Page 1

AN-536

a

APPLICATION NOTE

One Technology Way • P.O. Box 9106 • Norwood, MA 02062-9106 • 781/329-4700 • World Wide Web Site: http://www.analog.com

Dimensional Gaging Measurements with Model 3B17

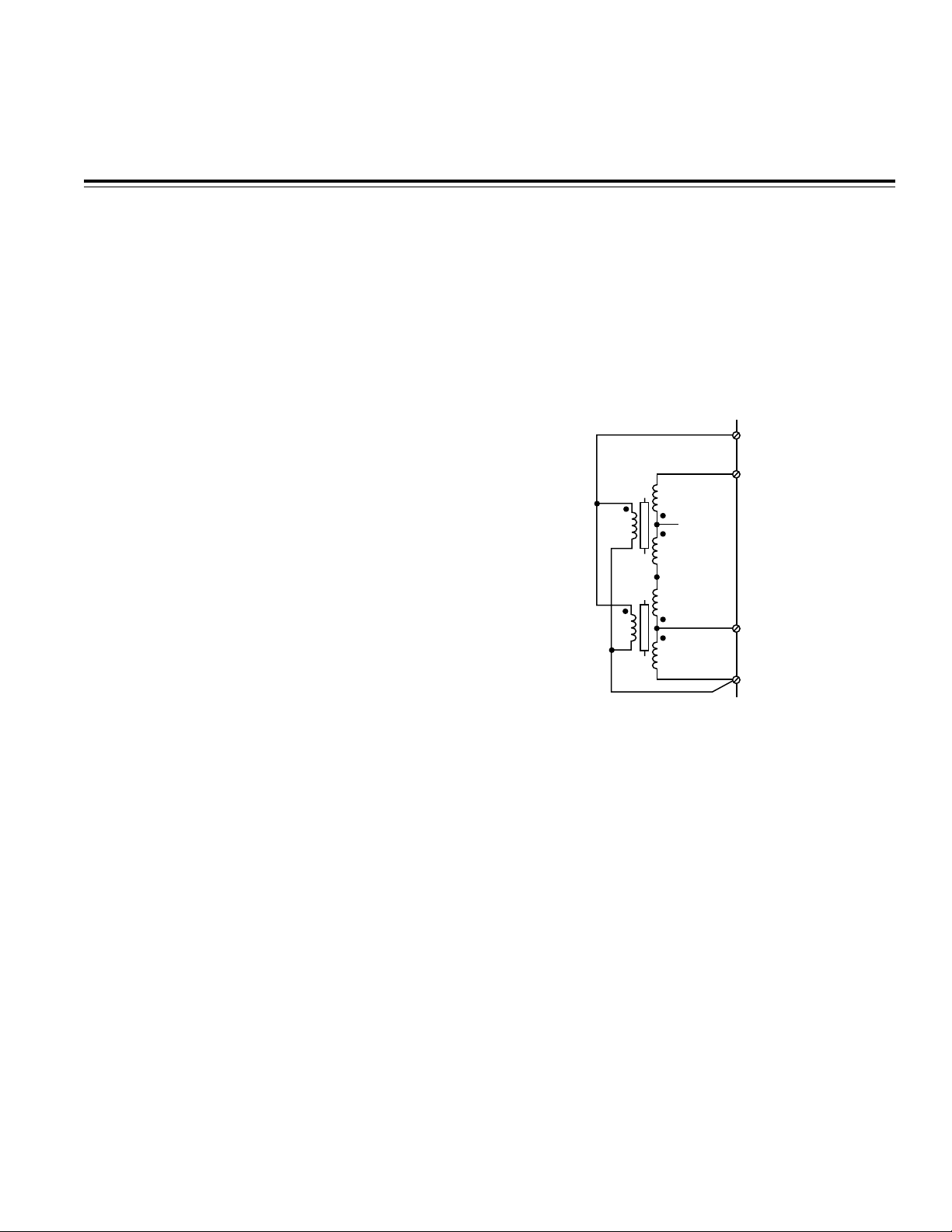

Linear Variable Displacement Transducers (LVDTs) are

common in gaging systems. Two LVDTs can be used to

measure the thickness or taper of an object. For a thickness measurement, the LVDTs are placed on either side

of the object to be measured. The LVDTs are positioned

such that there is a known maximum distance between

them in the fully retracted position. When the object to

be measured is placed between the two LVDTs, the displacement of both LVDTs are added together and then

the computer or control system will subtract this total

from the known distance between the LVDTs. Taper or

slope measurements are done by positioning the two

LVDTs at the same level at a known distance apart. If the

object to be measured is on the same level as the LVDTs,

both LVDTs would have the same reading. The difference between the displacements of the LVDTs divided

by the known difference in position will yield the slope.

