Isolated, Field Configurable Analog Input

FEATURES

Single-channel isolated signal-conditioning modules.

Accepts outputs from Thermocouple, millivolt, volt and

current signals.

Complete microcomputer-based data acquisition systems.

Can be remotely reconfigured for various sensor types and

input ranges.

APPLICATIONS

Process Monitoring & Control

Test Stand Automation

Machine Monitoring

Material Testing

Remote Energy Mangement

Laboratory Data Acquisition

PRODUCT OVERVIEW

The 6B Series delivers sensor-to-host signal-conditioning for

remote applications. Software-configurable for a wide variety of

sensor types, including: analog input, analog output, and digital

I/O, the 6B Series is intended for remote data acquisition,

machine monitoring, remote energy management and process

monitoring and control applications.

Including transformer-based isolation, ranging, linearization,

A/d conversion and RS-232C/RS-485 serial communication for

up to 256 channels per serial port, the 6B Series modules and

boards are a complete, low-cost interface between computers

and analog signals.

All 6B Series input/output modules are fully encapsulated and

identical in pin-out and size, facilitating their ability to be mixed

and matched with all other 6B Series modules on the same

backplane. The 6B Series is fully rated over the industrial

temperature range of -25

Each 6B Series module and board is a complete

microcontroller-based process monitoring and control system,

with all calibration, address and linearizing parameters stored in

non-volatile memory. Being microcontroller-based, 6b Series

o

C to +85oC.

6B11 / 6B11HV

modules can be configured for various sensor types, including

RTD and thermocouple, and a wide variety of input ranges. This

reduces the number of different modules that need to be used

in a given application and carried in inventory.

