Page 1

AN-395

a

ONE TECHNOLOGY WAY • P.O. BOX 9106

Interfacing the AD22100 Temperature Sensor to a Low Cost

The AD22100 is a new monolithic silicon temperature

sensor with several unique attributes. These attributes

make it easier to interface the AD22100 to microcontrollers than other temperature sensor ICs. Available in

both TO-92 and SOIC packages, the AD22100 features

single-supply operation, the ability to measure negative

temperatures without requiring a negative power supply, and a voltage output that is ratiometric to its power

supply, rather than to an absolute voltage.

Other IC temperature sensors rely on the physics of certain silicon circuit topologies to measure temperature. In

particular, the AD590, and its successors, make use of

the temperature coefficient of the differential voltage

between two silicon junctions (operating at different

current densities) to produce an output that is proportional to absolute temperature. This kind of circuit, often

called a PTAT circuit, is the basis of all IC temperature

sensors prior to the AD22100.

•

Single-Chip Microcontroller

APPLICATION NOTE

NORWOOD, MASSACHUSETTS 02062-9106

by Norm Bernstein

measure temperatures in the device’s operating range.

More importantly, the output is ratiometric to the power

supply, which eliminates the requirement for a precision

calibrated reference voltage in the measurement chain.

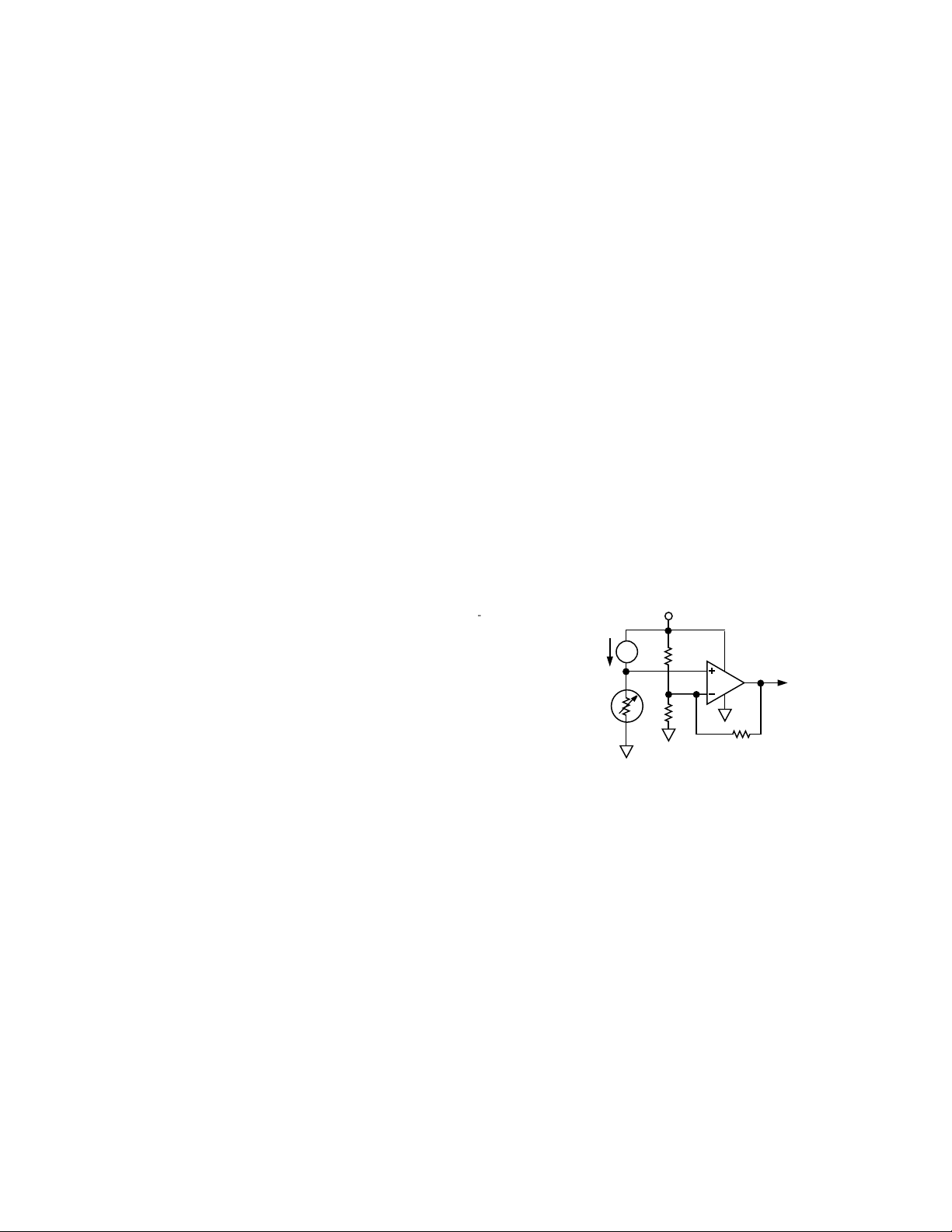

A simplified schematic of the AD22100 is shown in Figure 1. The temperature sensing resistor is excited by a

stable current source; since the temperature coefficient

of the sensing resistor is linear, the output is therefore a

voltage that is linear with respect to temperature.

V+

Ι

R

T

•

617/329-4700

V

OUT

The PTAT circuit, however, suffers from several liabilities. Since the circuit “pivots” at absolute zero, it is necessary to suppress an offset term of 273 °C in order to

make measurements at 0 °C. More importantly, PTAT

circuits are calibrated in

output voltages or currents that require a precision

measurement with respect to a calibrated reference.

The AD22100 does not use a PTAT circuit as the basis of

its measurement technique. Instead, the AD22100 uses

the temperature coefficient of a carefully deposited thin

film resistance, much like an RTD (Resistance Temperature Detector), as the measuring element. By using this

technique, the output of the circuit can be arranged such

that there is no need to suppress a large offset term to

absolute

units, and produce

Figure 1. Simplified Schematic

The other resistors in the circuit serve to establish a

particular output offset at a specified temperature and

power supply voltage (+1.375 V at 0 °C with V+ = 5 V),

and provide for a specified gain versus temperature at

the output (22.5 mV per °C). Most importantly, the circuit

configuration provides for ratiometricity; as the power

supply voltage changes, the output will remain at the

same ratio to the power supply voltage (assuming temperature is constant). This important attribute will be utilized in the interface example described in this

applications note.

Page 2

Interfacing the AD22100 to a Microcontroller

Since the output of an AD22100 is a voltage between

0 V and 5 V, an easy interface can be achieved by using a

microcontroller with a built in A/D circuit. There are a

number of such microcontrollers available on the market today, often with 8- or 10-bit resolution.

