+5 Volt, Parallel Input

a

FEATURES

Complete 12-Bit DAC

No External Components

Single +5 Volt Operation

1 mV/Bit with 4.095 V Full Scale

True Voltage Output, 65 mA Drive

Very Low Power –3 mW

APPLICATIONS

Digitally Controlled Calibration

Servo Controls

Process Control Equipment

PC Peripherals

GENERAL DESCRIPTION

The DAC8562 is a complete, parallel input, 12-bit, voltage output DAC designed to operate from a single +5 volt supply. Built

using a CBCMOS process, these monolithic DACs offer the

user low cost, and ease-of-use in +5 volt only systems.

Included on the chip, in addition to the DAC, is a rail-to-rail

amplifier, latch and reference. The reference (REFOUT) is

trimmed to 2.5 volts, and the on-chip amplifier gains up the

DAC output to 4.095 volts full scale. The user needs only supply a +5 volt supply.

The DAC8562 is coded straight binary. The op amp output

swings from 0 to +4.095 volts for a one millivolt per bit resolution, and is capable of driving ± 5 mA. Built using low temperature-coefficient silicon-chrome thin-film resistors, excellent

linearity error over temperature has been achieved as shown below in the linearity error versus digital input code plot.

Digital interface is parallel and high speed to interface to the

fastest processors without wait states. The interface is very simple requiring only a single

put sets the output to zero scale.

CE signal. An asynchronous CLR in-

Complete 12-Bit DAC

DAC8562

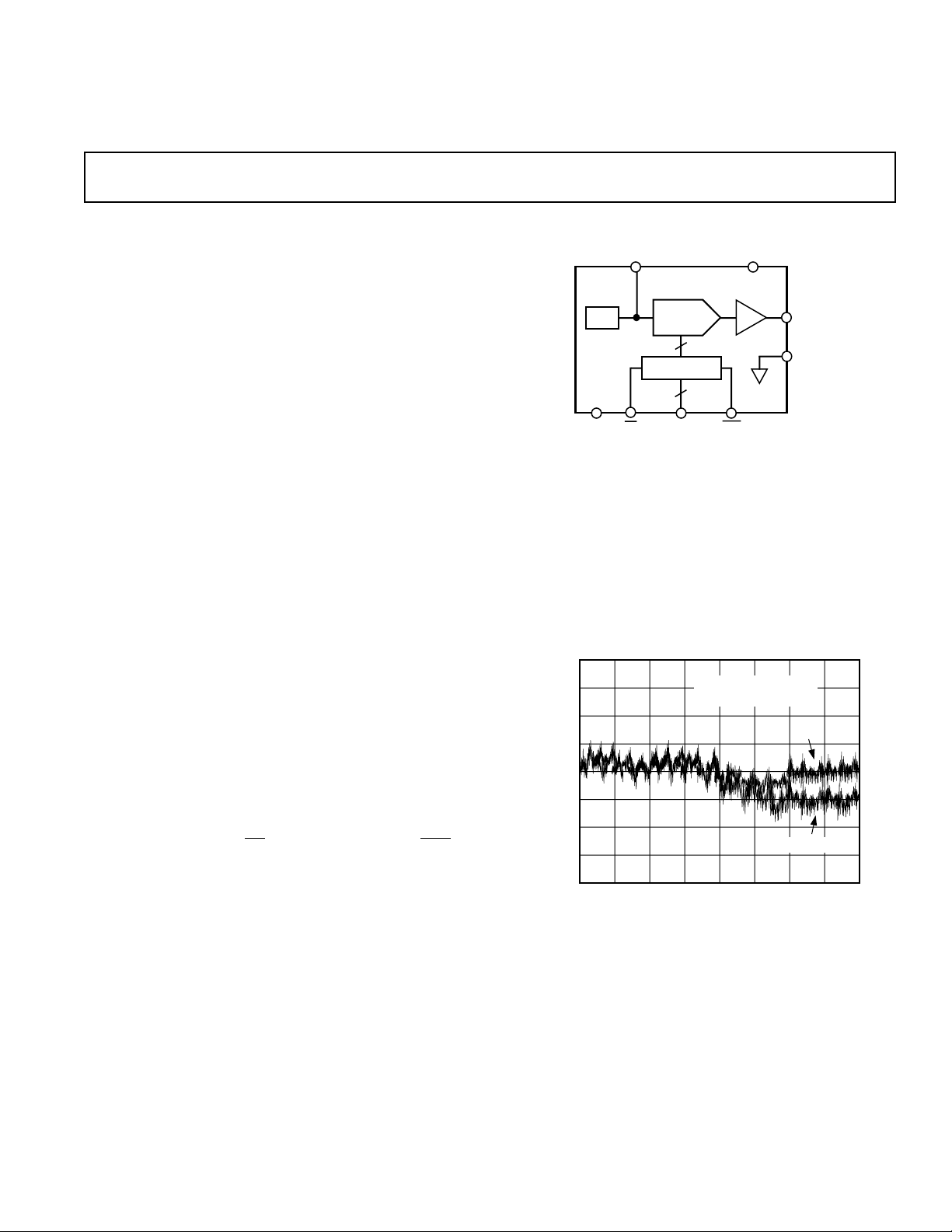

FUNCTIONAL BLOCK DIAGRAM

V

REFOUT

DAC-8562

DAC REGISTER

CE

12-BIT

DAC

DATA

12

12

REF

DGND

The DAC8562 is available in two different 20-pin packages,

plastic DIP and SOL-20. Each part is fully specified for operation over –40°C to +85°C, and the full +5 V ± 5% power supply

range.

For MIL-STD-883 applications, contact your local ADI sales

office for the DAC8562/883 data sheet which specifies operation over the –55°C to +125°C temperature range.

1

0.75

0.5

0.25

0

–0.25

LINEARITY ERROR — LSB

–0.5

–0.75

–1

0

VDD = +5V

T

A

DIGITAL INPUT CODE — Decimal

Figure 1. Linearity Error vs. Digital Input Code Plot

DD

V

AGND

CLR

= –55°C, +25°C, +125°C

–55°C

+25°C & +125°C

307220481024

OUT

4096

REV. A

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 617/329-4700 Fax: 617/326-8703

DAC8562–SPECIFICATIONS

ELECTRICAL CHARACTERISTICS

(@ VDD = +5.0 6 5%, RS = No Load, –408C ≤ TA ≤ +858C, unless otherwise noted)

