Page 1

AN-272

a

One Technology Way • P.O. Box 9106 • Norwood, MA 02062-9106 • 781/329-4700 • World Wide Web Site: http://www.analog.com

APPLICATION NOTE

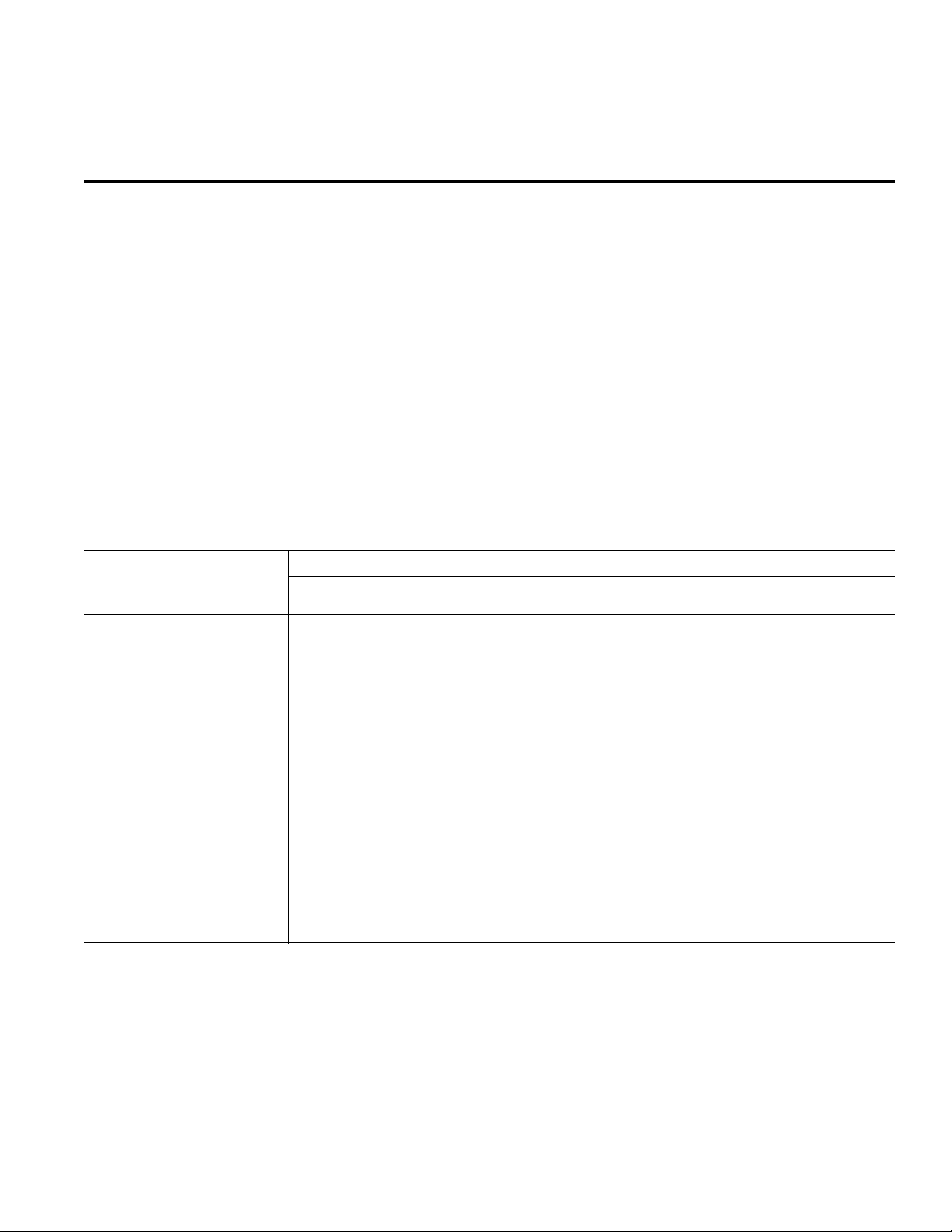

Accuracies of the AD590

The following tables contain maximum errors by grade

for applications involving limited temperature spans.

