Analog Devices ADXL05JH, ADXL05AH Datasheet

61 g to 65 g Single Chip Accelerometer

a

FEATURES

g

5 milliNoise Level 123 Less than the ADXL50

User Selectable Full Scale from 61 g to 65

Output Scale Selectable from 200 mV/g to 1 V/

Complete Acceleration Measurement System on a

Self Test on Digital Command

+5 V Single Supply Operation

1000

APPLICATIONS

Low Cost Sensor for Vibration Measurement

Tilt Sensing with Faster Response than Electrolytic or

More Sensitive Alarms and Motion Detectors

Affordable Inertial Sensing of Velocity and Position

GENERAL DESCRIPTION

The ADXL05 is a complete acceleration measurement system

on a single monolithic IC. The ADXL05 will measure accelerations with full-scale ranges of ±5 g to ±1 g or less. Typical noise

Resolution

Single Chip IC

g

Shock Survival

Mercury Sensors

g

g

with Signal Conditioning

ADXL05*

floor is 500 µg/√Hz, (12× less than the ADXL50), allowing signals below 5 milli-g to be resolved. The ADXL05 is a force balanced capacitive accelerometer with the capability to measure

both ac accelerations (typical of vibration) or dc accelerations

(such as inertial force or gravity). Three external capacitors and

a +5 volt regulated power supply are all that is required to

measure accelerations up to ±5 g. Three resistors are used to

configure the output buffer amplifier to set scale factors from

200 mV/g to 1 V/g. External capacitors may be added to the

resistor network to provide 1 or 2 poles of filtering. No additional active components are required to interface directly to

most analog to digital converters (ADCs).

The device features a TTL compatible self-test function that

can electrostatically deflect the sensor beam at any time to verify

that the sensor and its electronics are functioning correctly.

The ADXL05 is available in a hermetic 10-pin TO-100 metal

can, specified over the 0°C to +70°C commercial, and –40°C to

+85°C industrial temperature ranges. Contact factory for availability of automotive grade devices.

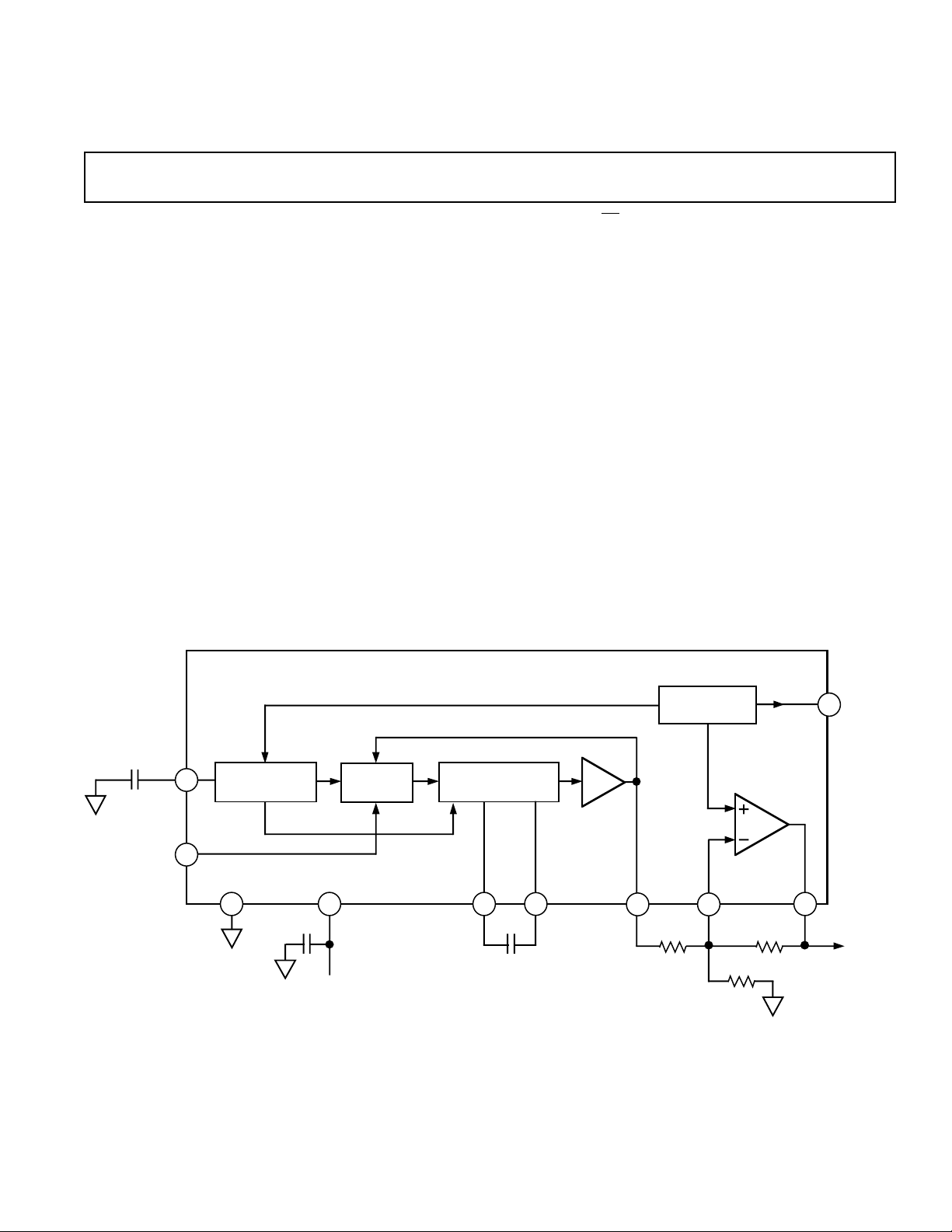

OSCILLATOR

DECOUPLING

CAPACITOR

C2

SELF-TEST

(ST)

*Patents pending.