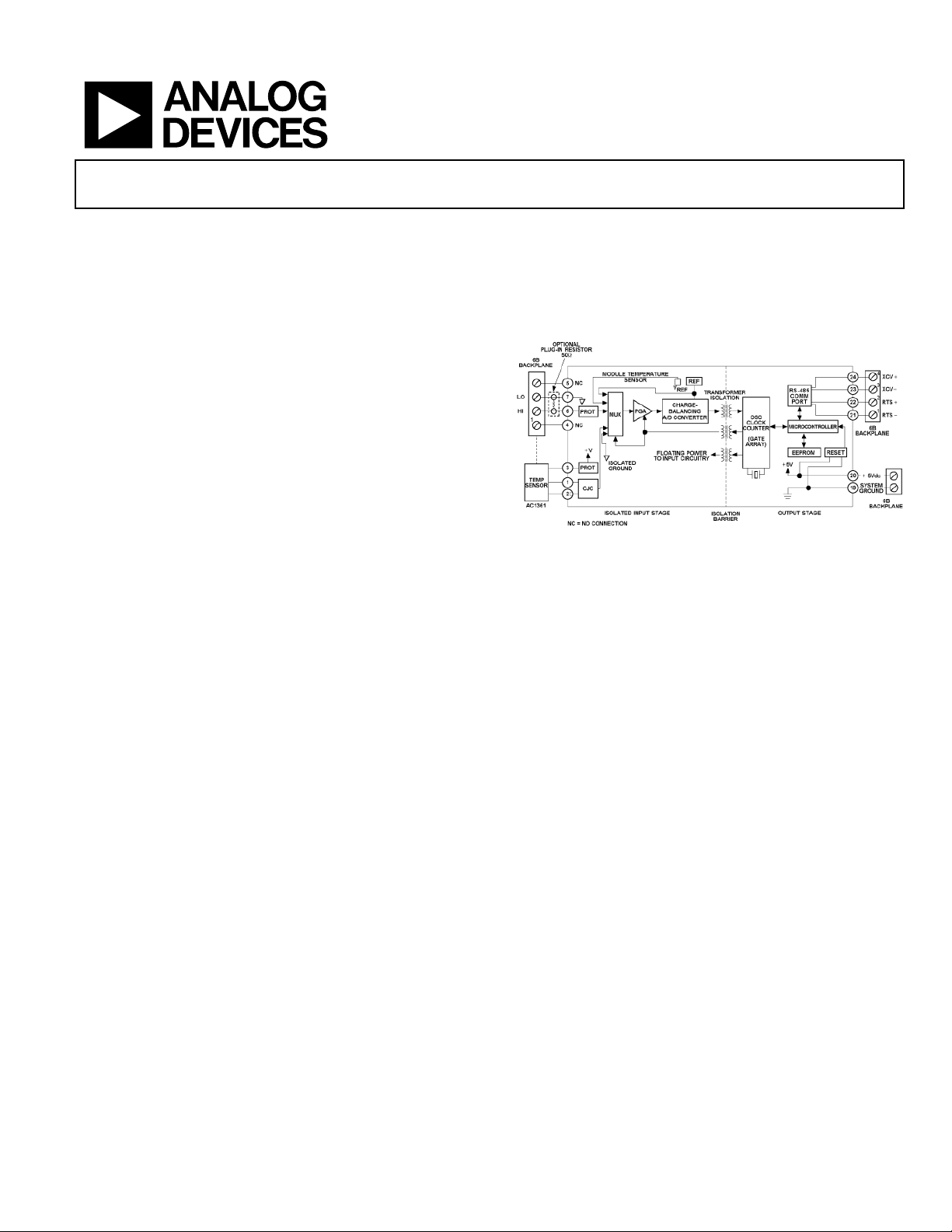

FUNCTIONAL BLOCK DIAGRAM

Figure 1. 6B11 & 6B11HV Functional Block Diagram

Designed for industrial applications, the 6B Series modules

incorporate transformer-based isolation with surface-mount

manufacturing technology – providing increased reliability at

low cost. The compact, rugged 6B Series analog modules can be

mixed and matched on a 16-channel backplane for high density,

remote process monitoring and control.

Communications between backplanes, modules and host is in

ASCII over an RS-232C link or RS-485 bi-directional serial bus.

Circuitry to convert RS-232C to RS485 is built into the 6B

backplane. Baud rates are software programmable, with speeds

up to 19.2 K Baud.

The 6B Series digital subsystem communication is compatible

with the overall 6B Series communication protocol. Each digital

I/O board can be configured for its address, baud rate and

checksum status. Connection to the 16 and 24-channel solid

state relay backplanes is by a 50-conductor ribbon cable. This

enables interfacing with input and outputs from 4 V to 240 V.

Power control modules are also available that can switch up to

3A and come with a variety of ratings for low voltage DC up to

280 VAC.

Rev. 0

Information furnished by Analog Devices is believed to be accurate and reliable.

However, no responsibility is assumed by Analog Devices for its use, nor for any

infringements of patents or other rights of third parties that may result from its use.

Specifications subject to change without notice. No license is granted by implication

or otherwise under any patent or patent rights of Analog Devices. Trademarks and

registered trademarks are the property of their respective companies.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700

Fax: 781.326.8703 © 2004 Analog Devices, Inc. All rights reserved.

www.analog.com

GENERAL DESCRIPTION

The 6B11 and 6B11HV are single-channel isolated signalconditioning modules which accept the outputs from

thermocouple, milli-volt, voltage, and process current signals.

Unlike conventional signal conditioners, the 6B11 and 6B11HV

are complete microcomputer-based data acquisition systems. A

major advantage of the onboard microcontroller is its ability to

be remotely reconfigured for various sensor types and input

ranges.

Synchronized Sampling – The synchronized sampling

command allows data to be sampled simultaneously from all

6B11, 6B11HV, 6B12, 6B12HV modules and all 6B50 boards in a

6B Series system. Each module or board stores the data in a

separate register within its microcontroller and can access the

data with a separate command.

