+5 V, Serial Input

7

8

1

2

3

4

5

6

REF 12-BIT DAC

DAC REGISTER

V

DD

V

OUT

GND

SERIAL REGISTER

12

12

CLR

LD

CS

CLK

SDI

a

FEATURES

Space Saving SO-8 or Mini-DIP Packages

Complete, Voltage Output with Internal Reference

1 mV/Bit with 4.095 V Full Scale

Single +5 Volt Operation

No External Components

3-Wire Serial Data Interface, 20 MHz Data Loading Rate

Low Power: 2.5 mW

APPLICATIONS

Portable Instrumentation

Digitally Controlled Calibration

Servo Controls

Process Control Equipment

PC Peripherals

GENERAL DESCRIPTION

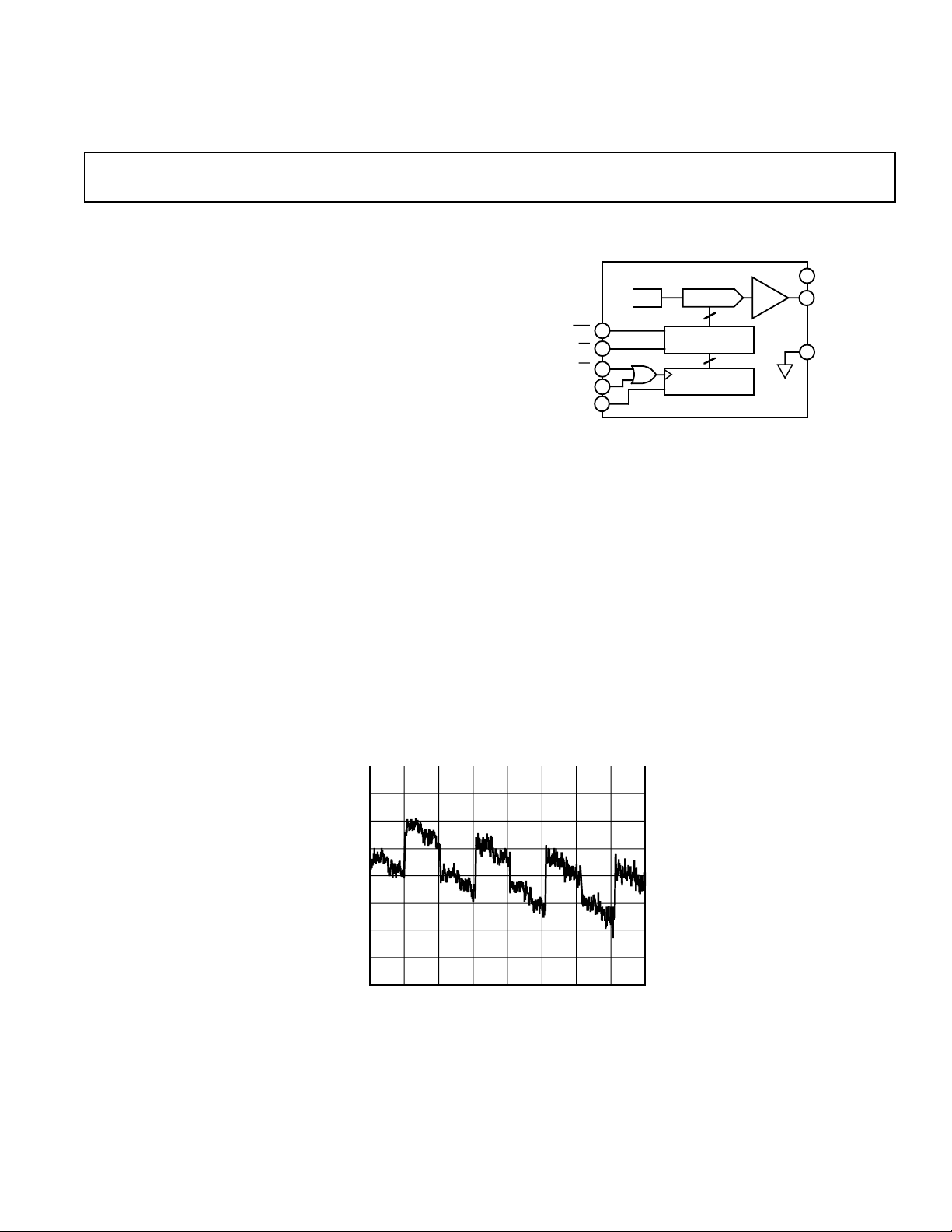

The DAC8512 is a complete serial input, 12-bit, voltage output

digital-to-analog converter designed to operate from a single

+5 V supply. It contains the DAC, input shift register and

latches, reference and a rail-to-rail output amplifier. Built using

a CBCMOS process, these monolithic DACs offer the user low

cost, and ease of use in +5 V only systems.

Coding for the DAC8512 is natural binary with the MSB loaded

first. The output op amp can swing to either rail and is set to a

range of 0 V to +4.095 V—for a one-millivolt-per-bit resolution.

It is capable of sinking and sourcing 5 mA. An on-chip reference

is laser trimmed to provide an accurate full-scale output voltage

of 4.095 V.

Complete 12-Bit DAC

DAC8512

FUNCTIONAL BLOCK DIAGRAM

Serial interface is high speed, three-wire, DSP compatible with

data in (SDI), clock (CLK) and load strobe (LD). There is also

a chip-select pin for connecting multiple DACs.

A CLR input sets the output to zero scale at power on or upon

user demand.

The DAC8512 is specified over the extended industrial (–40°C

to +85°C) temperature range. DAC8512s are available in plastic DIPs and SO-8 surface mount packages.

1.0

0.75

0.5

0.25

0

–0.25

LINEARITY ERROR – LSB

–0.5

–0.75

–1.0

0

DIGITAL INPUT CODE – Decimal

307220481024

4096

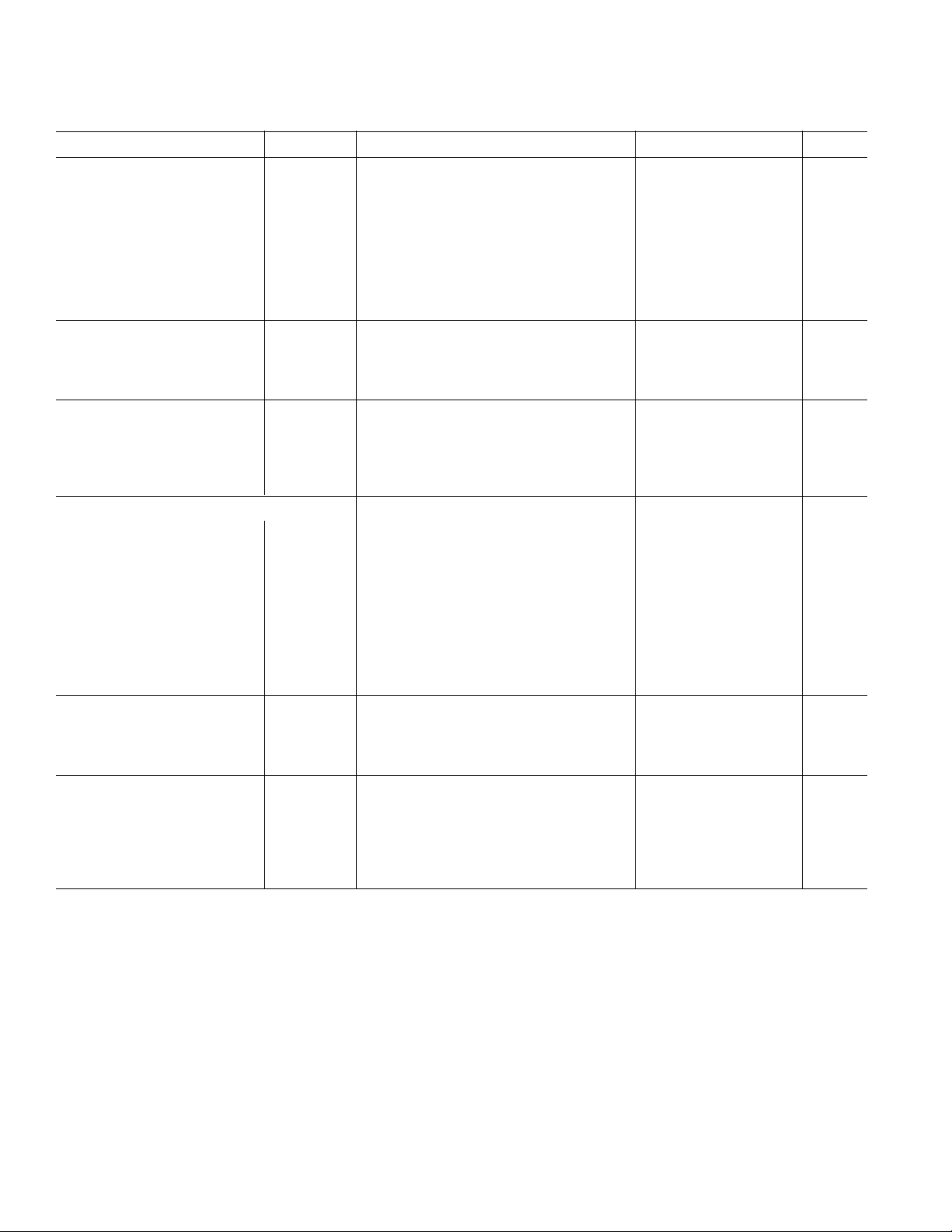

Linearity Error vs. Digital Input Code

REV. A

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 617/329-4700 World Wide Web Site: http://www.analog.com