Parameter Symbol Condition Min Typ Max Units

STATIC PERFORMANCE

Resolution N Note 2 12 Bits

Relative Accuracy INL E Grade –1/2 ± 1/4 +1/2 LSB

F Grade –1 ±3/4 +1 LSB

Differential Nonlinearity DNL No Missing Codes –1 ±3/4 +1 LSB

Zero-Scale Error V

Full-Scale Voltage V

ZSE

FS

Data = 000

Data - FFF

H

3

H

+1/2 +3 LSB

E Grade 4.087 4.095 4.103 V

F Grade 4.079 4.095 4.111 V

Full-Scale Tempco TCV

Notes 3, 4 ±16 ppm/°C

FS

ANALOG OUTPUT

Output Current I

OUT

Load Regulation at Half Scale LD

Capacitive Load C

L

REG

Data = 800

R

= 402 Ω to ∞, Data = 800

L

No Oscillation

H

4

±5 ±7mA

H

1 3 LSB

500 pF

REFERENCE OUTPUT

Output Voltage V

Output Source Current I

REF

REF

Line Rejection LN

Load Regulation LD

Note 5 5 7 mA

REJ

REGIREF

= 0 to 5 mA 0.1 %/mA

2.484 2.500 2.516 V

0.08 %/V

LOGIC INPUTS

Logic Input Low Voltage V

Logic Input High Voltage V

Input Leakage Current I

Input Capacitance C

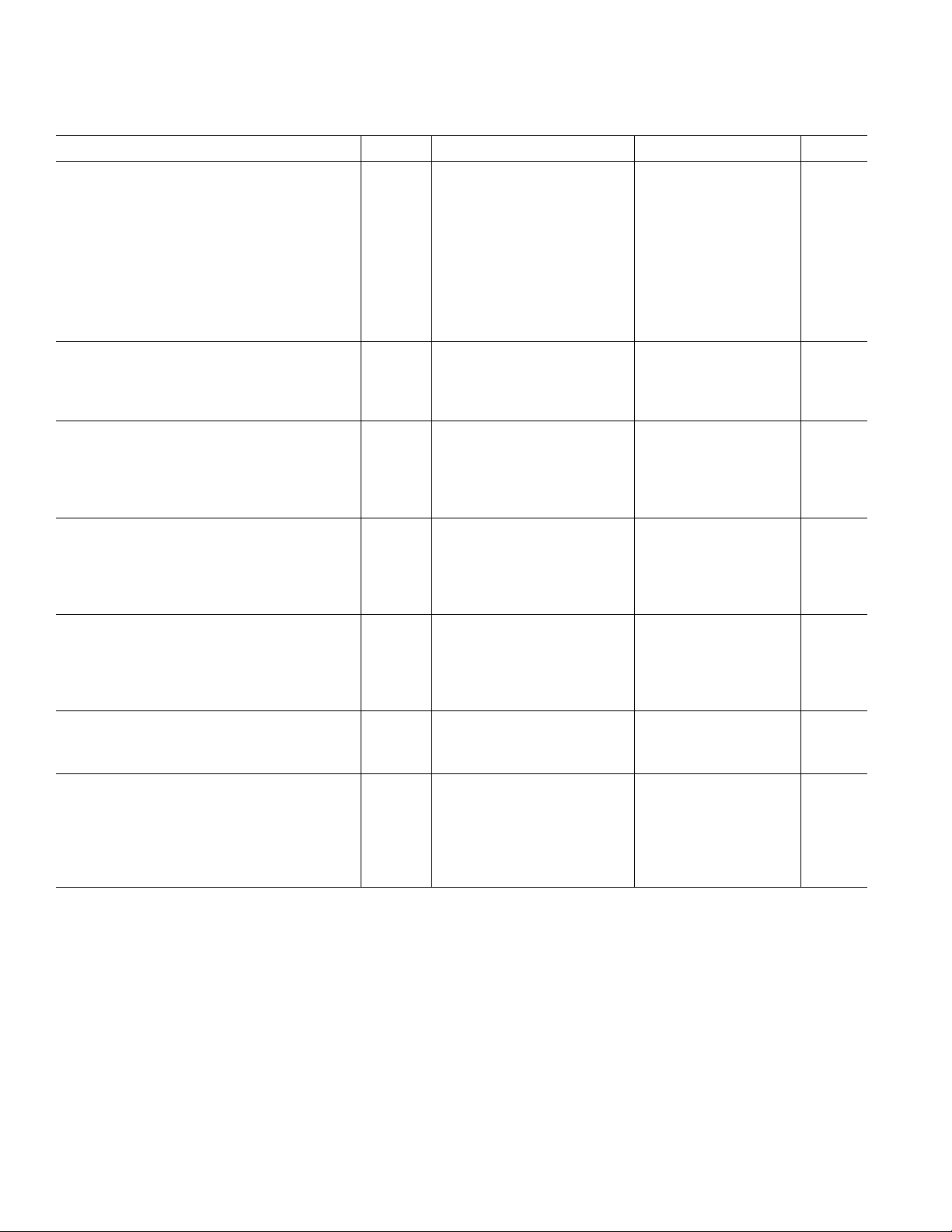

INTERFACE TIMING SPECIFICATIONS

1, 4

Chip Enable Pulse Width t

Data Setup t

Data Hold t

Clear Pulse Width t

AC CHARACTERISTICS

Voltage Output Settling Time

4

6

IL

IH

IL

IL

CEW

DS

DH

CLRW

t

S

2.4 V

Note 4 10 pF

30 ns

30 ns

10 ns

20 ns

To ±1 LSB of Final Value 16 µs

0.8 V

10 µA

Digital Feedthrough 35 nV sec

SUPPLY CHARACTERISTICS

Positive Supply Current I

Power Dissipation P

DD

DISS

VIH = 2.4 V, VIL = 0.8 V 3 6 mA

V

= 0 V, VDD = +5 V 0.6 1 mA

IL

VIH = 2.4 V, VIL = 0.8 V 15 30 mW

V

= 0 V, VDD = +5V 3 5 mW

IL

Power Supply Sensitivity PSS ∆VDD = ±5% 0.002 0.004 %/%

NOTES

1

All input control signals are specified with tr = tf = 5 ns (10% to 90% of +5 V) and timed from a voltage level of 1.6 V.

2

1 LSB = 1 mV for 0 to +4.095 V output range.

3

Includes internal voltage reference error.

4

These parameters are guaranteed by design and not subject to production testing.

5

Very little sink current is available at the REFOUT pin. Use external buffer if setting up a virtual ground.

6

The settling time specification does not apply for negative going transitions within the last 6 LSBs of ground. Some devices exhibit double the typical settling time in

this 6 LSB region.

Specifications subject to change without notice.

–2–

REV. A

1

0

0

0

1

1

FS

ZS

DB

11–0

V

OUT

t

CEW

t

DS

t

DH

DATA VALID

t

CLRW

t

S

t

S

±1 LSB

ERROR BAND

CE

CLR

DAC8562

(@ VDD = +5.0 V 6 5%, RL = No Load, TA = +258C, applies to part number DAC8562GBC only,

WAFER TEST LIMITS

Parameter Symbol Condition Min Typ Max Units

STATIC PERFORMANCE

Relative Accuracy INL –1 ±3/4 +1 LSB

Differential Nonlinearity DNL No Missing Codes –1 ±3/4 + 1 LSB

Zero-Scale Error V

Full-Scale Voltage V

Reference Output Voltage V

LOGIC INPUTS

Logic Input Low Voltage V

Logic Input High Voltage V

Input Leakage Current I

SUPPLY CHARACTERISTICS

Positive Supply Current I

Power Dissipation P

Power Supply Sensitivity PSS ∆VDD = ±5% 0.002 0.004 %/%

NOTE

1

Electrical tests are performed at wafer probe to the limits shown. Due to variations in assembly methods and normal yield loss, yield after packaging is not guaranteed

for standard product dice. Consult factory to negotiate specifications based on dice lot qualifications through sample lot assembly and testing.

unless otherwise noted)

ZSE

FS

REF

IL

IH

IL

DD

DISS

Data = 000

Data = FFF

H

H

4.085 4.095 4.105 V

+1/2 +3 LSB

2.490 2.500 2.510 V

0.8 V

2.4 V

10 µA

VIH = 2.4 V, VIL = 0.8 V 3 6 mA

V

= 0 V, VDD = +5 V 0.6 1 mA

IL

VIH = 2.4 V, VIL = 0.8 V 15 30 mW

V

= 0 V, VDD = +5 V 35mW

IL

ABSOLUTE MAXIMUM RATINGS*

VDD to DGND and AGND . . . . . . . . . . . . . . . . –0.3 V, +10 V

Logic Inputs to DGND . . . . . . . . . . . . . . .–0.3 V, V

V

to AGND . . . . . . . . . . . . . . . . . . . . .–0.3 V, VDD + 0.3 V

OUT

V

to AGND . . . . . . . . . . . . . . . . . .–0.3 V, VDD + 0.3 V

REFOUT

AGND to DGND . . . . . . . . . . . . . . . . . . . . . . . . . –0.3 V, V

I

Short Circuit to GND . . . . . . . . . . . . . . . . . . . . . . 50 mA

OUT

Package Power Dissipation . . . . . . . . . . . . . .(T

Thermal Resistance u

JA

+ 0.3 V

DD

max – TA)/u

J

DD

JA

20-Pin Plastic DIP Package (P) . . . . . . . . . . . . . . . . 74°C/W

20-Lead SOIC Package (S) . . . . . . . . . . . . . . . . . . . 89°C/W

Maximum Junction Temperature (T

max) . . . . . . . . . . 150°C

J

Operating Temperature Range . . . . . . . . . . . . .–40°C to +85°C

Storage Temperature Range . . . . . . . . . . . . . –65°C to +150°C

Lead Temperature (Soldering, 10 secs) . . . . . . . . . . . . +300°C

*Stresses above those listed under “Absolute Maximum Ratings” may cause

permanent damage to the device. This is a stress rating only and functional

operation of the device at these or any other conditions above those indicated in the

operational sections of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect device reliability.

Figure 2. Timing Diagram

Table I. Control Logic Truth Table

CE CLR DAC Register Function

H H Latched

L H Transparent

↑

+ H Latched with New Data

X L Loaded with All Zeros

H

↑

+ Positive Logic Transition; X Don't Care.

↑

+ Latched All Zeros

CAUTION

ESD (electrostatic discharge) sensitive device. The digital control inputs are diode protected;

however, permanent damage may occur on unconnected devices subject to high energy electrostatic

fields. Unused devices must be stored in conductive foam or shunts. The protective foam should be

discharged to the destination socket before devices are inserted.

