Page 1

AN-601

a

APPLICATION NOTE

One Technology Way • P.O. Box 9106 • Norwood, MA 02062-9106 • Tel: 781/329-4700 • Fax: 781/326-8703 • www.analog.com

Minimizing Power Consumption

of iMEMS

Introduction

Portable battery-powered devices are perhaps the largest growth market segment today. In an effort to reduce

the size and weight of these devices, battery capacity is

often minimized. To maintain good performance,

designers are forced to carefully examine their circuits

for ways to decrease power consumption.

This application note will outline methods to reduce the

power consumption of iMEMS accelerometers using

both hardware and software techniques. A special section will cover some techniques that are specific to

certain parts.

Basic Methods

There are three basic methods to reduce power

consumption:

• Lower the supply voltage

• Turn off the accelerometer when measurements are

not taking place

• Use clever software

All of the techniques outlined in this application note are

no more than extensions of these methods.

Lower the Supply Voltage

Often the most straightforward and lowest cost way to

reduce power consumption is to simply reduce the supply

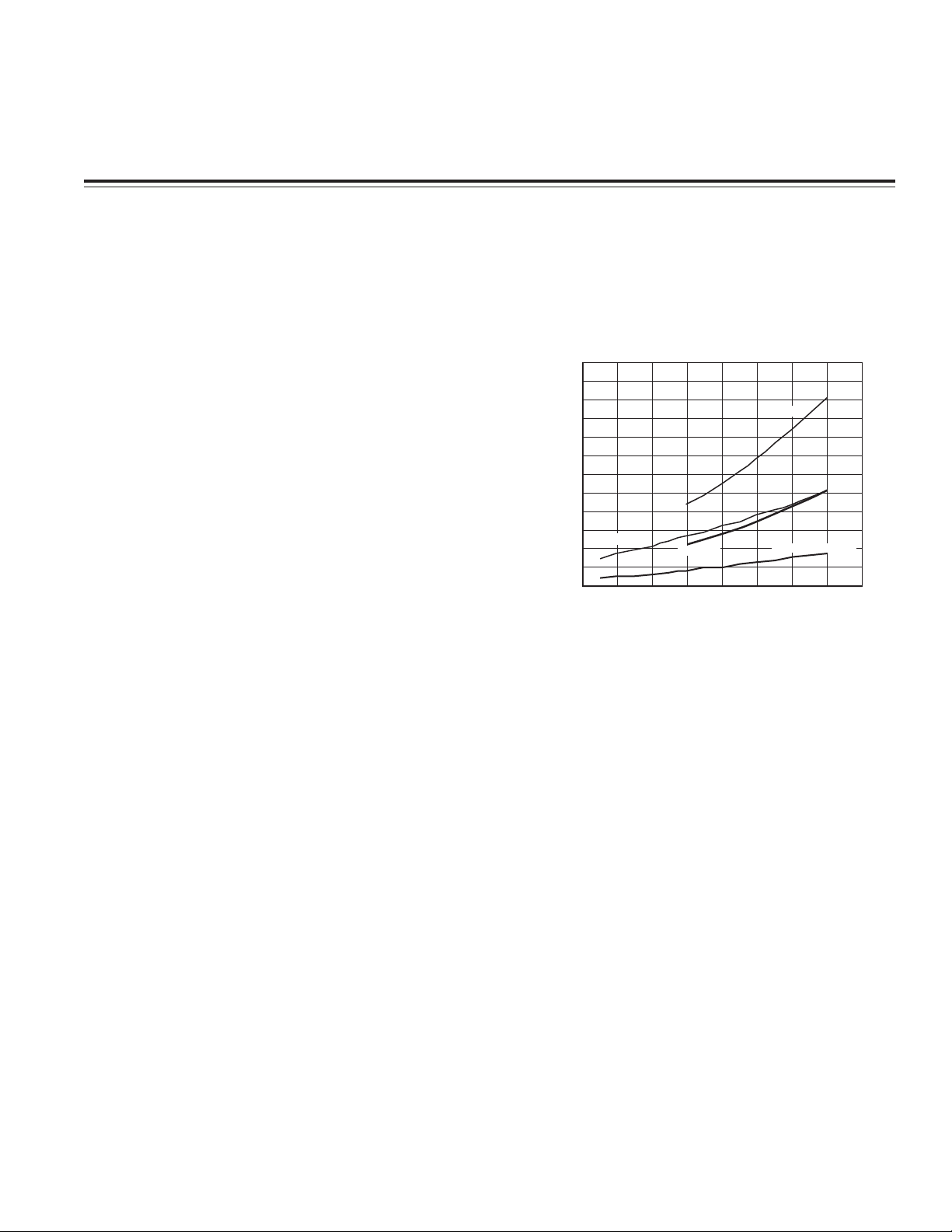

voltage. Figure 1 shows the typical power consumption versus the supply voltage for several iMEMS accelerometers.

While there are great power savings to be had by simply

lowering the supply voltage, there is a price to be paid

as well. As all these accelerometers are ratiometric, lowering their supply voltage will lower the sensitivity by

roughly the same ratio. The exception to this is the

PWM outputs of the ADXL202/ADXL210. These outputs

remain fairly constant as the supply voltage changes.

®

Accelerometers

by Harvey Weinberg

mW

Figure 1. Power Consumption vs. Supply Voltage for

Several Accelerometers

If the entire system is ratiometric (i.e., the A/D reference

voltage is proportional to V

ity is not a problem.

A potentially more serious problem is that the accelerometer’s noise performance is generally degraded as

the supply voltage is reduced. This cannot be mitigated

by using a ratiometric system and must be kept in mind

during system design.

Turn Off the Accelerometer

Turning off the accelerometer when measurement is not

occurring can result in great power savings. This is particularly true in applications where the sampling rate is

