Page 1

AN-379

a

ONE TECHNOLOGY WAY • P.O. BOX 9106

Mounting Considerations for ADXL Series Accelerometers

by Mike Shuster, Bob Briano and Charles Kitchin

As with all accelerometers, optimum performance

depends on proper mounting of the device. It must

be mounted so that the sensor is properly coupled to

the object for which acceleration is to be measured.

Also the effects of mechanical resonances must be

minimized.

All mechanical structures, no matter how ”solid,“ have

mechanical resonances that result in an output signal at

the resonant frequency that is larger than expected. Mechanical resonances cannot be eliminated completely.

The key to successfully reducing any serious problems

is to keep the resonant frequencies above the frequency

band of interest or to attenuate them to acceptable levels. Structures that seem benign at rest often mechanically resonate when vibrated at high frequency.

The ADXL Series of accelerometers are intended for PC

board mounting, and careful mechanical design of the

PC board is important. Resonances can be difficult to

determine before prototyping, but some precautions

can be taken.

1. Replace or firmly attach any individual components

that are flexible such as large through-hole components. Surface mount resistors and capacitors are

preferred because they will not vibrate on their leads.

2. Wire-wound resistors and electrolytic capacitors can

change values when they are vibrated. Again, ceramic surface mount components are best.

3. Mechanically couple a potentially problematic structure to one that has a high resonant frequency. An

example of this is to firmly attach PC boards to thick

bases.

4. Couple together several structures such that the combination has a dampened response: PC boards, card

cages, etc.

5. Cables inside moving structures should be tied down

firmly. Cables between a moving structure and a stationary one should be flexible and have a service

loop.

•

APPLICATION NOTE

NORWOOD, MASSACHUSETTS 02062-9106

6. Cavities, such as housings, can resonate. Filling cavities with suitable potting materials or epoxy is a good

solution for this, and also prevents components from

vibrating.

7. Keep all dimensions as small as possible because, in

general, smaller dimensions mean that the resonances are at higher frequencies.

8. Use silicon grease or other materials on mating surfaces to improve coupling between components that

are screwed together.

Many applications do not have strict requirements for

being resonance free, but in some cases resonances can

be critical to a successful system. The best way to test a

design for resonances is to shake it, using a calibrated

shaker, over the frequency band of interest using a reference accelerometer attached at critical points.

