Page 1

Engineer To Engineer Note EE - 145

Notes on using Analog Devices’ DSP componentsand development tools

Phone: (800) ANALOG-D or (781) 461-3881, FAX: (781) 461-3010, EMAIL: dsp.support@analog.com

Contributed by T. Lorenzen, European DSP Applications (Sept. 01)

SPI Booting of the ADSP-2191 using the Atmel AT25020N

on an EZ-KIT LITE Evaluation Board

Introduction:

Analog Devices ADSP-2191 i s the first DSP that provides booting via SPI. This note shows how

to interface an ATMEL EEPROM (AT25020) in order to boot the ADSP-2191 via the SPI

interface. With the help of a little project, this app note will describe how to create a loader file

which is stored in the EEPROM and used to boot the DSP. The loader file format as well as the

Hardware will be covered in order to build the whole project.

W2.0:

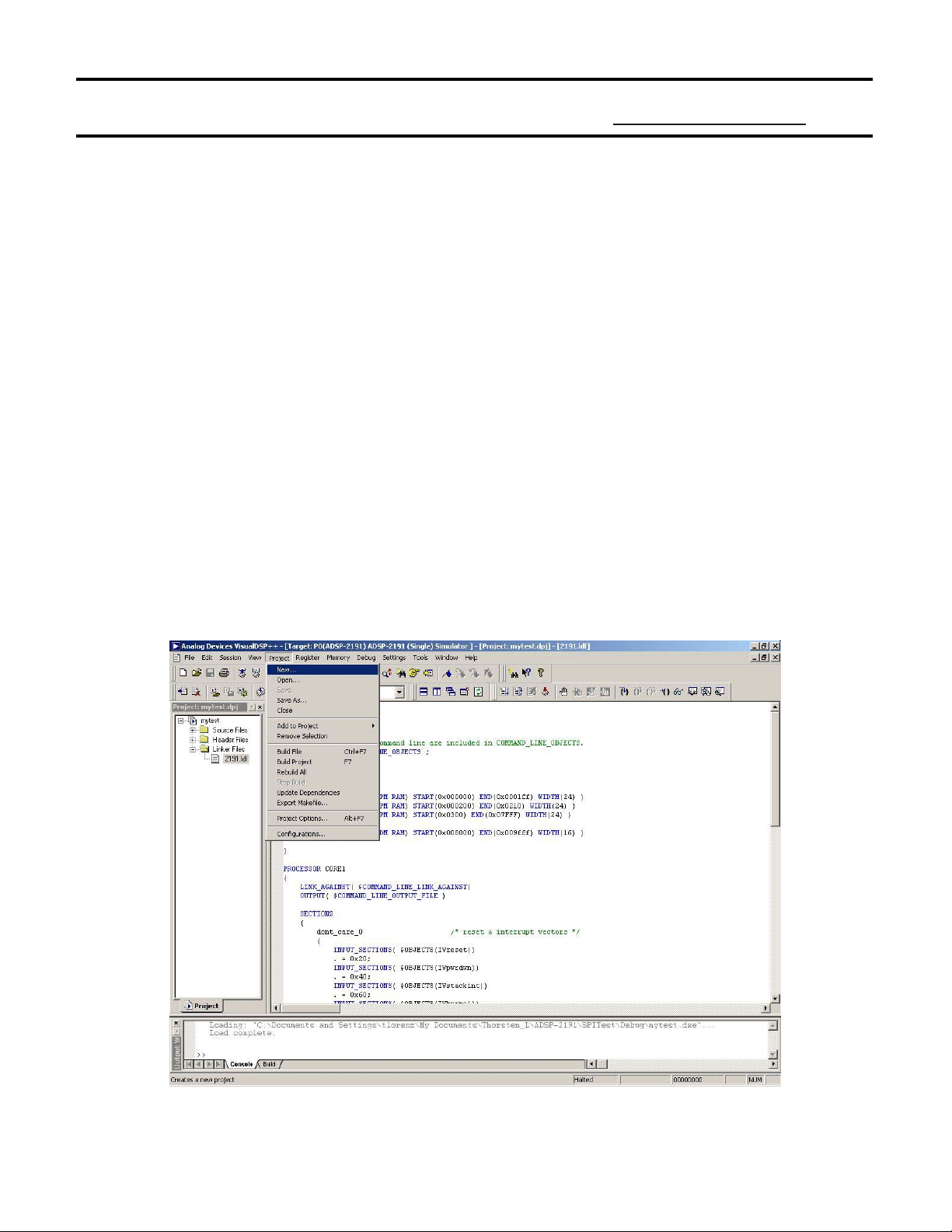

The latest version of VisualDSP++2.0 creates loader files suitable for SPI booting (Serial