4

7

COM

ADXL05

OSCILLATOR

C3

+5V

15

FUNCTIONAL BLOCK DIAGRAM

SENSOR

DEMODULATOR

C1

DEMODULATOR

CAPACITOR

32

C1

PREAMP

V

PR

8

REFERENCE

10

R1

+1.8V

V

IN–

BUFFER

AMP

R3

R2

+3.4V

V

REF

6

OUTPUT

9

V

OUT

REV. B

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

© Analog Devices, Inc., 1996

One Technology Way, P.O. Box 9106, Norwood. MA 02062-9106, U.S.A.

Tel: 617/329-4700 Fax: 617/326-8703

ADXL05–SPECIFICA TIONS

(TA = T

MIN

to T

, TA = +258C for J Grade Only, VS = +5 V, @ Acceleration = 0 g,

MAX

unless otherwise noted)

Parameter Conditions Min Typ Max Units

ADXL05J/A

SENSOR INPUT

Measurement Range Guaranteed Full Scale –5 +5 g

Nonlinearity Best Fit Straight Line, 5 g FS 0.2 % of FS

Alignment Error

Transverse Sensitivity

1

2

± 1 Degrees

± 2%

SENSITIVITY

Initial Sensitivity at V

Initial Sensitivity at V

Temperature Drift

PR

OUT

3

ZERO g BIAS LEVEL at V

Initial Offset 1.50 1.80 2.10 V

vs. Temperature

3

+25°C 175 200 225 mV/g

+25°C, R3/R1 = 5 0.875 1.000 1.125 V/g

± 0.5 % of Reading

PR

± 25/40 mV

vs. Supply VS = 4.75 V to 5.25 V 10 32 mV/V

NOISE PERFORMANCE at V

PR

Voltage Noise Density BW = 4 Hz to 1 kHz 500 1000 µg/√Hz

Noise in 100 Hz Bandwidth 5mg rms

Noise in 10 Hz Bandwidth 1.6 mg rms

FREQUENCY RESPONSE

3 dB Bandwidth

3 dB Bandwidth

4

4

C1 = 0.022 µF (See Figure 9) 1000 1600 Hz

C1 = 0.010 µF 4 kHz

Sensor Resonant Frequency 12 kHz

SELF TEST INPUT

Output Change at V

5

PR

ST Pin from Logic “0” to “1” –0.85 –1.00 –1.15 V

Logic “1” Voltage 2.0 V

Logic “0” Voltage 0.8 V

Input Resistance To Common 50 kΩ

+3.4 V REFERENCE

Output Voltage 3.350 3.400 3.450 V

Output Temperature Drift

3

±5mV

Power Supply Rejection DC, VS = +4.75 V to +5.25 V 1 10 mV/V

Output Current Sourcing 500 µA

PREAMPLIFIER OUTPUT

Voltage Swing 0.25 VS – 1.4 V

Current Output Source or Sink 30 80 µA

Capacitive Load Drive 100 pF

BUFFER AMPLIFIER

Input Offset Voltage

6

Delta from Nominal 1.800 V ±10 ±25 mV

Input Bias Current 520nA

Open-Loop Gain DC 80 dB

Unity Gain Bandwidth 200 kHz

Output Voltage Swing I

= ±100 µA 0.25 VS – 0.25 V

OUT

Capacitive Load Drive 1000 pF

Power Supply Rejection DC, VS = +4.75 V to +5.25 V 1 10 mV/V

POWER SUPPLY

Operating Voltage Range 4.75 5.25 V

Quiescent Supply Current 8.0 10.0 mA

TEMPERATURE RANGE

Operating Range J 0 +70 °C

Specified Performance A –40 +85 °C

Automotive Grade* –40 +125 °C

NOTES

1

Alignment error is specified as the angle between the true and indicated axis of sensitivity, (see Figure 2).

2

Transverse sensitivity is measured with an applied acceleration that is 90° from the indicated axis of sensitivity. Transverse sensitivity is specified as the percent of

transverse acceleration that appears at the V

3

Specification refers to the maximum change in parameter from its initial at +25°C to its worst case value at T

4

Frequency at which response is 3 dB down from dc response assuming an exact C1 value is used. Maximum recommended BW is 6 kHz using a 0.010 µF capacitor, refer to

Figure 9.

5

Applying logic high to the self-test input has the effect of applying an acceleration of –5 g to the ADXL05.

6

Input offset voltage is defined as the output voltage differential from 1.800 V when the amplifier is connected as a follower. The voltage at this pin has a temperature drift

proportional to that of the 3.4 V reference.

*Contact factory for availability of automotive grade devices.

All min and max specifications are guaranteed. Typical specifications are not tested or guaranteed.

