Page 1

AN-412

a

ONE TECHNOLOGY WAY • P.O. BOX 9106

Video-Standard Selection Circuit for the AD722 Using Low Cost Crystals

The AD722 has various options for receiving a subcarrier

reference frequency. This signal is input to FIN, Pin 3.

The choices are: a logic-level (TTL) clock signal at either

1 × FSC (Subcarrier Frequency = 3.579545 MHz for NTSC;

4.433619 MHz for PAL) or 4 × FSC; or just using a parallel

resonant crystal at 1 × FSC, whereby the on-chip oscil-

lator circuit will drive the crystal. All three options are

available for either NTSC or PAL operation.

If the lower cost, stand-alone crystal operation is

desired, there is only a single pin available to connect

a crystal. This does not directly avail itself to selecting

between the two different crystals required for either

NTSC or PAL operation in systems that offer both

video standards.

A low cost crystal selection circuit can be made that, in

addition to the two crystals, requires two low cost

diodes, two resistors and a logic inverter gate. The circuit selection can be driven by the STND signal that

already drives Pin 1 to select between NTSC and PAL

operation for the AD722.

•

NORWOOD, MASSACHUSETTS 02062-9106

APPLICATION NOTE

617/329-4700

•

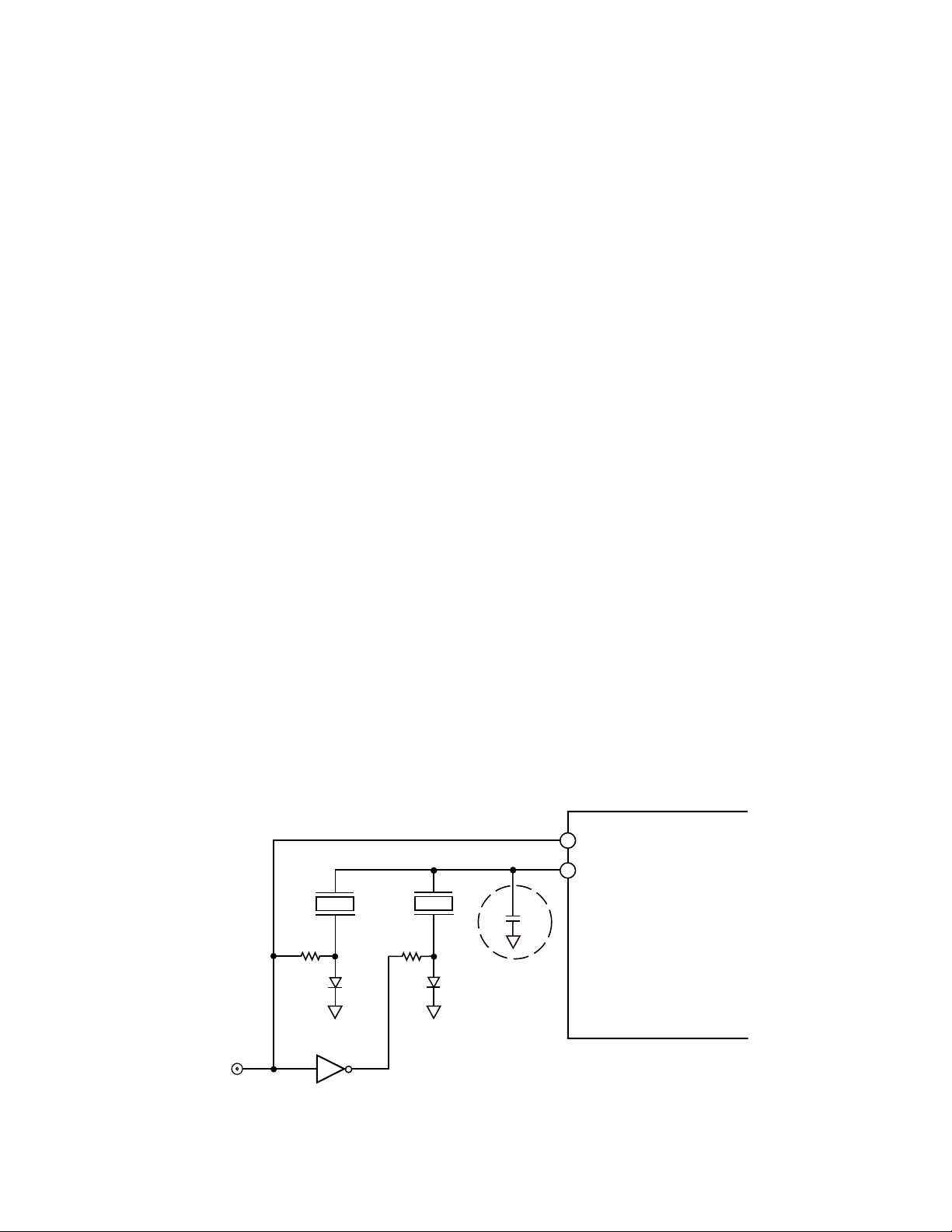

A schematic for such a circuit is shown in Figure 1. Each

crystal ties directly to FIN (Pin 3) with one terminal and

has the other terminal connected via a series diode to

ground. Each diode serves as a switch depending on

whether it is forward biased or has no bias.

Pin 1 (STND) of the AD722 is used to program the internal operation for either NTSC (HIGH) or PAL (LOW). For

NTSC operation in this application the HIGH signal is

also used to drive R1 and the input of inverter U1. This

creates a LOW signal at the output of U1.

The HIGH (+5 V) signal applied to R1 forward biases CR1

with approximately 450 µA of current. This turns the

diode “on” (low impedance with a forward voltage of

approximately 0.6 V) and selects Y1 as the crystal to run

the oscillator on the AD722. The bias across the diode

does not affect the operation of the oscillator.

The LOW (0 V) output of the inverter U1 is applied to R2.

This creates a 0 V bias condition across CR2 because its

cathode is also at ground potential. This diode is now in

