Page 1

AN-279

a

APPLICATION NOTE

One Technology Way • P.O. Box 9106 • Norwood, MA 02062-9106 • 781/329-4700 • World Wide Web Site: http://www.analog.com

Using the AD650 Voltage-to-Frequency Converter As a

Frequency-to-Voltage Converter

By Steve Martin

The AD650 is a versatile monolithic voltage-tofrequency converter (VFC) that utilizes a chargebalanced architecture to obtain high performance in

many applications. Like other charge-balanced VFCs,

the AD650 can be used in a reverse mode as a

frequency-to-voltage (F/V) converter. This application

note discusses the F/V architecture and operation,

component selection, a design example, and the

fundamental trade-off between output ripple and circuit

response time.

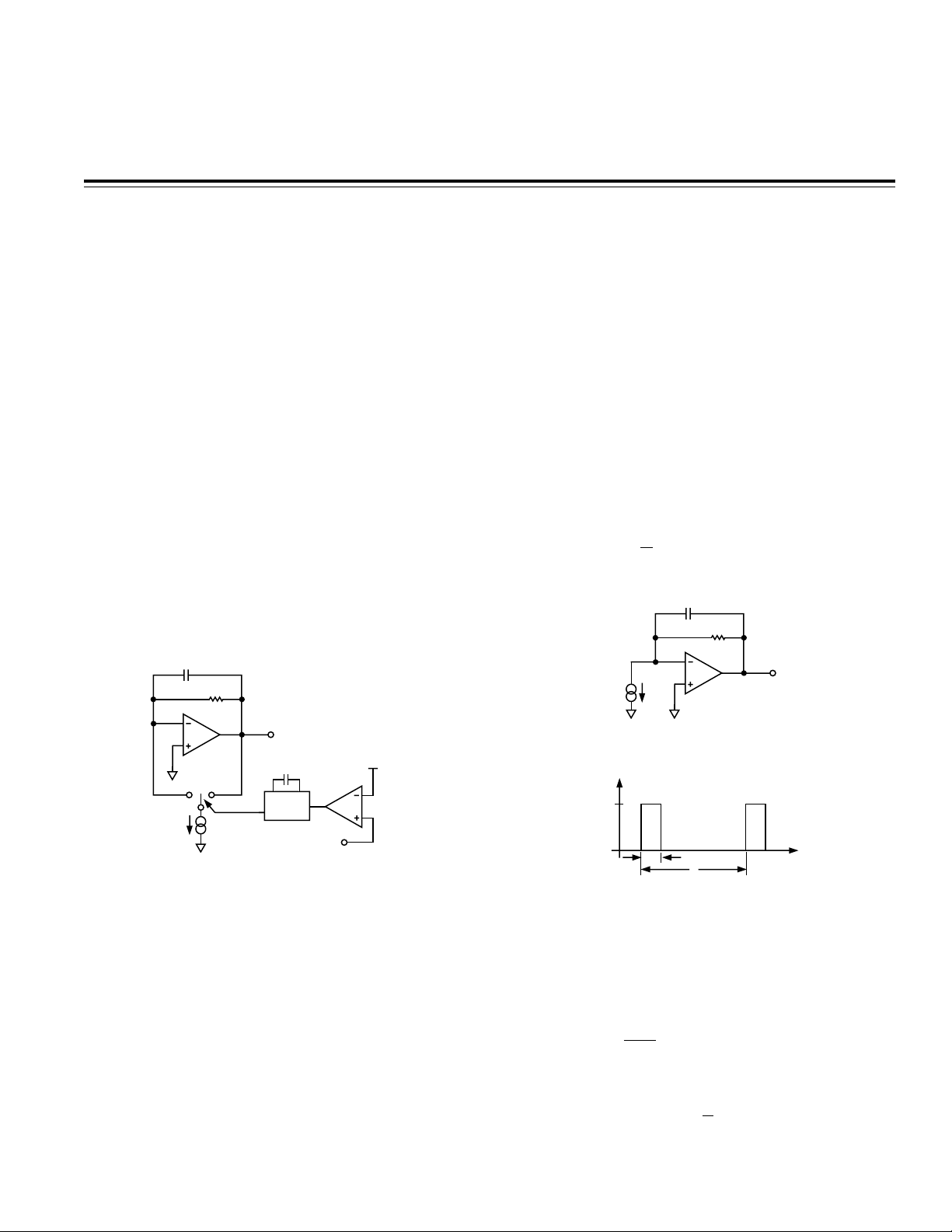

F/V CIRCUIT ARCHITECTURE

Figure 1 shows the major components of the frequencyto-voltage (F/V) converter. It includes a comparator, a

