4:1 HDMI/DVI Switch with Equalization,

DDC/CEC Buffers and EDID Replication

FEATURES

4 inputs, 1 output HDMI/DVI links

±8 kV ESD protection on input pins

HDMI 1.4a receive and transmit compliant

Supports 250 Mbps to 3 Gbps data rates and beyond

Supports 25 MHz to 300 MHz pixel clocks and beyond

Fully buffered unidirectional inputs/outputs

Switchable 50 Ω on-chip input terminations with manual

or automatic control on channel switch

Equalized inputs with low added jitter compensate for

more than 15 meters of HDMI cable at 3 Gbps

Loss of signal (LOS) detect circuit on TMDS clock

Output disable feature for reduced power dissipation

Bidirectional DDC buffers (SDA and SCL)

EDID replication reduces component count, while enabling

simultaneous access to all HDMI sources

5 V combiner provides power to EDID replicator and CEC

buffer when local system power is off

Bidirectional buffered CEC line with integrated pull-up

resistors (26 kΩ)

Hot plug detect pulse low on channel switch with

programmable pulse width or direct manual control

Standards compatible: HDMI, DVI, HDCP, I

80-lead, 14 mm × 14 mm LQFP RoHS-compliant package

APPLICATIONS

Advanced television (HDTV) sets

Projectors

A/V receivers

Set-top boxes

GENERAL DESCRIPTION

The ADV3002 is a complete HDMI™/DVI link switch featuring

equalized transition minimized differential signaling (TMDS)

inputs, ideal for systems with long cable runs. The ADV3002

includes bidirectional buffering for the DDC bus and CEC line,

with integrated pull-up resistors for the CEC line. Additionally,

the ADV3002 includes an EDID replication function that enables

one EDID EEPROM to be shared for all four HDMI ports.

The ADV3002 is provided in a space-saving, 80-lead LQFP

surface-mount, Pb-free plastic package and is specified to

operate over the 0°C to 85°C temperature range.

2

C

ADV3002

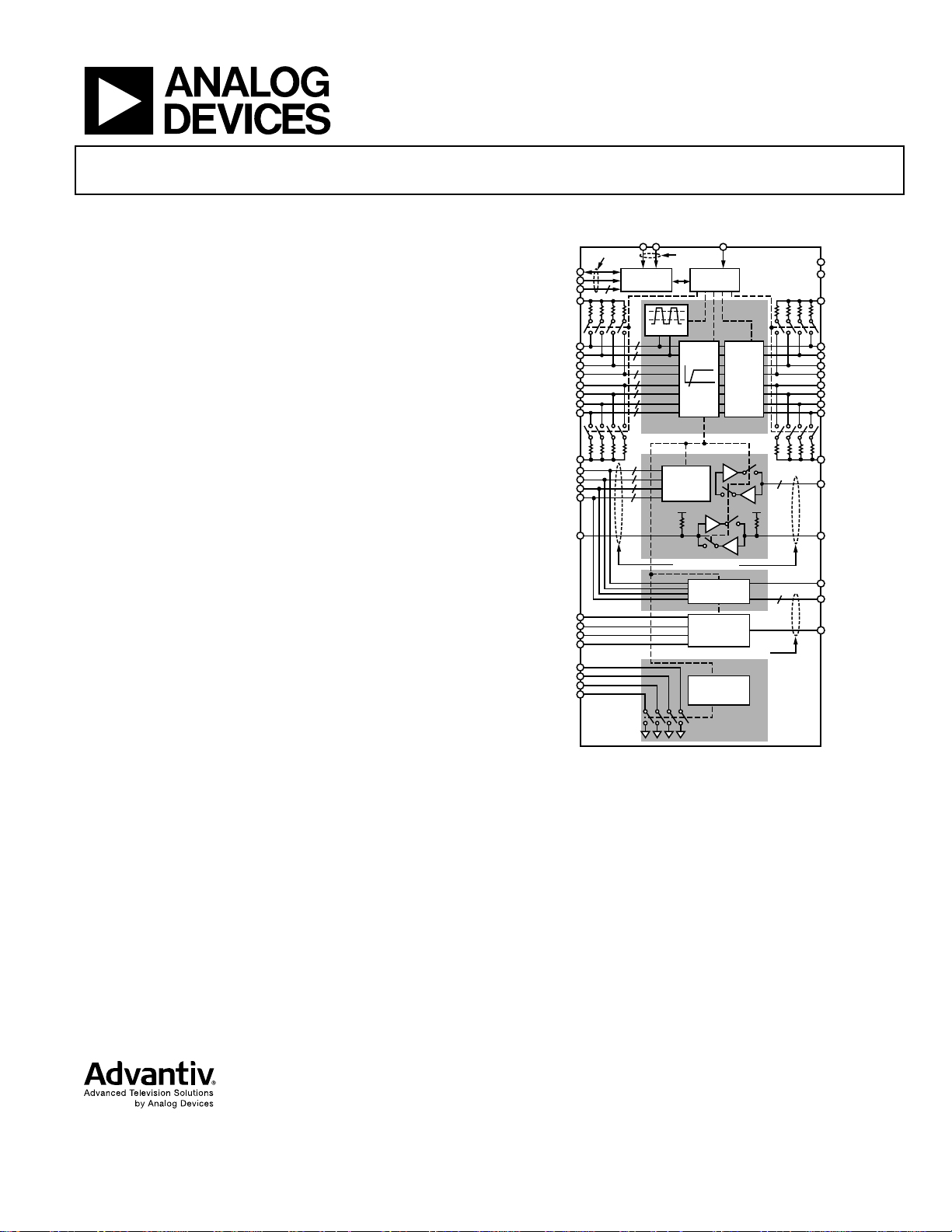

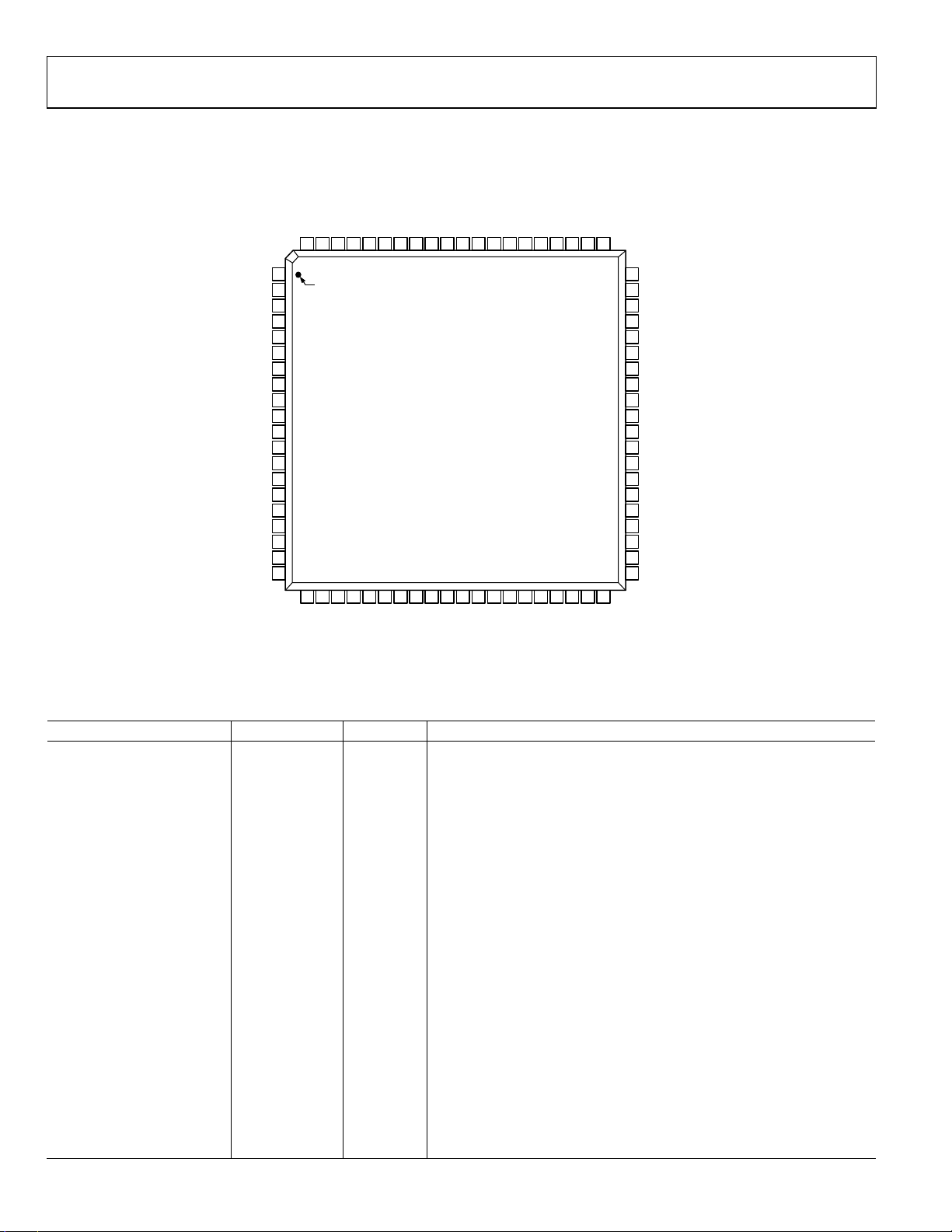

FUNCTIONAL BLOCK DIAGRAM

SEL[1:0] TX_EN

SERIAL

I2C_SDA

I2C_SCL

I2C_ADDR[ 1:0]

AVCC

IN_x_CLK+

IN_x_CLK–

IN_x_DATA2+

IN_x_DATA2–

IN_x_DATA1+

IN_x_DATA1–

IN_x_DATA0+

IN_x_DATA0–

AVCC

DDC_xxx_A

DDC_xxx_B

DDC_xxx_C

DDC_xxx_D

CEC_IN

P5V_A

P5V_B

P5V_C

P5V_D

HPD_A

HPD_B

HPD_C

HPD_D

+

–

+

–

+

–

+

–

2

CONFIG

INTERFACE

4

4

4

4

4

4

4

2

2

2

2

DDC/CEC

LOS

TMDS

EDID

PRODUCT HIGHLIGHTS

1. Input cable equalizer enables use of long cables at the input.

For a 24 AWG cable, the ADV3002 compensates for more

than 15 meters at data rates of up to 3 Gbps.

2. Auxiliary multiplexer isolates and buffers the DDC bus and

the CEC line, increasing total system capacitance limit.

3. EDID replication eliminates the need for multiple EDID

EEPROMs. EDID can be loaded from a single external

EEPROM or from a system microcontroller.

4. 5 V power combiner powers the EDID replicator and CEC

buffer when local system power is off.

5. Integrated hot plug detect pulse low on channel switch

with programmable pulse width or direct manual control.

RESETB

PARALLEL

CONTRO L

LOGIC

SWITCH

CORE

EQ

SWITCH

CORE

3.3V 3.3V

BIDIRECTI ONAL

REPLICATOR

CONTRO L

5V

COMBI NER

EDID EEPROM INTERFACE

HPD

CONTROL

HOT PLUG DETECT

Figure 1.

ADV3002

2

2

AVCC

AVEE

AVCC

+

OUT_CLK+

–

OUT_CLK–

+

OUT_DATA2+

–

OUT_DATA2–

+

OUT_DATA1+

–

OUT_DATA1–

+

OUT_DATA0+

–

OUT_DATA0–

AVCC

DDC_SCL_COM ,

DDC_SDA_COM

CEC_OUT

EDID_ENABLE

EDID_SCL,

EDID_SDA

AMUXVCC

07905-001

Rev. A

Information furnished by Analog Devices is believed to be accurate and reliable. However, no

responsibility is assumed by Anal og Devices for its use, nor for any infringements of p atents or other

rights of third parties that may result from its use. Specifications subject to chan ge without notice. No

license is granted by implication or otherwise under any patent or patent rights of Analog Devices.

Trademarks and registered trademarks are the property of their respective owners.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700 www.analog.com

Fax: 781.461.3113 ©2008–2011 Analog Devices, Inc. All rights reserved.