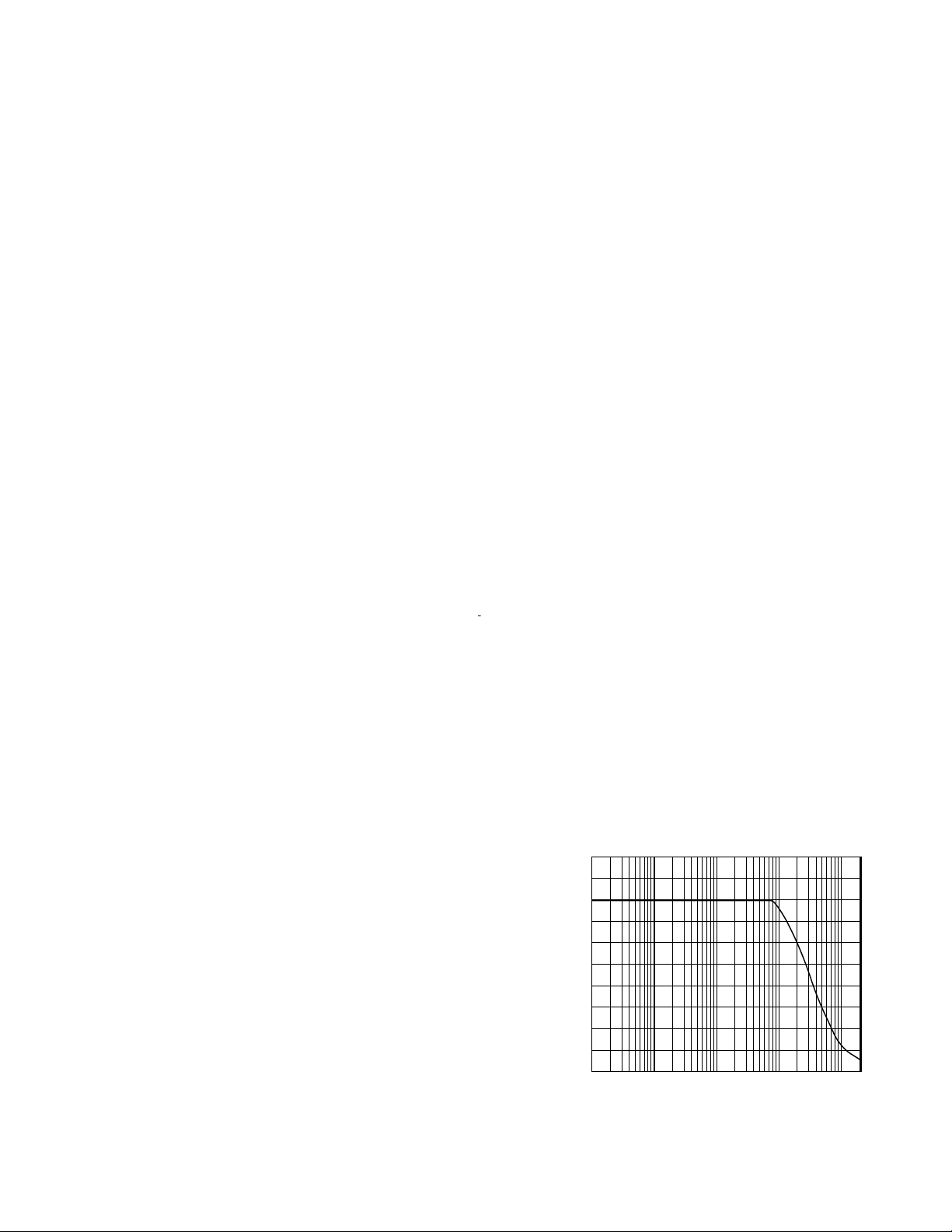

Figure 1 illustrates the ideal response of the ADXL50

which is achievable with proper fixturing or potting material. The sensor response is flat from dc to the

dominant pole set by the demodulator capacitor, typically at 1.3 kHz. Figure 2 shows the response of the

ADXL05.