Fax: 617/326-8703 © Analog Devices, Inc., 1996

DAC8512–SPECIFICATIONS

(@ V

ELECTRICAL CHARACTERISTICS

Parameter Symbol Condition Min Typ Max Units

STATIC PERFORMANCE

Resolution N Note 2 12 Bits

Relative Accuracy INL E Grade –1 ±1/4 +1 LSB

Differential Nonlinearity DNL No Missing Codes –1 ±3/4 +1 LSB

Zero-Scale Error V

Full-Scale Voltage V

Full-Scale Tempco TCV

ANALOG OUTPUT

Output Current I

Load Regulation at Full Scale L

Capacitive Load C

LOGIC INPUTS

Logic Input Low Voltage V

Logic Input High Voltage V

Input Leakage Current I

Input Capacitance C

INTERFACE TIMING SPECIFICATIONS

Clock Width High t

Clock Width Low t

Load Pulse Width t

Data Setup t

Data Hold t

Clear Pulse Width t

Load Setup t

Load Hold t

Select t

Deselect t

AC CHARACTERISTICS

4

Voltage Output Settling Time t

DAC Glitch 15 nV s

Digital Feedthrough 15 nV s

ZSE

FS

FS

OUT

REG

L

IL

IH

IL

IL

1, 4

CH

CL

LDW

DS

DH

CLRW

LD1

LD2

CSS

CSH

S

= +5.0 V 6 5%, –408C ≤ TA ≤ +858C, unless otherwise noted)

DD

F Grade –2 ±3/4 +2 LSB

Data = 000

Data = FFF

H

3

H

E Grade 4.087 4.095 4.103 V

+1/2 +3 LSB

F Grade 4.079 4.095 4.111 V

Notes 3, 4 16 ppm/°C

Data = 800

R

= 402 Ω to ∞, Data = 800

L

No Oscillation

H

4

H

±5 ±7mA

1 3 LSB

500 pF

0.8 V

2.4 V

10 µA

10 pF

30 10 ns

30 10 ns

20 ns

15 10 ns

15 5 ns

30 20 ns

15 ns

10 ns

30 ns

20 ns

To ±1 LSB of Final Value

5

16 µs

SUPPLY CHARACTERISTICS

Positive Supply Current I

Power Dissipation P

DD

DISS

VIH = 2.4 V, VIL = 0.8 V, No Load 1.5 2.5 mA

V

= 5 V, VIL = 0 V, No Load 0.5 1 mA

DD

VIH = 2.4 V, VIL = 0.8 V, No Load 7.5 12.5 mW

V

= 5 V, VIL = 0 V, No Load 2.5 5 mW

DD

Power Supply Sensitivity PSS ∆VDD = ±5% 0.002 0.004 %/%

NOTES

1

All input control signals are specified with tr = tf = 5 ns (10% to 90% of +5 V) and timed from a voltage level of 1.6 V.

2

1 LSB = 1 mV for 0 V to +4.095 V output range.

3

Includes internal voltage reference error.

4

These parameters are guaranteed by design and not subject to production testing.

5

The settling time specification does not apply for negative going transitions within the last 6 LSBs of ground. Some devices exhibit double the typical settling time in

this 6 LSB region.

Specifications subject to change without notice.

–2–

REV. A

DAC8512

WAFER TEST LIMITS

(@ VDD = +5.0 V 6 5%, TA = +258C, applies to part number DAC8512GBC only, unless otherwise noted)

Parameter Symbol Condition Min Typ Max Units

STATIC PERFORMANCE

Relative Accuracy INL –2 ± 3/4 +2 LSB

Differential Nonlinearity DNL No Missing Codes –1 ±0.7 +1 LSB

Zero-Scale Error V

Full-Scale Voltage V

ZSE

FS

Data = 000

Data = FFF

H

H

4.085 4.095 4.105 V

+1/2 +3 LSB

LOGIC INPUTS

Logic Input Low Voltage V

Logic Input High Voltage V

Input Leakage Current I

IL

IH

IL

2.4 V

0.8 V

10 µA

SUPPLY CHARACTERISTICS

Positive Supply Current I

Power Dissipation P

DD

DISS

VIH = 2.4 V, VIL= 0.8 V, No Load 1.5 2.5 mA

V

= 5 V, VIL = 0 V, No Load 0.5 1 mA

DD

VIH = 2.4 V, VIL = 0.8 V, No Load 7.5 12.5 mW

V

= 5 V, VIL = 0 V, No Load 2.5 5 mW

DD

Power Supply Sensitivity PSS ∆VDD = ±5% 0.002 0.004 %/%

NOTE

Electrical tests are performed at wafer probe to the limits shown. Due to variations in assembly methods and normal yield loss, yield after packaging is not guaranteed

for standard product dice. Consult factory to negotiate specifications based on dice lot qualifications through sample lot assembly and testing.

ABSOLUTE MAXIMUM RATINGS*

VDD to GND . . . . . . . . . . . . . . . . . . . . . . . . . . . –0.3 V, +10 V

Logic Inputs to GND . . . . . . . . . . . . . . . –0.3 V, V

V

to GND . . . . . . . . . . . . . . . . . . . . . –0.3 V, VDD + 0.3 V

OUT

I

Short Circuit to GND . . . . . . . . . . . . . . . . . . . . . . 50 mA

OUT

Package Power Dissipation . . . . . . . . . . . . . .(T

Thermal Resistance θ

JA

+ 0.3 V

DD

max – T

J

)/θ

A

8-Pin Plastic DIP Package (P) . . . . . . . . . . . . . . . . 103°C/W

8-Lead SOIC Package (S) . . . . . . . . . . . . . . . . . . . 158°C/W

Maximum Junction Temperature (T

max) . . . . . . . . . +150°C

J

Operating Temperature Range . . . . . . . . . . . . .–40°C to +85°C

Storage Temperature Range . . . . . . . . . . . . .–65°C to +150°C

Lead Temperature (Soldering, 10 secs) . . . . . . . . . . . . +300°C

*Stresses above those listed under “Absolute Maximum Ratings” may cause

permanent damage to the device. This is a stress rating only and functional

JA

operation of the device at these or any other conditions above those indicated in the

operational sections of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect device reliability .

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection.

Although the DAC8512 features proprietary ESD protection circuitry, permanent damage may

occur on devices subjected to high energy electrostatic discharges. Therefore, proper ESD

precautions are recommended to avoid performance degradation or loss of functionality.

ORDERING GUIDE

INL Temperature Package Package

Model (LSB) Range Description Option

DAC8512EP ±1 –40°C to +85°C 8-Pin P-DIP N-8

DAC8512FP ±2 –40°C to +85°C 8-Pin P-DIP N-8

DAC8512FS ±2 –40°C to +85° C 8-Lead SOIC SO-8

DAC8512GBC ±2 +25°C Dice

WARNING!

