Page 1

AN-603

a

One Technology Way • P.O. Box 9106 • Norwood, MA 02062-9106 • Tel: 781/329-4700 • Fax: 781/326-8703 • www.analog.com

APPLICATION NOTE

A Compact Algorithm Using the ADXL202

Duty Cycle Output

by Harvey Weinberg

Introduction

There are many applications where high accuracy measurement of acceleration is less important than having a

simple and compact software algorithm. This application

note outlines a decode algorithm that measures only the

pulsewidth (T1) output of the ADXL202 and translates it to

degrees of tilt. In this algorithm, the period (T2) is not

measured, and no binary division is used.

In PIC assembly code, a total of 199 bytes of program

memory and 18 bytes of data memory are used. Even

more efficient memory (particularly data memory) usage

can be had with further optimization. A flow chart of the

algorithm is included so that the user may modify it or

port it to any 4- or 8-bit microcontroller with little effort.

Using this technique, we simplify tilt angle calculation

down to a simple 1 s per degree relationship. Any

modulo-2 factor of 500 s (e.g., 1000 s, 2000 s, and so

on) may be used as required.

Error Sources

Scale error is the most significant error source encountered when using this algorithm. We assume that the

overall scale factor is 16 m

multiple) in this algorithm, but the actual scale factor

may be anything from 10% per

results in a ±8∞ error over ±40∞ of tilt. Another obvious

error source is having the wrong value for T2. A 1% error

in T2 will result in a 1% error in tilt angle resolution.

These errors may be eliminated by adding a trim to T2.

g

per s (or some modulo-2

g

to 15% per g. This

A discussion of error sources inherent in this method of

measurement is also included.

Principle of Operation

The ADXL202 outputs a pulsewidth modulated (PWM)

signal proportional to acceleration. Assuming that the

scale factor is fixed at 12.5

acceleration T T g duty cycle= (( 1/ 2) – (0 )) 12.5 %

Where T1 is the pulsewidth and T2 is the period of the

ADXL202’s PWM output.

In a temperature stable environment, we can assume

that the average value of

we can rearrange the formula for

acceleration T T at g T= (( 1– 2 0 ) 2) 12.5%

Over a range of ±35∞ of tilt, each degree of tilt is very

close to 16 m

can take advantage of very easy modulo-2 division to

minimize computational requirements when calculating

tilt angle. For example:

g

. By choosing particular values of T2, we

Ts

2 500

=

gs s

1 (500 ) (12.5%) 62.5

=¥=

sg s mg

1(162.5 ) 16

==

mm

%

per g:

T

2 does not change. Therefore

acceleration

m

mm

as:

Scale factor error and

together by adjusting

some modulo-2 multiple) relationship is maintained.

This is expressed by the following equation:

T scalefactor21 0016=¥(( ) ( . ))

So, for example, for a scale factor of 10%:

T2 s=¥=1 ((0.10) (0.016)) 625 m

Adjusting T2 to 625 s in this case would eliminate the

errors due to scale factor and

Since scale factor variation may result in such large

errors, trimming T2 by adding a potentiometer in series

with R

trim may be omitted in applications where one is interested only in changes in tilt angle, and errors due to

scale factor and T2 inaccuracy can be tolerated.

T2 may drift over temperature by as much as a few percent. This is very difficult to compensate for using this

type of algorithm. It is suggested that another algorithm

be used in situations where this is problematic.

as shown in Figure 1 is recommended. This

SET

T

2 error may be trimmed out

T

2 such that the 16 mg per s (or

T

2 accuracy.

