Page 1

µ

ONE TECHNOLOG Y WAY • P. O . BO X 9106 • NORWOOD, MASSACHUSETTS 02062-9106 • 781/329-4700

USING THE ADXL202 ACCELEROMETER AS A MULTIFUNCTION SENSOR

(TILT , VIBRATION AND SHOCK) IN CAR ALARMS

by Harvey Weinberg and Christophe Lemaire

By using an intelligent algor ithm, the ADXL202 (±2 g dual axis accelerometer) can serve as a low

cost, multifunction sensor for vehicle security systems, capable of acting simultaneously as a

shock/vibration detector as well as a tilt sensor (to detect towing or jacking up of the car). The

accelerometer’s output is passed through two parallel filters. A bandpass filter to extract

shock/vibration information, and a low pass filter to extract tilt information. This application note

describes the basics of such an implementation.

INTRODUCTI O N

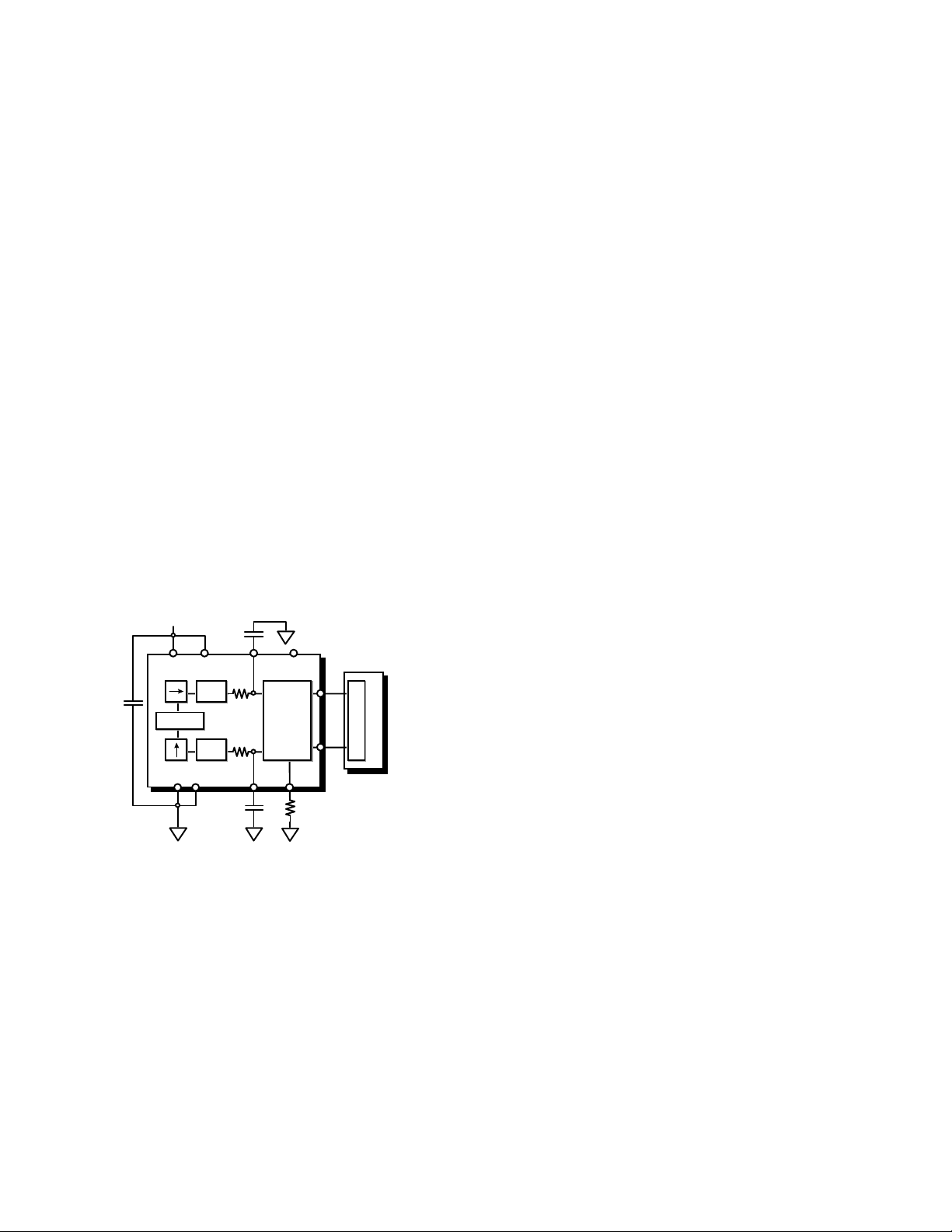

The ADXL202 is a low cost, low power, com plete

dual axis accelerometer with a measurement

g

range of ±2

. The ADXL202 outputs analog and

digital si gnals proportional to acceleration in each

of t h e s en si ti v e axes ( s ee Figu r e 1 ) .

