Page 1

AN-385

a

ONE TECHNOLOGY WAY • P.O. BOX 9106

Make Wide Temperature Range, Ultralow Drift Accelerometers

Using Low Cost Crystal Ovens

Commercial crystal ovens have been used for many

years to stabilize radio frequency oscillators which need

to maintain a near constant frequency over wide temperature ranges. These same products can be used to

maintain an accelerometer, such as the ADXL50 and

ADXL05, at a constant operating temperature. This effectively provides a very low drift, wide temperature range

acceleration measurement circuit.

The ADXL50 and ADXL05 accelerometers provide a

linear voltage output that varies directly with applied acceleration. With the ADXL50, the nominal sensitivity is

19 mV per g centered around a +1.8 volt 0 g offset. The

change in output voltage over temperature (i.e., drift) of

this offset is very small compared with the amplitude of

high g level signals but becomes more significant when

the accelerometer is measuring low g levels. In cases

where a true dc (i.e., gravity measuring) response is

needed, such as when measuring tilt angle, the 0 g offset

drift needs to be kept very low.

The crystal oven specified here, an Isotemp #M050570 is

available for $15.00 (in 100s), is small—only 3/4" in diameter by 1/2" high, and operates from the same +5 V supply voltage as the accelerometer. This particular model

maintains the accelerometer at +70 °C, which is just right

for our lowest cost “J” grade devices specified for operation over the 0 °C to +70°C commercial temperature

range. These ovens are available for operation at other

temperatures up to +95 °C and with different supply voltages. For an “A” –40 °C to +85°C industrial grade device,

an oven with an operating temperature of +85 °C should

be used; this will provide the greatest overall operating

temperature range. Note that, although the oven’s specified tolerance is ±3° C, its typical performance is much

better as long as the accelerometer is carefully fitted to

the oven as described in this application note.

