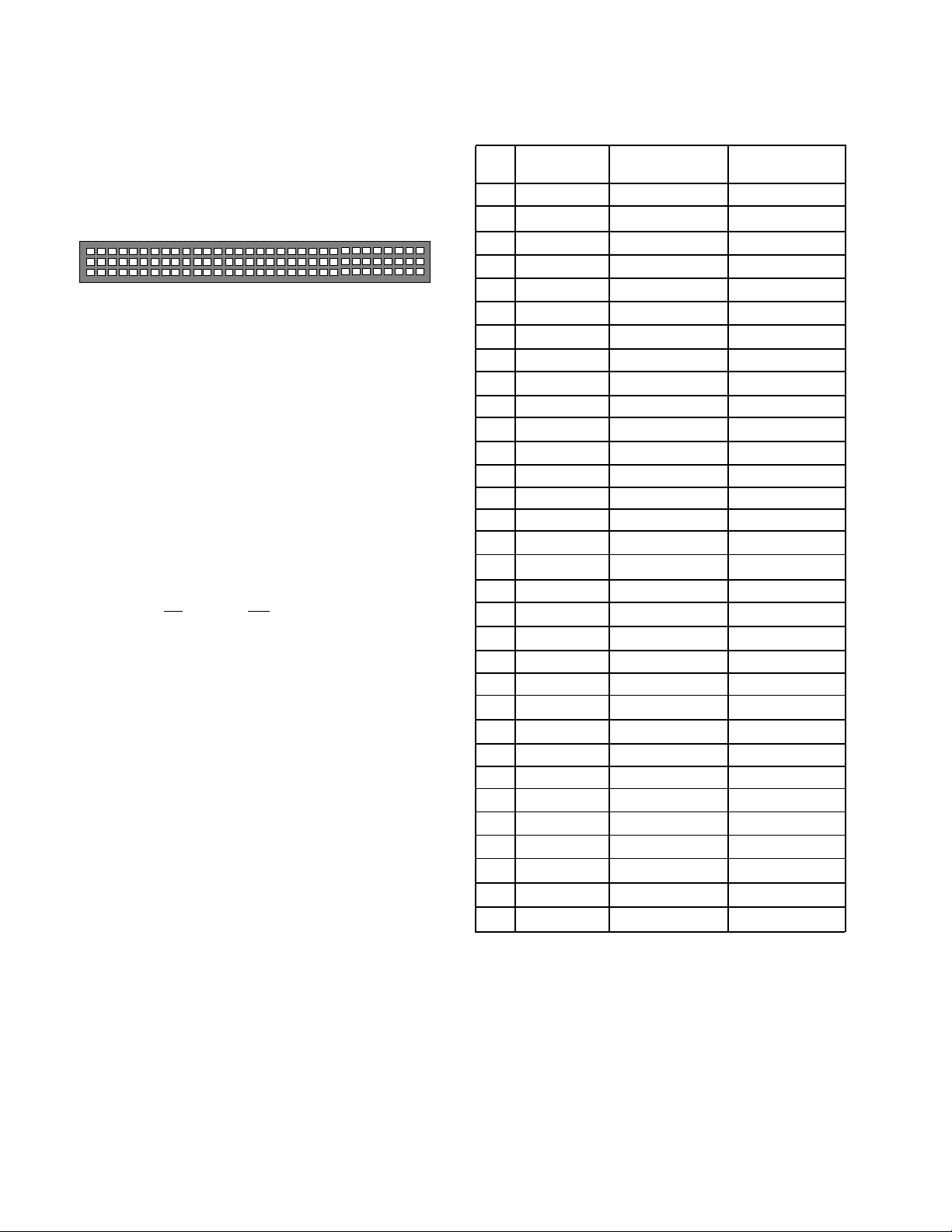

Interfacing to the evaluation board is via a 96-way connector,

J1. J1 is used to connect the evaluation board to the EVALBOARD CONTROLLER or other system. The pinout for

the J1 connector is shown in Figure 2 and its pin designations

are given in Table II.

1

A

B

C

1

Fig. 2. Pin Configuration for the 96-Way Connector, J1

96-Way Connector Pin Description

32

32

FL1 Flag one. This is a logic input and is connected

to the STBY pin of the AD7899. A logic high on

this pin allows normal operation of the AD7899.

A logic low on this pin puts the AD7899 into

standby mode.

D0-D13 Data Bit 0 to Data Bit 13. Bi-directional data

pins. These data bits provide the ADC conversion

results during a read operation.

RD Read. This is an active low logic input which is

used in conjunction with the CS pin to enable the

data outputs.

WR Write. A logic input. A rising edge on this input,

with

CS low and RD high latches the logic state

on D0-D3 into the channel select register. Software selection of channels is not supported by this

evaluation board.