(A – B)1 + (A – B)

–

B

+

LVDT 2

+

A

–

–

B

+

LVDT 1

+

A

–

Figure 1. Additive LVDT Connections

+EXC

2

A – B (SIGNAL)

A

–EXC

3B17

In a gaging application where many measurements are

made, and thus many LVDTs are used, the cost for

a signal conditioner for each transducer can be high.

One Analog Devices’ 3B17 LVDT signal conditioner can

be configured to handle two inputs for both the differential and additive applications, thus cutting the signal conditioning costs in half. Figure 1 shows two LVDTs connected

together with the input to the signal conditioning being the

sum of both LVDTs. The LVDTs should have matched

gains. Both LVDTs will receive the same excitation

signal up to a maximum of 20 mA. The demodulation

synch signal internal to the signal conditioner is two

times the voltage at Pin 3 of the conditioner (labeled A)

minus the voltage at Pin 2 (labeled A – B). This signal

should not vary more than +50%. Numerically this

indicates:

|

V

| > |(

A – B

)1 + (

A – B

A

1

)2|

MODEL 3B17 LVDT INPUT SIGNAL CONDITIONING

MODULE

The 3B17 is a nonisolated signal conditioning module

for LVDT interfacing. It provides a programmable, very

stable, low distortion ac excitation voltage for the transducer and accepts a 20 mV rms to 5 V rms input signal

from the LVDT. All gain and span adjustments are accomplished with screwdriver attachments on the top of

the module. The interpretation of the LVDT output voltage is done with a synchronous demodulator. This demodulator converts the ac output of the LVDT into a dc

voltage. It automatically compensates for any phase

error between primary and secondaries of the LVDT,

and eliminates the need for a phase adjustment. It also

rejects any residual quadrature or null voltage providing

accurate, linear ±10 volt and 4 mA–20 mA outputs.

Page 2

AN-536

+EXC

A – B

–

B

+

+

A

–

–EXC

P2

V/I

I

SPAN

I

PROTECTED

PRECISION

P1

1

2

3

4

OSCILLATOR

INPUT

PROTECTION

PROTECTION

RANGING CARD

(IF USED)