ESD SENSITIVE DEVICE

REV. A

–3–

DAC8512

SDI

CLK

CS

LD

SDI

CLK

LD

CLR

FS

V

OUT

ZS

D11 D10 D9 D8 D7 D6 D5 D3D4 D1D2 D0

t

css

t

ld1

t

t

ds

t

cl

dh

t

ch

t

ldw

t

s

±1 LSB

ERROR BAND

t

csh

t

ld2

t

clrw

t

S

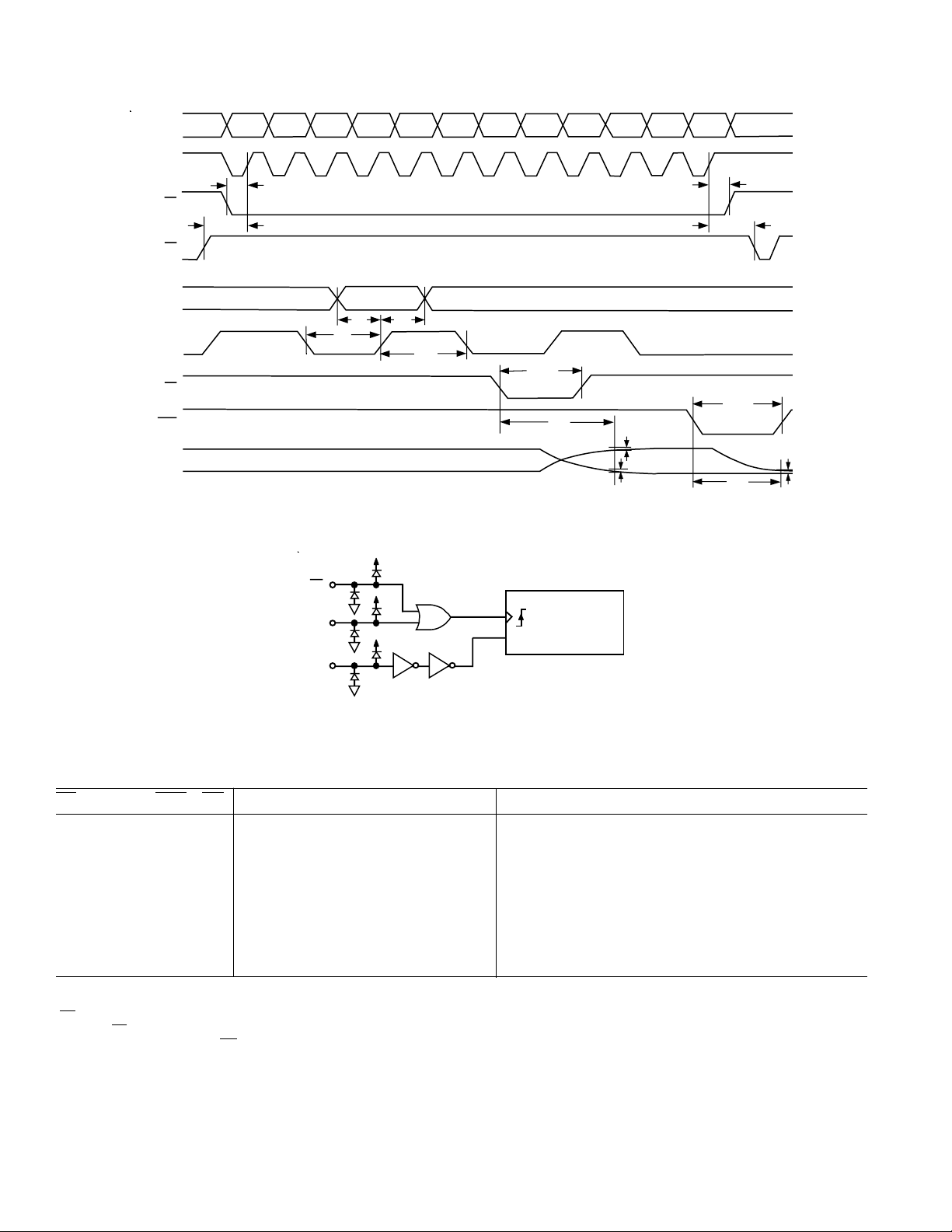

Figure 1. Timing Diagram

CS

ESD PROTECTION DIODES TO VDD AND GND

CLK

DATA

SDI

SHIFT

REGISTER

Figure 2. Equivalent Clock Input Logic

Table I. Control-Logic Truth Table

CS2CLK2CLR LD Serial Shift Register Function DAC Register Function

H X H H No Effect Latched

L L H H No Effect Latched

L H H H No Effect Latched

L ↑+ H H Shift-Register-Data Advanced One Bit Latched

↑+ L H H Shift-Register-Data Advanced One Bit Latched

HX H↓– No Effect Updated with Current Shift Register Contents

H X H L No Effect Transparent

H X L X No Effect Loaded with All Zeros

HX ↑+ H No Effect Latched All Zeros

NOTES

l

↑+ positive logic transition; ↓– negative logic transition; X = Don’t Care.

2

CS and CLK are interchangeable.

3

Returning CS HIGH avoids an additional “false clock” of serial data input.

4

Do not clock in serial data while LD is LOW.

–4–

REV. A

DAC8512

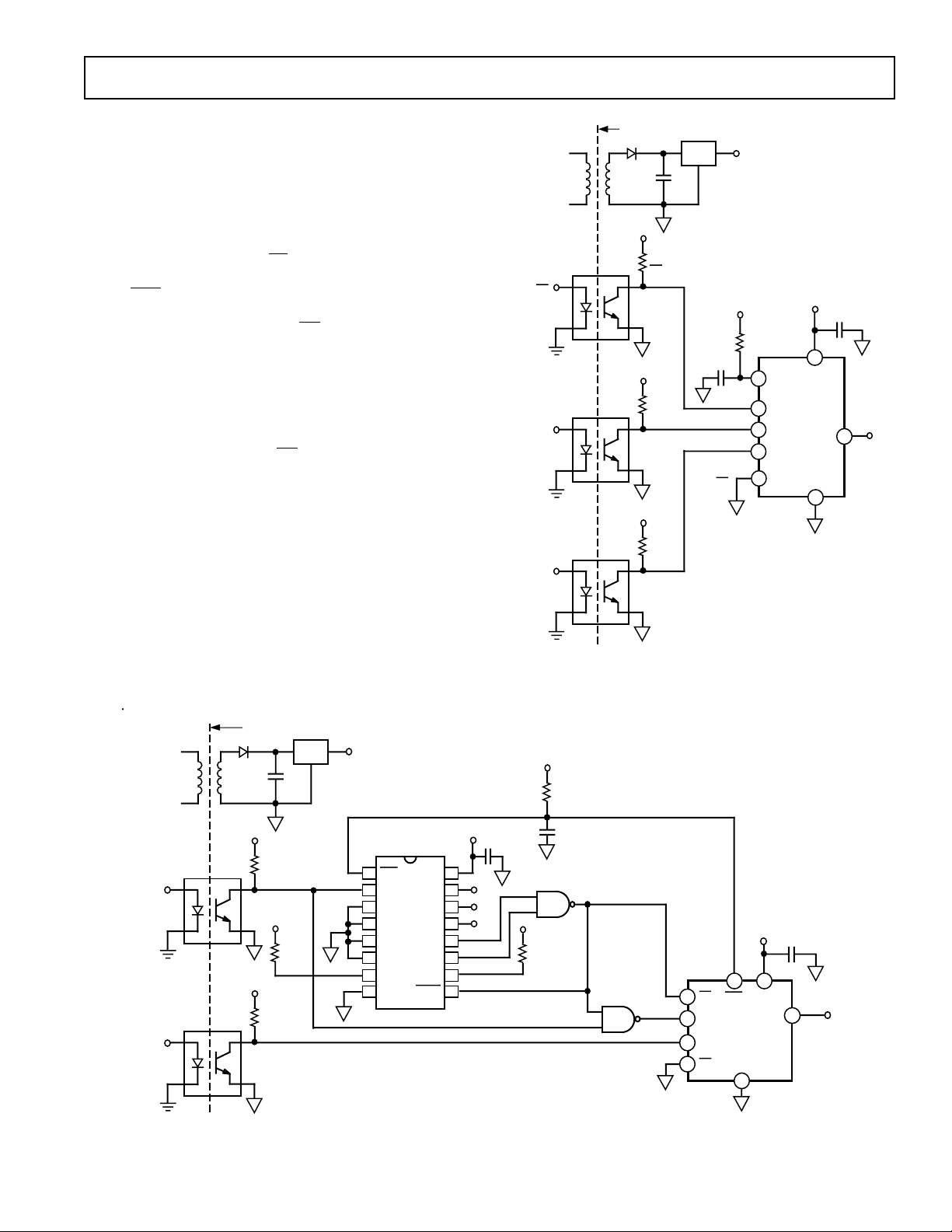

R1

R2

V

OUT

RAIL-TO-RAIL

OUTPUT

AMPLIFIER

R

BANDGAP

REFERENCE

2R

R

2R

2R

2R

SPDT

N-CH FET

SWITCHES

2R

AV = 4.095/2.5

= 1.638V/V

VOLTAGE SWITCHED 12-BIT

R-2R D/A CONVERTER

BUFFER

2.5V

PIN CONFIGURATIONS

SO-8 P-DIP-8 & Cerdip-8

V

CS

CLK

SDI

DD

1

DAC8512

2

TOP VIEW

3

(Not to Scale)

4

V

OUT

8

GND

7

CLR

6

LD

5

V

CS

CLK

SDI

DD

1

2

3

(Not to Scale)

4

DAC8512

TOP VIEW

8

V

OUT

GND

7

CLR

6

LD

5

PIN DESCRIPTIONS

Pin Name Description

1VDDPositive Supply. Nominal value +5 V, ± 5%.

CS Chip Select. Active low input.

2

3 CLK Clock input for the internal serial input shift register.

4 SDI Serial Data Input. Data on this pin is clocked into the

internal serial register on positive clock edges of the

CLK pin. The Most Significant Bit (MSB) is loaded

first.

LD Active low input which writes the serial register data

5

into the DAC register. Asynchronous input.

CLR Active low digital input that clears the DAC register to

6

zero, setting the DAC to minimum scale. Asynchronous

input.

7 GND Analog ground for the DAC. This also serves as the

digital logic ground reference voltage.

8V

Voltage output from the DAC. Fixed output voltage

OUT

range of 0 V to 4.095 V with 1 mV/LSB. An internal

temperature stabilized reference maintains a fixed

full-scale voltage independent of time, temperature and

power supply variations.

OPERATION

The DAC8512 is a complete ready to use 12-bit digital-to-analog

converter. It contains a voltage-switched, 12-bit, laser-trimmed

DAC, a curvature-corrected bandgap reference, a rail-to-rail

output op amp, a DAC register, and a serial data input register.

The serial data interface consists of a CLK, serial data in (SDI),

and a load strobe (

LD). This basic 3-wire interface offers maximum flexibility for interface to the widest variety of serial data

input loading requirements. In addition a

for multiple packaging loading and a power on reset

CS select is provided

CLR pin to

simplify start or periodic resets.