However, this approach, while certainly simple, is not

without liabilities. Microcontrollers with built-in A/D

capability are more expensive than the more ordinary

varieties. They usually do not allow for true ratiometric

operation (although a few provide for an external reference input, allowing at least limited ratiometric operation). Since they are usually based upon successive

approximation architectures, they don’t provide integration or normal mode rejection. Most importantly, 8 or 10

bits of A/D resolution is insufficient if the application

requires 0.1 °C resolution at the output.

The A/D architecture described in this application note is

well suited for extracting the best possible performance

from the AD22100. Based largely on firmware within the

microcontroller, this A/D offers the following attributes:

• true integrating A/D, fully ratiometric

• 14-bit resolution, produces 0.1°C resolution after

scaling and calibration

• requires only 2 microcontroller I/O pins, and does

not consume any counter-timer or interrupt

resources

• uses digital calibration

V

IN

V

FB

C1

COMP

+V

Q1

R1

Q2

IN

MICRO-

CONTROLLER

OUT

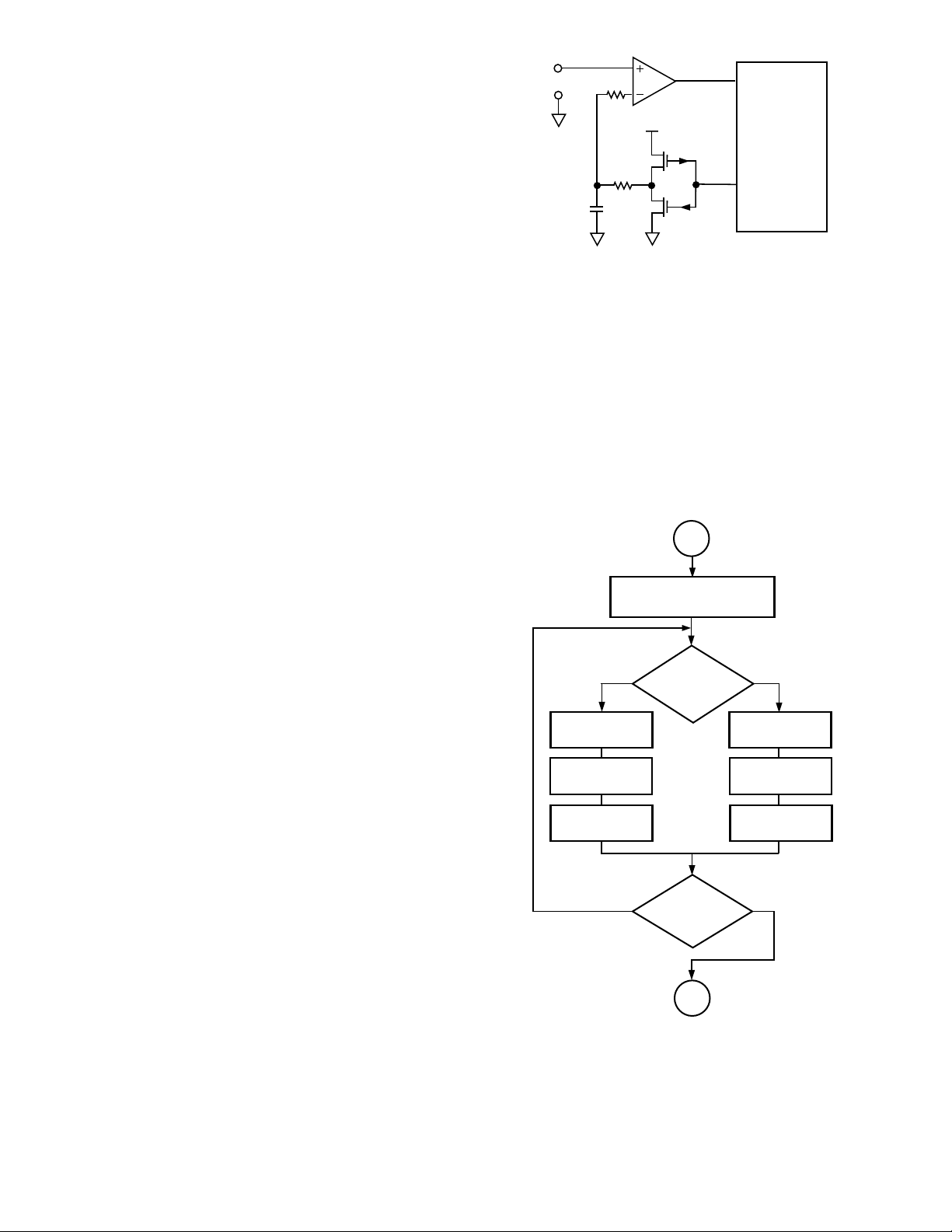

Figure 2. Simplified A/D Schematic

In addition to modulating the pulse train density according to the comparator output signal, the microcontroller

also keeps track of the density of the pulse train, as well

as the total time duration of the conversion cycle, via the

use of counter registers. The ratio of the pulse train density to the total conversion time is proportional to the

input voltage.

The A/D Conversion Firmware Loop

The A/D conversion process is controlled by a carefully

designed firmware loop. The loop is described in the

flowchart of Figure 3 below.

START

TOTAL –COUNT, OUTPUT–COUNT

INITIALIZE

REGISTERS

• extremely low cost

Furthermore, this A/D architecture can be adapted to a

wide variety of microcontroller types, including the very

low cost OTP (One Time Programmable) types. For the

purposes of this application note, we will illustrate the

circuit as implemented on an 80C51 Microcontroller

(available from Intel Corporation as well as others).

The A/D Circuit

The A/D circuit employed for this application note is an

integrating type that utilizes a very small kernel of code

(44 bytes) to control the conversion process. A

simplified schematic is shown in Figure 2. The input

signal is continuously compared to a feedback voltage

signal, which is generated by the microcontroller. The

microcontroller creates this feedback signal by generating a pulse train at the output pin whose density is proportional to the input signal. This pulse train is buffered

by Q1 and Q2, and filtered by R1 and C1 to produce a

linear voltage (the feedback voltage mentioned above).

Whenever the microcontroller senses that the feedback

voltage is less than the signal voltage, it increases the

density of the output pulse train. In this fashion, the

pulse train density is proportional to the input signal.

NO

CLEAR

DAC BIT

TOTAL–COUNT =

TOTAL–COUNT+1

(DELAY TO

EQUALIZE BRANCH

LENGTHS)

NO

IS SIGNAL

VOLTAGE >

FEEDBACK

VOLTAGE?

