Page 1

AN-703

Preliminary Technical Data

APPLICATION NOTE

One Technology Way • P.O. Box 9106 • Norwood, MA 02062-9106 • Tel: 781/329-4700 • Fax: 781/326-8703 • www.analog.com

Driving High Power LEDs

by Yuxin Li, Gang Liu, and Alan Li

INTRODUCTION

The ADP3806 is a switching mode power supply (SMPS)

controller featuring dual loop constant-voltage and

constant-current control; remote and accurate current

sensing; and shutdown and programmable, synchronizable switching frequency. For different application

requirements, it can be confi gured in a variety of topologies:

buck, boost, buck-boost, SEPIC, and CUK. This application

note guides the designs of controller circuits for driving

high power LEDs (light emitting diodes) by using the

ADP3806 to achieve an effi ciency of up to 95%.

Before using this application note for designing the circuits, download the ADP3806 data sheet from the ADI

website.

POWERING UP THE ADP3806

The minimum VCC is 6.25 V (undervoltage lockout UVLO

voltage) and the maximum VCC should not exceed 23 V,

which brings the switch driver voltage BST to 30 V, the

junction breakdown voltage. The recommended VCC

range is from 6.5 V to 20 V.

To e n s u r e a clean voltage source at the VCC pin, an RC

bypass network is used between the input source and

the IC. The decoupling capacitor can be in the value

range of 0.1 F to 22 F. The sh u tdown control pin SD

accepts external control logic input. If automatic startup

is preferred, a voltage divider from VCC can be used to

ensure that the voltage at this pin is below its limit, 10 V,

and above its logic high, 2.0 V.

A capacitor connected to the CT pin sets the switching

frequency. Recommended switching frequency is from

300 kHz to 750 kHz for the optimized trade-off between

the overall system physical size and the efficiency.

Higher switching frequency of up to 1 MHz demands

more gate-driving power and generates more switching

losses, resulting in lower effi ciency, while the inductors’

inductance can be scaled down to reduce the system’s

physical size and cost. Another drawback of using a

higher switching frequency is that the duty cycle range is

reduced so that the output voltage range is narrowed.

REG, REF, and BSTREG pins are output pins of three internal low dropout (LDO) regulators. Decouple them with

the recommended capacitors to ensure the stability of

the regulators.

The current sensing resistor along with the voltage at

the ISET pin determines the output current. The required

voltage at the ISET pin should be generated from the

2.5 V precision reference source REF pin. The maximum

output current from the REF pin is 500 A. To generate

a higher setting voltage, the voltage divider can run off

the REG pin (6 V). Note that the accuracy for REF is 1%,

and the accuracy for REG is 3%.

Across CS+ and CS– pins, a fi lter capacitor of about 220 nF

should be placed right next to the pins in the PCB layout

to fi lter out noise.

BUCK CONFIGURATION

To d rive L EDs w ith an output voltage lower than the input

power source voltage, a step-down topology Buck can

be used.