+2.7V TO 5.25V

C

DEMOD

DEMOD

X

DD

R

FILT

32kΩ

R

FILT

32kΩ

Y

FILT

VDDV

X SENSOR

C

DC

OSCILLATOR

Y SENSOR

X

FILT

ADXL202

MODULATOR

C

Y

DUTY

CYCLE

(DCM)

T2COM

SELF TEST

R

SET

X OUT

Y OUT

C

O

U

P

N

T

E

R

Figure 1. ADXL202 Block Diagram

Currently automotive security systems use

shock/vibration sensors to detect collision

or forced intrusion into the car. Typically, these

sensors are based on magneto-inductive sensing.

Sensors of this type generally have adequate

sensitivity, but fall short in other areas. Often

a fair am ount of signal conditi oning and trim ming

is required between the shock sensor and

microcontroller due to variations in magnetic

material and Hall effect sensor sensitivity

and their frequency response is fairly

unpredictable due to inconsistency in mounting.

In addition such sensors have no response

to gravity-induced acceleration, so they are

incapable of sensing inclination (a static

acceleration). Tilt sensing is the most di rect way

of detecting if a vehicle is being jacked up, about

to be towed, or being loaded onto a flatbed truck.

Some of the most common methods of car theft

today.

The ADXL202 is a true accelerometer, easily

capable of shock/vibration sensing with virtually

no external signal conditioning ci rcuit ry. Since the

ADXL202 is also sensitive to static (gravitat ional)

acceleration, tilt sensing is also possible. Tilt

sensing requires a very low noise floor which

usually necessitates restricting the bandwidth of

the accelerometer, while shock/vibration sensing

requires wide bandwidth. These conflicting

requirements may be met using clever design

techniques.

PRINCIPLE OF O PERATIO N

The ADXL202 is set up to acquire acceleration from

0 to 200 Hz (the maximum frequency of interest).