TERMINAL

COUNT

REACHED?

STOP

YES

SET

DAC BIT

TOTAL–COUNT =

TOTAL–COUNT+1

OUTPUT–COUNT =

OUTPUT–COUNT+1

YES

Figure 3. A/D Conversion Loop Flowchart

Referring to the flowchart in Figure 3, the conversion is

started by initializing the registers storing the total count

(used to count the total number of loop iterations) and

the registers storing the output count, to zero. Each time

–2–

Page 3

the loop is entered, the comparator output is tested: if it

indicates that the signal voltage is less than the feedback

voltage, the output bit (called the “DAC” bit, since it is

essentially a one-bit DAC) is set so that the feedback voltage will rise. If the comparator signal indicates that the

signal voltage is greater than the feedback voltage, the

DAC bit is cleared so that the feedback voltage will fall.

Whenever the DAC bit is set, the output count register is

incremented. Regardless of whether the DAC bit is set or

CONVERT:

MOV DPH,#0 ;the DPTR will be used to keep track

MOV DPL,#0 ;of the total loop count, so clear it

CLR A ;the ACC and B regs will store the raw

MOV B,A ;data, so clear them as well

;

;

; CVLOOP is the inner conversion loop, where the measurement actually

; takes place. In this example, we will loop 16384 times, for a 14 bit

; raw data result. The minimum loop time is 13 cycles, or 13 µs when

; running a 12 MHz clock, resulting in a conversion time of 212.992

; milliseconds.

;

CVLOOP:

JNB CVCMP,CVLOOP_UP ;test the comparator.. if it 2 cyc

CVLOOP_DOWN:

SETB CVFB ;going down, so set the bit... 1 cyc

NOP ; 1 cyc

NOP ;NOP’s equalize the time delays 1 cyc

INC DPTR ;increment the total loop count 2 cyc

SJMP CVLOOP_TEST ;now test for terminal count 2 cyc

;

CVLOOP_UP:

CLR CVFB ;going up, so clear the bit.. 1 cyc

ADD A,#1 ;increment the raw data 1 cyc

XCH A,B ;overflow to the B register 1 cyc

ADDC A,#0 ; 1 cyc

XC A,B ;and restore them 1 cyc

INC DPTR ;increment the total loop count 2 cyc

;

CVLOOP_TEST:

MOV BITTEST,DPH ;grab the upper byte of the dptr 2 cyc

JNB BITTEST.6,CVLOOP ;repeat until we overflow 14 bits 2 cyc

;

; The conversion is done; let’s leave the state of the feedback

; bit consistent to simplify the precharge process

;

CLR CVFB

;

; At this point, the B|A register pair has the raw data, scaled to

; 12 bits, and it is ratiometric to the power supply.

;

MOV RAWDAT,B ;store the result in RAWDAT

MOV RAWDAT+1,A

cleared, the total count is incremented, thereby keeping

track of the number of iterations of the loop. The conversion cycle is complete when the loop has executed the

desired number of iterations; in our example, the loop is

iterated 16,384 times to achieve a 14-bit result.

The loop is carefully constructed so that, regardless of

the result of the comparator test, it takes a fixed amount

of time to execute. Figure 4 is a listing of the actual code

;is low, we need to go up

Figure 4. The Inner Conversion Loop Firmware

–3–

Page 4

for the conversion loop, as used in the example project.

The loop takes just 13 microseconds to execute (a

12 MHz crystal is used in this example, which results in

1 microsecond instruction cycles). If the terminal count

criteria is set for 16,384 iterations, then the output count

will be equivalent to a 14-bit conversion. Using these

parameters, the total conversion cycle is 212.992 milliseconds, which is more than fast enough for the vast

majority of temperature measurement applications.

The choice of comparator can also affect circuit performance. In this architecture, the inputs of the comparator

are operated in common mode over nearly the entire

power supply range of the part. The limited CMRR

(Common-Mode Rejection Ratio) of the comparator

therefore affects the A/D converter linearity. In this example, the integral linearity error measured approximately 0.03%; a comparator with better CMRR would

reduce this error considerably.

