Page 1

AN-587

a

One Technology Way • P.O. Box 9106 • Norwood, MA 02062-9106 • Tel: 781/329-4700 • Fax: 781/326-8703 • www.analog.com

APPLICATION NOTE

Synchronizing Multiple AD9850/AD9851 DDS-Based Synthesizers

by David Brandon of Analog Devices, Inc.

INTRODUCTION

Many applications require the generation of two or

more sinusoidal signals with a known phase relationship (e.g., quadrature). The AD9850 and AD9851 DDS

ICs from Analog Devices are capable of providing such

signals. This application note offers detailed instructions on how to synchronize two or more of these

devices, and considers possible sources of phase error.

REF CLOCK

The first requirement for successful synchronization of

multiple AD9850/AD9851s is that there must be minimal

phase error between the REF CLK inputs to all DDSs.

Any difference in phase between REF CLK edges will result

in a proportional phase difference at the DDS outputs.

The user must employ careful clock distribution practice

in the layout of the PCB to ensure coincident REF CLK

edges (see Figure 1).

The AD9850/AD9851 REF CLK input circuitry is singleended so it is necessary that the REF CLK have minimum

input jitter and fast rise/fall times (less than 5 ns is recommended). A slow rise time on REF CLK can introduce

errors because the voltage trip point of the input circuit

varies from device to device. These attributes would

also apply to W_CLK and FQ_UD inputs.

AD9850/AD9851 I/O ACCESS DETAILS

Once a fast-edged and properly routed REF CLK signal is

provided, the next timing requirement is the coincident

transfer of the data into the DDS program registers. The

FQ_UD signal transfers the data to the DDS core. Synchronization of multiple DDSs requires that the FQ_UD

rising edge occur simultaneously at all DDSs, just like

the REF CLK. In addition, the FQ_UD must occur at the

proper time with respect to the REF CLK.