The tables reflect the worst case nonlinearities of the

AD590, which invariably occur at the ends of the specified temperature range. The “trims” in each table refer

to the error correction circuits on pages 4 and 5 of the

AD590 data sheet (Figures 4 and 7a). All accuracies

given below are ±°C. For example, ±1°C accuracy is

M GRADE

Number Temperature

Of Trims Span (8C) –55 –25 0 +25 +50 +75 +100 +125

None 10 0.6 0.5 0.6 0.6 0.7 0.7 0.7 0.9

None 25 0.8 0.8 0.7 0.7 0.8 0.8 1.0 1.1

None 50 1.0 0.9 0.8 0.9 0.9 1.1 1.2 —

None 100 1.3 1.4 1.3 1.4 1.5 — — —

None 150 1.5 1.6 1.6 —————

None 205 1.7 ———————

One 10 0.2 0.1 0.1 0.1 0.1 0.1 0.1 0.2

One 25 0.4 0.3 0.2 0.2 0.2 0.2 0.3 0.4

One 50 0.5 0.4 0.3 0.3 0.3 0.4 0.5 —

One 100 0.8 0.8 0.7 0.7 0.8 — — —

One150 0.90.90.9—————

One205 1.0———————

Two10 0.1******0.1

Two25 0.1******0.1

Two50 0.2*****0.2—

Two 100 0.2 0.1 * 0.1 0.2 — — —

Two150 0.30.20.3—————

Two205 0.3———————

*BeIow ±0.05° C

required over the +25°C to +75°C range, then trimming a

J grade device using the circuit of Figure 4 on the AD590

data sheet will result in a sensor of the required accuracy and range.

Lowest Temperature In Span (8C)

