AN-830

APPLICATION NOTE

One Technology Way • P.O. Box 9106 • Norwood, MA 02062-9106, U.S.A. • Tel: 781.329.4700 • Fax: 781.461.3113 • www.analog.com

Factors Affecting Sensor Response

by Susan Pratt

INTRODUCTION

Capacitance sensing has the potential to replace current user

input mechanisms in consumer devices. Products as diverse as

cell phones, digital cameras, MP3 players, and other portable

media players are all suitable for implementing capacitance

sensing. Capacitance sensing gives the user an interface with

greater sensitivity and control than standard mechanical input

technologies.

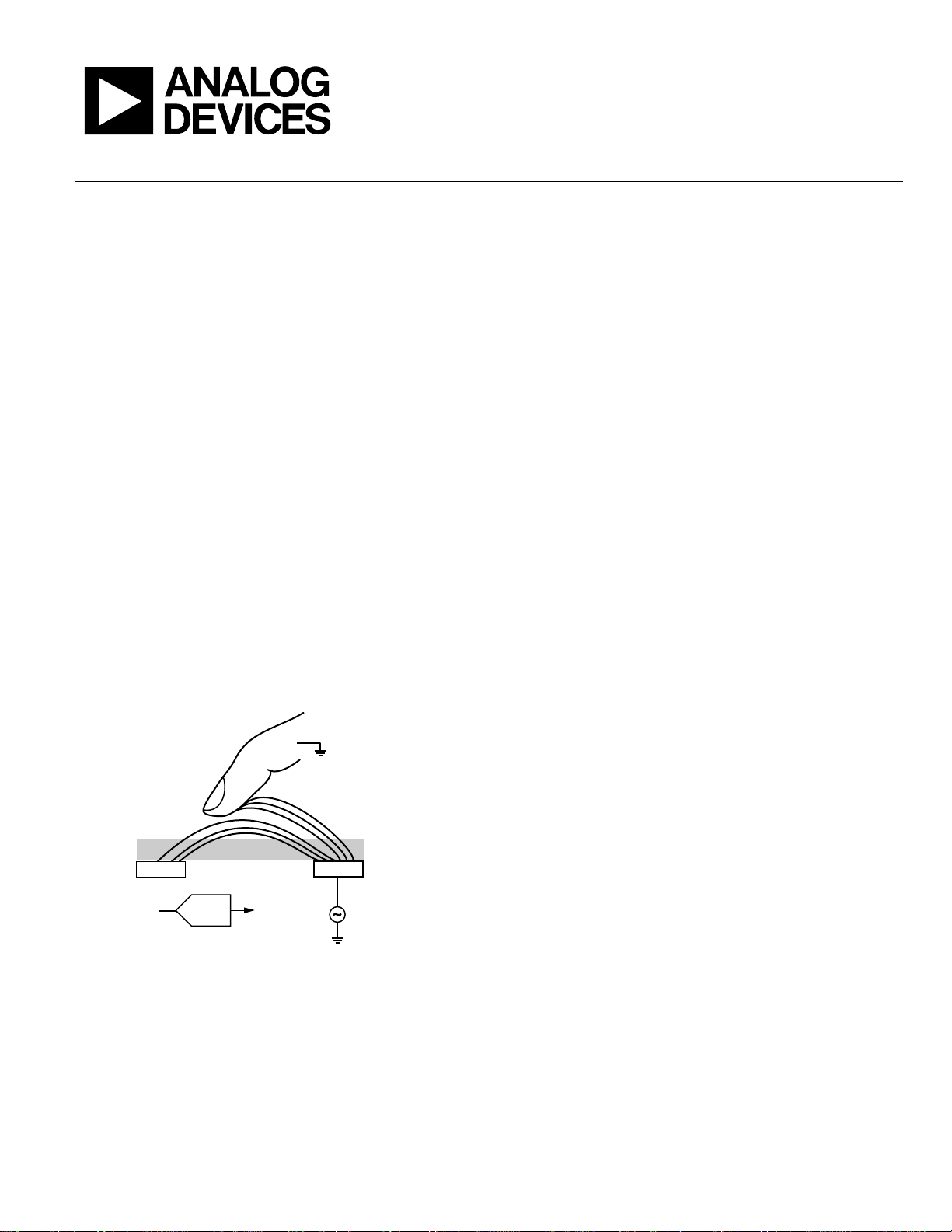

Analog Devices’ capacitance sensing solution has three

components: the AD7142 capacitive-to-digital converter IC,

sensors on the PCB, and software to communicate with the

AD7142. The solution consists of an excitation source

connected to a transmitter, which generates a capacitive field to

a receiver. The capacitive field lines measured at the receiver are

translated into the digital domain by a Σ-Δ analog-to-digital

converter. The total capacitance measured at the receiver

decreases when a grounded object, such as a finger, comes close

to the induced capacitive field. The excitation source and Σ-Δ

CDC are implemented on the AD7142, while the transmitter

and receiver are constructed on the sensor PCB.