one-shot with a switch, a constant current source, and a

lossy integrator. When the input signal crosses the

C

INT

R

INT

V

OUT

COMP

f

IN

–0.6V

C

OS

ONE

SHOT

␣

Figure 1. Circuit Architecture

threshold at the comparator input, the comparator

triggers the one-shot. The one-shot controls a single

pole double throw switch which directs the current

source to either the summing junction, or the output, of

the lossy integrator. When the one-shot is in its “on”

state, there is current injected into the input of the

integrator and its output rises. When the one-shot

period has passed, the current is steered to the output of

the integrator. Since the output is a low impedance

node, the current has no effect on the circuit and is

effectively turned off. During this time the output falls

due to the discharge of C

through R

INT

. When constant

INT

triggering is applied to the comparator, the integration

capacitor will charge to a relatively steady value and be

REV. B

maintained by constant charging and discharging. The

charge stored on C

is unaffected by loading

INT

because of the low output impedance of the op amp.

THEORY OF OPERATION

Figure 2 shows a simplified representation of the AD650

in the F/V mode. Figure 3 represents the current i(t)

delivered to the lossy integrator. The current can be

thought of as a series of charge packets delivered at

1

f

=

OS

IN

with constant amplitude (α) and

T

)

C

INT

R

INT

V

OUT

i(t)

␣

frequency

duration (t

Figure 2. Simplified Schematic

i(t)

␣

t

OS

T

t

Figure 3. Current i(t) into Integrator

From inspection of Figure 3, the average value of input

current is found by dividing the area of the current i(t) by

the period T. The dc component of the output voltage is

found by scaling the average input current by the

feedback resistor R

V

OUTAVG

=×α.

.

INT

t

OS

R

T

INT

(1a)

Equation 1a becomes a linear function of frequency

when f

is substituted for

IN

VtRf

OUTAVG OS INT IN

=× ××α

1

.

T

(1b)

Page 2

AN-279

Notice that the relationship between the average output

voltage and input frequency is a function of the one-shot

time constant and the feedback resistor but not of the

integration capacitor. This is because the integration

capacitor is an open circuit to dc. From Equation 1b it is

clear that the most practical way to trim the full-scale

voltage is to include a trim potentiometer in series with

R

. Typically, a 30% trim range will be required to

INT

absorb errors associated with t

and α.

OS

It is also important to characterize the transient

response of the integrator in order to determine settling

time of the F/V to a step change of input frequency. The

transfer function of the lossy integrator is given in the

frequency domain by:

1

VS

()

OUT

IS

()

IN

=

C

INT

S

+

RC

INT INT

1

(2)

×

which indicates that the natural or step response to a

change of input frequency is governed by an

exponential function with time constant π = R

INT

× C

INT.

With the average output voltage and transient response

known, the peak-peak output ripple can be determined

using Equation 3. Once this is determined, a design

algorithm can be developed (Reference 1).

The peak-peak ripple is given by:

//

tRC

()−()

OS OS

eee

V

=

PP

TIRC

−+ −

1

−

e

TIRC

Tt RC

1

××

α

R

(3)

where:

t

= one-shot time constant [seconds]

OS

T

= period of input frequency (1/fIN) [hertz]

R

= integration resistor [ohms]

C

= integration capacitor [farads]

α = current source value (1 mA for AD650) [amps]

Equation 3 accurately represents the ripple amplitude

for a given design. The following section shows how

this equation is used as an iterative part of the total

solution. Equation 3 can also be used to illustrate how

the ripple amplitude changes as a function of input

frequency. It is interesting to note that the ripple

amplitude changes only moderately with input

frequency and has its largest magnitude at the

minimum frequency.

