Page 1

AN-753

ADC

INPUT

(VIA MUX)

TOUCH

SCREEN

V

REF

V

CC

X+

REF+

SINGLE-ENDED METHOD

RATIOMETRIC METHOD

REF–

Y+

Y–

GND

APPLICATION NOTE

One Technology Way • P.O. Box 9106 • Norwood, MA 02062-9106 • Tel: 781/329-4700 • Fax: 781/326-8703 • www.analog.com

Conguring the AD7877

by Susan Pratt

INTRODUCTION

The AD7877 touch screen controller is a 12- bit successive approximation ADC with a synchronous serial

interface and low on resis tance switches for driving

touch screens. The AD7877 features direc t bat ter y

measurement on two inputs, temperature and touchpressure measurement.

The AD7877 has many user-programmable conversion

controls, including variable acquisition time, rst conversion delay, and averaging. It is ideal for battery-powered

systems, such as personal digital assistants, smar t

phones, and other portable equipment with resistive

touch screens.

The AD7877 requires conguration via the on- board

registers to fully utilize its features. This application

note goes through the conguration process step by

step, and explains how to congure the device for your

application.

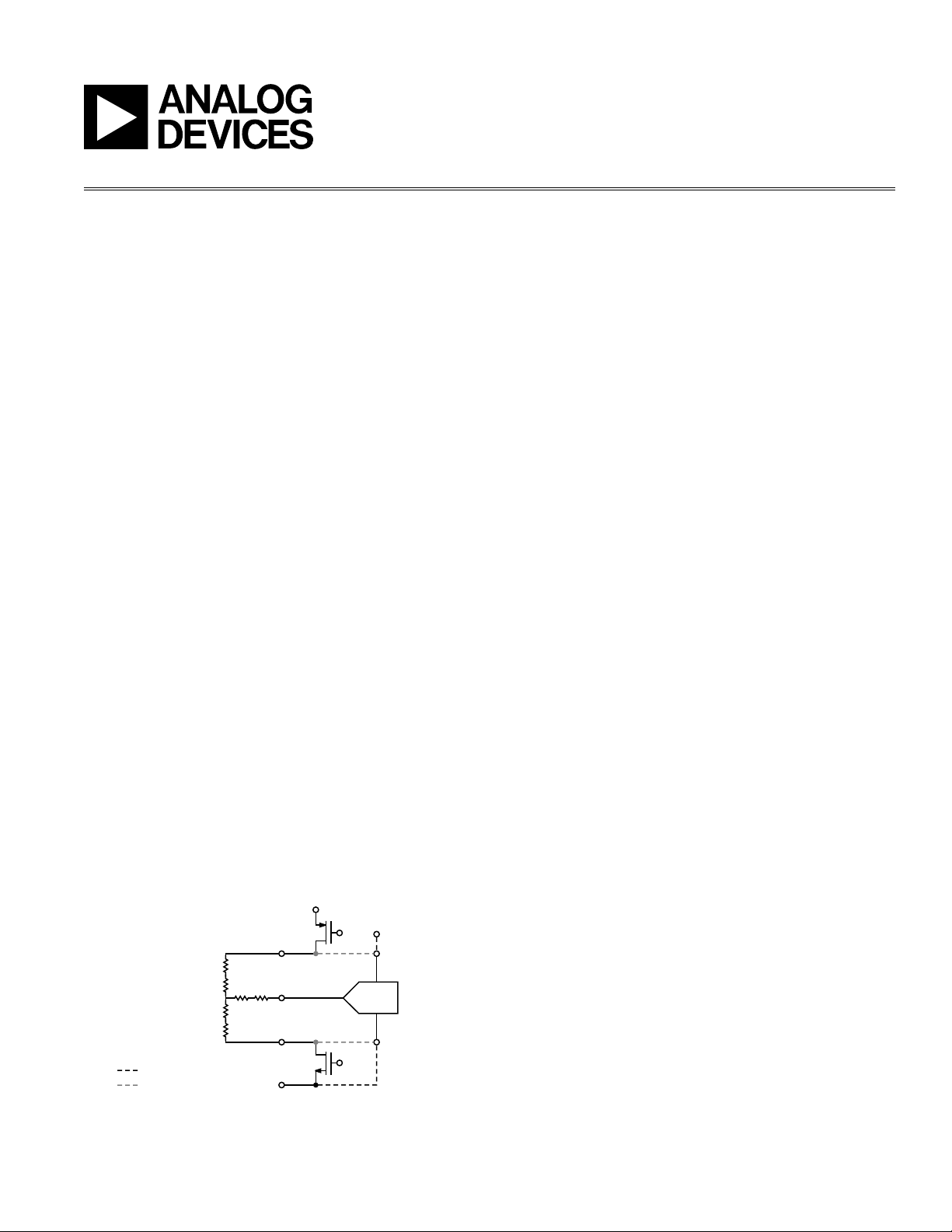

SINGLE-ENDED OR RATIOMETRIC MEASUREMENT

The main task of any touch screen controller is to take

accurate measurements from the touch screen. On the

AD7877, there are two measurement methods available:

single- ended or ratiometric. The difference between the

two methods is in the ADC reference voltage. In single ended mode, the ADC is referenced to ground and to

V

. (V

REF

an external reference). For the differential measurement,

the ADC is referenced to the screen excitation voltage.