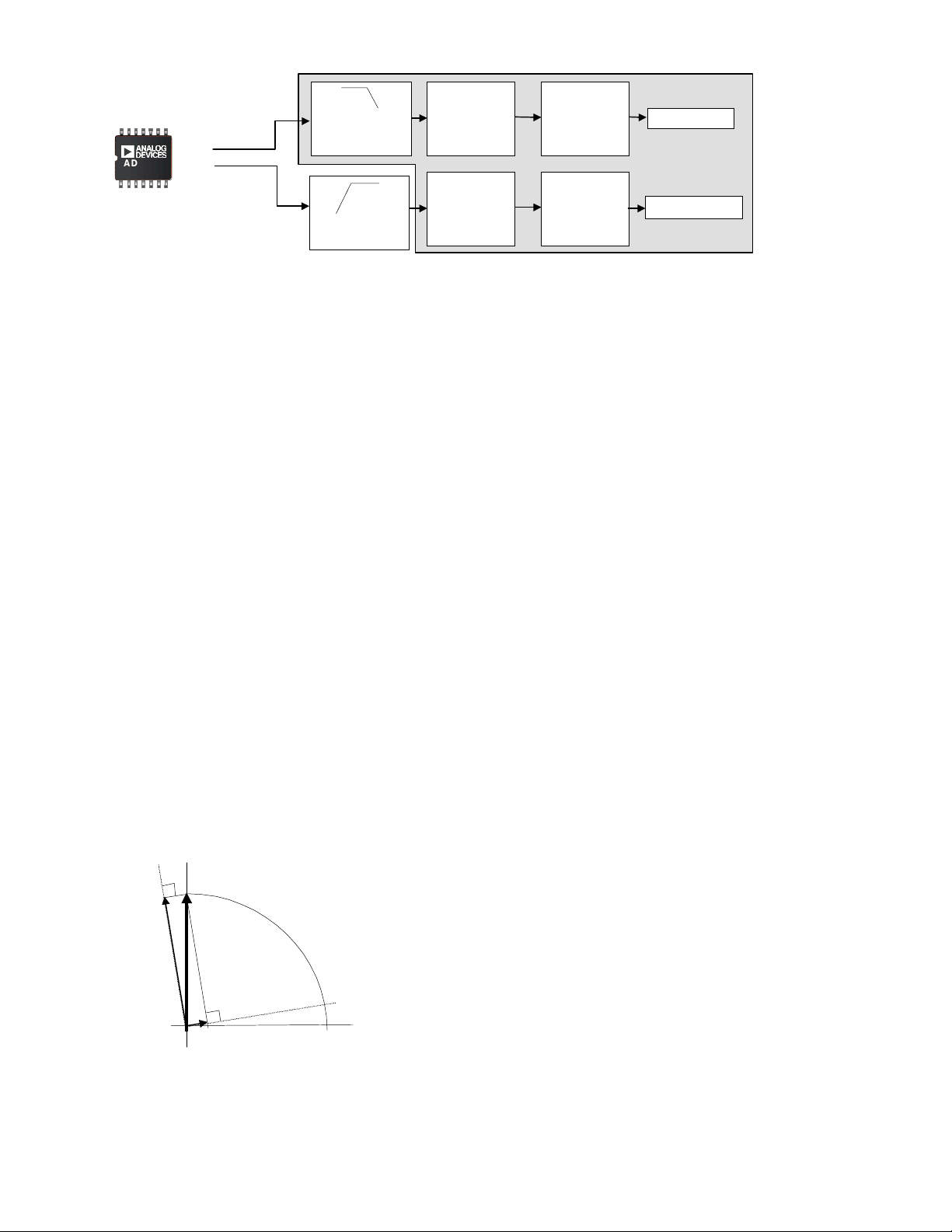

Figure 2 shows a block diagram of the system. The

accelerometer’s output is fed into two filters; a low

pass filter with a cor ner frequency at 12.5 Hz used to

lower the noise floor sufficiently for accurate tilt

sensing, and a band pass filter t o m i nim i ze the noise

in the shock/vibration pass band of int erest. The l ow

pass filtered (tilt ) output then goes to a differentiator

(described in the Tilt Sensing section) where the

determination is made as to whether the

accelerometer actually sensed tilt or some other

event such as noise or temperature drift. Then an

auto-zero block performs f urther signal processing to

reject temperature drift. The band pass filtered

output goes to an integrator (described in the

8/27/98 Rev. A

Page 2

ADXL202

200 Hz Low

Pass Filtered

Digital Output

12.5 Hz L ow P ass

Filter (Samples

Averaging)

Differentiator

Auto-Zero

Recalibration

Tilt Alarm

Low Cost

Analog Output

10 Hz High Pass

Analog Filter

Figure 2. Shock and Tilt Sensing Using the ADXL202

Shock Sensing section) that m easures vibrational

energy over a small period of time (40 ms).

A decision as to whether or not to set off the

alarm may then be made by the microcontroller.

Most of these tasks are most easily im plemented

in the digital domain and require very little

computati onal power.

Since the two measurements (shock/vibrati on and

tilt) are basically exclusive and only share

a common sensor, their respective signal

processing tasks will be described separately.

TILT SENSING

FUNDAMENTALS

The alarm system must detect a change in tilt

slow enough to be the result of the vehicle being

towed or jacked up, but must be immune

to temperature changes and movement due

to passing vehicles or wind. Note that the

ADXL202 is most sensitive to tilt when its

sensitive axes are perpendicular to the force of

gravity, i. e., parallel to t he earth’s surface. Figure

3 shows that the change in projection of a 1

gravity-induced acceleration vector on the axis of

sensitivity of the accelerometer will be more

significant if the axis is tilted 10 degrees from the

horizontal than if it is tilted by the same amount

from the vertical.

Axis of

Sensitivity

1 g

Axis of

Sensitivity

Figure 3. Tilt Sensitivity

Analog to

Digital

Converter

g

Integrator

Shock Alarm

However, the car may not always be level when

the alarm is activated, and while the zero

offset can be recalibrated for any initial

inclination, effectively the farther from the

horizontal the axes of sensitivity are, the less

sensitive the system will be to tilt (see ADXL202

datasheet, page 9). In most cases, this should

not be of great concern, since the sensitivi ty only

g

declines by about 2.5 m

per degree of tilt when

inclination goes from zero (horizontal) to thirty

degrees of tilt. Nevertheless, installation

guidelines should recommend that the tilt sensing

module containi ng the accelerometer be mounted

such that the axes of sensitivity be as level as

possible.

IMPLEMENTATION

In general we are interested in knowing if

the inclination of the car has changed more than

±5 degrees from it’s inclination when initially

parked. When the car is turned off, a

measurement of the car’s inclination is made.

If the car’s inclinat ion is changed by more than ±5

degrees, an alarm is tri ggered. Alternatively, the

rate of change of tilt may be evaluated and if

its absolute value is above 0.2 degrees per

second for several seconds the alarm may be

triggered.

Each technique has certain advantages. The

former algori thm is better at false alarm r ejection

due to jostling of the car, while the rate of change

algorithm may be set up to react more quickly.

Algorithms using a combination of both

techniques may be used as well. It is left

to the reader to decide which technique is best

for their application. While all of the concepts

presented here are valid for both algorithms,

for consistency this application note will describe

the former (absolut e incli nation) algor ithm .

