Page 1

AN-541

a

APPLICATION NOTE

One Technology Way • P.O. Box 9106 • Norwood, MA 02062-9106 • 781/329-4700 • World Wide Web Site: http://www.analog.com

Proper System Grounding Techniques for 6B Series Systems

INTRODUCTION

The 6B series of digital signal conditioning modules,

when properly applied and configured, can provide the

user with unsurpassed accuracy and stability in industrial data acquisition and control applications.

However, in order to obtain the maximum performance

from these modules, it is necessary to pay careful attention to the ways in which the 6B backplanes are powered

and grounded.

It has been our experience that, when faults and errors

are encountered in 6B applications, the culprit almost

invariably can be traced to system grounding techniques. The errors produced by bad grounding sometimes manifest themselves as unstable, noisy or erratic

readings from thermocouples, RTDs, or other signals.

Occasionally, the errors result in ”code faults,” i.e., disturbances to the execution of the microcontroller, which

is contained within the 6B itself. In severe cases, the errors can result in disturbances to the communications

between the 6B system and the host computer, or even

damage to the host computer’s communications ports.

Modeling a 6B Application

First, let’s consider the model for a typical industrial signal source, such as a thermocouple. The source has a dc

component, in the range of 100 mV or less, which is the

thermocouple signal itself; this component changes

with temperature, but since most temperature measurements are narrow bandwidth phenomenon (i.e.,

slowly changing), we can model the signal as dc.

The signal may also have an ac component, most typically a 50 Hz or 60 Hz “pickup” from adjacent power circuits. The 6B series modules are particularly good at

rejecting this ac component, since they employ an integrating converter design with a rectangular window of

integration linked to the power line frequency (and programmable for either 50 Hz or 60 Hz operation over the

communications interface).

Both of the signal components we’ve just discussed are

often referred to as “normal-mode signals,” since they

appear differentially between the sensor’s high and low

terminals. Normal-mode signals are the signals we

want to measure.