•

NORWOOD, MASSACHUSETTS 02062-9106

by Charles Kitchin

APPLICATION NOTE

617/329-4700

•

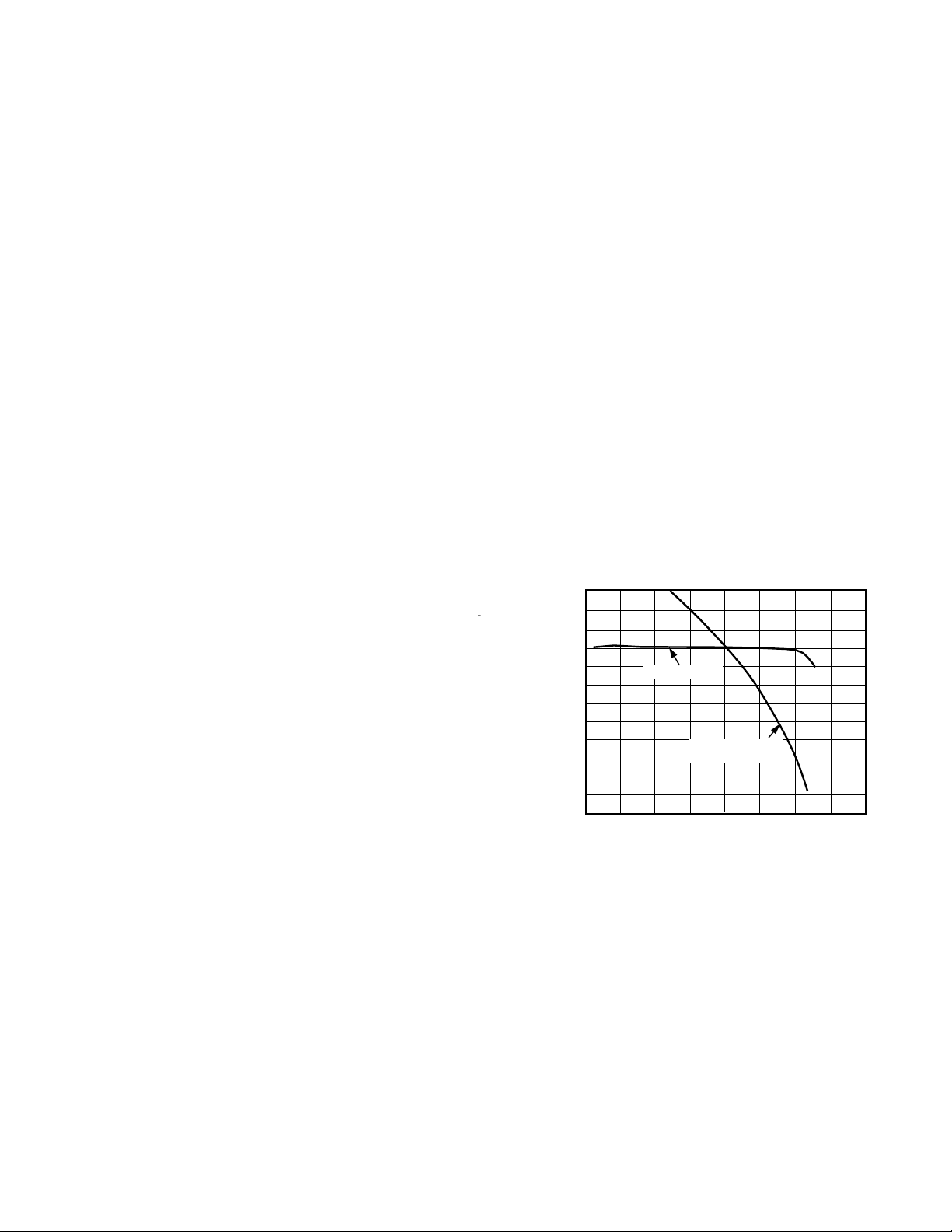

bias level is drifting at an average rate of 0.65 mV/ °C;

(note that the drift of this particular unit is a bit higher

than the 0.5 mV/ °C level of a typical ADXL50JH device).

With the accelerometer mounted inside the crystal oven,

the measured drift is reduced to less than 1 mV over

the entire –55 °C to +65°C range. Since the 0 g bias

drift of the ADXL05 is much lower than that of the

ADXL50, even better results can be obtained for low g

measurement.

+15

+10

+5

0

–5

–10

–15

–20

–25

MEASURED 0g UNIT – mV

–30

–35

–40

–45

Figure 1. ADXL50 0 g Drift With & Without Using the

Isotemp Model M050570 Crystal Oven

Because the oven can only apply power to

nal cavity (and cannot cool it down), its preset temperature must be higher than the planned operating

temperature. When the outside ambient temperature

increases to greater than 10 °C below the oven’s preset

temperature—in this case 60 °C (70°C minus 10°)—the

accelerometer’s temperature now begins to vary and its

0 g offset starts to change.

XL50 AND OVEN

UNCOMPENSATED

"J" GRADE ADXL50

TEMPERATURE – °C

heat

+105–35–55 +85+65+45+25+5–15

its inter-

Figure 1 shows the measured 0 g drift of a "J" grade

ADXL50 accelerometer alone and when placed inside a

M050570 crystal oven. By itself, the accelerometer’s 0 g

Page 2

The oven has a built-in proportional control that regulates its temperature: as the outside temperature drops,