REV. A

–3–

WARNING!

ESD SENSITIVE DEVICE

DAC8562

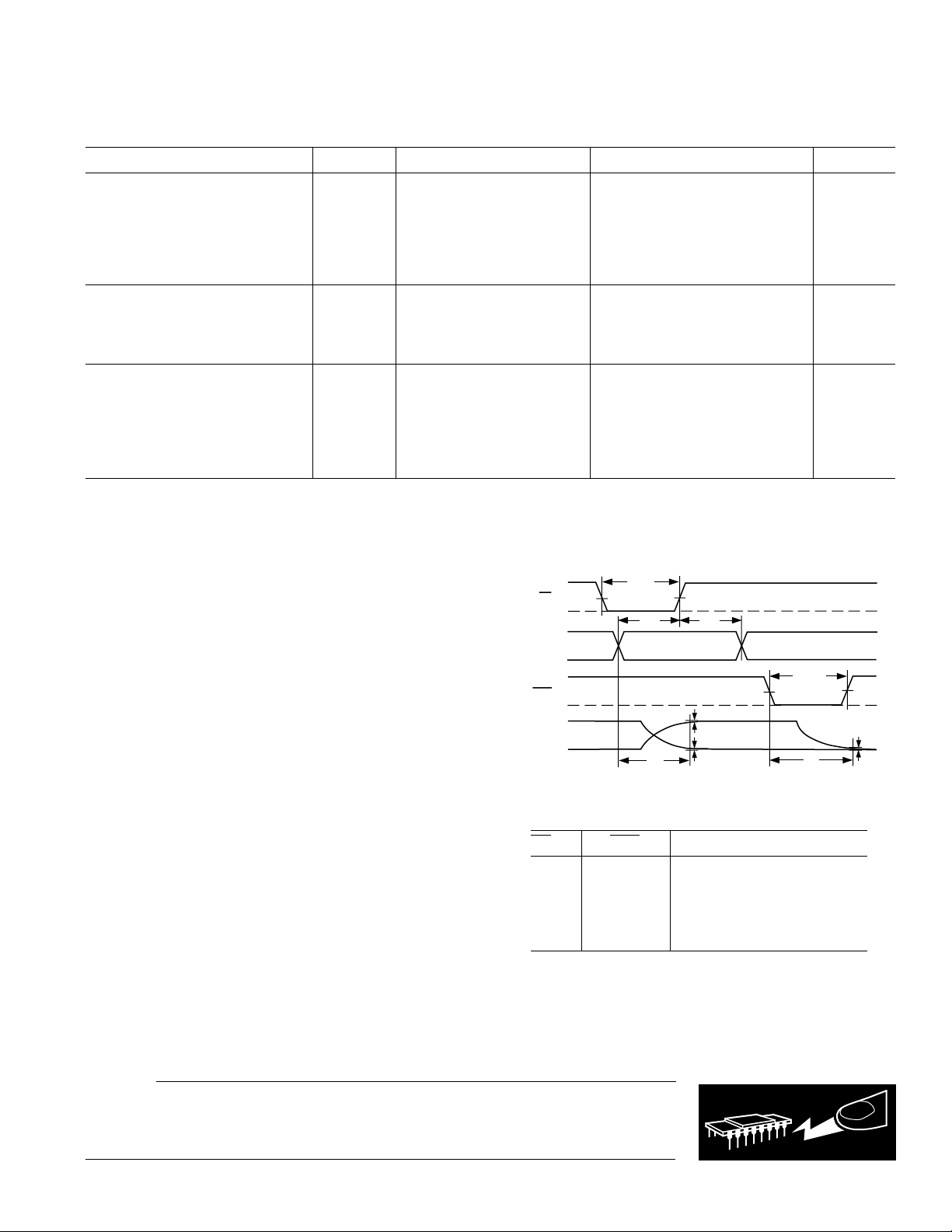

PIN CONFIGURATIONS

DB3

DB4

DB5

DB6

DB7

DB8

DB9

DB10

DB11

DGND

20-Pin P-DIP

(N-20)

1

2

3

4

DAC-8562

5

TOP VIEW

6

(Not to Scale)

7

8

9

10

NC = NO CONNECT

20

19

18

17

16

15

14

13

12

11

V

DD

DB2

DB1

DB0

CE

CLR

REFOUT

V

OUT

AGND

NC

SOL-20

(R-20)

1

DAC-8562

TOP VIEW

(Not to Scale)

ORDERING GUIDE

INL Temperature Package

Model (LSB) Range Option

DAC8562EP ±1/2 –40°C to +85°C N-20

DAC8562FP ±1 –40°C to +85°C N-20

DAC8562FS ±1 –40°C to +85°C R-20

DAC8562GBC ±1 +25°C Dice

DICE CHARACTERISTICS

AGND

13

V

OUT

REFOUT

14

15

CLR

16

CE

17

DB0

18

DB1

19

DB2

SUBSTRATE IS COMMON WITH VDD.

TRANSISTOR COUNT: 524

DIE SIZE: 0.70 X 0.105 INCH; 7350 SQ MILS

12

DGND

20 1

V

DD

DB11

10

9

DB10

8

7

DB9

6

DB8

5

DB7

DB6

4

3

DB5

2

DB4DB3

Table II. Nominal Output Voltage vs. Input Code

Binary Hex Decimal Output (V)

0000 0000 0000 000 0 0.000 Zero Scale

0000 0000 0001 001 1 0.001

0000 0000 0010 002 2 0.002

0000 0000 1111 00F 15 0.015

0000 0001 0000 010 16 0.016

0000 1111 1111 0FF 255 0.255

0001 0000 0000 100 256 0.256

0001 1111 1111 1FF 511 0.511

0010 0000 0000 200 512 0.512

0011 1111 1111 3FF 1023 1.023

0100 0000 0000 400 1024 1.024

0111 1111 1111 7FF 2047 2.047

1000 0000 0000 800 2048 2.048 Half Scale

1100 0000 0000 C00 3072 3.072

1111 1111 1111 FFF 4095 4.095 Full Scale

PIN DESCRIPTIONS

Pin Name Description

20 V

DD

Positive supply. Nominal value

+5 volts, ±5%.

1-9 DB0-DB11 Twelve Binary Data Bit inputs. DB11

17-19 is the MSB and DB0 is the LSB.

16

15

CE Chip Enable. Active low input.

CLR Active low digital input that clears the

DAC register to zero, setting the DAC

to minimum scale.

8 DGND Digital ground for input logic.

12 AGND Analog Ground. Ground reference for

the internal bandgap reference voltage,

the DAC, and the output buffer.

13 V

OUT

Voltage output from the DAC. Fixed

output voltage range of 0 V to 4.095 V

with 1 mV/LSB. An internal tempera-

ture stabilized reference maintains a

fixed full-scale voltage independent of

time, temperature and power supply

variations.

14 REFOUT Nominal 2.5 V reference output volt-

age. This node must be buffered if re-

quired to drive external loads.

11 NC No Connection. Leave pin floating.

–4–

REV. A

DAC8562

V

DD

V

OUT

AGND

N-CH

P-CH

OPERATION

The DAC8562 is a complete ready to use 12-bit digital-toanalog converter. Only one +5 V power supply is necessary for

operation. It contains a voltage-switched, 12-bit, laser-trimmed

digital-to-analog converter, a curvature-corrected bandgap reference, a rail-to-rail output op amp, and a DAC register. The parallel data interface consists of 12 data bits, DB0–DB11, and a

active low

will set all DAC register bits to zero causing the V

CE strobe. In addition, an asynchronous CLR pin

to be-

OUT

come zero volts. This function is useful for power on reset or

system failure recovery to a known state.

D/A CONVERTER SECTION

The internal DAC is a 12-bit voltage-mode device with an output that swings from AGND potential to the 2.5 volt internal

bandgap voltage. It uses a laser trimmed R-2R ladder which is

switched by N channel MOSFETs. The output voltage of the

DAC has a constant resistance independent of digital input

code. The DAC output (not available to the user) is internally

connected to the rail-to-rail output op amp.