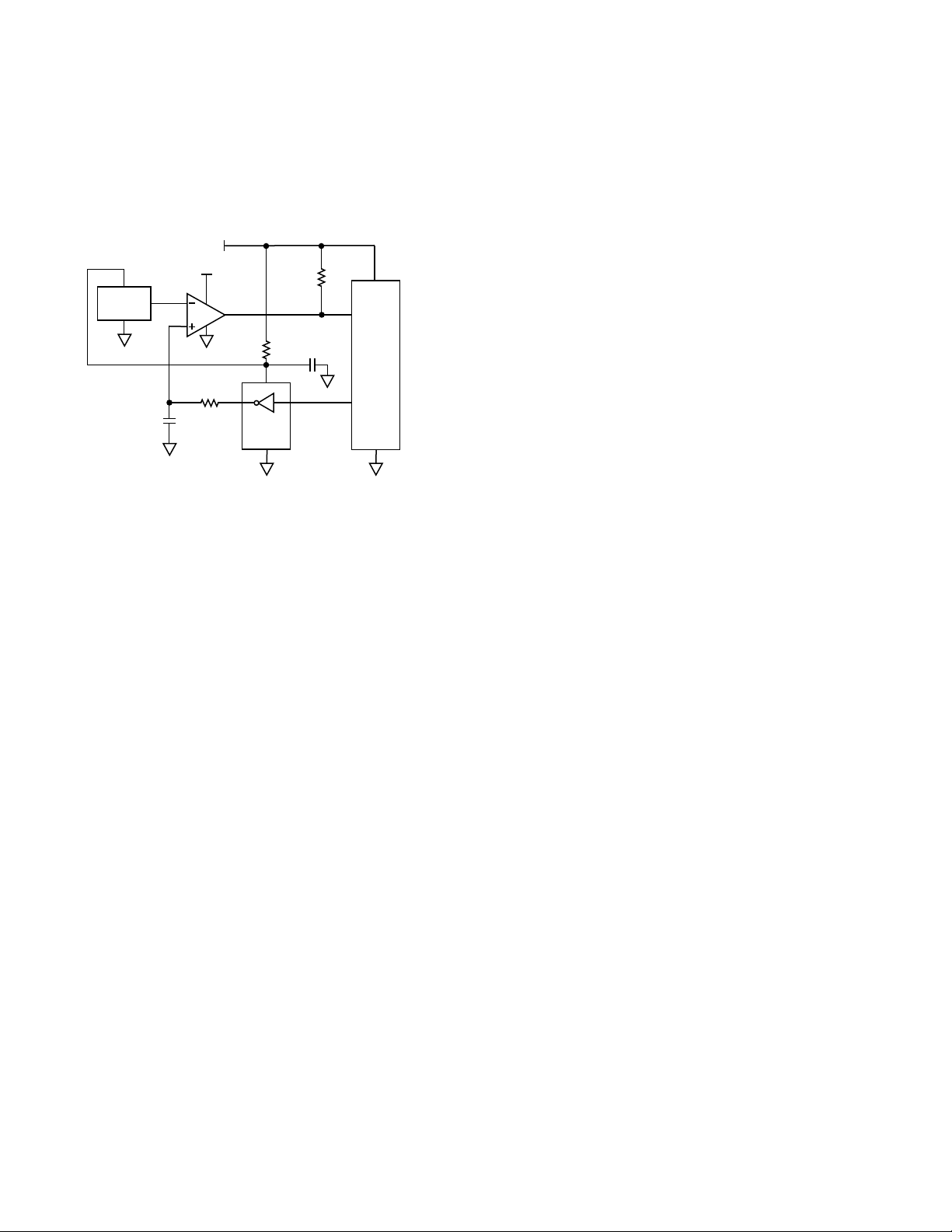

+5V

AD22100

SENSOR

0.22µF

(MYLAR)

LM393P

2

3

+9V

330k

8

4,5,6

1

100

14

2

74HC04

3,5,7,9,

11,13

10k

1µF/35V

+

1

1

8

P1.0

87C51

P1.7

Figure 5. Schematic

With this type of converter architecture, it is easy to adjust the parameters to trade off resolution for conversion speed. This can be done by changing the loop

termination criteria. In our example, the loop terminates

when there is an overflow out of 14 bits on the total

count register, but we could easily modify this for any

binary resolution.

Breadboard Circuit Description

The actual schematic of the breadboard constructed for

this application note is shown in Figure 5. In place of the

discrete FETs shown in the simplified schematic, we

chose to use a 74HC04 Hex Inverter, which is quite

inexpensive, is widely available, and works well in this

application. The comparator used was an LM393 dual

comparator (only one half was used), which is also quite

inexpensive and widely available. Unfortunately, the

LM393 requires a positive supply at least +1.5 volts

higher than the highest input signal, forcing the use of a

+9 volt power supply. It is possible to substitute a CMOS

comparator with rail-to-rail input swing capability,

thereby allowing the entire circuit to operate off +5 volts,

but at a slightly greater expense. If the LM393 is chosen,

the +9 volt supply could possibly be “stolen” from other

portions of the actual application circuit, such as the

charge pumps commonly used in TTL-to-RS232 converter chips.

The low-pass filter for the feedback circuit has a pole at

approximately 2 Hz. This setting was chosen so that the

ripple of the feedback voltage would be less than 1 LSB

at the comparator input. This filter limits the bandwidth

of the converter, and requires time to settle before the

conversion cycle starts. Because of this, a “precharge”

function is required (see “Precharging the Feedback

Voltage”).

The power supply for the DAC buffer (the 74HC04) and

the AD22100 is separately decoupled from the

microcontroller power supply via the 100 Ω series resistor and 1 µF shunt capacitor. This is done to minimize

noise generated from the microcontroller clock and I/O

functions.

Precharging the Feedback Voltage

This A/D converter design has a disadvantage in that the

conversion only works properly if the feedback voltage

is at (or at least very near) the input voltage at the start

of the conversion cycle. When the conversion process is

first started, this may not be the case.

There are a number of solutions to this problem, including the use of a hardware switch between the comparator inputs. The switch could be closed briefly to

“precharge” the filter capacitor before the conversion

cycle starts. This particular solution can’t be used with

an AD22100 sensor, because the sensor output structure

is configured as a current source with a weak pull-down

resistor; “precharging” to a lower voltage would be

very slow.

Another solution (and the one that was used in the

breadboard for this applications article) is the use of a

short “precharge” software loop which balances the

comparator inputs just before starting the conversion

cycle.

In an actual application, the precharge loop is necessary

if the conversion rate is continuous.

–4–

Page 5

A/D Converter Performance

4

3

2

1

0

–3

–4

–50

TEMPERATURE – °C

–25 0 25 50 75 100 125 150

ERROR – °C

–1

–2

MAXIMUM ERROR

TYPICAL ERROR

MAXIMUM ERROR

As measured on the bench (using a precision reference

voltage generator in place of the AD22100), this A/D

circuit delivered 14-bit resolution, less than 1 LSB of

“flicker,” and approximately 0.03% integral linearity

error. The integral linearity could be improved via the

use of a comparator with better CMRR, but this level of

performance was judged adequate for this application.

The converter’s worst nonlinearities occur at the

extreme ends of the input range where the pulse train

density is either very high or very low. This happens because the ripple caused by the pulse train cannot be adequately suppressed by the fixed pole of the RC filter. In

this particular application, this nonlinearity results in errors of a few tenths of a degree when the input is near

–50°C or +150°C (the specified operating range for the

AD22100).

Calibration and Scaling

Despite the ratiometric characteristic of both the A/D

converter and the AD22100 sensor, this circuit requires

calibration. An ideal implementation of this A/D architecture

shouldn’t

require calibration; for example, an

input of exactly one-half the supply voltage should result in a perfect 50% pulse train density, which should

result in an output of 8096 counts (one half of 16,384 iterations of the conversion loop).

The side benefit of electronic calibration is a significant

improvement of accuracy in temperature measurement.

Without electronic calibration, the accuracy of the

AD22100 is fairly good. The error of the least expensive

grade is typically ±0.5°C at 25°C, rising to ±0.75 over its

specified temperature range. However, an examination

of the typical maximum performance plot of the

AD22100 (see Figure 6) reveals that most of the errors

are caused by simple gain and offset errors, not by sensor nonlinearity. If we could correct for these terms, the

resulting accuracy would be significantly improved. Examination of actual AD22100 factory evaluation data

shows that the nonlinearity of the sensor between 0 °C

and 100 ° C is just a few tenths of a degree; if the sensor

were actually calibrated at 0 °C and 100 °C,

the overall

accuracy could be considerably improved over the data

sheet specifications!

Unfortunately, in the real world there are error sources

that result in a less than perfect transfer function. The

input offset voltage of the comparator causes a corresponding offset error at the output. Slew rate limitations

and other error sources in the hex inverter circuit can

also cause gain errors. Consequently, it is necessary to

calibrate the A/D for accurate operation.

The A/D output must also be scaled for use in most applications. We must compensate for the 0 °C offset term

(1.375 volts, or 27.5% of the power supply voltage), as

well as deal with the gain of the sensor (22.5 mV/ °C).