CS Chip Select. An active low logic input. A low

level on this input selects the AD7899.

FL0 Flag zero. This logic input is connected to the

CONVST input of the AD7899 via LK7. A low

to high transition on this input puts all the track/

holds into their hold mode and starts conversion

on the selected channels. In addition the state of

the channel sequence selection is also latched on

the rising edge of this input

IRQ2 Interrupt Request 2. This is a logic output and is

connected to the BUSY logic output on the

AD7899. This output will go high on the rising

edge of CONVST and will return low when

conversion is completed on all selected channels.

DGND Digital Ground. These lines are connected to the

digital ground plane on the evaluation board. It

allows the user to provide the digital supply via

the connector along with the other digital signals.

AGND Analog Ground. These lines are connected to the

analog ground plane on the evaluation board.

AV

DD

Analog +5V Supply. These lines are connected to

the V

supply line on the board via LK4.

DD

+12V +12V Supply. This line is connected to the +12V

supply line on the board via LK3.

-12V -12V Supply. This line is connected to the -12V

supply line on the board via LK5.

Table II. 96-Way Connector Pin Functions.

ROW a RowB RowC

1 FL1

2D0

3 SCLK1 D1 SCLK1

4 DGND DGND DGND

5D2

6D3

7D4

8

9RD D5 WR

10 D6 CS

11 D7

12 DGND DGND DGND

13 D8

14 D9

15 D10

16 DGND DGND DGND

17 FL0 D11 IRQ2

18 D12 D13

19

20 DGND DGND DGND

21 AGND AGND AGND

22 AGND AGND AGND

23 AGND AGND AGND

24 AGND AGND AGND

25 AGND AGND AGND

26 AGND AGND AGND

27 AGND

28 AGND

29 AGND AGND AGND

30 -12V AGND +12V

31

32 AVDD AVDD AVDD

Note : The unused pins of the 96-way connector are not shown.

–4–

REV. 0

Page 5

EV AL-AD7899CB

SOCKETS

There are six input sockets relevant to the operation of the

AD7899 on this evaluation board. The function of these

sockets is outlined in Table III.

Table III. Socket Functions

Socket Function

SK1 Sub-Miniature BNC Socket for the analog

input.

SK2 Sub-Miniature BNC Socket for the exter-

nal reference

SK3 Sub-Miniature BNC Socket for external

V

supply.

DRIVE

SK4 Sub-Miniature BNC Socket for BUSY

output.

SK5 Sub-Miniature BNC Socket for external

CONVST input.

SK6 Sub-Miniature BNC Socket for the exter-

nal CLKIN input.

CONNECTORS

There are two connectors on the AD7899 evaluation board

as outlined in Table IV.

Table IV. Connector Functions

Connector Function

J1 96-Way Connector for Parallel Interface con-

nections.

J2 External +12V, -12V +5V & A

connector.

GND

power

OPERATING WITH THE EVAL-BOARD

CONTROLLER

The evaluation board can be operated in a stand-alone mode

or operated in conjunction with the EVAL-BOARD CONTROLLER. The EVAL-BOARD CONTROLLER is available from Analog Devices under the order entry

"EVAL-BOARD CONTROLLER". When operated with

this control board, all supplies and control signals to operate

the AD7899 are provided by the EVAL-BOARD CONTROLLER. Software to communicate with the Control

Board and AD7899 is provided with the AD7899 evaluation

board package. This EVAL-BOARD CONTROLLER will

also operate with all Analog Devices evaluation boards which

end with the letters CB in their title.

The 96-way connector on the EVAL-AD7899CB plugs

directly into the 96-way connector on the EVAL-BOARD

CONTROLLER. The EVAL-BOARD CONTROLLER

provides all the supplies for the evaluation board. Itis

powered from a 12VAV transformer. Suitable transformers

are available from Analog Devices as an accessory under the

following part numbers:

EVAL-110VAC-US: For use in the U.S. or Japan

EVAL-220VAC-UK: For use in the U.K.

EVAL-220VAC-EU: For use in Europe

These transformers are also available for other suppliers

including Digikey (U.S.) and Campbell Collins (U.K.).

Connection between the EVAL-BOARD CONTROLLER

and the serial port of a PC is via a standard Centronics printer

port cable which is provided as part the EVAL-BOARD

CONTROLLER package. Please refer to the manual which

accompanies the EVAL-BOARD CONTROLLER for more

details on the EVAL-BOARD CONTROLLER package.

REV. 0

–5–

Page 6

EV AL-AD7899CB

Figure 2. AD7899 Main Screen

SOFTWARE DESCRIPTION

The software which controls the Evaluation Board Controller and hence the evaluation board has three main screens.