REV. 0

A = B = C

REF

CLK

OPTIMUM LAYOUT

DDS1

A

B

DDS2

C

DDS3

Figure 1. REF CLK Distribution

REF

CLK

DDS1

DDS2

DDS3

© Analog Devices, Inc., 2002

Page 2

AN-587

FACTORY CODES

SHIFT

REGISTER

SLEEP MODE

AD9851 6

MULTIPLIER

40

D

Q

CK

RCK

REGISTER

3

Q

Q

5

32

Q

R

DATA

W_CLK

FQ_UD

RESET

REF

CLK

CONTROL

FUNCTIONS

8

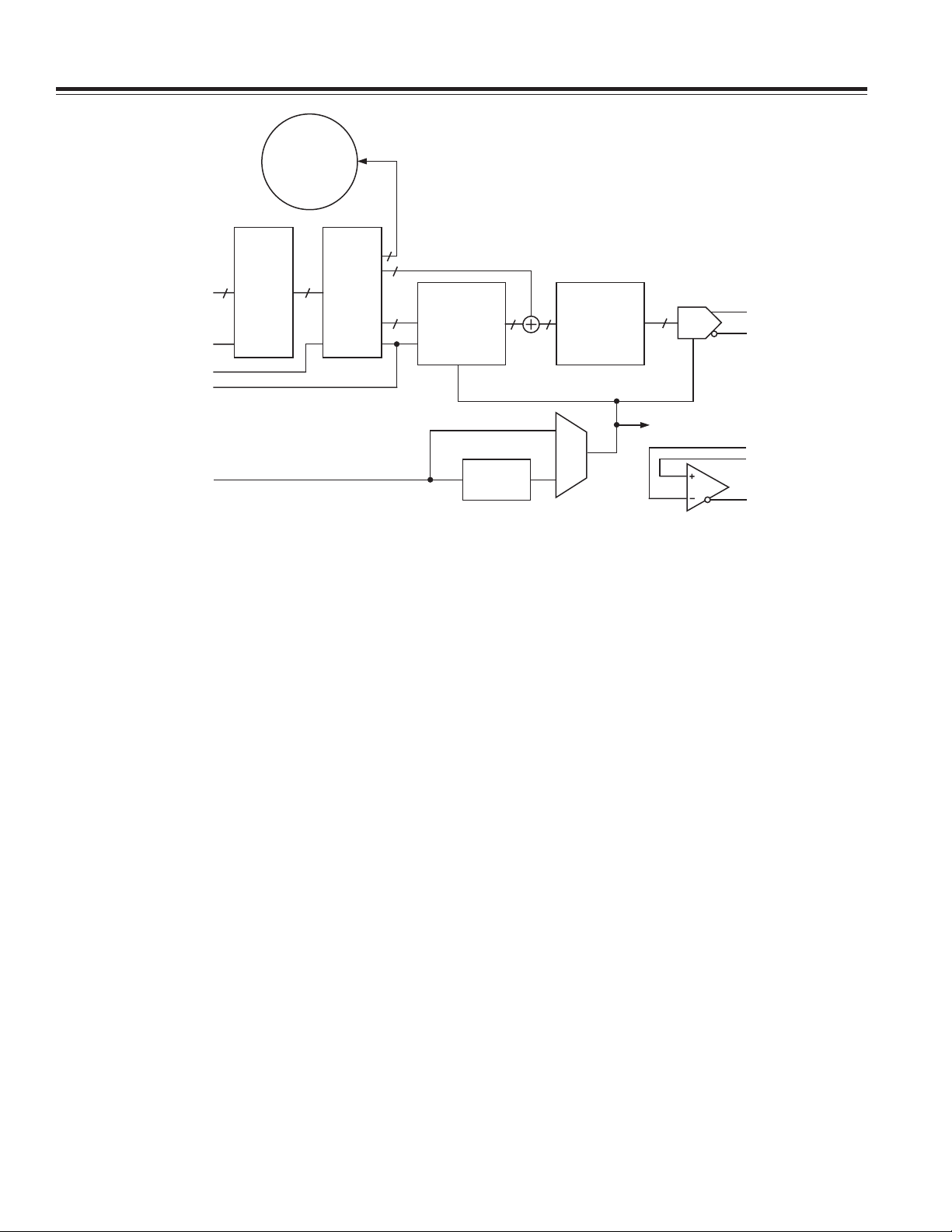

Figure 2. AD9850/AD9851 Functional Block Diagram

Figure 2 is a functional block diagram of the AD9850/AD9851.

There are only small differences between the two devices.

The AD9851 has a 6x clock multiplier (PLL) and MUX, but

the AD9850 does not.

There are two registers in front of the DDS core. The shift

register accepts five bytes in parallel mode or 40 bits in

serial mode. W_CLK latches data into this register. The

second register, after it is triggered by FQ_UD, presents the contents of the shift register to the DDS core

on the next rising edge of the SYSTEM CLOCK.

It is essential that a proper time relationship exist between

the FQ_UD and SYSTEM CLOCK (Figure 2). Improper timing of these signals can result in partial loading of the

tuning word, inhibiting the synchronization of the DDSs.

The FQ_UD must have proper setup times prior to a rising REF CLK edge. The proper timing will be addressed

in the Synchronization Instructions section, and is

shown in figures 4 and 6.

PHASE OFFSET

PHASE

ACCUMULATOR

R

6 REF CLK

MULTIPLIER

10

DAC

SYSTEM CLOCK

COMP

AD9851

14 14

PHASE

AMPLITUDE

MUX

TO

RESET

A RESET must be given after power-up and prior to

transferring any data to the DDS. This places the DAC

output to a known state, which becomes the common

reference point that allows the synchronization of multiple DDSs.

RESET forces the AD9850/AD9851’s phase state to become

COS(0). When new data is sent simultaneously to multiple DDSs, a coherent phase relationship is maintained,

or the relative phase can be shifted between devices by

means of the phase offset adjustment register. The

AD9850 and AD9851 have 5 bits of phase offset adjustments, amounting to a phase resolution of 11.25 degrees.

The phase offset adder is located between the phase accumulator and the phase-to-amplitude converter.

NOTE: The RESET does not reset the shift register. It

only resets the FQ_UD’s register and the phase accumulator to COS(0). The shift register should be treated as

containing “random” data after a RESET and may inadvertently contain a reserved “factory code” that causes

the DDS to behave in unintended ways. For this reason,

a FQ_UD should not be sent until the shift register has

been programmed with the intended data.