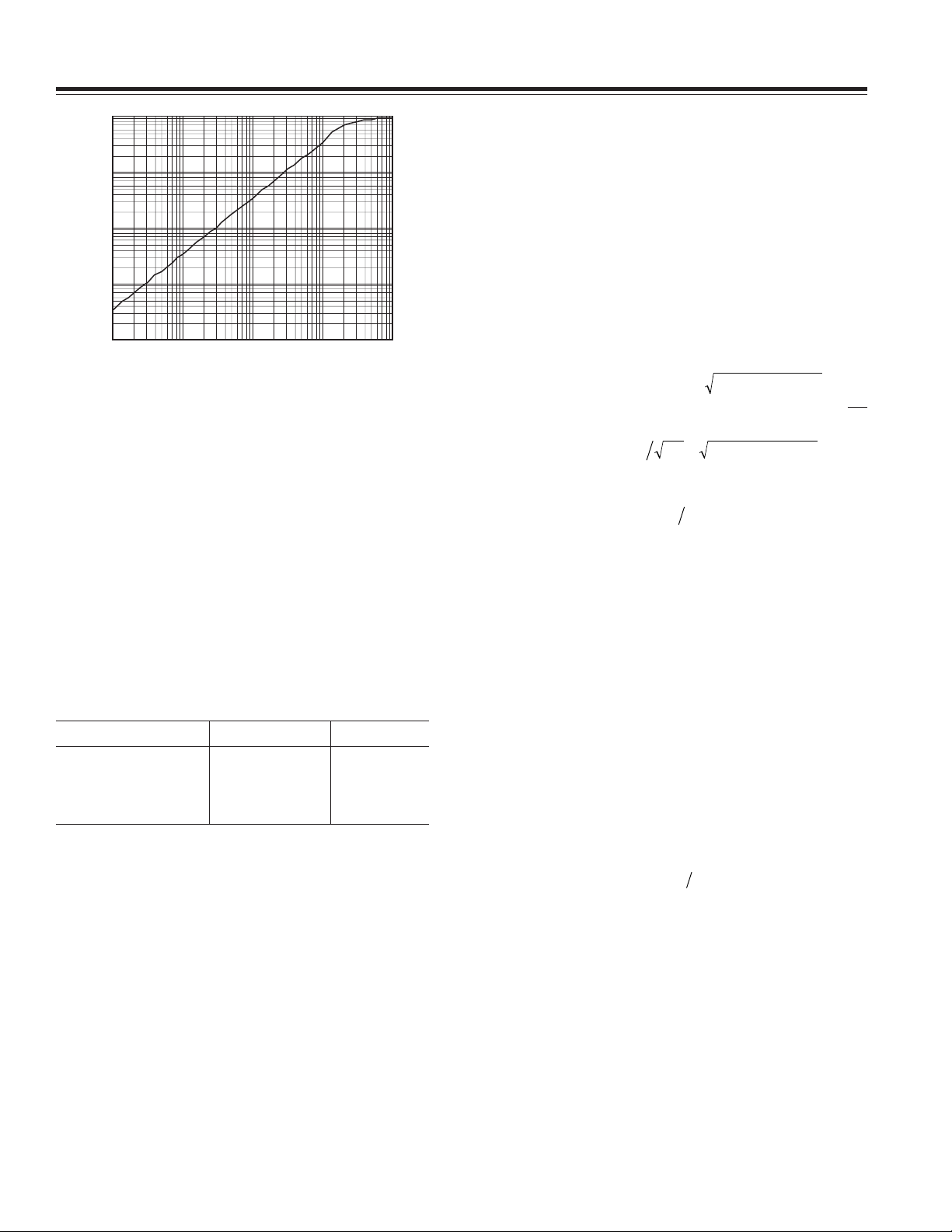

low. Figure 2 illustrates the average power consumed by

an ADXL150 versus the power cycling (sampling) frequency (for V

Note that the Nyquist criteria must be satisfied in any

case, and the sampling frequency must be at least twice

the input frequency.

30.0

25.0

20.0

15.0

10.0

5.0

0.0

2.5 6.53.5

ADXL250

ADXL105

= 5 V and a 25 s A/D conversion time).

DD

ADXL150

4.5 5.5

V

), this reduction of sensitiv-

DD

ADXL202/ADXL210

REV. 0

© Analog Devices, Inc., 2002

Page 2

AN-601

10

1

0.1

0.01

POWER CONSUMPTION – mW

0.001

11000010

SAMPLING FREQUENCY – Hz

100 1000

Figure 2. ADXL150 Average Power Consumption vs.

Power Cycling Frequency

In iMEMS accelerometers, the turn-on time is mainly a

function of the bandwidth. While higher bandwidths will

allow lower power operation (due to faster power

cycling rates), doing so generally results in more noise.

Many systems include an antialiasing filter between the

accelerometer and the A/D converter. The time constant

of this antialiasing filter must also be considered when

power cycling.

Table I shows the approximate turn-on time (including

the internal low-pass filter) for several accelerometers.

Faster turn-on times allow the user to very quickly turn

on the accelerometer, measure the acceleration, and

then turn off the accelerometer.

Table I. Accelerometer Turn-On Time

Model Bandwidth Turn On

ADXL202/ADXL210 5000 Hz 460 s

ADXL105 12 kHz 700 s

ADXL150/ADXL250 1 kHz 360 s

ADXL190 400 Hz 750 s

Earthquakes are low frequency (below 20 Hz), low g,

multiaxis events, so we will use an ADXL202 and sample

at 40 Hz (25 ms) to avoid aliasing.

In this design, we can assume that vibrations of less

than 200 m

g

can be ignored (an earthquake is defined as

having sufficient energy to cause accelerations greater

g

than 200 m

). So our peak-to-peak noise floor must be

less than 200 mg. Using a peak-to-peak to rms ratio of

6.6, we find:

rms noise

= 200 mg/6.6 = 30.3 mg

So we will select a bandwidth that will result in an rms

noise floor that is less than 30.3 mg.

Noise Noise Density bandwidth=¥¥16.