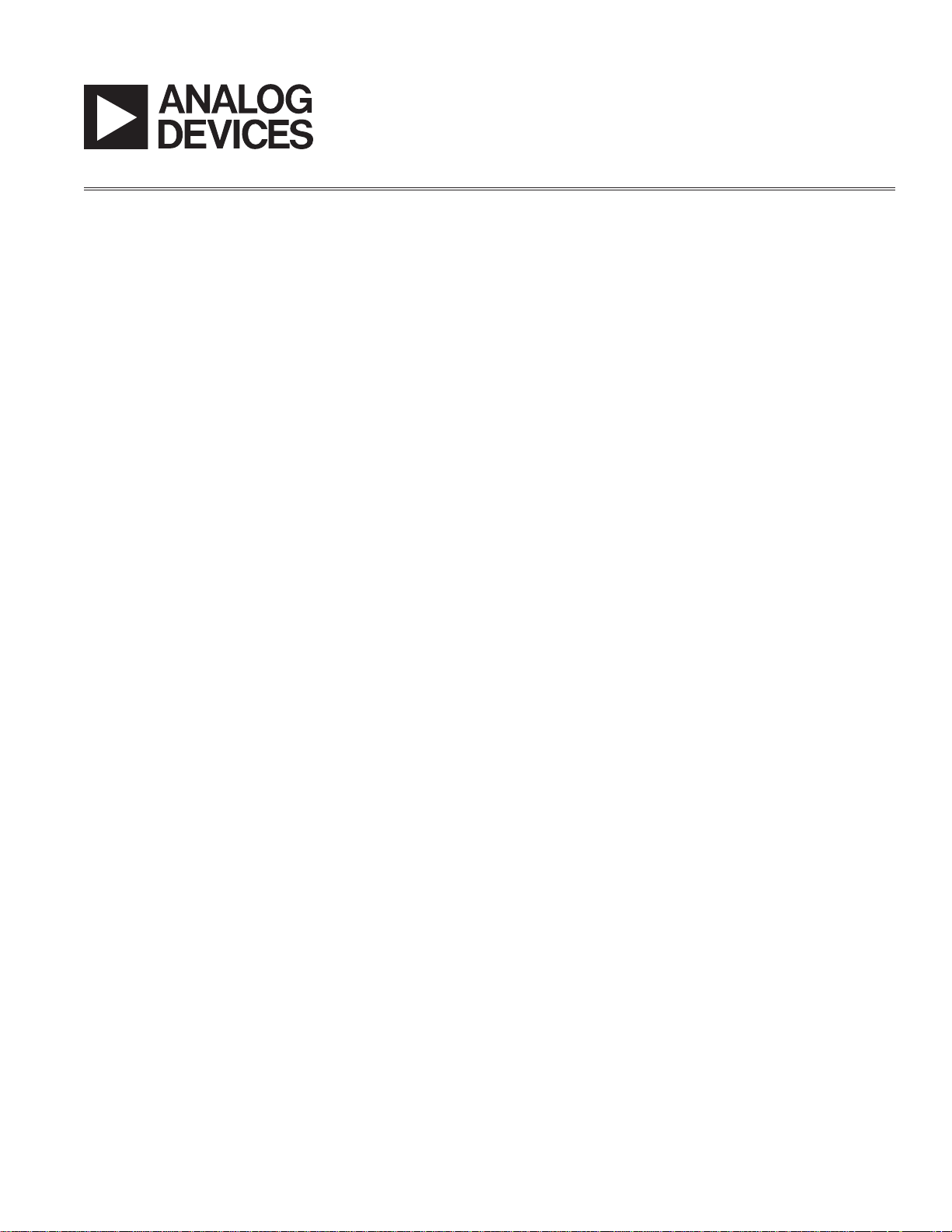

Figure 1 shows the Buck configuration circuit. This

scheme utilizes the synchronous rectification functionality of the controller to provide the highest power

conversion effi ciency. The controller and the power

stage can be powered up by either the same or different power sources. Using the same power source, the

input voltage range should be within the range of 6.5 V

to 20 V. With different power sources, the power stage

input voltage can be as low as 6.5 V, while the maximum

should not exceed 20 V.

Using proper MOSFETs, the output current can go up to

4 A, the sense resistor value, and the ISET voltage. The

output voltage can go from zero up to the power stage

input voltage.

The current sensing resistor, R

to minimize its power loss but high enough to provide

suffi cient signal for the control. The voltage across the

CS+ and CS– pins should be higher than 50 mV to activate

the synchronous rectifi cation function, that is, to switch

the lower MOSFET on and off. When (CS+ – CS–) voltage

is lower than 50 mV, the low-side MOSFET is not turned

on so its body diode conducts, causing extra conduction

loss. At the same time, the energy for driving the lower

MOSFET is saved. When the output current is lowered

far enough, turning off the lower MOSFET may result in

higher overall system effi ciency.

, should be low enough

CS

REV. PrA

Page 2

AN-703 Preliminary Technical Data

By using the circuit shown in Figure 1, the output current

equals

V

I

LED

ISET

=

R

25

CS

If the current sensing signal in the design is lower than

50 mV, a bias circuit, shown in Figure 2, is needed to fully

activate the synchronous functionality. By using a voltage

divider composed of RB1 and RB2, a bias voltage, V

BIAS

, is

generated at the CS+ pin. Thus, the sensing signal needed

to activate the synchronous rectifi cation function is V

lower than the 50 mV. If V

equals 50 mV, the synchro-

BIAS

BIAS

nous function is effective all the time. With this bias, the

output current is

VV

- 25

LED

=

ISET BIAS

R

25

CS

I

The current limit setting accuracy is obviously a little

lower with this added offset term. Also, the biasing

circuitry should draw minimum current from the VREF

pin, and fi ltering capacitor C4 should now be designed

to make a small enough time constant (recommend 0.3/

f

) with RB2 instead of RCS. Thus, C4 is much smaller

SW

than 200 nF.