D/A CONVERTER SECTION

The DAC is a 12-bit voltage mode device with an output that

swings from GND potential to the 2.5 volt internal bandgap

voltage. It uses a laser trimmed R-2R ladder which is switched

by N channel MOSFETs. The output voltage of the DAC has a

constant resistance independent of digital input code. The DAC

output is internally connected to the rail-to-rail output op amp.

AMPLIFIER SECTION

The DAC’s output is buffered by a low power consumption precision amplifier. This amplifier contains a differential PNP pair

input stage which provides low offset voltage and low noise, as

well as the ability to amplify the zero-scale DAC output voltages. The rail-to-rail amplifier is configured in a gain of 1.6384

(= 4.095 V/2.5 V) in order to set the 4.095 volt full-scale output

(1 mV/LSB). See Figure 3 for an equivalent circuit schematic of

the analog section.

DICE CHARACTERISTICS

2

CS

3

CLK

SUBSTRATE IS COMMON WITH VDD.

NUMBER OF TRANSISTORS: 642

DIE SIZE: 0.055 inch × 0.106 inch; 5830 sq mils

V

DD

1

4

SDI LD

V

OUT

8

GND

7

GND

7

6

CLR

Figure 3. Equivalent DAC8512 Schematic of Analog

Portion

The op amp has a 16 µs typical settling time to 0.01%. There

are slight differences in settling time for negative slowing signals

5

vs. positive. See the oscilloscope photos in the typical performances section of this data sheet.

REV. A

–5–

DAC8512

OUTPUT SECTION

The rail-to-rail output stage of this amplifier has been designed

to provide precision performance while operating near either

power supply.

V

DD

P-CH

V

N-CH

OUT

AGND

Figure 4. Equivalent Analog Output Circuit

Figure 4 shows an equivalent output schematic of the rail-to-rail

amplifier with its N channel pull down FETs that will pull an

output load directly to GND. The output sourcing current is

provided by a P channel pull up device that can supply GND

terminated loads, especially at the low supply tolerance values of

4.75 volts. Figures 5 and 6 provide information on output swing

performance near ground and full-scale as a function of load. In

addition to resistive load driving capability the amplifier has also

been carefully designed and characterized for up to 500 pF capacitive load driving capability.

POWER SUPPLY

The very low power consumption of the DAC8512 is a direct

result of a circuit design optimizing use of the CBCMOS process. By using the low power characteristics of the CMOS for

the logic, and the low noise, tight matching of the complementary bipolar transistors good analog accuracy is achieved.

For power consumption sensitive applications it is important to

note that the internal power consumption of the DAC8512 is

strongly dependent on the actual logic input voltage levels

present on the SDI,

CS, LD, and CLR pins. Since these inputs

are standard CMOS logic structures they contribute static

power dissipation dependent on the actual driving logic V

V

voltage levels. The graph in Figure 9 shows the effect on to-

OL

OH

and

tal DAC8512 supply current as a function of the actual value of

input logic voltage. Consequently use of CMOS logic vs. TTL

minimizes power dissipation in the static state. A V

the SDI,

CS and CLR pins provides the lowest standby power

= 0 V on

IL

dissipation of 2.5 mW (500 µA × 5 V).

As with any analog system, it is recommended that the DAC8512

power supply be bypassed on the same PC card that contains the

chip. Figure 10 shows the power supply rejection versus frequency performance. This should be taken into account when using

higher frequency switched mode power supplies with ripple frequencies of 100 kHz and higher.

One advantage of the rail-to-rail output amplifier used in the

DAC8512 is the wide range of usable supply voltage. The part

is fully specified and tested over temperature for operation from

+4.75 V to +5.25 V. If reduced linearity and source current capability near full scale can be tolerated, operation of the DAC8512

is possible down to +4.3 volts. The minimum operating supply

voltage versus load current plot, in Figure 11, provides information for operation below V

TIMING AND CONTROL

= +4.75 V.

DD

The DAC8512 has a separate serial input register from the

12-bit DAC register that allows preloading of a new data value

into the serial register without disturbing the present DAC output voltage. After the new value is fully loaded in the serial input register it can be asynchronously transferred to the DAC

register by strobing the

sensitive

LD strobe that should be returned high before any

LD pin. The DAC register uses a level

new data is loaded into the serial input register. At any time the

contents of the DAC register can be reset to zero by strobing

the

CLR pin which causes the DAC output voltage to go to

zero volts. All of the timing requirements are detailed in Figure

1 along with the Table I Control-Logic Truth Table.

–6–

REV. A

5

80

–100

–60

–80

1

–20

–40

0

20

40

60

32

OUTPUT VOLTAGE – Volts

OUTPUT CURRENT – mA

POS0

CURRENT0

LIMIT0

NEG

CURRENT

LIMIT

DATA = 800

H

RL TIED TO +2V

10

90

100

0%

TIME = 20µs/DIV

20µs

1V

RL = NO LOAD

C

L

= 110pF

T

A

= +258C

1V/DIV

4

3

2

OUTPUT VOLTAGE – Volts

1

0

10

RL TIED TO +5V

DATA = 000H

100 100k10k1k

LOAD RESISTANCE – V

VDD = +5V

T

= +258C

A

RL TIED TO AGND

RL TIED TO AGND

D = FFFH

DATA = FFF

H

Typical Performance Characteristics — DAC8512

100

VDD = +5V

DATA = 000

10

TA = +858C

1

0.1

OUTPUT PULL-DOWN VOLTAGE – mV

0.01

1

H

TA = +258C

TA = –408C

10 1000100

OUTPUT SINK CURRENT – mA

Figure 5. Output Swing vs. Load

50mV

100

90

10

0%

OUTPUT NOISE VOLTAGE – 500µV/DIV

2mS

CODE = FFFH = 4095

BW = 630kHz

SCALE = 100X

TA = +258C

TIME = 2ms/DIV

10

Figure 8. Broadband Noise

5.0

∆VFS ≤ 1 LSB

4.8

DATA = FFF

TA = +258C

4.6

MIN – Volts

4.4

DD

V

4.2

4.0

0.01 0.1 101.0

H

PROPER OPERATION

WHEN V

VOLTAGE ABOVE

CURVE

0.04 0.4 4.0

OUTPUT LOAD CURRENT – mA

DD

SUPPLY

Figure 6. Pull-Down Voltage vs. Output Sink Current Capability

4.0

3.2

2.4

1.6

SUPPLY CURRENT – mA

0.8

0.0

0

LOGIC VOLTAGE VALUE – Volts

VDD = +5V

T

= +258C

A

NO LOAD

3241

5

Figure 9. Supply Current vs. Logic

Input Voltage

5

LD

0

– Volts

2.048

OUT

V

2.038

2.028

2.018

204810 TO 2047

TIME – 200ns/DIV

10

VDD = 5V

= +258C

T

A

Figure 7. Short Circuit Current

100

VDD = +5V 6200mV AC

= +258C

T

80

60

40

20

POWER SUPPLY REJECTION – dB

0

10

A

DATA = FFF

100 100k10k1k

FREQUENCY – Hz

H

Figure 10. Power Supply Rejection

vs. Frequency

Figure 11. Minimum Supply Voltage

vs. Load

REV. A

Figure 12. Midscale DAC Glitch

Figure 13. Large Signal Settling Time

Performance

–7–

DAC8512 — Typical Performance Characteristics

2.0

–2.0

4096

–1.0

–1.5

5120

0.0

–0.5

0.5

1.0

1.5

358430722560204815361024

DIGITAL INPUT CODE – Decimal

LINEARITY ERROR – LSB

VDD = +5V

T

A

= –408C, +258C, +858 C

+258 C & +858C

–408C

4

0

125

1

–25–50

2

3

1007550250

TEMPERATURE – 8C

SUPPLY CURRENT – mA

V

LOGIC

= 2.4V

DATA = FFF

H

NO LOAD

VDD = +4.75V

VDD = +5.25V

VDD = +5.0V

5

LD

0

16µs

1mV/DIV

OUTPUT VOLTAGE

TIME – 10µs/DIV

VDD = +5V

T

A

R

L

Figure 14. Rise Time Detail

60

50

40

30

20

NUMBER OF UNITS

10

0

0

–12

TOTAL UNADJUSTED ERROR – mV

TUE = ∑INL + ZS + FS

SS = 300 UNITS

TA = +25

= +258C

= NO LOAD

8

C

+12+40–4–8 +8

5

LD

0

1mV/DIV

OUTPUT VOLTAGE

TIME – 10µs/DIV

VDD = +5V

T

RL = NO LOAD

Figure 15. Fall Time Detail

4.115

4.110

4.105

AVG + 3σ

4.100

4.095

AVG

4.090

4.085

FULL-SCALE OUTPUT – Volts

4.080

4.075

AVG – 3σ

–25–50

VDD = +5V

NO LOAD

SS = 300 PCS

TEMPERATURE – 8C

= +258C

A

Figure 16. Linearity Error vs. Digital

Code

3

DATA = 000

NO LOAD

2

1

ZERO-SCALE – mV

0

125

1007550250

–1

–25–50

TEMPERATURE – 8C

V

DD

= +5.0V

1007550250

H

125

Figure 17. Total Unadjusted Error

Histogram

10

Hz

√

1

0.1

OUTPUT NOISE DENSITY – µV/

0.01

10

Figure 20. Output Voltage Noise vs.