–2–

REV. 0

Page 3

AN-587

SYNCHRONIZATION INSTRUCTIONS

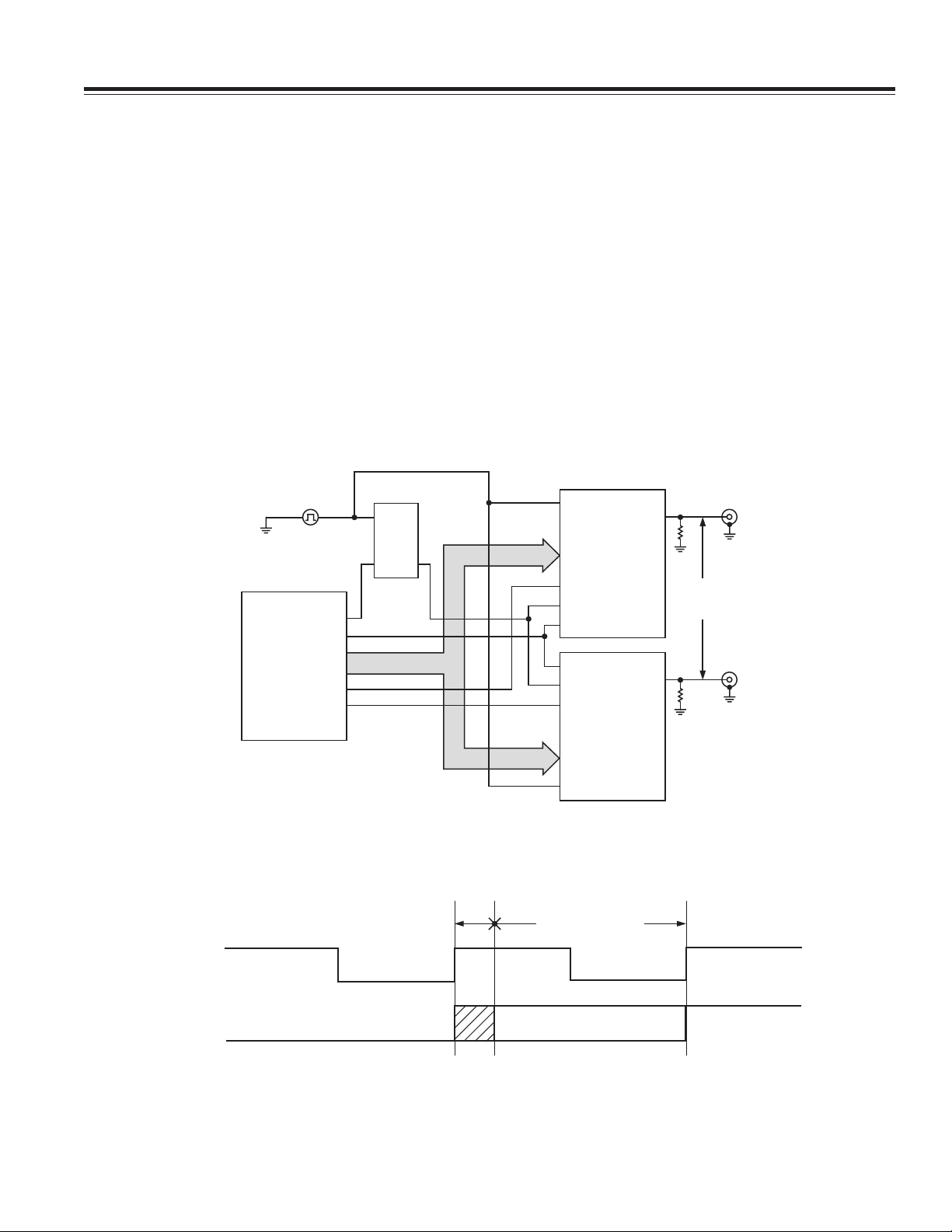

Figure 3 presents one possible reference design for successful synchronization of multiple DDSs. This example

shows how to place two DDSs into a quadrature phase

relationship.