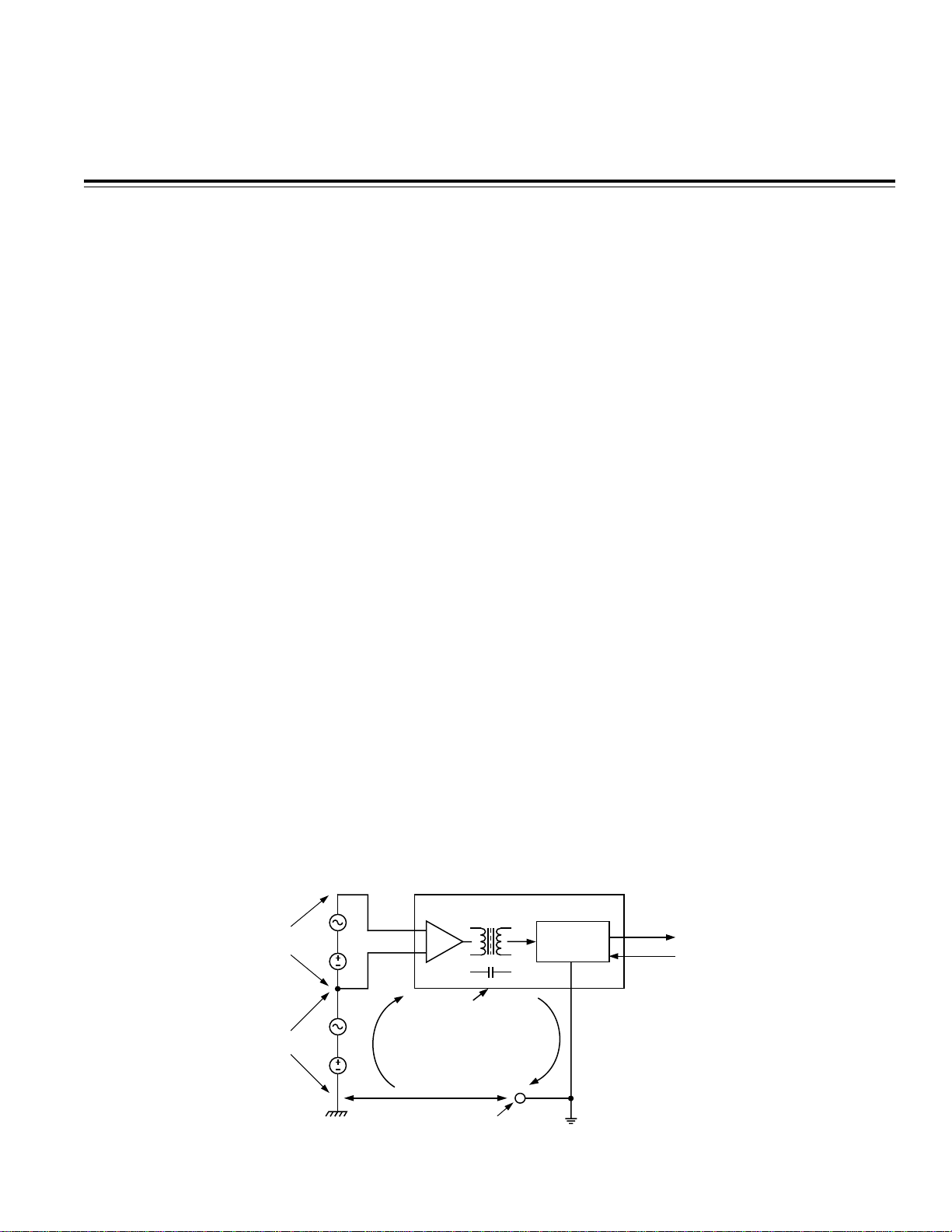

All of these effects can frequently be avoided via the use

of proper grounding and shielding techniques. As an aid

to understanding the problem, consider the diagram in

Figure 1, which illustrates a single 6B module application.

NORMAL-

MODE SIGNAL

COMMON-

MODE SIGNAL

A

BARRIER

CAPACITANCE

CONNECT GROUND

STUD TO REFERENCE

POINT OF COMMONMODE SIGNAL

Figure 1. Normal-Mode and Common-Mode Signals in a 6B Application

6B MODULE

HEAVY

GROUND STUD

In addition to the normal-mode components of our signal, a “common-mode” signal present may also be. The

common-mode signal is that signal which appears between the low side of the normal-mode signal, and

earth ground or any other point of reference. The com-

MICRO-

CONTROLLER

RS-485 OR RS-232

COMMUNICATIONS

POWER (NONISOLATED)

GROUND FOR MODULE

Page 2

AN-541

mon-mode signal is often unintentional, and caused by

ground drops between earth ground potential near the

signal source and earth ground potential near the 6B

system. In these cases, the common-mode signal can be

dc, ac, or a combination of the two.

In some applications, the common-mode signal may be

completely intentional; cases such as these include applications where the sensor, such as a thermocouple, is

in electrical contact with a high electrical potential (for

example, a thermocouple “buried” within the stator of

an electric motor). In such a case, the design depends on

the isolation characteristics of the 6B module to reject

the common-mode signal and measure only the normalmode component. In situations like these, the commonmode component is mostly ac, and frequently at power

line frequency and potential. Another example can be

found in aluminum manufacturing (electrolytic reduction), where measurements are often made of voltage

and current at each crucible, and the crucible itself is at

an elevated dc potential with respect to earth ground.

Finally, there are some applications in which there is no

intentional common-mode component to the signal, but

the user is employing an isolated signal conditioner like

the 6B in order to preclude damage in the event of an

error such as a short circuit or an unintentional miswiring of the system.

The isolation barrier within the 6B module (as with most

of Analog Devices’ industrial signal conditioning products) is a magnetic barrier, built in the form of a transformer. This kind of barrier offers superb rejection of

common-mode signals within a reasonable bandwidth,

but is not perfect. The barrier has capacitance and fast

common-mode transients can cause impulse currents to

flow through the barrier in an effort to find their way

back to the common, or ground, of their source.

