Page 1

AN-374

1.5

g

150m

g

15m

g

1.5m

g

150µ

g

3dB BANDWIDTH – Hz

NOISE LEVEL – Peak to Peak

NOISE LEVEL – rms

10

g

1m

g

10m

g

100m

g

1

g

10 100 1k

ADXL05

ADXL50

a

ONE TECHNOLOGY WAY • P.O. BOX 9106

Using Accelerometers in Low g Applications

INTRODUCTION

Accelerometers can be used in a wide variety of low

applications such as tilt and orientation, vibration analysis, motion detection, etc. This application note explains

how to best apply the ADXL50 (50

accelerometers when measuring signals at the low end

of their respective full-scale ranges. Although each

accelerometer is specified according to its full scale

(clipping)

i.e., its minimum discernible input level, is extremely important when measuring low

The limiting resolution is predominantly set by the measurement noise “floor” which includes the ambient

background noise and the noise of the accelerometer itself. The level of the noise floor varies directly with the

bandwidth of the measurement. As the measurement

bandwidth is reduced, the noise floor drops, improving

the signal-to-noise ratio of the measurement and its

limiting resolution.

g

level, the limiting resolution of the device,

g

) and ADXL05 (5 g)

g

accelerations.

•

NORWOOD, MASSACHUSETTS 02062-9106

by Charles Kitchin

g

APPLICATION NOTE

617/329-4700

•

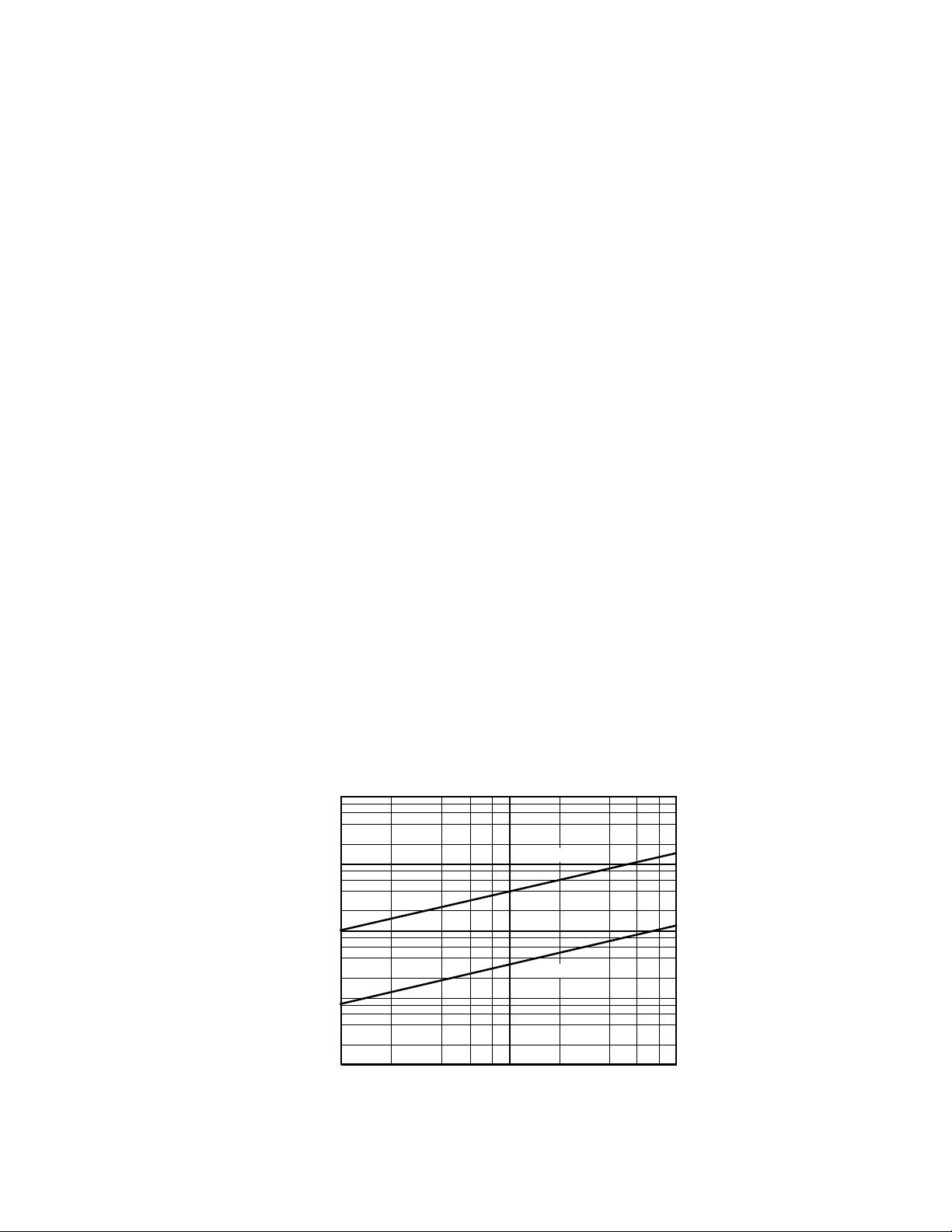

DEVICE BANDWIDTH VS. MEASUREMENT RESOLUTION

The output noise of the ADXL50 and ADXL05 scales

with the square root of the measurement bandwidth.

The maximum amplitude of the noise, its peak-to-peak

value, approximately defines the worst-case resolution