Specifications subject to change without notice.

output. This is the algebraic sum of the alignment and the inherent sensor sensitivity errors, (see Figure 2).

PR

MIN

to T

MAX

.

–2–

REV. B

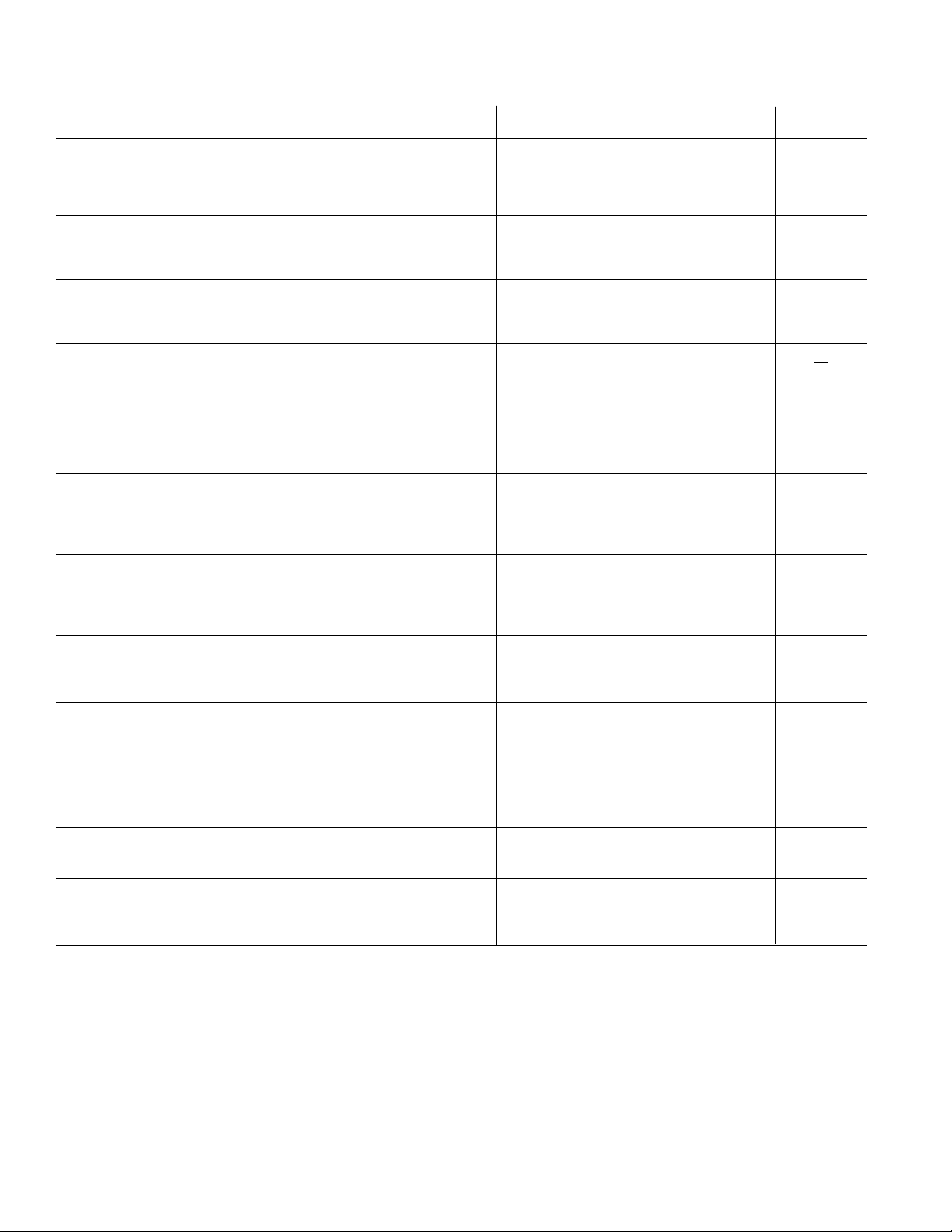

System Performance Specifications–ADXL05

0.022µF

0.022µF

COM

C2

4

ADXL05

C1

C1

2

3

5

+3.4V

REF

6

PRE-AMP

8

V

PR

C4

1.8V

10

V

R1

IN–

R2

BUFFER

AMP

R3

1

+5V

C3

0.1µF

9

V

OUT

NOMINAL VALUES:

R1 = 49.9kΩ

R3 = 249kΩ

R2 = 640kΩ

AC COUPLED CONNECTION (61.5 g Full Scale)

(@ V

Terminal (Pin 9), unless otherwise noted. 0 g Bias Level = +2.5 V, C1 = 0.022 mF, R2 = 2.57 R3

OUT

ADXL05J/A

Parameter Conditions Min Typ Max Units

Buffer Gain G = R3/R1* 5

FULL-SCALE RANGE –1.5 +1.5 g

SENSITIVITY @

Temperature Drift T

ZERO g BIAS LEVEL @ +25°C 2.5 V

Temperature Drift +25°C to T

FREQUENCY RESPONSE C4 = 3.3 µF, R1 = 49.9 kΩ 1 1000 Hz

*Note: Resistor tolerance will affect system accuracy. Use of ±1% (or better) metal film resistors is recommended.