The output capacitor, C

, is optional. It smoothes the

OUT

voltage and current across the LEDs.

The input capacitor, C

, is needed to absorb the input ripple

IN

current. Normally, two 10 F/25 V ceramic capacitors are

enough.

The inductor, L, determines the ripple current. It is recommended that the ripple current be about one-third of the

nominal output current to optimize both the system size

and the effi ciency. The peak inductor current is there

II

= 115.

LPEAK LEDM

fore,

where:

is the peak current of the inductor.

I

LPEAK

is the maximum average current in the LEDs.

I

LEDM

The inductor should be chosen based on two criteria.

First, the inductor saturation current should be larger

than the maximum peak current, I

, in the inductor.

LPEAK

Second, the inductor’s maximum dc current rating should

be larger than the load dc average current, I

LED

.

The recommended bootstrap capacitance is 10 nF. A

0.5 A Schottky diode is recommended as the bootstrap

diode. This diode must be placed on the PCB as close to

the BST and BSTREG pins as possible.

C

, CCL, and RC compose the loop compensation net-

CH

work of the closed loop. They need to be designed

carefully to ensure system stability and control speed.

The control (duty cycle, d) to inductor current (i

) transfer

L

function is a constant given by

iS

()

L

d

=

25

DV

IN

Rf L

CS SW

where:

D is the duty cycle of the steady state.

is the switching frequency of the power stage.

f

SW

This is valid below half of the switching frequency and

with the assumption that the output voltage is constant.

It is obvious that a simple integrator is adequate to compensate the loop with infi nite dc gain. To set a bandwidth

of f

), the compensation component CCL needs to be

C(C

gDV

C

CL

MIN

=

Rf L

25 w

CS SW C

where:

= 0.002 is the transconductance of the current loop

g

M

error amplifi er.

R

can be set to zero.

C

can be set to be open.

C

CH

LEDs are not critical to the driving transition, so the system loop bandwidth can be low. It is recommended that

the bandwidth is designed to be 1/30th of the switching

frequency for the buck confi guration.

MOSFETs can be chosen based on their dc voltage/

current ratings, switching speed (gate charges), and

thermal capability.

Note that the BSTREG regulator needs to provide the

entire gate-driving energy to drive both the high-side

MOSFET and the high- side driver itself. Because the

maximum output current, I

lator is ⱕ 3 mA, the gate charge, Q

, of the BSTREG regu -

BSTREG

, of the high-side

G

MOSFET and the switching frequency should satisfy

IQf

>

BSTREG G SW

If more gate-driving capability is needed, use an external

NPN transistor, QBST, in the emitter follower confi guration (see Figure 2) to deliver more current.

–2–

REV. PrA

Page 3

Preliminary Technical Data AN-703

VIN7V–20V

C1

R1

22F

10⍀

124

VCC

2

R2

100k⍀

CT

C2

100nF

C3

200pF

R3

51k⍀

C

CL

R

C

C

CH

SYS–

3

SYS+

4

ISYS

5

LIMIT

6

CT

7

8

9

10

11

12

ADP3806

SYNC

REG

REF

SD

COMP

LC AGND

SW

DRVH

BST

BSTREG

DRVL

PGND

CS+

CS–

ISET

BATSEL

BAT

C6

23

22

21

20

19

18

17

16

15

14

13

10nF

D1

MBR052

C5

1F

C4

200nF

TO SET THE OUTPUT CURRENT

R

CLBRCLT

SW1

SW2

C

IN

L

V

OUT

=0TOV

IN

LED1

C

OUT

LED2

R

CS

Figure 1. Driving LEDs with the ADP3806 in Buck Confi guration

VIN7V–20V

C1

R1

22F

10⍀

124

VCC

2

R2

100k⍀

CT

C2

100nF

C3

200pF

R3

51k⍀

C

CL

R

C

C

CH

SYS–

3

SYS+

4

ISYS

5

LIMIT

6

CT

7

8

9

10

11

12

ADP3806

SYNC

REG

REF

SD

COMP

LC AGND

SW

DRVH

BST

BSTREG

DRVL

PGND

CS+

CS–

ISET

BATSEL

BAT

C6

23

22

21

20

19

18

17

16

15

14

13

10nF

QBST

BBMT6428

C5

1F

OUTPUT

CURRENT BOOSTER

C4

??