In this application, we are assuming that the user requires a signed binary integer output with a resolution

of 0.1°C; this implies that the output must be 03E8H

(1000 counts) when the sensor is at 100 °C, and 0 counts

when the sensor is at 0 °C.

The normal method of calibration for analog circuits is

the use of trim potentiometers. Since this circuit already

includes a microcontroller, we can eliminate trim potentiometers in favor of electronic digital calibration. Furthermore, we can combine the scaling and calibration

into a pair of simple procedures.

Calibration at 0 °C and 100 °C is convenient, as well. If no

controlled temperature chamber is available, a fairly

close approximation to these temperatures can be

achieved with ice water and boiling water (although

altitude and contaminants might degrade the accuracy

somewhat).

The mathematics of calibration and scaling are most

easily understood by referring to the graph in Figure 7.

Prior to calibration and scaling, the natural output of the

converter is an unsigned 14-bit integer (represented by

the trace labeled “A” on the graph). If we were to assume a perfect converter, operating at 5 volts, then the

numerical values for this trace would be 11,878 counts

at 100 °C (3.625 V/5 V times 16,384), and 4,506 counts at

0°C (1.375 V/5 V times 16,384). The theoretical zero

crossing of this trace occurs at –61.111 °C.

Figure 6. Typical AD22100 Performance

–5–

Page 6

A/D TRANSFER

FUNCTION BEFORE

OFFSET CORRECTION

N(span)

A/D TRANSFER

FUNCTION AFTER

OFFSET CORRECTION

N(fs)

A/D TRANSFER

FUNCTION AFTER

SPAN CORRECTION

TEMPERATURE

+100°C

(3.625V)

–50°C

(0.25V)

N(ofs)

OFFSET

DIGITAL OUTPUT

0°C

(1.375V)

A

B

C

Figure 7. Scaling/Calibration Graph

The desired final output should be 0 for 0 °C, so the easiest way to deal with the offset term is to simply save the

output value observed when the sensor is at zero

(denoted N(ofs) on the graph of Figure 7), and use this

value (by subtraction) to compensate for offset error on

subsequent conversions. Correcting for offset in this

fashion corrects not only for the intrinsic offset term

(i.e., the 1.375 volt bias), but also for any additional offset terms, such as comparator offset, which may exist.

To perform this offset calibration, a firmware routine

was written that can be triggered by a command via a

serial link, an interrupt, or even a simple push-button

(which we used on the breadboard) to perform a conversion on the input and save the value. Prior to activating

this routine, the sensor must be stabilized at 0 °C. The

code for the offset calibration procedure is shown in

Figure 8.

After this calibration takes place, the A/D transfer function is now like line B in Figure 7 where a 0 °C input

produces a binary output of 0.

Note that the routine computes the twos complement of

the conversion data before storing it in the OFSVAL

holding register. This is done because, in all subsequent

applications, we will be using this value as a subtraction

from an A/D reading. Since subtraction is the same as

the addition of the twos complement of a number, it is

convenient to take the twos complement right now, and

store the value that way. Later, when this particular

coefficient is applied, it will simply need to be added.

; ZERO_CAL: The zero calibration procedure simply takes a

; sample of t he A/D reading at conditions of i nput = 0°C (1.375

; volts). This sample is stored in RAM (or EEPROM) and will

; be used in the scaling procedure. To apply this value, we

; simply subtract it from the current reading, which should

; result in an output of 0 for a 0 °C input.

;

; Since we will always apply this value by subtraction, we

; might as well take the twos complement of this number

; right now, and store it that way. When we need to apply it,

; all we’ll have to do is add.

;

;

ZERO_CAL:

ACALL CONVERT ;take a sample of the input

MOV B,RAWDAT+1 ;load RAWDAT into B|A (in reve rse

MOV A,RAWDAT ;order to save an instruction)

CPL A ;complement it

XCH A,B ;as well as the other byte

CPL A

ADD A,#1 ;now add 1

XCH A ,B

ADDC A,#0

MOV OFSVAL,A ;save it (it’s in reverse order)

MOV OFSVAL+1,B

RET

Figure 8. Offset Calibration Routine

Calibration and scaling of the span term is slightly more

complicated. Once the offset has been calibrated, the

converter output transfer function ranges from 0 at 0 °C,

to N(span) at 100 °C, as shown in Figure 7. It is necessary

to scale each conversion such that the converter produces N(f

), which would be 1000 at 100 °C. This could be

S

done by computing 1000/N(span), and using this quotient as a multiplicative calibration factor, to be applied

to each A/D conversion after compensating for offset.

This would produce line C in Figure 7, which is the desired output transfer function.

Unfortunately, since N(span) is significantly larger than

1000; the ratio is less than unity, and can’t be easily represented in integer math. If floating-point routines were

available, the process would be simple; however, many

small microcontroller applications can’t afford the

memory space and execution speed penalty of true

floating-point math, and for the sake of simplicity this

application is restricted to integer mathematics.

Therefore, a simple trick will be employed; the ratio will

be scaled up so that the calibration factor is in the integer range. After the span calibration factor has been

multiplied with the offset compensated data, it will be a

simple matter to divide the result by the scale factor to

return to the desired units.

–6–

Page 7

To perform this operation, a pair of extended integer

math routines will be used. MULT32R multiplies two

16-bit numbers to produce a 32-bit result, and DIV32R

divides a 32-bit number by a 16-bit number to produce a

16-bit quotient, rounded up to the next integer by the

remainder. The routines themselves are not reproduced

here, but are available on request from the author.

;

;

; SPAN_CAL : the span calibration procedure takes a sample of

; the A/D value at conditions of 100 °C (3.625 V) and from that

; computes a multiplicative calibration coefficient that will

; be used to both calibrate as well as scale each A/D

; reading.

;

;

SPAN_CAL:

;

ACALL CONVERT ;grab a fresh sample

;

; first, retrieve the raw data, and subtract the offset

; calibration value.

;

MOV B,OFSVAL ;load OFSVAL into B|A

MOV A,OFSVAL+1

;

; Now add it to RAWDAT (it was already in 2s comp form)

;

ADD A,RAWDAT+1

XCH A, B

ADDC A,RAWDAT

XCH A, B

;

; Now move this into the denominator

;

MOV DEN,B

MOV DEN+1,A

;

; And preload the numerator with 65,536,000 (03E80000H)

;

MOV NUM,#03H

MOV NUM+1,#00E8H

MOV NUM+2,#00H

MOV NUM+3,#00H

;

; Finally, divide to produce the span calibration factor

;

LCALL DIV32R

;

; The quotient now has the span calibration factor;

; let’s store it

;

MOV SPNVAL,NUM+2

MOV SPNVAL+1,NUM+3

;

RET

;

Figure 9. Span Calibration Routine

A/D Output Data Scaling

Once the calibration routines have been performed, the

registers SPNVAL and OFSVAL contain the data necessary to both calibrate and scale each A/D conversion.