Peripheral Interface) automatically. Open Analog Devices VisualDSP++2.0 and make a new

project. Add the linker description file (LDF) of the ADSP-2191 to the project first. This file

defines the entire address range of the DSP and identifiers individual sections of memory with

labels.

Figure 1 create a new project with VisualDSP++ 2.0

Copyright 2001, Analog Devices, Inc. All rights reserved. Analog Devices assumes no responsibility for customer productdesign ort he use or applicationof customers’ products or

for any infringements of patents or rights of others which m ay result from Analog Devices assistance. All trademarks andlogos are property of their respective holders. Information

furnished by AnalogDevices Applications and DevelopmentTools Engineers is believed to be accurate and reliable, however no responsibility is assumedbyAnalogDevices

regarding thetechnical accuracy of the content provided in allAnalog Devices’ Engineer-to-Engineer Notes.

1

Page 2

Engineer To Engineer Note EE - 145

Notes on using Analog Devices’ DSP componentsand development tools

Phone: (800) ANALOG-D or (781) 461-3881, FAX: (781) 461-3010, EMAIL: dsp.support@analog.com

Finally, add an existing assembly file of your choice (or create a new asm file to add) and the

header file “def2191.h” which defines all of the ADSP-2191’s memory-mapped registers. If the

ADSP-2191 processor is selected the project can now be build.

This way VisualDSP++2.0 will build an executable file “filename.dxe” which is required for

debugging your program on the simulator or l oading it to and debugging it on the DSP via the

emulator.

Note:

Ensure you have the most recent loader “elfloader.exe”. Find one in the zip file.