+25°C 875 1000 1,125 mV/g

MIN

to T

MAX

MIN

or T

MAX

±0.5 % of Reading

2/5 mV

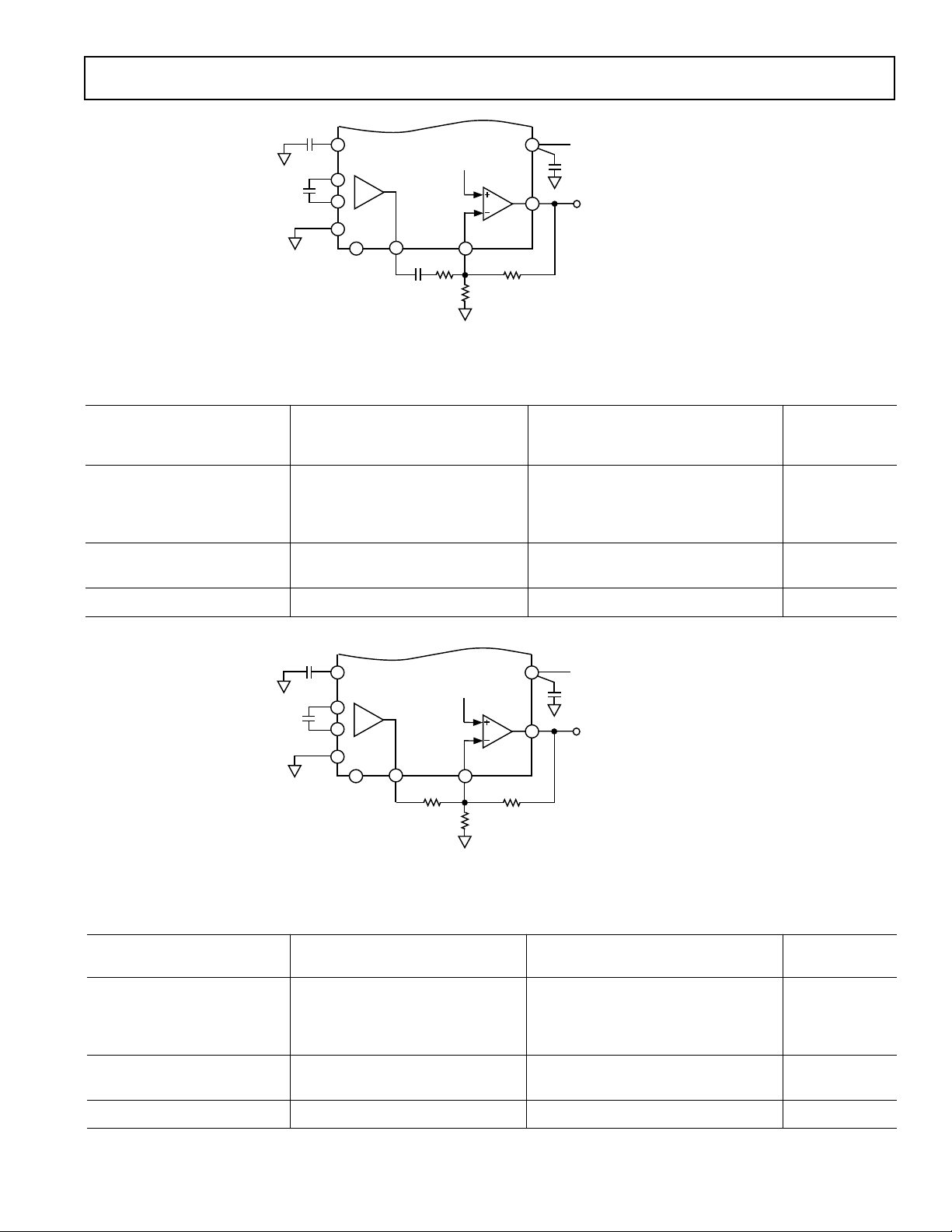

0.022µF

0.022µF

COM

C2

4

ADXL05

C1

C1

2

3

5

+3.4V

REF

6

PRE-AMP

8

V

PR

1.8V

10

V

R1

IN–

R2

BUFFER

AMP

R3

1

+5V

C3

0.1µF

9

V

OUT

NOMINAL VALUES:

R1 = 49.9kΩ

R3 = 100kΩ (G=2)

R2 = 255kΩ (G=2)

DC COUPLED CONNECTION (62 g Full Scale)

(@ V

Terminal (Pin 9), unless otherwise noted. 0 g Bias Level = +2.5 V, C1 = 0.022 mF, R2 = 2.57 R3)

OUT

ADXL05J/A

Parameter Conditions Min Typ Max Units

Buffer Gain G = R3/R1* 2

FULL-SCALE RANGE –2 +2 g

SENSITIVITY @

Temperature Drift T

ZERO g BIAS LEVEL @ +25°C 1.75 2.5 3.2 V

Temperature Drift +25°C to T

FREQUENCY RESPONSE dc 1000 Hz

*Note: Resistor tolerance will affect system accuracy. Use of ±1% (or better) metal film resistors is recommended.

+25°C 350 400 450 mV/g

MIN

to T

MAX

MIN

or T

MAX

±0.5 % of Reading

±50/80 mV

REV. B

–3–

ADXL05

WARNING!