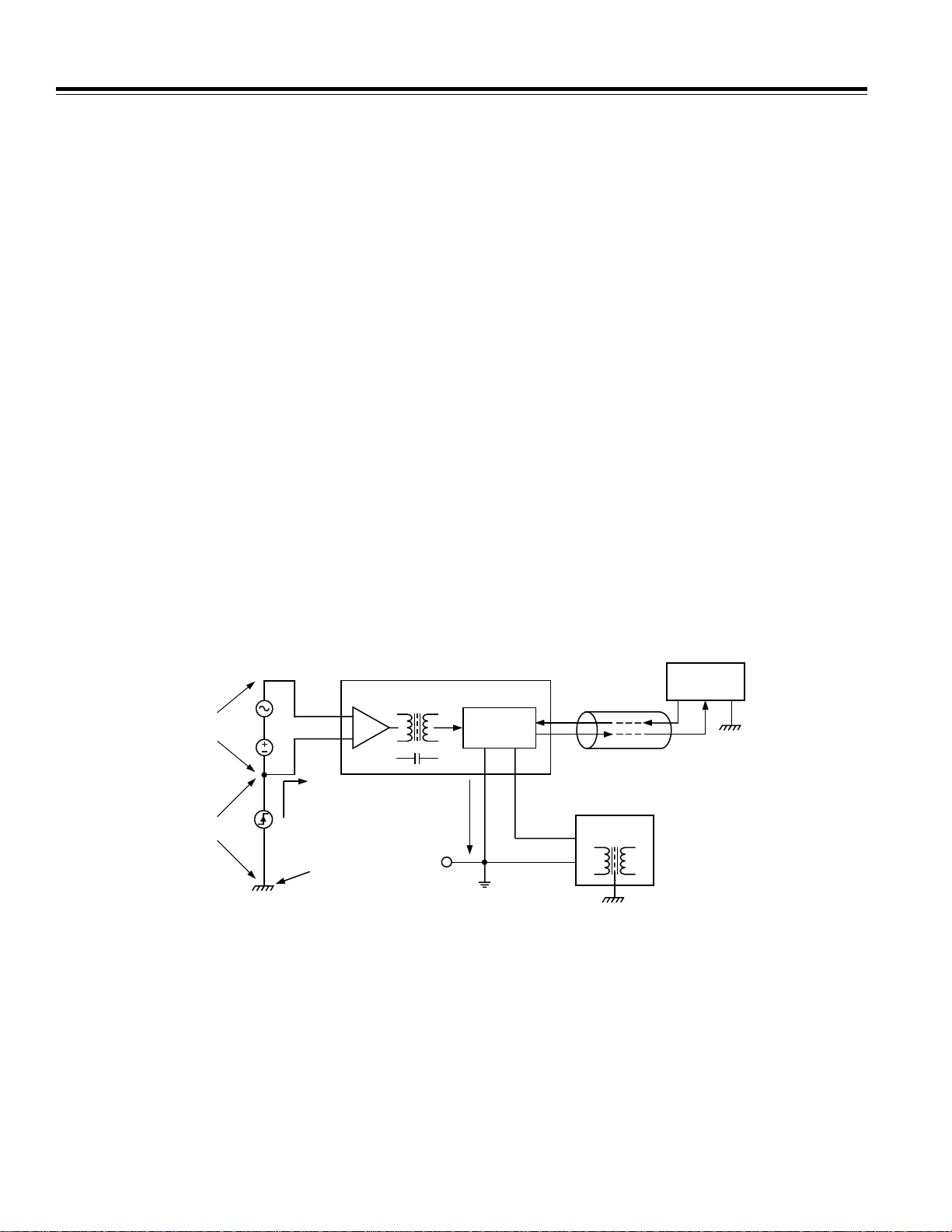

Consider the diagram in Figure 2, where a very fast transient appears in common-mode at the input to a 6B. Due

to barrier capacitance, the transient generates an impulse of current that needs to return to the source from

which it is generated. In this case, the return path is via

the 6B’s nonisolated ground (which is in common with

the 6B power supply ground).

