Page 1

AN-402

a

ONE TECHNOLOGY WAY • P.O. BOX 9106

Replacing Output Clamping Op Amps with Input Clamping Amps

INTRODUCTION

Various systems like ultrasound and imaging systems,

have instances where the analog signal might suddenly

spike to a voltage extreme. But many downstream circuits like A/D drivers place restrictions on the analog input signal levels in order to maintain their performance.

These devices can draw excessive current in an overdrive condition or else be driven into a region of saturation which will have a long recovery time.

Various clamp amps can be used in these systems to restrict signal excursions at their outputs to protect downstream devices. So far most of the clamping amplifiers

have relied upon an output clamping architecture and

are called output clamp amps (OCAs). A new architecture called an input clamp amp (ICA) offers superior

clamping accuracy and lower distortion.

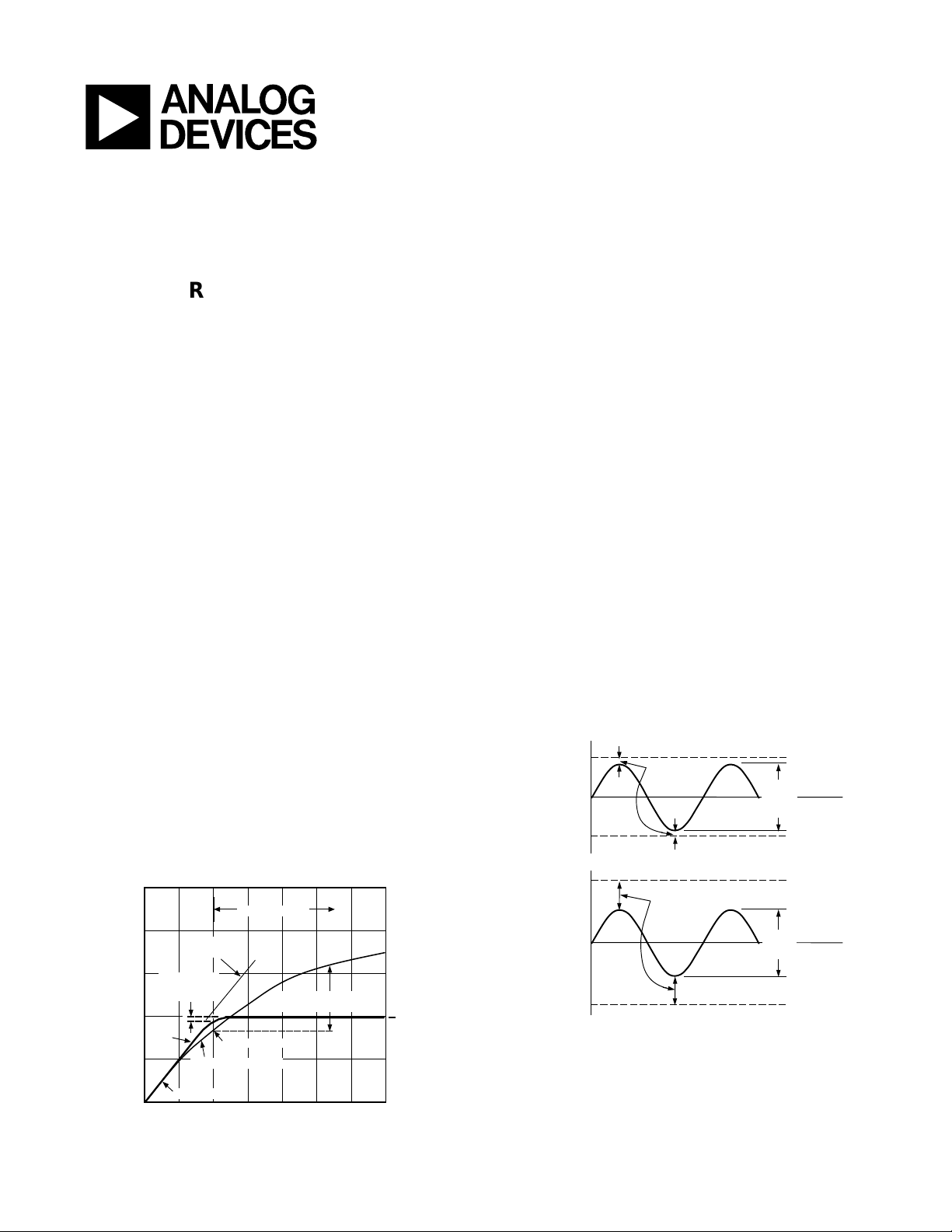

Figure 1 illustrates the relative performance of the two

devices. It can be seen that the ICA more closely tracks a

straight line in the linear region up to the point that it

bends over into the clamp region. On the other hand, the

OCA breaks away from a straight line sooner as it approaches the clamp voltage. Of course the extent to

which the response more closely tracks a straight line is

indicative of the amplifier’s linearity in that region.