Software Configuration – The 6B11 and 6B11HV linearize and

compensate J, K, T, E, R, S and B thermocouples. Additionally,

these modules also digitize milli-volt and voltage ranges from

6B11 / 6B11HV

15mV to +5V as well as 0 to +20mA process current inputs.

+

Software is used to configure the 6B11 and 6B11HV modules

for address, input range, baud rae, data format, checksum status

and integration time. All programmable parameters are stored

in the nonvolatile memory of the module.

Each analog input signal is conditioned and scaled by a

programmable-gain amplifier and digitized by a 16-bit

integrating converter under microprocessor control. The

digitized value is passed serially across a magnetically isolated

barrier (1500 V rms – Model 6B11, 2500 V rms – Model

6B11HV) and clocked in by a custom controller chip. The onboard microprocessor then converts the data into engineering

units as determined by the channel parameters. In between

conversions, the microprocessor auto zeros the offset and gain

by monitoring the on-board temperature and compensating for

reference drift. Cold junction compensation (CJC) is also

performed at this stage. The 6B11 and 6B11HV use

compensation factors to ensure the highest accuracy possible.

.

.

Figure 2

Rev. 0 | Page 2 of 8

6B11 / 6B11HV

Models 6B11 and 6B11HV

Range Description

(Software Configurable)

±15 mV ±0.03 % FS ±0.06 % FS ±0.02 % FS

±50 mV ±0.015 % FS ±0.04 % FS ±0.01 % FS

±100 mV ±0.0055 % FS ±0.03 % FS ±0.005 % FS

±500 mV ±0.005 % FS ±0.03 % FS ±0.002 % FS

±1 V ±0.005 % FS ±0.03 % FS ±0.005 % FS

±5 V ±0.005 % FS ±0.03 % FS ±0.0015 % FS

±20 mA ±0.008 % FS2 ±0.03 % FS2 ±0.005 % FS

J Thermocouple, 0°C to 760°C ±0.4°C ±0.75°C ±0.14°C

K Thermocouple, 0°C to 1000°C ±0.5°C ±0.75°C ±0.22°C

T Thermocouple, -100°C to +400°C ±0.5°C ±0.75°C ±0.2°C

E Thermocouple, 0°C to +1000°C ±0.5°C ±0.75°C ±0.2°C

R Thermocouple, +500°C to +1750°C ±0.63°C ±1.5°C ±0.3°C

S Thermocouple, +500°C to +1750°C ±0.62°C ±1.5°C ±0.4°C

B Thermocouple, +500°C to +1800°C ±1.2°C ±2.0°C ±0.7°C

1

Accuracy is given for 6B11 and 6B11HV module only. When measuring thermocouple signals, the CJC temperature sensor error should

be added to the module accuracy to compute the system accuracy. The AC1361 CJC temperature sensor is provided on each channel of

the 6B Series backplanes.

2

Does not include the error of the current to voltage input resistor, Model AC1381.

Accuracy1

(Typical)

Accuracy1

(Maximum)

Noise

(Peak-to-Peak)

6B11 and 6B11HV Specifications

(typical @ +25°C and Vs = +5 V dc)

Description Model 6B11 and 6B11HV

Inputs, Software Selectable

Thermocouple Types J, K, T, E, R, S, B

mV ±15 mV to ±500 mV (Refer to Model Table)

Volt ±1 V; ±5 V

Current Range ±20 mA

Communications

Protocol RS-485

Baud Rates, Software Selectable 300K, 600K, 1.2K, 2.4K. 9.6K, 19.2K

Accuracy

Initial @ +25°C Refer to Model Table

Input Offset vs. Temperature

Span vs. Temperature ±3 ppm/°C (±25 ppm/°C, maximum)

Cold Junction Compensation1

Initial Accuracy @ +25°C ±0.25°C (±0.75°C, maximum)

Accuracy, +5°C to +45°C ±0.5°C (±0.0125°C/°C)

±0.3µ V/°C

Rev. 0 | Page 3 of 8

Loading...

Loading...