For the ADXL202 with a typical

Noise Hz bandwidth=¥¥500 g 1.6m

noise density

of 500 g/

Hz:

÷

Rearranging the equation;

Bandwidth noise noise density=¥()(. )

22

16

In this example, the maximum bandwidth is approximately 2.3 kHz. Using the closest standard value, we can

set the bandwidth to 2 kHz. Therefore

C

and CY are

X

0.0022 F and the noise floor is approximately 28 m

rms (185 mg peak to peak).

For the ADXL202, the turn-on time is approximately:

TCms

=¥=160 0 3.

ON X

where

C

is in F. The 0.3 s is the turn-on time of the

X

accelerometer itself, while the 160

C

(or

C

X

) term is

Y

the settling time of the bandwidth limiting filter. Using a

0.0022 F capacitor, the turn-on time to steady state is

approximately 650 s. The analog outputs and an A/D

converter will be used, so a conversion time of 25 s

must be added. So the total ontime is 675 s.

g

Adding a single-pole low-pass filter (antialiasing) to the

accelerometer output will lengthen the turn-on time by

5/(2

f

) seconds, where f is the corner frequency of the filter.

For example, restricting the bandwidth of an accelerometer to 50 Hz by adding a single-pole low-pass filter

would add 15.9 ms to the settling time.

Low Power Design Example

Most low power designs appear in devices that measure

movements that take place infrequently. These applications are ideal for power cycling. A good example is an

automatic shutoff gas valve. In the event of an earthquake, the valve shuts down the natural gas supply to

prevent ruptured gas pipes from leaking. Minor tremors

(as can be created by large trucks passing by) and single

impulse shocks (as would be generated by bumping into

the valve) should be ignored.

Therefore the average power consumed is:

600 0 675 25 16 2

Amsms A¥=(. ) .

with a 5 V supply. Lowering the supply voltage to 3 V will

reduce the average current consumption to 10.8 A.

Obviously, 200 mg peak-to-peak noise is too high to

make a good measurement. Therefore, if a measure-

g

ment of greater than 200 m

is made, the sampling

speed can be increased for a few seconds to 800 Hz and

groups of 20 samples can be averaged. This will bring

the noise floor down to approximately 6 m

peak to peak), allowing more precise measurement.

More power will be used at this time, but as this happens infrequently, the average power consumed will

still be under 20 A.

–2–

g

rms (42 m

REV. 0

g

Page 3

AN-601

Software can then determine if the higher acceleration

(>200 m

g

) was actually caused by an earthquake or just

a single impulse event due to jostling and take appropriate action.

The ADXL202/ADXL210

With its PWM outputs, the ADXL202/ADXL210 is a special

case and merits special attention when power cycling.

Using the PWM Outputs

The duty cycle modulator of the ADXL202/ADXL210

runs asynchronously to the rest of the accelerometer.

Since we have no way of knowing what state the PWM

output will be in when the accelerometer analog output

data is valid, we must wait at least one T2 period after

the specified turn-on time (to ensure the data is valid).

This leads to two conclusions:

1. Using the analog outputs and an A/D converter

rather than the PWM outputs will allow faster power

cycling and therefore the lowest power operation.

2. If we choose to use the PWM outputs with power

cycling, we should use the shortest T2 time possible.

However, using a short T2 implies using a fast

counter, which is normally inconsistent with low

power operation.

Although not explicitly specified in its data sheet, the

maximum PWM frequency is typically 5 kHz (R

SET

=

25 kW). Therefore, the additional overhead needed to

use the PWM outputs will be at least 400 s (two T2

periods—one period wait for valid data and another

period for measurement) to calculate the counter time.

The ADXL202 has a total dynamic range of ±4

g

or

Ω8000 mgΩ. At T2 = 5 kHz, 1 mg per count = [(1/5 kHz)/

8000 m

g

] total range or 250 ns per mg). In addition, if we

want to use such a fast T2 period and maintain 10 m

g

resolution (for the ADXL202), we would need a counter

that counts in 250 ns increments.

Even if only 32 mg resolution (roughly equivalent to 2∞

of tilt) were sufficient, the counter increment would rise

to 800 ns, still too fast for most low power 8-bit

microcontrollers.