of a measurement. The peak-to-peak noise is approximately equal to 6.6 times its rms value (for an average

uncertainty of 0.1%).

The bandwidth of the accelerometer can be easily reduced by adding low-pass or bandpass filtering. Figure

1 shows the noise vs. bandwidth characteristics of the

ADXL50 and ADXL05 devices.

As shown by the figure, device noise drops dramatically

as the operating bandwidth is reduced. For

example, when operated in a 1 kHz bandwidth, the

ADXL05 typically has a peak-to-peak noise level of

130 m

g

. With ±5 g applied accelerations, this 130 m

resolution limit is normally quite satisfactory; but for

g

Figure 1. Noise Level vs. 3 dB Bandwidth

Page 2

smaller acceleration levels the noise is now a much

greater percentage of the signal. As shown by Figure 1,

when the device bandwidth is rolled off to 100 Hz, the

peak-to-peak noise level is reduced to approximately

40 m

g

, and at 10 Hz it is down to 10 mg.

0

g

offset trimming, and output scaling. Two tables are included with the figure which provide practical component

values for various full-scale

g

levels and approximate circuit bandwidths. For bandwidths other than those listed,

use the formula:

Alternatively, the signal-to-noise ratio may be improved

considerably by using a microprocessor to perform

multiple measurements and then compute the average

signal level. When using this technique, the signal level

will be increased directly with the number of measurements while the noise will only increase by their square

root. For example, with 100 measurements, the signal-tonoise ratio will be increased by a factor of 10 (20 dB).