The sensor PCB is glued to the underside of the case or

covering of the finished product. The capacitive field lines

extend above the sensor PCB for about 4 mm. The field also

extends above any covering material over the sensor PCB. One

advantage of this sensor arrangement is that the user is never in

contact with the sensor PCB itself, so there is no wear on the

sensor.

The case or covering material housing consumer products such

as MP3 players, digital still cameras, and handsets, is made from

a variety of materials. Materials such as plastic or glass are

suitable covering materials for use with capacitance sensing;

metal cannot be used.

The response of the capacitance sensor depends on three

factors:

• The size and type of the sensor element

• The size of the object touching the sensor

• The thickness and type of the covering material

Each of these factors affects the magnitude of change measured

by the CDC when the sensor is touched. If the change in CDC

output is very small, then it becomes difficult to differentiate

between the sensor-touched and the sensor-not-touched

conditions. This application note details how each of these

factors affects the sensor response and can be used as a

guideline when deciding the size and form of the sensor

RX

16-BIT

DATA

Σ-Δ

ADC

Figure 1. Capacitance Sensing

TX

EXCITATION

SIGNAL

240kHz

05849-001

configuration, as well as the covering plastic specification.

Rev. 0 | Page 1 of 8

AN-830

TABLE OF CONTENTS

Introduction ...................................................................................... 1

Table of Contents.............................................................................. 2

Revision History ........................................................................... 2

Factors Affecting Sensor Response ................................................ 3

Sensor Element ............................................................................. 3

Object Touching the Sensor........................................................ 3

Covering Material......................................................................... 3

Button Sensor.................................................................................... 4

Button Sensor Response .............................................................. 4

Slider Sensor...................................................................................... 5

Slider Sensor Response ................................................................ 5

Recommendations............................................................................ 6

REVISION HISTORY

12/05—Revision 0: Initial Version

Rev. 0 | Page 2 of 8

AN-830

FACTORS AFFECTING SENSOR RESPONSE

SENSOR ELEMENT

The size of the sensor element determines the size of the

capacitive field induced between the transmitter and receiver.

A smaller sensor element has a smaller field to interfere with

than a larger sensor element. If the sensor element is too small,

there is not a sufficient change in capacitance measured by the

CDC when the sensor is touched.

The type of sensor element is also important. For a button

sensor, only on/off or touch/no touch information is required.

A button can tolerate some loss of sensor response, as long as it

is possible to determine if the button is touched or not. A slider

sensor, however, must output position data relating to the

length of the slider. A reduction in sensor response for a slider

reduces the number of CDC codes that are used to describe a

full traverse of the slider, thus affecting the resolution and

accuracy of the slider sensor position data.

OBJECT TOUCHING THE SENSOR

For all applications, the object touching the sensor is a finger or

hand, which is naturally grounded. However, the size of the

object touching the sensor is not constant; finger size can vary

from person to person, or indeed the same person can use

different fingers at different times to activate the sensors.

Consumer devices need to be designed for a range of finger

sizes, from small to large, to ensure that everyone can operate

the device successfully.

Any grounded object can activate Analog Devices’ sensors. For

this application note, a grounded metal probe was used to

simulate a finger during the data gathering experiments. Three

probes of different sizes were used to simulate different finger

sizes: 5 mm, 10 mm, and 15 mm diameter probes.

COVERING MATERIAL

The properties of the material covering the sensor must be

looked at closely. The capacitive field extends about 4 mm to 5

mm above the sensor PCB. This field must extend above any

covering material in order for the sensor to work. The material

must not absorb too much of the capacitive field. Some types of

plastic are more conductive than others, and so more of the

capacitive field gets through.