In Figure 3, the D flip-flop enables the FQ_UD to be synchronous with the REF CLK and provides a setup time

delay. Proper operation may require additional time delay

in the FQ_UD path. This delay depends upon the CK-to-Q

propagation time of the flip-flop. The recommended

timing relationship between the FQ_UD (Pin 8) and the

REF CLK (Pin 9) is depicted in Figure 4.

Here are some general instructions and recommendations

for placing two DDSs into a

quadrature

phase relationship

(refer to Figure 3). There are two sets of instructions, with

and without the 6 REF CLK multiplier enabled.

CK

D FLOP

DQ

FQ_UD

RESET

MICROPROCESSOR

OR FPGA

W_CLK-1

W_CLK-2

8-BIT DATABUS

Instructions for synchronizing two DDSs in quadrature

without the AD9851’s 6 REF CLK multiplier enabled:

1. Power up all devices and apply the common REF CLK.

2. Send a common RESET with a minimum high time of

five REF CLK periods.

3. Program DDS #1 to the desired frequency and a

phase offset of 0 degrees

without

issuing an FQ_UD.

4. Program DDS #2 to the same frequency and a phase

offset of 90 degrees without issuing an FQ_UD.

5. Assert a

common

FQ_UD. This will result in the DAC

outputs becoming active simultaneously at the correct frequency and phase offset as programmed.

6. See Figure 4 for the recommended timing between

REF CLK and FQ_UD.

REF CLK

AD9850/AD9851

#1

DATA

W_CLK

FQ_UD

RESET

RESET

FQ_UD

W_CLK

AD9850/AD9851

#2

DATA

90

PHASE

DIFFERENCE

REV. 0

REF CLK

FQ_UD

REF CLK

Figure 3. Application Circuit

AD9850/AD9851 TIMING RELATIONSHIP

WITHOUT THE 6 REF CLK MULTIPLIER ENABLED

1.5ns

(MIN)

NOT

VALID

THIS TIMING CAN BE TRANSLATED INTO A MINIMUM SETUP

TIME OF 0ns AND A MINIMUM HOLD TIME OF 2 SYSTEM

CLOCK PERIODS.