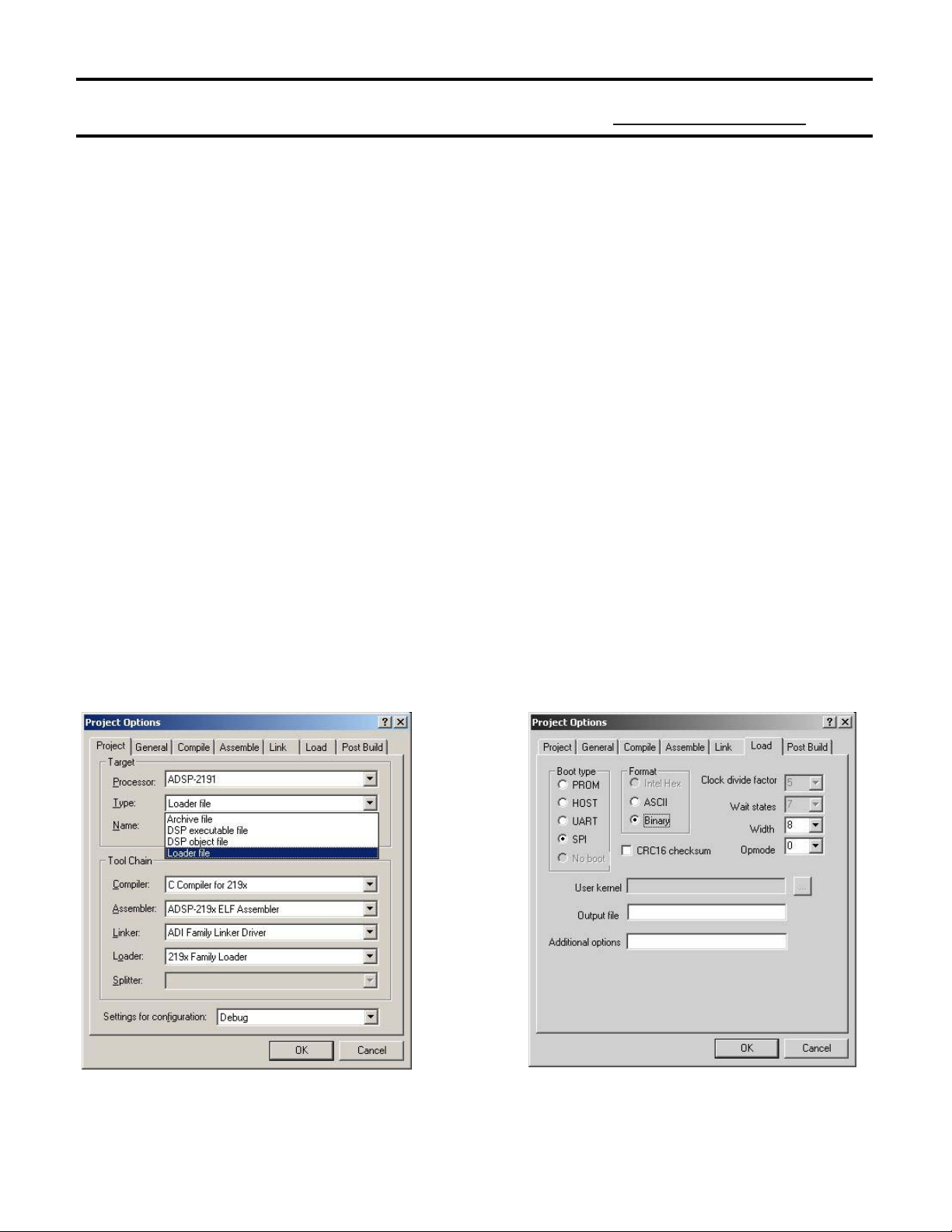

To prepare VisualDSP++ 2.0 SPI booting please open the “Project Options” dialog box from the

“Project” menu. As shown in figure 2, on the project option tab change the option “type” in the

“target” frame from “DSP e xecutable file” to “ Loader file”. This causes VisualDSP++ 2.0 to

create a l oader file which can be stored in non-volatile memory of your choice. The ADSP-2191

is able to boot from different memory types. To select the appropriate booting device, select the

“Loader” tab control in the “Project Options” box and set the Boot Type” to “SPI”. Select binary

format in the “Format” frame to create a binary file that i s suitable for the most common

programmers as shown in figure 3. The ASCII format lets the VisualDSP++ 2.0 l oader

“elfloader.exe” build a loader file in ASCII format. This file can be accessed by any text editor

easily. The binary file can be accessed by using a binary editor only. Finally, press the “OK”

button on the dialog “Project Options” and again rebuild the whole project again. A file with the

same name as the project and the extension .ldr will be generated. This .ldr file can be loaded

by a programmer and written to the booting device (in this case to the AT25020 EEPROM)

straight forward.

Figure 2 “Project” options dedicated to your project Figure 3 “Loader” options dedicated to your project

Copyright 2001, Analog Devices, Inc. All rights reserved. Analog Devices assumes no responsibility for customer productdesign ort he use or application of customers’products or

for any infringements of patents or rights of others which m ay result from Analog Devices assistance. All trademarks andlogos are property of their respective holders. Information

furnished by AnalogDevices Applications and DevelopmentTools Engineers is believed to be accurate and reliable, however no responsibility is assumedbyAnalogDevices

regarding thetechnical accuracy of the content provided in allAnalog Devices’ Engineer-to-Engineer Notes.

2

Page 3

Engineer To Engineer Note EE - 145

Notes on using Analog Devices’ DSP componentsand development tools

Phone: (800) ANALOG-D or (781) 461-3881, FAX: (781) 461-3010, EMAIL: dsp.support@analog.com