The screen shown in Figure 1 shows the screen which appears

when the software is run. The main function of this screen is

to allow the user to read a predetermined number of samples

from the evaluation board and display them in both the time

and frequency domain. The screen can be divided into 3

sections. The upper third of the screen contains the control

buttons, the menu bar and various status windows. The

control buttons allow the user to enter the setup menu, take

samples and get information about the software. The menu

bar allows the user to select which printer port is to be used

to control the Evaluation Board Controller, load and save

data etc. The status windows indicate the setup of the

evaluation board/device, number of samples taken and any

information/error messages that are generated.

The middle third of the screen is a Digital Storage

Oscilloscope (DSO). When samples are uploaded from the

Evaluation Board Controller they are displayed here. The

samples can be displayed either as integer values or as

voltages (determined by the input range of the device in

question). Once samples have been displayed clicking at any

point in the graph will display the sample number and value

of the point directly beneath the cursor. Along the axis of the

graph are the "zoom handles". These allow the user to zoom

in and out to get a closer look at a particular sample if

required. When another set of samples is taken the graph will

attempt to display all values collected unless the Hold Zoom

check box is ticked. In this case the graph will keep the same

axis settings as for the previous set of data samples. Additional check boxes are provided to give the user control over

the vertical and horizontal grids and data points.

The lower third of the screen will show either a Fast

Fourier Transform (FFT) of the data or a Histogram which

shows the number of occurrances of each particular code read

back. The FFT (the default option) is typically used when the

user is concerned with examining an ADC's performance in

the frequency domain while the Histogram will give an

indication of the ADC's performance to DC signals. The

option displayed can be toggled by clicking on the FFT

Mode/Histogram Mode button in the top right of the screen.

Figure 3 shows how the main screen looks when the Histogram Option is selected.

–6–

REV. 0

Page 7

EV AL-AD7899CB

Figure 3. AD7899 Main Screen - Histogram Mode

Setup Screen

The Setup Screen is responsible for allowing the user to load

a configuration file for the evaluation board. The configuration file will give the software detailed information about the

evaluation board and part connected to the Evaluation Board

Controller such as number of bits, maximum sampling rate,

power supply requirements etc. The configuration file also

tells the software the name of the DSP program file which it

should download to the Evaluation Board Controller. These

files are supplied by Analog Devices with the evaluation

board. Figure 4 shows the Setup Screen.

SETTING UP THE EVALUATION BOARD

CONTROLLER

The following text describes how the evaluation board

Evaluation Board Controller and software should be set up

for the user to begin using the complete system. The

Evaluation Board Controller and evaluation board should be

connected together (via the 96 way connector). The power

should be applied to the Evaluation Board Controller. At this

stage the red LED should be flashing which indicates that the

Evaluation Board Controller is functional and ready to

REV. 0

–7–

receive instructions. The software which should have

been installed should be loaded before the printer port

cable is connected between the Evaluation Board Controller and the PC. This will ensure that the printer port

has been initialized properly. The printer port cable can

then be connected between the PC and the Evaluation

Board Controller.

Running the Software

With the hardware setup the user is now in a position to

use the software to control the Evaluation Board Controller and evaluation board. In the software the user

should select the File menu and click on Setup. This will

display the setup form. A window on the left of the setup

form list all the available configuration files. The configuration files are text based files which contain information about the particular evaluation board to be tested.

The information will cover such things as the part name,

number of samples to be taken, default and maximum

sampling frequency power supply settings etc. The

configuration file also contains the name of the DSP

program file which is to be downloaded to the Evaluation

Board Controller. The user should select the relevant

Page 8

EV AL-AD7899CB

Figure 4. The Setup Screen

configuration file and click Load. The Evaluation Board

Controller will be reset and the DSP program will be

downloaded. When the download has been completed the

power supply settings indicated in the configuration file are

set and the user may hear some of the relays clicking. The

pull-down menus items such as number of samples and

sampling frequency will have been set to the default values

specified by the configuration file. The user is free to change

these at will. Once all the settings had been decided the user

can click Close to return to the main form.

Taking Samples

When the user clicks Sample the software will instruct the

Evaluation Board Controller to take the required number of

samples at the required frequency from the evaluation board.

These samples are then uploaded and displayed. An FFT and

Histogram are also calculated and displayed. If the user clicks

Cont Samp the software will repeat the process indefinitely

until the user clicks the button again. While the software is

continuously sampling data the other control buttons are

disabled.

Other Buttons

The Reset button will cause the Evaluation Board Controller

to perform a reset function. When this happens the power

supplies are turned off and the program in DSP memory is

lost. The user should repeat the setup instructions to download another program if required.

The Quit button will exit the software, the program running

on the Evaluation Board Controller is not terminated.

MENU BAR ITEMS

The main screen of the Evaluation Board Controller contains

a number of options available as pull-down menu items. The

functions of these are listed below.