Y1

R1

10kΩ

NTSC

U1

HC04

Y2

PAL

R2

10kΩ

CR1

IN4148

Figure 1. Crystal Selection Circuit

CR2

IN4148

0-5pF

Optional

NOTES: Y1 = 3.579545MHz

STND

1

3

FIN

Y2 = 4.433620MHz

AD722

Page 2

the “off” (high impedance) state, because it takes

approximately 600 mV of forward bias to turn a diode “on”

to any significant degree. The “off” condition of the

diode does, however, look like a capacitor of a few pF.

For PAL operation, the STND signal that drives Pin 1 is

set LOW (0 V). This programs the AD722 for PAL operation, deselects the NTSC crystal (Y1), because CR1 has

no bias voltage across it and selects the PAL crystal (Y2)

by forward biasing CR2.

In order to ensure that the circuits described above

operate under the same conditions with either crystal

selected, it is important to use a logic signal from a

CMOS type logic family whose output swings fully from

ground to +5 V when operating on a +5 V supply. Other

TTL type logic families don’t swing this far and might

cause problems as a result of variations in the diode bias

voltages between the two different crystal selection

modes.

FREQUENCY TUNING

A parallel resonant crystal, which is the type required for

the AD722 oscillator, will work at its operating

frequency when it has a specified capacitance in parallel

with its terminals. For the AD722 evaluation board, it

was found that approximately 10 pF was required across

either the PAL or NTSC crystal for proper tuning. The

parallel capacitance specified for these crystals is 17 pF

for the NTSC crystal and 20 pF for the PAL crystal.

The parasitic capacitance of the PC board, packaging

and the internal circuitry of the AD722 appear to be contributing 7 pF–10 pF in shunt with the crystal. A direct

measurement of this was not made, but the value is

inferred from the measured results.

With the crystal selection circuit described above, the

unselected crystal and diode provide additional shunt

capacitance across the selected crystal. The evaluation

board tested actually required no additional capacitance

in order to run at the proper frequency for each video

standard. However, depending on the layout, some circuits might require a small capacitor from FIN (Pin 3) to

ground to operate with the chrominance at the proper

frequency.