REV. 0

© Analog Devices, Inc., 2002

Page 2

AN-603

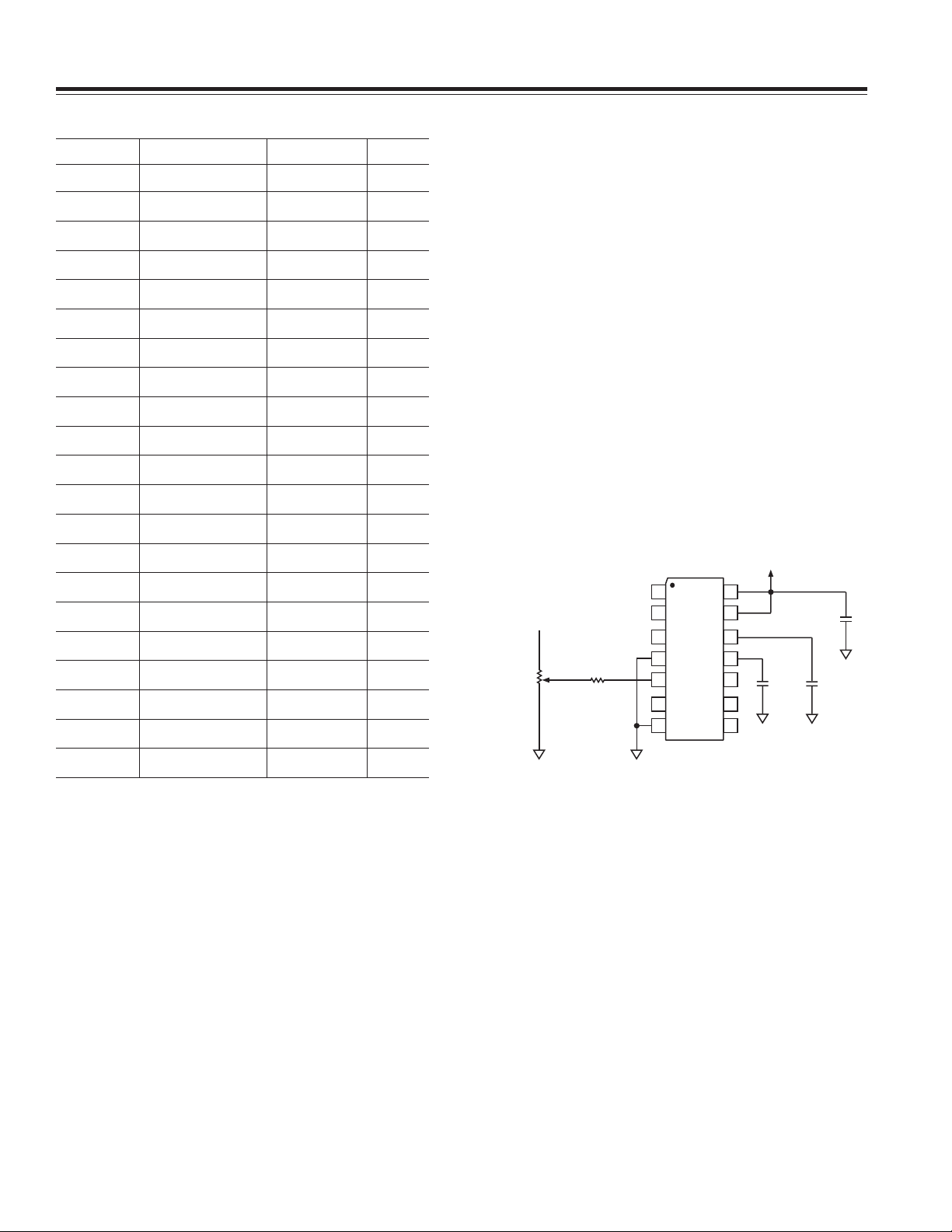

Table I. Tilt Angle vs. Error

Tilt Angle

g

Generated T1 in s Error

00.000 0 0

20.034 2 0

40.069 4 0

60.104 6 0

80.139 8 0

10 0.173 10 0

12 0.207 12 0

14 0.241 15 1

16 0.275 17 1

18 0.309 19 1

20 0.342 21 1

22 0.374 23 1

24 0.406 25 1

26 0.438 27 1

The assumption that over ±35∞ of tilt, each degree of tilt is

very close to 16 m

one degree of tilt is 17.45 m

14.38 m

g

. While at first glance this looks like a large

g

, is of course an approximation. At 1∞,

g

; at 35∞, one degree

of tilt is

source of error, it turns out that it only works out to ±1∞ of

error over a ±40∞ range of tilt as shown in Table I.

There is normally a certain amount of “jitter” in T2.