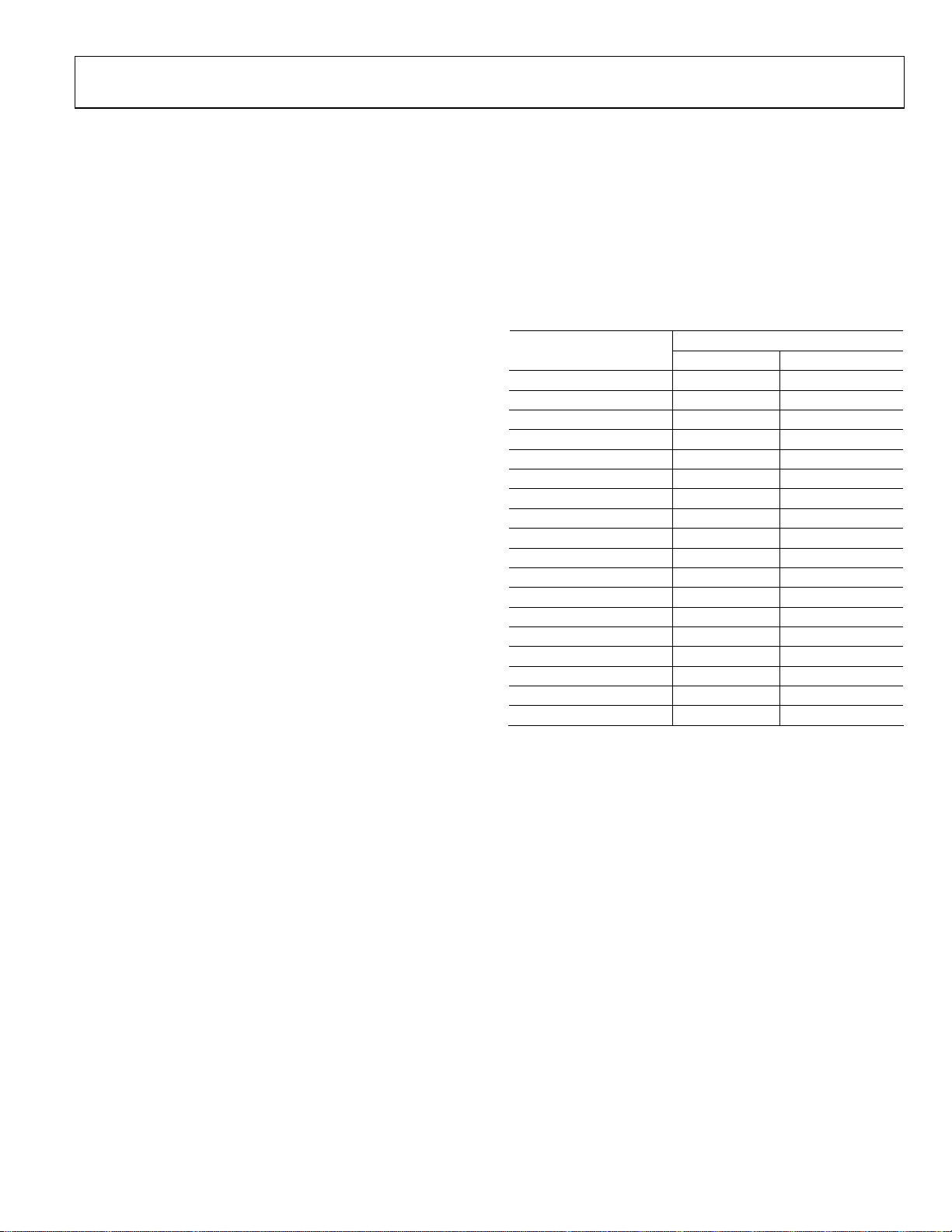

factor for a variety of plastic polymers. The dissipation factor is

a measure of how lossy the material is. The lower the dissipation

factor, the more of the capacitive field passes through the

material.

Table 1.

Polymer Material

LDPE 0.15 0.08

HDPE 0.24 .20

PP 0.4 0.5

PVC-plasticized 80 120

PS 0.1 to 0.4 0.05 to 0.4

ABS 3 to 8 2 to15

PMMA 40 to 60 4 to 40

POM 5 5

PTFE 0.2 0.2

PCTFE 1 20

PC 0.7 10

PET 2 20

PI 2 5

PUR-linear 120 70

PUR-thermoset 50 50

PUR-thermoplas 30 60

CAB 6 21

Silicone 5 to 13 7

Glass is also a suitable covering material. However, metal

cannot be used as a covering material

For this application note, the sensor PCBs were covered in ABS

that ranged in thickness from 0.5 mm to 4 mm.

Tabl e 1 shows the dissipation

Dissipation Factor (x 10-3)

@50 Hz @1 MHz

Rev. 0 | Page 3 of 8

AN-830

BUTTON SENSOR

A button sensor is the simplest sensor element to implement.

The button can be circular, square, or a custom shape. A button

sensor can be any size, from 5 mm × 5 mm square upwards.

Figure 2 shows a typical button sensor design.

05849-002

Figure 2. Button Sensor

BUTTON SENSOR RESPONSE

A10 mm × 10 mm square button sensor was used to gather

typical button sensor response data. To simulate a user’s finger,

grounded metal probes of various sizes were used to activate the

button. The sensor PCB was placed under plastic varying from

0.5 mm thick to 4 mm thick. The sensor response is defined as

the change in CDC output code between the sensor-touched

condition and sensor-not-touched condition.