Each time an A/D conversion is made, the DATA_SCALE

routine is called. This routine subtracts the previously

established offset count OFSVAL, multiplies the A/D

reading with SPNVAL, and then divides the product by

65,536 to restore the 0.1 °C/LSB scale we desire. The

DATA_SCALE routine is illustrated in Figure 10.

;

; DATA_SCALE: a routine which applies the span and offset

; compensation values to the raw A/D reading, and produces an

; integer output with units of 0.1 °C. From this point, the

; user application can transmit or display the results

; easily.

;

DATA_SCALE:

;

; The first order of business is to subtract off the offset

; compensation value from the reading

;

MOV B,OFSVAL ;load OFSVAL into B|A

MOV A,OFSVAL+1

;

; Now add it to RAWDAT

;

ADD A,RAWDAT+1

XCH A ,B

ADDC A,RAWDAT

; (XCH A,B) ;no point in actually doing this,

;we’ll switch the order in the

;next two instructions

;

; Now we want to move this into the multiplicand

; i n preparation for multiplying with the calibration factor

;

MOV MCAND,A

MOV MCAND+1,B

;

; Load the multiplier with the span calibration factor

;

MOV MPLIER,SPNVAL

MOV MPLIER+1,SPNVAL+1

;

; OK, multiply them!

;

LCALL MULT32

;

; The result must be divided by 65,536 to produce an output

; scaled to 0.1 °C. The product of the previous multiply is

; already in the denominator registers, and it is a 32 bit

; result, so we can effectively divide by 65,536 simply by

; taking the upper 2 bytes as our output

;

; The result is our finished data, and we want to place it

; into the SCALEDAT register

;

MOV SCALEDAT,NUM

MOV SCALEDAT+1,NUM+1

;

RET

;

–7–

Figure 10. Output Data Scaling Routine

Page 8

Circuit Performance

The circuit for this applications note was bench tested

by substituting a precision reference voltage generator

in the place of the AD22100. This test was performed to

reveal the underlying accuracy of the circuit, complete

with all mathematics (i.e., calibration and scaling).

The circuit was found to be nearly perfectly accurate to

within the resolution of the scaling parameters over the

majority of the operating range. The error rises very

slightly at the low end of the range; this is probably due

to limitations of the CMRR of the comparator, along

with errors in the feedback voltage generator (i.e., the

74HC04 and the RC filter). Performance could undoubtedly be improved with additional circuit refinement, but

the existing performance is more than adequate for applications requiring 0.1 °C resolution.

Nonvolatile Calibration Storage

As has been shown, the digital calibration procedures

and routines are excellent replacements for trim potentiometers. They simply require a means of producing

the proper input (0 °C and 100°C) to create an accurate

two point calibration of the circuit.

However, this calibration technique lacks one of the fundamental attributes of potentiometers: nonvolatility.

When circuit power is lost, the contents of random access memory are lost, and with it, the calibration factors. Fortunately, nonvolatility can be achieved quite

easily by the inclusion of an EEPROM (Electrically Erasable Programmable Read Only Memory). There are a

number of these devices available on the market that

are quite inexpensive, easily interfaced via just a few

serial lines, and easy to program.

The EEPROM is organized as 64 separate 16-bit registers. Accordingly, a pair of bytes are established in RAM,

labeled NVDLO and NVDHI, to serve as a buffer for

writes and reads to/from the EEPROM. To write to

EEPROM, first load NVDHI and NVDLO with the desired

data, then load the accumulator with the address (within

EEPROM) that the data will be written to. Finally, call

NVWR to write the data.