Since the duty cycle does not change as a result of this

jitter, T1 changes proportionally with T2. This error

source in minimized in the 0

g

calibration routine by taking the average value of T1 over 16 readings. This is not

done in normal sampling to allow wider bandwidth

operation. If wide bandwidth is not a concern, the user

may wish to modify the algorithm to include a similar

averaging scheme in normal sampling to minimize this

error due to T2 jitter.

The final source of error is from aliasing in the duty cycle

modulator itself. As discussed in the ADXL202 data

sheet, the analog bandwidth should be limited to

1/10 the duty cycle modulator frequency. So for a T2

period of 1000 s, the analog bandwidth should be

100 Hz or less.

V

DD

28 0.469 29 1

30 0.500 31 1

32 0.529 33 1

34 0.559 34 0

36 0.587 36 0

38 0.615 38 0

40 0.642 40 0

20k⍀

50k⍀

Y

FILT

Figure 1. Circuit for Trimming T2

C

DC

X

FILT

–2–

REV. 0

Page 3

Program Listing and Flow Chart

;***********************************************************************

;

;********** 202-T1.ASM ***************************************

;********** REVISION: 0 ***************************************

;

; RELEASED: SEPT. 16, 1998

; REVISED:

;

; THIS SOFTWARE USES T1 MEASUREMENTS ONLY TO DETERMINE ACCELERATION

; EXPERIENCED BY THE ADXL202. THE OUTPUT IS A 1-BYTE HEXADECIMAL

; NUMBER PER AXIS OF RANGE 00 TO FF. THE MOST SIGNIFICANT BIT IS A SIGN

; BIT. A 1 IN THE MSB INDICATES POSITIVE ACCELERATION. A 0 IN THE MSB

AN-603

; INDICATES NEGATIVE ACCELERATION. TO MAKE THE SOFTWARE AS COMPACT AS

; POSSIBLE, T2 IS ASSUMED TO HAVE A FIXED VALUE. VARIATION FROM THIS

; VALUE WILL RESULT IN ERROR. IT IS ALSO ASSUMED THAT THE FACTOR OF

; IS FIXED AS SHOWN IN THE TABLE BELOW. SO FOR TILT MEASUREMENT OVER

; ⫾40 DEGREES, THIS ROUTINE IS ACCURATE TO APPROXIMATELY ONE DEGREE.

; SINCE THE OUTPUT IS A 1-BYTE NUMBER, RESPONSE IS LIMITED TO ⫾ 1 g.

;

; T2 (IN mSEC)

; 1000 0.008 2

; 2000 0.004 4

; 4000 0.002 8

; 8000 0.001 16

;

;======================================================================

g

/T1 (HOW MANY g FOR 1 mSEC) mSEC/DEGREE

g

/T1

LIST P=16C62A ;SPECIFY PROCESSOR

;======================================================================

REV. 0

–3–

Page 4

AN-603

;======================================================================

;

; REGISTER DEFINITIONS

;

;======================================================================

W EQU H'0000'

F EQU H'0001'

;----- REGISTER FILES--------------------------------------------------

INDF EQU H'0000'

TMR0 EQU H'0001'

PCL EQU H'0002'

STATUS EQU H'0003'

FSR EQU H'0004'

PORTA EQU H'0005'

PORTB EQU H'0006'

PORTC EQU H'0007'

PCLATH EQU H'000A'

INTCON EQU H'000B'

PIR1 EQU H'000C'

TMR1L EQU H'000E'

TMR1H EQU H'000F'

T1CON EQU H'0010'

TMR2 EQU H'0011'

T2CON EQU H'0012'

SSPBUF EQU H'0013'

SSPCON EQU H'0014'

CCPR1L EQU H'0015'

CCPR1H EQU H'0016'

CCP1CON EQU H'0017'

–4–

REV. 0

Page 5

OPTION_REG EQU H'0081'

TRISA EQU H'0085'

TRISB EQU H'0086'

TRISC EQU H'0087'

PIE1 EQU H'008C'

PCON EQU H'008E'

PR2 EQU H'0092'

SSPADD EQU H'0093'

SSPSTAT EQU H'0094'

;----- STATUS BITS ----------------------------------------------------

AN-603

IRP EQU H'0007'

RP1 EQU H'0006'

RP0 EQU H'0005'

NOT_TO EQU H'0004'

NOT_PD EQU H'0003'