ESD SENSITIVE DEVICE

ABSOLUTE MAXIMUM RATINGS*

Acceleration (Any Axis, Unpowered for 0.5 ms) . . . . . . 1000 g

Acceleration (Any Axis, Powered for 0.5 ms) . . . . . . . . . . 500 g

+V

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . –0.3 V to +7.0 V

S

Package Characteristics

Package u

JA

10-Pin TO-100 130°C/W 30°C/W 5 Grams

Output Short Circuit Duration

(V

, V

, V

PR

OUT

Operating Temperature . . . . . . . . . . . . . . . . .–55°C to +125°C

Storage Temperature . . . . . . . . . . . . . . . . . . .–65°C to +150°C

*Stresses above those listed under “Absolute Maximum Ratings” may cause

permanent damage to the device. This is a stress rating only; the functional

operation of the device at these or any other conditions above those indicated in the

Terminals to Common) . . . . . . .Indefinite

REF

ORDERING GUIDE

Model Temperature Range

ADXL05JH 0°C to +70°C

ADXL05AH –40°C to +85°C

operational sections of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect device reliability.

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection.

Although the ADXL05 features proprietary ESD protection circuitry, permanent damage may

occur on devices subjected to high energy electrostatic discharges. Therefore, proper ESD

precautions are recommended to avoid performance degradation or loss of functionality.

Drops onto hard surfaces can cause shocks of greater than 1000 g

and exceed the absolute maximum rating of the device. Care

should be exercised in handling to avoid damage.

u

JC

Device Weight

PIN DESCRIPTION

+5 V The power supply input pin.

C2 Connection for an external bypass capacitor (nominally 0.022 µF)

C1 Connections for the demodulator capacitor, nominally 0.022 µF.

COM The power supply common (or “ground”) connection.

V

ST The digital self-test input. It is both CMOS and TTL compatible.

V

V

V

used to prevent oscillator switching noise from interfering with

other ADXL05 circuitry. Please see the section on component

selection.

See the section on component selection for application information.

Output of the internal 3.4 V voltage reference.

REF

The ADXL05 preamplifier output providing an output voltage of

PR

200 mV per g of acceleration.

Output of the buffer amplifier.

OUT

The inverting input of the uncommitted buffer amplifier.

IN–

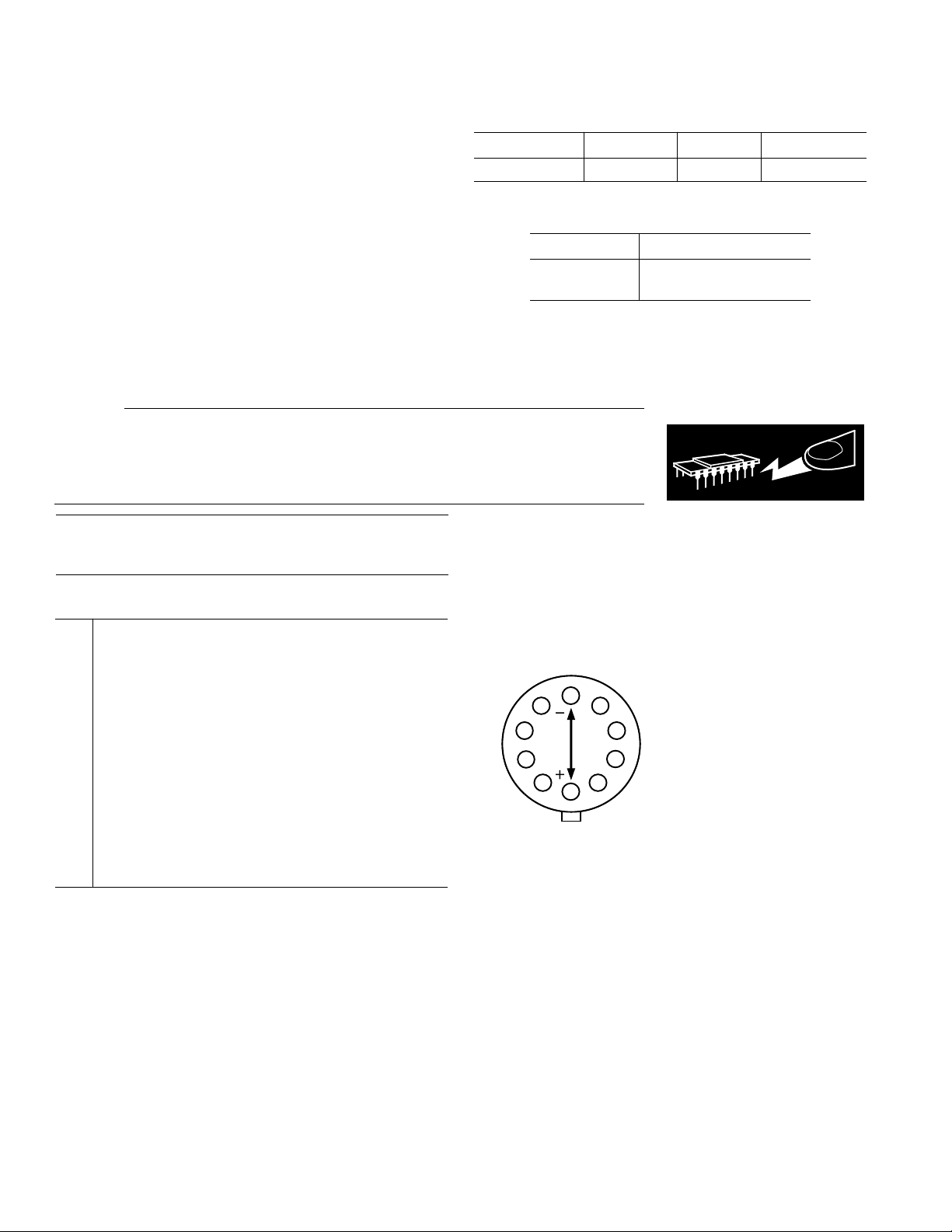

CONNECTION DIAGRAM

10-Header (TO-100)