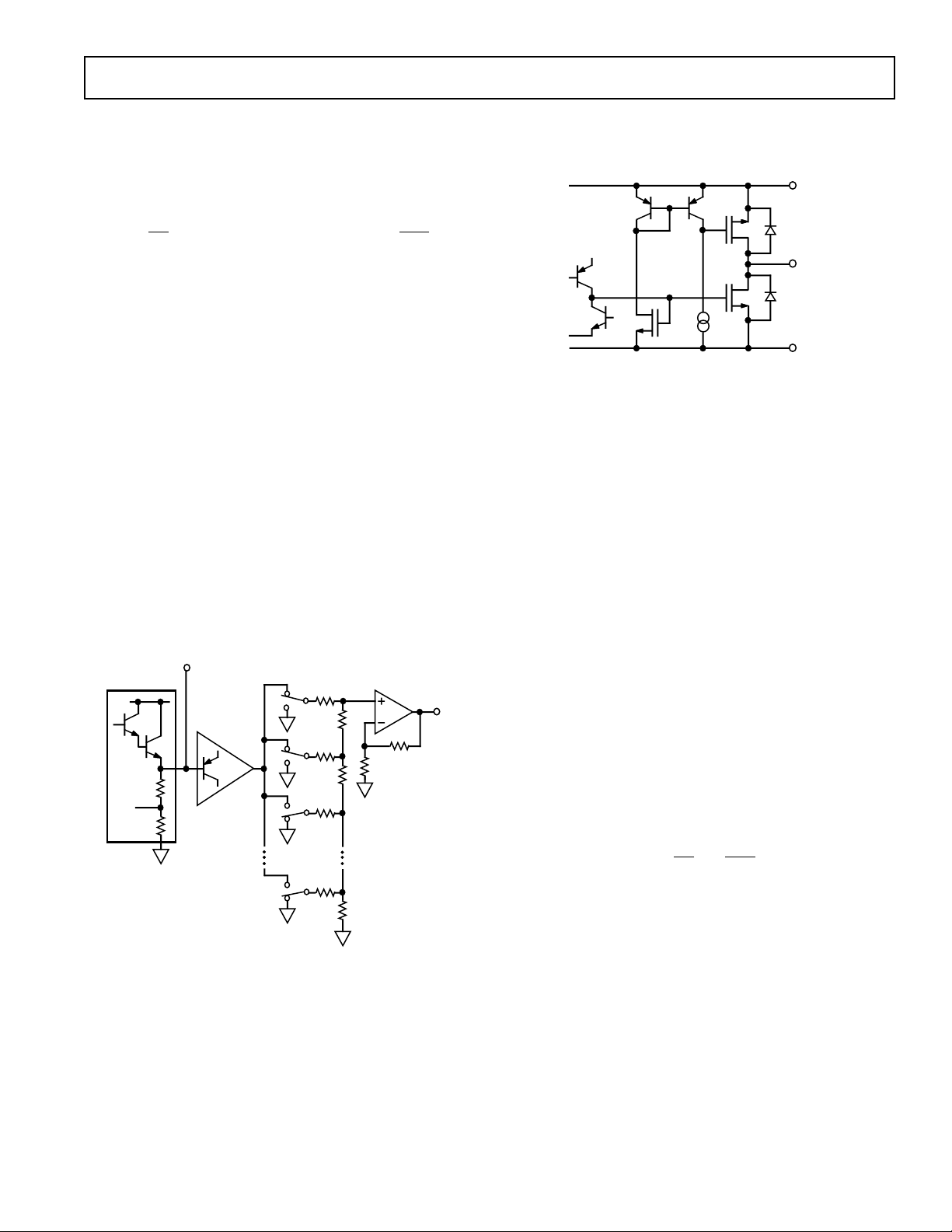

AMPLIFIER SECTION

The internal DAC’s output is buffered by a low power consumption precision amplifier. This low power amplifier contains

a differential PNP pair input stage which provides low offset

voltage and low noise, as well as the ability to amplify the zeroscale DAC output voltages. The rail-to-rail amplifier is configured in a gain of 1.6384 (= 4.095 V/2.5 V) in order to set the

4.095 volt full-scale output (1 mV/LSB). See Figure 3 for an

equivalent circuit schematic of the analog section.

REFOUT

BANDGAP

REFERENCE

2.5V

VOLTAGE SWITCHED 12-BIT

R-2R D/A CONVERTER

BUFFER

SPDT

N ch FET

SWITCHES

RAIL-TO-RAIL

OUTPUT

2R

R

2R

R

2R

2R

2R

AMPLIFIER

R2

R1

AV = 4.096/2.5

= 1.636V/V

V

OUT

Figure 3. Equivalent DAC8562 Schematic of

Analog Portion

The op amp has a 16 µs typical settling time to 0.01%. There

are slight differences in settling time for negative slewing signals

versus positive. See the oscilloscope photos in the Typical Performances section of this data sheet.

OUTPUT SECTION

The rail-to-rail output stage of this amplifier has been designed

to provide precision performance while operating near either

power supply. Figure 4 shows an equivalent output schematic of

the rail-to-rail amplifier with its N channel pull down FETs that

will pull an output load directly to GND. The output sourcing

current is provided by a P channel pull-up device that can supply GND terminated loads, especially important at the –5%

supply tolerance value of 4.75 volts.

Figure 4. Equivalent Analog Output Circuit

Figures 5 and 6 in the typical performance characteristics section provide information on output swing performance near

ground and full scale as a function of load. In addition to resistive load driving capability, the amplifier has also been carefully

designed and characterized for up to 500 pF capacitive load

driving capability.

REFERENCE SECTION

The internal 2.5 V curvature-corrected bandgap voltage reference is laser trimmed for both initial accuracy and low temperature coefficient. The voltage generated by the reference is

available at the REFOUT pin. Since REFOUT is not intended

to drive external loads, it must be buffered–refer to the applications section for more information. The equivalent emitter follower output circuit of the REFOUT pin is shown in Figure 3.

Bypassing the REFOUT pin is not required for proper operation. Figure 7 shows broadband noise performance.

POWER SUPPLY

The very low power consumption of the DAC8562 is a direct

result of a circuit design optimizing use of the CBCMOS process. By using the low power characteristics of the CMOS for

the logic, and the low noise, tight matching of the complementary bipolar transistors, good analog accuracy is achieved.

For power-consumption sensitive applications it is important to

note that the internal power consumption of the DAC8562 is

strongly dependent on the actual logic-input voltage-levels

present on the DB0–DB11,

CE and CLR pins. Since these inputs are standard CMOS logic structures, they contribute static

power dissipation dependent on the actual driving logic V

V

voltage levels. The graph in Figure 9 shows the effect on to-

OL

OH

and

tal DAC8562 supply current as a function of the actual value of

input logic voltage. Consequently for optimum dissipation use

of CMOS logic versus TTL provides minimal dissipation in the

static state. A V

= 0 V on the DB0–DB11 pins provides the

INL

lowest standby dissipation of 600 µA with a +5 V power supply.

REV. A

–5–

DAC8562

80

–100

–60

–80

1

–20

–40

0

20

40

60

32

OUTPUT VOLTAGE – Volts

OUTPUT CURRENT – mA

POS0

CURRENT0

LIMIT0

NEG

CURRENT

LIMIT

DATA = 800H

R

L

TIED TO +2V

As with any analog system, it is recommended that the

DAC8562 power supply be bypassed on the same PC card that

contains the chip. Figure 10 shows the power supply rejection

versus frequency performance. This should be taken into account when using higher frequency switched-mode power supplies with ripple frequencies of 100 kHz and higher.

One advantage of the rail-to-rail output amplifier used in the

DAC8562 is the wide range of usable supply voltage. The part is

fully specified and tested over temperature for operation from

+4.75 V to +5.25 V. If reduced linearity and source current capability near full scale can be tolerated, operation of the

DAC8562 is possible down to +4.3 volts. The minimum operating supply voltage versus load current plot, in Figure 11, provides information for operation below V

= +4.75 V.

DD

Typical Performance Characteristics

5

4

3

2

OUTPUT VOLTAGE – Volts

1

0

10

RL TIED TO +5V

DATA = 000H

100 100k10k1k

LOAD RESISTANCE – Ω

VDD = +5V

T

= +25°C

A

RL TIED TO AGND

RL TIED TO AGND

D = FFFH

DATA = FFFH

Figure 5. Output Swing vs. Load

100

VDD = +5V

DATA = 000H

10

TA = +85°C

1

0.1

OUTPUT PULLDOWN VOLTAGE – mV

0.01

1

10 1000100

OUTPUT SINK CURRENT – µA

Figure 6. Pull-Down Voltage vs.

Output Sink Current Capability

TIMING AND CONTROL

The DAC8562 has a 12-bit DAC register that simplifies interface to a 12-bit (or wider) data bus. The latch is controlled by

the Chip Enable (

a data bus, wiring

CE) input. If the application does not involve

CE low allows direct operation of the DAC.