Using a counter that runs at 1 MHz (1 s per count) and

maintaining 10 m

g

resolution, we would have to run T2

at approximately 1.25 kHz. In this case, the T2 overhead

would rise to 1.6 ms compared to the approximately

25 s that an A/D converter would take to complete a

conversion. Clearly, the overall system design becomes

more involved when we are looking to minimize power

consumption and use the PWM outputs of the ADXL202/

ADXL210. Often the best choice when looking to minimize

both component cost and power consumption is to use

an A/D converter along with the ADXL202/ADXL210.

The exception to this is when the sampling rate is very

low. In a system where a measurement is only made

from time to time, the additional time required to use the

PWM output is not a great handicap. The high resolution

and low cost (i.e., no A/D converter required) may be

more important than the additional power consumption.

Reducing Turn-On Time with Charge Conservation

In the majority of applications, most of the turn-on time of

the ADXL202/ADXL210 is attributable to the time constant

of the bandwidth limiting filter (formed by the internal

32 kW resistors and C

or CY). The CX and CY values are

X

normally dictated by the resolution required in the application. Many tilt sensing applications are low speed in

nature and are therefore good candidates for power

cycling. However, these applications often require high

resolution and large C

and CY values are mandated,

X

resulting in long turn-on times. In many cases, the turn-on

time can be greatly reduced by conserving the charge on

C

and CY.