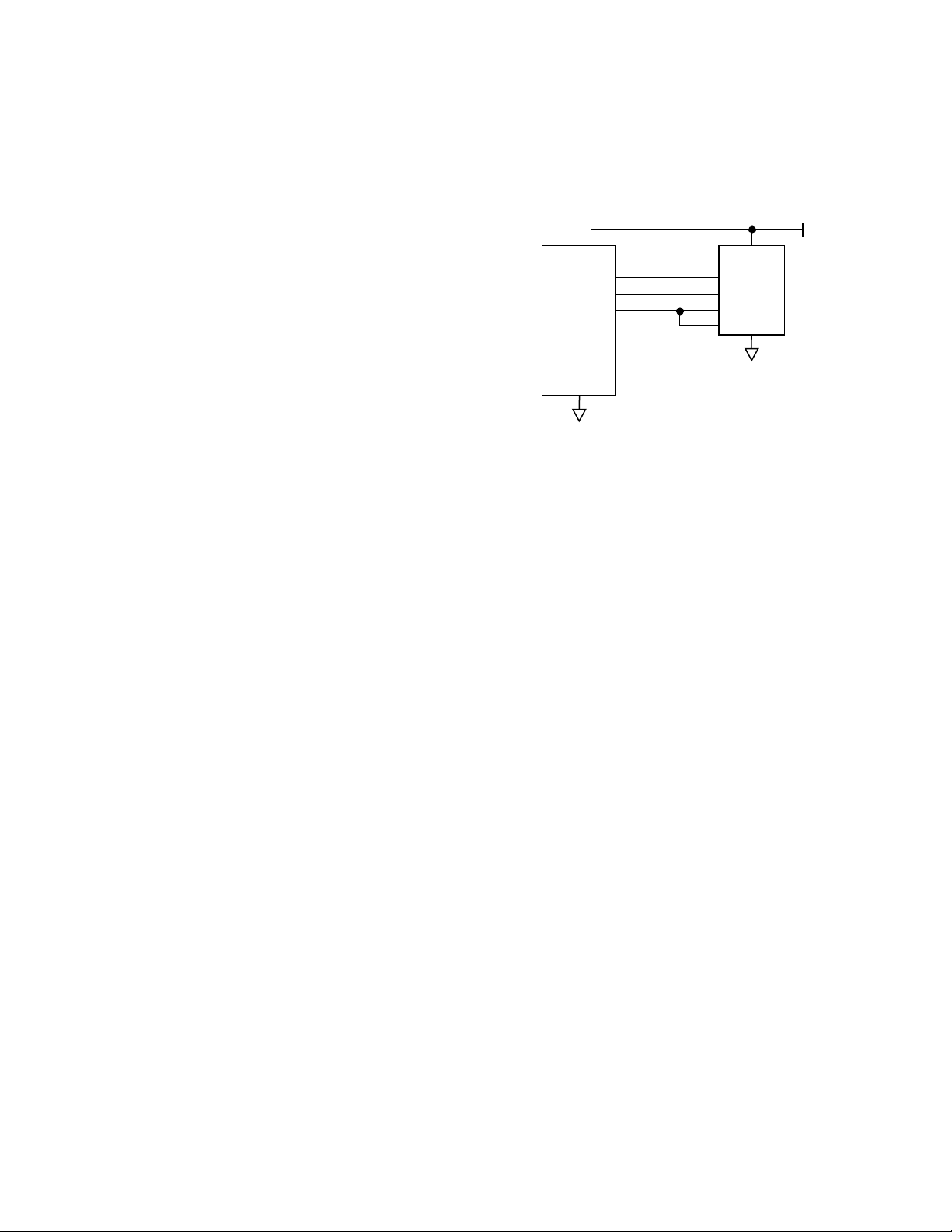

+5V

80C51

NVSK

NVCS

NVDIO

NSC93C06

SK

CS

DI

DO

Figure 11. Interface to a 93C06 EEPROM

Reading data from EEPROM is accomplished by loading

the accumulator with the address (within EEPROM) to

be retrieved, and then calling the NVRD routine. The desired data will be loaded to the NVDHI and NVDLO registers when the routine returns.

Reading from EEPROM is relatively fast (approximately

70 microseconds per byte), but writing to EEPROM is

much slower; this is because the EEPROM location must

first be erased before it can be written. Erasure takes

approximately 10 milliseconds per location. The firmware

routines for accessing this EEPROM are shown below.

For this applications circuit, the component chosen was

the NMC93C06 (from National Semiconductor), which

is a 256-bit CMOS EEPROM, available in either an 8-pin

DIP package, or in an 8-pin SOIC package. The calibration factors require only 4 bytes (32 bits) of storage, so

the device will be left with plenty of capacity for other

functions. This part uses a simple three-wire serial interface, and can be driven by any three available I/O

pins on our 80C51 microcontroller. The schematic of

this interface is shown in Figure 11. The software required to access this device uses a technique commonly

known as “bit-banging,” where we use microcontroller

instructions to actually clock the EEPROM.

–8–

Page 9

;

; NVWR — Write to NV memory. This is accomplished by

; first enabling writes, then erasing the target register,

; then writing to the target register, then disabling writes.

;

NVWR:

PUSH A

LCALL NSWRE ;first enable write

POP A

PUSH A

LCALL NSEREG ;erase the register

POP A

LCALL NSWR ;now write the register

LCALL NSWRD ;and disable write

RET

;

;

; NVRD — read a register pair

;

;

NVRD: ORL A,#080H ;ready to read a reg

LCALL NSTART ;start bit

LCALL SHFOUT ;send the command

SETB NVDIO ;set bit hi to read data

LCALL SHFTIN ;read the hi byte

MOV NVDHI,A

LCALL SHFTIN ;read the low byte

MOV NVDLO,A

CLR NVCS ;all done

RET

;

;

; support routines for NVRD and NVWR

;

;

; SHFTIN — shift in eight bits from the NV memory

;

;

SHFTIN: MOV R2,#8 ;eight bits

SETB NVDIO ;input routine; set NVDIO to “1”

;

IN10: SETB NVSK ;raise the clock

NOP ;delay for NSC parts

RL A ;make room for the data

MOV C,NVDIO ;get the data

MOV ACC.0,C ;place it in the accum

CLR NVSK ;and clear the clock

;

DJNZ R2,IN10 ;do this eight times

RET

;

;

; SHFOUT — send eight bits to NV memory

;

;

SHFOUT: MOV R2,#8 ;eight times

OUT10:

RL A ;get the top bit into the carry

MOV C,ACC.0 ;via the LSB

MOV NVDIO,C ;set the data line

;

SETB NVSK ;now strobe it in

NOP

CLR NVSK

;

DJNZ R2,OUT10 ;do it again

RET

;

;

NSEREG: ORL A,#0C0H ;Ready to erase a register

LCALL NSTART ;start bit

LCALL SHFOUT ;send the command

NS200:

CLR NVCS ;start the timeout

LCALL NSDLY

LCALL CKEVNT ;finish with a clock event

RET

;

NSWR: ORL A,#040H ;ready to write a register

LCALL NSTART ;start bit

LCALL SHFOUT ;send the command

MOV A,NVDHI ;send the hi byte

LCALL SHFOUT

MOV A,NVDLO ;send the low byte

LCALL SHFOUT

SJMP NS200 ;finish with the timeout cycle

;

;

NSWRE: MOV A,#30H ;write enable

LCALL NSTART

SJMP NS100

;

NSWRD: CLR A ;write disable

LCALL NSTART

SJMP NS100

;

NSTART: CLR NVDIO ;start bit for NSC parts

NOP

SETB NVCS

NOP

SETB NVSK

NOP

NOP

CLR NVSK

NOP

SETB NVDIO

NOP

SETB NVSK

NOP

NOP

CLR NVSK

RET

;

; CKEVNT — performs a single clock cycle to signal the

; end of a programming sequence for the NSC part

;

CKEVNT: SETB NVCS

SETB NVSK

NOP

NOP

CLR NVSK

CLR NVCS

RET

;

; NSDLY — provides the minimum 10 ms delay to the

; EEPROM

;

;

NSDLY: MOV R2,#5

NSDL05: MOV R3,#230

;

NSDL10: NO P ;the NSDL10 loop contains eight

NO P ; in struction cycles. At 1 1.0592 MHz,

SETB NVSK ;the loop takes 8 * 1.085 us; do

NOP ;this 230 times for a total of 2

; ms.

NOP ;5 iterations of the loop gives 10

;ms.

CLR NVSK

DJNZ R3,NSDL10

;

DJNZ R2,NSDL05

RET

;

; NS100 — common ending sequence for several routines

;

NS100:

SETB NVCS

LCALL SHFOUT

CLR NVCS

RET

;

–9–

Page 10

Using the EEPROM in the Applications Circuit

The best way to employ the EEPROM capability to the

circuit is to save the calibration factors (SPNVAL and

OFSVAL) whenever the ZERO_CAL and SPAN_CAL procedures are executed (although not shown in the code

examples contained in this applications note, the

EEPROM writes would occur at the end of each of these

routines, when the SPNVAL and OFSVAL registers are

updated).

The initialization procedure for the application would

typically contain routines which, after power-up, read

the calibration values from EEPROM and load the

SPNVAL and OFSVAL registers. In this way, the circuit

would start with the calibration parameters that were

last saved in EEPROM.