The data latch is level triggered and acquires data from the data

bus during the time period when

high, the data is latched into the register and held until

CE is low. When CE goes

CE re-

turns low. The minimum time required for the data to be

present on the bus before

setup time (t

) as seen in Figure 2. The data hold time (tDH) is

DS

CE returns high is called the data

the amount of time that the data has to remain on the bus after

CE goes high. The high speed timing offered by the DAC8562

provides for direct interface with no wait states in all but the

fastest microprocessors.

TA = +25°C

TA = –40°C

Figure 7. I

OUT

vs. V

OUT

100

90

10

0%

OUTPUT NOISE VOLTAGE – 500µV/DIV

Figure 8. Broadband Noise

50mV

TIME = 1ms/DIV

1ms

TA = 25°C

NBW = 630kHz

5

4

3

2

SUPPLY CURRENT – mA

1

0

0

LOGIC VOLTAGE VALUE – Volts

VDD = +5V

= +25°C

T

A

3241

5

Figure 9. Supply Current vs. Logic

Input Voltage

–6–

100

VDD = +5V ±200mV AC

= +25°C

T

80

60

40

20

POWER SUPPLY REJECTION – dB

0

10

A

DATA = FFFH

100

FREQUENCY – Hz

100k10k1k

Figure 10. Power Supply Rejection

vs. Frequency

REV. A

5.0

0

5

VDD = +5V

T

A

= +25°C

OUTPUT VOLTAGE

1mV/DIV

DATA

TIME – 10µs/DIV

16µs

5

0

4

3

2

1

0

10

90

100

0%

TIME = 20µs/DIV

20µs

1V

INPUT

OUTPUT

5V

V

DD

= +5V

T

A

= +25°C

+25°C & +85°C

VDD = +5V

T

A

= –40°C, 25°C, +85°C

–40°C

2.0

1.5

1.0

0.5

0.0

–0.5

–1.0

–1.5

–2.0

0 1024 1536 2048 2560 3072 3584 4096512

DIGITAL INPUT CODE – Decimal

LINEARITY ERROR – LSB

3

–1

125

0

–25–50

1

2

1007550250

TEMPERATURE – °C

ZERO-SCALE – mV

DATA = 000H

NO LOAD

V

DD

= +5.0V

4.8

4.6

MIN – Volts

4.4

DD

V

4.2

∆VFS ≤ 1 LSB

DATA = FFFH

= +25°C

T

A

PROPER OPERATION

WHEN V

DD

VOLTAGE ABOVE

CURVE

SUPPLY

2.048

2.038

– Volts

2.028

OUT

V

2.018

CE

DAC8562

5

0

DATA = 204810 TO 2047

10

4.0

0.04

0.01 0.1 101.0

OUTPUT LOAD CURRENT – mA

0.4 4.0

Figure 11. Minimum Supply

Voltage vs. Load

5

DATA

0

16µs

VDD = +5V

T

= +25°C

1mV/DIV

OUTPUT VOLTAGE

A

TIME – 10µs/DIV

Figure 14. Output Voltage Rise

Time Detail

TIME – 200ns/DIV

Figure 12. Midscale Transition

Performance

Figure 15. Output Voltage Fall

Time Detail

Figure 13. Large Signal Settling

Time

Figure 16. Linearity Error vs.

Digital Code

REV. A

50

TUE = INL+ZS+FS

Σ

SS = 300 UNITS

T

= +25°C

40

A

30

20

NUMBER OF UNITS

10

0

–6–8

–2–4

2

TOTAL UNADJUSTED ERROR – LSB

Figure 17. Total Unadjusted

Error Histogram

4.125

4.115

VDD = +5V

NO LOAD

SS = 300 PCS

4.105

4.095

FULL-SCALE OUTPUT –Volts

4.085

1610 1268 1440

4.075

–50 –25 0 25 50 75 100 125

TEMPERATURE –

Figure 18. Full-Scale Voltage

vs. Temperature

AVG +1σ

AVG –1σ

°

C

AVG

Figure 19. Zero-Scale Voltage vs.

Temperature

–7–

DAC8562

10

8

6

4

2

0

–2

–4

–6

–8

–10

–50 –25 0 25 50 75 100 125

AVG +1σ

AVG –1σ

X

VDD = +5V

SAMPLE SIZE = 300

TEMPERATURE –

°C

V

REF OUT

ERROR –mV

DAC8562

–Typical Performance Characteristics

10

Hz

1

0.1

OUTPUT NOISE DENSITY – µV/

0.01

10

100

FREQUENCY – Hz

VDD = +5V

= 25°C

T

A

DATA = FFF

Figure 20. Output Voltage Noise

Density vs. Frequency

2V

100

90

V

DD

0V

V

REF

0V

10

0%

2V

TIME = 1µs/DIV

TA = +25°C

=

R

L

∞

1µs

5

4

H

100k10k1k

3

READINGS NORMALIZED

2

TO ZERO HOUR TIME POINT

1

0

–1

–2

–3

OUTPUT VOLTAGE CHANGE – mV

–4

135 UNITS TESTED

–5

200

0

HOURS OF OPERATION AT +125°C

AVG

VDD = +5V

DATA = FFF

RANGE

1000600 800400

H

1200

Figure 21. Long-Term Drift

Accelerated by Burn-In

DATA

OUT

V

1

0

A4 0.040 V DLY

100

90

5mV/DIV

10

0%

5mV

5V

CE = HIGH

B

Lw

TIME = 20µs/DIV

13.82

5µs

µs

8

7

6

5

4

3

2

SUPPLY CURRENT – mA

1

0

VDD = +5.0V

VDD = +4.75V

–25–50

TEMPERATURE – °C

VDATA = +2.4V

NO LOAD

VDD = +5.25V

Figure 22. Supply Current vs.

Temperature

125

1007550250

Figure 23. Reference Startup vs.

Time

0.005

0.004

0.003

0.002

0.001

REF LOAD REGULATION – %/mA

0.000

Figure 26. Reference Load

Regulation vs. Temperature

σ

AVG + 3

AVG

AVG – 3

VDD = +5V

IL = 5mA

∆

SAMPLE SIZE = 302 PCS

0

–25

–50

TEMPERATURE – °C

Figure 24. Digital Feedthrough vs.

Time

0.10

0.08

0.06

AVG + 3 σ

σ

REF LINE REGULATION – %/Volt

125

25

10050 75

0.04

0.02

0.00

–50

AVG

AVG – 3

–25

0

TEMPERATURE – °C

Figure 25. Reference Error vs.

Temperature

VDD = +4.75 TO +5.25V

SAMPLE SIZE = 302 PCS

σ

125

25

10050 75

Figure 27. Reference Line

Regulation vs. Temperature

–8–

REV. A

DAC8562

15

16

DGND

AGND

V

DD

DATA

13

DAC-8562

12

10µF

0.1µF

V

OUT

TO OTHER

ANALOG CIRCUITS

20

+5V

10

TO POWER GROUND

CE

CLR

APPLICATIONS SECTION

Power Supplies, Bypassing, and Grounding

All precision converter products require careful application of

good grounding practices to maintain full-rated performance.

Because the DAC8562 has been designed for +5 V applications,

it is ideal for those applications under microprocessor or microcomputer control. In these applications, digital noise is prevalent; therefore, special care must be taken to assure that its

inherent precision is maintained. This means that particularly

good engineering judgment should be exercised when addressing the power supply, grounding, and bypassing issues using the

DAC8562.

The power supply used for the DAC8562 should be well filtered

and regulated. The device has been completely characterized for

a +5 V supply with a tolerance of ± 5%. Since a +5 V logic supply is almost universally available, it is not recommended to

connect the DAC directly to an unfiltered logic supply without

careful filtering. Because it is convenient, a designer might be

inclined to tap a logic circuit s supply for the DAC’s supply.

Unfortunately, this is not wise because fast logic with nanosecond transition edges induces high current pulses. The high transient current pulses can generate glitches hundreds of millivolts

in amplitude due to wiring resistances and inductances. This

high frequency noise will corrupt the analog circuits internal to

the DAC and cause errors. Even though their spike noise is

lower in amplitude, directly tapping the output of a +5 V system

supplies can cause errors because these supplies are of the

switching regulator type that can and do generate a great deal of

high frequency noise. Therefore, the DAC and any associated

analog circuitry should be powered directly from the system

power supply outputs using appropriate filtering. Figure 28

illustrates how a clean, analog-grade supply can be generated

from a +5 V logic supply using a differential LC filter with separate power supply and return lines. With the values shown, this

filter can easily handle 100 mA of load current without saturating the ferrite cores. Higher current capacity can be achieved

with larger ferrite cores. For lowest noise, all electrolytic capacitors should be low ESR (Equivalent Series Resistance) type.