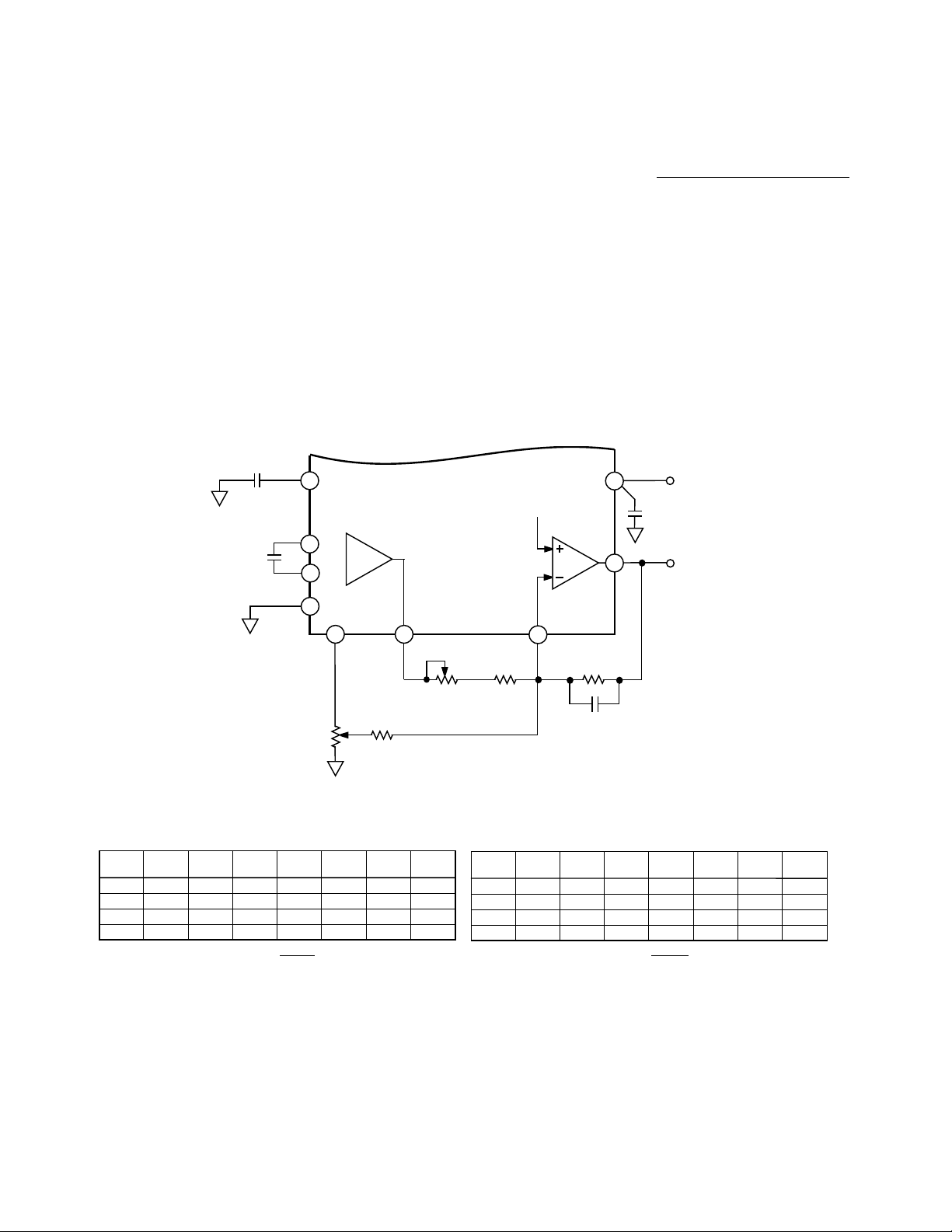

Low-Pass Filtering

The bandwidth of either accelerometer can be reduced by

providing post filtering. Figure 2 shows how the buffer

amplifier can be connected to provide 1-pole post filtering,

C2

4

0.022µF

0.022µF

C1

COM

C1

2

3

5

+3.4V

REF

ADXL50 OR ADXL05

PRE-AMP

6

8

V

PR

Capacitor C4 (Farads) =

2 π×R3(Ω)×3dB BW (Hz)

1

or simply scale the value of capacitor C4 accordingly, i.e.,

for an application with a 50 Hz bandwidth, the value of C4

will need to be twice as large as its 100 Hz value. If further

noise reduction is needed while maintaining the maximum possible bandwidth, then a 2- or 3-pole post filter is