Page 2

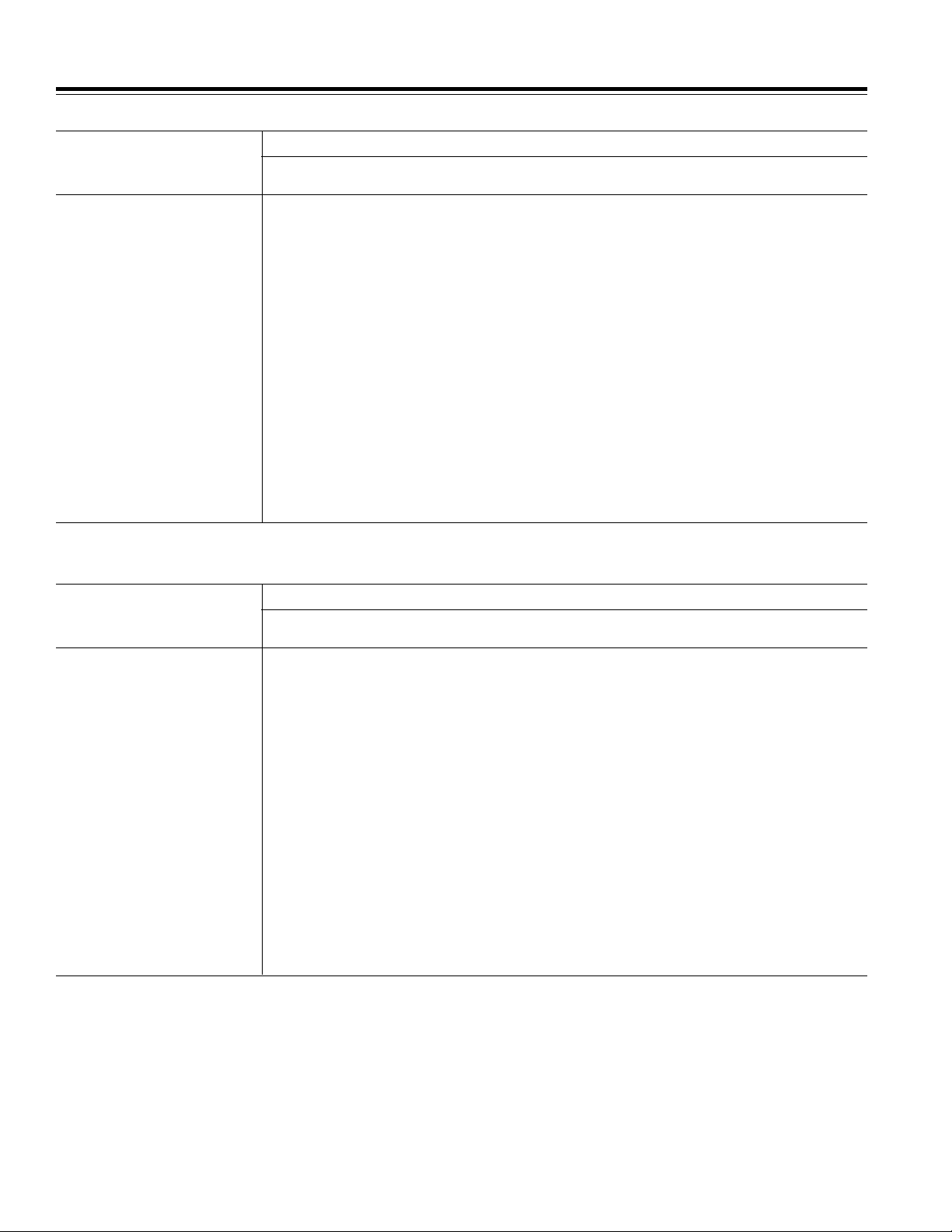

AN-272

L GRADE

Lowest Temperature In Span (8C)

Number Temperature

Of Trims Span (8C) –55 –25 0 +25 +50 +75 +100 +125

None 10 1.0 1.0 1.1 1.1 1.2 1.3 1.4 1.6

None 25 1.3 1.3 1.3 1.4 1.5 1.6 1.7 1.9

None 50 1.9 1.8 1.7 1.8 1.9 2.1 2.4 —

None 100 2.4 2.4 2.4 2.4 2.7 — — —

None 150 2.7 2.6 2.8 —————

None 205 3.0 ———————

One 10 0.2 0.1 0.1 0.1 0.1 0.1 0.1 0.2

One 25 0.5 0.4 0.3 0.3 0.3 0.3 0.4 0.5

One 50 1.0 0.8 0.6 0.6 0.6 0.8 1.0 —

One 100 1.3 1.2 1.1 1.1 1.3 — — —

One150 1.41.31.4—————

One205 1.6———————

Two10 0.1******0.1

Two25 0.1******0.1

Two50 0.2*****0.2—

Two 100 0.3 0.2 0.1 0.2 0.3 — — —

Two150 0.30.20.3—————

Two205 0.4———————

*BeIow ±0.05°C

K GRADE

Lowest Temperature In Span (8C)

Number Temperature

Of Trims Span (8C) –55 –25 0 +25 +50 +75 +100 +125

None 10 2.1 2.3 2.5 2.7 2.9 3.1 3.3 3.6

None 25 2.6 2.7 2.8 3.0 3.2 3.5 3.8 4.2

None 50 3.8 3.5 3.4 3.6 3.8 4.3 5.1 —

None 100 4.2 4.3 4.4 4.6 5.1 — — —

None 150 4.8 4.8 5.3 —————

None 205 5.5 ———————

One 10 0.2 0.1 0.1 0.1 0.1 0.1 0.1 0.2

One 25 0.6 0.4 0.3 0.3 0.3 0.4 0.5 0.6

One 50 1.2 1.0 0.7 0.7 0.7 1.0 1.2 —

One 100 1.5 1.4 1.3 1.3 1.5 — — —

One150 1.71.51.7—————

One205 2.0———————

Two10 0.1******0.1

Two25 0.20.1****0.10.2

Two 50 0.3 0.1 * * * 0.1 0.2 —

Two 100 0.5 0.3 0.2 0.3 0.7 — — —

Two150 0.60.50.7—————

Two205 0.8———————

*BeIow ±0.05° C

–2–

Page 3

AN-272

J GRADE

Lowest Temperature In Span (8C)

Number Temperature

Of Trims Span (8C) –55 –25 0 +25 +50 +75 +100 +125

None 10 4.2 4.6 5.0 5.4 5.8 6.2 6.6 7.2

None 25 5.0 5.2 5.5 5.9 6.0 6.9 7.5 8.0

None 50 6.5 6.5 6.4 6.9 7.3 8.2 9.0 —

None 100 7.7 8.0 8.3 8.7 9.4 — — —

None 150 9.2 9.5 9.6 —————

None 205 10.0 ———————

One 10 0.3 0.2 0.2 0.2 0.2 0.2 0.2 0.3

One 25 0.9 0.6 0.5 0.5 0.5 0.6 0.8 0.9

One 50 1.9 1.5 1.0 1.0 1.0 1.5 1.9 —

One 100 2.3 2.2 2.0 2.0 2.3 — — —

One150 2.52.42.5—————

One205 3.0———————

Two10 0.1******0.1

Two25 0.20.1****0.10.2

Two 50 0.4 0.2 0.1 * * 0.1 0.2 *

Two 100 0.7 0.5 0.3 0.7 1.0 — — —

Two150 1.00.71.2—————

Two205 1.5———————

*BeIow ±0.05°C

I GRADE

Lowest Temperature In Span (8C)