ADV3002

TABLE OF CONTENTS

Features.............................................................................................. 1

Applications....................................................................................... 1

General Description ......................................................................... 1

Functional Block Diagram .............................................................. 1

Product Highlights ........................................................................... 1

Revision History ............................................................................... 2

Specifications..................................................................................... 3

TMDS Performance Specifications............................................ 3

Auxiliary Channel Performance Specifications........................ 3

Power Supply and Control Logic Specifications ...................... 4

Absolute Maximum Ratings............................................................ 5

Thermal Resistance ...................................................................... 5

ESD Caution.................................................................................. 5

Pin Configuration and Function Descriptions............................. 6

Typical Performance Characteristics ............................................. 8

Theory of Operation ...................................................................... 12

TMDS Input Channels............................................................... 12

TMDS Output Channels ...........................................................12

DDC Buffers................................................................................ 13

EDID Replication....................................................................... 13

5 V Combiner ............................................................................. 15

CEC Buffer .................................................................................. 16

Hot Plug Detect Control ........................................................... 16

Loss of Signal Detect.................................................................. 16

Serial Control Interface ................................................................. 17

Reset ............................................................................................. 17

Write Procedure.......................................................................... 17

Read Procedure........................................................................... 18

Register Map ................................................................................... 19

Applications Information.............................................................. 21

HDMI Multiplexer for Advanced TV ..................................... 21

Cable Lengths and Equalization............................................... 24

PCB Layout Guidelines.............................................................. 24

Outline Dimensions....................................................................... 27

Ordering Guide .......................................................................... 27

REVISION HISTORY

8/11—Rev. 0 to Rev. A

Changed Data Rate = 2.25 Gbps to

Data Rate = 3 Gbps........................................................ Throughout

Changes to Features Section and Product Highlights Section ... 1

Changes to Table 1............................................................................ 3

Changes to Figure 4 Caption and Figure 6 Caption..................... 8

Added Figure 5 and Figure 7; Renumbered Sequentially ........... 8

Moved Figure 8 and Figure 10 ........................................................ 9

Changes to Figure 8 Caption and Figure 10 Caption .................. 9

Added Figure 9 and Figure 11......................................................... 9

Changes to Figure 12 and Figure 15............................................. 10

Changes to TMDS Input Channels Section and TMDS Output

Channels Section ............................................................................ 12

Changes to Figure 31...................................................................... 16

Changes to Cable Lengths and Equalization Section ................ 24

12/08—Revision 0: Initial Version

Rev. A | Page 2 of 28

ADV3002

SPECIFICATIONS

TA = 27°C, AVCC = 3.3 V, AMUXVCC = 5 V, AVEE = 0 V, data rate = 3 Gbps, differential input swing = 1000 mV, TMDS outputs

terminated with external 50 Ω resistors to 3.3 V, unless otherwise noted.

TMDS PERFORMANCE SPECIFICATIONS

Table 1.

Parameter Test Conditions/Comments Min Typ Max Unit

DYNAMIC PERFORMANCE

Maximum Data Rate (DR) per Channel NRZ 3 Gbps

Maximum Clock Rate 300 MHz

Bit Error Rate (BER) PRBS 223 − 1 10−9

Added Data Jitter DR ≤ 3 Gbps, PRBS 27 − 1 40 ps p-p

Added Clock Jitter 1 ps rms

Differential Intrapair Skew At output 1 ps

Differential Interpair Skew At output 35 ps

EQUALIZATION PERFORMANCE

High Frequency Gain Boost frequency = 1.5 GHz 16 dB

INPUT CHARACTERISTICS

Input Voltage Swing Differential 150 1200 mV

Input Common-Mode Voltage (V

OUTPUT CHARACTERISTICS

High Voltage Level Single-ended high speed channel AVCC − 200 AVCC + 10 mV

Low Voltage Level Single-ended high speed channel AVCC − 600 AVCC − 400 mV

Rise/Fall time (20% to 80%) DR = 3 Gbps 75 190 ps

TERMINATION

Input Termination Resistance Single-ended 50 Ω

Output Termination Resistance Single-ended 50 Ω

LOSS OF SIGNAL (LOS) DETECT

Frequency Cutoff LOS_FC (see Figure 31) 5 MHz

Amplitude Threshold

) AVCC − 800 AVCC mV

ICM

Clock rate = 300 MHz, LOS_THR = 00

35 mV

(see Figure 31)

AUXILIARY CHANNEL PERFORMANCE SPECIFICATIONS

Table 2.

Parameter Test Conditions/Comments Min Typ Max Unit

DDC CHANNELS

Input Capacitance, C

Input Low Voltage, VIL 0.5 V

Input High Voltage, VIH 0.7 × AMUXVCC V

Output Low Voltage, VOL IOL = 5 mA 0.25 0.4 V

Rise Time 10% to 90%, C

Fall Time 90% to 10%, C

Leakage VIN = 5.0 V 10 μA

DC bias = 2.5 V, ac voltage = 3.5 V p-p, f = 100 kHz 5 15 pF

AUX

= 50 pF, R

LOAD

= 50 pF, R

LOAD

= 2 kΩ 1.45 μs

PULL-UP

= 2 kΩ 20 250 ns

PULL-UP

Rev. A | Page 3 of 28

ADV3002

Parameter Test Conditions/Comments Min Typ Max Unit

CEC CHANNEL

Input Capacitance, C

Input Low Voltage, VIL 0.8 V

Input High Voltage, VIH 2.0 V

Output Low Voltage, VOL IOL = 3 mA 0.1 0.6 V

Output High Voltage, VOH 2.5 V

Rise Time

Fall Time

Pull-Up Resistance 26 kΩ

Leakage Off-leakage test conditions1 1.8 μA

HOT PLUG DETECT

Output Low Voltage, VOL RPU = 800 Ω 0.25 0.4 V

1

Off leakage test conditions are described in the HDMI Compliance Test Specification 1.3c Section 8, Test ID 8-14. To measure CEC leakage, connect the CEC line to

3.63 V via 26 kΩ ± 5 % resistor with an ammeter in series and with the power mains disabled.

POWER SUPPLY AND CONTROL LOGIC SPECIFICATIONS

Table 3.

Parameter Test Conditions/Comments Min Typ Max Unit

POWER SUPPLY

AVCC Operating range (3.3 V ± 10%) 3.0 3.3 3.6 V

P5V_x 4.7 5 5.5 V

AMUXVCC Output voltage, total load1 = 50 mA 4.0 5 5.5 V

QUIESCENT CURRENT

AVCC Outputs disabled 40 60 mA

Outputs enabled 170 150 mA

P5V_x Main power on 0.5 10 mA

Main power off 20 30 mA

AMUXVCC Main power on 20 30 mA

Main power off 0.5 10 mA

POWER DISSIPATION

Outputs disabled 232 381 mW

Outputs enabled 661 885 mW

I2C® AND LOGIC INPUTS2

Input High Voltage, VIH 2.4 V

Input Low Voltage, VIL 1.0 V

I2C AND LOGIC OUTPUTS2

Output High Voltage, VOH I

Output Low Voltage, VOL I

1

The total load current includes current drawn by the ADV3002 as well as external devices powered from the AMUXVCC supply.

2

The ADV3002 I2C control and logic input pins are listed as Control in the Type column in . I2C pins are 5 V tolerant and based on the 3.3 V I2C bus specification. Table 6

DC bias = 1.65 V, ac voltage = 2.5 V p-p, f = 100 kHz 5 15 pF

AUX

10% to 90%, C

= 3 kΩ

R

PULL-UP

90% to 10%, C

R

= 3 kΩ

PULL-UP

OH

OL

= 1500 pF, R

LOAD

= 1500 pF, R

LOAD

= 27 kΩ; or C

PULL-UP

= 27 kΩ; or C

PULL-UP

= 7200 pF,

LOAD

= 7200 pF,

LOAD

= −2 mA AVCC V

= +2 mA 0.4 V

75 250 μs

0.2 50 μs

Rev. A | Page 4 of 28

ADV3002

ABSOLUTE MAXIMUM RATINGS

Table 4.

Parameter Rating

AVCC to AVEE 3.7 V

P5V_x 5.8 V

AMUXVCC AVCC − 0.3 V < AMUXVCC < 5.8 V

Internal Power Dissipation 1.2 W

TMDS Single-Ended Input

Voltage

TMDS Differential Input

Voltage

Voltage at TMDS Output V

DDC Input Voltage AVEE − 0.3 V < VIN < AMUXVCC + 0.3 V

CEC Input Voltage AVEE − 0.3 V < VIN < 4.0 V

I2C Logic Input Voltage

(EDID_SCL, EDID_SDA,

I2C_SCL, I2C_SDA)

Parallel Input Voltage

(I2C_ADDR[1:0],

RESETB)

Parallel Input Voltage

(SEL[1:0], TX_EN)

Storage Temperature Range −65°C to +125°C

Operating Temperature

Range

Junction Temperature 150°C

ESD Protection (HBM) on

HDMI Input Pins

ESD Protection (HBM) on

All Other Pins

AVC C − 1.4 V < V

2.0 V

< 3.7 V

OUT

AVEE − 0.3 V < V

AVEE − 0.3 V < V

AVEE − 0.3V < V

0°C to +85°C

±8 kV

±2.5 kV

< AVCC + 0.3 V

IN

< 4.0 V

IN

< AMUXVCC + 0.3 V

IN

< AVCC + 0.3 V

IN

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only; functional operation of the device at these or any

other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

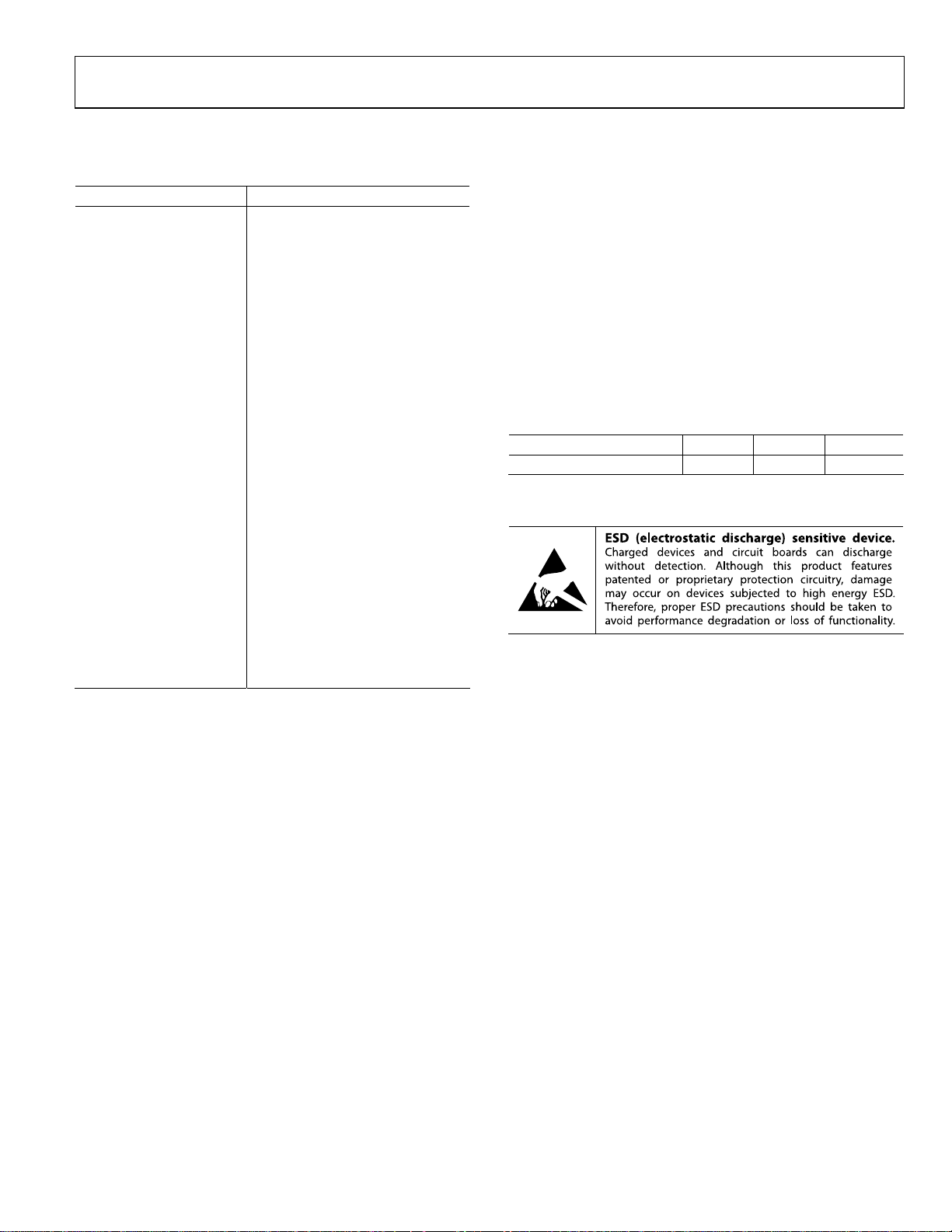

THERMAL RESISTANCE

θJA is specified for the worst-case conditions; a device soldered

in a 4-layer JEDEC circuit board for surface-mount packages.