TO SET THE

OUTPUT CURRENT

D1

MBR052

R

CLBRCLT

C

IN

SW1

L

SW2

C

RB2

RB3

RB1

CURRENT SENSING BIAS

OUT

V

OUT

=0TOV

R

CS

IN

LED1

LED2

REV. PrA

Figure 2. Biasing the Current Sensing Input to Accommodate Low Input Signal

–3–

Page 4

AN-703 Preliminary Technical Data

BOOST CONFIGURATION

If the output voltage is higher than the input power

source voltage to power a series of LEDs, step-up conversion is used.

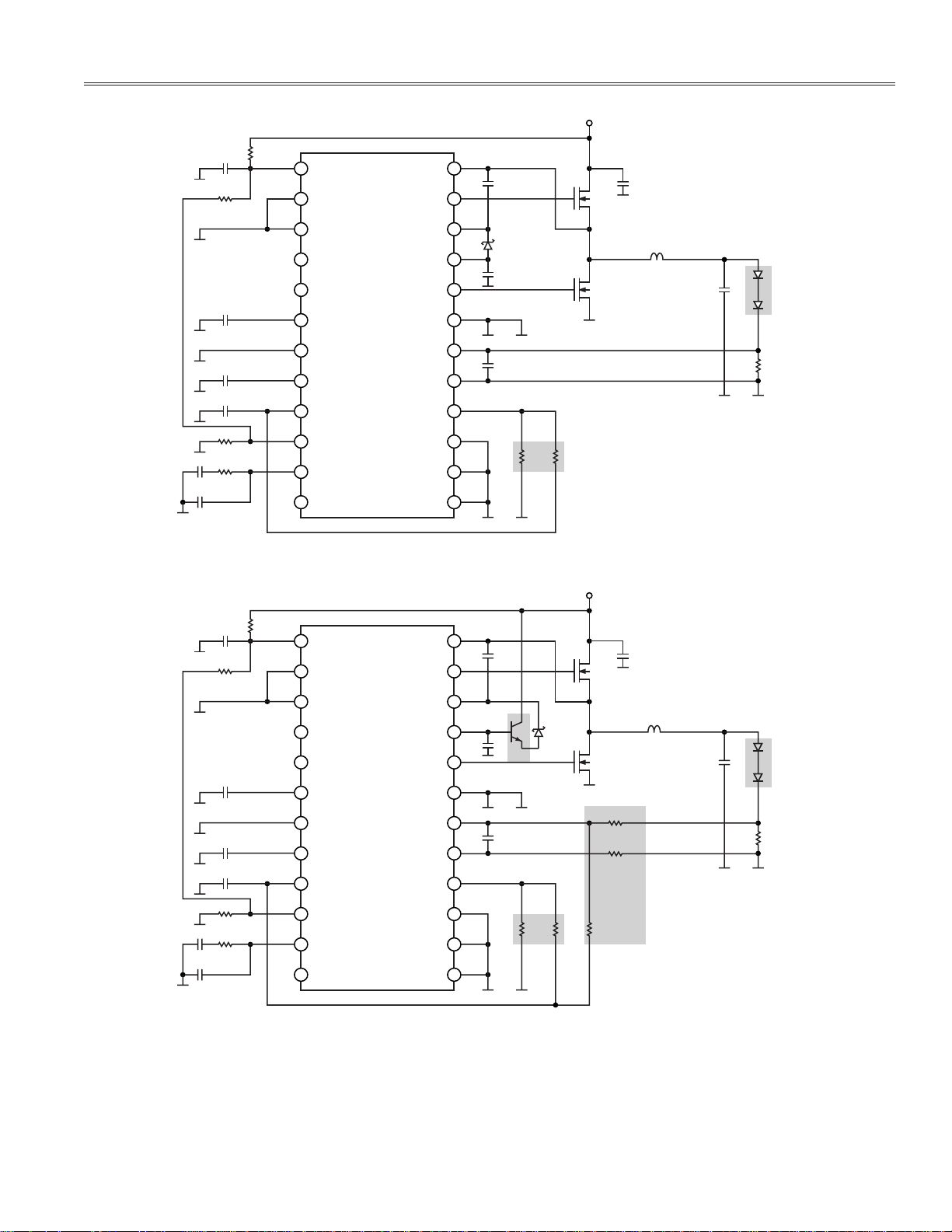

Figure 3 shows the boost confi guration using the ADP3806

to drive LEDs. This scheme utilizes the main driving output DRVH to control the main switch SW1, with the diode

switch SW2 used for rectifi cation.