For the purpose of the following discussion,

we will assume a less than perfect tilt sensitivity

g

for the accelerometer of 15 m

or 75 m

g

for 5 degrees. The ADXL202 will be

per degree of tilt ,

set up to have a bandwidth of 200 Hz so that

vibration may be detected. A 200 Hz bandwidth

will result in a noise floor of:

g

Page 3

g

Noise = 500 µ

Noise = 8.5 m

or 34 m

peak to rms ratio of 4:1), well within our 75 m

requirement. For reliability purposes, we would

like to have a noise floor about 10 times lower

than this, or around 8 m

a car takes at least a few seconds, we are free

to narrow the bandwidth to lower the noise floor.

An analog or digital low pass filter may be used,

but since low pass filteri ng in the digital domain i s

very simple, it is the preferred method. By

taking the average of 16 samples we reduce the

effective bandwidth to 12.5 Hz (200 Hz/16

samples). The resulting noise performance is

approximately 8.7 m

to our target.

Lowering the noise floor even further, by taking up

to 128 samples for example, would result i n about

3 m

to easily detect the 15 m

resulting from a change in tilt of less than a

degree.

The t ypi cal zero

ADXL202 is 2 m

tilt alarm could be as low as 15 m

conceivable that temperature drift alone would

cause a false alarm (a car parked overnight

could easily experience more than 7.5 °C

in ambient temperature change). Therefore we

will include a differentiator to reject temperature

drift.

In the event of the car being jacked up or lifted for

towing, we would expect the rate of change in tilt

to be faster than five degrees or 75 m

(or 1.25 m

acceleration is measured it is compared to the

previous reading. If the change is less than 1.25

mg per second we know that the change in

accelerometer output is due to temperature drift.

We can now add an auto-zero block that adjusts

our “zero g” reference (that is the static

acceleration sensed when the car was initially

parked) to compensate for zero

temperature.

SHOCK SENSING

Generally for automotive shock/vibration sensing

we are interested in signals between 10 and 200

Hz. Since the response of the ADXL202 extends

from DC to 5 kHz, a band pass filter will have

to be added to remove out of band signals. This

band pass filter is most easily implemented in

the analog domain (Figure 4 shows a simple 10

Hz high pass filter). When coupled with the 200

g

peak-to-peak of noise (using a peak-to-

g

peak-to-peak of noise, which would allow us

√Hz x (√200 x 1.5) rms

g

rms

g

. Since towing

g

peak-to-peak, close enough

g

of static acceleration

g

drift due to temperature for the

g

/°C. Since our trigger point for a

g

, it is

g

per minute

g

per second). Each time the

g

drift due to

Hz low pass filter (from Xfilt and Yfilt on

the ADXL202), a 10 to 200 Hz bandpass filter is

realized.

g

0.15 µF

100 kΩ

Figure 4. 10 Hz High Pass Filter

Whi le analog bandpass fi ltering i s very sim pl e and

requires no software overhead from the

microcontroller, it does necessitate having an

analog to digit al converter. Today, even low cost

microcontrollers can commonly be found,

integrating an A to D converter on board.

Bandpass filtering in the digital domain may be

more effective, but may require a more powerful

processor than one normally finds in automobile

security systems. There are several methods for

implementing band pass filters in the digital

domain. Specific recommendations will not be

given here since processor selection will influence

what method will be most efficient.

Whether a digital or analog bandpass filter is

used, the Nyquist criteria for signal sampling

must be satisfi ed. That is that we must sampl e at

at least twice the maximum frequency of int erest.

Sampling at 400 Hz (for our 200 Hz pass band)

gives us one sample every 2.5 ms. Our very

simple software integrator will take the sum of the

absolute value of 16 samples and evaluate i f there

is suffici ent energy in that 40 ms period of tim e to

warrant setting off the alarm (i. e. is the sum of 16

samples greater than some set point). It is

assumed that no events will be missed in 40 ms.

DESIGN TRADE-O FFS

The ADXL202 has digital (Pulse W idt h Modulated)

g

as well as analog (312 mV/

either output may be used. Using the PWM

interface for tilt sensing is recommended for two

reasons:

1. We are interested in very small acceleration

signals (on the order of 3 m

correspond to approximately .94 mV.

Probably not resolvable by the on board A to

D converter of any microcontr oller likely to be

used in this applicat ion. The resoluti on of the

pulse width modulator of the ADXL202 is

around 14 bits. Sufficient for resolution of 3

g

acceleration signals.

m

) outputs. In theory,

g

). This would

Page 4

2. All signal processing will be done in the digital

domain.

An analog interface for the shock/vi bration sensor

is recommended since, as previously mentioned,

bandpass filtering in the digital domain may be

beyond the capability of many microcontrollers.

In addition using the PWM interface to acquire

200 Hz bandwidth requires that the PWM

frequency be at least 4 Khz. 10 bit resolution

implies that the microcontroller have a timer

resolution of approximately 250 ns. Once again,

probably beyond the capability of most

microcontrollers.

Loading...

Loading...