About Ratiometric Circuits

Ratiometric circuits are ones in which the critical output

or parameter is specified as a

ence voltage or power supply, instead of as an

ratio

to either the refer-

absolute

value. The ratiometric property is very useful, because it

sometimes allows the designer to ignore the effects of

changing power supply or reference voltages on the desired output or input signal.

An example of an explicitly

non

-ratiometric circuit is a

Zener diode, biased by a resistor to a positive power

supply. As the power supply varies, the voltage across

the Zener remains constant in

absolute

units (volts in

this particular case). When building reference circuits,

nonratiometricity is certainly a useful attribute, since we

don’t want the reference voltage varying with the supply.

Previous generation silicon temperature sensors were

decidedly nonratiometric; their outputs were scaled to

absolute volts or absolute current. The AD590, for example, produces an output current of 1 microamp per

degree Kelvin. To use these sensors, it is necessary to

connect them to an A/D converter that is calibrated in

absolute

volts (which implies that the A/D converter

needed a precision stable reference of some kind). The

AD22100, conversely, produces an output that can be

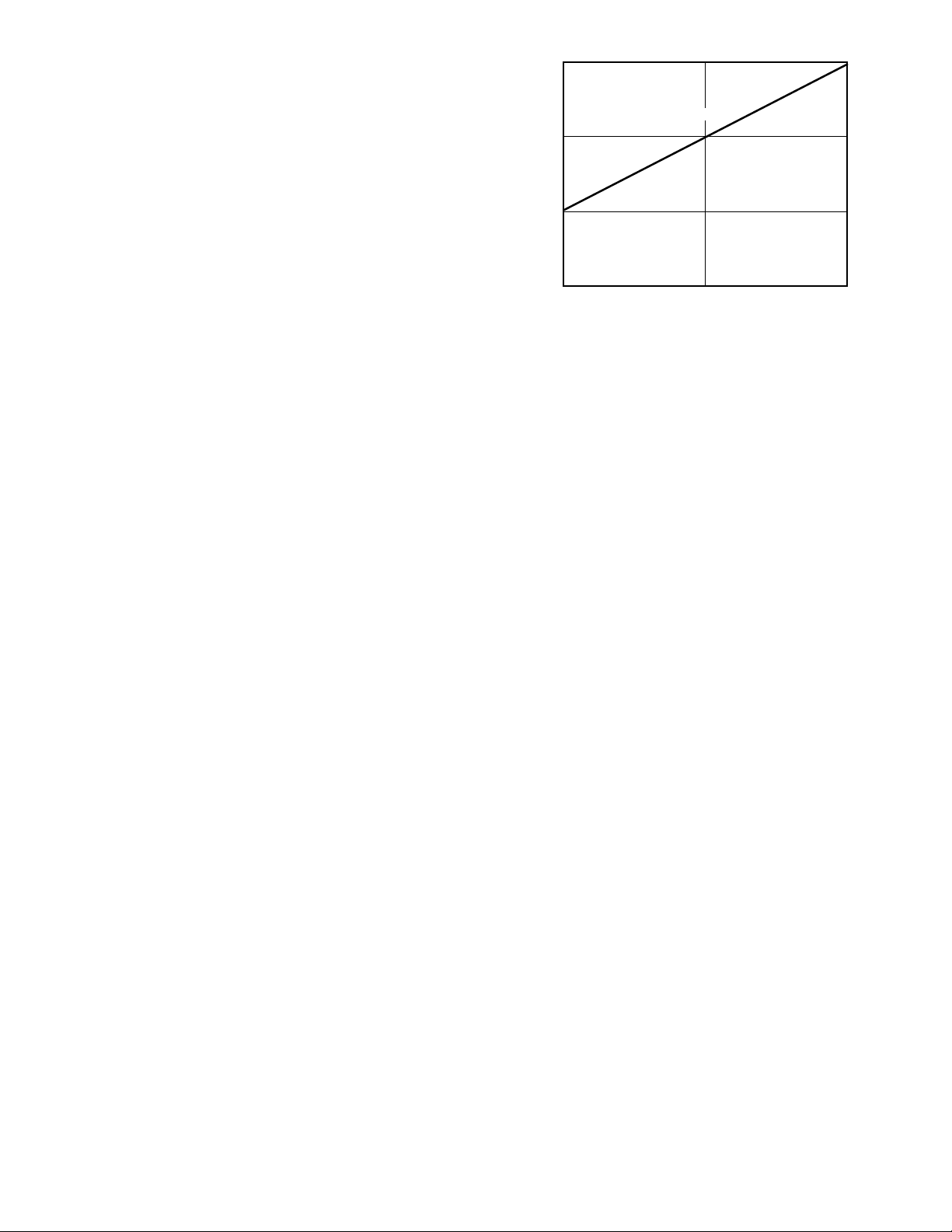

described as a ratio of its own power supply. The graph

of Figure 12 illustrates this behavior.

As shown in the graph, the output of the AD22100 (at a

constant temperature) remains the same percentage of

the supply voltage. At 0 °C, the output is nominally 27.5%

of the supply voltage, and that ratio is maintained over a

wide supply voltage range.

+1.5125

AD22100 OUTPUT

+1.375

OUTPUT – Volts

+1.2375

+4.5

+5 +5.5

SUPPLY – Volts

Figure 12. Output Voltage vs. Supply Voltage

This characteristic is particularly advantageous if the

AD22100 output is being fed to an A/D converter (which

is ratiometric by nature). By using the same voltage for

the A/D reference as that being used for the AD22100

supply, the A/D output will remain constant regardless

of changes in the supply voltage. Therefore, no precision reference is needed, and supply drift is not a

concern.

In actual practice, no device is completely ratiometric;

various factors usually result in a slight shift in the ratio

as the supply voltage is varied. In the AD22100, the

change in ratio (relative to indicated temperature) is approximately 0.08 °C for a 5 volt to 5.5 volt change in supply voltage. This error is small enough to be neglected in

most applications.

In the breadboard constructed for this application note,

the change in indicated temperature for a power supply

change of 4.5 volts to 5.5 volts was less than 0.2 °C, indicating that the A/D converter is behaving ratiometrically,

as expected.

Conclusion

This application note has described the unique features

and attributes of the AD22100 Temperature Sensor, and

has also described a novel method of interfacing the

AD22100 Temperature Sensor to a low cost, single-chip

microcontroller. We have demonstrated the principle of

ratiometricity and have shown how that attribute can be

used to good advantage. The ideas, circuits, and concepts presented in this application note may serve as a

springboard for other kinds of applications, as well.

–10–

Page 11

–11–

Page 12

E2029–12–5/95

–12–

PRINTED IN U.S.A.

Loading...

Loading...