θ

is specified for the exposed pad soldered to the circuit board

JC

with no airflow.

Table 5. Thermal Resistance

Package Type θJA θ

80-Lead LQFP (ST-80-2) 51.3 15.3 °C/W

Unit

JC

ESD CAUTION

Rev. A | Page 5 of 28

ADV3002

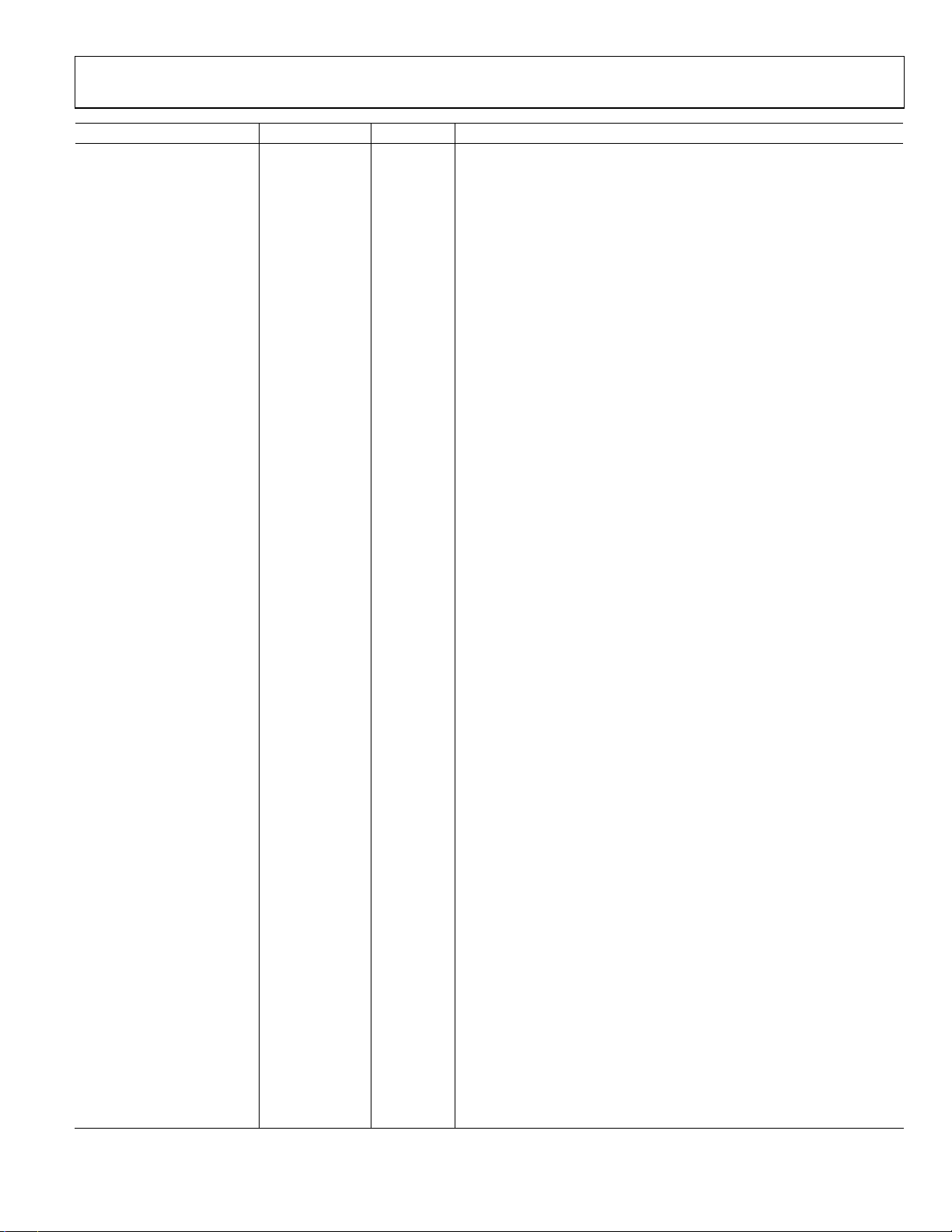

PIN CONFIGURATION AND FUNCTION DESCRIPTIONS

P5V_A79P5V_B78P5V_C77P5V_D76DDC_SDA_A75DDC_SCL_A74DDC_SDA_B73DDC_SCL_B72DDC_SDA_C71DDC_SCL_C70DDC_SDA_D69DDC_SCL_D68DDC_SDA_COM67DDC_SCL_COM66CEC_IN65CEC_OUT64AMUXVCC63EDID_ENABLE62EDID_SDA61EDID_SCL

80

39

40

I2C_ADDR1

I2C_SDA

60

IN_C_DATA2+

59

IN_C_DATA2–

58

HPD_C

57

IN_C_DATA1+

56

IN_C_DATA1–

55

HPD_D

54

IN_C_DATA0+

53

IN_C_DATA0–

52

AVC C

51

IN_C_CLK+

50

IN_C_CLK–

49

I2C_ADDR0

48

IN_D_DATA2+

47

IN_D_DATA2–

46

AVE E

45

IN_D_DATA1+

44

IN_D_DATA1–

43

AVC C

42

IN_D_DATA0+

41

IN_D_DATA0–

IN_B_CLK–

IN_B_CLK+

HPD_B

IN_B_DATA0–

IN_B_DATA0+

HPD_A

IN_B_DATA1–

IN_B_DATA1+

AVC C

IN_B_DATA2–

IN_B_DATA2+

SEL0

IN_A_CLK–

IN_A_CLK+

SEL1

IN_A_DATA0–

IN_A_DATA0+

AVC C

IN_A_DATA1–

IN_A_DATA1+

1

PIN 1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

24

25

23

AVE E

TX_EN

IN_A_DATA2+

OUT_DATA2+

IN_A_DATA2–

26

27

OUT_DATA2–

ADV3002

(Not to Scale)

28

29

I2C_SCL

OUT_DATA1+

TOP VIEW

30

31

AVE E

OUT_DATA1–

33

34

35

36

32

AVC C

OUT_CLK+

OUT_DATA0–

OUT_DATA0+

38

37

RESETB

OUT_CLK–

IN_D_CLK–

IN_D_CLK+

Figure 2. Pin Configuration

Table 6. Pin Function Descriptions

Pin No. Mnemonic Type Description

1 IN_B_CLK− TMDS High Speed TMDS Input B Clock Complement.

2 IN_B_CLK+ TMDS High Speed TMDS Input B Clock.

3 HPD_B HPD Hot Plug Detect Output B.

4 IN_B_DATA0− TMDS High Speed TMDS Input B Data Complement.

5 IN_B_DATA0+ TMDS High Speed TMDS Input B Data.

6 HPD_A HPD Hot Plug Detect Output A.

7 IN_B_DATA1− TMDS High Speed TMDS Input B Data Complement.

8 IN_B_DATA1+ TMDS High Speed TMDS Input B Data.

9, 18, 33, 43, 52 AVCC Power Positive Analog Supply 3.3 V.

10 IN_B_DATA2− TMDS High Speed TMDS Input B Data Complement.

11 IN_B_DATA2+ TMDS High Speed TMDS Input B Data.

12 SEL0 Control Channel Select Parallel Control LSB.

13 IN_A_CLK− TMDS High Speed TMDS Input A Clock Complement.

14 IN_A_CLK+ TMDS High Speed TMDS Input A Clock.

15 SEL1 Control Channel Select Parallel Control MSB.

16 IN_A_DATA0− TMDS High Speed TMDS Input A Complement.

17 IN_A_DATA0+ TMDS High Speed TMDS Input A Data.

19 IN_A_DATA1− TMDS High Speed TMDS Input A Data Complement.

20 IN_A_DATA1+ TMDS High Speed TMDS Input A Data.

21, 30, 46 AVEE Power Negative Analog Supply 0.0 V.