recommended. These provide a much steeper roll-off of

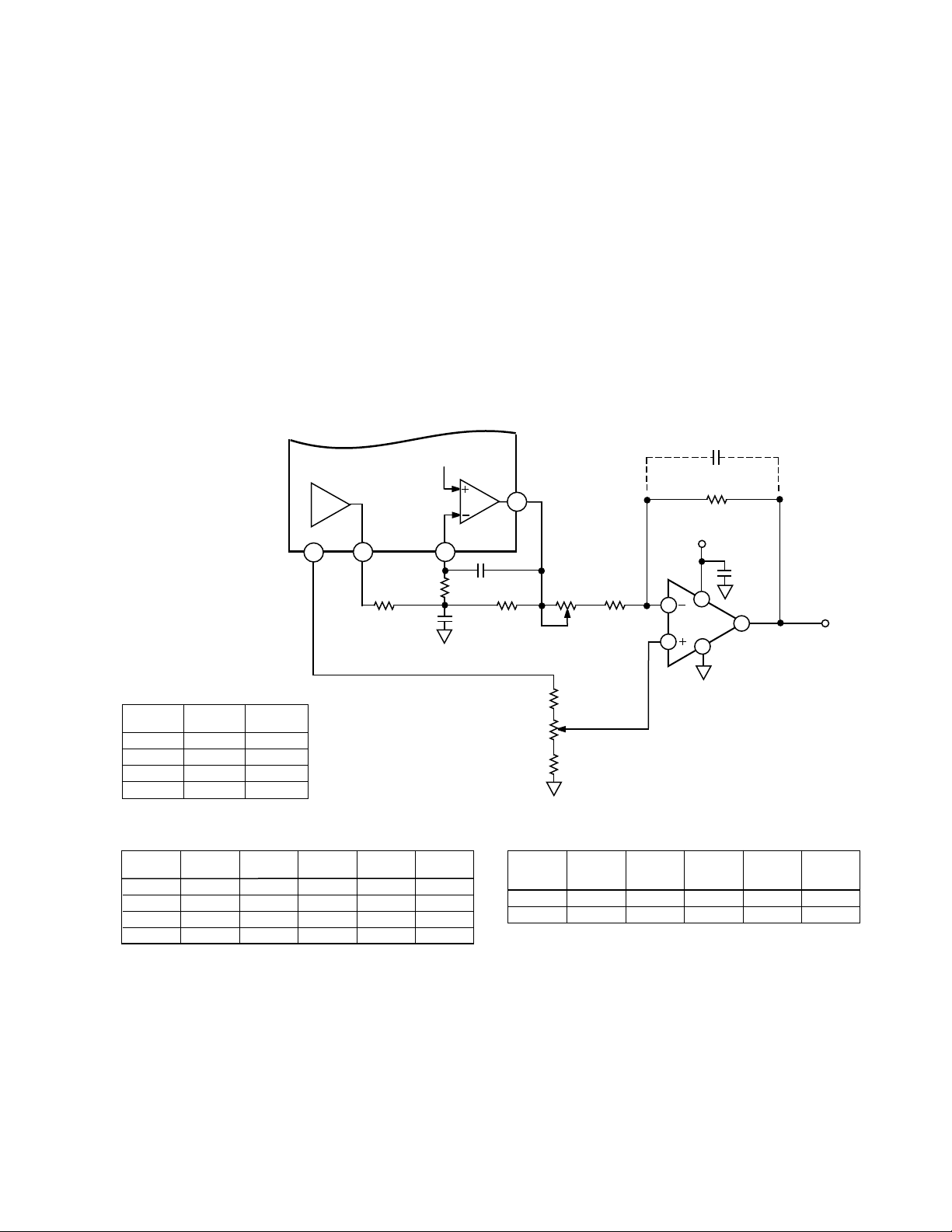

noise above the pole frequency. Figure 3 shows a circuit

that uses the buffer amplifier to provide 2-pole post filtering. Component values for the 2-pole filter were selected

to operate the buffer at unity gain.

0.1µF

+5V

V

OUT

R1a

R1b

1.8V

10

BUFFER

–

V

IN

1

AMP

9

R3

OPTIONAL SCALE

0

g

LEVEL

TRIM

FACTOR TRIM*

R2

50kΩ

*TO OMIT THE OPTIONAL SCALE FACTOR

TRIM , REPLACE R1a AND R1b WITH A

C4

FIXED VALUE 1% METAL FILM RESISTOR.

SEE VALUES SPECIFIED IN TABLES BELOW.

ADXL50 COMPONENT VALUES FOR VARIOUS

FULL-SCALE RANGES AND BANDWIDTHS

FULL

SCALE

±10

±20

±10

±20

mV

3dB

R1a

per

g

BW (Hz)

200

g

g

g

g

100

200

100

100

100

10

10

3dB BW =

R1b

kΩ

kΩ

21.5

5

23.7

5

21.5

5

23.7

5

1

2π R3 C4

R3

kΩ

249

137

249

137

R2

kΩ

100

100

100

100

C4

µF

0.0068

0.01

0.068

0.01

ADXL05 COMPONENT VALUES FOR VARIOUS

FULL-SCALE RANGES AND BANDWIDTHS

FULL

SCALE

±1

g

±2

g

±4

g

±5

g

mV

per

2000

1000

500

400

3dB

g

BW (Hz)

10

100

200

300

3dB BW =

R1a

kΩ

10

10

10

10

R1b

kΩ

24.9

35.7

35.7

45.3

1

2π R3 C4

301

200

100

100

R3

R2

kΩ

100

100

100

100

C4

µF

0.056

0.0082

0.0082

0.0056

kΩ

Figure 2. Using the Buffer Amplifier to Provide 1-Pole Post Filtering Plus Scale Factor and 0 g Level Trimming

–2–

Page 3

Capacitors C3 and C4 were chosen to provide 3 dB bandwidths of 10 Hz, 30 Hz, 100 Hz, and 300 Hz.