1.6

CLAMP REGION

1.4

OUT

1.2

1.0

AD8036

OUTPUT VOLTAGE – V

0.8

0.6

0.6 2.00.8 1.0 1.2 1.4 1.6 1.8

Figure 1. Output Clamp Error vs. Input Clamp Error

LINEAR

EXTENSION

CLAMP

ERROR – 25mV

AD8036

(ICA)

OUTPUT CLAMP AMP

LINEAR REGION

CLAMP ERROR – >200mV

OUTPUT CLAMP

NEAR CLAMP REGION

INPUT VOLTAGE – +V

IN

CLAMP

LEVEL

•

NORWOOD, MASSACHUSETTS 02062-9106

APPLICATION NOTE

617/329-4700

•

To compensate for this added distortion, OCAs are required to have their clamping levels set wider than the

maximum excursion of interest if minimum distortion is

desired. Therefore, when substituting an ICA for an

OCA, the clamp region can be narrowed without adding

extra distortion. This will lower the voltages experienced by downstream circuitry during overdrive. In

most designs, making this adjustment requires only a

minor modification to the circuit that generates the

clamp voltages.

Figure 2 illustrates this concept. The amplitude of the

linear signal for each type of amplifier is the same. However, the upper and lower clamp levels of the OCA must

be set wider in order to preserve the signal linearity due

to the larger near-clamp distortion region. Thus for overdrive conditions, the downstream circuitry will see

larger signals when driven by an OCA than an ICA.

NEAR CLAMP

DISTORTION

INPUT

CLAMP

AMP

OUTPUT

CLAMP

AMP

REGION

NEAR CLAMP

DISTORTION

REGION

Figure 2. Comparison of Near-Clamp Distortion

Regions of ICA vs. OCA

In addition the overdrive response will be further improved as a result of the superior overdrive characteristics of the ICA. The output of an ICA will not go more

than 10 mV past the level set by the clamps for clamping

stages with low gain. On the other hand, an OCA will

HIGH CLAMP LEVEL

MAX

LINEAR

SIGNAL

REGION

LOW CLAMP LEVEL

HIGH CLAMP LEVEL

MAX

LINEAR

SIGNAL

LOW CLAMP LEVEL

Page 2

overshoot by a few hundred millivolts depending on the

magnitude of the overdrive signal. Once again Figure 1

illustrates this concept. The ICA performance can be

seen to be relatively flat in the clamp region independent of the magnitude of the overdrive, while the OCA

output keeps on increasing along with increasing overdrive amplitude.

NONINVERTING OPERATION

Unity Gain

For the case of substituting for a noninverting OCA, the

most important consideration is the gain at which the

clamp amp is operating. This is because the output

clamping level for an ICA is a function of the closed loop

gain of the amplifier.

The first two input clamp amps, the AD8036 and

AD8037, introduced by Analog Devices operate with an

ICA structure. But because of differences in their operation, except for circuits that operate with a gain of +1,

substituting an ICA into a design that has been implemented with an OCA is not a “drop-in” replacement,

even though the pinouts of the parts are identical. However, because the pinouts are identical, the required circuit modifications will, in general, be not too extensive.

Each configuration though must be handled on a caseby-case basis. The following details the considerations

for making this substitution.

Inverting Operation

The first consideration is the polarity of operation of the

op amp. The input clamping op amp architecture of the

AD8036 and AD8037 does not operate in the inverting

mode. Therefore it is not possible to directly replace an

OCA with an ICA for inverting configurations. In order to

benefit from the ICA’s superior clamping characteristics

in inverting applications, a separate inverting stage is

required.