AMP

V

SPAN

A + B

DEMOD

V

OUT

ZERO

JUMPERS

V

ZERO

OUTPUT

PROTECTION

3B17

I

OUT

I

OUT

RETURN

LOOP V+

LOOP COM

COM

V

OUT

+15V

PWR COM

–15V

1

R

2

L

Figure 2. Block Diagram of Model 3B17

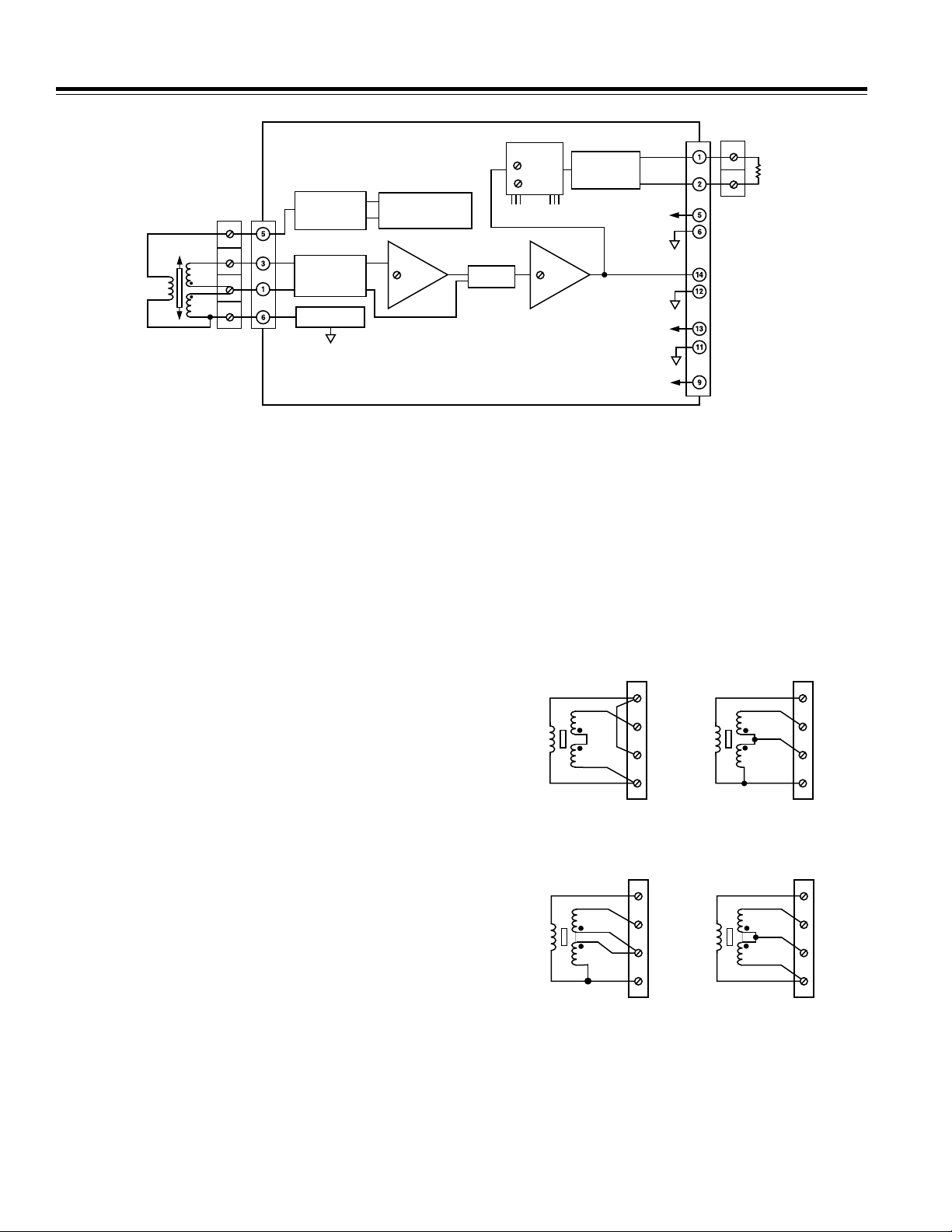

INSIDE THE 3B17

The 3B17 accepts inputs from 4-wire, 5-wire and 6-wire

LVDTs or RVDTs. A block diagram of Model 3B17 is

shown in Figure 2.

The 3B17 provides an ac excitation of 1 V rms to 5 V rms

at frequencies ranging from 1 kHz to 10 kHz on input

screw terminals 1 and 4. The ac excitation is limited to a

20 mA rms load; this sets a lower circuit primary imped-

ance of 50 Ω for a 1 V excitation and 250 Ω for a 5 V

excitation. If the primary impedance of the LVDT/RVDT

is below 50 Ω, the impedance of the LVDT/RVDT can be

increased by increasing the excitation frequency. Input

protection of up to 130 V rms is provided for the excitation and input circuitry. The signal is amplified to provide the high level voltage output.

The 3B17 is designed to compensate for error terms

typically found in LVDT or RVDT applications, such as

quadrature voltages (voltages that are 90° out-of-phase

to the output signal) and null voltages. Quadrature and

null voltages can appear at the differential output of the

LVDT/RVDT; they can be caused by interwinding capacitance and winding asymmetries or a fixed-phase shift

from the primary to the secondary of the LVDT/RVDT.

The two secondary windings are identified as A and B,

with the normal output being A – B. (Refer to Figure 1).

The 3B17 generates the function A + B (a voltage that is

in phase with the secondaries and nearly invariant with

the core replacement) by manipulating the A and A – B

outputs. Since A + B is much larger than the quadrature

voltage, A + B can drive the demodulator, eliminating

the need to manually trim the phase of the demodulator.

In addition, the 3B17 automatically rejects any residual

quadrature voltages.

You can adjust the voltage output over ±5 V from the

center setting of the LVDT/RVDT. After you adjust the

voltage output, you can independently adjust the 130 V

ac protected current output over a ±5% span range for

zero and span.

OTHER LVDT CONNECTIONS

A 6-wire LVDT is shown connected to the 3B17 in Figure

2. 4-wire and 5-wire connections are shown in Figures

3a, 3b, 4a and 4b.

1

2

3

4

1

2

3

4

a. b.

Figure 3. Four-Wire LVDT Connections

11

2

3

4

2

3

4

a. b.

Figure 4. Five-Wire LVDT Connections

–2–

Page 3

AN-536

USING THE 3B17 FOR DIFFERENTIAL COIL

CONDITIONING

The 3B17-D version of the 3B17 module can be used for

differential coil applications as shown in Figure 5. The

3B17-D is intolerant of a capacitive load across the excitation terminals that is greater than 100 pF. Any capacitor that is across the entire differential coil must be

removed.

1

+EXC

2

HI

3B17-D

3

LO

4

–EXC

Figure 5. Differential Coil Connection

USING NONSPECIFIED EXCITATION VOLTAGE AND

FREQUENCY

Whenever possible, the voltage and frequency of the

excitation provided by the 3B17 module should match

the voltage and frequency of the LVDT/RVDT specification. If this results in an excitation current of more than

20 mA rms load on the excitation pins of the 3B17, the

following procedure is recommended;

• Decrease the excitation voltage to 1 V rms. The 3B17

operates at gains of up to 230 (V

DC OUT/VRMS IN

), and

can support the increased gain demand;

• Increase the frequency to 10 kHz; this increases the

primary impedance. Keep in mind that the primary to

secondary phase shift changes, however, the internal

synchronization automatically compensates for any

change in phase shift. In addition, the linearity of the

LVDT/RVDT may change when operated at a different

frequency than specified. Consult the LVDT/RVDT

data sheet or manufacturer for more information.

E3306–5–4/98

–3–

PRINTED IN U.S.A.

Loading...

Loading...