Number Temperature

Of Trims Span (8C) –55 –25 0 +25 +50 +75 +100 +125

None 10 8.4 9.2 10.0 10.8 11.6 12.4 13.2 14.4

None 25 10.0 10.4 11.0 11.8 12.0 13.8 15.0 16.0

None 50 13.0 13.0 12.8 13.8 14.6 16.4 18.0 —

None 100 15.2 16.0 16.6 17.4 18.8 — — —

None 150 18.4 19.0 19.2 —————

None 205 20.0 ———————

One 10 0.6 0.4 0.4 0.4 0.4 0.4 0.4 0.6

One 25 1.8 1.2 1.0 1.0 1.0 1.2 1.6 1.8

One 50 3.8 3.0 2.0 2.0 2.0 3.0 3.8 —

One 100 4.8 4.5 4.2 4.2 5.0 — — —

One150 5.54.85.5—————

One205 5.8———————

Two 10 0.3 0.2 0.1 * * 0.1 0.2 0.3

Two 25 0.5 0.3 0.2 * 0.1 0.2 0.3 0.5

Two 50 1.2 0.6 0.4 0.2 0.2 0.3 0.7 —

Two 100 1.8 1.4 1.0 2.0 2.5 — — —

Two150 2.62.02.8—————

Two205 3.0———————

*BeIow ±0.05°C

–3–

Page 4

AN-272

NOTES

1. All accuracies excluding the 205°C span are guaranteed, not tested; the 205°C span accuracies are tested

for by testing each device at –55°C, +25°C, +125°C and

+150°C.

2. All one-trim accuracies excluding the 205°C span assume that the trim is made at the midpoint in the

span; the 205°C span assumes a trim at +25°C.

3. All two-trim accuracies excluding the 205°C span assume that the trims are made at the endpoints of the

span; the 205°C span assumes that trims are made at

approximately 0°C and +140°C.

4. All accuracies exclude:

a. Trim error in calibration technique used;

b. Repeatability error;

c. Long-term drift errors.

In precision applications, the actual errors encountered

are usually dependent upon sources of error that are often overlooked in error budgets.

A)

Trim Error

error arises from such sources as:

1. Poor thermal coupling between the device to be

calibrated and the reference sensor;

2. Reference sensor errors;

is usually the largest error source. This

B)

Repeatability Errors

the package. The magnitude of this error is solely a

function of the magnitude of the temperature span

over which the device is used. For example, thermal

shocks between 0°C and 100°C will result in an extremely low hysteresis, for a repeatability error of

less than ±0.05°C. When the thermal shocks are widened to –55°C and +150°C, the device will typically

exhibit a repeatability of ±0.05°C, with ±0.10°C

maximum being guaranteed.

C)

Long-Term Drift Errors

operating temperature and the magnitude of the

thermal shocks experienced by the device. Extended use of the device at temperatures above

100°C typically results in a long term drift of

±0.03°C; the guaranteed maximum is ±0.10° C. Oper-

ating temperatures below 100°C induce no measurable drifts in the device. In addition to operating

temperature, the severity of the thermal shocks incurred will determine the absolute stability of the

device. For thermal shock spans of less than 100°C,

the drift is difficult to measure (< 0.03°C). However,

for 200°C spans the device may drift by as much as

±0.10°C after 20 such shocks. If severe, quick shocks

are necessary in the application of the device, simulated life tests are recommended for a thorough

evaluation of the error introduced by such shocks.

arise from a strain hysteresis of

are related to the average

E488a–0–4/98

3. Device to be calibrated is not permitted to thermally settle;

4. θ

is radically different for the trim and the

CA

application.

PRINTED IN U.S.A.

–4–

Loading...

Loading...