Z EQU H'0002'

DC EQU H'0001'

C EQU H'0000'

;----- INTCON BITS ----------------------------------------------------

GIE EQU H'0007'

PEIE EQU H'0006'

T0IE EQU H'0005'

INTE EQU H'0004'

RBIE EQU H'0003'

T0IF EQU H'0002'

INTF EQU H'0001'

REV. 0

–5–

Page 6

AN-603

RBIF EQU H'0000'

;----- PIR1 BITS ------------------------------------------------------

SSPIF EQU H'0003'

CCP1IF EQU H'0002'

TMR2IF EQU H'0001'

TMR1IF EQU H'0000'

;----- T1CON BITS -----------------------------------------------------

T1CKPS1 EQU H'0005'

T1CKPS0 EQU H'0004'

T1OSCEN EQU H'0003'

NOT_T1SYNC EQU H'0002'

T1INSYNC EQU H'0002' ;BACKWARD COMPATIBILITY

TMR1CS EQU H'0001'

TMR1ON EQU H'0000'

;----- T2CON BITS -----------------------------------------------------

TOUTPS3 EQU H'0006'

TOUTPS2 EQU H'0005'

TOUTPS1 EQU H'0004'

TOUTPS0 EQU H'0003'

TMR2ON EQU H'0002'

T2CKPS1 EQU H'0001'

T2CKPS0 EQU H'0000'

;----- SSPCON BITS ----------------------------------------------------

–6–

REV. 0

Page 7

WCOL EQU H'0007'

SSPOV EQU H'0006'

SSPEN EQU H'0005'

CKP EQU H'0004'

SSPM3 EQU H'0003'

SSPM2 EQU H'0002'

SSPM1 EQU H'0001'

SSPM0 EQU H'0000'

;----- CCP1CON BITS ---------------------------------------------------

CCP1X EQU H'0005'

AN-603

CCP1Y EQU H'0004'

CCP1M3 EQU H'0003'

CCP1M2 EQU H'0002'

CCP1M1 EQU H'0001'

CCP1M0 EQU H'0000'

;----- OPTION BITS ----------------------------------------------------

NOT_RBPU EQU H'0007'

INTEDG EQU H'0006'

T0CS EQU H'0005'

T0SE EQU H'0004'

PSA EQU H'0003'

PS2 EQU H'0002'

PS1 EQU H'0001'

PS0 EQU H'0000'

;----- PIE1 BITS ------------------------------------------------------

REV. 0

–7–

Page 8

AN-603

SSPIE EQU H'0003'

CCP1IE EQU H'0002'

TMR2IE EQU H'0001'

TMR1IE EQU H'0000'

;----- PCON BITS ------------------------------------------------------

NOT_POR EQU H'0001'

;----- SSPSTAT BITS ---------------------------------------------------

D EQU H'0005'

I2C_DATA EQU H'0005'

NOT_A EQU H'0005'

NOT_ADDRESS EQU H'0005'

D_A EQU H'0005'

DATA_ADDRESS EQU H'0005'

P EQU H'0004'

I2C_STOP EQU H'0004'

S EQU H'0003'

I2C_START EQU H'0003'

R EQU H'0002'

I2C_READ EQU H'0002'

NOT_W EQU H'0002'

NOT_WRITE EQU H'0002'

R_W EQU H'0002'

READ_WRITE EQU H'0002'

UA EQU H'0001'

BF EQU H'0000'

;======================================================================

–8–

REV. 0

Page 9

;

; RAM DEFINITION

;

;======================================================================

__MAXRAM H'BF'

__BADRAM H'08'-H'09', H'0D', H'18'-H'1F'

__BADRAM H'88'-H'89', H'8D', H'8F'-H'91',H'95'-H'9F'

;======================================================================

;

; RAM EQUATES

AN-603

;

;======================================================================

T1X_1 EQU 20

T1X_0 EQU 21

ARGL EQU 22

ARGH EQU 23

ACCHI EQU 24

ACCLO EQU 25

T1Y_1 EQU 26

T1Y_0 EQU 27

T1XCAL_2 EQU 28

T1XCAL_1 EQU 29

T1XCAL_0 EQU 2A

T1YCAL_2 EQU 2B

T1YCAL_1 EQU 2C

T1YCAL_0 EQU 2D

X_ACCEL EQU 2E

Y_ACCEL EQU 2F

T1CAL_COUNT EQU 30

REV. 0

–9–

Page 10

AN-603

ROTCNT EQU 31

;======================================================================

;