REV. 0

can be either the internal reference voltage or

REF

Figure 1. Measurement Methods

The advantage of using the single -ended method is that

the touch screen does not need to be powered except

during signal acquisition. Signal acquisition takes only

a portion of the total conversion time. This method can

result in signicant power savings in the system, as the

screen itself can draw more than 1 mA while powered.

This method also has some disadvantages. Voltage

drops across the internal switches cause errors in the

measurement, as they reduce the apparent excitation

voltage across the screen. In addition, this method

can only be used when VCC is close to V

the ADC is saturated (when VCC > V

REF

the full range of the ADC is not used (VCC < V

, otherwise

REF

), or conversely,

). The

REF

single - ended method is particularly suited for batteryoperated systems where power is at a premium. It is only

recommended for applications that use the nger as an

input device, and therefore do not need high accuracy

measurements.

Using the touch screen excitation voltage as the ADC

referen ce gives a ratiometric measurement of the

input signal. This method is more accurate than the

single - ended method because voltage drops across the

internal switches do not have any effect on the measured

results. However, the screen needs to be powered at all

times in order to provide the ADC with its reference. For

applications such as handwriting recognition, where the

measured touch screen position must be accurate, the

ratiometric method is recommended.

AVERAGING

The signals measured from the touch screen can be

noisy. To minimize low level noise, the AD7877 can

automatically perform averaging on the measured input

signals. The AD7877 can be programmed to perform one,

four, eight, or sixteen consecutive measurements on the

same channel, and write the averaged result to the result

register. The more averages the part performs, the longer

each measurement takes. When choosing the amount of

averaging in the system, the time available for conversions needs to be taken into account. The amount of

averaging required will depend on the noise factors in

the specic system, but in general, at least four averages

are recommended for each measurement.

Page 2

AN-753

–3–

AN-753

FIRST CONVERSION DELAY = 8.19ms

FIRST CONVERSION DELAY = 1.024ms

FIRST CONVERSION DELAY = 500ns

REV. 0

STOPACQ

In most applications, the touch screen is placed directly

on top of the LCD. Periodic noise from the display can

interfere with the touch screen measurements. As the

LCD horizontal lines are written, noise is generated that

can be coupled onto the touch screen. This specic

type of noise is generally framed by an LCD control

signal related to the horizontal refresh phase. HSYNC

and Vcom are the two typical control signals found on

different types of LCDs. The noise can be framed by the

high or low period of these signals, or it may be worse

at the signal transitions.

If the user sees periodic noise in the system, an analysis

should be performed to determine if the noise is coming

from the LCD, and whether there is a control signal

available that frames the noise. This control signal

should be tied directly to the AD7877 StopAc q pin,

provided the signal level is suitable. Even if the control

signal does not frame all the noise but frames at least

some of it, greater accuracy will be obtained by using

the StopAcq feature.

The StopAcq feature can be used with any signal to

control the acquisition period of the AD7877. Its recommended use is in prevention of noise pickup from the

LCD as described earlier, but that does not preclude its

use for other purposes.

Figure 2 graphically illustrates the ef fect of the rst

conversion delay on the accuracy of the touch screen

results. The correc t first conversion delay value for

the particular touch screen used in this experiment is

1.024 ms. The samples taken from the touch screen using

this value are in green and clearly show that all points

on the touch screen can be measured correctly. Plenty

of samples are gathered all over the screen.

If the rst conversion delay is set too small, then the

range of values read from the screen is severely limited.

In this case, the signal has not had time to settle, so the

input value is being measured while the signal is still

ramping up to its true value. As illustrated by the red

samples, vast areas of the screen will never register as

being touched.

If the rst conversion delay is too large, then not enough

samples are measured to gain suf cient information

from the screen. The black samples illustrate this. While

positions from the full screen area can be measured, the

time between samples is too great. If the touched position was to move quickly, not enough samples would be

taken to track these changes. Applications such as writing on the screen would be impossible with too large a

rst conversion delay.