Frequency

100 100k10k1k

FREQUENCY – Hz

VDD = +5V

T

= +258C

A

DATA = FFF

Figure 18. Full-Scale Voltage vs.

Temperature

5

4

H

3

2

1

0

–1

–2

–3

READINGS NORMALIZED

OUTPUT VOLTAGE CHANGE – mV

TO ZERO HOUR TIME POINT

–4

–5

200

0

HOURS OF OPERATION AT +1258C

135 UNITS TESTED

AVERAGE

1000600 800400

RANGE

1200

Figure 21. Long Term Drift Accelerated by Burn-In

–8–

Figure 19. Zero-Scale Voltage vs.

Temperature

Figure 22. Supply Current vs.

Temperature

REV. A

Typical Performance Characteristics—

DAC8512

APPLICATIONS SECTION

Power Supplies, Bypassing, and Grounding

All precision converter products require careful application of

good grounding practices to maintain full rated performance.

Because the DAC8512 has been designed for +5 V applications,

it is ideal for those applications under microprocessor or microcomputer control. In these applications, digital noise is prevalent; therefore, special care must be taken to assure that its

inherent precision is maintained. This means that particularly

good engineering judgment should be exercised when addressing the power supply, grounding, and bypassing issues using the

DAC8512.

The power supply used for the DAC8512 should be well filtered

and regulated. The device has been completely characterized for

a +5 V supply with a tolerance of ± 5%. Since a +5 V logic supply is almost universally available, it is not recommended to

connect the DAC directly to an unfiltered logic supply without

careful filtering. Because it is convenient, a designer might be

inclined to tap a logic circuit’s supply for the DAC’s supply.

Unfortunately, this is not wise because fast logic with nanosecond transition edges induce high current pulses. The high transient current pulses can generate glitches hundreds of millivolts

in amplitude due to wiring resistances and inductances. This

high frequency noise will corrupt the analog circuits internal to

the DAC and cause errors. Even though their spike noise is

lower in amplitude, directly tapping the output of a +5 V system

supply can cause errors because these supplies are of the switching regulator type that can and do generate a great deal of high

frequency noise. Therefore, the DAC and any associated analog

circuitry should be powered directly from the system power supply outputs using appropriate filtering. Figure 23 illustrates how

a clean, analog-grade supply can be generated from a +5 V logic

supply using a differential LC filter with separate power supply

and return lines. With the values shown, this filter can easily

handle 100 mA of load current without saturating the ferrite

cores. Higher current capacity can be achieved with larger ferrite

cores. For lowest noise, all electrolytic capacitors should be low

ESR (Equivalent Series Resistance) type.

FERRITE BEADS:

TTL/CMOS

LOGIC

CIRCUITS

2 TURNS, FAIR-RITE

#2677006301

100µF

ELECT

.

10-22µF

TANT.

+5V

0.1µF

CER.

+5V

RETURN

the ground connection of the DAC8512 be connected to a high

quality analog ground, such as the one described above. Generous bypassing of the DAC’s supply goes a long way in reducing

supply line-induced errors. Local supply bypassing consisting of

a 10 µF tantalum electrolytic in parallel with a 0.1 µF ceramic is

recommended. The decoupling capacitors should be connected

between the DAC’s supply pin (Pin 1) and the analog ground

(Pin 7). Figure 24 shows how the ground and bypass connections should be made to the DAC8512.

+5V

CS

CLR

SCLK

SDI

1

2

6

5

LD

3

4

V

DD

DAC8512

GND

7

TO ANALOG GROUND

V

8

OUT

10µF

0.1µF

V

OUT

Figure 24. Recommended Grounding and Bypassing

Scheme for the DAC8512

Unipolar Output Operation

This is the basic mode of operation for the DAC8512. As shown

in Figure 24, the DAC8512 has been designed to drive loads as

low as 2 kΩ in parallel with 500 pF. The code table for this operation is shown in Table II.

+5V

1

V

DD

GND

7

10µF

V

OUT

0V ≤ V

≤ 4.095V

8

2kΩ

OUT

500pF

CLR

SCLK

SDI

0.1µF

CS

2

6

DAC8512

5

LD

3

4

Figure 25. Unipolar Output Operation

+5V

POWER SUPPLY

Figure 23. Properly Filtering a +5 V Logic Supply Can Yield

a High Quality Analog Supply

In order to fit the DAC8512 in an 8-pin package, it was necessary to use only one ground connection to the device. The

ground connection of the DAC serves as the return path for

supply currents as well as the reference point for the digital input thresholds. The ground connection also serves as the supply

rail for the internal voltage reference and the output amplifier.

Therefore, to minimize any errors, it is recommended that

REV. A

–9–

Table II. Unipolar Code Table

Hexadecimal Number Decimal Number Analog Output

in DAC Register in DAC Register Voltage (V)

FFF 4095 +4.095

801 2049 +2.049

800 2048 +2.048

7FF 2047 +2.047

000 0 0

DAC8512

+5V

10µF

+

0.1µF

1

8

7

4

3

2

5

6

DAC8512

V

DD

GND

R1

10kΩ

R2

12.7k

R3

247kΩ

6

5

4

8

7

–5V ≤ V

O

≤ +5V

+5V

–5V

A2

P2

10kΩ

ZERO SCALE

ADJUST

P3

500Ω

R4

23.7kΩ

FULL SCALE

ADJUST

–2.5V

CLR

LD

CS

SCLK

SDI

0.1µF

+5V

REF03

A1

–2.5V

0.01µF

100Ω

P1

10kΩ

2.5V

TRIM

2

6

5

4

2

1

3

A1, A2 = 1/2 OP295

Operating the DAC8512 on +12 V or +15 V Supplies Only

Although the DAC8512 has been specified to operate on a

single, +5 V supply, a single +5 V supply may not be available in

many applications. Since the DAC8512 consumes no more than

2.5 mA, maximum, then an integrated voltage reference, such as

the REF02, can be used as the DAC8512 +5 V supply. The

configuration of the circuit is shown in Figure 26. Notice that

the reference’s output voltage requires no trimming because of

the REF02’s excellent load regulation and tight initial output

voltage tolerance. Although the maximum supply current of the

DAC8512 is 2.5 mA, local bypassing of the REF02’s output

with at least 0.1 µF at the DAC’s voltage supply pin is recom-

mended to prevent the DAC’s internal digital circuits from affecting the DAC’s internal voltage reference.

+12V OR +15V

2

REF02

4

0.1µF

SCLK

6

CS

CLR

LD

SDI

2

6

5

3

4

1

V

DD

DAC8512

GND

7

0.1µF

8

V

OUT

By adding a pull-down resistor from the output of the DAC8412

to a negative supply as shown in Figure 27, offset errors can

now be read at zero code. This configuration forces the output

p-channel MOSFET to source current to the negative supply

thereby allowing the designer to determine in which direction the

offset error appears. The value of the resistor should be such that,

at zero code, current through the resistor is 200 µA, maximum.

Bipolar Output Operation

Although the DAC8512 has been designed for single-supply operation, bipolar operation is achievable using the circuit illustrated in Figure 28. The circuit uses a single-supply, rail-to-rail

OP295 op amp and the REF03 to generate the –2.5 V reference

required to level-shift the DAC output voltage. Note that the –

2.5 V reference was generated without the use of precision resistors. The circuit has been configured to provide an output

voltage in the range –5 V ≤ V

≤ +5 V and is coded in com-

OUT

plementary offset binary. Although each DAC LSB corresponds

to 1 mV, each output LSB has been scaled to 2.44 mV. Table

III provides the relationship between the digital codes and output voltage.

The transfer function of the circuit is given by:

V

= –1 mV × Digital Code ×

O

R4

R1

+ 2.5 ×

R4

R2

and, for the circuit values shown, becomes:

= –2.44 mV × Digital Code + 5 V

V

O

Figure 26. Operating the DAC8512 on +12 V or +15 V

Supplies Using a REF02 Voltage Reference

Measuring Offset Error

One of the most commonly specified endpoint errors associated

with real world nonideal DACs is offset error.

In most DAC testing, the offset error is measured by applying

the zero-scale code and measuring the output deviation from 0

volt. There are some DACs where offset errors may be present

but not observable at the zero scale because of other circuit limitations (for example, zero coinciding with single-supply ground).

In these DACs, nonzero output at zero code cannot be read as

the offset error. In the DAC8512, for example, the zero-scale

error is specified to be ±3 LSBs. Since zero scale coincides with

zero volt, it is not possible to measure negative offset error.

Figure 27. Measuring Zero-Scale or Offset Error

CS

2

6

CLR

5

LD

SDI

3

4

SCLK

SET CODE = 000

+5V

0.1µF

1

V

DD

DAC8512

GND

7

AND MEASURE V

H

8

OUT

R

V–

200µA, MAX

V

OUT

–10–

Figure 28. Bipolar Output Operation

REV. A

DAC8512

910

6

11 12

14 15

7

3254

R2

5.1kΩ

R1

510kΩ

C1

0.02µF

C2

47µF

D1

1N4001C347µF

1N5231

5.1V

ZENER

D2

1N4001

R3

470Ω

–5V

INVERTERS = CD4049

Table III. Bipolar Code Table

Hexadecimal Number Decimal Number Analog Output

in DAC Register in DAC Register Voltage (V)

F

FF 4095 –4.9976

801 2049 –2.44E–3

800 2048 0

7FF 2047 +2.44E–3

000 0 +5

To maintain monotonicity and accuracy, R1, R2, and R4 should

be selected to match within 0.01% and must all be of the same

(preferably metal foil) type to assure temperature coefficient

matching. Mismatching between R1 and R2 causes offset and gain

errors while an R4 to R1 and R2 mismatch yields gain errors.