22 IN_A_DATA2− TMDS High Speed TMDS Input A Data Complement.

23 IN_A_DATA2+ TMDS High Speed TMDS Input A Data.

Rev. A | Page 6 of 28

07905-002

ADV3002

Pin No. Mnemonic Type Description

24 TX_EN Control TMDS Output Enable Parallel Control.

25 OUT_DATA2+ TMDS High Speed TMDS Output.

26 OUT_DATA2− TMDS High Speed TMDS Output Complement.

27 I2C_SCL Control Serial Control Clock Input.

28 OUT_DATA1+ TMDS High Speed TMDS Output.

29 OUT_DATA1− TMDS High Speed TMDS Output Complement.

31 OUT_DATA0+ TMDS High Speed TMDS Output.

32 OUT_DATA0− TMDS High Speed TMDS Output Complement.

34 OUT_CLK+ TMDS High Speed TMDS Output Clock.

35 OUT_CLK− TMDS High Speed TMDS Output Clock Complement.

36 RESETB Control Configuration Registers Reset. Active low.

37 IN_D_CLK− TMDS High Speed TMDS Input D Clock Complement.

38 IN_D_CLK+ TMDS High Speed TMDS Input D Clock.

39 I2C_ADDR1 Control Serial Control External Address MSB.

40 I2C_SDA Control Serial Control Data Input/Output.

41 IN_D_DATA0− TMDS High Speed TMDS Input D Data Complement.

42 IN_D_DATA0+ TMDS High Speed TMDS Input D Data.

44 IN_D_DATA1− TMDS High Speed TMDS Input D Data Complement.

45 IN_D_DATA1+ TMDS High Speed TMDS Input D Data.

47 IN_D_DATA2− TMDS High Speed TMDS Input D Data Complement.

48 IN_D_DATA2+ TMDS High Speed TMDS Input D Data.

49 I2C_ADDR0 Control Serial Control External Address LSB.

50 IN_C_CLK− TMDS High Speed TMDS Input C Clock Complement.

51 IN_C_CLK+ TMDS High Speed TMDS Input C Clock.

53 IN_C_DATA0− TMDS High Speed TMDS Input C Data Complement.

54 IN_C_DATA0+ TMDS High Speed TMDS Input C Data.

55 HPD_D HPD Hot Plug Detect Output D.

56 IN_C_DATA1− TMDS High Speed TMDS Input C Data Complement.

57 IN_C_DATA1+ TMDS High Speed TMDS Input C Data.

58 HPD_C HPD Hot Plug Detect Output C.

59 IN_C_DATA2− TMDS High Speed TMDS Input C Data Complement.

60 IN_C_DATA2+ TMDS High Speed TMDS Input C Data.

61 EDID_SCL Control External EDID EEPROM Serial Interface Clock.

62 EDID_SDA Control External EDID EEPROM Serial Interface Data.

63 EDID_ENABLE Control EDID Replication Enable.

64 AMUXVCC Power Positive Power Supply 5.0 V.

65 CEC_OUT CEC Consumer Electronics Control Output.

66 CEC_IN CEC Consumer Electronics Control Input.

67 DDC_SCL_COM DDC Display Data Channel Serial Clock Common Input/Output.

68 DDC_SDA_COM DDC Display Data Channel Serial Data Common Input/Output.

69 DDC_SCL_D DDC Display Data Channel Serial Clock Input/Output D.

70 DDC_SDA_D DDC Display Data Channel Serial Data Input/Output D.

71 DDC_SCL_C DDC Display Data Channel Serial Clock Input/Output C.

72 DDC_SDA_C DDC Display Data Channel Serial Data Input/Output C.

73 DDC_SCL_B DDC Display Data Channel Serial Clock Input/Output B.

74 DDC_SDA_B DDC Display Data Channel Serial Data Input/Output B.

75 DDC_SCL_A DDC Display Data Channel Serial Clock Input/Output B.

76 DDC_SDA_A DDC Display Data Channel Serial Data Input/Output A.

77 P5V_D Power 5 V HDMI Supply from Source D.

78 P5V_C Power 5 V HDMI Supply from Source C.

79 P5V_B Power 5 V HDMI Supply from Source B.

80 P5V_A Power 5 V HDMI Supply from Source A.

Rev. A | Page 7 of 28

ADV3002

V

V

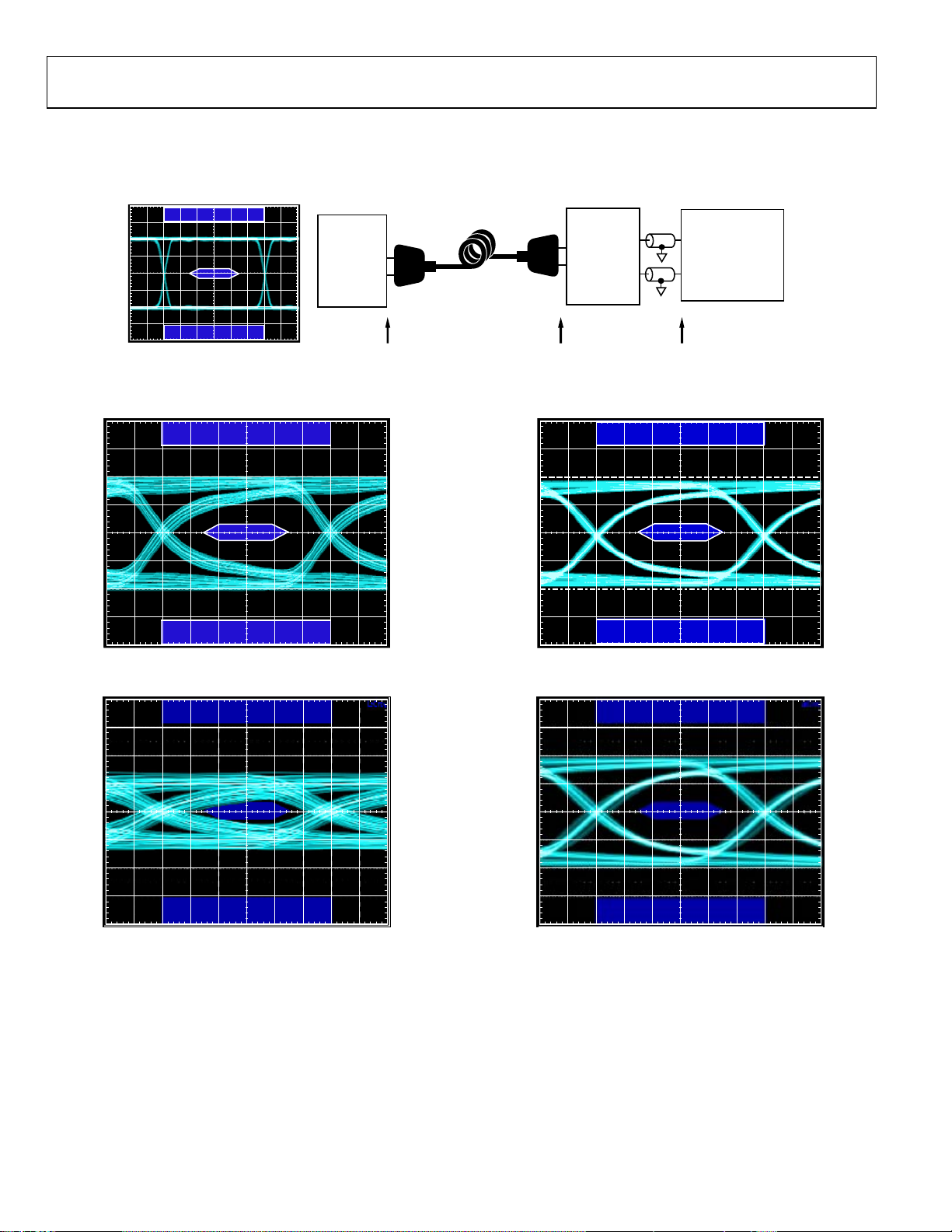

TYPICAL PERFORMANCE CHARACTERISTICS

TA = 27°C, AVCC = 3.3 V, AMUXVCC = 5.0 V, AVEE = 0 V, differential input swing = 1000 mV, pattern = PRBS 27 − 1, data rate = 3 Gbps,

TMDS outputs terminated with external 50 resistors to 3.3 V, unless otherwise noted.

HDMI CABLE

DIGITAL

PATTERN

GENERATOR

ADV3002

EVALUATIO N

BOARD

SMA COAX CABLE

SERIAL DATA

ANALYZER

REFERENCE EYE DI AGRAM AT TP1

Figure 3. Test Circuit for Eye Diagrams

250mV/DI

0.167UI/DI V AT 2.25Gb ps

Figure 4. Eye Diagram at TP2 for 2 Meter Cable, Data Rate = 2.25 Gbps

TP1 TP2 TP3

250mV/DI

07905-022

0.167UI/DI V AT 2.25Gbps

Figure 6. Eye Diagram at TP3 for 2 Meter Cable, Data Rate = 2.25 Gbps

07905-021

07905-024

250mV/DIV

0.167UI/DIV AT 3.0Gbps

Figure 5. Eye Diagram at TP2 for 2 Meter Cable, Data Rate = 3 Gbps

07905-205

250mV/DIV

0.167UI/DIV AT 3.0Gbps

Figure 7. Eye Diagram at TP3 for 2 Meter Cable, Data Rate = 3 Gbps

07905-207

Rev. A | Page 8 of 28

ADV3002

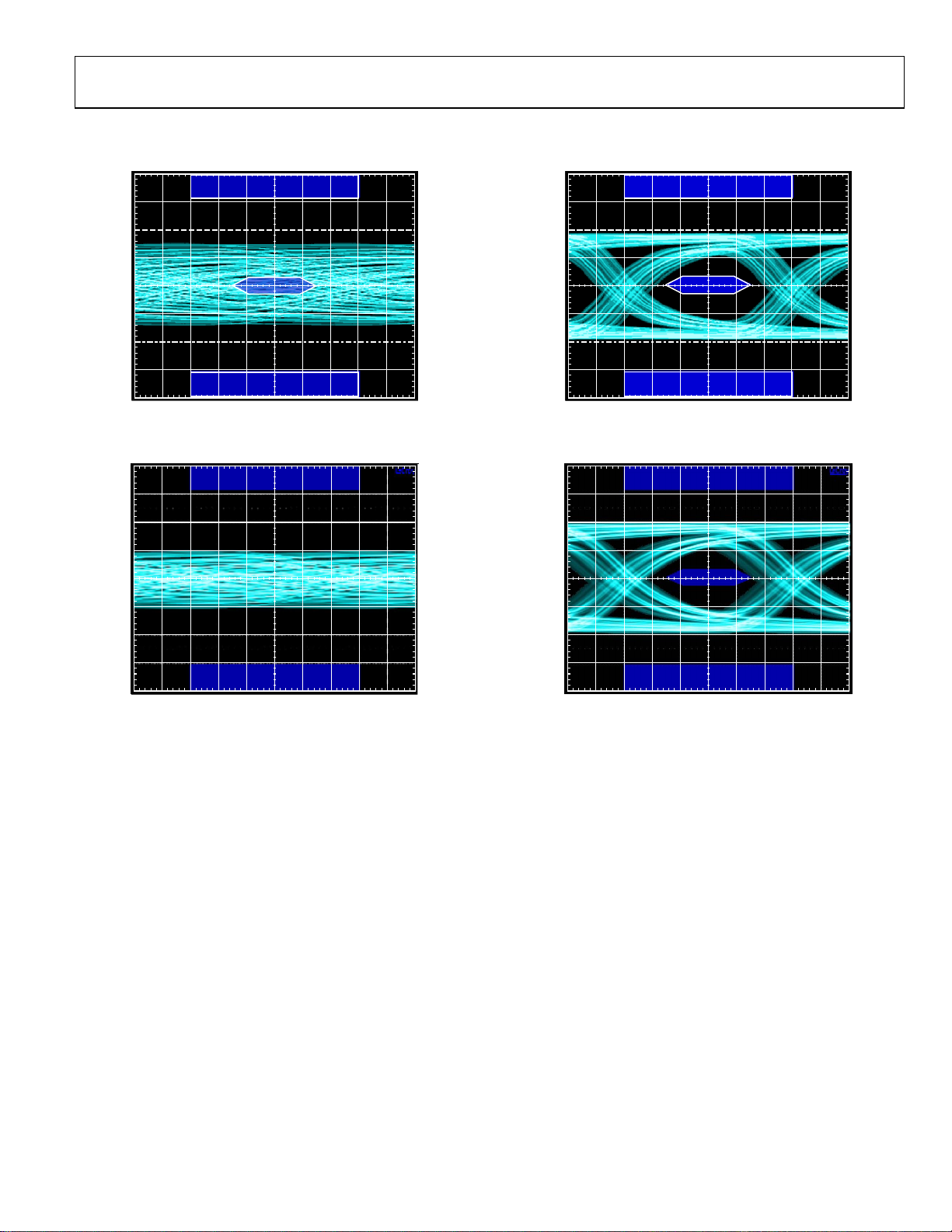

V

V

TA = 27°C, AVCC = 3.3 V, AMUXVCC = 5.0 V, AVEE = 0 V, differential input swing = 1000 mV, pattern = PRBS 27 − 1, data rate = 3 Gbps,

TMDS outputs terminated with external 50 resistors to 3.3 V, unless otherwise noted.

250mV/DI

0.167UI/DI V AT 2.25Gb ps

07905-023

Figure 8. Eye Diagram at TP2 for 20 Meter 24 AWG Cable,

Data Rate = 2.25 Gbps

250mV/DIV

0.167UI/DIV AT 3.0Gbps

07905-209

Figure 9. Eye Diagram at TP2 for15 Meter 24 AWG Cable, Data Rate = 3 Gbps

250mV/DI

0.167UI/DI V AT 2.25Gbps

Figure 10. Eye Diagram at TP3 for 20 Meter 24 AWG Cable,

Data Rate = 2.25 Gbps

250mV/DIV

0.167UI/DIV AT 3.0Gbps

Figure 11. Eye Diagram at TP3 for 15 Meter 24 AWG Cable,

Data Rate = 3 Gbps

07905-025

07905-211

Rev. A | Page 9 of 28

ADV3002

TA = 27°C, AVCC = 3.3 V, AMUXVCC = 5.0 V, AVEE = 0 V, differential input swing = 1000 mV, pattern = PRBS 27 − 1, data rate = 3 Gbps,

TMDS outputs terminated with external 50 resistors to 3.3 V, unless otherwise noted.

