ANALOG DEVICES AN-776 Service Manual

AN-776

HSYNC

BAIN

C

A0

GAIN

C

SOGIN

C

RAIN

C

AD9981

BAIN

C

HSYNC

A0

GAIN

C

SOGIN

C

RAIN

C

AD9981

VDD

VSOUT

VSOUT

10k

L

L

L

APPLICATION NOTE

One Technology Way • P.O. Box 9106 • Norwood, MA 02062-9106 • Tel: 781/329-4700 • Fax: 781/461-3113 • www.analog.com

Dual AD9981 Design Guideline to Achieve UXGA Resolutions

by Del Jones

INTRODUCTION

Pixel clock speeds in excess of 110 MHz can be achieved

with the AD9981 by using a dual chip “ping - pong”

conguration. A dual chip solution is different from an

alternate pixel sampling solution in that full refresh rates

can be maintained.

There are many ways to implement a dual AD 9981

design. This application notes serves to make the user

aware of the considerations that should be weighed

when implementing this conguration. Among the variables are layout and routing constraints, clock selection,

graphics controller requirements, and maximum speed

requirements.

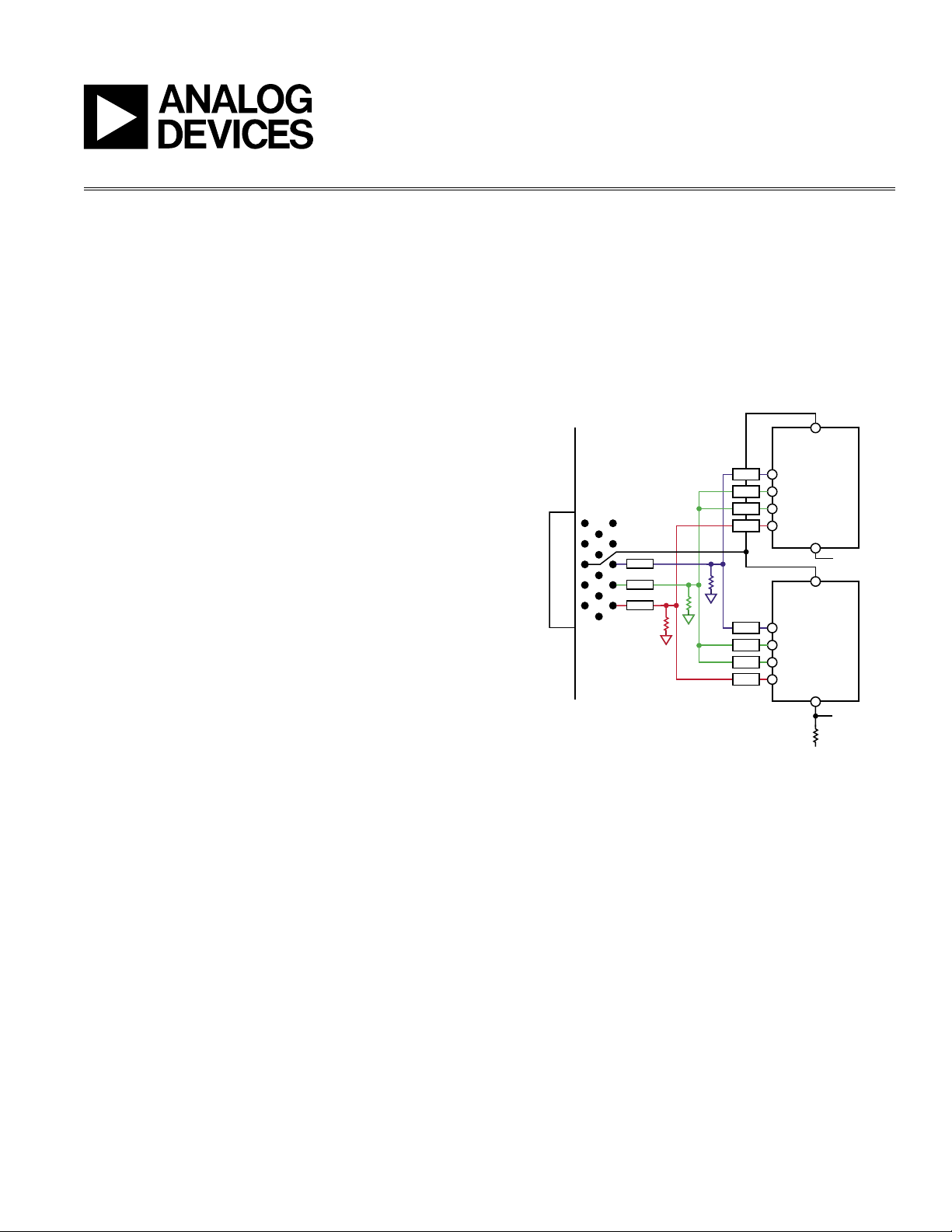

Analog Input Layout and Routing

When laying out and routing the analog inputs (R, G, B,

and HSYNC), several factors should be considered. The

trace lengths of the R, G, and B inputs should be kept

as equal as possible, while also keeping the routes

direct (no zigzagging) to maintain equal propagation

delays. The branches to each of the AD9981’s analog

inputs should be kept as short as possible. The 75

terminators on the RGB inputs should be placed as close

to the branch junctions as possible. Lastly, each R, G,

and B branch requires its own coupling capacitor. These

considerations are illustrated in Figure 1.