FERRITE BEADS:

TTL/CMOS

LOGIC

CIRCUITS

2 TURNS, FAIR-RITE

#2677006301

100µF

ELECT.

10-22µF

TANT.

0.1µF

CER.

+5V

The DAC8562 includes two ground connections in order to

minimize system accuracy degradation arising from grounding

errors. The two ground pins are designated DGND (Pin 10)

and AGND (Pin 12). The DGND pin is the return for the digital circuit sections of the DAC and serves as their input threshold reference point. Thus DGND should be connected to the

same ground as the circuitry that drives the digital inputs.

Pin 12, AGND, serves as the supply rail for the internal voltage

reference and the output amplifier. This pin should also serve as

the reference point for all analog circuitry associated with the

DAC8562. Therefore, to minimize any errors, it is recommended that the AGND connection of the DAC8562 be connected to a high quality analog ground. If the system contains

any analog signal path carrying a significant amount of current,

then that path should have its own return connection to Pin 12.

It is often advisable to maintain separate analog and digital

grounds throughout a complete system, tying them common to

one place only. If the common tie point is remote and an accidental disconnection of that one common tie point were to

occur due to card removal with power on, a large differential

voltage between the two commons could develop. To protect

devices that interface to both digital and analog parts of the system, such as the DAC8562, it is recommended that the common ground tie points be provided at each such device. If only

one system ground can be connected directly to the DAC8562,

it recommended that the analog common be used. If the

system’s AGND has suitably low impedance, then the digital

signal currents flowing in it should not seriously affect the

ground noise. The amount of digital noise introduced by connecting the two grounds together at the device will not adversely

affect system performance due to loss of digital noise immunity.

Generous bypassing of the DAC’s supply goes a long way in reducing supply line-induced errors. Local supply bypassing consisting of a 10 µF tantalum electrolytic in parallel with a 0.1 µF

ceramic is recommended. The decoupling capacitors should be

connected between the DAC’s supply pin (Pin 20) and the analog ground (Pin 12). Figure 29 shows how the DGND, AGND,

and bypass connections should be made to the DAC8562.

+5V

POWER SUPPLY

Figure 28. Properly Filtering a +5 V Logic Supply

Can Yield a High Quality Analog Supply

REV. A

+5V

RETURN

Figure 29. Recommended Grounding and Bypassing

Scheme for the DAC-8562

–9–

DAC8562

15

16

DGND

AGND

DATA

DAC-8562

13

V

OUT

+12V OR +15V

10

CE

CLR

1

12

0.1µF

4

REF-02

6

2

0.1µF

15

16

DGND

AGND

V

DD

DATA

DAC-8562

13

0.1µF

V

OUT

+5V

10

CE

CLR

20

12

200µA MAX

V–

Unipolar Output Operation

This is the basic mode of operation for the DAC8562. As shown

in Figure 30, the DAC8562 has been designed to drive loads as

low as 820 Ω in parallel with 500 pF. The code table for this operation is shown in Table III.

+5V

V

20

DD

AGND

12

10µF

0V ≤ V

≤ 4.095V

13

820

Ω

OUT

500pF

0.1µF

DATA

DAC-8562

CE

16

15

CLR

DGND

10

Figure 30. Unipolar Output Operation

Table III. Unipolar Code Table

Hexadecimal Number Decimal Number Analog Output

in DAC Register in DAC Register Voltage (V)

FFF 4095 +4.095

801 2049 +2.049

800 2048 +2.048

7FF 2047 +2.047

000 0 0

Operating the DAC8562 on +12 V or +15 V Supplies Only

Although the DAC8562 has been specified to operate on a

single, +5 V supply, a single +5 V supply may not be available in

many applications. Since the DAC8562 consumes no more than

6 mA, maximum, then an integrated voltage reference, such as

the REF02, can be used as the DAC8562 +5 V supply. The

configuration of the circuit is shown in Figure 31. Notice that

the reference’s output voltage requires no trimming because of

the REF02’s excellent load regulation and tight initial output

voltage tolerance. Although the maximum supply current of the

DAC8562 is 6 mA, local bypassing of the REF02’s output with

at least 0. 1 µF at the DAC’s voltage supply pin is recommended

to prevent the DAC’s internal digital circuits from affecting the

DAC’s internal voltage reference.

Figure 31. Operating the DAC8562 on +12 V or +15 V

Supplies Using a REF02 Voltage Reference

Measuring Offset Error

One of the most commonly specified endpoint errors associated

with real-world nonideal DACs is offset error.

In most DAC testing, the offset error is measured by applying

the zero-scale code and measuring the output deviation from

0 volt. There are some DACs where offset errors may be present

but not observable at the zero scale because of other circuit limitations (for example, zero coinciding with single supply ground).

In these DACs, nonzero output at zero code cannot be read as

the offset error. In the DAC8562, for example, the zero-scale error is specified to be +3 LSBs. Since zero scale coincides with

zero volt, it is not possible to measure negative offset error.

By adding a pull-down resistor from the output of the

DAC8562 to a negative supply as shown in Figure 32, offset errors can now be read at zero code. This configuration forces the

output P-channel MOSFET to source current to the negative

supply thereby allowing the designer to determine in which direction the offset error appears. The value of the resistor should

be such that, at zero code, current through the resistor is 200 µA

maximum.

Figure 32. Measuring Zero-Scale or Offset Error

–10–

REV. A

CE

CLR

DATA

10µF

16

15

+5V

20

V

DD

DAC-8562

REFOUT

AGND

DGND

10

V

12

0.1µF

OUT

DAC8562

8

4

FULL SCALE

ADJUST

P2

Ω

500

1

–5V ≤ VO ≤ +5V

R4

Ω

23.7k

R1

Ω

13

14

R5

10k

10k

R2

12.7k

–2.5V

R6

10k

Ω

Ω

6

5

A2

7

R3

247k

P1

Ω

10k

ZERO SCALE

ADJUST

Ω

A1, A2 = 1/2 OP-295

+5V

2

A1

3

–5V

Figure 33. Bipolar Output Operation

Bipolar Output Operation

Although the DAC8562 has been designed for single supply operation, bipolar operation is achievable using the circuit illustrated in Figure 33. The circuit uses a single supply, rail-to-rail

OP295 op amp and the DAC’s internal +2.5 V reference to generate the –2.5 V reference required to level-shift the DAC output voltage. The circuit has been configured to provide an

output voltage in the range –5 V ≤ V

≤ +5 V and is coded in

OUT

complementary offset binary. Although each DAC LSB corresponds to 1 mV, each output LSB has been scaled to 2.44 mV.

Table IV provides the relationship between the digital codes and

output voltage.

The transfer function of the circuit is given by:

V

=−1mV × Digital Code ×

O

R4

R1

+2.5 ×

R4

R2

and, for the circuit values shown, becomes:

VO= –2.44 mV × Digital Code + 5 V

Table IV. Bipolar Code Table

Hexadecimal Number Decimal Number Analog Output

in DAC Register in DAC Register Voltage (V)

FFF 4095 –4 9976

801 2049 –2.44E–3

800 2048 0

7FF 2047 +2.44E–3

000 0 +5

To maintain monotonicity and accuracy, R1, R2, R4, R5, and

R6 should be selected to match within 0.01% and must all be of

the same (preferably metal foil) type to assure temperature coefficient matching. Mismatching between R1 and R2 causes offset

and gain errors while an R4 to R1 and R2 mismatch yields gain

errors.

For applications that do not require high accuracy, the circuit illustrated in Figure 34 can also be used to generate a bipolar

output voltage. In this circuit, only one op amp is used and no

potentiometers are used for offset and gain trim The output

voltage is coded in offset binary and is given by:

VO=1 mV × Digital Code ×

–REFOUT ×

R4

R3 + R4

R2

R1

× 1 +

R2

R1

For the ±2 5 V output range and the circuit values shown in the

table, the transfer equation becomes:

VO=1. 2 2 mV × Digital Code –2.5V

Similarly, for the ±5 V output range, the transfer equation becomes:

VO= 2. 44 mV × Digital Code –5V

Note that, for ±5 V output voltage operation, R5 is required as a

pull-down for REFOUT. Or, REFOUT can be buffered by an

op amp configured as a follower that can source and sink current.