X

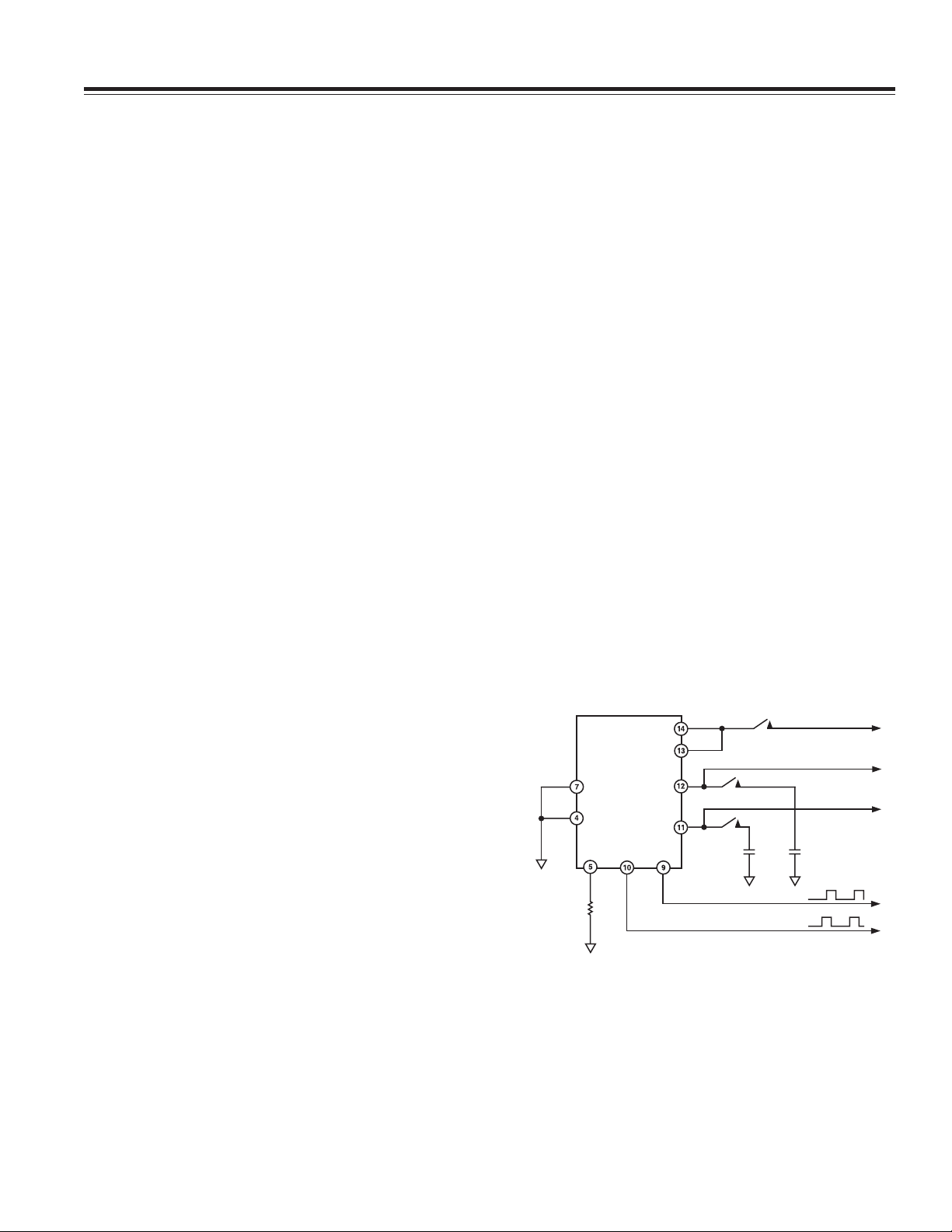

Figure 3 shows a typical circuit used for charge conservation. C

and S3) just prior to the removal of V

and CY are switched out of the circuit (via S2

X

to the ADXL202/

DD

ADXL210 (via S1). They are switched back in just after (a

few ms) V

is applied to the ADXL202/ADXL210. This

DD

removes any path for the filter capacitors to discharge

(other than leakage through C

, CY, and the switches

X

themselves). In an actual system, a CMOS analog switch

would be used for S1, S2, and S3.

By keeping the filter capacitors (CX and CY) from discharging, we can speed up the settling time as shown in Figure 4.

This allows us to turn off the accelerometer quickly and

conserve power. Note that it takes the same time to arrive

at steady state with or without charge conservation.

V

R

SET

ADXL202

COM

COM

T2

X

Y

X

OUTYOUT

V

DD

DD

FILT

FILT

S1

S2

S3

C

C

Y

X

Figure 3. Charge Conservation Circuit

If the goal is to arrive at measurements that are accurate

within a certain tolerance of the steady state output

(100 m

g

as an example), it can be realized more quickly

by using charge conservation. Figure 4 shows the C

Y

(Pin 11) output of a system that is being power cycled

10 ms ON/17 ms OFF, for an effective bandwidth of