FQ_UD MUST OCCUR

WITHIN THIS RANGE

VALID

Figure 4. Proper Timing Relationship between REF CLK and FQ_UD

–3–

Page 4

AN-587

CH4

CH1 200mV M 5.00s CH4

2.40V

2.00V

4

1

: 30.0s

@: 29.8s

4

FUD

AD9851 DDS OUTPUT

PLL LOCK TIME

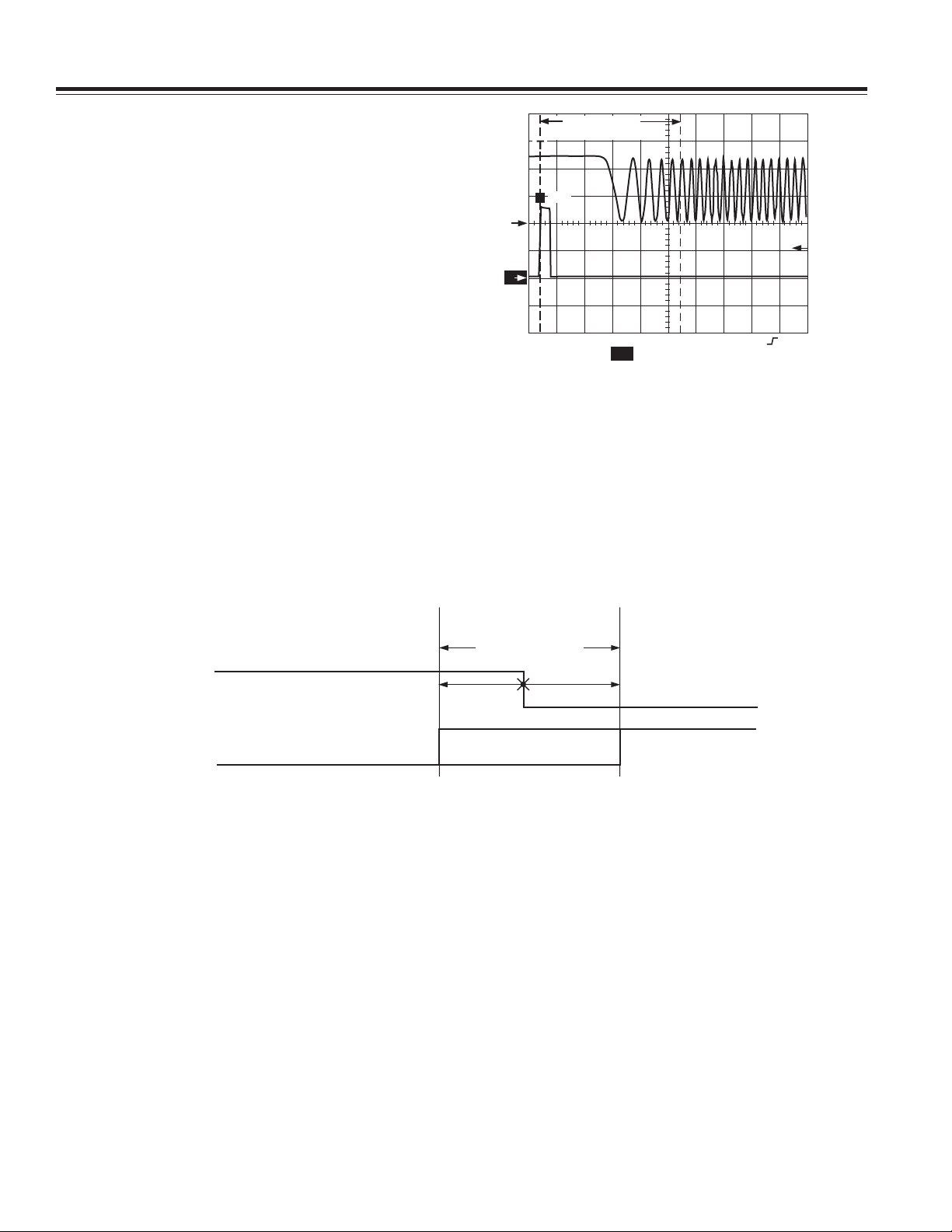

Considerations When Using the 6 REF CLK Multiplier

on the AD9851

The 6 REF CLK multiplier of the AD9851 must be used

with care when synchronizing multiple DDSs because the

PLL lock time will vary from device to device. This means

that the number of system clock cycles delivered to the

phase accumulator at lock time could vary.

This problem is addressed by asserting RESET followed

by programming the tuning word for all devices to zero.

This sets the phase accumulator’s phase to zero and prevents the accumulator from incrementing while the PLL

locks. Once the PLLs lock, all the DDSs are holding at

zero phase. Since all the devices are clocked by a common REF CLK and the PLLs are phase-locked to REF

CLK, all system clock signals will be phase coherent

(assuming a proper REF CLK signal is routed to each

DDS, as previously discussed).

A typical PLL lock time is approximately 30 s. Due to

variations in IC processing and temperature effects on

lock time, it is recommended to allow at least 100 s for

locking to occur (refer to Figure 5).

Figure 5. Typical PLL Lock Time

NOTE: Since the 6 REF CLK multiplier locks to the falling edge of REF CLK, the FQ_UD signal should be

referenced to the falling edge of REF CLK. The recommended timing relationship between the FQ_UD (Pin 8)

and the REF CLK (Pin 9) is depicted in Figure 6.

REF CLK

FQ_UD

AD9851 TIMING RELATIONSHIP

WITH THE 6 REF CLK MULTIPLIER ENABLED

*

FQ_UD MUST OCCUR

WITHIN THIS RANGE

X(ns) Y(ns)

VALID

* FQ_UD SHOULD BE REFERENCED TO THE FALLING EDGE OF REF CLK AND THE

VA LID TIMING RANGE SHALL BE RELATIVE TO A PERCENTAGE OF REF CLK’S PERIOD.

THE VALID TIMING RANGE IS NOT NECESSARILY SYMMETRICAL ABOUT REF CLK’S

FA LLING EDGE. TABLE I DESCRIBES THE “X” AND “Y” SET UP TIME RANGE GIVEN REF

CLK’S FREQUENCY, VCC, AND TEMPERATURE MINIMUM HOLD TIME IS 2 SYSTEM CLK PERIODS.