In this configuration, the nominal buffer amplifier output will be +1.8 V ± the scale factor of the accelerometer,

either 19 mV/

g

for the ADXL50 or 200 mV/g for the

ADXL05. An AD820 external op amp allows

noninteractive adjustment of 0

g

offset and scale factor.

The external op amp offsets and scales the output to

provide a +2.5 V ± 2 V output over a wide range of fullscale

g

levels.

Additional Noise Reduction Techniques

In addition to reducing circuit noise, any electromagnetic interference (EMI) needs to be considered.

Shielded wire should be used for connecting the accelerometer to any equipment or circuitry that is more than

a few inches away. A common problem is that of 60 Hz

PRE-AMP

ADXL50

1.8V

OR

ADXL05

V

IN

R5

42.2kΩ

10

–

2-POLE FILTER

COMPONENT VALUES

3dB

BW (Hz)

300

100

30

10

C3µF

0.027

0.082

0.27

0.82

C4µF

0.0033

0.01

0.033

0.1

6

V

REF

8

V

PR

R1

82.5kΩ

BUFFER

AMP

9

C4

R3

C3

82.5kΩ

2-POLE FILTER

40.2kΩ

20kΩ

71.5kΩ

pickup from ac line voltage. This can be minimized by

physically moving the device away from power leads, or

if that is not practical, using proper shielding and

grounding techniques. In most cases, it is advisable to

ground the cable’s shield at only one end and connect a

separate common lead between the circuits; this will

help to prevent ground loops. Also, if the accelerometer

is inside or near a metal enclosure, this should be

grounded as well.

Another area to consider is mechanical resonance of the

overall measurement system. The use of a highly flexible shielded wire will greatly help to prevent secondary

resonance effects of wire vibrating at its natural frequency. A shielded cable with a silicone jacket and silicone insulation such as that produced by Cooner Wire

Company of Chatsworth, California, is recommended.

OPTIONAL CAPACITOR

FOR 3-POLE FILTERING

2

AD820

3

R5

+5V

7

4

0.01µF

6

OFFSET AND

SCALING

AMPLIFIER

OUTPUT

V

OUT

+3.4V

R6

R7

R4a

SCALE

FACTOR

TRIM

0

g

LEVEL

TRIM

R4b

FULL

SCALE

±1

g

±2

g

±4

g

±5

g

ADXL05 OFFSET AND SCALING

AMPLIFIER COMPONENT VALUES

mV per

2000

1000

500

400

g

GAIN

10.00

4.98

2.50

2.00

R4a

kΩ

10

10

10

10

Figure 3. Two-Pole Filtering Circuit with Gain and 0 g Offset Adjustment

R4b

kΩ

24.9

35.7

35.7

45.3

301

200

100

100

ADXL50 OFFSET AND SCALING

AMPLIFIER COMPONENT VALUES

R5

kΩ

SCALE

FACTOR IN

mV/

g

200

100

MAX

INPUT

±10

±20

GAIN

g

10.53

g

5.26

R4a

kΩ

5

5

R4b

kΩ

21.5

23.7

R5

kΩ

249

137

–3–

Page 4

OFFSET DRIFT CONSIDERATIONS

When using an accelerometer with a dc (gravity sensing)

response, the 0

ture drift. When the accelerometer must measure low

g

offset level will exhibit some tempera-

g

levels over wide temperature ranges, the 0 g drift can become large in proportion to the signal amplitude. If a dc

response is truly needed, there are a number of design

options available. One very straightforward approach is to

use a low cost crystal oven to maintain the accelerometer

at a constant temperature. These ovens are particularly

useful in high accuracy tilt applications. After the circuit

has been built and is operating correctly, the crystal oven

can be mounted over the accelerometer and powered off

the same +5 V power supply. Figure 4 shows the basic circuit.