DESIGN PROCEDURE

Recall from looking at Figure 3, that the one-shot “on”

time will be some fraction of the total input period. This

is the time that the circuit integrates the current signal α.

The output ripple can be minimized by allowing the

current source to be on during the majority of this

period. This is achieved by choosing the one-shot time

constant so that it occupies almost the full period of the

input signal when this period is at its minimum (or the

input frequency at its maximum). To design safely and

allow for component tolerance at f

, make t

MAX

OS

approximately equal to 90% of the minimum period.

Given t

C

OS

, the value of the one-shot timing capacitor,

OS

, is determined from Equation 1 in the AD650 data

sheet. This equation has been rearranged and appears

here as:

−

t sec

−×

C

where

(NOTE: For maximum linearity performance use a low dielectric absorption capacitor for COS.)

OS

=

OS

t

OS

×

6.8 10

is in seconds and

7

3

10

3

sec F

/

C

is in farads.

OS

(4)

Once COS is known, the integration resistor is uniquely

determined from the full-scale equation (Equation 1b),

since t

, α, fIN, and V

OS

are known. This leaves only the

OUT

integration capacitor as the final unknown.

C

is chosen by first determining the response time of

INT

the device being measured. If, for example the

frequency signal to be measured is derived from a

mechanical device such as an aircraft turbine shaft, the

momentum of the shaft and the blades should be used

to determine the response time. The time constant of

the F/V is then set to match the time constant of the

mechanical system. It may be set somewhat lower,

depending on the desired total response time of the

mechanical and electrical system. Remember to allow

several time constants (N) for the F/V to approach its

final value. For the first iteration of C

use the following

INT

expression:

C

Mechanical sponse Time

=

INT

Re

×

NR

INT

(5)

where N is the number of time constants chosen to

allow adequate settling. Table I may be used to

determine the number of time constants required for

given settling accuracy.

–2–

REV. B

Page 3

AN-279

DETERMINE VARIABLES: f

MIN

, f

MAX

RESPONSE TIME , FULL-SCALE

VOLTAGE, MAXIMUM ACCEPTABLE RIPPLE.

CALCULATE:

tOS = 0.9/f

MAX

FIND COS GIVEN t

OS

USING

EQUATION 4.

FIND R

INT

GIVEN V FULL-SCALE

AND t

OS

USING EQUATION 1b.

DETERMINE N BY SYSTEM ACCURACY

USING TABLE I (DEFAULT TO 6 IF UNSURE).

FIND C

INT

USING EQUATION 5.

DECREASE N TO

TRADE RESPONSE

TIME

FOR RIPPLE

CALCULATE RIPPLE USING EQUATION 3

AND f

MIN

.

RIPPLE

TOO

LARGE?

C

INT

IS KNOWN.

DESIGN

COMPLETE.

YES

NO

Table I. Settling Accuracy vs. Number of Time Constants

# of Time

Constants

(N) # of Bits % Accuracy

4.16 6 1.6

4.85 7 0.8

5.55 8 0.4

6.23 9 0.2

6.93 10 0.1

7.62 11 0.05

8.30 12 0.024

9.00 13 0.012

9.70 14 0.006

10.4 15 0.003

11.0 16 0.0015

A larger number of time constants will give a more

responsive circuit but will also increase the ripple at the

F/V output. A practical approach is to start with 8-bit

settling accuracy, using N = 6 time constants, and

increase or decrease N depending on ripple content.

The ripple content is calculated using Equation 3.

Remember that the ripple amplitude will change with

frequency and will be largest at the lowest frequency. It

is also important to note that while in some cases the

ripple amplitude may be large, the average value of the

output voltage will always represent the input frequency

(unless the ripple gets too close and “clips” at the

positive supply rail). Figure 4 shows an example of how

output ripple amplitude will change with input

frequency for a typical application. This graph was

obtained by plotting Equation 3 over the full range of

input frequencies. For design purposes it is only

necessary to calculate ripple at the worst case frequency

(f

). Figure 5 summarizes the design procedure.