To a v oid ov e r voltage output, the voltage loop can be

connected to set the maximum allowable output voltage, V

. Because the internal reference is 2.5 V, the

OUTM

maximum output voltage is set by

RR

=+25.

OVPT OVPB

R

OVPB

V

OUTM

Choose appropriate voltage divider resistance to set the

overvoltage protection point, V

C1

R1

22F

10⍀

R2

100k⍀

CT

C2

100nF

C3

200pF

51k⍀

R3

C

CL

R

C

C

CH

.

OUTM

124

VCC

2

SYS–

3

SYS+

4

ISYS

5

LIMIT

6

CT

7

8

9

10

11

12

ADP3806

SYNC

REG

REF

SD

COMP

LC AGND

SW

DRVH

BST

BSTREG

DRVL

PGND

CS+

CS–

ISET

BATSEL

BAT

23

22

21

20

19

18

17

16

15

14

13

The output capacitor, C

, is optional. Without it, the

OUT

current fl owing into the LEDs is discontinuous and fl uctuates at a duty of (1 – D), where D is the duty cycle of

the PWM control. With the output capacitor, the current

in the LEDs can be shaped smoother. Appropriate output

capacitance is needed to achieve the required driving

current pattern.

The current sensing resistor, R

, needs to be large

CS

enough to generate suffi cient signal for the controller.

The maximum differential input voltage between CS+

and CS– is 160 mV.

C

, CCL, and RC need to be designed carefully to ensure

CH

system stability and control speed. This design is different

from that of the buck confi guration.

With this confi guration, the output is always connected

to the input power supply via SW2 and the inductor, even

when the controller is in shutdown mode. This may pose

some issues for specifi c applications.

VIN2VIN1 7V–20V

C

IN

L

C5

1F

C4

200nF

TO SET THE

OUTPUT CURRENT

R

OVPBRCLBRCLT

SW2

SW1

R

OVPT

TO SET THE MAXIMUM

OUTPUT VOLTAGE

C

V

OUT

OUT=VIN

+1AND UP

LED1

LED2

R

CS

Figure 3. Driving LEDs with the ADP3806 in Boost Confi guration

–4–

REV. PrA

Page 5

Preliminary Technical Data AN-703

SEPIC CONFIGURATION

The SEPIC confi guration provides an output that can be

either higher or lower than the input voltage at a cost

of an additional inductor and capacitor. A SEPIC confi guration using the ADP3806 to drive LEDs is shown in

Figure 4.

The output stage is very similar to the boost confi guration, except that the rectifi cation switch, SW2, conducts

when the main switch, SW1, is on.

C1

R1

22F

10⍀

124

VCC

2

R2

100k⍀

CT

C2

100nF

C3

200pF

51k⍀

R3

C

CL

R

C

C

CH

SYS–

3

SYS+

4

ISYS

5

LIMIT

6

CT

7

8

9

10

11

12

ADP3806

SYNC

REG

REF

SD

COMP

LC AGND

SW

DRVH

BST

BSTREG

DRVL

PGND

CS+

CS–

ISET

BATSEL

BAT

23

22

21

20

19

18

17

16

15

14

13

The output capacitor, C

, CCL, and RC need to be designed carefully to ensure

C

CH

, is optional.

OUT

system stability and control speed. This design is different

from that of the buck confi guration.

Unlike the boost confi guration, the output is isolated to the

input source when the controller is in shutdown mode.

VIN2VIN1 7V–20V

C

IN

L1

C

C5

1F

C4

200n

TO SET THE

OUTPUT CURRENT

R

OVPBRCLBRCLT

R

SW1

R

TO SET THE MAXIMUM

OUTPUT VOLTAGE

OVPT

SW2

L2

C

OUT

V

OUT

LED1

LED2

R

CS

REV. PrA

Figure 4. Driving LEDs with the ADP3806 in the SEPIC Confi guration

–5–

Page 6

AN-703 Preliminary Technical Data

CUK CONFIGURATION

The CUK confi guration provides an inverted output that

can be either higher or lower in magnitude than the input

voltage. Figure 5 shows the CUK confi guration using the

ADP3806 to drive LEDs.