1.0

ALL CABLES = 24 AWG

0.9

0.8

0.7

0.6

0.5

0.4

0.3

DETERMINISTIC JITTER (UI)

0.2

0.1

0

0 10203

1080p, 12-BI T

1080p, 10-BI T

1080p, 8-BI T

720p

3Gbps

INPUT CABLE L ENGTH (m)

0

07905-026

Figure 12. Jitter vs. Input Cable Length

100

90

80

70

60

50

40

JITTER (ps)

30

20

10

0

0 0.5 1.0 1.5 2.0 2.5 3.0 3.5

DETERMINISTIC JITTER

RANDOM JITT ER

DATA RATE (Gbp s)

07905-027

Figure 13. Jitter vs. Data Rate

100

90

80

70

60

50

40

JITTER (ps)

30

20

10

0

2.0 2.2 2.4 2.6 2.8 3.0 3.2 3.4 3.6

DETERMINISTIC JITTER

RANDOM JITT ER

SUPPLY VOLTAGE (V)

07905-028

Figure 14. Jitter vs. Supply Voltage

100

90

80

70

60

50

40

JITTER (ps)

30

20

10

0

0 1020304050607080

DETERMINISTIC JITTER

RANDOM JITTER

TEMPERATURE (° C)

Figure 15. Jitter vs. Temperature

1000

800

600

400

EYE HEIGHT (mV)

200

0

0 0.5 1.0 1.5 2.0 2.5 3.0 3.5

DATA RATE (Gb ps)

Figure 16. Eye Height vs. Data Rate

1000

800

600

400

EYE HEIGHT (mV)

200

0

2.0 2.2 2.4 2.6 2.8 3. 0 3.2 3.4 3.6

SUPPLY VOLTAGE (V)

Figure 17. Eye Height vs. Supply Voltage

07905-029

07905-030

07905-031

Rev. A | Page 10 of 28

ADV3002

100

90

80

70

60

50

40

30

DETERMINISTIC JITTER (ps)

20

10

0

0 0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 1.8 2.0

EQ = 18dB

DIFFERENTIAL INPUT SWING (V)

Figure 18. Deterministic Jitter vs. Input Swing

250

07905-032

100

90

80

70

60

50

40

JITTER (ps)

30

20

10

0

2.0 2.2 2.4 2.6 2.8 3.0 3.2 3.4 3.6

DETERMINISTIC JITTER

RANDOM JITT ER

INPUT COMMON-MODE VOLT AGE (V)

Figure 21. Jitter vs. Input Common-Mode Voltage

0.6

07905-035

200

150

100

RISE/FALL TIME (ps)

50

0

0 1020304050 607080

DATA RI SE TIME @ 2 .25Gb ps

DATA FALL TIME @ 2.25Gbps

CLOCKRISETIME@225MHz

CLOCK FALL TIME @ 225MHz

TEMPERATURE (°C)

Figure 19. Rise/Fall Time vs. Temperature

100

90

80

70

60

50

40

30

20

TERMINATION RESISTANCE ( Ω)

10

0

0 10 20304050 607080

TEMPERATURE (° C)

07905-033

07905-034

0.5

0.4

0.3

0.2

0.1

OUTPUT LOGIC LOW VOLTAG E (V)

0

02468

LOAD CURRENT (mA)

DDC

CEC

HPD

10

07905-036

Figure 22. Output Logic Low Voltage vs. Load Current (DDC, CEC, and HPD)

Figure 20. Termination Resistance vs. Temperature

Rev. A | Page 11 of 28

ADV3002

A

V

A

V

THEORY OF OPERATION

The primary function of the ADV3002 is to switch up to four

HDMI/DVI sources to one HDMI/DVI sink. Each HDMI/DVI

link consists of four differential, high speed channels and four

auxiliary single-ended, low speed signals. The high speed channels

include a data-word clock and threeTMDS data channels running

at 10× the data-word clock frequency for data rates up to 3 Gbps.

The four low speed control signals are the display data channel

(DDC) bus (SDA and SCL), the consumer electronics control

(CEC) line, and the hot plug detect (HPD) signal.

The ADV3002 also includes an integrated EDID SRAM,

eliminating the need for an external EDID EEPROM for each

HDMI connector. A typical HDMI multiplexer is shown in

Figure 23. The simplified implementation using the ADV3002

is shown in Figure 24.

DDC

5V

HDMI A

HDMI B

HDMI C

HDMI D

HDMI A

HDMI B

DDC

5V

DDC

5V

DDC

5V

DDC

5V

DDC

5V

DDC

EDID A

EDID B

EDID C

EDID D

2

2

4:1

HDMI

2

2

MUX

2

DDC

Figure 23. Typical HDMI Multiplexer

2

2

ADV3002

2

2

DDC

HDMI

Rx

HDMI

Rx

07905-003

TMDS INPUT CHANNELS

Each high speed input differential pair terminates to the 3.3 V

power supply through a pair of 50 Ω on-chip resistors, as shown

in Figure 25. The state of the input terminations can be configured

automatically or programmed manually by setting the appropriate

bits in the TMDS input termination control register, as shown

in Tabl e 10 .

The input equalizer can be manually configured to provide two

different levels of high frequency boost: 4 dB or 16 dB for 3 Gbps

data. The equalizer (EQ) level defaults to 16 dB after reset. No

specific cable length is suggested for a particular equalization

setting because cable performance varies widely between manufacturers; however, in general, the equalization of the ADV3002

can be set to 16 dB without degrading the signal integrity, even for

short input cables.

CC

50Ω 50Ω

IN+

IN–

AVEE

NOTES

1. IN+ REF ERS TO IN_x_CLK+/ IN_x_D ATAx+ PINS.

2. IN– REFERS TO IN_x_CLK–/IN_x_D ATAx– PINS.

Figure 25. High Speed Input Simplified Schematic

CABLE

EQ

07905-005

TMDS OUTPUT CHANNELS

Each high speed output differential pair is terminated to the 3.3 V

power supply through a pair of 50 Ω on-chip resistors, as shown

in Figure 26. This termination is user-selectable; it can be

turned on or off by programming the TX_OTO bit of the TMDS

output control register, as shown in Tab l e 10 .

CC

5V

HDMI C

DDC

5V

HDMI D

Figure 24. Simplified Implementation Using the ADV3002

2

2

AMUXVCC

MICROCONTROLLER

EDID DDC

EXTERNAL

EDID EEPROM

OR SYSTEM

07905-004

OUT+ OUT–

NOTES

1. OUT+ REF ERS TO OUT_CLK+ AND OUT_D ATAx+ PINS.

2. OUT– REF ERS TO OUT_CLK– AND OUT_D ATAx– PINS.

Figure 26. High Speed Output Simplified Schematic

The output termination resistors of the ADV3002 back

terminate the output TMDS transmission lines. These back

terminations, as recommended in the HDMI 1.4 specification,

act to absorb reflections from impedance discontinuities on the

output traces, improving the signal integrity of the output traces

and adding flexibility to how the output traces can be routed.

50Ω 50Ω

DISABLE I

AVEE

OUT

ESD

PROT.

07905-006

Rev. A | Page 12 of 28

ADV3002

For example, interlayer vias can be used to route the ADV3002

TMDS outputs on multiple layers of the printed circuit board

(PCB) without severely degrading the quality of the output signal.

The output has a disable feature that places the outputs in tristate

mode. Bigger wire-OR’ed arrays can be constructed using the

ADV3002 in this mode.

The ADV3002 requires output termination resistors when the high

speed outputs are enabled. Termination can be internal and/or

external. The internal terminations of the ADV3002 are enabled

by default after reset. External terminations can be provided either

by on-board resistors or by the input termination resistors of an

HDMI/DVI receiver. If both the internal terminations are enabled

and external terminations are present, set the output current level

to 20 mA by programming the TX_OCL bit of the TMDS output

control register, as shown in Tabl e 10 (20 mA is the default

upon reset). If only external terminations are provided (if the

internal terminations are disabled), set the output current level

to 10 mA by programming the TX_OCL bit of the TMDS output

control register. The high speed outputs must be disabled if

there are no output termination resistors present in the system.

DDC BUFFERS

The DDC buffers are 5 V tolerant bidirectional lines that carry

extended display identification data (EDID) and high bandwidth

digital content protection (HDCP) encryption. The ADV3002

provides switching and buffering for the DDC buses. The DDC

buffers are bidirectional, and fully support arbitration, clock

synchronization, and other relevant features of a standard

2

mode I

C bus.

EDID REPLICATION

The ADV3002 EDID replication feature reduces the total system

cost by eliminating the need for an EDID EEPROM for each

HDMI port. With the ADV3002, only a single external EDID is

necessary. The ADV3002 stores the EDID information in an

on-chip SRAM. This enables the EDID information to be

simultaneously accessible to all four HDMI ports. The ADV3002

combines the 5 V power from the four HDMI sources such that

the EDID information can be available even when the system

power is off. A block diagram of the ADV3002 DDC buffering

and EDID replication scheme is shown in Figure 27.

HDMI

PORT A

HDMI

PORT B

HDMI

PORT C

HDMI

PORT D

SRAM

2

I

C

MASTER

EDID

CONTROL

2

I

C

READ/

WRITE

SLAVE

2

2

2

2

2

I

C

READ

SLAVE

2

I

C

READ

SLAVE

2

I

C

READ

SLAVE

2

2

DDC

MUX

2

2

2

I

C

READ/

WRITE

SLAVE

22

EDID_[SCL/SDA]

2

2

I2C_[SCL /SDA]

HDMI

Rx

EXTERNAL

EDID

EEPROM

v1.3

MCU

07905-007

Figure 27. EDID Replication Block Diagram

Rev. A | Page 13 of 28

ADV3002

Source Physical Address Assignment

In HDTV applications where the CEC function is available, the

EDID contains the source physical address (SPA); a unique value

for each HDMI port. Because the memory in the ADV3002 is

volatile, the SPA must be stored in the external EDID EEPROM.

Rather than require a larger external EEPROM to store the SPA,

because all 256 bytes of memory are needed for typical EDID

information, the ADV3002 takes advantage of EDID information

that is always a fixed value, such as the 24-bit IEEE registration

identifier (0x000C03). The 24 bits of the IEEE registration identifier

are replaced with the desired SPA values. When a source requests

the IEEE registration identifier, the ADV3002 responds with the

fixed value (0x000C03). The ADV3002 then automatically

calculates the correct checksum for each port based on the SPA

stored for that port in the vendor specific data block (VSDB).

CEC-enabled devices have a source physical address (SPA) that

allows the CEC controller to address the specific physical devices

and control switches. The SPA is comprised of four fields or

nibbles. Each field is a 4-bit number; therefore, each field can be

any one of 16 possible values (0x0 through 0xF). Each HDMI

input port is assigned a unique SPA as shown in Figure 28. In

any CEC-enabled device, only one of the four fields is unique

per port. In HDMI sink applications, where the sink is the root

device, only the W field is unique per port, whereas the X, Y,

and Z fields are always set to zero.

SPA = W. X. Y. Z

A typical vendor specific data block (VSDB) is shown in Table 7.

When using the ADV3002 EDID replicator, the VSDB should

be replaced with the one shown in Table 8, whereby the port

specific field can be assigned to any of the four fields (W, X, Y, or Z)

depending on the value set in the override select bits as shown

in Table 9.

When calculating the checksum for Block 1 of the EDID, do not

use the custom values entered in place of the IEEE registration

identifier in the calculation; instead, use the IEEE registration

identifier values (0x000C03). Include the values in Byte 4 and

Byte 5 of the VSDB in the calculation.

Table 7. Typical Vendor Specific Data Block (VSDB)

Byte No. 7 6 5 4 3 2 1 0

0

1

2

3

4 SPA Field W SPA Field X

5 SPA Field Y SPA Field Z

6 to N Remainder or VSDB is stored in Byte 6 through Byte N

Table 8. Vendor Specific Data Block with ADV3002

Byte No. 7 6 5 4 3 2 1 0

0

1 Port A SPA override field Port B SPA override field

2 Port C SPA override field Port D SPA override field

3 Not used Override select (see Table 9)

4 Default W field Default X field

5 Default Y field Default Z field

6 to N Remainder or VSDB is stored in Byte 6 through Byte N

Table 9. Override Select Assignment

Override Select

Bit 3 Bit 2 Bit 1 Bit 0

1 0 0 0 W

0 1 0 0 X

0 0 1 0 Y

0 0 0 1 Z

HDMI

PORT A

SPA = W

. XA.YA. Z

A

HDMI

PORT B

SPA = W

B

HDMI

PORT C

SPA = W

C

HDMI

PORT D

SPA = W

D

Figure 28. SPA Assignments

Vendor specific tag

. XB.YB. Z

. XC.YC. Z

. XD.YD. Z

A

B

ADV3002

C

D

07905-008

Length (= N)

code (= 3)

24-bit IEEE registration identifier (0x000C03)

(least significant byte first)

Vendor specific

Length (= N)

tag code (= 3)

Field Replaced by

Port-Specific SPA

Rev. A | Page 14 of 28

ADV3002

EDID Replication with External EEPROM

The ADV3002 has dedicated pins to interface to an external

EDID EEPROM: EDID_SDA and EDID_SCL. In the default

configuration, after the first hot plug event or system power-up,

the internal I

2

C master in the ADV3002 copies the contents of

the external EDID EEPROM into the on-chip SRAM. While the

EDID is being copied, the HPD signals for all four ports are held

low by the ADV3002. A flowchart of the start-up procedure is

shown in Figure 29. The entire start-up procedure takes less than

10 ms. The EDID replication feature can be disabled using the

EDID_ENABLE pin.