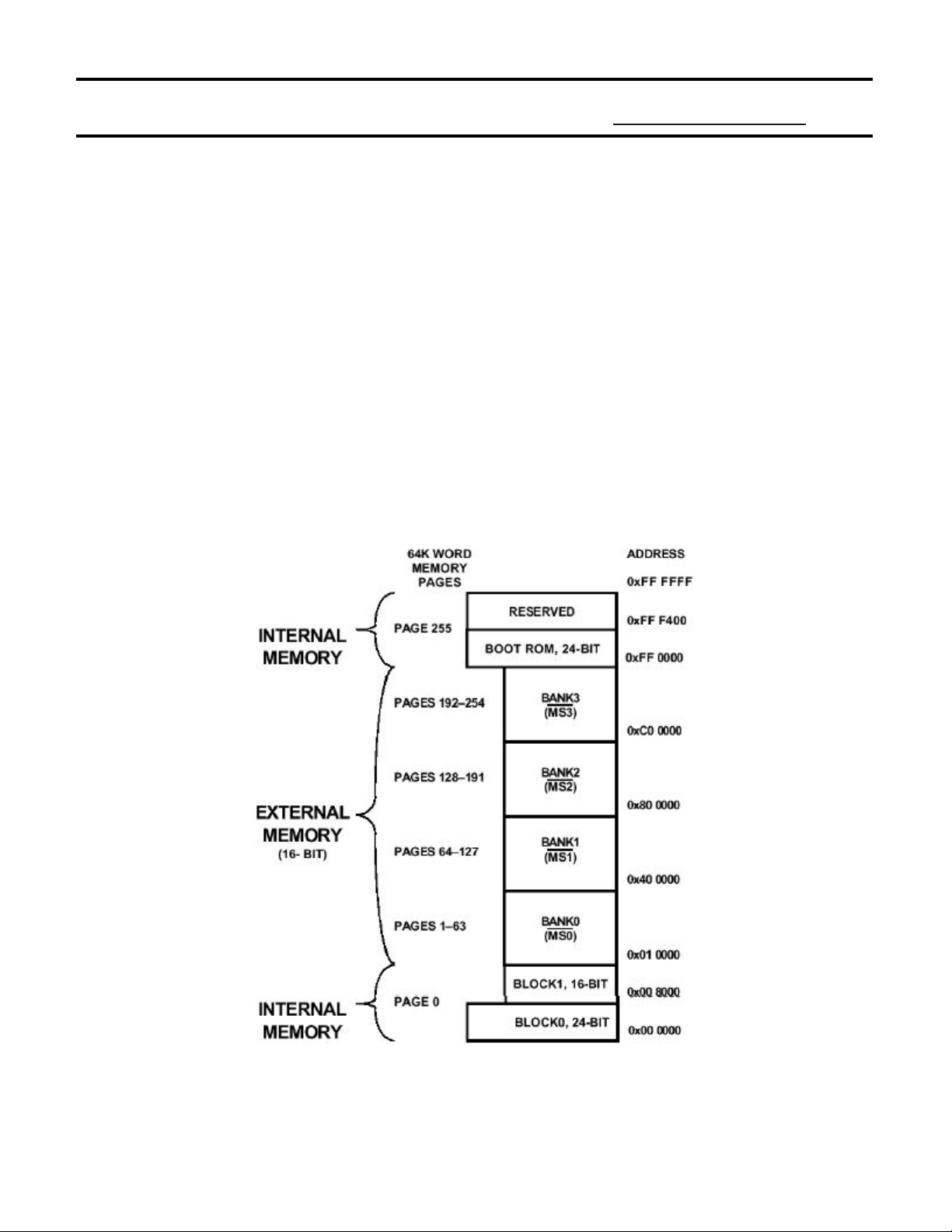

ADSP-2191 Startup basics:

The ADSP-2191 has a booting scheme that is different from former ADI DSPs. The boot kernel

is located on-chip and stored in a 24-bit wide, 1K ROM. After a hardware reset the processor

starts running at address FF0000h. Automatically the boot kernel will be processed. There are

three input pins on the ADSP-2191 whose input state upon hard /RESET determines the

booting mode. The state of the three pins (OPMODE, BMODE0 and BMODE1) are sampled on

the rising edge of /RESET and are captured into the corresponding bits (0,1 and 2) of the

System Configuration Register by software (boot kernel). In the case of SPI booting the kernel

branches to the SPI booting subroutine. It initializes the SPI port using SPISS0 and sends the

first commands to the SPI EEPOM. Referring to the AT25020 data sheet the first byte sent to

the EEPROM in order to receive data is the value “0x3” (Read Timing). Followed by this

command the starting address is sent ( 0x0 in this case). For more information see, section titled

Hardware investigations. Received data coming from the serial EEPROM will then be unpacked

and stored in the appropriate memory locations as the following section will explain.