MIN

DESIGN EXAMPLE

The rpm of an automobile’s engine is to be monitored

for use by an on-board computer. The rpm signal that

will be generated from an F/V converter is to be digitized

with an 8-bit A/D converter. The rpm range of the engine

extends from 300 rpm to 7000 rpm. A 200-tooth flywheel

at these rotational speeds will generate pulses from

1 kHz up to 23 kHz. The response time to a step change

in throttle position of the engine has been measured, in

neutral, to be 400 ms. The goal is to design an F/V

converter that will respond at approximately the same

rate as the engine, or faster, and will have ripple that is

undetectable by the A/D converter. The A/D converter

has a 10-volt full scale.

1. Let t

be 0.9 × 1/f

OS

= 0.9 × 43.5 µs = 39 µs.

MAX

2. Find COS = 0.0057 µF (from Equation 4) (an impractical

value for polystyrene, but tantalum may be used with

reduced linearity).

V

3.

R

=

INT

mA s kHz

13923

10

××

=

11.14µΩ

k

(from

Equation 1b).

0.015

0.011

– p-p

0.008

OUT

V

0.004

0.000

1000 6500

Figure 4. P-P Ripple vs. Frequency (See Design

Example)

REV. B

RIPPLE VS. FREQUENCY

12000 17500 23000

f

IN

Figure 5. Design Flowchart

–3–

Page 4

AN-279

(If R

, the load seen by the amplifier, is less than

INT

1kΩ, then t

4. From Table I, an RC network can settle to eight bits in

six time constants so:

C

=

INT

5. Ripple = 6.25 mV @ 300 rpm and 0.67 mV @ 7000 rpm

(from Equation 3).

6. 1/2 LSB size for an 8-bit converter with 10 V full scale

is 19.5 mV. Fortunately, the ripple is below the

quantization level on the first iteration. If desired, the

integration capacitor may be lowered to reduce

response time of the F/V converter.

7. Guessing C

program gives a maximum ripple content of 12.5 mV

and a response time of 200 ms.

THE TRADE-OFF BETWEEN RIPPLE AND RESPONSE

TIME

In many instances some compromise must be made

between ripple and response time. If response time is of

primary importance, the integration capacitor may be

lowered at the expense of increased ripple. Similarly, if

ripple is paramount, the integration capacitor must be

increased resulting in slower response. The design

procedure outlined above assumes that ripple content is

the less desirable effect. Rather than increasing C

low-pass filter could be used, but this also slows the

response time. An approximation to determine total

response time of two cascaded systems, each with

separate response times, can be found by using the

“root sum of squares” technique.

TTT

TOTAL A B

This leads to the “three-to-one” rule, i.e., if TA is more

than three times T

be ignored, hence, T

system.

must be reevaluated.)

OS

ms

40610

1146. Ω

(

)

INT

=+

=

F

µ

.

k

= 3.0 µF or using an iterative computer

22

and their squares are added, TB may

B

is the total response time of the

A

INT

, a

SUMMARY

Low cost voltage-to-frequency converters can be used in

the frequency-to-voltage mode. Trade-offs exist

between output settling time and ripple with the

selection being application-specific. However, by using

the design guidelines highlighted in this note, optimized

performance can be achieved in many applications.

References

1

McGillem, C. D., and G. R. Cooper,

Discrete Signal and System Analysis

Continuous and

, Second Edition.

New York: CBS College Publishing, 1984.

2

Analog Devices Inc. AD650 Data Sheet. Latest version

can be found on www.analog.com.

15.5mV

200s

100

0%

⌬

V1

90

10

5mV

Figure 6. Typical Ripple Output

100.10ms

t1.70V

20ms

100

0%

A1

90

10

1V

⌬

Figure 7. Response to Step Change in Frequency

E01373–0–9/00 (rev. B)

–4–

PRINTED IN U.S.A.

REV. B

Loading...

Loading...