about 18 Hz. With V

tion architecture with C

= 5 V and using a charge conserva-

DD

and CY 0.1 F, the average

X

current used is:

REV. 0

–3–

Page 4

AN-601

A

A

IAmsms

=¥ =600 10 27 222mm()

AVG

After 17 ms, the CX and CY voltage droops down to

1.81 V. 10 ms after V

are 2.471 V. That is within 28 mV (or 92 mg) of the

C

Y

is applied to the ADXL202, CX and

DD

steady state output in this case.

2.5

2.0

WITH CHARGE

CONSERVATION

1.5

(PIN 11) – V

1.0

CAP

V

0.5

0

–0.005 0.0200.005

0

WITHOUT CHARGE

CONSERVATION

0.010 0.015

TIME – Sec

Figure 4. Voltage with and without Charge Conservation

Had charge conservation not been used, we would have

had an error of 107 mV (or 342 m

state output after 10 ms. To get to within 92 m

g

) versus the steady

g

of steady

state output without charge conservation, we would

have had to wait 14.1 ms after turn-on, resulting in an

average current consumption of:

IAmsms

=¥ =600 14.1 27 313mm()

AVG

a difference of 41%.

Had we lowered the supply voltage to 3.3 V, the average

current consumed would be 146 A with charge conservation and 207 A without.

Note that the time required to arrive within 100 m

g

of

the steady state response depends a great deal on the

amount of droop, which is chiefly determined by the

switch leakage.