Figure 6. Proper Timing Relationship Using the 6⫻ Multiplier

–4–

REV. 0

Page 5

AN-587

Instructions for synchronizing two DDSs in quadrature

with the AD9851’s 6 REF CLK multiplier enabled:

1. Power up all devices and apply the common REF CLK.

2. Send a common RESET with a minimum high time of

five REF CLK periods.

3. In parallel or serial mode, write the following instructions to DDS #1

W0 = 01 hex W1 = 00 hex W2 = 00 hex

W3 = 00 hex W4 = 00 hex

4. Repeat step 3 for DDS #2.

5. Assert a

NOTE: This will set each DDS to a tuning word of zero

and engage each REF CLK multiplier simultaneously.

The tuning word of zero will keep the DAC outputs at a

zero phase until the PLLs have finished locking.

IMPORTANT: Remember to keep the REF CLK multiplier

enabled when writing a new tuning word and phase

offset.

6. Program DDS #1 to the desired frequency and a

phase offset of 0 degrees

7. Program DDS #2 to the same frequency and a phase

offset of 90 degrees without issuing an FQ_UD.

common

without

issuing an FQ_UD:

FQ_UD and wait at least 100 ms.

without

issuing an FQ_UD.

Table I. Setup Time Range between FQ_UD

and REF CLK per Frequency, VCC, and Temperature

VCC = 5 V

REF CLK

Frequency

(x) ns (MHz) (y) ns

8 5–7 4

5 7–10 4

3 10–15 3

2 15–20 3

1 20–30 2

VCC = 3.3 V

REF CLK

Frequency

(x) ns (MHz) (y) ns

7 5–7 7

5 7–10 6

2.5 10–15 4

2 15–20 3

Note: Includes Temperature (–40∞C to +85∞ C)

8. Assert a

outputs becoming active simultaneously at the correct frequency and phase offset as programmed.

9. See Figure 6 for the recommended timing between

FQ_UD and REF CLK.

common

FQ_UD. This will result in the DAC

REV. 0

–5–

Page 6

AN-587

CH1

2

CH4

T

T

T

T

100mV M 20.0ns CH4 2.36V

2.00V

1

4

: 96.8s

@: –800ps

DDS2 OUTPUT

DDS1 OUTPUT

CH3 2.00V

3

100mV

18 RISING EDGES

OF THE SYSTEM

CLOCK PLUS THE

SETUP TIME

CH2

30MHz REFERENCE CLOCK

(6-PLL MODE)