TOP VIEW

OUT

COM

6

6

7

7

AXIS OF

AXIS OF

8

8

9

9

5

5

SENSITIVITY

SENSITIVITY

10

10

V

IN–

C2

4

4

C1

3

3

2

2

1

1

+5V

NOTES:

C1

AXIS OF SENSITIVITY IS ALONG A LINE

BETWEEN PIN 5 AND THE TAB.

THE CASE OF THE METAL CAN

PACKAGE IS CONNECTED TO PIN 5

(COMMON).

ARROW INDICATES DIRECTION OF

POSITIVE ACCELERATION ALONG AXIS

OF SENSITIVITY.

V

REF

ST

V

PR

V

–4–

REV. B

ADXL05

+1g

INDICATED POLARITY IS THAT

OCCURRING AT V

PR

.

TAB

PIN 5

+

–

GLOSSARY OF TERMS

Acceleration: Change in velocity per unit time.

Acceleration Vector: Vector describing the net acceleration

acting upon the ADXL05 (A

XYZ

).

g: A unit of acceleration equal to the average force of gravity

occurring at the earth’s surface. A g is approximately equal to

32.17 feet/s

2

, or 9.807 meters/s2.

Nonlinearity: The maximum deviation of the ADXL05 output

voltage from a best fit straight line fitted to a plot of acceleration

vs. output voltage, calculated as a % of the full-scale output

voltage (@ 5 g).

Resonant Frequency: The natural frequency of vibration of

the ADXL05 sensor’s central plate (or “beam”). At its resonant

frequency of 12 kHz, the ADXL05’s moving center plate has a

peak in its frequency response with a Q of 3 or 4.

Sensitivity: The output voltage change per g unit of accelera-

tion applied, specified at the V

pin in mV/g.

PR

Sensitive Axis (X): The most sensitive axis of the accelerometer sensor. Defined by a line drawn between the package tab

and Pin 5 in the plane of the pin circle. See Figures 2a and 2b.

Sensor Alignment Error: Misalignment between the

ADXL05’s on-chip sensor and the package axis, defined by

Pin 5 and the package tab.

Total Alignment Error: Net misalignment of the ADXL05’s

on-chip sensor and the measurement axis of the application.

This error includes errors due to sensor die alignment to the

package, and any misalignment due to installation of the sensor

package in a circuit board or module.

Transverse Acceleration: Any acceleration applied 90° to the

axis of sensitivity.

Transverse Sensitivity Error: The percent of a transverse acceleration that appears at the V

output. For example, if the

PR

transverse sensitivity is 1%, then a +10 g transverse acceleration

will cause a 0.1 g signal to appear at V

(1% of 10 g). Trans-

PR

verse sensitivity can result from a sensitivity of the sensor to

transverse forces or from misalignment of the internal sensor to

its package.

Transverse Y Axis: The axis perpendicular (90°) to the pack-

age axis of sensitivity in the plane of the package pin circle. See

Figure 2.

Transverse Z Axis: The axis perpendicular (90°) to both the

package axis of sensitivity and the plane of the package pin

circle. See Figure 2.

Polarity of the Acceleration Output

The polarity of the ADXL05 output is shown in the Figure 1.

When oriented to the earth’s gravity (and held in place), the

ADXL05 will experience an acceleration of +1 g. This corresponds to a change of approximately +200 mV at the V

PR

output pin. Note that the polarity will be reversed to a negative

going signal at the buffer amplifier output V

, due to its

OUT

inverting configuration.