; CONFIGURATION BITS

;

;======================================================================

_CP_ALL EQU H'3F8F'

_CP_75 EQU H'3F9F'

_CP_50 EQU H'3FAF'

_CP_OFF EQU H'3FBF'

_PWRTE_ON EQU H'3FBF'

_PWRTE_OFF EQU H'3FB7'

_WDT_ON EQU H'3FBF'

_WDT_OFF EQU H'3FBB'

_LP_OSC EQU H'3FBC'

_XT_OSC EQU H'3FBD'

_HS_OSC EQU H'3FBE'

_RC_OSC EQU H'3FBF'

;======================================================================

;***** PROGRAM ******

;***** MAIN PROGRAM *****

;***** RESET ROUTINE *****

ORG 0000

GOTO PROG_START ;GO TO START OF PROGRAM

GOTO PROG_START

GOTO PROG_START ;THESE COMMANDS ARE HERE TO

–10–

REV. 0

Page 11

GOTO PROG_START ;KICK THE PROGRAM COUNTER PAST

RETURN ;THE INTERRUPT VECTORS IN CASE

RETURN ;OF A GLITCH

PROG_START

CLRF PORTA

CLRF PORTB

CLRF PORTC

BSF STATUS,5 ;RAM PAGE 1

MOVLW B'11111111' ;SET UP THE I/O PORTS

MOVWF TRISA ;PORT A, ALL INPUTS

MOVLW B'11111111'

AN-603

MOVWF TRISB ;PORT B, ALL INPUTS

MOVLW B'11111111'