Figure 4 Memory Map of the ADSP2191

Copyright 2001, Analog Devices, Inc. All rights reserved. Analog Devices assumes no responsibility for customer productdesign ort he use or application of customers’products or

for any infringements of patents or rights of others which m ay result from Analog Devices assistance. All trademarks andlogos are property of their respective holders. Information

furnished by AnalogDevices Applications and DevelopmentTools Engineers is believed to be accurate and reliable, however no responsibility is assumedbyAnalogDevices

regarding thetechnical accuracy of the content provided in allAnalog Devices’ Engineer-to-Engineer Notes.

3

Page 4

Engineer To Engineer Note EE - 145

Notes on using Analog Devices’ DSP componentsand development tools

Phone: (800) ANALOG-D or (781) 461-3881, FAX: (781) 461-3010, EMAIL: dsp.support@analog.com

Serial Peripheral Interface (SPI):

The ADSP-2191 serial peripheral interface is an industry standard synchronous serial link that

helps the DSP communicate with multiple SPI-compatible devices. The SPI peripheral is a

synchronous, 4-wire inter-face consisting of two data pins, MOSI (Master Out Slave In) and

MISO (Master In Slave Out); one device select pin, SPISS (SPI Slave Select); and a gated clock

pin, SCK (Serial Clock). With the two data pins, it allows for full-duplex operation to other SPIcompatible devices. The SPI also includes programmable baud rates, clock phase, and clock

polarity. The SPI can operate in a multi-master environment by interfacing with several other

devices, acting as either a master device or a slave device. In a multi-master environment, the

SPI interface uses open drain data pad driver outputs to avoid data bus contention. Figure 5

provides a block diagram of the AD SP-2191 SPI Interface. The interface is essentially a shift

register that serially transmits and receives data bits, one bit a time at the SCK rate, to/from

other SPI devices. SPI data is transmitted and received at the same time through the use of a

shift r egister. When an SPI transfer occurs, data is simultaneously transmitted, or shifted out

serially via the shift register, as new data is received, or shifted in serially at the other end of the

same shift register. The SCK synchronizes the shifting and sampling of the data on the two

serial data pins, MOSI and MISO.

Figure 5 ADSP-2191 SPI Block Diagram

Copyright 2001, Analog Devices, Inc. All rights reserved. Analog Devices assumes no responsibility for customer productdesign ort he use or application of customers’products or

for any infringements of patents or rights of others which m ay result from Analog Devices assistance. All trademarks andlogos are property of their respective holders. Information

furnished by AnalogDevices Applications and DevelopmentTools Engineers is believed to be accurate and reliable, however no responsibility is assumedbyAnalogDevices

regarding thetechnical accuracy of the content provided in allAnalog Devices’ Engineer-to-Engineer Notes.

4

Page 5

Engineer To Engineer Note EE - 145

Control Word (16 bits):

Flag (16 bits):

Start Address (16 bits):

Page (16 bits):

Word Count (16 bits):

Data Words (16 bits or 24 bits):

Flag (16 bits):

Start Address (16 bits):

Notes on using Analog Devices’ DSP componentsand development tools

Phone: (800) ANALOG-D or (781) 461-3881, FAX: (781) 461-3010, EMAIL: dsp.support@analog.com

Boot stream format:

During booting the kernel follows a protocol to decode the loader file as shown below. The data

received from the SPI EEPROM is eight bits wide. Each byte received will be checked, shifted

together and than stored in memory. The processor stores the Header (Control Word, Flag (or

known as TAG) , Start Address, Page and Word Count) in data memory at first. With help of

these contents the processor knows where to store the instructions or data.

TheControlWordwillbestoredinmemoryatthe

beginning of the boot sequence, only. But these values

are ignored completely during SPI booting. It can just

be booted in 8 bit mode as well as with having no wait

states are required.

(SPI Width 8 bits) (Wait State Information’s 8 bits)

Each instruction or data block starts with a flag. This

flag includes whether to store the instr./data in DM or

PM. As well as zero filling or final block detection.

The start address indicates the location of the first DM

or PM word in memory. The address will be

incremented by 1 for all following words automatically.