Similar to the buck confi guration, the output current is

continuous, with fewer pulsating components compared

to both the boost and the SEPIC confi gurations.

C1

R1

22F

10⍀

124

VCC

2

R2

100k⍀

CT

C2

100nF

C3

200pF

51k⍀

R3

C

CL

R

C

C

CH

SYS–

3

SYS+

4

ISYS

5

LIMIT

6

CT

7

8

9

10

11

12

ADP3806

SYNC

REG

REF

SD

COMP

LC AGND

SW

DRVH

BST

BSTREG

DRVL

PGND

CS+

CS–

ISET

BATSEL

BAT

23

22

21

20

19

18

17

16

15

14

13

Similarly, the output capacitor, C

, CCL, and RC need to be designed carefully to ensure

C

CH

, is optional.

OUT

system stability and control speed. This design is different

from that of the buck confi guration.

The output is isolated to the input source when the

controller is in shutdown mode.

VIN2VIN1 7-20V

C

IN

L1

CR

C5

1F

C4

200nF

TO SET THE OUTPUT CURRENT

R

CLBRCLT

SW1

SW2

L2

C

OUT

V

OUT

LED1

LED2

R

CS

Figure 5. Driving LEDs with the ADP3806 in the CUK Confi guration

–6–

REV. PrA

Page 7

Preliminary Technical Data AN-703

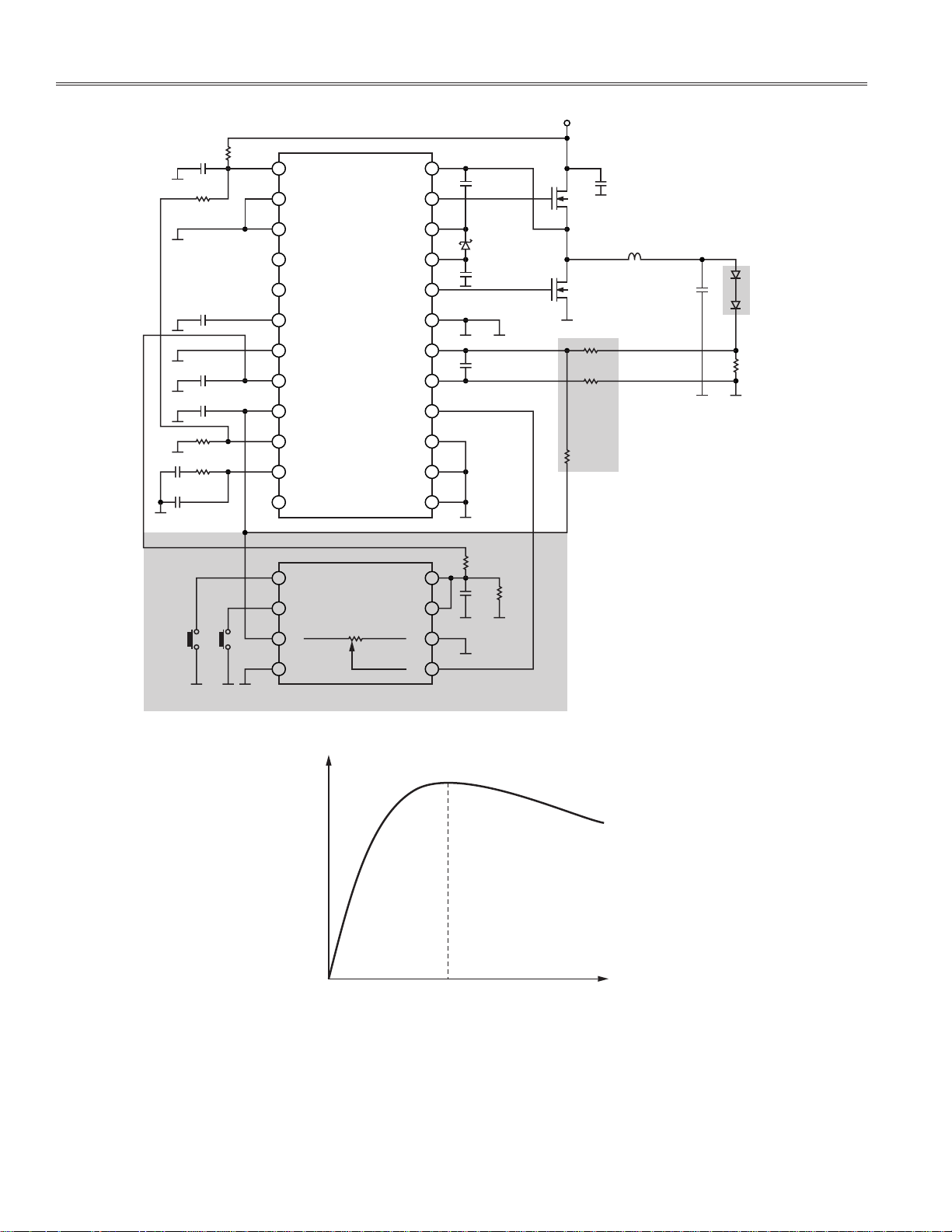

BRIGHTNESS CONTROL

Brightness control can be implemented easily by controlling the voltage at Pin ISET. Referring to the data sheet,

the output current, I

, is set by V

OUT

(voltage at the ISET

ISET

pin) by

V

I

OUT

ISET

=

R

25

CS

There are two basic ways to adjust the brightness control. The fi rst is to control the output current by changing

V

at the ISET pin. This can be done simply by using a

ISET

potentiometer running off the 6 V V

rail or 2.5 V V

REG

REF

reference.

To minimize the board space, layout infl exibility, and

reliability concern, users may consider using a digital

potentiometer, AD5228, rather than its mechanical

counterpart for the brightness control. AD5228 is a low

cost, 32-step, manual control digital potentiometer that

features a built-in debouncer and zero-scale/midscale

selectable preset. As shown in Figure 6, an AD5228 with

two external push buttons adds in the circuit fl exibility

with brightness control.

This control is simple but may be ineffi cient because

the effi ciency of LEDs tends to be higher at their full cur-

rent rating and lower at reduced current. To overcome