Figure 1. Output Polarity at V

PR

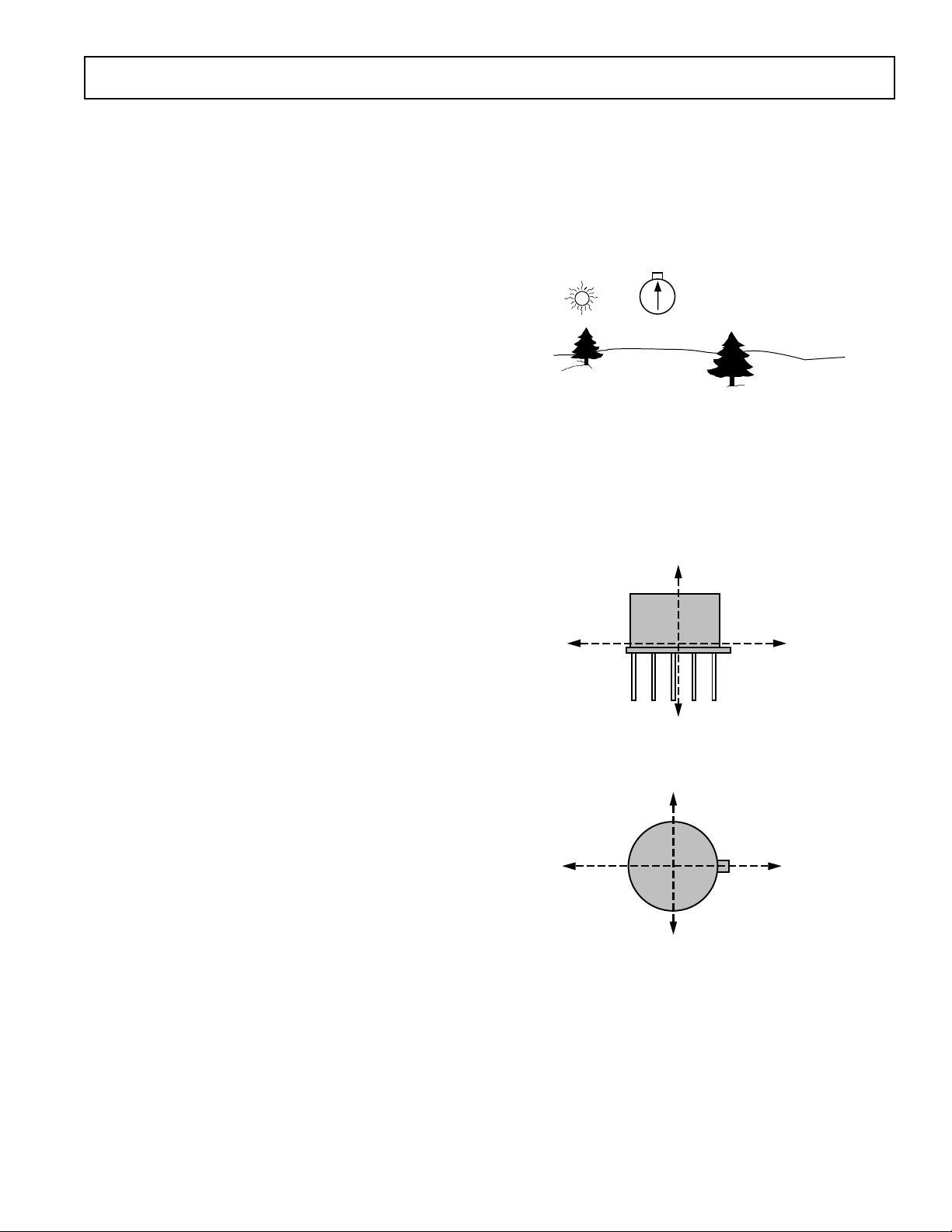

Acceleration Vectors in Three Dimensions

The ADXL05 is a sensor designed to measure accelerations that

result from an applied force. The ADXL05 responds to the

component of acceleration on its sensitive X axis. Figures 2a

and 2b show the relationship between the sensitive “X” axis and

the transverse “Z” and “Y” axes as they relate to the TO-100

Z

SIDE VIEW

X

PIN 5

TRANSVERSE Z AXIS

TAB

Z

X

SENSITIVE (X) AXIS

Figure 2a. Sensitive X and Transverse Z Axis

Y

TOP VIEW

X

PIN 5

TRANSVERSE Y AXIS

SENSITIVE (X) AXIS

TAB

X

REV. B

Y

Figure 2b. Sensitive X and Transverse Y Axis

–5–

ADXL05

10

90

100

0%

0.5ms

package. Figure 2c describes a three dimensional acceleration

vector (A

component of interest. To determine A

of acceleration in the XY plane (A

) which might act on the sensor, where AX is the

XYZ

, first, the component

X

) is found using the cosine

XY

law:

A

= A

XY

A

Therefore: Nominal V

–Z AXIS

Y AXIS

(cosθXY) then

XYZ

= AXY (cosθX)

X

= 200 mV/g (A

PR

θxy

θx

Axy

) (cosθXY) cosθ

XYZ

Axyz

Ax

X

X AXIS

Figure 2c. A Vector Analysis of an Acceleration Acting

Upon the ADXL05 in Three Dimensions

Note that an ideal sensor will react to forces along or at angles

to its sensitive axis but will reject signals from its various transverse axes, i.e., those exactly 90° from the sensitive “X” axis.

But even an ideal sensor will produce output signals if the transverse signals are not exactly 90° to the sensitive axis. An acceleration that is acting on the sensor from a direction different

from the sensitive axis will show up at the ADXL05 output at a

reduced amplitude.

Table I shows the percentage signals resulting from various θ

X

angles. Note that small errors in alignment have a negligible

effect on the output signal. A 1° error will only cause a 0.02%

error in the signal. Note, however, that a signal coming 1° off of

the transverse axis (i.e., 89° off the sensitive axis) will still contribute 1.7% of its signal to the output. Thus large transverse

signals could cause output signals as large as the signals of

interest. Table I may also be used to approximate the effect of

the ADXL05’s internal errors due to misalignment of the die to

the package. For example: a 1 degree sensor alignment error will

allow 1.7% of a transverse signal to appear at the output.