The page extents the address in order to access more

memory.

Instructions are placed in PM . one by one,

consecutively. Word Count indicates the number of

instructions following this header.

Finally the instructions, just as many as instr. are

countered in Word Count as many 24 bits Data Words

are expected. Beginning after Word Count and placed

in memory dedicated to the Flag Word and starting at

the address held in Start Address.

(Indicates the memory locations 16 bits or 24 bits)

(Indicates the start address of the corresponding

memorylocation)

(Extents the address range to access higher memory)

(Holds the number of words (instructions or data)

that must be loaded starting at the start address )

(Instructions or data by it self)

Flag Function

0x00 24 bit PM

0x01 16 bit DM

0x02 Final PM

0x03 Final DM

0x04 Zero-init PM

0x05 Zero-init DM

0x06 Zero-init Final PM

0x07 Zero-init Final DM

0x08 Reserved

Table 1 Boot Flags (Tags)

Copyright 2001, Analog Devices, Inc. All rights reserved. Analog Devices assumes no responsibility for customer productdesign ort he use or application of customers’products or

for any infringements of patents or rights of others which m ay result from Analog Devices assistance. All trademarks andlogos are property of their respective holders. Information

furnished by AnalogDevices Applications and DevelopmentTools Engineers is believed to be accurate and reliable, however no responsibility is assumedbyAnalogDevices

regarding thetechnical accuracy of the content provided in allAnalog Devices’ Engineer-to-Engineer Notes.

The following Flag

indicates the next

instr./data words s toring

in different areas.

(Indicates the memory locations DM or PM)

(Indicates the start address of the corresponding

memorylocation)

Figure 6 Boot stream format

5

Page 6

Engineer To Engineer Note EE - 145

Notes on using Analog Devices’ DSP componentsand development tools

Phone: (800) ANALOG-D or (781) 461-3881, FAX: (781) 461-3010, EMAIL: dsp.support@analog.com

Format of the loader file “Filename.ldr”:

This section will describe the loader file that has been build by VisualDSP++ 2.0. The whole file

will be analyzed and will explain how the processor does unpacks the contents in order to place

the code and data to the right location in DSPs memory.

Figure 7 shows the file in ASCII format. The programmer has to pl ace the data starting at

address 0x0 in the EEPROM. Each line (address) contains one byte (byte wise organized). The

next job is to unpack the data by the boot kernel as shown in table 2.

Address 0x0:

2F

00

00

00

00

00

00

00

01

00

00

20

1C

04

00

01

00

00

00

DF

01

00

00

00

02

00

00

0E

00

00

30

50

14

00

50

08

00

50

00

00

40

00

10

06

00

C0

15

00

C0

15

00

C0

15

00

C0

15

00

C0

15

00

C0

15

00

C0

15

00

00

00

F3

FF

1F

07

00

F0

FE

00

00

10

01

Figure 7 Loader file created by VisualDSP++ 2.0

Copyright 2001, Analog Devices, Inc. All rights reserved. Analog Devices assumes no responsibility for customer productdesign ort he use or application of customers’products or

for any infringements of patents or rights of others which m ay result from Analog Devices assistance. All trademarks andlogos are property of their respective holders. Information

furnished by AnalogDevices Applications and DevelopmentTools Engineers is believed to be accurate and reliable, however no responsibility is assumedbyAnalogDevices

regarding thetechnical accuracy of the content provided in allAnalog Devices’ Engineer-to-Engineer Notes.

6

Page 7

Engineer To Engineer Note EE - 145

Notes on using Analog Devices’ DSP componentsand development tools

Phone: (800) ANALOG-D or (781) 461-3881, FAX: (781) 461-3010, EMAIL: dsp.support@analog.com

2F Wait State

Table 2, figure 7 and figure 8 show how the

booted data will be shifted together and

placed in memory correctly. The first byte

received from the EEPROM is 0x02F (Wait

State) using the loader file above. This byte

will be stored in a 16 bit memory space. The

following zero (Width) at the next address.

The first word of the header (Flag) will be

loaded now as it can be seen in table 2. Two

bytes must be shifted together in order to

form the first sixteen bit value. The LSByte is

received first and placed into the shifter of

the DSP . The MSByte at next and shifted to

the LSB. The 16 bit result is stored into a

place in data memory. The whole header is

unpacked the same way. After the header is

completely transferred the first instruction

following the header is unpacked and placed

in memory. It works as follows.