POWER-UP, RESET,

OR FIRST HOT PLUG

<100µs

COPY EDID INFORMATION

<10ms

Figure 29. EDID Replication Start-Up Flowchart with External EEPROM

WAIT

FOR EDID POWER-UP

TO ADV3002 SRAM

DETERMINE SPA

AND CHECKSUM

WAIT FOR EDID

REQUEST

RESPOND TO EDID

REQUEST

HPD ALL PORTS = L OW

HPD ALL PORTS = HI GH

Writing to the EDID EEPROM

The EDID data can be written to the external EEPROM by

2

writing data via the I

C control interface or via the HDMI A

DDC inputs. In both cases, the EDID write procedure is as

follows:

1. Write Value 0x96 to the EDID EEPROM write protect

password register, Register 0x0F. The ADV3002 fixed part

address is required to write to this register.

2. Write the EDID data to the EEPROM fixed part address.

Data must be written one byte at a time.

3. Write Value 0x00 to the EDID EEPROM write protect

password register, Register 0x0F.

07905-009

EDID Replication with External Microcontroller

The on-chip SRAM can be preloaded using an external microcontroller. Prior to loading the SRAM, disable the I

2

C master by

writing 0x01 to the EDID replication mode register, Register 0x0E.

The microcontroller can then write EDID information into the

SRAM via the ADV3002 I

2

C control interface. The writes to the

SRAM should be to the fixed part address of 0xA0. When the

EDID copy process is complete, enable the EDID replication

function by writing 0x00 to the EDID replication mode register

(Register 0x0E). The EDID_SDA and EDID_SCL pins are

unused when an external microcontroller is used to program

the SRAM. These pins can be tied either high or low through a

resistor, but should not be left floating.

Reset

Pullling the RESETB pin low initiates a restart of the EDID

replication procedure shown in Figure 29 when the local system

supply is on. If the local system supply is off, the RESETB pin

has no effect.

5 V COMBINER

The 5 V combiner circuit combines the four 5 V supplies from

the four HDMI sources and provides the necessary power to the

ADV3002 EDID replication circuit, the CEC buffer, as well as

the external EDID EEPROM, if applicable. The combiner circuit is

designed such that the current limits on each of the 5 V supplies

are not exceeded when the local system power is either on or off.

A simplified circuit diagram of the 5 V combiner is shown in

Figure 30. The combiner detects the presence of the voltage on

the 5 V pin (P5V_x) from the HDMI connectors and closes the

respective internal switch to connect the 5 V to AMUXVCC. If

the local system 3.3 V and 5 V supplies are available, then the

combiner opens all the switches.

DETECT

P5V_A

DETECT

P5V_B

DETECT

P5V_C

DETECT

P5V_D

Figure 30. 5 V Combiner Simplified Circuit Diagram

AMUXVCC

07905-010

Rev. A | Page 15 of 28

ADV3002

1

0

1

0

FD

LOS_FC

AD

LOS_THR

LOS_STATUS[3:0]

07905-011

CEC BUFFER

The CEC buffer is bidirectional and includes integrated on-chip

pull-up resistors. The CEC buffer isolates capacitance from the

PCB and local system microcontroller, which is particularly

advantageous in systems where the microcontroller is not placed

near the HDMI connectors. The integrated on-chip pull-up

resistors are connected to an internal 3.3 V supply that is generated

from the AMUXVCC supply; thus, the CEC buffer is fully compliant

with the CEC line degradation specifications, when the local

system power supply is either on or off.

HOT PLUG DETECT CONTROL

The HPD lines going into the ADV3002 are normally high

impedance but are pulled low for greater than 100 ms when a

channel switch occurs. This pull-down pulse width can be

changed by modifying the value in the hot plug detect pulse

width control register (Register 0x05), as shown in Tab l e 10 .

Also, the HPD pulse can be manually controlled using the hot

plug detect manual override control register (Register 0x06), as

shown in Tab l e 10 .

LOSS OF SIGNAL DETECT

The TMDS clock line of each HDMI input has a loss of signal

(LOS) monitor attached to it. The purpose of the LOS monitor

is to determine if there is activity in the HDMI link. A simplified

circuit diagram of the LOS detector is shown in Figure 31. The

LOS monitors are disabled by default. The LOS monitors can be

enabled by programming the LOS_EN bit of the LOS detect control

register (Register 0x07). When enabled, the status of each HDMI

input can be read in the LOS detect status register (Register 0x10).

A logic high LOS_STATUS bit of a given HDMI input indicates

an inactive input; a logic low LOS_STATUS bit indicates an

active input. Three conditions need to be fulfilled for an HDMI

input to be considered active:

FREQUENCY

TMDS CLO CK

INPUT[x]

Figure 31. Loss of Signal Detect Simplified Circuit Diagram

DETECTO R

AMPLIT UDE

DETECTO R

LOS Autosquelch

The LOS detect circuit can be used to automatically disable the

TMDS signal path. Setting the LOS_RX_EN bit in the LOS

control register (Register 0x07) causes the selected TMDS input

to be disabled when an LOS event occurs on that input. In this

case, the TMDS signal path is enabled when the active signal

conditions previously listed are met.

• The TMDS input termination resistors must be enabled. By

default, the ADV3002 TMDS input termination resistors

are enabled only on the selected input.

• The TMDS clock frequency exceeds the frequency cutoff

(LOS_FC). Refer to Tab l e 1 for the value of the LOS frequency

cutoff.

• TMDS clock differential amplitude exceeds the LOS threshold

set in the LOS detect control register (Register 0x07). Refer

to Tab l e 1 for the value of the LOS amplitude threshold.

Rev. A | Page 16 of 28

ADV3002

SERIAL CONTROL INTERFACE

RESET

On initial power-up, or at any point in operation, the ADV3002

register set can be restored to the default values by pulling the

RESETB pin low according to the specification in Tabl e 3.

During normal operation, however, the RESETB pin must

be pulled up to 3.3 V.

WRITE PROCEDURE

To write data to the ADV3002 register set, an I2C master (such

as a microcontroller) needs to send the appropriate control

signals to the ADV3002 slave device. The signals are controlled

2

by the I

the procedure, see Figure 32. The steps for a write procedure are

as follows:

1. Send a start condition (while holding the I2C_SCL line

2. Send the ADV3002 part address (seven bits). The upper five

3. Send the write indicator bit (0).

4. Wait f or t he ADV3002 to acknowledge the request.

5. Send the register address (eight bits) to which data is to be

C master, unless otherwise specified. For a diagram of

high and pulling the I2C_SDA line low).

bits of the ADV3002 part address are the static value [10010]

and the two LSBs are set by Input Pins I2C_ADDR[1:0].

This transfer should be MSB first.

written. This transfer should be MSB first.

I2C_SCL

GENERAL CASE

I2C_SDA

EXAMPLE

I2C_SDA

*THE SWITCHING/UPDATE DELAY BEGINS AT THE FALLING EDGE OF THE LAST DATA BIT;

FOR EXAMPLE, THE FALLING EDGE JUST BEFORE STEP 8.

START FIXED ADDR PART REGIS TER ADDR DATA STOP

1 2 3 4 5 6 7 8 9

R/W

ACK ACKADDR

Figure 32. I C Write Procedure

2

6. Wait f or t he ADV3002 to acknowledge the request.

7. Send the data (eight bits) to be written to the register

whose address was set in Step 5. This transfer should be

MSB first.

8. Wait f or t he ADV3002 to acknowledge the request.

9. Do one of the following:

a. Send a stop condition (while holding the I2C_SCL

line high and pulling the I2C_SDA line high) and

release control of the bus to end the transaction

(shown in Figure 32).

b. Send a repeated start condition (while holding the

I2C_SCL line high and pulling the I2C_SDA line low)

and continue from Step 2 in this procedure to perform

another write.

c. Send a repeated start condition (while holding the

I2C_SCL line high and pulling the I2C_SDA line low)

and continue from Step 2 of the read procedure (in the

Read Procedure section) to perform a read from

another address.

d. Send a repeated start condition (while holding the

I2C_SCL line high and pulling the I2C_SDA line low)

and continue from Step 8 of the read procedure (in the

Read Procedure section) to perform a read from the

same address set in Step 5 of the write procedure.

*

ACK

07905-012

Rev. A | Page 17 of 28

ADV3002

I2C_SCL

GENERAL CASE

I2C_SDA

EXAMPLE

I2C_SDA

FIXED PART

START

1 2 3 4 5 6 7 8 9 10 11 12 13

ADDR

ADDR

R/W

REGISTER ADDR

ACK

Figure 33. I C Read Procedure

READ PROCEDURE

To read data from the ADV3002 register set, an I2C master

(such as a microcontroller) needs to send the appropriate

control signals to the ADV3002 slave device. The signals are

controlled by the I

diagram of the procedure, see Figure 33. The steps for a read

procedure are as follows:

1. Send a start condition (while holding the I2C_SCL line

high and pulling the I2C_SDA line low).

2. Send the ADV3002 part address (seven bits). The upper five

bits of the ADV3002 part address are the static value [10010]

and the two LSBs are set by Input Pins I2C_ADDR[1:0].

This transfer should be MSB first.

3. Send the write indicator bit (0).

4. Wait f or t he ADV3002 to acknowledge the request.

5. Send the register address (eight bits) from which data is to

be read. This transfer should be MSB first.

6. Wait f or t he ADV3002 to acknowledge the request.

7. Send a repeated start condition (SR) by holding the

I2C_SCL line high and pulling the I2C_SDA line low.

8. Resend the ADV3002 part address (seven bits) from Step 2.

The upper five bits of the ADV3002 part address compose

the static value [10010]. The two LSBs are set by Input Pins

I2C_ADDR[1:0]. This transfer should be MSB first.

9. Send the read indicator bit (1).

10. Wait f or t he ADV3002 to acknowledge the request.

11. Read the data from the ADV3002. The ADV3002 serially

transfers the data (eight bits) held in the register indicated

by the address set in Step 5. This data is sent MSB first.

2

C master unless otherwise specified. For a

FIXED PART

SR

ACK

2

ADDR

12. Do one of the following:

a. Send a no acknowledge (NACK) followed by a stop

condition (while holding the I2C_SCL line high and

pulling the SDA line high) and release control of the

bus to end the transaction (shown in Figure 33).

b. Send a no acknowledge (NACK) followed by a

repeated start condition (while holding the I2C_SCL

line high and pulling the I2C_SDA line low) and

continue from Step 2 of the write procedure (see the

previous Write P r o cedu r e section) to perform a write.

c. Send a no acknowledge (NACK) followed by a repeated

start condition (while holding the I2C_SCL line high

and pulling the I2C_SDA line low) and continue from

Step 2 of this procedure to perform a read from another

address.

d. Send a no acknowledge (NACK) followed by a repeated

start condition (while holding the I2C_SCL line high

and pulling the I2C_SDA line low) and continue from

Step 8 of this procedure to perform a read from the

next byte.

e. Send an acknowledge (ACK) and read the next byte of

data. Continue from Step 11.

13. Send a stop condition (while holding the I2C_SCL line

high and pulling the I2C_SDA line high).