FIRST CONVERSION DELAY

The nature of the touch screen measurement process

means that voltages are being switched on and off the

touch screen pins in rapid sequence. To get both X and

Y positions, voltage needs to be switched across rst the

X then the Y layer, while the Y+ or X+ input is switched

to the ADC. Once the voltages are switched, the input

signal will require a settling time before it reaches its

true value. Taking a measurement before the signal is

settled gives an erroneous result.

The AD7877 can be programmed to add an automatic

delay before each touch screen measurement commences. The delay should be long enough to allow the

input signal to settle. The AD7877 rst conversion delay

can be 500 ns, 128 µs, 1.024 ms, or 8.19 ms. The user

should calculate the settling time of the input signal and

then choose a rst conversion delay that is at least as

long. Note that the choice of rst conversion delay will

add to the total conversion time. The rst conversion

delay happens automatically before the rst conversion

is performed on the AD7877, before each touch screen

positional measurement, and after the nal conversion

in a sequence.

Figure 2. Effect of First Conversion Delay on

Touch Screen Results

–2–

REV. 0

Page 3

ACQUISITION TIME

11 0

AUX

3

AUX

2

AUX

1

Z

2

X+Y+

NOT

USED

Z

1

TEMP

2

TEMP

1

BAT

2

BAT

1

The AD7877 has sample-and - hold circuitry to control

acquisition of the input signal. One of the most com mon errors made when integrating a touch screen into

an application is miscalculation of the acquisition time

required to capture the input signal correctly. The acqui sition time depends on a number of factors, including the

source impedance and capacitance of the input signal,

and the input RC of the controller itself.

The addition of a low-pass lter to the touch screen pins

has a large ef fect on the acquisition time. While a lter

can help reduce noise, it also increases the acquisition

time required to successfully measure the input signal.

The user must remember to add any resistances or

capacitances from these lters to their acquisition time

calculation. For the AD7877, the following equation

can be used to get a rough idea of the acquisition time

required for an input signal for 12-bit accuracy.

t

~= (RIN + 100 ) (CIN + 30 pF) 10

ACQ

where:

RIN is the source impedance.

100 is the input impedance of the AD7877.

CIN is the input capacitance of the source.

30 pF is the input capacitance of the AD7877.

The AD7877 allows the user to choose from acquisition

times of 2 µs, 4 µs, 8 µs, or 16 µs by writing to an on-chip

register. The user calculates the required acquisition

time for the circuit, and picks the most suitable acquisition time from the options available on the AD7877.

USING THE SEQUENCER AND TIMER

To minimize host intervention when the AD7877 is run ning, the part has an on - board sequencer and timer.

These can be programmed by the user to ensure the

AD7877 per f orms conversions automatically at set

intervals, or when the screen is touched. The sequencer

is used to choose whic h conversions occur in the

sequence. This allows the AD7877 to run in a standalone

mode, where the only host intervention required af ter

setup is to read the result registers. The on- chip timer

does not have to be used, but it can be set to expire every

512 µs, 1.024 ms, or 8.19 ms.

There are two sequence registers on the AD7877. One

of the sequenc e regis ter s contains the conver sion

sequence for use when the screen is touched, known as

master mode. The second sequence register contains

the conversion sequence for use in slave mode. Each bit

in the registers corresponds to a conversion on one of

the AD7877‘s input channels. To add a conversion to the

sequence, the corresponding bit in the sequence register

is set. To remove the conversion from the sequence, the

bit is cleared.

AN-753

Figure 3. Sequence Register Bits

To trigger a conversion sequence every time the screen

is touched, the AD7877 should be put into master

mode by setting Bit 0 and Bit 1 of Control Register 1

to Control Register 11’b. Once the sequence of conversions is nished and the results are in the registers, the

DAV interrupt will signal to the host that new data is

available. The sequence of conversions in the master

mode sequence register will be repeated automatically

every time the screen is touched. If the screen remains

touched for a long time, for example, if someone is

writing on the screen, then the timer can be used to

trigger the sequence. However, when the screen is not

being touched, the timer cannot trigger the conversion sequence. Master mode is useful for a number of

applications. It can automatically gather positional data

while a user writes on the screen. It requires little host

intervention, as the AD7877 will only interrupt the host

once new data is written to the registers when the screen

is touched.

There is a second sequence register on the AD7877 for

use in slave mode. The AD7877 can be placed into slave

mode by setting Bit 0 and Bit 1 of the control register

to 10’b. The conversion sequence in the slave mode

sequence register is performed once when the part is put

into slave mode. The sequence is repeated automatically

when a timer event occurs, irrespective of whether the

screen is touched or not. If the timer is not set, then the

user needs to write to Control Register 1 again to trigger

the slave mode sequence.

REV. 0

–3–

Page 4

AN05206–0–1/05(0)

© 2005 Analog Devices, Inc. All rights reserved. Trademarks and registered trademarks are the property of their respective owners.

–4–

Loading...

Loading...