6

3

0

–3

–6

–9

–12

–15

–18

NORMALIZED SENSITIVITY – dB

–21

–24

1 10k10 100 1k

Figure 1. Ideal Response of the ADXL50

FREQUENCY – Hz

•

617/329-4700

Page 2

9

6

3

0

–3

–6

–9

–12

–15

NORMALIZED SENSITIVITY – dB

–18

–21

1 10k10

FREQUENCY – Hz

100 1k

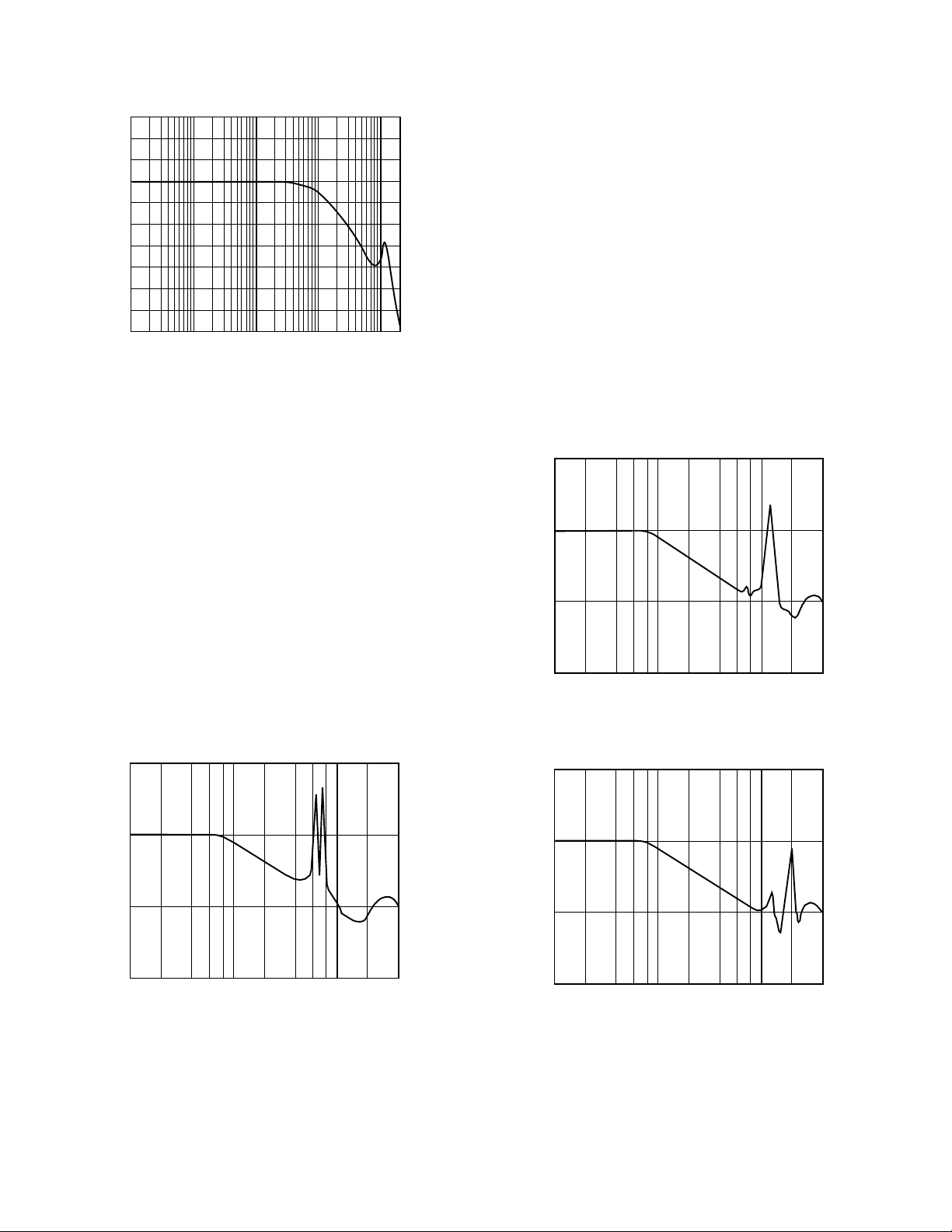

By applying a small drop of epoxy under the seating plane

of the accelerometer‘s package, firmly attaching it to the

PC board, the resonant peak will shift to a higher frequency (approximately 12 kHz) as shown in Figure 4. This

example illustrates the effectiveness that simple changes

can have on this or any other resonating component.

The ultimate solution to the problem of vibrating components is to pot the entire board and all of its components

with a suitable material. Figure 5 demonstrates that when

encapsulated with paraffin wax (used because it is easily

removable) the resonant peak is pushed out in frequency

to approximately 20 kHz. Other more permanent potting

materials can further reduce or eliminate the resonances.

E1895a–5–5/95

Figure 2. ADXL05 Ideal Response

(This can be varied by changing the demodulator capacitor. See application note AN-377. The sensing beam has a

natural resonant frequency at 24 kHz.

Using the ADXL50 as an example, possible solutions for

mechanical resonances will be illustrated. (The response

of the ADXL05 will be very similar.)

All of the following measurements were made using an

aluminum cube designed to hold a PC board which

mounts directly to a shaker.

If the accelerometer is mounted to a PC board by soldering

the leads only, then it will resonate in a complex manner

in the range from 7 kHz to 9 kHz. This is caused by the

accelerometer‘s package moving on its leads with respect

to the PC board. Figure 3 illustrates a typical response

from the ADXL50 when soldered to a PC board. The amplitude and frequency will vary depending on how it is held

when soldered.

190

The ADXL50 when properly mounted will not likely be the

limiting component. Many other structures can resonate

in a complex subsystem in the range of a few kHz if you are

not careful.

190

19

1.9

SENSITIVITY – mV/g

0.19

100 1k 10k

FREQUENCY – Hz

Figure 4. Response of the ADXL50 when Soldered and

Epoxied to a PC Board

190

19

1.9

SENSITIVITY – mV/g

0.19

100 1k 10k

FREQUENCY – Hz

Figure 3. Response of the ADXL50 when Soldered to a

PC Board

The resonance at 7 kHz will not affect the response of the

ADXL50 over its typical rated bandwidth of 1.3 kHz. However, if signals at 7 kHz are potential problems, then lowpass filtering or better mounting methods may be taken.

19

1.9

SENSITIVITY – mV/g

0.19

100 1k 10k

FREQUENCY – Hz

Figure 5. Response of the ADXL50 Potted with Paraffin

Wax

–2–

PRINTED IN U.S.A.

Loading...

Loading...