For applications that do not require high accuracy, the circuit

illustrated in Figure 29 can also be used to generate a bipolar

output voltage. In this circuit, only one op amp is used and no

potentiometers are used for offset and gain trim. The output

voltage is coded in offset binary and is given by:

V

= 1 mV × Digital Code ×

O

R2

–2.5

×

R1

R4

R3+R4

×

R2

1+

R1

Generating a Negative Supply Voltage

Some applications may require bipolar output configuration but

only have a single power supply rail available. This is very common in data acquisition systems using microprocessor-based

systems. In these systems, +12 V, +15 V, and/or +5 V are only

available. Shown in Figure 30 is a method of generating a negative supply voltage using one CD4049, a CMOS hex inverter,

operating on +12 V or +15 V. The circuit is essentially a charge

pump where two of the six are used as an oscillator. For the values shown, the frequency of oscillation is approximately 3.5 kHz

and is fairly insensitive to supply voltage because R1 > 2 × R2.

The remaining four inverters are wired in parallel for higher output current. The square wave output is level translated by C2 to

a negative-going signal, rectified using a pair of 1N4001s, and

then filtered by C3. With the values shown, the charge pump

will provide an output voltage of –5 V for current loadings in the

range 0.5 mA ≤ I

≤ I

≤ 7 mA with a +12 V supply.

OUT

≤ 10 mA with a +15 V supply and 0.5 mA

OUT

Figure 29. Bipolar Output Operation without Trim

For the ±2.5 V output range and the circuit values shown in the

table, the transfer equation becomes:

Similarly, for the ±5 V output range, the transfer equation

becomes:

REV. A

+5V

REF03

CS

2

CLR

6

LD

5

SDI

3

4

V

O

SCLK

VO = 2.44 mV × Digital Code – 5 V

0.1µF

2

6

4

+5V

1

V

DD

DAC8512

GND

7

+2.5V

0.1µF

R1

R3

8

V

OUT

R2

2

A1

3

A1 = 1/2 OP295

R4

R1

RANGE R2

65V

10k

10k

62.5V

+5V

–5V

8

10k

20k

1

4

R3

10k

10k

= 1.22 mV × Digital Code – 2.5 V

V

R4

15.4k + 274

43.2k + 499

Figure 30. Generating a –5 V Supply When Only +12 V

or +15 V Is Available

A High-Compliance, Digitally Controlled Precision Current

Source

The circuit in Figure 31 shows the DAC8512 controlling a

high-compliance precision current source using an AMP05 in-

O

strumentation amplifier. The AMP05’s reference pin becomes

the input, and the “old” inputs now monitor the voltage across a

precision current sense resistor, R

. Voltage gain is set to unity,

CS

so the transfer function is given by the following equation:

V

IN

=

I

OUT

R

CS

If R

equals 100 Ω, the output current is limited to +10 mA

CS

with a 1 V input. Therefore, each DAC LSB corresponds to

2.4 µA. If a bipolar output current is required, then the circuit

in Figure 28 can be modified to drive the AMP05’s reference

pin with a ±1 V input signal.

Potentiometer P1 trims the output current to zero with the input at 0 V. Fine gain adjustment can be accomplished by adjusting R1 or R2.

–11–

DAC8512

FULL-SCALE

ADJUST

A1 = 1/2 OP295

+5V

6

2

8

DAC8512FP

1

CS

CLR

5

3

4

LD

SCLK

SDI

7

3

2

A1

1

+5V

0.1µF

V

S

LOAD

2N2222

R1

4.02kΩ

P1

200Ω

100k

0.1µF

R1

REF02

+15V

4

R2

5kΩ

17

18

7

AMP05

1

4

CS

SDI

6

LD

P1

100kΩ

5

–15V

2

6

5

3

4

2

2

CLR

SCLK

+15V

0.1µF

6

12

8

9

11

0.1µF

1

DAC8512FZ

7

0.1µF

R

CS

100Ω

10

0mA ≤ I

OUT

2.4µA/ BIT

R3

3k

8

R4

1k

Figure 31. A High-Compliance, Digitally Controlled

Precision Current Source

A Single-Supply, Programmable Current Source

The circuit in Figure 32 shows how the DAC8512 can be used

with an OP295 single-supply, rail-to-rail output op amp to provide a digitally programmable current sink from V

SOURCE

consumes less than 3.8 mA, maximum. The DAC’s output voltage is applied across R1 by placing the 2N2222 transistor in the

+5V

+5V

1

DAC8512

7

+5V

1

DAC8512

7

6

2

5

3

4

6

2

5

3

4

1kΩ

2

1/6

74HC05

CLR

HDAC/LDAC

LD

SCLK

SDI

1

Figure 33. A Digitally Programmable Window Detector

≤ 10mA

that

0.1µF

8

0.1µF

8

OP295’s feedback loop. For the circuit values shown, the fullscale output current is 1 mA which is given by the following

equation:

OUT

DW × 4.095V

=

R1

I

where DW = DAC8512’s binary digital input code.

Figure 32. A Single-Supply, Programmable Current

Source

The usable output voltage range of the current sink is +5 V to

+60 V. The low limit of the range is controlled by transistor

saturation, and the high limit is controlled by the collector-base

breakdown voltage of the 2N2222.

A Digitally Programmable Window Detector

A digitally programmable, upper/lower limit detector using two

DAC8512s is shown in Figure 33. The required upper and

lower limits for the test are loaded into each DAC individually

by controlling HDAC/

LDAC. If a signal at the test input is not

within the programmed limits, the output will indicate a logic

zero which will turn the red LED on.

V

IN

+5V

3

5

C1

4

7

C2

6

12

C1, C2 = 1/4 CMP-404

0.1µF

2

1

+5V

R1

604Ω

RED LED

PASS/FAIL

+5V

T1

34

1/6

74HC05

R2

604Ω

GREEN LED

T1

–12–

REV. A

Opto-Isolated Interfaces for Process Control Environments

0.1µF

+5V

5

6

8

DAC8512

1

CS

3

4

7

2

0.1µF

10kΩ

+5V

V

OUT

+5V

+5V

+5V

10kΩ

SCLK

10kΩ

SDI

10kΩ

LD

LD

SCLK

SDI

+5V

REG

+5V

POWER

HIGH VOLTAGE

ISOLATION

In many process control type applications, it is necessary to provide an isolation barrier between the controller and the unit being controlled. Opto-isolators can provide isolation in excess of

3 kV. The serial loading structure of the DAC8512 makes it

ideal for opto-isolated interfaces as the number of interface lines

is kept to a minimum.

Illustrated in Figure 34 is an opto-isolated interface using the

DAC8512. In this circuit, the

CS line is always LOW to enable

the DAC, and the 10 kΩ/1 µF combination connected to the

DAC’s

CLR pin sets a turn-on time constant of 10 ms to reset

the DAC upon application of power. Three opto-couplers are

then used for the SDI, SCLK, and

LD lines.

Often times reducing the number of interface lines to two lines

is required in many control environments. The circuit illustrated

in Figure 35 shows how to convert a two-line interface into the

three control lines required to control the DAC8512 without using one shots. This technique uses a counter to keep track of the

clock cycles and, when all the data has been input to the DAC,

the external logic generates the

LD pulse.

DAC8512

POWER

SCLK

SDI

HIGH VOLTAGE

ISOLATION

+5V

+5V

10kΩ

+5V

10kΩ

10kΩ

+5V

REG

Figure 34. An Opto-Isolated DAC Interface

+5V

+5V

74HC161

1

2

3

4

5

6

7

8

CLR

CLK

A

B

C

D

ENP

GND

V

RCO

ENT

LOAD

16

CC

15

NC

Q

14

NC

A

13

Q

Q

Q

NC

B

12

C

11

D

10

9

0.1µF

+5V

10kΩ

1µF

1/4 74HCOO

1

X

2

+5V

10kΩ

3

1/4 74HCOO

4

Y

5

+5V

0.1µF

1

6

5

6

LD

3

SCLK

SDI

4

2

CS

V

CLR

DD

DAC8512

GND

7

8

V

OUT

REV. A

Figure 35. A Two-Wire, Opto-lsolated DAC Interface

–13–

DAC8512

V

OUT3

DAC8512

#3

V

OUT2

DAC8512

#2

V

OUT1

DAC8512

#1

8

4

5

2

3

6

V

CC

1G

1A

1B

2G

2A

2B

GND

1Y0

1Y1

1Y2

1Y3

2Y0

2Y1

2Y2

2Y3

12

1kΩ

+5V

16

1

2

3

15

14

13

8

11

10

9

7

6

5

4

NC

NC

NC

NC

+5V

ENABLE

CODED

ADDRESS

C1

0.1µF

74HC139

V

OUT4

DAC8512

#4

+5V

R1

1k

SCLK

SDI

LD

8

4

5

2

3

6

8

4

5

2

3

6

8

4

5

2

3

6

COUNTER

CLK

Q

D

Q

C

Q

B

Q

A

LOAD

(X)

DAC8512

CLK (Y)

LOAD = QC · Q

DAC8512 CLK = LOAD · SCLK

LOAD DAC

D

Figure 36. Opto-lsolated Two-Wire Serial Interface Timing Diagram

The timing diagram of Figure 36 can be used to understand the

operation of the circuit. Only two opto-couplers are used in the

circuit; one for SCLK and one for SDI. The 74HC161 counter

in incremented on every rising edge of the clock. Additionally,

the data is loaded into the DAC8512 on the falling edge of the

clock by inverting the serial clock using gate “Y.” The timing

diagram shows that after the twelfth bit has been clocked the

output of the counter is binary 1011. On the very next rising

clock edge, the output of the counter changes to binary 1100

upon which the output of gate “X” goes LOW to generate the

LD pulse. The LD signal is connected to both the DAC’s LD

and the counter’s LOAD pins to prevent the thirteenth rising

clock edge from advancing the DAC’s internal shift register.