Clock Source Selection

There are three methods that can be used for clocking

data. An external clock source can be used to clock

both AD9981s as well as the data latching device(s)

(graphics controller). This method requires external PLL

circuitry and special high speed clock layout and routing

considerations.

A second option is to use the PLL in chip 1 to drive chip 2.

This method would require chip 2 to be congured for

external clock operation, using the negative edge of

chip 1’s DATACK to sample the RGB data. This method

employs the most direct routing of HSYNC. The HSYNC

could be routed directly to chip 1, and then routed to

the second device. (Although the second device does

not use HSYNC to generate a clock, it is still needed

to provide a timing reference for other functions, such

as clamping.) The problem with this option is that it

causes difculty in setting the correct clock phase of

chip 2 because of the added propagation delay between

REV. 0

HSYNC and chip 1’s data clock output. It will also cause

ongoing clock phase difculty in chip 2 because of the

variability of chip 1’s data clock propagation delay over

time and temperature.

Figure 1. Analog Input Routing

The recommended method for clocking is to use the

PLLs in both chips . This method requires special at ten -

tion to HSYNC input layout, as shown in Figure 1. If very

careful attention is paid to keeping the branch lengths

identical (avoiding zigzagging), then the skew between

the two chips’ sampling clock and digital outputs will be

negligible.

Sampling Clock Inversion

All three clocking methods described earlier require

chip 2 to sa mpl e RGB dat a 180 out of ph ase with

chip 1. This can be achieved by using the phase adjustment control. The initial phase setting of chip 2 would

be offset 180 (nominally, 16 steps) from chip 1’s initial

phase setting. Using this method, the data output from

chip 2 will be shif ted by 1/2 pixel clock. This method

allows both chips to run their clocks at half of the

ef fective data rate. Chip 1 would capture odd data on

its sampling edge, while chip 2 captures even data on

its sampling edge (180 out of phase from chip 1).

AN-776

–3–

AN-776

REV. 0

The timing issues associated with data capture are

negligible if the capture device has separate capture

clocks for each data port (odd and even data). If only

one clock pin is available on the latching device (graphics

controller, ASIC, and so on) for both ports, it will be necessar y to invert the clock internal to the latching device.

This would be true unless the latching device has the

ability to capture data on either edge of the data clock.

Figure 2 illustrates the basic timing relation between the

incoming data pixels and the digitized output data for

both devices.

Clock Phase Adjustment

Although the internal clock delays should be the same,

each chip’s phase will need to be adjusted separately.

Phase differences between the two chips can come from

layout trace length variations in HSYNC or RGB inputs,

and from normal internal chip variations.

Since each chip is running at half speed, the phase

adjustment step sizes are doubled with respect to the

full speed clock. This results in 1/2 the number of useable

phase adjustment steps (16 instead of 32) since the

phase adjustment range will now cover two full speed

pixels rather than one.

It is recommended that the phase adjustment for the

two devices be performed independently since the

optimal phase setting for each device may not differ by

exactly 16 phase steps (for various reasons). To speed

the phase selection algorithm, a limited phase selection

process could be used on device 2 after the full process

is performed on device 1. If the optimal phase setting

(OPS1) is less than 16 on device 1, then it is reasonable to

expect that the optimal phase setting for device 2 (OPS2)

is OPS1 + 16 4 (wrap around if result is > 31). If OPS1

is ≥ 16 then OPS2 = OPS1 – 16 4 (wrap around if result

is < 0). Therefore, the second step of the phase selection

algorithm (for device 2) can be limited to those steps that

are expected to be the optimal setting.

Interpart Difference Adjustments

Dual ADC applications are sensitive to the differences

bet ween the t wo ADCs. These differences can come

from gain, offset, and linearity.

Gain and Offset

Dual ADC applications are highly sensitive to gain and

offset errors between the two chips. Any dif ference

between odd and even pixels is highly visible. Therefore,

accurate gain and offset adjustment is required for each

chip. Fortunately, the AD9981 has the automatic clamp

feedback feature. When enabled, the clamp feedback

automatically eliminates the channel -to - channel differences in offset for all channels.

While the dif ferences in channel -to - channel gain will

not affect the image as much as differences in of fset,

it is still recommended that any channel-to -channel

gain mismatch be minimized using a one -time factory

calibration scheme.

Linearity/Dithering

Dual ADC applications are also sensitive to differences

in linearity between the two devices. The use of 10 - bit

ADCs greatly improves the linearity performance of

a dual ADC application so that dithering may not be

necessary. However, if the application’s requirements

prove to be stringent, dithering can be used to enhance

the linearity even further. The dithering method requires

that on every other data frame the even and odd device

be swapped. For example, during frame one, device

1 processes odd pixels and device 2 processes even

pixels. During frame two, device 1 processes even pixels

while device 2 processes odd pixels. Dithering allows

the eye to essentially “average” the effect of the linearity

differences as well as differences in offset and gain.

Device Addressing

Each AD9981 requires a different serial bus address.

This is achieved using the A0 / VSOUT pin, shown in

Figure 1.

–2–

REV. 0

Loading...

Loading...