+5V

0.1µF

R2

2

A1

3

R4

A1 = 1/2 OP-295

R3

R2

10k

10k

10k

20k

+5V

8

4

–5V

1

R4

15.4k + 274

43.2k + 499

V

O

CE

CLR

DATA

16

15

20

V

DD

REFOUT

DAC-8562

AGND

DGND

10

OUT

R5

4.99k

R1

10k

10k

R1

Ω

R3

14

V

13

OUT

12

V

RANGE

±2.5V

±5V

Figure 34. Bipolar Output Operation Without

Trim Version 1

REV. A

–11–

DAC8562

15

16

DGND

AGND

DATA

DAC-8562

13

+15V

10

CE

CLR

20

12

0.1µF

4

REF-02

6

2

0.1µF

18k

10pF

470k

P1

100kΩ

10M

OFFSET

TRIM

47pF

SYMMETRY

TRIM

P2

500kΩ

V

OUT

+15V

–15V

30k

+15V

–15V

0.1µF

0.1µF

+15V

18k

V

IN

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

SSM-2018

+5V

C

CON

1µF

R6

825

R7

1kΩ

*

0V ≤ VC ≤ +2.24V

* – PRECISION RESISTOR PT146

1kΩ COMPENSATOR

Ω

Ω

Ω

Ω

Ω

Ω

Alternatively, the output voltage can be coded in complementary

offset binary using the circuit in Figure 35. This configuration

eliminates the need for a pull-down resistor or an op amp for

REFOUT The transfer equation of the circuit is given by:

VO= –1 mV × Digital Code ×

×

R4

R3 + R4

× 1 +

R2

R1

R2

R1

+ REFOUT

and, for the values shown, becomes:

VO=−2.44 mV × Digital Code + 5 V

R2

R1

V

O

R3

R1 = R3 = 10k

R4

O

R2

23.7k + 715

R4

13.7k + 169

Ω

Ω

DAC-8562

REFOUT

V

OUT

V

RANGE

±5V

Figure 35 Bipolar Output Operation Without

Trim Version 2

Generating a Negative Supply Voltage

Some applications may require bipolar output configuration, but

only have a single power supply rail available. This is very common in data acquisition systems using microprocessor-based systems. In these systems, only +12 V, +15 V, and/or +5 V are

available. Shown in Figure 36 is a method of generating a negative supply voltage using one CD4049, a CMOS hex inverter,

operating on +12 V or +15 V. The circuit is essentially a charge

pump where two of the six are used as an oscillator. For the values shown, the frequency of oscillation is approximately 3.5 kHz

and is fairly insensitive to supply voltage because R1 > 2 3 R2.

The remaining four inverters are wired in parallel for higher output current. The square-wave output is level translated by C2 to

a negative-going signal, rectified using a pair of 1N4001s, and

then filtered by C3. With the values shown, the charge pump

will provide an output voltage of –5 V for current loading in the

range 0.5 mA ≤ I

0.5 mA ≤ I

INVERTERS = CD4049

3254

R1

510k

Audio Volume Control

The DAC8562 is well suited to control digitally the gain or

attenuation of a voltage controlled amplifiers. In professional

≤ 7 mA with a +12 V supply.

OUT

R2

5.1k

Ω

0.02µF

≤ 10 mA with a +15 V supply and

OUT

Ω

C1

6

7

910

11 12

14 15

C2

47µF

D2

1N4001

D1

1N4001

R3

470

C3

47µF

Ω

Figure 36. Generating a –5 V Supply When

Only +12 V or +15 V Are Available

1N5231

5.1V

ZENER

–5V

audio mixing consoles, music synthesizers, and other audio processors, VCAs, such as the SSM2018, adjust audio channel gain and

attenuation from front panel potentiometers. The VCA provides a

clean gain transition control of the audio level when the slew rate of

the analog input control voltage, V

, is properly chosen. The cir-

C

cuit in Figure 37 illustrates a volume control application using the

DAC8562 to control the attenuation of the SSM2018.

Figure 37. Audio Volume Control

Since the supply voltage available in these systems is typically

±15 V or ±18 V, a REF02 is used to supply the +5 V required

to power the DAC. No trimming of the reference is required because of the reference’s tight initial tolerance and low supply

current consumption of the DAC8562. The SSM2018 is configured as a unity-gain buffer when its control voltage equals

0 volt. This corresponds to a 000

code from the DAC8562.

H

Since the SSM2018 exhibits a gain constant of –28 mV/dB

(typical), the DAC’s full-scale output voltage has to be scaled

down by R6 and R7 to provide 80 dB of attenuation when the

digital code equals FFF

. Therefore, every DAC LSB corre-

H

sponds to 0.02 dB of attenuation. Table V illustrates the attenuation versus digital code of the volume control circuit.

Table V. SSM2018 VCA Attenuation vs.

DAC8562 Input Code

Hexadecimal Number Control Voltage VCA Attenuation

in DAC Register (V) (dB)

000 0 0

400 +0.56 20

800 +1.12 40

C00 +1.68 60

FFF +2.24 80

–12–

REV. A

DAC8562

To compensate for the SSM2018’s gain constant temperature

coefficient of –3300 ppm/°C, a 1 kΩ, temperature-sensitive

resistor (R7) manufactured by the Precision Resistor Company with a temperature coefficient of +3500 ppm/°C is used.

A C

of 1 µF provides a control transition time of 1 ms which

CON

yields a click-free change in the audio channel attenuation. Symmetry and offset trimming details of the VCA can be found in

the SSM2018 data sheet.

Information regarding the PT146 1 kΩ “Compensator” can be

obtained by contacting:

Precision Resistor Company, Incorporated

10601 75th Street North

Largo, FL 34647

(813) 541-5771

A High-Compliance, Digitally Controlled Precision Current Source

The circuit in Figure 38 shows the DAC8562 controlling a

high-compliance, precision current source using an AMP05 instrumentation amplifier. The AMP05’s reference pin becomes

the input, and the “old” inputs now monitor the voltage across a

precision current sense resistor, R

. Voltage gain is set to unity,

CS

so the transfer function is given by the following equation:

V

I

OUT

If R

equals 100 Ω, the output current is limited to +10 mA

CS

IN

=

R

CS

with a 1 V input. Therefore, each DAC LSB corresponds to

2.4 µA. If a bipolar output current is required, then the circuit

in Figure 33 can be modified to drive the AMP05’s reference

pin with a ±1 V input signal.

Potentiometer P1 trims the output current to zero with the input at 0 V. Fine gain adjustment can be accomplished by adjusting R1 or R2.

A Digitally Programmable Window Detector

A digitally programmable, upper/lower limit detector using two

DAC8562s is shown in Figure 39. The required upper and

lower limits for the test are loaded into each DAC individually

by controlling HDAC/

LDAC. If a signal at the test input is not

within the programmed limits, the output will indicate a logic

zero which will turn the red LED on.

100k

R1

17

18

+15V

2

REF-02

4

R2

5kΩ

7

AMP-05

1

4

6

CLR

100kΩ

CE

DATA

5

P1

16

15

2

0.1µF

6

9

11

0.1µF

–15V

DAC-8562

DGND

10

+15V

12

20

0.1µF

8

AGND

12

0.1µF

R

CS

100Ω

10

0mA ≤ I

2.4µA/ LSB

R3

3k

13

R4

1k

OUT

≤ 10mA

Figure 38. A High-Compliance, Digitally Controlled

Precision Current Source

REV. A

74HC05

HDAC/LDAC

CLR

1/6

V

IN

+5V

0.1µF

13

3

5

C1

4

7

C2

6

12

13

C1, C2 = 1/4 CMP-404

2

1

+5V

+5V

0.1µF

1k

Ω

DATA

16

DAC-8562

15

DGND AGND

16

DAC-8562

15

DGND AGND

20

12

10

+5V

0.1µF

20

10

12

Figure 39. A Digitally Programmable Window Detector

–13–

+5V

R1

604Ω

RED LED

2

1

PASS/FAIL

3

T1

1/6

74HC05

4

+5V

R2

604Ω

GREEN LED

T1

DAC8562

Decoding Multiple DAC8562s

The CE function of the DAC8562 can be used in applications

to decode a number of DACs. In this application, all DACs receive the same input data; however, only one of the DACs’

CE

input is asserted to transfer its parallel input register contents

into the DAC. In this circuit, shown in Figure 40, the

CE timing is generated by a 74HC139 decoder and should follow the

DAC8562’s standard timing requirements. To prevent timing

errors, the 74HC139 should not be activated by its

ENABLE

input while the coded address inputs are changing. A simple

timing circuit, R1 and C1, connected to the DACs’

CLR pins

resets all DAC outputs to zero during power-up.