Decode:

Flag: data is 24 bits wide and must

be placed i n PM.

Address: start address is 0x0

Page: Internal memory space

Word Count: only one instruction

00 Width

00 00 Flag 24 bit data PM

00 00 Address

00 00 Page

00 01 Word count

1C 20 00 Instruction //Jump Start

00 04 Flag Zero init PM

00 01 Address

00 00 Page

01 DF Word count

00 00 Flag 24 bit data PM

02 00 Address

00 00 Page

00 0E Word count

50 30 00 Instruction //i0 = 0x300;

50 00 14 Instruction //m0 = 0x0001;

50 00 08 Instruction //l0 = 0x000;

40 00 00 Instruction //ax0 = 0x0000;

06 10 00 Instruction //reg(b0) = ax0;

The same procedure starts at the next flag

15 C0 00 Instruction //ax0 = pm(i0+=m0);

again.

Received Bytes

D7 D0

Wait States

Data Width

LSB of the Flag

MSB of the Flag

LSB of the Address

MSB of the Address

LSB of the Page

MSB of the Page

LSB of Word Count

MSB of Word Count

LSB of Instr./data

8-15 of Instr./data

MSB of Instr./data

Table 2 Unpacking

Copyright 2001, Analog Devices, Inc. All rights reserved. Analog Devices assumes no responsibility for customer productdesign ort he use or application of customers’products or

for any infringements of patents or rights of others which m ay result from Analog Devices assistance. All trademarks andlogos are property of their respective holders. Information

furnished by AnalogDevices Applications and DevelopmentTools Engineers is believed to be accurate and reliable, however no responsibility is assumedbyAnalogDevices

regarding thetechnical accuracy of the content provided in allAnalog Devices’ Engineer-to-Engineer Notes.

15 C0 00 Instruction //ax0 = pm(i0+=m0);

15 C0 00 Instruction //ax0 = pm(i0+=m0);

15 C0 00 Instruction //ax0 = pm(i0+=m0);

15 C0 00 Instruction //ax0 = pm(i0+=m0);

15 C0 00 Instruction //ax0 = pm(i0+=m0);

15 C0 00 Instruction //ax0 = pm(i0+=m0);

00 00 00 Instruction //NOP;

1F FF F3 Instruction //Jump Loop1;

00 07 Flag Zero init final DM

FE F0 Address

00 00 Page

01 10 Word count //272 locations

Figure 8 Loader file decoded (DSP format)

7

Page 8

Engineer To Engineer Note EE - 145

Notes on using Analog Devices’ DSP componentsand development tools

Phone: (800) ANALOG-D or (781) 461-3881, FAX: (781) 461-3010, EMAIL: dsp.support@analog.com

The next block is implemented to fill a defined area with zeros. In order to save EEPROM

memory space zero filling will be done automatically. As shown in Table 1 flags will force the

boot kernel to fill a certain memory area by zeros. No data must be added to the header. The

header i ncludes start address and word count to specify the area to be filled. After this is done

the next header can be processed.

By convention, the final block is always of the type “zero fill DM”. This and the contents of the

flag (0x07) lets the DSP jump to zero at the internal PM space to start executing the loaded

code.

Hardware investigations:

The AT25020 can be connected to the DSP easily as shown in figure 9. This EE-Note i s

dedicated to the ADDS-2191M-EZLITE to connect the SPI EEPROM. The Bread Board

Connector P9 offers all the signals are required for the connection.

Note:

A ceramic capacitor (100nF) connected to the power supply and placed very close to the device

(AT25020) to decouple.

Four pull up resistors (10k) connected to the pins ensure a defined state of the DSP pins.

Figure 9 Schematic of the circuit placed on the Bread Board Area

Copyright 2001, Analog Devices, Inc. All rights reserved. Analog Devices assumes no responsibility for customer productdesign ort he use or application of customers’products or

for any infringements of patents or rights of others which m ay result from Analog Devices assistance. All trademarks andlogos are property of their respective holders. Information

furnished by AnalogDevices Applications and DevelopmentTools Engineers is believed to be accurate and reliable, however no responsibility is assumedbyAnalogDevices

regarding thetechnical accuracy of the content provided in allAnalog Devices’ Engineer-to-Engineer Notes.