The transient current will follow the path of least resistance back to its source. If the 6B system has no ground

connection to the ground of the source of the transient,

the ground potential will follow whatever path it can find

to return to its source. If it can find a return path locally

(i.e., near the 6B backplane itself), then it will even attempt to return via the communications ground, thereby

putting the control computer in jeopardy!

6B MODULE

NORMAL-

MODE SIGNAL

COMMON-

MODE SIGNAL

A

WITH NO GROUND STUD

CONNECTION, TRANSIENT CURRENT MUST RETURN VIA POWER

SUPPLY OR COMMUNICATIONS

LINE GROUNDS

FAST TRANSIENT

CURRENT WANTS TO

RETURN HERE

MICRO-

CONTROLLER

DC POWER

SUPPLY

Figure 2. Transient Current Return Path Without Ground Stud Connection

CONTROL

COMPUTER

–2–

Page 3

AN-541

Solving the Problem

The designers of the 6B took this into consideration

when creating the 6B subsystem. We have provided a

heavy ground stud on each backplane, connected to the

nonisolated ground of the system. The purpose of this

ground stud is to provide a suitable connection point for

attaching a ground lead that will divert transient current

through the isolation barrier, back to its source.

It is important that the application be wired such that

any potential transient currents be diverted back to their

source via a heavy wire from this ground stud. Without

this ground, transient currents will choose whatever

path they can find to return to their source. One possible

path is via the power supply used to power the 6B backplane; all transformer-based power supplies have capacitance between their outputs and the power line, and

sometimes this barrier capacitance can reach hundreds

of picofarads, making them an attractive path to the

transient current

Where Do Fast Transients Come From?

Many industrial environments are, unfortunately, a rich

source of high current fast transient signals. Things like

motor controllers, etc., often use IGBT (Insulated Gate

Bipolar Transistor) devices, or SCR (Silicon Controlled

Rectifier) devices as control elements; these devices can

generate transients as fast as several thousand volts per

microsecond, or faster, and often switch currents on the

order of tens or even hundreds of amperes! The magnetic fields created by these transients are pervasive,

and difficult to suppress.

How to Minimize the Transient Problem

Unfortunately, grounding methodologies don’t lend

themselves to “cookbook” analysis, because every situation is different. However, the following considerations

if no more suitable path is provided!

are good ones to follow when dealing with 6B signal

conditioning subsystems.

1.

Use the ground stud.

sure to attach the ground stud to the most likely point

of reference where common mode transients originate. Often, this point is earth ground near the source

of heavy equipment or high power sources associated with the measurement being made. Use a heavy

lead, as short as possible, in as straight a route as

possible, for best results.

2.

Ground the power supply

supply being used to power the 6B backplane. Its own

barrier capacitance may be significant, and can represent a path to earth ground. However,

use the power supply in place of the ground stud on

the backplane, because this can exacerbate the

problems.

3.

Consider isolating the communications lines.

severe cases, fast transients may actually attempt to

return to their point of origin via the ground conductors of the RS-485 communications connection

to/from the 6B system. While this situation is rare, it

has been known to happen and can cause faults or

even damage to the computer being used to interface

to the 6B subsystem.

Normally, the proper use of the ground stud can prevent

this situation. In extreme cases, however, it may be

helpful to use an isolation barrier on the communications port of the 6B to prevent these transients from using this path. A number of RS-485 and/or RS-232C

isolation devices are available, or the Applications staff

at Analog Devices can recommend devices for this

purpose.

When wiring a 6B backplane, be

. Don’t ignore the power

don’t

try to

In very

E3337–0–6/98

–3–

PRINTED IN U.S.A.

Loading...

Loading...