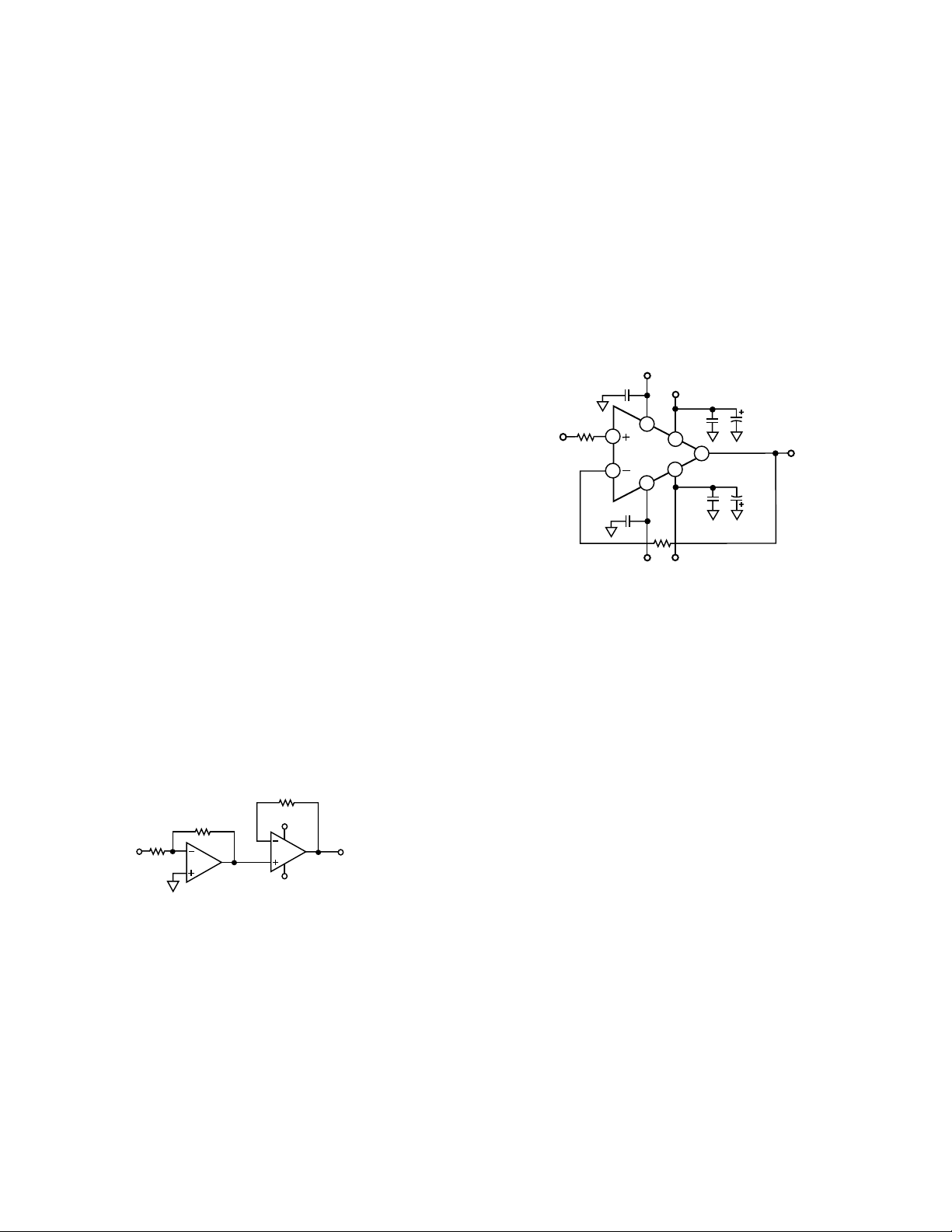

Figure 3 shows a circuit with an inverting stage followed

by an ICA, the AD8036 in a noninverting configuration

for providing the overall function of an inverting clamping amplifier. The circuit shown will have a gain of

–R

and will clamp at VH and VL. The operation of the

F/RI

clamping stage will be explained further in the next section. In all clamp circuits, V

must be greater than VL, but

H

the two can be anywhere within the output range of the

part.

140Ω

V

R

F

R

I

V

IN

2

6

3

H

2

8

V

6

H

3

V

L

AD8036

5

V

L

V

OUT

Figure 3. Inverting Clamping Circuit

For circuits that require a gain of more than (minus) 1,

the designer has a choice as to how to distribute the

gain between the inverting stage and the clamp stage.

For greatest accuracy, the ICA should operate at lower

gains because the clamp accuracy is a function of the

gain as will be detailed in the next section. Additional

required gain can be provided in the inverting stage.

The first case to consider is a noninverting unity gain.