SUBCARRIER FREQUENCY MEASUREMENT

It has been found to be extremely difficult to measure

the oscillation frequency of the AD722 when operating

with a crystal. The only place where a CW oscillation is

present is at the FIN pin. However, probing with any type

of probe (even a low capacitance FET probe) at this node

will either kill the oscillation or change the frequency of

oscillation, so the unprobed oscillating frequency cannot be discerned. Neither the composite video nor

chroma signals have the subcarrier represented in a CW

fashion (the LUMA signal does not contain any of the

subcarrier). This makes it virtually impossible to accurately measure the subcarrier frequency of these signals

with any oscilloscope technique.

Two methods have been found that can be used to measure the subcarrier oscillating frequency accurately. The

first method uses a spectrum analyzer like the HP3585A

that has an accurate frequency counter built in. By looking at either the COMP or CHROMA output of the AD722

a spectrum can be observed that displays the tone of the

subcarrier frequency as the largest lobe.

The CHROMA or COMP output of the AD722 should be

input into the spectrum analyzer either by means of a

scope probe into the 1 MΩ input port or a 75 Ω cable that

can be directly terminated by the 75 Ω input termination

selection of the HP3585A. Each of these signals has

present at least the color burst signal on almost every

line which will be the dominant tone in the frequency

band near its nominal frequency. Sidelobes will be

observed on either side of the central lobe spaced at

50 Hz (PAL) or 60 Hz (NTSC) intervals due to the vertical

scanning rate of the video signals. There will also be

sidelobes on either side at about 15.75 kHz intervals, but

these will not be observable with the span set to only a

few kHz.

The center frequency of the spectrum analyzer should

be set to the subcarrier frequency of the standard that is

to be observed. The span should be set to 1 kHz–3 kHz

and the resolution bandwidth (RBW) set to between

10 Hz to 100 Hz. A combination of wider frequency span

and narrower RBW will require a long time for sweeping

the entire range. Increasing the RBW will speed up the

sweep at the expense of widening the “humps” in the

subcarrier tone and the sideband tones.

Once the subcarrier is located, it can be moved to the

center of the display and the span can be narrowed to

cover only that range that is necessary to see it. The

RBW can then be narrowed to produce an acceptably

fast sweep with good resolution.

The marker can now be placed at the location of the

subcarrier tone and the frequency counter turned on.

The next scan across the location of the marker will

measure and display the subcarrier frequency to better

than 1 Hz resolution.

A second means for measuring the subcarrier frequency

of an AD722 operating from a crystal involves equipment even more specialized than a spectrum analyzer.

The technique requires a Tektronix VM700A video system measurement instrument.

The VM700A has a special measurement mode that

enables it to directly measure the frequency of one

subcarrier in a video waveform with respect to an internally stored reference or a simultaneously supplied reference. The instrument gives a reading of the relative

frequencies of the reference and test signals in units of

0.1 Hz. This is not a direct reading of the subcarrier frequency in MHz but a relative reading in Hz of the difference in frequency between the two signals.

–2–

Page 3

If the reference video source is supplied by a video generator that has a CW subcarrier output, its CW subcarrier

can be measured with a frequency counter to accurately

determine its frequency. The AD722 circuit under test

can then be measured relative to this reference by using

the built in colorburst measuring function of the

VM700A, and the offset frequency measured can be

added to or subtracted from the measured frequency of

the CW subcarrier to determine the operating frequency

of the DUT.

It should be noted that the VM700A is a highly specialized video measurement instrument. In order for it to

synchronize on a video signal, the synchronization pattern of the signal must adhere very closely to the appropriate video standard. In particular, a video signal that is

missing equalization and serration pulses from the vertical blanking interval will cause the “Loss of sync” message to be displayed by the VM700A. Many such signals

might make a perfectly acceptable picture on a monitor,

but will not be recognized by the VM700A.

CONCLUSIONS

A low cost crystal selection circuit for the AD722 can be

made with a few simple parts in addition to the PAL and

NTSC crystals. The signal that performs the selection is

one that is already needed to program the selection for

the AD722. Two means are detailed for measuring the

subcarrier frequency out of an AD722 when it is running

with a crystal.

E2115–9–2/96

–3–

PRINTED IN U.S.A.

Loading...

Loading...