The ovens may be purchased from Isotemp Research, Inc.,

P.O. Box 3389, Charlottesville, VA 22903, phone 804-295-

3101. For more details on crystal oven compensation, refer to application note AN-385.

Other methods for 0

g

drift compensation include using a

low cost temperature sensor such as the AD590 to supply

a microprocessor with the device temperature. If the drift

curve of the accelerometer is stored in the µP, then a software program can be used to subtract out the drift. This

method works well, removing both the linear and nonlinear components of the drift. But due to device-to-device

variation, it requires that the drift curve of each individual

accelerometer be known (or measured). Alternatively,

various drift compensation circuits can be used to subtract

out the

linear portion of the accelerometer’s drift by using

a temperature sensor and op amp to supply a small compensation current. This hardware approach does not use a

µP but does require calibrating the compensation circuitry

for each device. For more details on software and hardware drift compensation, refer to application note AN-380.

ADXL50

OR

ADXL05

PRE-AMP

V

PR

6

+3.4V

REF

FS MEASUREMENT

V

PR

RANGE*

±10

g

±2

g

8

R1

SENSITIVITY

1.8V

10

OUTPUT

100mV/

500mV/

V

IN

g

g

BUFFER

AMP

–

1

9

R3

C

F

BUFFER

GAIN

5.26

2.50

C3

0.1µF

V

OUT

0g TOLERANCE.

PR

+5V

V

OUT

R1 R3

26.1k

40.2k

137k

100k

ISOTEMP

1µF

1.5µF

0.022 µF

0.022µF

ADXL50

ADXL05

C2

4

C1

2

3

C1

5

COM

0g OUTPUT – +2.5V

3dB Bw – 1Hz

DEVICE

*FS RANGE NUMBERS ARE CONSERVATIVE TO ALLOW FOR V

Figure 4. Low g DC Coupled (Tilt) Circuit Using Crystal Oven Compensation

M050570

+5V

+VDC

1

3

0VDC

C

F

2

NC

–4–

Page 5

AC Coupling

If a dc (gravity) response is not required—for example in

motion sensing or vibration measurement applications—ac coupling can be used between the preamplifier output and the buffer input as shown in Figure 5.

Because ac coupling removes the dc component of the

output, the preamp output signal may be amplified considerably without increasing the 0

g

level drift. If capacitor C5 is added to the ac coupling circuit, forming a

1-pole low-pass filter, then a bandpass function is provided that will attenuate any signals other than those

within the pass band. A typical ac coupled frequency response is shown in Figure 6.

The low frequency roll-off, F

, due to the ac coupling net-

L

work is:

F

L

1

=

R1C

2 π

4

In this case, the high frequency roll-off, FH, is determined

by the 1-pole post filter R3, C5.

If ac coupling is used, the self-test feature must be monitored at V

, rather than at the buffer output (since the

PR

self test output is a dc voltage).

20

10

LOW FREQUENCY ROLL-OFF ( FL )

0

–10

–20

NORMALIZED OUTPUT LEVEL – dB

–30

0.1 1 10 100 1k

HIGH FREQUENCY ROLL-OFF ( FH )

FREQUENCY – Hz

Figure 6. Typical Output vs. Frequency Curve when AC

Coupling V

to the Buffer

PR

Note that capacitor C4 should be a nonpolarized, low

leakage type. If a polarized capacitor is used, tantalum

types are preferred, rather than electrolytic. With polarized capacitors, V

should be measured on each device

PR

and the positive terminal of the capacitor connected toward either V

or VIN—whichever is more positive.

PR

COMPONENT

VALUES ARE

APPROXIMATE.

FOR MAXIMUM

ACCURACY,

SCALE FACTOR

TRIMMING SHOULD BE

EMPLOYED.