For OCAs, the clamping levels are simply equal to the

voltages applied to V

(Pin 8) and VL (Pin 5). For an ICA,

H

these voltages are multiplied by the closed loop gain in

order to calculate the clamping levels. But since the gain

is +1, the ICA and OCA will both have the same clamping

levels. Thus, a direct substitution can be made. Figure 4

is an example of a unity gain clamping circuit.

V

CH

0.1µF

100Ω

V

IN

3

2

0.1µF

8

V

H

AD8036

V

L

5

300Ω

V

CL

+5V

0.1µF

7

4

0.1µF

R

F

–5V

10µF

6

10µF

V

OUT

Figure 4. Unity Gain Noninverting Clamp

Since we are talking about a noninverting unity gain, the

amplifier chosen must also exhibit stable operation at

unity gain. Of the two ICAs, the AD8036 is compensated

for operation at unity gain. Thus, the AD8036 is a “drop

in” replacement for an OCA in noninverting unity gain

applications. It will provide the same gain and clamp at

the same levels as the OCA.

Gains of Two or More

When the noninverting gain of the clamp amp is two or

greater, the AD8037 can be used for its wider bandwidth, as it is compensated for noise gains of two or

greater. However, the voltages applied to the clamp pins

will have to be changed to maintain the same clamping

levels, because the clamping levels are a function of the

closed loop gain of the amplifier. The following equations summarize the calculations for obtaining the

proper clamp voltages:

V

= G ×

= G ×

V

H

V

L

where: V

CH

V

CL

is the high output clamping level

CH

V

is the low output clamping level

CL

G is the gain of the amplifier configuration

V

is the voltage applied to VH (Pin 8)

H

V

is the voltage applied to VL (Pin 5)

L

–2–

Page 3

In general, to maintain the same clamping levels as for

an OCA, the voltage applied to either clamp pin should

be set at the value desired for the clamp level divided by

the closed-loop gain of the amplifier. For example, if the

amplifier operates at a gain of two and it is desired to

clamp on the high side at 1 V, then the voltage applied to

V

(Pin 8) should be 1 V/2 or 0.5 V. Similarly, if it is de-

H

sired to set the lower clamp at –1 V, then the voltage

applied to V

(Pin 5) should be –1 V/2 or –0.5 V. Fig-

L

ure 5 is a schematic for a clamping stage using an

AD8037 with a gain of 2.

V

H

0.1µF

V

100Ω

IN

R

G

274Ω

3

49.9Ω

2

0.1µF

8

V

H

AD8036

V

L

5

274Ω

V

L

+5V

0.1µF

7

4

0.1µF

R

F

–5V

10µF

6

10µF

V

OUT

Figure 5. Gain-of-Two Noninverting Clamp

The above implies that an input offset in the clamp circuit will be multiplied by the gain of the op amp stage.

To obtain the best clamping accuracy, the clamp amp

should be set for a low gain and any additional necessary gain be provided by another gain stage prior to the

clamping stage. The greater accuracy of an ICA over an

OCA can be practically realized for clamping stages with

gain of up to 10.

The discussion of distortion in the near-clamp region

still applies. The clamping window must be slightly

larger than the maximum signal excursion for which

lowest distortion is desired. A/Ds will have a region between maximum signal level to be converted and maxi-

mum overdrive signal level that does not compromise

its specifications. It is within this region that the clamping levels should be set.

Clamping with an Offset

Some op amp applications require a dc offset voltage at

their output. These are generally configured in the inverting mode where the offset can be produced by a dc

voltage that is simply summed through a summing resistor as an additional input to the amplifier. Since an

ICA does not support inverting mode clamping, it is not

possible to clamp with this configuration.

Noninverting circuits can be created that offer both gain

and offset. However, because there is an interaction

among the resistors used to vary the gain and offset,

the design is not as straightforward as for inverting

configurations.

Figure 6 shows a noninverting configuration of an

AD8037 that provides clamping and also has an

offset. The circuit shows a driver for an AD9002, an 8-bit,

125 MSPS A/D converter and illustrates some of the considerations for using an AD8037 with offset and clamping. The analog input range of the AD9002 is from

ground to –2 V. The input should not go far outside of

this range in order to avoid drawing excessive current.

The input is symmetrical about ground with an amplitude of 1 V p-p.

For the AD8037 to operate at a gain of two, a 301 Ω feedback resistor is chosen as recommended by the data

sheet. For a gain of two the parallel combination of resistors R1 and R3 must be equal to the feedback resistor

R2. Thus

R

1 × R3/(R1 + R3) = R2 = 301 Ω

The reference used to provide the offset is the AD780

whose output is 2.5 V. To find the value of R3, first assume that the input at the noninverting input is at 0 V.