ADDR

R/W

DATA ST OP

ACK NACK

07905-013

Rev. A | Page 18 of 28

ADV3002

REGISTER MAP

Table 10. Register Map

Address Default Register Name Bit Bit Name Description

0x00 0x00 Channel select control 7:3 Unused Unused

2 CH_SRC 0: input selected by SEL[1:0] parallel pins

1:0 CH[1:0] channel 00: Input A selected if CH_SRC = 1

select 01: Input B selected if CH_SRC = 1

10: Input C selected if CH_SRC = 1

11: Input D selected if CH_SRC = 1

0x01 0x07 TMDS output control 7:4 Unused Unused

3 TX_EN_SRC 0: TMDS output enable controlled by the TX_EN parallel pin

1: TMDS output enable controlled by the TX_EN bit

2 TX_EN 0: TMDS output disabled if TX_EN_SRC = 1

1: TMDS output enabled if TX_EN_SRC = 1

1 TX_OCL 0: TMDS output current = 10 mA

1: TMDS output current = 20 mA

0 TX_OTO 0: TMDS output termination = off

1: TMDS output termination = on

0x02 0x02 TMDS input control 7:2 Unused Unused

1 EQ_SEL 0: TMDS equalizer boost = 6 dB

1: TMDS equalizer boost = 18 dB

0 ISIGN 0: TMDS input polarity = standard

1: TMDS input polarity = inverse

0x03 0x0F TMDS input termination 7:4 ITO_SRC[3:0] 0000: input termination control is automatic

control 1111: input termination control is manual

3:0 ITO_CTL[3:0]

0x04 0x07 Auxiliary buffer enables 7:3 Unused Unused

2 Reserved Reserved; set to 1

1 DDC_EN 0: DDC buffer disabled

1: DDC buffer enabled

0 CEC_EN 0: CEC buffer disabled

1: CEC buffer enabled

0x05 0x05

Hot plug detect pulse

width control

7:0 HPD_PW[7:0] Pulse width = decimal (HPD_PW) × step size (24 ms typical)

1: input selected by channel select control register, CH[1:0]

channel select

0000: all input terminations off if input termination control

is manual

0001: Input A termination on if input termination control is

manual

0010: Input B termination on if input termination control is

manual

0100: Input C termination on if input termination control is

manual

1000: Input D termination on if input termination control is

manual

1111: all input terminations on if input termination control

is manual

Rev. A | Page 19 of 28

ADV3002

Address Default Register Name Bit Bit Name Description

0x06 0x00 Hot plug detect manual 7:5 Unused Unused

override control 4 HPD_SRC

3:0 HPD_CTL[3:0]

0001: HPD_A = low if HPD_SRC = 1

0010: HPD_B = low if HPD_SRC = 1

0100: HPD_C = low if HPD_SRC = 1

1000: HPD_D = low if HPD_SRC = 1

1111: all HPD outputs = low if HPD_SRC = 1

0x07 0x00 Loss of signal detect control 7:6 Unused Unused

5:4 LOS_THR[1:0] 00: LOS Threshold 0

01: LOS Threshold 1

10: LOS Threshold 2

11: LOS Threshold 3

3 Unused Unused

2 LOS_RX_EN 0: TMDS autosquelch disabled

1: TMDS autosquelch enabled

1 Reserved Reserved; set to 0

0 LOS_EN 0: LOS detect disabled

1: LOS detect enabled

0x0E 0x00 EDID replication mode 7:1 Unused Unused

(write only) 0 EDID_REPL_EN 0: EDID replicator enabled; for use with an external EEPROM

(write only)

0x0F 0x00 7:0 PASSWD[7:0] 0x00: write protect enabled; EDID EEPROM writes not allowed

0x10 0x00 Loss of signal detect status 7:4 Unused Unused

3:0 LOS_STATUS[3:0] 0000: TMDS active on all inputs

(read only) 0001: loss of signal detected on Input A

0010: loss of signal detected on Input B

0100: loss of signal detected on Input C

1000: loss of signal detected on Input D

1111: loss of signal detected on all inputs

0xFE 0x03 Revision 7:0 REV[7:0] (read only) 0x03: read only

0xFF 0xC2 Device ID 7:0 ID[7:0] (read only) 0xC2: read only

EDID EEPROM write

protect password

(write only)

(write only)

0: hot plug detect control is automatic; pulse width set by

hot plug detect pulse width control register

1: hot plug detect control is manual; hot plug detect state

is set by HPD_CTL[3:0]

0000: HPD outputs are high impedance (pulled up to 5 V

via external resistor)

1: EDID replicator disabled; external microcontroller can

write the SRAM; write only

0x96: write protect disabled; EDID EEPROM writes from Port A

2

C control are allowed; write only

or I

Rev. A | Page 20 of 28

ADV3002

APPLICATIONS INFORMATION

HDMI MULTIPLEXER FOR ADVANCED TV

The ADV3002 is a complete HDMI/DVI link switch featuring

equalized TMDS inputs, ideal for systems with long cable runs.

The ADV3002 includes bidirectional buffering for the DDC bus

and CEC line, with integrated pull-up resistors for the CEC line.

Additionally, the ADV3002 includes an EDID replication function

that enables one EDID EEPROM to be shared for all four HDMI

ports. Alternatively, a system standby microcontroller can be

used instead of a dedicated EDID EEPROM to load the ADV3002

SRAM. Simplified application schematics are shown in Figure 37

and Figure 38 illustrating these two options.

HDTV SET

ADV3002

MAIN PCB

HDMI

Rx

OR

SoC

5V_COMBINED

AMUXVCC

ADV3002

CEC_OUT CEC_I N

3kΩ

6kΩ

Figure 35. CEC Circuit

MCU

07905-015

5 V Power

The individual 5 V power from each HDMI source can be routed

to the respective 5 V inputs of the ADV3002. The ADV3002

combines these four 5 V supplies into one labeled AMUXVCC

to support EDID replication and CEC functionality when the

local system power is off. An internal 5 V supply must be provided

so that power is not drawn from the HDMI sources when the

local system power is on. When the local supply is off, this internal

5 V should be high impedance. This can be assured by using a

Schottky diode, as shown in Figure 36.

P5V_A

07905-014

Figure 34. ADV3002 as an HDMI Multiplexer in an HDTV

TMDS Signals

TMDS signals can be routed from an HDMI connector directly

to the inputs of the ADV3002. Additional components are not

required for the TMDS signals.

DDC Signals

For the DDC input signals, 47 k pull-up resistors to 5 V are

recommended.

CEC Signal

The CEC buffer in the ADV3002 provides a fully compliant

input in situations where a general-purpose microcontroller is

used to interpret CEC commands. The rise time of the CEC

buffer is set by the time constant of the pull-up resistance and

the capacitance on the node. A 2 k pull-up resistor to 3.3 V is

recommended for optimal output rise times. If a 3.3 V is not

available when the system power is off, a Thevenin equivalent

2 k pull-up resistor to 3.3 V is shown in Figure 35.

5V INTERNAL

P5V_B

AMUXVCC

P5V_C

P5V_D

07905-016

Figure 36. 5 V Power Connections

Rev. A | Page 21 of 28

ADV3002

V

V

OPTION 1

AMUXVCC

D2+

D2–

D1+

D1–

D0+

D0–

CLK+

CLK–

HPD

DDC_SCL

DDC_SDA

CEC

D2+

D2–

D1+

D1–

D0+

D0–

CLK+

CLK–

HPD

DDC_SCL

DDC_SDA

CEC

D2+

D2–

D1+

D1–

D0+

D0–

CLK+

CLK–

HPD

DDC_SCL

DDC_SDA

CEC

D2+

D2–

D1+

D1–

D0+

D0–

CLK+

CLK–

HPD

DDC_SCL

DDC_SDA

CEC

5V

5V

5V

5V

TMDS

47kΩ1kΩ 47kΩ

TMDS

47kΩ1kΩ

47kΩ1kΩ 47kΩ

47kΩ1kΩ 47kΩ

47kΩ

TMDS

TMDS

5

AMUXVCC

IN_A_DATA2+

IN_A_DATA2–

IN_A_DATA1+

IN_A_DATA1–

IN_A_DATA0+

IN_A_DATA0–

IN_A_CLK+

IN_A_CLK–

P5V_A

HPD_A

DDC_SCL_A

DDC_SDA_A

IN_B_DATA2+

IN_B_DATA2–

IN_B_DATA1+

IN_B_DATA1–

IN_B_DATA0+

IN_B_DATA0–

IN_B_CLK+

IN_B_CLK–

P5V_B

HPD_B

DDC_SCL_B

DDC_SDA_B

CEC_IN

IN_C_DATA2+

IN_C_DATA2–

IN_C_DATA1+

IN_C_DATA1–

IN_C_DATA0+

IN_C_DATA0–

IN_C_CLK+

IN_C_CLK–

P5V_C

HPD_C

DDC_SCL_C

DDC_SDA_C

IN_D_DATA2+

IN_D_DATA2–

IN_D_DATA1+

IN_D_DATA1–

IN_D_DATA0+

IN_D_DATA0–

IN_D_CLK+

IN_D_CLK–

P5V_D

HPD_D

DDC_SCL_D

DDC_SDA_D

3.3

AVC C

OUT_DATA2+

OUT_DATA2–

OUT_DATA1+

OUT_DATA1–

OUT_DATA0+

OUT_DATA0–

DDC_SCL_COM

DDC_SDA_COM

ADV3002

I2C_ADDR[1:0]

EDID_ENABLE

AVE E

OUT_CLK+

OUT_CLK–

I2C_SCL

I2C_SDA

CEC_OUT

EDID_SCL

EDID_SDA

RESETB

TX_EN

SEL[1:0]

AMUXVCC

10kΩ

10kΩ

AMUXVCC

10kΩ

0.001µF0.01µF 0.01µF0.1µF1µF

TMDS

AMUXVCC

2kΩ

2kΩ

2kΩ 2kΩ 2kΩ

OPTIONAL

AVC C

10kΩ 10kΩ

1µF

D2+

D2–

D1+

D1–

D0+

D0–

CLK+

CLK–

DDC_SCL

DDC_SDA

3.3V STANDBY

HDMI

Rx

STANDBY

MCU

07905-017

Figure 37. Simplified Application Circuit Diagram (Option 1—No External EEPROM)

Rev. A | Page 22 of 28

ADV3002

V

V

OPTION 2

AMUXVCC

1kΩ

TMDS

47kΩ1kΩ 47kΩ

TMDS

47kΩ

47kΩ1kΩ 47kΩ

47kΩ1kΩ 47kΩ

47kΩ

TMDS

TMDS

D2+

D2–

D1+

D1–

D0+

D0–

CLK+

CLK–

HPD

DDC_SCL

DDC_SDA

CEC

D2+

D2–

D1+

D1–

D0+

D0–

CLK+

CLK–

HPD

DDC_SCL

DDC_SDA

CEC

D2+

D2–

D1+

D1–

D0+

D0–

CLK+

CLK–

HPD

DDC_SCL

DDC_SDA

CEC

D2+

D2–

D1+

D1–

D0+

D0–

CLK+

CLK–

HPD

DDC_SCL

DDC_SDA

CEC

5V

5V

5V

5V

5

AMUXVCC

IN_A_DATA2+

IN_A_DATA2–

IN_A_DATA1+

IN_A_DATA1–

IN_A_DATA0+

IN_A_DATA0–

IN_A_CLK+

IN_A_CLK–

P5V_A

HPD_A

DDC_SCL_A

DDC_SDA_A

IN_B_DATA2+

IN_B_DATA2–

IN_B_DATA1+

IN_B_DATA1–

IN_B_DATA0+

IN_B_DATA0–

IN_B_CLK+

IN_B_CLK–

P5V_B

HPD_B

DDC_SCL_B

DDC_SDA_B

CEC_IN

IN_C_DATA2+

IN_C_DATA2–

IN_C_DATA1+

IN_C_DATA1–

IN_C_DATA0+

IN_C_DATA0–

IN_C_CLK+

IN_C_CLK–

P5V_C

HPD_C

DDC_SCL_C

DDC_SDA_C

IN_D_DATA2+

IN_D_DATA2–

IN_D_DATA1+

IN_D_DATA1–

IN_D_DATA0+

IN_D_DATA0–

IN_D_CLK+

IN_D_CLK–

P5V_D

HPD_D

DDC_SCL_D

DDC_SDA_D

3.3

AVC C

OUT_DATA2+

OUT_DATA2–

OUT_DATA1+

OUT_DATA1–

OUT_DATA0+

OUT_DATA0–

DDC_SCL_COM

DDC_SDA_COM

ADV3002

I2C_ADDR[1:0]

EDID_ENABLE

AVE E

OUT_CLK+

OUT_CLK–

I2C_SCL

I2C_SDA

CEC_OUT

EDID_SCL

EDID_SDA

RESETB

TX_EN

SEL[1:0]

10kΩ

AMUXVCC

10kΩ

AMUXVCC

10kΩ

0.001µF0.01µF 0.01µF0.1µF1µF

TMDS

AMUXVCC

2kΩ

2kΩ

2kΩ 2kΩ 2kΩ

OPTIONAL

3.3V STANDBY

2kΩ 2kΩ

1µF

D2+

D2–

D1+

D1–

D0+

D0–

CLK+

CLK–

DDC_SCL

DDC_SDA

3.3V STANDBY

HDMI

Rx

MCU

3.3V STANDBY

EDID

EEPROM

07905-018

Figure 38. Simplified Application Diagram (Option 2—External EDID EEPROM)

Rev. A | Page 23 of 28

ADV3002

CABLE LENGTHS AND EQUALIZATION

The ADV3002 offers two levels of programmable equalization

for the high speed inputs: 4 dB and 16 dB. The equalizer of the

ADV3002 supports video data rates of up to 3 Gbps and can

equalize more than 15 meters of 24 AWG HDMI cable at 3 Gbps,

which corresponds to the video format, 1080p with 12-bit Deep

Color. The length of cable that can be used in a typical HDMI/

DVI application depends on a large number of factors including

• Cable quality: the quality of the cable in terms of conductor

wire gauge and shielding. Thicker conductors have lower

signal degradation per unit length.