This prevents false loading of data into the DAC8512. Inverting

the DAC’s serial clock allows sufficient time from the CLK edge

to the

LD edge, and from the LD edge to the next clock pulse

all of which satisfies the timing requirements for loading the

DAC8512.

After loading one address of the DAC, the entire process can repeated to load another address. If the loading is complete, then

the clock must stop after the thirteenth pulse of the final load.

The DAC’s clock input will be pulled high and the counter reset

to zero. As was shown in Figure 35, both the 74HC161’s and

the DAC8512’s

CLR pins are connected to a simple R-C timing

circuit that resets both ICs when the power in turned on. The

circuit’s time constant should be set longer than the power supply turn-on time and, in this circuit, is set to 10 ms, which

should be adequate for most systems. This same two-wire interface can be used for other three-wire serial input DACs.

Decoding Multiple DAC8512s

The CS function of the DAC8512 can be used in applications

to decode a number of DACs. In this application, all DACs receive the same input data; however, only one of the DAC’s

input is asserted to transfer its serial input register contents into

the destination DAC register. In this circuit, shown in Figure 37,

the

CS timing is generated by a 74HC139 decoder and should

follow the DAC8512’s standard timing requirements. To prevent timing errors, the 74HC139 should not be activated by its

CS

–14–

ENABLE input while the coded address inputs are changing. A

simple timing circuit, R1 and C1, connected to the DACs’

CLR

pins resets all DAC outputs to zero during power-up.

Figure 37. Decoding Multiple DAC8512s Using the CS Pin

REV. A

CS

CLR

LD

SCLK

SDI

V

+625mV

IN

R1

619Ω

0.1µF

2

6

5

DAC8512FZ

3

4

R2

4.32kΩ

DAC8512

V+

AD600JN

1

2

3

4

5

6

7

8

V+

1

7

REF

8

16

15

14

13

12

11

10

9

R6

2.26kΩ

1µF

0.1µF

V+

V–

0.1µF

R3

402Ω

R4

402Ω

0 ≤ VG ≤ 1.25V

R7

1kΩ

R5

806Ω

V+

0.1µF

2

AD844

3

6

0.1µF

V–

R4

49.9Ω

SUPPLY DECOUPLING NETWORK

+5V

10µF

FB = FAIR RITE

V+

V–

#2743001111

10µF

–5V

V

OUT

0.01dB/BIT

Figure 38. A Digitally Controlled, Ultralow Noise VCA

A Digitally Controlled, Ultralow Noise VCA

The circuit in Figure 38 illustrates how the DAC8512 can be

used to control an ultralow noise VCA, using the AD600/

AD602. The AD600/AD602 is a dual, low noise, wideband,

variable gain amplifier based on the X-AMP topology.* Both

channels of the AD600 are wired in parallel to achieve a

wideband VCA which exhibits an RTI (Referred To Input)

noise voltage spectral density of approximately 1 nV/√

Hz. The

output of the VCA requires an AD844 configured in a gain of 4

to account for signal loss due to input and output 50 Ω terminations. As configured, the total gain in the circuit is 40 dB.

Since the output of the DAC8512 is single quadrant, it was necessary to offset the AD600’s gain control voltage so that the gain

of the circuit is 0 dB for zero scale and 40 dB at full scale. This

was achieved by setting C1LO and C2LO to +625 mV using R1

and R2. Next, the output of the DAC8512 was scaled so that

the gain of the AD600 equaled 20 dB when the digital input

code equaled 800

. The frequency response of the VCA as a

H

function of digital code is shown in Figure 39.

+70

+60

+50

+40

+30

+20

+10

SYSTEM GAIN – dB

–10

–20

–30

4095

3072

2048

1024

0

0

100k 100M10M1M10k

FREQUENCY – Hz

Figure 39. VCA Frequency Response vs. Digital Code

*For more details regarding the AD600 or AD602, please consult the AD600/

AD602 data sheet.

REV. A

–15–

DAC8512

A Serial DAC, Audio Volume Control

The DAC8512 is well suited to control digitally the gain or attenuation of a voltage controlled amplifier. In professional audio

mixing consoles, music synthesizers, and other audio processors,

VCAs, such as the SSM2018, adjust audio channel gain and attenuation from front panel potentiometers. The VCA provides a

clean gain transition control of the audio level when the slew

rate of the analog input control voltage, V

, is properly chosen.

C

The circuit in Figure 40 illustrates a volume control application

using the DAC8512 to control the attenuation of the SSM2018.

+15V

10MΩ

P1

100kΩ

OFFSET

TRIM

+15V

V

0.1µF

REF02

IN

+15V

–15V

0.1µF

2

4

18kΩ

CS

CLR

LD

6

2

6

5

3SCLK

4SDI

500kΩ

P2

SYMMETRY

TRIM

1

2

3

4

5

6

7

8

47pF

+5V

1

DAC8512

7

470kΩ

10pF

18kΩ

16

15

14

SSM2018

0.1µF

13

12

11

10

9

R6

825Ω

8

1kΩ

* – PRECISION RESISTOR

PT146

1kΩ COMPENSATOR

30kΩ

0.1µF

0V ≤ VC ≤ +2.24V

R7

*

C

1µF

V

+15V

–15V

CON

OUT

Figure 40. A Serial DAC, Audio Volume Control

Since the supply voltage available in these systems is typically

±15 V or ±18 V, a REF02 is used to supply the +5 V required

to power the DAC. No trimming of the reference is required because of the reference’s tight initial tolerance and low supply

current consumption of the DAC8512. The SSM2018 is configured as a unity-gain buffer when its control voltage equals 0

volt. This corresponds to a 000

code from the DAC8512.

H

Since the SSM2018 exhibits a gain constant of –28 mV/dB

(typical), the DAC’s full-scale output voltage has to be scaled

down by R6 and R7 to provide 80 dB of attenuation when the

Table IV. SSM-2018 VCA Attenuation vs.

DAC8512 Input Code

Hexadecimal Number Control VCA

in DAC Register Voltage (V) Attenuation (dB)

000 0 0

400 +0.56 20

800 +1.12 40

C00 +1.68 60

FFF +2.24 80

digital code equals FFFH. Therefore, every DAC LSB corresponds to 0.02 dB of attenuation. Table IV illustrates the attenuation vs. digital code of the volume control circuit.

To compensate for the SSM2018’s gain constant temperature

coefficient of –3300 ppm/°C, a 1 kΩ, temperature-sensitive resistor (R7) manufactured by the Precision Resistor Company

with a temperature coefficient of +3500 ppm/°C is used. A

C

of 1 µF provides a control transition time of 1 ms which

CON

yields a click-free change in the audio channel attenuation. Symmetry and offset trimming details of the VCA can be found in

the SSM2018 data sheet.

Information regarding the PT146 1 kΩ “Compensator” can be

obtained by contacting:

Precision Resistor Company, Incorporated

10601 75th Street North

Largo, Fl 34647

(813) 541-5771

An Isolated, Programmable, 4-20 mA Process Controller

In many process control system, applications, two-wire current

transmitters are used to transmit analog signals through noisy

environments. These current transmitters use a “zero-scale” signal current of 4 mA that can be used to power the transmitter’s

signal conditioning circuitry. The “full-scale” output signal in

these transmitters is 20 mA. The converse approach to process

control can also be used; a low-power, programmable current

source can be used to control remotely located sensors or devices in the loop.

A circuit that performs this function is illustrated in Figure 41.