MICROPROCESSOR INTERFACING

DAC-8562–MC68HC11 INTERFACE

The circuit illustrated in Figure 41 shows a parallel interface between the DAC8562 and a popular 8-bit microcontroller, the

M68HC11, which is configured in a single-chip operating

mode. The interface circuit consists of a pair of 74ACT11373

transparent latches and an inverter. The data is loaded into the

latches in two 8-bit bytes; the first byte contains the four most

significant bits, and the lower 8 bits are in the second byte. Data

is taken from the microcontroller’s port B output lines, and

three interface control lines,

CLR, CE, and MSB/LSB, are controlled by the M68HC11's PC2, PC1, and PC0 output lines, respectively. To transfer data into the DAC, PC0 is set, enabling

U1’s outputs. The first data byte is loaded into U1 where the

four least significant bits of the byte are connected to

MSB–DB8. PC0 is then cleared; this latches U1’s inputs and

enables U2’s outputs. U2s outputs now become DB7–DB0.

The DAC output is updated with the contents of U1 and U2

when PC1 is cleared. The DAC’s

CLR input, controlled by the

M68HC11’s PC2 output line, provides an asynchronous clear

function that sets the DAC’s output to zero. Included in this section is the source code for operating the DAC-8562–M68HC11

interface.

+5V

R1

ENABLE

CODED

ADDRESS

+5V

0.1µF

1k

DATA

+5V

Ω

16

15

14

13

1

2

3

8

74HC139

V

CC

1G

1A

1B

2G

2A

2B

GND

1Y0

1Y1

1Y2

1Y3

2Y0

2Y1

2Y2

2Y3

C1

0.1µF

4

5

6

7

12

NC

11

NC

10

NC

9

NC

Ω

1k

15

16

DAC-8562

15

16

DAC-8562

15

16

DAC-8562

15

16

DAC-8562

#2

#1

#3

V

OUT1

13

V

OUT2

13

V

OUT3

13

V

OUT4

13

#4

Figure 40. Decoding Multiple DAC8562s Using the CE Pin

*M6BHC11

PC2

PC1

PC0

PB7

PB6

PB5

PB4

PB3

PB2

PB1

PB0

74ACT11373

13

CLR

CE

MSB/ LSB

74HC04

1

C

23

1D

22

2D

21

2

3D

20

4D

1

5D

16

6D

15

7D

14

8D

24

OC

U1

1Q

2Q

3Q

4Q

5Q

6Q

7Q

8Q

1

NC

2

NC

3

NC

4

NC

9

10

11

12

PC2

PC1

74ACT11373

13

C

23

1D

22

2D

21

3D

20

4D

1

5D

16

6D

15

7D

14

8D

24

OC

U2

1Q

2Q

3Q

4Q

5Q

6Q

7Q

8Q

1

2

3

4

9

10

11

12

*ADDITIONAL PINS OMITTED FOR CLARITY

Figure 41. DAC8562 to MC68HC11 Interface

*DAC-8562

15

CLR

16

CE

9

MSB

8

DB10

7

DB9

6

DB8

5

DB7

4

DB6

3

DB5

2

DB4

1

DB3

19

DB2

18

DB1

17

LSB

U3

13

V

OUT

–14–

REV. A

DAC8562

DAC8562 – M68HC11 Interface Program Source Code

*

* DAC8562 to M68HC11 Interface Assembly Program

* Adolfo A. Garcia

* September 14, 1992

*

* M68HC11 Register definitions

*

PORTB EQU $1004

PORTC EQU $1003 Port C control register

* “0,0,0,0;0,CLR/,CE/,MSB-LSB/”

DDRC EQU $1007 Port C data direction

*

* RAM variables: MSBS are encoded from 0 (Hex) to F (Hex)

* LSBS are encoded from 00 (Hex) to F (Hex)

* DAC requires two 8-bit loads

*

MSBS EQU $00 Hi-byte: “0,0,0,0;MSB,DB10,DB9,DB8”

LSBS EQU $01 Lo-byte: “DB7,DB6,DB5,DB4;DB3,DB2,

DB1,DB0”

*

* Main Program

*

ORG $C000 Start of user’s RAM in EVB

INIT LDS #$CFFF Top of C page RAM

*

* Initialize Port C Outputs

*

LDAA #$07 0,0,0,0;0,1,1,1

STAA DDRC CLR/,CE/, and MSB-LSB/ are now enabled

as outputs

LDAA #$06 0,0.0,0;0,1,1,0

* CLR/-Hi, CE/-Hi, MSB-LSB/-Lo

STAA PORTC Initialize Port C Outputs

*

* Call update subroutine

*

BSR UPDATE Xfer 2 8-bit words to DAC8562

JMP $E000 Restart BUFFALO

*

* Subroutine UPDATE

*

UPDATE PSHX Save registers X, Y, and A

PSHY

PSHA

*

* Enter contents of the Hi-byte input register

*

LDAA #$0A 0,0,0,0;1,0,1,0

STAA MSBS MSBS are set to 0A (Hex)

*

* Enter Contents of’ Lo-byte input register

*

LDAA #$AA 1,0,1,0;1,0,1,0

STAA LSBS LSBS are set to AA (Hex)

*

LDX #MSBS Stack pointer at 1st byte to send via Port B

LDY #$1000 Stack pointer at on-chip registers

*

* Clear DAC output to zero

*

BCLR PORTC,Y $04 Assert CLR/

BSET PORTC,Y $04 De-assert CLR/

*

* Loading input buffer latches

*

BSET PORTC,Y $01 Set hi-byte register load

TFRLP LDAA 0,X Get a byte to transfer via Port B

STAA PORTB Write data to input register

INX Increment counter to next byte for transfer

CPX #LSBS+1 Are we done yet ?

BEQ DUMP If yes, update DAC output

BCLR PORTC,Y $01 Latch hi-byte register and set lo-byte register

load

BRA TFRLP

*

DAC8562–M68HC11 Interface Program Source Code (Continued)

* Update DAC output with contents of input registers

*

DUMP BCLR PORTC,Y $02 Assert CE/

BSET PORTC,Y $02 Latch DAC register

*

PULA When done, restore registers X, Y & A

PULY

PULX

RTS ** Return to Main Program **

REV. A

–15–

DAC8562

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).

0.145

(3.683)

MIN

0.125

(3.175)

MIN

20-Pin Plastic DIP (P-Suffix)

20

PIN 1

1

1.07 (27.18) MAX

0.021 (0.533)

0.015 (0.381)

0.11 (2.79)

0.09 (2.28)

LEAD NO. 1 IDENTIFIED BY DOT OR NOTCH

LEADS ARE SOLDER OR TIN-PLATED KOVAR OR ALLOY 42.

0.065 (1.66)

0.045 (1.15)

11

0.255 (6.477)

0.245 (6.223)

10

0.135 (3.429)

0.125 (3.17)

SEATING

PLANE

PIN 1

0.011 (0.275)

0.005 (0.125)

20-Pin Cerdip (R-Suffix)

0.32 (8.128)

0.30 (7.62)

15

°

0

0.011 (0.28)

0.009 (0.23)

PIN 1

0.20 (5.0)

0.14 (3.56)

0.15 (3.8)

0.125 (3.18)

20

1

0.97 (24.64)

0.935 (23.75)

0.02 (0.5)

0.016 (0.14)

0.11 (2.79)

0.09 (2.28)

LEAD NO. 1 IDENTIFIED BY DOT OR NOTCH

LEADS ARE SOLDER OR TIN-PLATED KOVAR OR ALLOY 42.

0.07 (1.78)

0.05 (1.27)

11

10

0.28 (7.11)

0.24 (6.1)

0.18 (4.57)

0.125 (3.18)

SEATING

PLANE

0.32 (8.128)

0.29 (7.366)

0.011 (0.28)

0.009 (0.23)

15

°

0

°

C1713–24–10/92

20-Lead SOIC (S-Suffix)

20

1

0.512 (13.00)

0.496 (12.60)

0.050 (1.27)

BSC

11

10

0.022 (0.56)

0.014 (0.36)

0.299 (7.60)

0.291 (7.40)

0.419 (10.65)

0.404 (10.00)

0.107 (2.72)

0.089 (2.26)

0.015 (0.38)

0.007 (0.18)

0.034 (0.86)

0.018 (0.46)

–16–

PRINTED IN U.S.A.

REV. A

Loading...

Loading...