Table I. Ideal Output Signals for Off Axis Applied

Accelerations Disregarding Device Alignment and

Transverse Sensitivity Errors

% of Signal Appearing Output in gs for a 5 g

θ

X

at Output Applied Acceleration

0 100% 5.000 (On Axis)

1° 99.98% 4.999

2° 99.94% 4.997

3° 99.86% 4.993

5° 99.62% 4.981

10° 98.48% 4.924

30° 86.60% 4.330

45° 70.71% 3.536

60° 50.00% 2.500

80° 17.36% 0.868

85° 8.72% 0.436

87° 5.25% 0.263

88° 3.49% 0.175

89° 1.7% 0.085

90° 0% 0.000 (Transverse Axis)

Mounting Fixture Resonances

A common source of error in acceleration sensing is resonance

of the mounting fixture. For example, the circuit board that the

ADXL05 mounts to may have resonant frequencies in the same

range as the signals of interest. This could cause the signals

measured to be larger than they really are. A common solution

to this problem is to dampen these resonances by mounting the

ADXL05 near a mounting post or by adding extra screws to

hold the board more securely in place.

When testing the accelerometer in your end application, it is

recommended that you test the application at a variety of frequencies in order to ensure that no major resonance problems

exist (refer to Analog Devices Application Note AN-379).

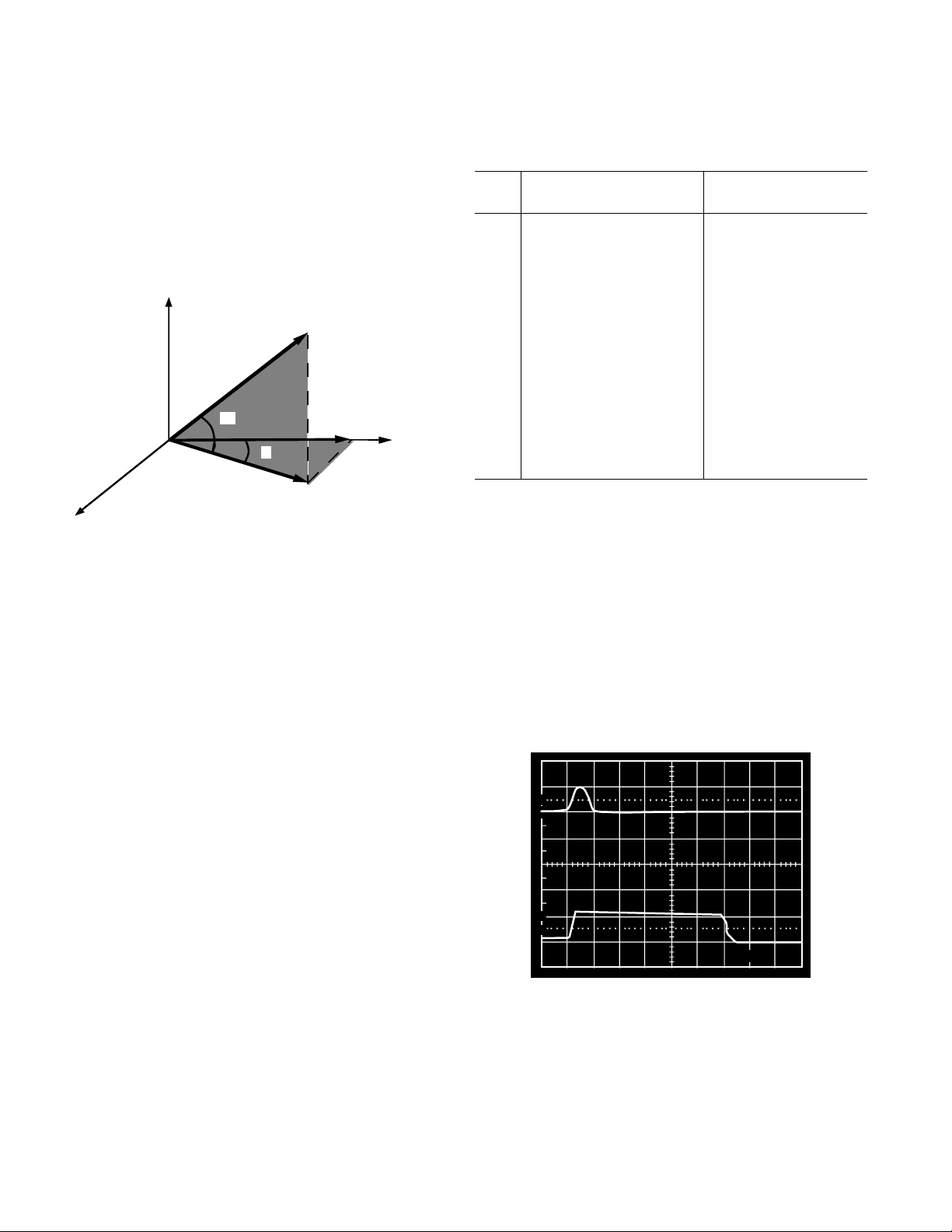

Figure 3. 500 g Shock Overload Recovery. Top Trace, PCB

Reference Accelerometer Output: 500 g/Vertical Division.

Bottom Trace, ADXL05 Output at V

–6–

PR

REV. B

Loading...

Loading...