• Data rate: the data rate being sent over the cable. The signal

degradation of HDMI cables increases with data rate.

• Edge rates: the edge rates of the source input. Slower input

edges result in more significant data eye closure at the end

of a cable.

• Receiver sensitivity: the sensitivity of the terminating

receiver.

As such, no particular equalizer setting is recommended for

specific cable types or lengths. In nearly all applications, the

ADV3002 equalization level can be set to high, or 18 dB, for all

input cable configurations at all data rates, without degrading the

signal integrity.

PCB LAYOUT GUIDELINES

The ADV3002 switches two distinctly different types of signals,

both of which are required for HDMI and DVI video. These

signal groups require different treatment when laying out a PCB.

The first group of signals carries the A/V data. HDMI/DVI video

signals are differential, unidirectional, and high speed (up to

3 Gbps). The channels that carry the video data must be controlled

impedance, terminated at the receiver, and capable of operating

up to at least 3 Gbps. It is especially important to note that the

differential traces that carry the TMDS signals should be designed

with a controlled differential impedance of 100 Ω. The ADV3002

provides single-ended 50 Ω terminations on-chip for both its

inputs and outputs, and both the input and output terminations

can be enabled or disabled through the serial interface. Output

termination is recommended but not required by the HDMI

standard but its inclusion improves the overall system signal

integrity.

The A/V data carried on these high speed channels is encoded

by a technique called TMDS, and in the case of HDMI, is also

encrypted according to the HDCP standard.

The second group of signals consists of low speed auxiliary

control signals used for communication between a source and a

sink. Depending upon the application, these signals can include

the DDC bus (this is an I

and HDCP encryption keys between the source and the sink),

the CEC line, and the HPD line. These auxiliary signals are

bidirectional, low speed, and transferred over a single-ended

transmission line that does not need to have controlled impedance.

2

C bus used to send EDID information

The primary concern with laying out the auxiliary lines is ensuring

that they conform to the I

excessive capacitive loading.

2

C bus standard and do not have

TMDS Signals

In the HDMI/DVI standard, four differential pairs carry the

TMDS signals. In DVI, three of these pairs are dedicated to

carrying RGB video and sync data. For HDMI, audio data

interleaves with the video data; the DVI standard does not incorporate audio information. The fourth high speed differential pair

is used for the A/V data-word clock, and runs at one-tenth the

speed of the TMDS data channels.

The ADV3002 buffers the TMDS signals, and the input traces

can be considered electrically independent of the output traces.

In most applications, the quality of the signal on the input

TMDS traces are more sensitive to the PCB layout. Regardless

of the data being carried on a specific TMDS channel, or

whether the TMDS line is at the input or the output of the

ADV3002, all four high speed signals should be routed on a

PCB in accordance with the same RF layout guidelines.

Layout for the TMDS Signals

The TMDS differential pairs can be either microstrip traces

(routed on the outer layer of a board) or stripline traces (routed

on an internal layer of the board). If microstrip traces are used,

there should be a continuous reference plane on the PCB layer

directly below the traces. If stripline traces are used, they must

be sandwiched between two continuous reference planes in the

PCB stack-up. Additionally, the p and n of each differential pair

must have a controlled differential impedance of 100 Ω. The

characteristic impedance of a differential pair is a function of

several variables including the trace width, the distance separating

the two traces, the spacing between the traces and the reference

plane, and the dielectric constant of the PCB binder material.

Interlayer vias introduce impedance discontinuities that can

cause reflections and jitter on the signal path; therefore, it is

preferable to route the TMDS lines exclusively on one layer of the

board, particularly for the input traces. Additionally, to prevent

unwanted signal coupling and interference, route the TMDS

signals away from other signals and noise sources on the PCB.

Both traces of a given differential pair must be equal in length

to minimize intrapair skew. Maintaining the physical symmetry

of a differential pair is integral to ensuring its signal integrity;

excessive intrapair skew can introduce jitter through duty cycle

distortion (DCD). Always route the p and n of a given differential pair together to establish the required 100 Ω differential

impedance. Leave enough space between the differential pairs

of a given group to prevent the n of one pair from coupling with

the p of another pair. For example, one technique is to make the

interpair distance four to 10 times wider than the intrapair spacing.

Rev. A | Page 24 of 28

ADV3002

Any one group of four TMDS traces (Input A, Input B, Input C,

Input D, or the output) should have closely matched trace

lengths to minimize interpair skew. Severe interpair skew can

cause the data on the four different channels of a group to arrive

out of alignment with one another. A good practice is to match

the trace lengths for a given group of four channels to within

0.05 inches on FR4 material.

Minimizing intrapair and interpair skew becomes increasingly

important as data rates increase. Any introduced skew constitutes a correspondingly larger fraction of a bit period at higher

data rates.

Though the ADV3002 features input equalization and output

preemphasis, minimizing the length of the TMDS traces is needed

to reduce overall system signal degradation. Commonly used

PCB material, such as FR4, is lossy at high frequencies; therefore,

long traces on the circuit board increase signal attenuation,

resulting in decreased signal swing and increased jitter through

intersymbol interference (ISI).

Controlling the Characteristic Impedance of a TMDS Differential Pair

The characteristic impedance of a differential pair depends on

a number of variables, including the trace width, the distance

between the two traces, the height of the dielectric material

between the trace and the reference plane below it, and the

dielectric constant of the PCB binder material. To a lesser

extent, the characteristic impedance also depends upon the

trace thickness and the presence of solder mask. Many

combinations can produce the correct characteristic impedance.

Generally, working with the PCB fabricator is required to obtain

a set of parameters to produce the desired results.

One consideration is how to guarantee a differential pair with

a differential impedance of 100 Ω over the entire length of the

trace. One technique to accomplish this is to change the width

of the traces in a differential pair based on how closely one trace

is coupled to the other. When the two traces of a differential pair

are close and strongly coupled, they should have a width that

produces a100 Ω differential impedance. When the traces split

apart to go into a connector, for example, and are no longer so

strongly coupled, the width of the traces need to be increased to

yield a differential impedance of 100 Ω in the new configuration.

Ground Current Return

In some applications, it can be necessary to invert the output

pin order of the ADV3002. This requires a designer to route the

TMDS traces on multiple layers of the PCB. When routing differential pairs on multiple layers, it is necessary to also reroute

the corresponding reference plane to provide one continuous

ground current return path for the differential signals. Standard

plated through-hole vias are acceptable for both the TMDS

traces and the reference plane. An example of this is illustrated

in Figure 39.

THROUGH-HOL E VIAS

SILKSCREEN

LAYER 1: SIGNAL (MIC ROSTRI P)

PCB DIELECTRI C

LAYER 2: GND (REFERENCE PLANE)

PCB DIELECTRI C

LAYER 3: PWR

(REFERENCE PLANE )

PCB DIELECTRI C

LAYER 4: SIGNAL (MIC ROSTRI P)

SILKSCREEN

KEEP REFERENCE PL ANE

ADJACENT TO SI GNAL ON ALL

LAYERS TO P ROVIDE CONTINUOUS

GROUND CURRENT RETURN PATH.

Figure 39. Example Routing of Reference Plane

TMDS Terminations

The ADV3002 provides internal 50 Ω single-ended terminations

for all of its high speed inputs and outputs. It is not necessary to

include external termination resistors for the TMDS differential

pairs on the PCB.

The output termination resistors of the ADV3002 back terminate

the output TMDS transmission lines. These back terminations

act to absorb reflections from impedance discontinuities on the

output traces, improving the signal integrity of the output traces

and adding flexibility to how the output traces can be routed.

For example, interlayer vias can be used to route the ADV3002

TMDS outputs on multiple layers of the PCB without severely

degrading the quality of the output signal.

Auxiliary Control Signals

There are four single-ended control signals associated with each

source or sink in an HDMI/DVI application. These are hot plug

detect (HPD), consumer electronics control (CEC), and two

display data channel (DDC) lines. The two signals on the DDC

bus are SDA and SCL (serial data and serial clock, respectively).

The DDC and CEC signals are buffered and switched through

the ADV3002, and the HPD signal is pulsed low by the ADV3002.

These signals do not need to be routed with the same strict

considerations as the high speed TMDS signals.

In general, it is sufficient to route each auxiliary signal as a

single-ended trace. These signals are not sensitive to impedance

discontinuities, do not require a reference plane, and can be

routed on multiple layers of the PCB. However, it is best to

follow strict layout practices whenever possible to prevent the

PCB design from affecting the overall application. The specific

routing of the HPD, CEC, and DDC lines depends upon the

application in which the ADV3002 is being used.

07905-019

Rev. A | Page 25 of 28

ADV3002

For example, the maximum speed of signals present on the

auxiliary lines are 100 kHz I

any layout that enables 100 kHz I

2

C data on the DDC lines, therefore,

2

C to be passed over the DDC

bus should suffice. The HDMI 1.3a compliance test specification,

however, places a strict 50 pF limit on the amount of capacitance

that can be measured on either SDA or SCL at the HDMI input

connector. The 50 pF limit includes the HDMI connector, the

PCB, and whatever capacitance is seen at the input of the

ADV3002, or an equivalent receiver. There is a similar limit of

150 pF of input capacitance for the CEC line. The benefit of the

ADV3002 is that it buffers these lines, isolating the output

capacitance so that only the capacitance at the input side

contributes to the specified limit.

The parasitic capacitance of traces on a PCB increases with

trace length. To help ensure that a design satisfies the HDMI

specification, make the length of the CEC and DDC lines on the

PCB as short as possible. Additionally, if there is a reference

plane in the layer adjacent to the auxiliary traces in the PCB

stackup, relieving or clearing out this reference plane immediately

under the auxiliary traces significantly decreases the amount of

parasitic trace capacitance. An example of the board stackup is

shown in Figure 40.

W3W 3W

SILKSCREEN

LAYER 1: SIGNAL (MICROSTRIP)

PCB DIEL ECTRI C

LAYER 2: GND (REFERENCE PLANE)

PCB DIEL ECTRI C

LAYER 3: PWR (REFERENCE PLANE)

PCB DIEL ECTRI C

LAYER 4: SIGNAL (MICROSTRIP)

SILKSCREEN

REFERENCE LAYER

RELIEVED UNDERNEAT H

MICROSTRIP

Figure 40. Example Board Stackup for Auxiliary Control Signals

07905-020

HPD is a dc signal presented by a sink to a source to indicate

that the source EDID is available for reading. The trace routing

of this signal is not critical, but it should be routed as directly as

possible.

When the ADV3002 is powered up, the DDC/CEC inputs of the