File Menu:

Setup Menu: Selecting this option displays the Setup Screen

as shown in Figure 3.

Load Raw Data: Selecting this option allows the user to load

data which had been saved by the software during a previous

session.

Save Raw Data: Selecting this option allows the user to save

the current set of sample data points. The data can be

reloaded to the Evaluation Board Controller software at a

later date or can be used by other programs for further

analysis

Save Binary Data: Selecting this option allows the user to

save the current set of sample data points. The data is saved

in binary format as a text file. This method can be useful for

examining code flicker, looking for stuck bits etc.

Save FFT Data: Selecting this option allows the user to save

the current set of FFT data points. FFT data cannot be

reloaded into the Evaluation Board Controller software but

can be loaded into other software packages for further

analysis.

Exit: Quits the program.

Printer Port:

This menu item allows the user to select which printer port

should be used for communication with the Evaluation Board

Controller.

LPT1: This option selects 0x378 as the printer port

address. This is the default option.

LPT2: This option selects 0x278 as the printer port

address.

PRN: This option selects 0x3BC as the printer port

address.

Help:

This menu item gives information about the current revision

of software for the particular evaluation board being used.

–8–

REV. 0

Page 9

EV AL-AD7899CB

SOFTWARE CONFIGURATION FILES

Software Configuration Files give the Evaluation Board Controller software information on how the software and hardware

should perform . They contain information such as the name of the DSP program to download, the default and maximum

sample frequencies, the number of samples to take and the power supply settings to use. A typical Software Configuration File

(*.cfg) is shown in Table V.

Table V.: Typical Software Configuration File.

[EVAL-CONTROL BOARD]

partname:AD7899

programname:ad7899.PRG

samplefrequency:100000

maxsamplefrequency:380000

samples:2048

+/-15V:on

dvdd:5:on

avdd:5:on

bus:on

;options 2scomp, binary

dataformat:2scomp

numberofbits:14

inputVmax:2.5

inputVmin:-2.5

Table VI.: Eval-AD7899CB Bill Of Materials.

Item Qty RefDes Description Manufacturer/Disti Disti Number

1 6 C1 C4 C5 C7 C9 C12 10uF 16V TAJ_B Tantalum cap AVX/FEC FEC 498-737

2 16 C2 C3 C6 C8 C10 C11 C13 C14 100nF 0805 Ceramic Capacitor AVX/FEC FEC 499-687

C15 C16 C18 C20 C22 C24 C26 C28

3 6 C17 C19 C21 C23 C25 C27 47uF 16V TAJ_C Tantalum cap AVX/FEC FEC 197-32

5 3 C30 C31 C32 22pF 0805 Ceramic Capacitor AVX/FEC FEC 317-500

6 2 R1 R2 0W 0.1W 0805 Resistor Multicomp/FEC FEC 772-239

7 3 R3 R4 R5 180W 0.1W 0805 Resistor Multicomp/FEC FEC 911-768

8 1 R6 10kW 0.1W 0805 Resistor Multicomp/FEC FEC 911-975

9 1 J1 DIN41612-96 Harting/FEC FEC 104-986

10 1 J2 4 pin terminal block Augat/FEC FEC 151-787

11 7 LK1 LK2 LK3 LK4 LK5 LK7 LK8 4 pin header (2x2) Harwin/FEC FEC 148-535

12 2 LK6 LK9 6 pin header 3x2) Harwin/FEC FEC 148-535

13 9 LK1-9 "0.1"" pitch Jumper Socket" Harwin/FEC FEC 150-410

14 6 SK1 SK2 SK3 SK4 SK5 SK6 50W SMB socket (vertical) MACOM/FEC FEC 310-682

15 1 U1 AD7899AR-1 Analog Devices ADI Free Issue

16 1 U2 74HC04N Philips/FEC FEC 380-362

17 1 U3 AD845KN Analog Devices ADI Free Issue

18 1 U4 AD780AN Analog Devices ADI Free Issue

19 2 U5 U6 74HC541D Philips/FEC FEC 492-607

20 1 U1 28 pin SOIC Socket Yamaichi/Radiatron IC179-28375-300

21 1 U2 14 pin DIP solder socket Harwin/FEC FEC 738-529

22 16 U3 U4 Ultra low profile sockets Harwin/FEC FEC 519-935

23 4 Rubber stick-on feet 3M/FEC FEC 148-922

REV. 0

–9–

Page 10

EV AL-AD7899CB

Figure 5. AD7899 Evaluation Board Circuit Diagram.

–10–

REV. 0

Page 11

EV AL-AD7899CB

Figure 6. Component Side Artwork.

REV. 0

Figure 7. Solder Side Artwork.

–11–

Page 12

EV AL-AD7899CB

Figure 8. Component Side Silkscreen Artwork.

–12–

REV. 0

Loading...

Loading...