The measured output from the CDC is shown in

data shows clearly that the response from the sensor decreases

with respect to increasing plastic thickness. The response from

the button sensor becomes insufficient when the CDC output

falls below 500 codes. At this point, it becomes difficult to

differentiate between a true sensor activation and noise in the

CDC codes. A 10 mm button can be successfully used with up

to 4 mm plastic on top. For smaller sensors, the response is less

Figure 3. The

than that of larger sensors. For a 5mm button, the sensor

response could fall to about 500 codes. For 5 mm buttons, it is

recommended that the covering plastic be 2 mm or less to

ensure proper sensor operation.

Also noteworthy is the effect the probe size has on the sensor

response. A small probe can only decrease the measured

capacitance at the receiver by a small amount. This trend holds

for finger size also—the smaller the finger, the smaller the

response from the sensor.

14000

12000

10000

8000

6000

4000

CDC OUTPUT CODE CHANGE

2000

0

15mm PROBE

10mm PROBE

5mm PROBE

0.5 4.03.53.02.52.01.51.0

PLASTIC THICKNESS (mm)

Figure 3. Button Sensor Response

05849-003

Rev. 0 | Page 4 of 8

AN-830

SLIDER SENSOR

A slider sensor element is useful for scrolling through menus, or

lists of data, quickly and easily. Slider sensors should be greater

than 25 mm in length and greater than 5 mm in width to give

sufficient response to implement scrolling functions. The

maximum length recommended is about 45 mm.

Figure 4

shows a typical slider sensor design.

05849-004

Figure 4. Slider sensor

SLIDER SENSOR RESPONSE

The slider has two responses that can be measured: the

activation response (is the slider touched?) and the position

data output or scrolling movement response. The data gathered

for this application note used a slider of 12 mm in width and

28 mm in length. To simulate a user’s finger, grounded metal

probes of various sizes were used to touch the slider. The sensor

PCB was placed under plastic of thickness varying from 0.5 mm

thick to 4 mm thick. Both the slider activation and slider

position response were measured, with the slider response

being defined as the change in CDC codes between the sensor

touched and sensor not touched conditions.

Figure 5 shows data gathered from the slider to measure the

activation level. The data clearly shows that the thicker the

plastic, the smaller the response from the sensor. The activation

measurement tells us when the slider has been touched. In this

way, the slider’s functionality is similar to a button’s on/off

functionality and can tolerate some degree of reduction in the

sensor response.

Figure 6 shows the response of the slider while scrolling. Again,

the same trends are clear: the best response from the sensor is

achieved using thin covering plastic and a large probe. The

scrolling or position data response from the slider is not

tolerant to reductions in sensor response. If the sensor response

is good, the difference in codes for the slider is 14000; this

means that there is a large code change while scrolling the

length of the slider. When the sensor response falls, there is a

much smaller change in code while scrolling the length of the

slider. This translates into less resolution or accuracy in the

scroller position data.

8000

7000

6000

5000

4000

3000

2000

CDC OUTPUT CODE CHANGE

1000

0

0.5 4.03.53.02.52.01.51.0

15mm PROBE

10mm PROBE

5mm PROBE

PLASTIC THICKNESS (mm)

Figure 5. Slider Sensor Activation Response

05849-005

16000

14000

12000

10000

8000

6000

4000

CDC OUTPUT CODE CHANGE

2000

0

15mm PROBE

10mm PROBE

5mm PROBE

0.5 4.03.53.02.52.01.51.0

PLASTIC THICKNESS (mm)

Figure 6. Slider Sensor Position Data Response

05849-006

Rev. 0 | Page 5 of 8

AN-830

RECOMMENDATIONS

To achieve the best response from any sensor element, here are

a number of recommendations.

• The covering plastic should have a maximum thickness of

2 mm. This is a general guideline, based on measurements

taken with ABS. Other materials may tolerate thickness

above or below this. Because sensor size and finger size

also affect the sensor response, it may be possible to alter

the design to operate at plastic thicknesses above 2 mm.

• Sensor elements should be as big as the design allows.

When designing the sensor elements, they should always

meet the minimum size requirements set for that sensor

type.

• Thought should be given to the target market to ensure

that the sensor responds well to the upper and lower

distributions of finger size in that market. If designing a

toy, then the sensor should be designed to operate best

using a child’s average finger size.

For further information on Analog Devices’ capacitance

sensing, go to www.analog.com.

Rev. 0 | Page 6 of 8

AN-830

NOTES

Rev. 0 | Page 7 of 8

AN-830

NOTES

©2005 Analog Devices, Inc. All rights reserved. Trademarks and

registered trademarks are the property of their respective owners.

AN05849-0-12/05(0)

Rev. 0 | Page 8 of 8

Loading...

Loading...