Switch Selection

The performance of a charge conservation system

depends greatly on the switch selected. The 74HC4016,

and others like it, perform fairly well. However certain

switches, such as the metal gate CMOS 4016 type,

should be avoided because of their high ON resistance

at supply voltages of 5 V or less. The 4066 and 74HC4066

should also be avoided because their internal architecture tends to discharge the filter capacitors when

switched, precisely the opposite of what we wish to do.

There are many CMOS analog switches available that

will work satisfactorily in this application. It is important

to try out the switch you choose to see if its performance

is adequate.

Using I/O Ports Instead of Switches

In minimal systems, the CMOS analog switch may be eliminated totally at the expense of some power consumption.

V

2M⍀

ADXL202

COM

COM

T2

X

Y

X

OUTYOUT

V

DD

DD

FILT

FILT

MICROCONTROLLER

I/O

V

I/O

I/O

A

IN

DD

COM

I/O

A

I/O

IN

3 V

Figure 5. Using Microcontroller I/O

Rather than using CMOS analog switches to high side

switch the capacitors (as shown in Figure 3), one can use

the output ports of a microcontroller to low side switch

the capacitors as shown in Figure 5. Here the bandwidth

limiting capacitors, R

, and the ADXL202/ADXL210 are

SET

three-stated when no measurements are being made so

as to remove any discharge path for CX and CY. As the

duty cycle outputs are not being used, we are free to

choose a high value for R

, allowing us to save a few

SET

microamps.

Using I/O ports is usually a very low cost and compact

solution since no additional components are required.

However, it is generally lower performance than analog

CMOS switches since microcontroller I/O ports are not

optimized for low leakage. Figure 6 outlines a model of

the nodes at the filter capacitors when both sides are connected to I/O ports that are in Three-State mode. The

value of the “leakage” resistors depends on the construction of the given microcontroller. Obviously, the charged

capacitor will discharge through the leakage resistors.

The performance of the system shown in Figure 5 is

described in Table II. A Microchip Technology PIC16C73

was used. Different microcontrollers may yield different

results because of differences in the I/O structure.

–4–

REV. 0

Page 5

A

IN

X

FILT

R

LEAKAGE

500k

AN-601

/

⍀

I/O

R

LEAKAGE

500k

⍀

Automatic Shut-Off Gas Valve Revisited

Looking back at the earlier low power design example,

we can further reduce the power consumption by using

the charge conservation techniques discussed here.

Figure 6. Model of Microcontroller Ports when in

Three-State Mode

Table II. Peak-to-Peak Output Error vs. On Time for Figure 5

= 3.3 V, Sampling Rate = 36 Hz, and Bandwidth = 18 Hz

V

DD

T

ON

Infinity 0 400 A0 m

11 ms 17 ms 157 A 32 m

9 ms 19 ms 128 A 80 m

7 ms 21 ms 100 A 160 m

5 ms 23 ms 87 A 320 m

T

OFF

I

AVG

Error

g

g

g

g

g

If a slower (than 36 Hz) sampling rate could be tolerated,

additional power savings can be realized by lengthening

the T

sampling rate) system with a T

time. For example, a 10 Hz bandwidth (20 Hz

OFF

of 11 ms and a T

ON

OFF

of

39 ms would consume 87 A while still settling to within

32 m

g

using the circuit shown in Figure 5.

Using a circuit similar to Figure 5, but with C

and C

X

0.0022 F, the settling time to 200 mg is approximately

430 s plus 25 s of A/D acquisition time. So the average

current consumed is:

600 455 25 10 9

Asms A==.

with a 5 V supply and only 7.3 A with a 3 V supply

(a 33% reduction in current consumption compared to

the previous example).

Conclusion

While iMEMS accelerometers are inherently low power

devices, several techniques are available to designers to

lower their power consumption even further. Generally,

lower power operation results in degraded noise performance. It is therefore important for the designer to

understand the compromises they will be making in pursuing very low power operation. Current consumption

of well under 100 A is feasible in many low speed

applications and even under 10 A in some cases.

Y

REV. 0

–5–

Page 6

–6–

Page 7

–7–

Page 8

E03046–0–10/02(0)

–8–

PRINTED IN U.S.A.

Loading...

Loading...