this problem, a PWM brightness control scheme can be

used.

By periodically shorting the ISET pin down to AGND,

V

shows a pattern of PWM, as does the output cur-

ISET

rent, I

. With an open-drain MOSFET connected to the

OUT

ISET pin, the brightness of the output can be controlled

by a digital signal, which can be generated by a micro controller.

It takes time for the controller to react to the control

signal, so the frequency of this brightness control PWM

signal should be much lower than the bandwidth of the

control loop, which is much slower than the switching

frequency. The brightness PWM signal can be in the

range of 50 Hz to 500 Hz.

Figure 7 shows a typical high brightness LED’s effi ciency

curve versus its driving current. I

is the optimal driving

OPT

current point with the highest light emitting effi ciency.

The effi ciency optimized brightness control approach is

to drive the LEDs with a PWM current pattern. The current changes from zero to I

at a duty D

OPT

. This leads

BRI

to the maximum light-emitting output at the continuous

I

driving. Whe n more lig ht output is needed, raise the

OPT

driving current.

REV. PrA

–7–

Page 8

AN-703 Preliminary Technical Data

VIN7V–20V

C1

R1

22F

10⍀

124

VCC

2

R2

100k⍀

SYS–

3

SYS+

4

ISYS

5

LIMIT

CT

6

CT

C2

100nF

C3

200pF

51k⍀

R3

C

CL

R

C

C

CH

7

8

9

10

11

12

ADP3806

SYNC

REG

REF

SD

COMP

LC AGND

SW

DRVH

BST

BSTREG

DRVL

PGND

CS+

CS–

ISET

BATSEL

BAT

C6

23

22

21

20

10nF

D1

MBR052

C5

1F

SW1

SW2

C

IN

L

V

OUT

=0TOV

IN

LED1

C

OUT

LED2

19

18

17

16

15

14

13

C4

200nF

RB2

RB3

RB1

CURRENT SENSING BIAS

R

CS

PR04631–0–3/04(PrA)

PUSH-UP BUTTON

PUSH-DOWN BUTTON

OUTPUT CURRENT SETTING

Figure 6. Brightness Control Using AD5228 Manual Control Digital Potentiometer

RB1

124

PU

PD

A

GND

ADP5228

2

3

4

VDD

PRE

B

W

1k⍀

RB2

10k⍀

CB

23

100nF

22

21

LIGHT EMITTING EFFICIENCY

I

LED DRIVING CURRENT

OPT

Figure 7. Typical High Brightness LED’s Effi ciency

© 2004 Analog Devices, Inc. All rights reserved. Trademarks and registered trademarks are the property of their respective owners.

–8–

REV. PrA

Loading...

Loading...