This will force the inverting input to also be at 0 V, which

+5V

806Ω

8

V

H

AD8037

V

L

5

–5V

R2

301Ω

0.1µF

+5V

–5V

7

4

0.1µF

0.1µF

6

–2V to 0V

10µF

10µF

1N5712

49.9Ω

CLAMPING

RANGE

–2.1V to +0.1V

0.1µF

AD9002

V

= –2V TO 0V

IN

SUBSTRATE

DIODE

–5.2V

10µF

0.1µF

+5V

AD780

V

IN

–0.5V to +0.5V

2.5V

0.1µF

49.9Ω

R3

750Ω

499Ω

0.1µF

R1

100Ω

100Ω

3

2

100Ω

806Ω

Figure 6. Gain of Two, Noninverting with Offset AD8037 Driving an AD9002—8-Bit, 125 MSPS A/D Converter

–3–

Page 4

creates a condition where no current flows through R2.

The output now wants to be at –1 V (midpoint of range

that corresponds to input midpoint), so a current of

1 V/301 Ω or 3.32 mA will flow in R2. Since no current

flows in either R1 or into the inverting input of the op

amp, this same current must flow in R3. Thus

2.5

V

= (3.32 mA) R3 or R3 = 750 Ω.

The above equation then yields a value for R1 of 499 Ω.

It is desirable to clamp the signal so that the output goes

no more than 100 mV outside of the A/D’s maximum input signal range in either direction. Thus the high level

clamping should occur at +0.1 V and the low level

clamping should occur at –2.1 V as seen at the output.

Because the clamping is done at the input stage, a

clamping level as seen at the output is affected by not

only the gain of the circuit as previously described, but

also by the offset. Thus, in order to obtain the clamping

levels desired, V

must be biased at +550 mV, while V

H

must be biased at –550 mV. The voltage dividers created

by the 806 Ω and 100 Ω resistors between the supplies

and ground are used to create the clamp voltages.

In general the clamping levels as seen at the output can

be calculated by the following:

V

=

V

+ G ×

+ G ×

V

V

H

L

where V

CH

OFF

V

=

V

CL

OFF

is the offset voltage that appears at the

OFF

output.

Another way to look at setting the clamp levels is by not-

ing that the clamp signals (V

and VL) are alternate non-

H

inverting inputs that are selected when the conventional

noninverting input goes outside the “window” that they

establish. See Figure 7. It is desired to clamp 100 mV

higher and lower than the maximum excursion of the

input signal with a gain of two. Therefore, V

should be

H

50 mV above the maximum input signal excursion of

+0.5 V or +550 mV. Likewise, V

should be 50 mV below

L

the minimum input signal excursion of –0.5 V or

–550 mV. The 50 mV in each case will be multiplied by

two to yield 100 mV, while the same offset will be applied to both the input signal and the clamps.

R

F

140Ω

–V

IN

+V

IN

V

V

+1

+1

H

+1

L

A

S1

B

C

C

H

C

L

A1

S1

> V

V

IN

H

VL ≤ VIN ≤ V

< V

V

IN

L

H

A2

+1

A B C

0 1 0

1 0 0

0 0 1

V

OUT

E2089–9–11/95

Figure 7. AD8036/AD8037 Clamp Amp System

The 1N5712 Schottky diode is used for protection from

L

forward biasing the substrate diode in the AD9002 during power up transients.

OTHER CONSIDERATIONS

In general, the resistors used to generate the voltages

for V

and VL should be kept below 1k. This will minimize

H

errors due to bias current. It is also recommended to use

a 0.1 µF capacitor to ground close to the op amp for bypassing V

and VL. If one or both of the clamp inputs is

H

not used, the pin or pins can be left floating and the amplifier will function the same as one without clamping. If

the either or both clamp pins are dynamically driven and

it is desired to create a nonclamping situation, then V

H

can be biased at +V for no clamping for positive excursions, while V

can be biased at –V for no clamping at

L

negative excursions.

CONCLUSION

Input clamp amps (ICAs) offer superior clamping performance than output clamp amps (OCAs). For most applications an ICA can be used to replace an OCA, but

depending on various circuit details, modifications will

have to be made to successfully complete the change.

The successful use of ICAs requires that each circuit be

approached on a case-by-case basis. The techniques

offered describe the circuit changes required to handle

the most common situations.

–4–

PRINTED IN U.S.A.

Loading...

Loading...