IN

IN

g

g

DESIRED

LOW

FREQUENCY

LIMIT, F

L

30

10

3

1

0.1

DESIRED

LOW

FREQUENCY

LIMIT, F

L

30

30

3

1

0.1

SCALE

FACTOR

mV/

200

100

200

100

200

SCALE

FACTOR

mV/

1000

200

1000

200

200

R1

VALUE

IN kΩ

24

24

24

24

24

R1

VALUE

IN kΩ

49.9

249

49.9

249

249

PRE-AMP

ADXL50

CLOSEST

C4

VALUE

0.22µF

0.68µF

2.2µF

6.8µF

68µF

ADXL05

CLOSEST

C4

VALUE

0.10µF

0.022µF

1.0µF

0.68µF

6.8µF

ADXL50 OR ADXL05

V

PR

8

V

PR

DESIRED

FREQUENCY

LIMIT, F

DESIRED

FREQUENCY

LIMIT, F

HIGH

300

300

100

100

10

HIGH

300

300

100

100

10

C4

R1

IN kΩ

H

249

127

249

127

249

IN kΩ

H

R3

R3

249

249

249

249

249

1.8V

10

–

V

IN

R2

CLOSEST

C5

VALUE

0.002µF

0.0039µF

0.0068µF

0.01µF

0.068µF

CLOSEST

C5

VALUE

0.002µF

0.002µF

0.0068µF

0.0068µF

0.068µF

BUFFER

AMP

R3

C5

V

9

VALUE

OF R2

FOR +2.5V

0

g

LEVEL

640kΩ

326kΩ

640kΩ

326kΩ

640kΩ

VALUE

OF R2

FOR +2.5V

0

g

LEVEL

640kΩ

640kΩ

640kΩ

640kΩ

640kΩ

OUT

Figure 5. AC Coupling the VPR Output to the Buffer Input

–5–

Page 6

GAIN SELECTION ISSUES

0

g

(a)

0

g

(b)

–1

g

(c)

+1

g

(d)

INDICATED POLARITY IS THAT

OCCURING AT V

PR

The uncommitted amplifier incorporated into the ADXL50

and ADXL05 devices allows the user to readily set the

scale factor to the desired voltage output per

g

of applied

acceleration. However, some caution is advised in not setting the scale factor, too high as the output buffer could

run out of “headroom,” i.e., the buffer’s output can go as

low as 0.25 volts and as high as 4.75 volts. This means the

buffer’s maximum output swing is +2.5 V ± 2.25 V. If the

gain is too high, the buffer can clip on periodic transient

accelerations; or it can clip due to the fact that the 0

g

off-

set drift is also amplified along with the signal.

Therefore, use only enough gain in the buffer as is neces-

sary to override any transmission losses between the accelerometer and any following circuitry (i.e., to keep the

system’s signal to noise ratio high).

Using the Earth’s Gravity to Calibrate the Accelerometer

Both the 0g offset and scale factor of the ADXL50 and

ADXL05 devices may be roughly calibrated by using the

1

g

(average) acceleration of the Earth’s gravity. Figure 7

shows how gravity and package orientation affect the output polarity. Note that the output polarity is that which appears at V

; the output at V

PR

will have the opposite sign

OUT

(due to the buffer amplifier’s inverting configuration).

With its axis of sensitivity in the vertical plane, the accelerometer should register a 1

g

acceleration, either positive

or negative, depending on orientation. With the axis of

sensitivity in the horizontal plane, no acceleration (0

g

)

should be indicated.

Calibrate the accelerometer by placing it on its side with

its axis of sensitivity oriented as shown in “a.” The 0

g

offset potentiometer, RT, (as shown in Figure 2) is then

roughly adjusted for midscale: +2.5 V at the buffer output.

Figure 7. Using the Earth’s Gravity to Calibrate the

ADXL50 and ADXL05 Accelerometers

If the optional scale factor trimmer, R1a, is to be used, it

should be adjusted next. The package axis should be oriented as in “c” (pointing down) and the output reading

noted. The package axis should then be rotated 180° to

position “d” and R1a adjusted so that the output voltage

indicates a change of 2

the circuit scale factor at the buffer output is 200 mV per

g

s in acceleration. For example, if

g

then the scale factor trim should be adjusted so that an

output change of 400 mV is indicated.

Adjusting the circuit’s scale factor will have some effect

on its 0

g

level, so this should be readjusted, as before, but

this time checked in both positions “a” and “b.” If there is

a difference in the 0

g

reading, a compromise should be

selected so that the reading in each direction is equal distant from +2.5 V. Scale factor and 0

g

offset adjustments

should be repeated until both are correct.

APPLICATIONS ASSISTANCE

For applications assistance contact Charles Kitchin,

Accelerometer Applications, Analog Devices Semiconductor, 831 Woburn St., Wilmington, MA 01887. Phone:

617-937-1665.

E2007–9–3/95

,

PRINTED IN U.S.A.

–6–

Loading...

Loading...