more current is applied to its internal heater to maintain

a constant temperature inside the oven. This means

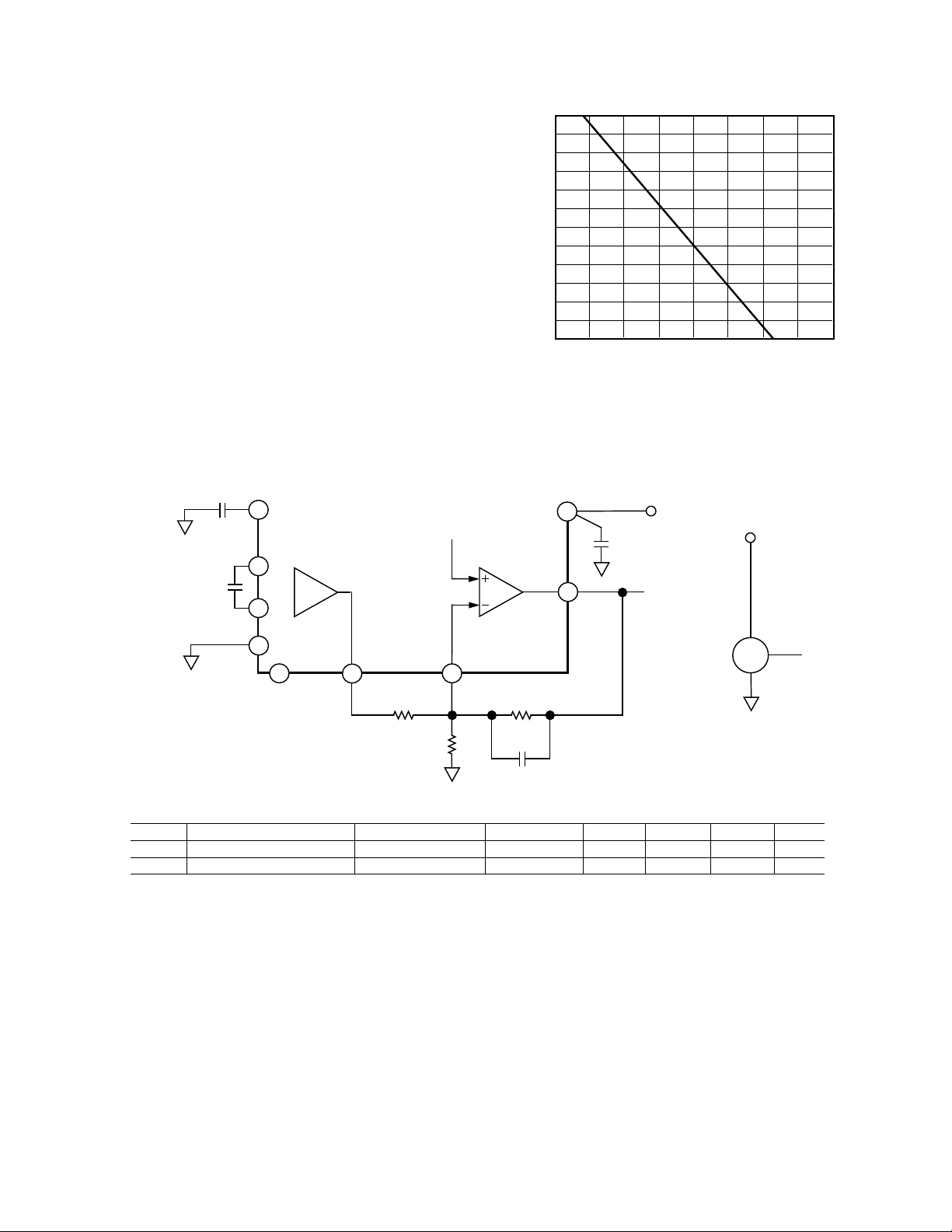

that the oven will consume more power at lower temperatures and less at higher approaching zero at its preset temperature. Figure 2 shows the measured current

consumption of a typical M050570 (+5 V, 70 °C) model

oven vs. temperature.

600

500

400

300

200

A typical low g measurement circuit using the accelerometer/oven combo is shown in Figure 3. In this circuit,

low-pass filtering provided by capacitor Cf, reduces the

measurement bandwidth to approximately 1 Hz, and

lowers the noise floor, improving resolution. The crystal oven and accelerometer are both powered by the

same +5 volt supply, although they should be connected to the supply using separate leads. This prevents

any transient signals from the current powering the

oven from interfering with the accelerometer's circuitry.

4

C2

0.022µF

C1

0.022µF

COM

0g OUTPUT – +2.5V

3dB Bw – 10Hz

ADXL50 OR ADXL05

2

3

5

6

+3.4V

REF

PRE-AMP

V

PR

8

V

PR

R1

100

TYPICAL CURRENT CONSUMPTION – Ma

0

TEMPERATURE – °C

+105–35–55 +85+65+45+25+5–15

Figure 2. Isotemp Model M050570 Crystal Oven

Typical Current Consumption vs. Temperature

1

1.8V

BUFFER

AMP

10

V

IN–

R2

R3

C

F

C3

0.1µF

9

V

OUT

+5V

V

OUT

ISOTEMP

M050570

+5V

1

3

+VDC

2NC

0VDC

DEVICE FS MEASUREMENT RANGE* OUTPUT SENSITIVITY BUFFER GAIN R1 R2 R3 CF

ADXL50 ±10g 100mV/g 5.26 26.1k 351k 137k 0.1 µF

ADXL05 ±2 g 500mV/g 2.50 40.2k 255k 100k 0.15µF

*FS RANGE NUMBERS ARE CONSERVATIVE TO ALLOW FOR V

0g TOLERANCE.

PR

Figure 3. Low g DC Coupled (Tilt) Circuit Using Crystal Oven Compensation

–2–

Page 3

HEAT SINK COMPOUND

ACCELEROMETER'S CAN

SEAL AIRSPACE BETWEEN

OUTSIDE OF OVEN AND

TOP OF PRINTED CIRCUIT

BOARD WITH RED RTV

COMPOUND

Figure 4. Mechanically Mounting the Crystal Oven to the Accelerometer

USE THERMAL

ON TOP & SIDES OF

ISOTEMP

M050570

ADXL50 OR ADXL05

PRINTED CIRCUIT BOARD

The circuit can be built on a small card such as the 0.8 ″

square ADXL50 evaluation card. After the circuit has

been built up and is operating properly, the crystal oven

can be installed over the accelerometer as shown in Figure 4. After applying silicon heat sink compound to the

top and sides of the accelerometer’s can (being careful

not to use too much or get any compound on the leads),

slide the oven over the accelerometer until it is firmly

seated against the bottom edge of the can.

Then run the oven’s leads through the breadboard and

solder them to the bottom side of the board. The oven

has three leads: one is +5 V, the center lead is not used,

and the third is power supply common (ground). Be sure

that the +5 V supply lead used for the oven is a separate

wire from that powering the accelerometer. The last

step is to seal any air gap between the bottom of the

oven and the top of the PC board using red RTV compound or a similar material.

The circuit’s scale factor may be user trimmed for

extremely high accuracy by substituting a trim potentiometer and metal film resistor combination for R1.

This adjustment should be made only after the

accelerometer’s temperature has settled out at the

oven’s preset temperature.

The crystal ovens may be purchased ( and Free samples

are available) from Isotemp Research, Inc., P.O. Box

3389, Charlottesville, VA. 22903. Phone: 804-295-3101,

Fax 804-977-1849.

ADXL50HX and ADXL05HX sample packs are available

from any Analog Devices sales office or distributor.

–3–

Page 4

E1952–7.5–10/94

–4–

PRINTED IN U.S.A.

Loading...

Loading...