8

Page 9

Engineer To Engineer Note EE - 145

SPI Clock

SPISS

MOSI

SPI Clock

SPI Clock

MISO

Notes on using Analog Devices’ DSP componentsand development tools

Phone: (800) ANALOG-D or (781) 461-3881, FAX: (781) 461-3010, EMAIL: dsp.support@analog.com

The diagrams illustrates how the EEPROM can

be accessed. After reset the DSP initializes the

SPI Port 0, asserts the chip select line

(SPISS0) and starts the transfer. As i t can be

seen at the clock line the DSP is configured to

transfer data eight bits wide. The Bit rate is set

to run at 122.0 kHz.

Diagram 1 Timing of the SPI Clock and Chip select line(SPISS)

Diagram 2 shows the Transfer line to the

EEPROM (MOSI) “Master Out Slave In”. The

first sent byte puts the EEPROM in read mode

(referring to AT25020 Data Sheet). The next

one sets the start address which is zero in this

case. Starting from this point on the EEPROM

sends the data continuously as l ong as the SPI

port is requesting (Clock runs). The MOSI line

will be held to low for ever after the start

address has been sent.

Diagram 2 Timing of the SPI Clock and Transfer line (MOSI)

Once the read instruction and the start address

received by the EEPROM the first data will be

sent immediately on the next clock cycles.

Diagram 3 shows the first byte coming from

address zero of the EEPROM. The EEPROM

increments the address pointer automatically

and sends the second data on the next clock

cycles. This way the whole program code will

be transferred to the DSP. After transfer the

boot kernel disables the SPI port again and

starts executing the code placed in program

memory of the DSP by jumping to

PM address 0.

Diagram 3 Timing of the SPI Clock and Receiver line (MISO)

Copyright 2001, Analog Devices, Inc. All rights reserved. Analog Devices assumes no responsibility for customer productdesign ort he use or application of customers’products or

for any infringements of patents or rights of others which m ay result from Analog Devices assistance. All trademarks andlogos are property of their respective holders. Information

furnished by AnalogDevices Applications and DevelopmentTools Engineers is believed to be accurate and reliable, however no responsibility is assumedbyAnalogDevices

regarding thetechnical accuracy of the content provided in allAnalog Devices’ Engineer-to-Engineer Notes.

9

Page 10

Engineer To Engineer Note EE - 145

Notes on using Analog Devices’ DSP componentsand development tools

Phone: (800) ANALOG-D or (781) 461-3881, FAX: (781) 461-3010, EMAIL: dsp.support@analog.com

Finally the diagram 4 shows a part of the data transfer to the DSP.

Diagram 4 Timing of the SPI Clock and Receiver line (MISO)

Conclusion:

This note should have given an idea on how a DSP can be booted via the SPI interface.

Furthermore it has been described the hole project from beginning to the end of booting via SPI

in hard- and software. Attached to this document please find the DSP software project used to

create this file and the latest loader patch. (elfldr2191.dll).

References:

- VisualDSP++ 2.0 Getting Started Guide for ADSP-21xx DSPs

- VisualDSP++ 2.0 Linker and Utilities Manual for ADSP-21xx DSPs

- ADSP-2191 EZ –KIT LITE Manual

- ADSP-2191 Hardware Reference Manual

- All documents:

http://www.analog.com/industry/dsp/tech_doc/gen_purpose.html

- ATMEL AT25020 data sheet

- http://www.atmel.com

Copyright 2001, Analog Devices, Inc. All rights reserved. Analog Devices assumes no responsibility for customer productdesign ort he use or application of customers’products or

for any infringements of patents or rights of others which m ay result from Analog Devices assistance. All trademarks andlogos are property of their respective holders. Information

furnished by AnalogDevices Applications and DevelopmentTools Engineers is believed to be accurate and reliable, however no responsibility is assumedbyAnalogDevices

regarding thetechnical accuracy of the content provided in allAnalog Devices’ Engineer-to-Engineer Notes.

10

Loading...

Loading...