Using the DAC8512 as the controller, the circuit provides a

programmable output current of 4 mA to 20 mA, proportional

to the DAC’s digital code. Biasing for the controller is provided

by the REF02 and requires no external trim for two reasons:

(1) the REF02’s tight initial output voltage tolerance and (2) the

low supply current consumption of both the OP90 and the

DAC8512. The entire circuit, including opto-couplers, consumes less than 3 mA from the total budget of 4 mA. The OP90

regulates the output current to satisfy the current summation at

the noninverting node of the OP-90. The KCL equation at

Pin 3 is given by:

–16–

I

OUT

=

1

1 mV ×Digital Code ×R3

×

R7

R1

+

R2

×R3

V

REF

REV. A

DAC8512

PC1

PC0

SCK

MOSI

SS

CLK

SDI

LD

MC68HC11* DAC8512*

CS

CLR

*ADDITIONAL PINS OMITTED FOR CLARITY

R2

976kΩ

P2

P1

10kΩ

20mA

80.6k

R3

10kΩ

ILQ-1

50Ω

4mA

ADJUST

D1

R4

54.9k

D1 = HP5082-2810

+5V

CLR

LD

SCLK

SCI

6

5

DAC8512

3

4

1

R1

200kΩ

8

7

CLK

ADJUST

360Ω

Figure 41. An Isolated, Programmable, 4-20 mA Process Controller

For the values shown in Figure 41,

= 3.9 µA × Digital Code + 4 mA

I

OUT

giving a full-scale output current of 20 mA when the

DAC8512’s digital code equals FFF

. Offset trim at 4 mA is

H

provided by P2, and P1 provides the circuit’s gain trim at 20 mA.

These two trims do not interact because the noninverting input

of the OP90 is at virtual ground. The Schottky diode, D1, is required in this circuit to prevent loop supply power-on transients

from pulling the noninverting input of the OP90 more than

300 mV below its inverting input. Without this diode, such transients could cause phase reversal of the OP90 and possible

latchup of the controller. The loop supply voltage compliance of

the circuit is limited by the maximum applied input voltage to

the REF02 and is from +12 V to +40 V.

MICROPROCESSOR INTERFACING

DAC8512–MC68HC11 Interface

The circuit illustrated in Figure 42 shows a serial interface between the DAC8512 and the MC68HC11 8-bit microcontroller. SCK of the 68HC11 drives SCLK of the DAC8512, while

the MOSI output drives the serial data line, SDI, of the

DAC8512. The DAC’s

CLR, LD, and CS signals are derived

from port lines PC1, PD5, and PC0, respectively, as shown.

For correct operation of the serial interface, the 68HC11 should

be configured such that its CPOL bit is set to 1 and its CPHA

bit is also set to 1. When the serial data is to be transmitted to

the DAC, PC0 is taken low, asserting the DAC’s

CS input.

When the 68HC11 is configured in this manner, serial data on

3

2

6

7

6

OP90

4

SCLK

REPEAT FOR SDI, LD, & CLR

REF02

4

150Ω

R6

R5

100k

2

R7

100Ω

Q1

2N1711

4–20mA

V

LOOP

+12 TO +40V

R

L

100Ω

Figure 42. DAC8512–MC68HC11 Interface

MOSI is valid on the rising edge of SCLK. The 68HC11 transmits its serial data in 8-bit bytes (MSB first), with only eight rising clock edges occurring in the transmit cycle. To load data to

the DAC8512’s input serial register, PC0 is left low after the

first eight bits are transferred, and a second byte of data is then

transferred serially to the DAC8512. During the second byte

load, the first four most significant bits of the first byte are

pushed out of the DAC’s input shift register. At the end of the

second byte load, PC0 is then taken high. To prevent an accidental advancing of the internal shift register, SCLK must already be asserted before PC0 is taken high. To transfer the

contents of the input shift register to the DAC register, PD5 is

taken low, asserting the DAC’s

LD input. The DAC’s CLR input, controlled by the 68HC11’s PC1 port, provides an asynchronous clear function, setting the DAC output to zero.

Included in this section is the source code for operating the

DAC8512—M68HC11 interface.

REV. A

–17–

DAC8512

DAC8512–M68HC11 Interface Program Source Code

*

PORTC EQU $1003 Port C control register

* “0,0,0,0;0,0,CLR/,CS/”

DDRC EQU $1007 Port C data direction

PORTD EQU $1008 Port D data register

* “0,0,LD/,SCLK;SDI,0,0,0

DDRD EQU $1009 Port D data direction

SPCR EQU $1028 SPI control register

* “SPIE,SPE,DWOM,MSTR;CPOL,CPHA,SPRl,SPR0”

SPSR EQU $1029 SPI status register

* “SPIF,WCOL,0,MODF;0,0,0,0”

SPDR EQU $102A SPI data register; Read-Buffer; Write-Shifter

*

* SDI RAM variables: SDI1 is encoded from 0 (Hex) to F (Hex)

* SDI2 is encoded from 00 (Hex) to FF (Hex)

* DAC requires two 8-bit loads; upper 4 bits of SDI1

* are ignored.

*

SDI1 EQU $00 SDI packed byte 1 “0,0,0,0;MSB,DB10,DB9,DB8”

SDI2 EQU $01 SDI packed byte 2 “DB7,DB6,DB5,DB4;DB3,DB2,DB1,DB0”

*

ORG $C000 Start of user’s RAM in EVB

INIT LDS #$CFFF Top of C page RAM

*

LDAA #$03 0,0,0,0;0,0,1,1

* CLR/-Hi, CS/-Hi

STAA PORTC Initialize Port C Outputs

LDAA #$03 0,0,0,0;0,0,1,1

STAA DDRC CLR/ and CS/ are now enabled as outputs

*

LDAA #$30 0,0,1,1;0,0,0,0

* LDI-Hi,SCLK-Hi,SDI-Lo

STAA PORTD Initialize Port D Outputs

LDAA #$38 0,0,1,1;1,0,0,0

STAA DDRD LD/,SCLK, and SDI are now enabled as outputs

*

LDAA #$5F

STAA SPCR SPI is Master,CPHA=1,CPOL=1,Clk rate=E/32

*

BSR UPDATE Xfer 2 8-bit words to DAC8512

JMP $E000 Restart BUFFALO

*

UPDATE PSHX Save registers X, Y, and A

PSHY

PSHA

*

LDAA #$0A 0,0,0,0;1,0,1,0

STAA SDI1 SDI1 is set to 0A (Hex)

*

LDAA #$AA 1,0,1,0;1,0,1,0

STAA SDI2 SDI2 is set to AA (Hex)

*

LDX #SDI1 Stack pointer at 1st byte to send via SDI

LDY #$1000 Stack pointer at on-chip registers

*

BCLR PORTC,Y $02 Assert CLR/

BSET PORTC,Y $02 De-assert CLR/

*

BCLR PORTC,Y $01 Assert CS/

*

–18–

REV. A

TFRLP LDAA 0,X Get a byte to transfer via SPI

STAA SPDR Write SDI data reg to start xfer

*

WAIT LDAA SPSR Loop to wait for SPIF

BPL WAIT SPIF is the MSB of SPSR

* (when SPIF is set, SPSR is negated)

INX Increment counter to next byte for xfer

CPX #SDI2+1 Are we done yet ?

BNE TFRLP If not, xfer the second byte

*

*Update DAC output with contents of DAC register

*

BCLR PORTD,Y $20 Assert LD/

BSET PORTD,Y $20 Latch DAC register

*

BSET PORTC,Y $01 De-assert CS/

PULA When done, restore registers X, Y & A

PULY

PULX

RTS ** Return to Main Program **

DAC8512

REV. A

–19–

DAC8512

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).

8-Pin Plastic DIP (P Suffix)

8

1

0.430 (10.92)

0.348 (8.84)

0.210

(5.33)

MAX

0.160 (4.06)

0.115 (2.93)

0.022 (0.558)

0.014 (0.356)

8-Pin Cerdip (Z Suffix)

0.005 (0.13) MIN 0.055 (1.4) MAX

1

0.405 (10.29) MAX

0.200

(5.08)

MAX

0.200 (5.08)

0.125 (3.18)

0.100

(2.54)

BSC

5

4

0.280 (7.11)

0.240 (6.10)

0.070 (1.77)

0.045 (1.15)

0.015

(0.381) TYP

SEATING

PLANE

58

0.310 (7.87)

0.220 (5.59)

4

0.060 (1.52)

0.015 (0.38)

0.130

(3.30)

MIN

0°- 15°

0.070 (1.78)

0.030 (0.76)

0.150

(3.81)

MIN

0.325 (8.25)

0.300 (7.62)

0.015 (0.381)

0.008 (0.204)

0.320 (8.13)

0.290 (7.37)

0.015 (0.38)

0.008 (0.20)

0.195 (4.95)

0.115 (2.93)

C1734–xx–11/96

PIN 1

0.0098 (0.25)

0.0040 (0.10)

0.023 (0.58)

0.014 (0.36)

0.100 (2.54)

BSC

SEATING PLANE

8-Lead SOIC (S Suffix)

58

0.1574 (4.00)

0.1497 (3.80)

1

0.1968 (5.00)

0.1890 (4.80)

0.0500

(1.27)

BSC

4

0.0192 (0.49)

0.0138 (0.35)

0.2440 (6.20)

0.2284 (5.80)

0.0688 (1.75)

0.0532 (1.35)

SEATING

PLANE

0°-15°

0.0196 (0.50)

0.0099 (0.25)

0.0098 (0.25)

0.0075 (0.19)

0.0500 (1.27)

0.0160 (0.41)

× 45°

SEE DETAIL

ABOVE

0°- 8°

PRINTED IN U.S.A.

–20–

REV. A

Loading...

Loading...