MOVWF TRISC ;PORT C, ALL INPUTS

BCF STATUS,5 ;SET RAM PAGE 0

MAIN_LOOP

CALL CHECK_CAL ;CHECK IF CALIBRATION ROUTINE

CALL READ_T1 ;READ ACCELERATION

MOVF T1X_1,0 ;CHECK ACCELERATION POLARITY

SUBWF T1XCAL_1,0

BTFSS STATUS,C

GOTO ACCX_GT_ZX

;SHOULD BE PERFORMED

REV. 0

BTFSS STATUS,Z

GOTO ACCX_LT_ZX

MOVF T1X_0,0

SUBWF T1XCAL_0,0

BTFSS STATUS,C

–11–

Page 12

AN-603

GOTO ACCX_GT_ZX

MOVF T1XCAL_0,0

MOVWF ACCLO

MOVF T1XCAL_1,0

MOVWF ACCHI

MOVF T1X_0,0

MOVWF ARGL

MOVF T1X_1,0

MOVWF ARGH

CALL SUB_16X16

BCF STATUS,C ;DIVIDE BY 2 (1 SHIFT) IF T2=1000mS

ACCX_LT_ZX ;X ACCELERATION IS NEGATIVE

RRF ACCHI,1 ;DIVIDE BY 4 (2 SHIFTS) IF T2=2000mS

RRF ACCLO,0 ;DIVIDE BY 8 (3 SHIFTS) IF T2=4000mS

MOVWF X_ACCEL

BCF X_ACCEL,7 ;CLEAR THE SIGN BIT AS ACCEL IS -

GOTO DO_Y_AXIS

ACCX_GT_ZX ;X ACCELERATION IS POSITIVE

MOVF T1X_0,0

MOVWF ACCLO

MOVF T1X_1,0

MOVWF ACCHI

MOVF T1XCAL_0,0

MOVWF ARGL

MOVF T1XCAL_1,0

MOVWF ARGH

CALL SUB_16X16

BCF STATUS,C ;DIVIDE BY 2 (1 SHIFT) IF T2=1000mS

RRF ACCHI,1 ;DIVIDE BY 4 (2 SHIFTS) IF T2=2000mS

RRF ACCLO,0 ;DIVIDE BY 8 (3 SHIFTS) IF T2=4000mS

MOVWF X_ACCEL

–12–

REV. 0

Page 13

BSF X_ACCEL,7 ;SET THE SIGN BIT AS ACCEL IS +

DO_Y_AXIS

MOVF T1Y_1,0 ;CHECK FOR ACCELERATION POLARITY

SUBWF T1YCAL_1,0

BTFS S STATUS,C

GOTO ACCY_GT_ZY

BTFS S STATUS,Z

GOTO ACCY_LT_ZY

MOVF T1Y_0

SUBWF T1YCAL_0,0

BTFSS STATUS,C

AN-603

GOTO ACCY_GT_ZY

ACCY_LT_ZY ;Y ACCELERATION IS NEGATIVE

MOVF T1YCAL_0,0

MOVWF ACCLO

MOVF T1YCAL_1,0

MOVWF ACCHI

MOVF T1Y_0,0

MOVWF ARGL

MOVF T1Y_1,0

MOVWF ARGH

CALL SUB_16X16

BCF STATUS,C ;DIVIDE BY 2 (1 SHIFT) IF T2=1000mS

RRF ACCHI,1 ;DIVIDE BY 4 (2 SHIFTS) IF T2=2000mS

RRF ACCLO,0 ;DIVIDE BY 8 (3 SHIFTS) IF T2=4000mS

REV. 0

MOVWF Y_ACCEL

BCF Y_ACCEL,7 ;CLEAR THE SIGN BIT AS ACCEL IS -

GOTO MAIN_LOOP

ACCY_GT_ZY ;Y ACCELERATION IS POSITIVE

MOVF T1Y_0,0

–13–

Page 14

AN-603

MOVWF ACCLO

MOVF T1Y_1,0

MOVWF ACCHI

MOVF T1YCAL_0,0

MOVWF ARGL

MOVF T1YCAL_1,0

MOVWF ARGH

CALL SUB_16X16

BCF STATUS,C ;DIVIDE BY 2 (1 SHIFT) IF T2=1000mS

RRF ACCHI,1 ;DIVIDE BY 4 (2 SHIFTS) IF T2=2000mS

RRF ACCLO,0 ;DIVIDE BY 8 (3 SHIFTS) IF T2=4000mS

MOVWF Y_ACCEL

BSF Y_ACCEL,7 ;SET THE SIGN BIT AS ACCEL IS +

GOTO MAIN_LOOP

;***** SUBROUTINES *****

;**********************************************************************

CHECK_CAL ;THIS SUBROUTINE READS THE "CAL" PIN (RA4). IF IT

;IS HI, A SIMPLE CALIBRATION ROUTINE IS PERFORMED

;TO MEASURE THE 0

;T1 ARE AVERAGED (BY ADDING TOGETHER AND THEN

;DIVIDING BY 16) TO INCREASE ACCURACY.