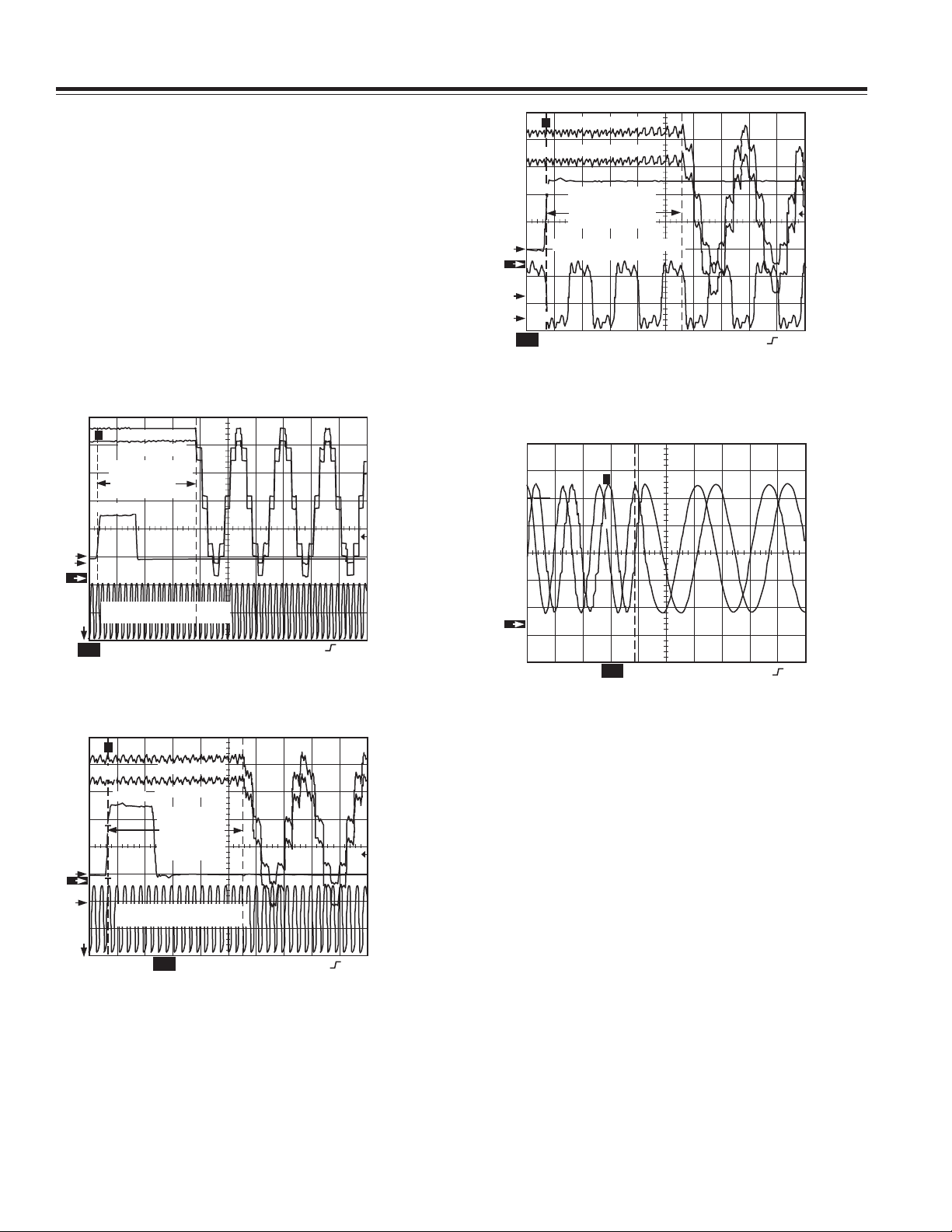

SUMMARY

With proper care and procedure, synchronization can be

achieved among multiple DDSs. The following figures

show how two AD9851s can be synchronized. In

Figure 7, the REF CLK frequency is set to 10 MHz and in

Figure 8, it is set to 180 MHz. Both are in non-PLL

mode. In Figure 9, REF CLK is set to 30 MHz, with PLL

enabled (system clock = 180 MHz). Figure 10 shows two

AD9851s remaining in quadrature, even as the frequency

changes. Quadrature is denoted by the cursor positions on the two signals.

Also shown in Figures 7 through 9 is the fixed pipeline

delay of 18 rising edges of the system clock plus the

setup time. This delay is measured with the cursors

shown in the figures.

T

DDS1 OUTPUT

T

DDS2 OUTPUT

18 RISING EDGES

OF THE SYSTEM

CLOCK PLUS

THE SETUP TIME

T

FQ_UD

: 1.72s

@: 1.69s

Figure 9. DDS Synchronization – Max System CLK

(PLL Mode)

: 1.13s

@: 1.64s

T

T

4

2

1

10MHz REFERENCE CLOCK

3

(NON-PLL MODE)

100mV M 500ns CH4

CH1

CH3 2.00V

CH2

CH4

100mV

2.00V

1.28V

Figure 7. DDS Synchronization – 10 MHz System CLK

T

T

4

2

1

3

CH1

100mV M 20.0ns CH4

CH3 2.00V

Figure 8. DDS Synchronization – Max System CLK

DDS1 OUTPUT

DDS2 OUTPUT

FQ_UD

18 RISING

EDGES OF

THE SYSTEM

CLOCK PLUS

THE SETUP

180MHz REFERENCE CLOCK

(NON-PLL MODE)

100mV

CH2

2.00V

CH4

1.28V

: 96.8s

@: –400ps

2

CH1

100mV M 500ns CH4

CH2

Figure 10. DDS Quadrature Synchronization

2.70V100mV

–6–

REV. 0

Page 7

–7–

Page 8

E02808–0–5/02(0)

–8–

PRINTED IN U.S.A.

Loading...

Loading...