BTFSS PORTA,3 ;IS RA4 HI

RETURN ;IF NOT THEN NO CAL ROUTINE

CLRF T1XCAL_2 ;IF YES THEN ACQUIRE CAL DATA

g

VALUE OF T1. SIXTEEN SAMPLES OF

CLRF T1XCAL_1 ;START BY CLEARING ALL

CLRF T1XCAL_0 ;OF THE CALIBRATION REGISTERS

CLRF T1YCAL_2

CLRF T1YCAL_1

CLRF T1YCAL_0

–14–

REV. 0

Page 15

ZCAL_A

AN-603

MOVLW 10 ;SET AVERAGING COUNTER TO 16

MOVWF T1CAL_COUNT

MOVF T1CAL_COUNT,1 ;TEST IF 16 PASSES HAVE OCCURRED BY

BTFSC STATUS,Z ;TESTING IF THE LOOP COUNTER = 0

GOTO ZCAL_B

CALL READ_T1 ;READ T1

MOVF T1X_0,0 ;DO AVERAGING CALCULATIONS OF T1X

ADDWF T1XCAL_0,1

BTFSS STATUS,C ;CHECK IF A CARRY WAS GENERATED

GOTO ZCAL_C

MOVLW 01 ;IF A CARRY WAS GENERATED INCREMENT

ADDWF T1XCAL_1

BTFSC STATUS,C ;CHECK IF A CARRY WAS GENERATED

INCF T1XCAL_2,1

ZCAL_C

MOVF T1X_1,0

ADDWF T1XCAL_1

BTFSC STATUS,C ;CHECK IF A CARRY WAS GENERATED

INCF T1XCAL_2

MOVF T1Y_0,0

ADDWF T1YCAL_0,1 ;DO AVERAGING CALCULATIONS OF T1Y

BTFSS STATUS,C

GOTO ZCAL_D

MOVLW 01

ADDWF T1YCAL_1

ZCAL_D

REV. 0

BTFSC STATUS,C

INCF T1YCAL_2,1

MOVF T1Y_1,0

ADDWF T1YCAL_1

–15–

Page 16

AN-603

BTFSC STATUS,C

INCF T1YCAL_2

DECF T1CAL_COUNT ;DECREMENT LOOP COUNTER

GOTO ZCAL_A ;LOOP

ZCAL_B

MOVLW 04 ;DIVIDE T1CAL BY 16

MOVWF ROTCNT

ZCAL_E

RRF T1XCAL_2,1

RRF T1XCAL_1,1

RRF T1XCAL_0,1

RRF T1YCAL_2,1

RRF T1YCAL_1,1

RRF T1YCAL_0,1

MOVLW 01

SUBWF ROTCNT,1

BTFSS STATUS,Z

GOTO ZCAL_E

RETURN

;**********************************************************************

READ_T1 ;THIS SUBROUTINE ACQUIRES T1X AND T1Y

;T1X IS IN REGISTERS T1X_1,T1X_0

;T1Y IS IN REGISTERS T1Y_1,T1Y_0

CLRF T1CON ;SET TIMER 1 TO ZERO

CLRF TMR1L

EDGE1

EDGE2

CLRF TMR1H

BTFSC PORTB,2 ;WAIT FOR RISING EDGE

GOTO EDGE1

–16–

REV. 0

Page 17

EDGE3

AN-603

BTFSS PORTB,2

GOTO EDGE2

BSF T1CON,TMR1ON ;TURN TIMER 1 ON

NOP ;WAIT 3 mSEC TO DEGLITCH

NOP

NOP

BTFSC PORTB,2 ;LOOK FOR FALLING EDGE

GOTO EDGE3

BCF T1CON,TMR1ON ;STOP TIMER 1 TO READ RELIABLY

MOVFT MR1H,0

MOVWF T1X_1

EDGE4

EDGE5

MOVF TMR1L,0

MOVWF T1X_0

CLRF TMR1L ;CLEAR THE TIMER RESULT REGISTERS

CLRF TMR1H ;IN PREPARATION FOR T1Y CAPTURE

BTFSC PORTB,1 ;LOOK FOR THE RISING EDGE ON

GOTO EDGE4 ;Y CHANNEL

BTFSS PORTB,1

GOTO EDGE5

BSF T1CON,TMR1ON ;TURN TIMER 1 BACK ON AT RISING EDGE

NOP ;WAIT 3 mSEC TO DEGLITCH

NOP

NOP

EDGE6

REV. 0

BTFSC PORTB,1 ;LOOK FOR FALLING EDGE SIGNIFYING

GOTO EDGE6 ;THE END OF T1Y

BCF T1CON,TMR1ON ;STOP TIMER 1 TO READ END OF T1Y

MOVF TMR1H,0

–17–

Page 18

AN-603

MOVWF T1Y_1

MOVF TMR1L,0

MOVWF T1Y_0

RETURN

;**********************************************************************

SUB_16X16 ;THIS SUBROUTINE PERFORMS A 16 BIT BY 16 BIT

;SUBTRACTION.

;(ACCHI,ACCLO)=(ACCHI,ACCLO)-(ARGH,ARGL)

COMF ARGL

INCF ARGL

BTFSC STATUS,2

DECF ARGH

COMF ARGH ;NEGATE ZERO

MOVF ARGL,W ;THEN ADD

ADDWF ACCLO,F

BTFSC STATUS,W

INCF ACCHI

MOVF ARGH,W

ADDWF ACCHI,F

RETURN

;*********************************************************************

END

–18–

REV. 0

Page 19

–19–

Page 20

E03048–0–7/02(0)

–20–

PRINTED IN U.S.A.

Loading...

Loading...